Lochinvar Mini Copper-Fin MCW226CE, Mini Copper-Fin MCW271CE, Mini Copper-Fin MCW316CE, Mini Copper-Fin MCW361CE, Mini Copper-Fin MCW501CE Installation, Commissioning And Maintenance Instructions

...

MCW91CE

MCB501CE

INS0023 Issue No 6 | August 2011

The Mini Copper-Fin® range

High Efficiency Gas Fired Water Heaters and

Boilers

Installation, Commissioning and

Maintenance Instructions

Models:

MCW136CE

MCW181CE

MCW226CE

MCW271CE

MCW316CE

MCW361CE

MCW401CE

MCW501CE

MCB91CE

MCB136CE

MCB181CE

MCB226CE

MCB271CE

MCB316CE

MCB361CE

MCB401CE

2

Table of Contents

1.0 INTRODUCTION ...................................................................................................................................................................................................................................... 4

2.0 PRINCIPAL PARTS ................................................................................................................................................................................................................................. 5

3.0 TECHNICAL DATA .................................................................................................................................................................................................................................. 7

4.0 GENERAL REQUIREMENTS .................................................................................................................................................................................................................. 9

4.1 RELATED DOCUMENTS ................................................................................................................................................................................................................. 9

5.0 WATER QUALITY .................................................................................................................................................................................................................................. 10

6.0 LOCATION ............................................................................................................................................................................................................................................. 10

6.1 PLANT ROOM VENTILATION ....................................................................................................................................................................................................... 10

6.2 GENERAL REQUIREMENTS ......................................................................................................................................................................................................... 10

6.3 CLEARANCES ................................................................................................................................................................................................................................ 10

7.0 GAS SUPPLY ......................................................................................................................................................................................................................................... 11

7.1 SERVICE PIPES ............................................................................................................................................................................................................................. 11

7.2 METERS.......................................................................................................................................................................................................................................... 11

7.3 GAS SUPPLY PIPES ...................................................................................................................................................................................................................... 11

7.4 BOOSTED SUPPLIES .................................................................................................................................................................................................................... 11

7.5 PLANT-ROOM CONTROL VALVE ................................................................................................................................................................................................ 11

7.6 EQUIPMENT GAS SYSTEM LEAK CHECK .................................................................................................................................................................................. 11

8.0 FLUE SYSTEM ....................................................................................................................................................................................................................................... 12

8.1 FLUE SYSTEM GENERAL REQUIREMENTS .............................................................................................................................................................................. 12

8.2 FLUE SYSTEMS ............................................................................................................................................................................................................................. 12

8.3 FLUE MATERIALS – CONVENTIONAL FLUE INSTALLATIONS ................................................................................................................................................ 12

8.4 MULTIPLE FLUE INSTALLATION ................................................................................................................................................................................................. 13

8.5 FAN DILUTION SYSTEMS ............................................................................................................................................................................................................. 13

8.6 B ALA NCED COMPARTME NT S ..................................................................................................................................................................................................... 13

9.0 AIR SUPPLY .......................................................................................................................................................................................................................................... 13

9.1 NATURAL VENTILATION............................................................................................................................................................................................................... 13

9.2 MECHANICAL VENTILATION........................................................................................................................................................................................................ 14

10.0 WATER CONNECTIONS ....................................................................................................................................................................................................................... 16

10.1 WATER HEATERS ......................................................................................................................................................................................................................... 16

10.1.1 GENERAL ........................................................................................................................................................................................................................ 16

10.1.2 OPEN VENTED SYSTEM ARRANGEMENT ................................................................................................................................................................. 16

10.1.3 UNVENTED SYSTEM ARRANGEMENT ....................................................................................................................................................................... 16

10.1.4 WATER PRESSURE GAUGE ......................................................................................................................................................................................... 16

10.1.5 DRAIN VALVES ............................................................................................................................................................................................................... 16

10.1.6 EXPANSION VESSEL SIZING ....................................................................................................................................................................................... 17

10.1.7 DE-STRATIFICATION ..................................................................................................................................................................................................... 17

10.1.8 CIRCULATING PUMPS .................................................................................................................................................................................................. 17

10.1.9 PIPEWORK SIZE ............................................................................................................................................................................................................ 18

10.2 HEATING BOILERS........................................................................................................................................................................................................................ 19

10.2.1 GENERAL ........................................................................................................................................................................................................................ 19

10.2.2 OPEN VENTED SYSTEM ARRANGEMENT ................................................................................................................................................................. 19

10.2.3 SEALED SYSTEM ARRANGEMENT ............................................................................................................................................................................. 19

10.2.4 DRAIN VALVES ............................................................................................................................................................................................................... 19

10.2.5 EXPANSION VESSEL SIZING ....................................................................................................................................................................................... 20

10.2.6 PRIMARY CIRCULATING PUMPS ................................................................................................................................................................................. 20

10.3 POOL HEATING ............................................................................................................................................................................................................................. 21

10.4 FLOW SWITCH ............................................................................................................................................................................................................................... 21

11.0 ELECTRICAL SUPPLY ......................................................................................................................................................................................................................... 21

11.1 E LECTRICAL CONNECT IONS ...................................................................................................................................................................................................... 22

11.2 EXTERNAL CONTROLS ................................................................................................................................................................................................................ 22

11.3 ARC WELDING PRECAUTIONS ................................................................................................................................................................................................... 22

