Lochinvar Mini Copper-Fin MCW226CE, Mini Copper-Fin MCW271CE, Mini Copper-Fin MCW316CE, Mini Copper-Fin MCW361CE, Mini Copper-Fin MCW501CE Installation, Commissioning And Maintenance Instructions

...Page 1

MCW91CE

MCB501CE

INS0023 Issue No 6 | August 2011

The Mini Copper-Fin® range

High Efficiency Gas Fired Water Heaters and

Boilers

Installation, Commissioning and

Maintenance Instructions

Models:

MCW136CE

MCW181CE

MCW226CE

MCW271CE

MCW316CE

MCW361CE

MCW401CE

MCW501CE

MCB91CE

MCB136CE

MCB181CE

MCB226CE

MCB271CE

MCB316CE

MCB361CE

MCB401CE

Page 2

2

Table of Contents

1.0 INTRODUCTION ...................................................................................................................................................................................................................................... 4

2.0 PRINCIPAL PARTS ................................................................................................................................................................................................................................. 5

3.0 TECHNICAL DATA .................................................................................................................................................................................................................................. 7

4.0 GENERAL REQUIREMENTS .................................................................................................................................................................................................................. 9

4.1 RELATED DOCUMENTS ................................................................................................................................................................................................................. 9

5.0 WATER QUALITY .................................................................................................................................................................................................................................. 10

6.0 LOCATION ............................................................................................................................................................................................................................................. 10

6.1 PLANT ROOM VENTILATION ....................................................................................................................................................................................................... 10

6.2 GENERAL REQUIREMENTS ......................................................................................................................................................................................................... 10

6.3 CLEARANCES ................................................................................................................................................................................................................................ 10

7.0 GAS SUPPLY ......................................................................................................................................................................................................................................... 11

7.1 SERVICE PIPES ............................................................................................................................................................................................................................. 11

7.2 METERS.......................................................................................................................................................................................................................................... 11

7.3 GAS SUPPLY PIPES ...................................................................................................................................................................................................................... 11

7.4 BOOSTED SUPPLIES .................................................................................................................................................................................................................... 11

7.5 PLANT-ROOM CONTROL VALVE ................................................................................................................................................................................................ 11

7.6 EQUIPMENT GAS SYSTEM LEAK CHECK .................................................................................................................................................................................. 11

8.0 FLUE SYSTEM ....................................................................................................................................................................................................................................... 12

8.1 FLUE SYSTEM GENERAL REQUIREMENTS .............................................................................................................................................................................. 12

8.2 FLUE SYSTEMS ............................................................................................................................................................................................................................. 12

8.3 FLUE MATERIALS – CONVENTIONAL FLUE INSTALLATIONS ................................................................................................................................................ 12

8.4 MULTIPLE FLUE INSTALLATION ................................................................................................................................................................................................. 13

8.5 FAN DILUTION SYSTEMS ............................................................................................................................................................................................................. 13

8.6 B ALA NCED COMPARTME NT S ..................................................................................................................................................................................................... 13

9.0 AIR SUPPLY .......................................................................................................................................................................................................................................... 13

9.1 NATURAL VENTILATION............................................................................................................................................................................................................... 13

9.2 MECHANICAL VENTILATION........................................................................................................................................................................................................ 14

10.0 WATER CONNECTIONS ....................................................................................................................................................................................................................... 16

10.1 WATER HEATERS ......................................................................................................................................................................................................................... 16

10.1.1 GENERAL ........................................................................................................................................................................................................................ 16

10.1.2 OPEN VENTED SYSTEM ARRANGEMENT ................................................................................................................................................................. 16

10.1.3 UNVENTED SYSTEM ARRANGEMENT ....................................................................................................................................................................... 16

10.1.4 WATER PRESSURE GAUGE ......................................................................................................................................................................................... 16

10.1.5 DRAIN VALVES ............................................................................................................................................................................................................... 16

10.1.6 EXPANSION VESSEL SIZING ....................................................................................................................................................................................... 17

10.1.7 DE-STRATIFICATION ..................................................................................................................................................................................................... 17

10.1.8 CIRCULATING PUMPS .................................................................................................................................................................................................. 17

10.1.9 PIPEWORK SIZE ............................................................................................................................................................................................................ 18