11.4 WI RI NG DI AGRAM ......................................................................................................................................................................................................................... 23

12.0 COMMISSIONING AND TESTING ........................................................................................................................................................................................................ 25

12.1 E LE CTRICAL INSTA LLATION ....................................................................................................................................................................................................... 25

12.2 GAS INSTALLATION ...................................................................................................................................................................................................................... 25

12.3 WA T ER CO N NE CTIONS ............................................................................................................................................................................................................... 25

12.4 COMMISSIONING THE EQUIPMENT ........................................................................................................................................................................................... 25

12.4.1 GENERAL CHECKS PRIOR TO LIGHTING .................................................................................................................................................................. 25

12.4.2 EQUIPMENT CHECKS PRIOR TO LIGHTING .............................................................................................................................................................. 25

12.4.3 PROCEDURE FOR INITIAL LIGHTING ......................................................................................................................................................................... 26

12.4.4 GAS PRESSURE ADJUSTMENT AND COMBUSTION CHECKS................................................................................................................................ 26

12.5 WATER HEATER TEMPERATURE ADJUSTMENT PROCEDURE ............................................................................................................................................ 27

12.6 BOILER TEMPERATURE ADJUSTMENT PROCEDURE ............................................................................................................................................................ 27

12.7 INSTALLATION NOISE .................................................................................................................................................................................................................. 27

13.0 LPG FUEL .............................................................................................................................................................................................................................................. 27

13.1 RELATED DOCUMENTS ............................................................................................................................................................................................................... 27

13.2 PROPANE INJECTORS ................................................................................................................................................................................................................. 28

13.3 CONVERSION TO LPG .................................................................................................................................................................................................................. 28

13.4 LPG COMMISSIONING AND TESTING ........................................................................................................................................................................................ 28

3

14.0 MAINTENANCE ..................................................................................................................................................................................................................................... 28

14.1 GENERAL ....................................................................................................................................................................................................................................... 28

14.2 MAINTENANCE SCHEDULE ......................................................................................................................................................................................................... 29

14.2.1 ADDITIONAL REQUIREMENTS FOR WATER HEATERS ........................................................................................................................................... 29

14.3 DRAINING THE WATER SYSTEM ................................................................................................................................................................................................ 29

14.4 WATER HEATER SERVICING ...................................................................................................................................................................................................... 29

14.4.1 REMOVING SCALE AND SEDIMENT FROM THE STORAGE VESSEL ..................................................................................................................... 29

14.4.2 SACRIFICIAL MAGNESIUM ANODES .......................................................................................................................................................................... 29

14.5 CLEANING THE HEAT EXCHANGER .......................................................................................................................................................................................... 30

14.6 REFILLING THE SYSTEM ............................................................................................................................................................................................................. 31

14.7 OTHER CHECKS ............................................................................................................................................................................................................................ 32

14.7.1 RELIEF VALVES ............................................................................................................................................................................................................. 32

14.7.2 FLUE SYSTEM ................................................................................................................................................................................................................ 32

14.8 TTB DEVICE ................................................................................................................................................................................................................................... 32

14.9 FAULT FINDING ............................................................................................................................................................................................................................. 32

15.0 USER INSTRUCTIONS .......................................................................................................................................................................................................................... 33

4

1.0 INTRODUCTION

• The Lochinvar Mini Copper-Fin range is a floor standing direct gas fired water heater or boiler. The

equipment comprises a copper finned tube heat exchanger surrounded with a high density, light weight

refractory insulation. A durable outer steel jacket assembly provides structural integrity and easy

disassembly. The gas train includes black iron inlet manifold(s) a nd stainless steel atmospheric burner

assemblies.

• The burners are initiated by a full ignition sequence control that incorporates an intermittent pilot

assembly and rectification supervision of the flame.

• For the correct operation of the appliance when used as a water heater, it is essential that a suitably

sized, glanded-construction bronze pump is utilised to maintain a constant water flow rate through the

heat exchanger. When used as a water heater, the M ini Copper-Fin should also be used in conjunction

with an appropriately sized storage vessel (available from Lochinvar Limited as an ancillary option).

• This equipment is intended for use on Group H Natural Gas (2

The information relating to propane firing is to be found in Section 13: LPG FUEL. This equipment

MUST NOT use gas other than that for which it has been designed and adjusted.

• This equipment must be installed by a competent person, registered with a H.S.E. approved body. All

installations must conform to the relevant Gas Safety and Building Regulations. Health & Safety

requirements must also be taken into account when installing any equipment. Failure to comply with the

above may lead to prosecution.

• If the equipment is to be connected to an unvented (pressurised) system, care must be taken to ensure

all extra safety requirements are satisfied should a high or low-pressure condition occur in the system.

• The equipment is designed for direct connection to a flue system via the draught diverter built in to the

equipment casing. The flue outlets from more than one unit may be connected to a single chimney.

• Ancillary Options:

• Primary Circulating Pump (MCW91-361CE) Omega 4-60-2ZS

• Primary Circulating Pump (MCW401-501CE) Omega 4-90-2ZS

• Direct Storage Cylinder (297 litre) LST66

• Direct Storage Cylinder (450 litre) LST100

• Direct Storage Cylinder (747 litre) LST166

• Direct Storage Cylinder (1155 litre) LST250

• Unvented/Boosted Water System Kits Contact Lochinvar Limited

• De-stratification Pump Kit WH9

• Pre-Fabricated Interconnecting Pipework Contact Lochinvar Limited

• Stacking Frame (MCW/MCB91-181CE) MSF3050

• Stacking Frame (MCW/MCB226-361CE) MSF3051

• Stacking Frame (MCW/MCB401-501CE) MSF3052

• Stacking Frame (MCW + Storage) Contact Lochinvar Limited

nd

Family) and LPG propane (3rd Family).