10.2 HEATING BOILERS........................................................................................................................................................................................................................ 19

10.2.1 GENERAL ........................................................................................................................................................................................................................ 19

10.2.2 OPEN VENTED SYSTEM ARRANGEMENT ................................................................................................................................................................. 19

10.2.3 SEALED SYSTEM ARRANGEMENT ............................................................................................................................................................................. 19

10.2.4 DRAIN VALVES ............................................................................................................................................................................................................... 19

10.2.5 EXPANSION VESSEL SIZING ....................................................................................................................................................................................... 20

10.2.6 PRIMARY CIRCULATING PUMPS ................................................................................................................................................................................. 20

10.3 POOL HEATING ............................................................................................................................................................................................................................. 21

10.4 FLOW SWITCH ............................................................................................................................................................................................................................... 21

11.0 ELECTRICAL SUPPLY ......................................................................................................................................................................................................................... 21

11.1 E LECTRICAL CONNECT IONS ...................................................................................................................................................................................................... 22

11.2 EXTERNAL CONTROLS ................................................................................................................................................................................................................ 22

11.3 ARC WELDING PRECAUTIONS ................................................................................................................................................................................................... 22

11.4 WI RI NG DI AGRAM ......................................................................................................................................................................................................................... 23

12.0 COMMISSIONING AND TESTING ........................................................................................................................................................................................................ 25

12.1 E LE CTRICAL INSTA LLATION ....................................................................................................................................................................................................... 25

12.2 GAS INSTALLATION ...................................................................................................................................................................................................................... 25

12.3 WA T ER CO N NE CTIONS ............................................................................................................................................................................................................... 25

12.4 COMMISSIONING THE EQUIPMENT ........................................................................................................................................................................................... 25

12.4.1 GENERAL CHECKS PRIOR TO LIGHTING .................................................................................................................................................................. 25

12.4.2 EQUIPMENT CHECKS PRIOR TO LIGHTING .............................................................................................................................................................. 25

12.4.3 PROCEDURE FOR INITIAL LIGHTING ......................................................................................................................................................................... 26

12.4.4 GAS PRESSURE ADJUSTMENT AND COMBUSTION CHECKS................................................................................................................................ 26

12.5 WATER HEATER TEMPERATURE ADJUSTMENT PROCEDURE ............................................................................................................................................ 27

12.6 BOILER TEMPERATURE ADJUSTMENT PROCEDURE ............................................................................................................................................................ 27

12.7 INSTALLATION NOISE .................................................................................................................................................................................................................. 27

13.0 LPG FUEL .............................................................................................................................................................................................................................................. 27

13.1 RELATED DOCUMENTS ............................................................................................................................................................................................................... 27

13.2 PROPANE INJECTORS ................................................................................................................................................................................................................. 28

13.3 CONVERSION TO LPG .................................................................................................................................................................................................................. 28

13.4 LPG COMMISSIONING AND TESTING ........................................................................................................................................................................................ 28

Page 3

3

14.0 MAINTENANCE ..................................................................................................................................................................................................................................... 28

14.1 GENERAL ....................................................................................................................................................................................................................................... 28

14.2 MAINTENANCE SCHEDULE ......................................................................................................................................................................................................... 29

14.2.1 ADDITIONAL REQUIREMENTS FOR WATER HEATERS ........................................................................................................................................... 29

14.3 DRAINING THE WATER SYSTEM ................................................................................................................................................................................................ 29

14.4 WATER HEATER SERVICING ...................................................................................................................................................................................................... 29

14.4.1 REMOVING SCALE AND SEDIMENT FROM THE STORAGE VESSEL ..................................................................................................................... 29

14.4.2 SACRIFICIAL MAGNESIUM ANODES .......................................................................................................................................................................... 29

14.5 CLEANING THE HEAT EXCHANGER .......................................................................................................................................................................................... 30

14.6 REFILLING THE SYSTEM ............................................................................................................................................................................................................. 31

14.7 OTHER CHECKS ............................................................................................................................................................................................................................ 32

14.7.1 RELIEF VALVES ............................................................................................................................................................................................................. 32

14.7.2 FLUE SYSTEM ................................................................................................................................................................................................................ 32

14.8 TTB DEVICE ................................................................................................................................................................................................................................... 32

14.9 FAULT FINDING ............................................................................................................................................................................................................................. 32

15.0 USER INSTRUCTIONS .......................................................................................................................................................................................................................... 33

Page 4

4

1.0 INTRODUCTION

• The Lochinvar Mini Copper-Fin range is a floor standing direct gas fired water heater or boiler. The

equipment comprises a copper finned tube heat exchanger surrounded with a high density, light weight

refractory insulation. A durable outer steel jacket assembly provides structural integrity and easy

disassembly. The gas train includes black iron inlet manifold(s) a nd stainless steel atmospheric burner

assemblies.