5

2.0 PRINCIPAL PARTS

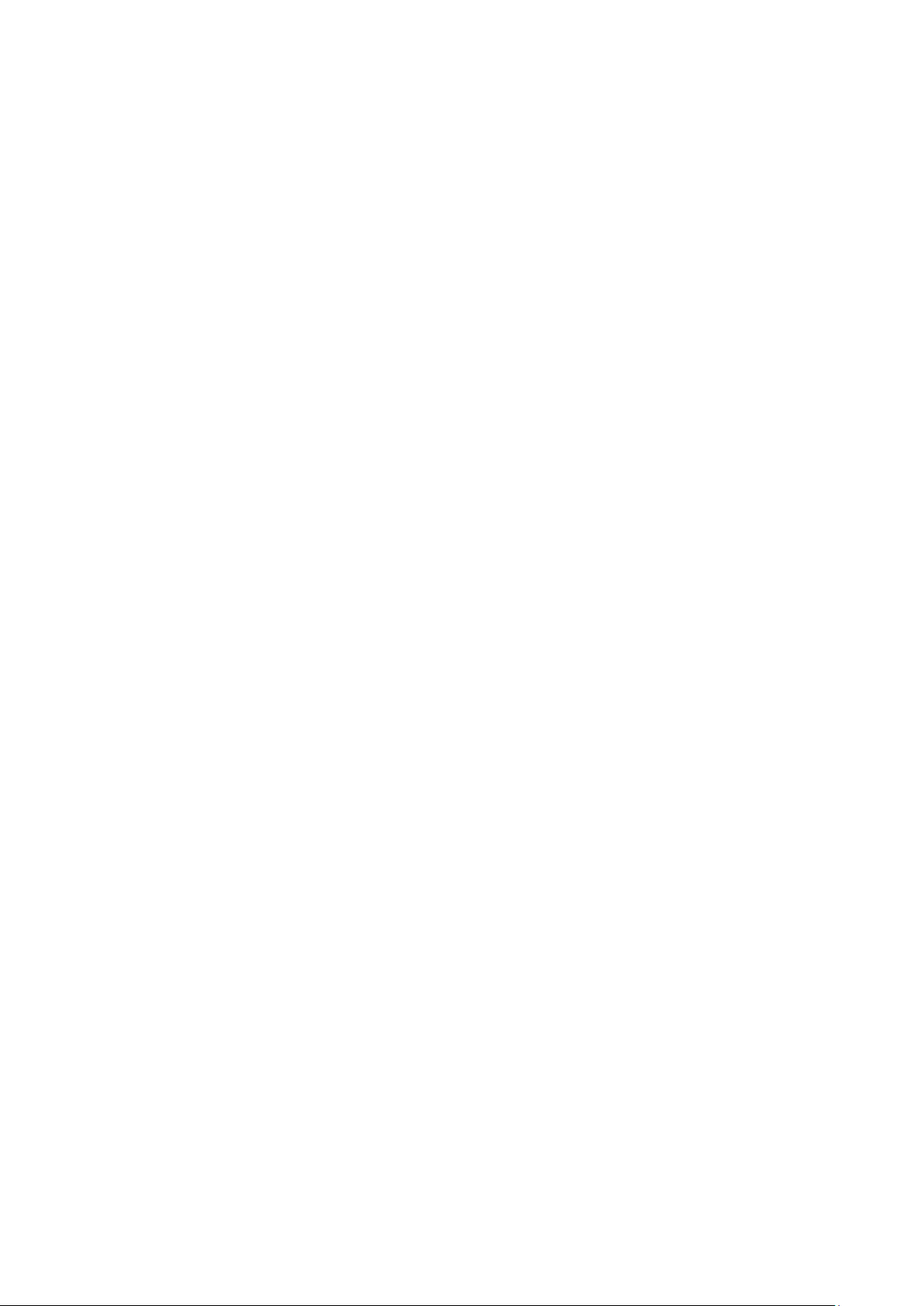

FIGURE 2.1 EXPLODED DIAGRAM

FIGURE 2.2 EXPLODED DIAGRAM – CONTRO L PANEL ASSEMBLY

6

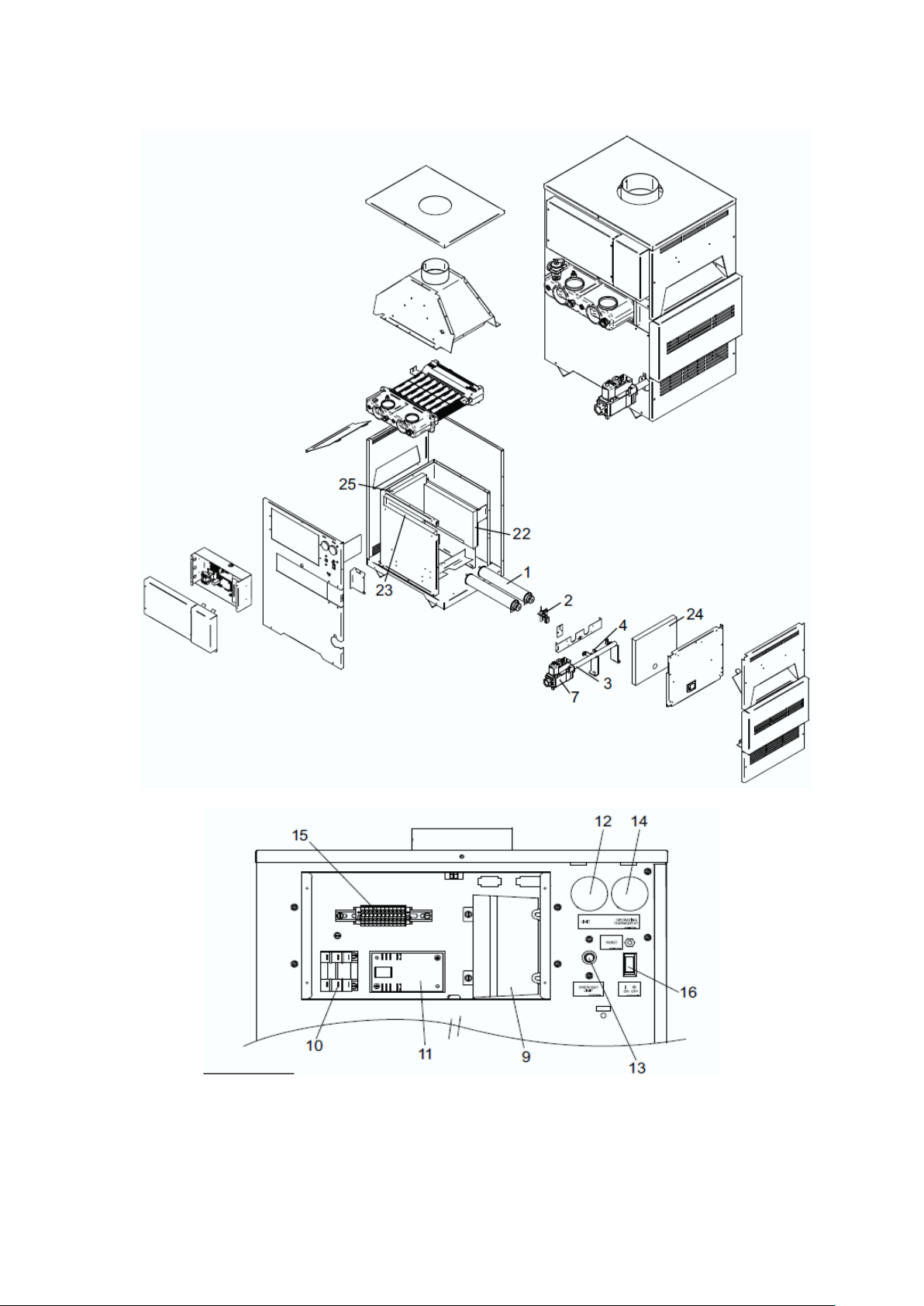

FIGURE 2.3 EXPLODED DIAGRAM – HEAT EXCHANGER

ITEM

DESCRIPTION

ITEM

DESCRIPTION

1

Main burner bar

14

Control thermostat

2

Pilot burner assembly

15

Terminal str ip

3

Burner manifold

16

On/off switch

4

Main burner injector

17

Heat exchan ger

5

Gas inlet flange

18

‘V’ baffle

6

Manifold fla nge

19

Temperature gauge

7

Gas valve

20

Pressure/temperature relief valve

8

Gas valve

21

Bulbwell pocket

9

Sequence cont rol

22

Right side fi bre board

10

Relay

23

Left side fibre board

11

Time delay relay

24

Front fibre b oard

12

High limit thermostat

25

Rear fibre board

13

Overheat thermostat

FIGURE 2.4 EXPLODED DIAGRAM - GAS MANIFOLD ASSEMBLY

TABLE 2.1 REMOVABLE COMPONENTS

7

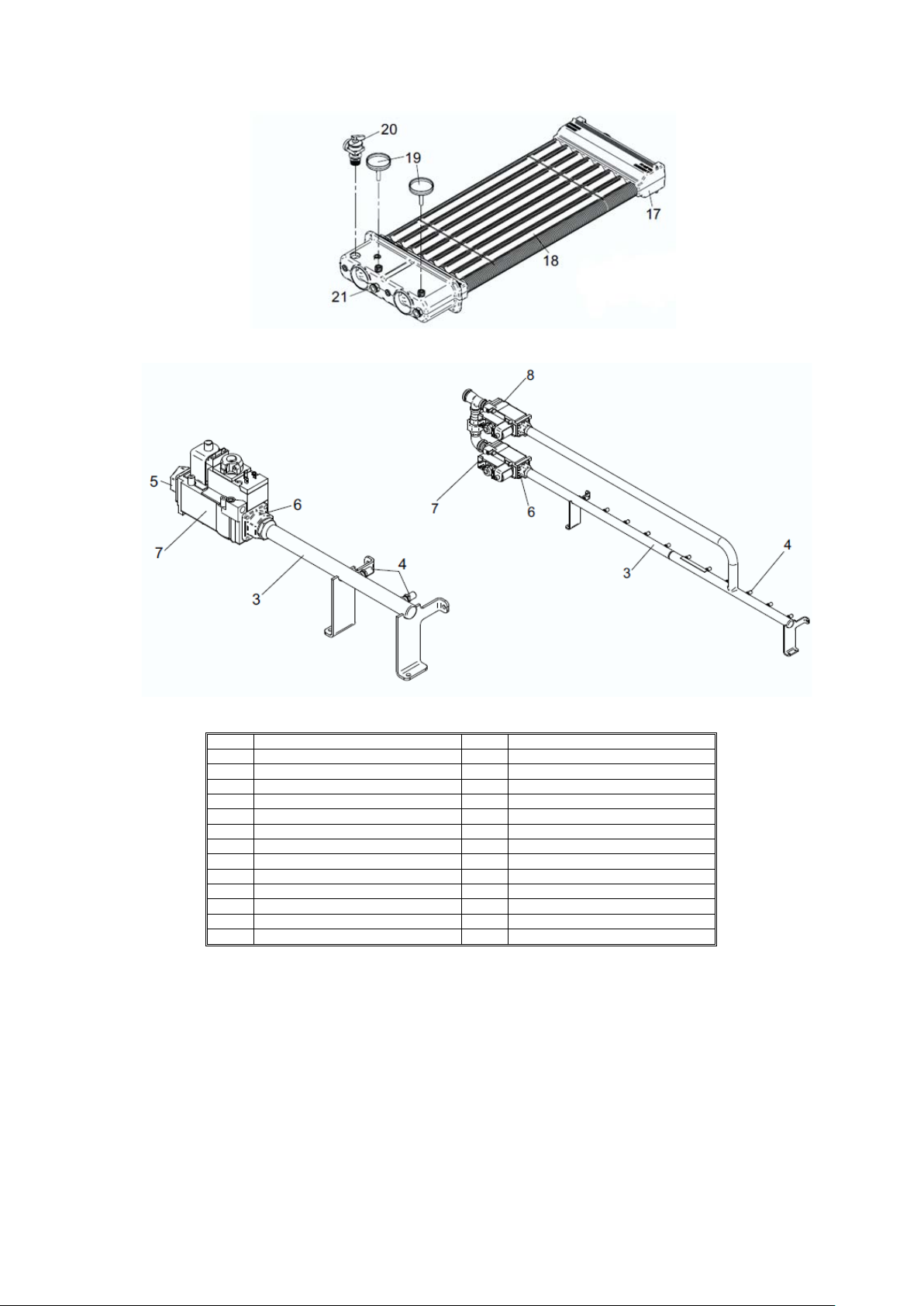

3.0 TECHNICAL DATA

Model Number

MC91CE

MC136CE

MC181CE

MC226CE

MC271CE

MC316CE

MC361CE

MC401CE

MC501CE

GENERAL DATA

Input (gross) - kW

26.4

39.6

52.8

65.9

79.1

92.3

105.5

117.2

146.5

Input (net) - kW

23.8

35.6

47.0

59.4

71.3

83.1

95.1

105.6

132.0

Output - kW (80°/60°)

20.8

31.0

41.4

52.3

62.7

73.2

83.6

93.0

118.8

Recovery Rat e (44° ∆T) - l/hr

432

648

864

1044

1260

1476

1692

1872

2340

Recovery Rat e (50° ∆T) - l/hr

380

570

760

919

1109

1299

1489

1647

2059

Shipping Weight - kg

57

64

71

84

89

99

104

127

132

WATER DATA

Water content - litres

3

3.2

3.4

3.5

3.6

3.7

3.8

4.2

4.5

Water connections (F&R) –

“BSP

Max. Water Pr essure - bar

11

11

11

11

11

11

11

11

11

Min. Water Pressure - bar

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

Maximum water temperature

Maximum water temperature

(boilers) - °C

GAS DATA (G20)

Gas inlet connection – “BSP

¾”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

1”

Gas Flow Rate - m3/hr

2.51

3.77

5.03

6.27

7.53

8.79

10.05

11.16

13.91

Burner Pressure - mbar

8.7

8.7

8.7

8.7

8.7

8.7

8.7

8.7

8.7

Minimum Gas Inlet Pressure mbar

Maximum Gas Inlet Pressure -

GAS DATA (G31)

Gas inlet connection – “BSP

¾”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

1”