• The burners are initiated by a full ignition sequence control that incorporates an intermittent pilot

assembly and rectification supervision of the flame.

• For the correct operation of the appliance when used as a water heater, it is essential that a suitably

sized, glanded-construction bronze pump is utilised to maintain a constant water flow rate through the

heat exchanger. When used as a water heater, the M ini Copper-Fin should also be used in conjunction

with an appropriately sized storage vessel (available from Lochinvar Limited as an ancillary option).

• This equipment is intended for use on Group H Natural Gas (2

The information relating to propane firing is to be found in Section 13: LPG FUEL. This equipment

MUST NOT use gas other than that for which it has been designed and adjusted.

• This equipment must be installed by a competent person, registered with a H.S.E. approved body. All

installations must conform to the relevant Gas Safety and Building Regulations. Health & Safety

requirements must also be taken into account when installing any equipment. Failure to comply with the

above may lead to prosecution.

• If the equipment is to be connected to an unvented (pressurised) system, care must be taken to ensure

all extra safety requirements are satisfied should a high or low-pressure condition occur in the system.

• The equipment is designed for direct connection to a flue system via the draught diverter built in to the

equipment casing. The flue outlets from more than one unit may be connected to a single chimney.

• Ancillary Options:

• Primary Circulating Pump (MCW91-361CE) Omega 4-60-2ZS

• Primary Circulating Pump (MCW401-501CE) Omega 4-90-2ZS

• Direct Storage Cylinder (297 litre) LST66

• Direct Storage Cylinder (450 litre) LST100

• Direct Storage Cylinder (747 litre) LST166

• Direct Storage Cylinder (1155 litre) LST250

• Unvented/Boosted Water System Kits Contact Lochinvar Limited

• De-stratification Pump Kit WH9

• Pre-Fabricated Interconnecting Pipework Contact Lochinvar Limited

• Stacking Frame (MCW/MCB91-181CE) MSF3050

• Stacking Frame (MCW/MCB226-361CE) MSF3051

• Stacking Frame (MCW/MCB401-501CE) MSF3052

• Stacking Frame (MCW + Storage) Contact Lochinvar Limited

nd

Family) and LPG propane (3rd Family).

Page 5

5

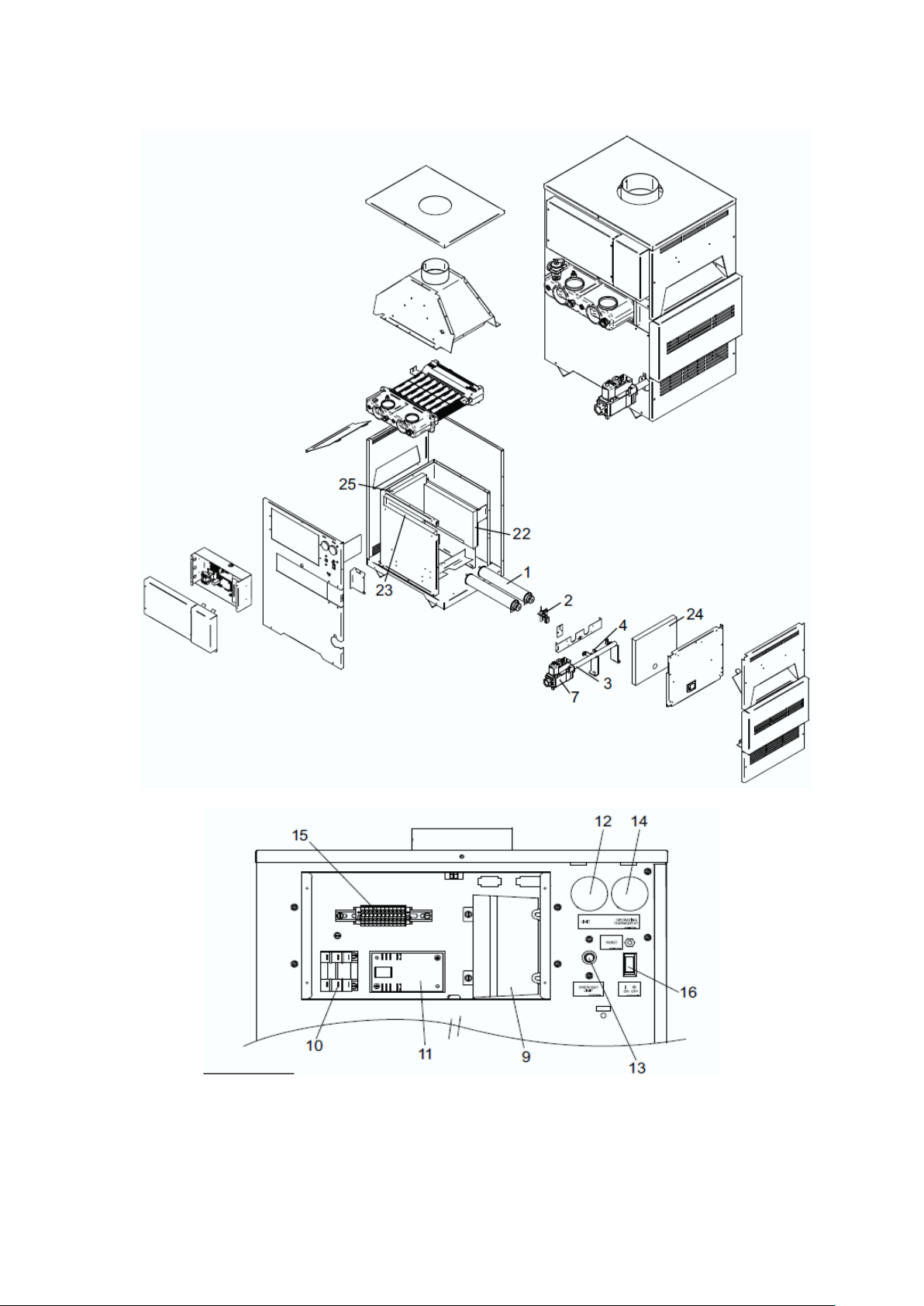

2.0 PRINCIPAL PARTS

FIGURE 2.1 EXPLODED DIAGRAM

FIGURE 2.2 EXPLODED DIAGRAM – CONTRO L PANEL ASSEMBLY

Page 6

6

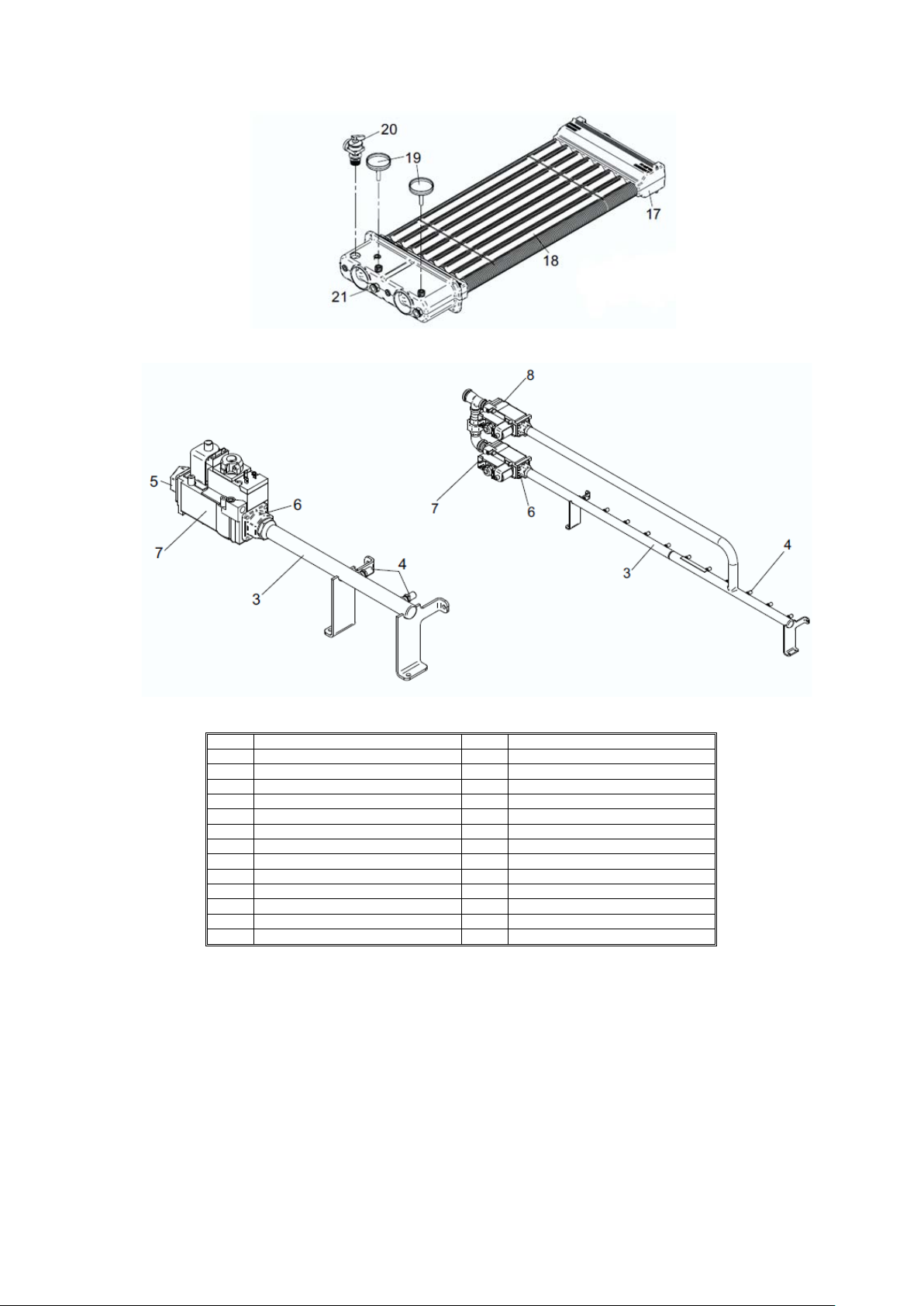

FIGURE 2.3 EXPLODED DIAGRAM – HEAT EXCHANGER

ITEM

DESCRIPTION

ITEM

DESCRIPTION

1

Main burner bar

14

Control thermostat

2

Pilot burner assembly

15

Terminal str ip

3

Burner manifold

16

On/off switch

4

Main burner injector

17

Heat exchan ger

5

Gas inlet flange

18

‘V’ baffle

6

Manifold fla nge

19

Temperature gauge

7

Gas valve

20

Pressure/temperature relief valve

8

Gas valve

21

Bulbwell pocket

9

Sequence cont rol

22

Right side fi bre board