Gas Flow Rate - m3/hr

0.99

1.49

1.98

2.48

2.97

3.47

3.97

4.41

5.51

Burner Pressure - mbar

26.0

26.0

26.0

26.0

26.0

26.0

26.0

26.0

26.0

Minimum Gas Inlet Pressure mbar

Maximum Gas Inlet Pressure mbar

FLUE DATA

Flue spigot diameter - mm

126

152

178

178

200

200

228

250

250

Flue gas volume - m3/min

0.79

1.25

1.64

2.07

2.52

2.92

3.39

3.79

4.73

Maximum flue gas temp. - ⁰C

140

140

130

130

160

160

160

160

160

2 2 2 2 2 2 2 2 2

(water heaters) - °C

mbar

90 90

105 105 105 105 105 105 105 105 105

17.5 17.5 17.5 17.5 17.5 17.5 17.5 17.5 17.5

25 25 25 25 25 25 25 25 25

27 27 27 27 27 27 27 27 27

45 45 45 45 45 45 45 45 45

90 90 90 90 90 90 90

TABLE 3.1: TECHNICAL DATA

8

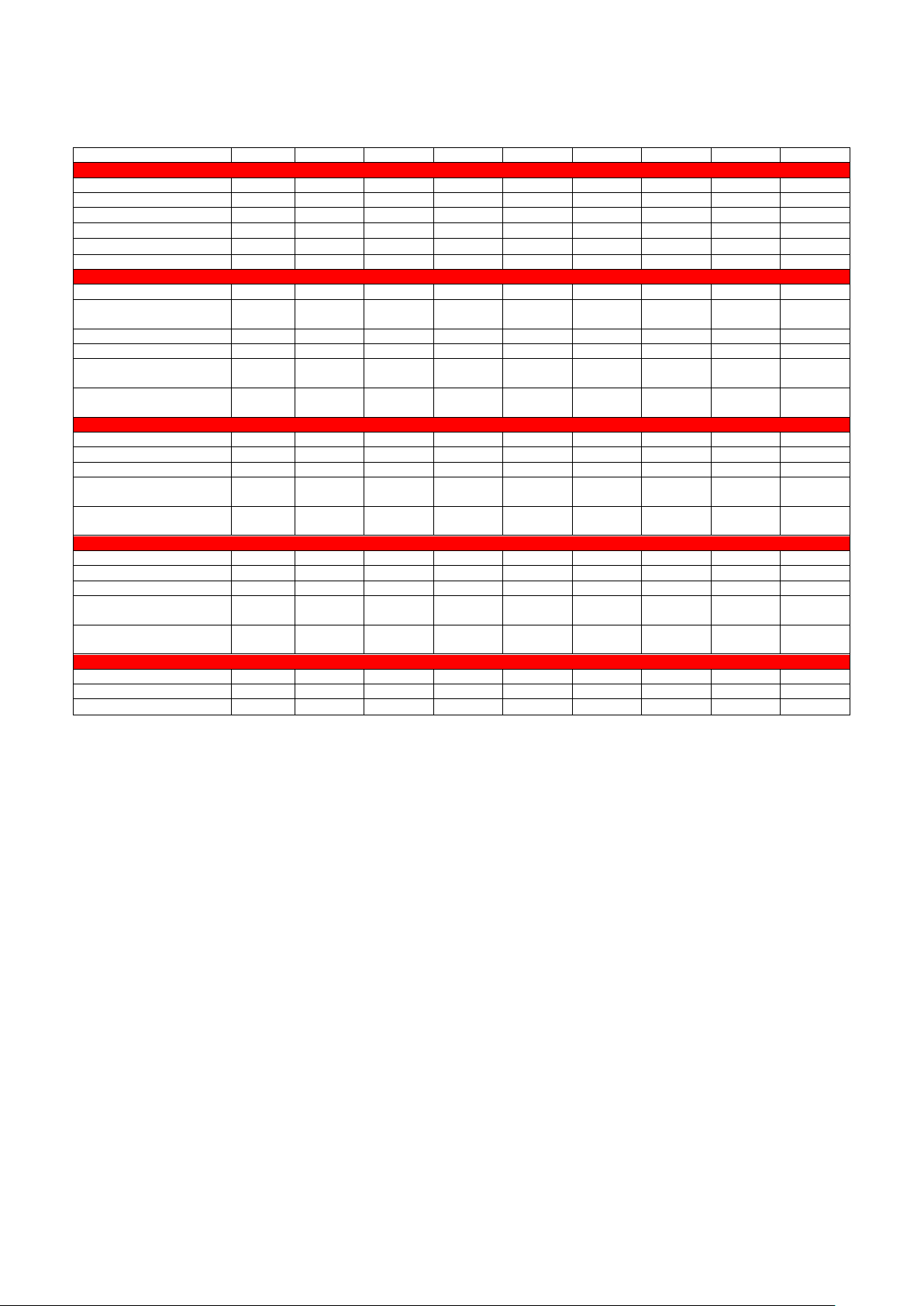

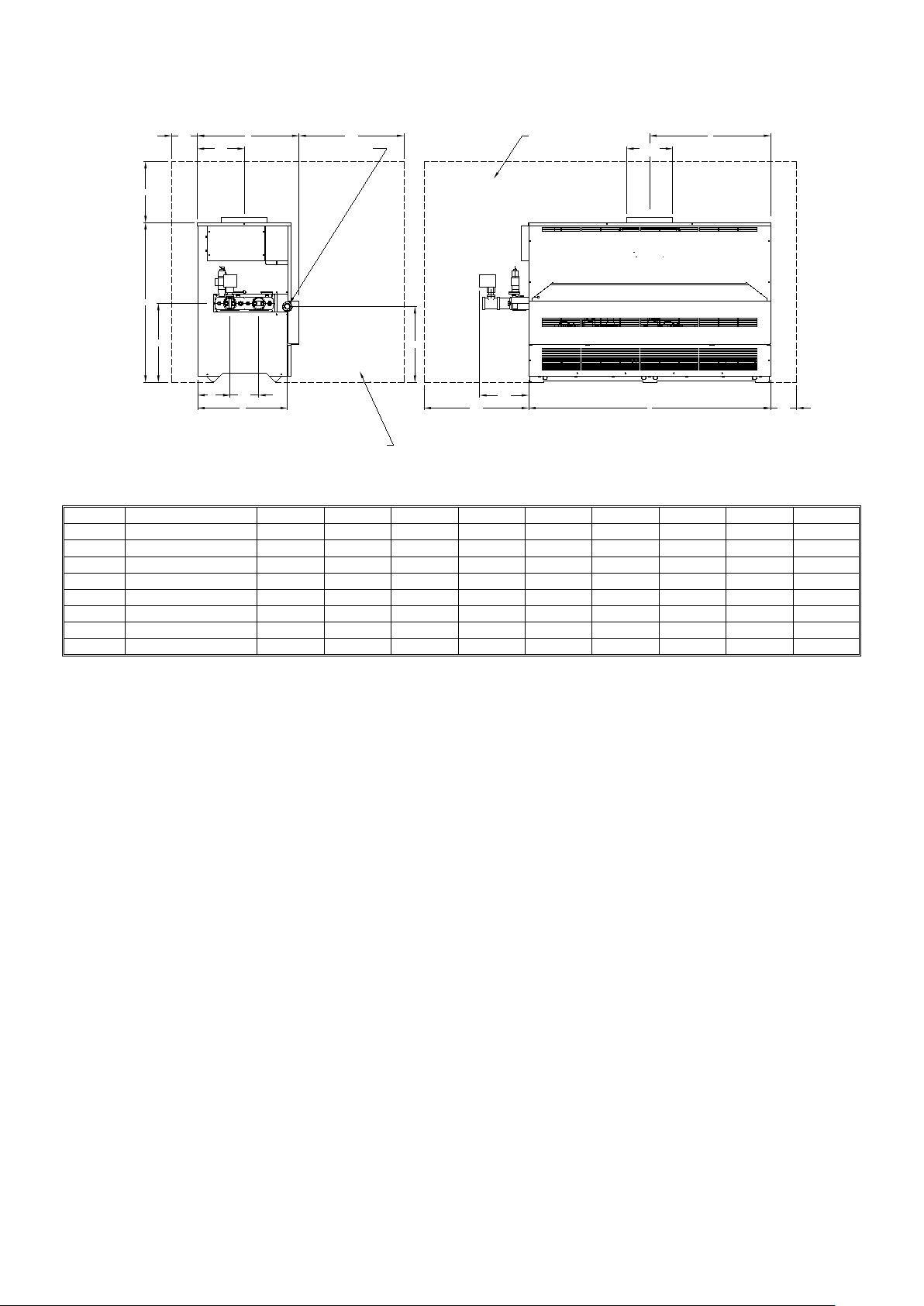

Dimension

Description

MC91CE

MC136CE

MC181CE

MC226CE

MC271CE

MC316CE

MC361CE

MC401CE

MC501CE

A

Overall height of heater

750

750

750

750

750

750

750

750

876

B

Overall width of heater

394

495

597

673

749

825

902

1130

1334

C

Overall depth of heater

546

546

546

546

546

546

546

559

559

D

Centreline of flue

197

248

298

337

375

413

451

565

667

E

Flue diameter

126

152

178

178

203

203

228

254

254

F

Height of ga s inlet

171

171

171

171

171

171

171

171

321

G

Centreline of gas inlet

475

475

475

475

475

475

475

475

493

H

Service clearance above

355

355

355

737

737

737

737

737

737

152

H

A

432

260

OUTLET

C

INLET

610

GAS CONNECTION

RECOMMENDED CLEARANCES

F

E DIA

D

178 159

G

(TO CENTRE OF GAS INLET)

RECOMMENDED CLEARANCES

263

610

FIGURE 3.1: DIMENSIONS

TABLE 3.1: DIMENSIONS

B

152

9

4.0 GENER AL REQUIREMENTS

The Lochinvar Mini Copper-Fin has been designed to operate trouble free for many years. These instructions

should be followed closely to obtain the maximum usage and efficiency of the equipment. PLEASE read the

instructions fully before installing or using the appliance.

4.1 RELATED DOCUMENTS

It is law that all gas appliances are installed by competent persons, in accordance with The Gas Safety

(Installation and Use) Regulations 1998. Failure to install appliances correctly could lead to prosecution. It is in

your own interest, and that of safety, to ensure that this law is complied with.

The installation of the equipment MUST be in accordance with the relevant requirements of the Gas Safety

Regulations, Building Regulations, I.E.E. Regulations and the bylaws of the local water undertaking. The

installation should also be in accordance with any relevant requirements of the local gas distributor and local

authority.

In addition the installation should follow the relevant guidance offered in the following documents. It is not

practical to list all relevant information but emphasis is placed on the following documents, as failure to comply

with the guidance given will almost certainly result in an unsatisfactory installation:

BS EN 1858: 2003 Chimneys. Components. Concrete flue blocks

BS 5440-1: 2008 Installation and maintenance of flues and ventilation for gas appliances of rated input

not exceeding 70kW net (1st, 2nd and 3rd family gases)

Part 1: Specification for installation and maintenance of flues

BS 5440-2: 2009 Installation and maintenance of flues and ventilation for gas appliances of rated input

not exceeding 70kW net (1st, 2nd and 3rd family gases)

Part 2: Specification for installation and maintenance of ventilation for gas

appliances

BS 6644: 2005 Specification for Installation of g as fired hot water boilers of rated inputs between

70kW

nd

+ A1: 2008 (net) and 1.8MW (net) (2

and 3rd family gasses)

BS 6700: 1997 Design, installation, testing and maintenance of services supplying water for

domestic use within buildings and their curtilages

BS 6880: 1988 Code of practice for low temperature hot water systems of output greater than 45kW

Parts 1, 2 and 3

BS 7074: 1989 Application, selection and installation of expansion vessels and ancillary equipment

Parts 1and 2 for sealed systems

BS 7671: 2008 Requirements for electrical installations, I.E.E. wiring regulations seventeenth edition

CP 342: Code of practice for centralised hot water supply-buildings other than dwellings

Part 2 1974

IGE/UP/1: Installation pipework on industrial and commercial premises

Edition 2

IGE/UP/2: Gas installation pipework, boosters and compressors on industrial and commercial

Edition 2 premises

10

IGE/UP/4: Commissioning of gas fired plant on industrial and commercial premises

Edition 2

IGE/UP/10: Installation of flued gas appliances in industrial and commercial premises

Edition 3

Gas Safety (Installation and Use) Regulations 1998 (England, Scotland & Wales)

CIBSE: Guide parts A, B and C

H.S.E. guidance Automatically controlled steam and hot water boilers

note PM5:

Third edition of the 1956 Clean Air Act Memorandum on Chimney Heights

Manufacturer's notes must not be taken in any way as overriding statutory obligations.

5.0 WATER QUALITY

Water supply quality may adversely affect the efficiency and performance of water heaters and hot water systems.

The situation can intensify where higher temperatures or demands exist.

Water hardness should not exceed 205ppm CaCO

and TDS (Total Dissolved Solids) of untreate d water should

3

not exceed 350ppm. If these values are exceeded, contact Lochinvar Limited for further guidance.

6.0 LOCATION

6.1 PLANT ROOM VENTILATION

The Lochinvar Mini Copper-Fin may only be installed in a room that complies with the appropriate ventilation

requirements. For further details, please refer to Section 9: AIR SUPPLY or to BS5440-2 or BS6644 as

appropriate.

6.2 GENERAL REQUIREMENTS

Corrosion of the heat exchanger and flue system may occur if air for combustion contains certain chemical

vapours. Such corrosion may result in poor combustion and create a risk of asphyxiation. Aerosol propellants,

cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes and process chemicals are corrosive. Products of this sort should not be stored near the water

heater or outside by the air intake (if applicable). The fitting of this equipment in a situation where aerosols or

other chemicals may be entrained into the combustion air will invalidate the warranty.

The equipment must be installed on a level, non-combustible surface that is capable of adequately supporting its

weight (when filled with water) and any ancillary equipment. The operation of the equipment must not cause the

temperature of any combustible material in the vicinity of the equipment and its flue to exceed 65 °C. If such a

situation is unavoidable, appropriate insulation should be provided.

Locate the equipment so that if the appliance or any connecting pipework should leak, water damage will not

occur. When such locations cannot be avoided it is recommended that a suitable drain pan be installed under the

equipment. The pan should be adequately drained but must not restrict the combustion or ventilation airflow.

6.3 CLEARANCES

The location chosen for the equipment must permit the provision for a satisfactory flue system and an adequate air

supply. The location must also provide adequate space for servicing and air circulation around each unit. This

includes any electrical trunking laid across the floor and to the appliance.

See Figure 3.1 and Table 3.1 for dimensions and clearances. Further details regarding locations are given in

BS5440 or BS6644 as appropriate.

11

7.0 GAS SU PPLY

The Lochinvar Mini Copper-Fin range is suitable for use on second and third family gasses 2H - G20 - 20mbar and

3P - G31 - 37mbar. Details relating to Natural Gas (2H) appear below; for details relating to Propane (3P)

please refer to Section 13: LPG FUEL.

7.1 SERVICE PIPES

The local gas distributor must be consulted at the installation planning stage in order to establish the availability of

an adequate supply of gas. An existing service pipe must not be used without prior consultation with the local gas

distributor.

7.2 METERS

A new gas meter will be connected to the service pipe by the local gas distributor contractor. An existing gas

meter should be checked, preferably by the gas distributor, to ensure that it is adequate to deal with the rate of gas

supply required.

7.3 GAS SUPPLY PIPES

Supply pipes must be fitted in accordance with IGE/UP/2. Pipework from the meter to the equipment must be of

adequate size. The complete installation must be purged and tested as described in IGE/UP/1. Refer to Section

13: LPG FUEL for information on LPG pipework installation guidance.

7.4 BOOSTED SUP PLIES

Where it is necessary to employ a gas pressure booster, the controls must include a low-pressure cut-off switch at

the booster inlet. The local gas distributor must be consulted before a gas pressure booster is fitted. For details of

how to connect a low-pressure cut-off switch, please refer to Section 11: ELECTRICAL SUPPLY.

7.5 PLANT-ROOM CONTROL VALVE

A manual valve for plant-room isolation must be fitted in the gas supply line. It must be clearly identified and

readily accessible for operation, preferably by an exit.

7.6 EQUIPMENT G AS SYSTEM LEAK CHECK

An approved isolating valve and union should be installed for each unit in a convenient and safe position

and be clearly marked. Ensure that the manual gas service valve is in the OFF position. Although the

equipment receives a gas leak check and gas train component integrity check prior to leaving the factory, transit

and installation may cause disturbance to unions, fittings and components. During commissioning a further test

for tightness should be carried out on the equipment gas pipework and components.

Care must be taken not to allow leak detection fluid on or near any electrical parts or connections.

Loading...

Loading...