10

Relay

23

Left side fibre board

11

Time delay relay

24

Front fibre b oard

12

High limit thermostat

25

Rear fibre board

13

Overheat thermostat

FIGURE 2.4 EXPLODED DIAGRAM - GAS MANIFOLD ASSEMBLY

TABLE 2.1 REMOVABLE COMPONENTS

Page 7

7

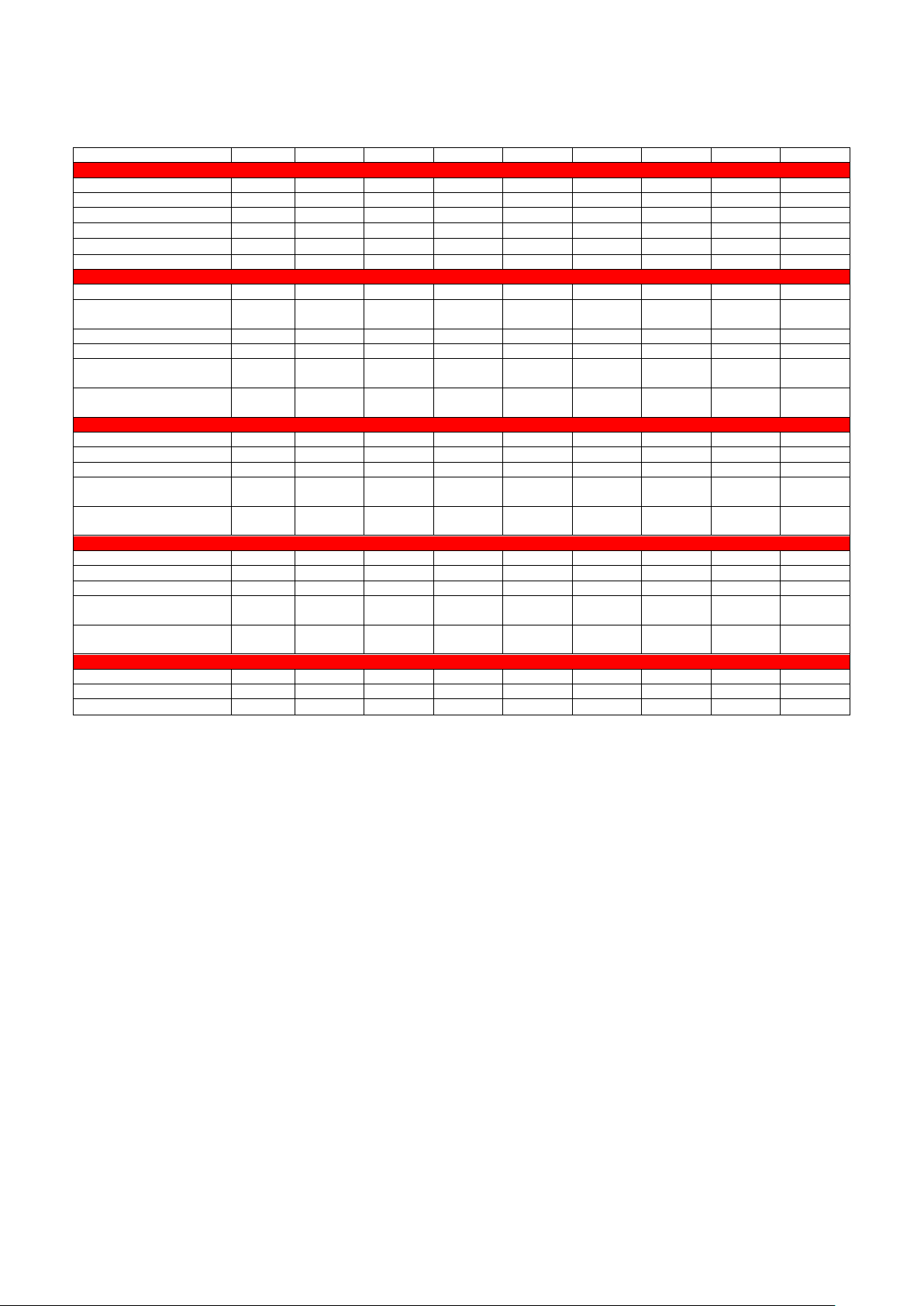

3.0 TECHNICAL DATA

Model Number

MC91CE

MC136CE

MC181CE

MC226CE

MC271CE

MC316CE

MC361CE

MC401CE

MC501CE

GENERAL DATA

Input (gross) - kW

26.4

39.6

52.8

65.9

79.1

92.3

105.5

117.2

146.5

Input (net) - kW

23.8

35.6

47.0

59.4

71.3

83.1

95.1

105.6

132.0

Output - kW (80°/60°)

20.8

31.0

41.4

52.3

62.7

73.2

83.6

93.0

118.8

Recovery Rat e (44° ∆T) - l/hr

432

648

864

1044

1260

1476

1692

1872

2340

Recovery Rat e (50° ∆T) - l/hr

380

570

760

919

1109

1299

1489

1647

2059

Shipping Weight - kg

57

64

71

84

89

99

104

127

132

WATER DATA

Water content - litres

3

3.2

3.4

3.5

3.6

3.7

3.8

4.2

4.5

Water connections (F&R) –

“BSP

Max. Water Pr essure - bar

11

11

11

11

11

11

11

11

11

Min. Water Pressure - bar

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.5

Maximum water temperature

Maximum water temperature

(boilers) - °C

GAS DATA (G20)

Gas inlet connection – “BSP

¾”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

1”

Gas Flow Rate - m3/hr

2.51

3.77

5.03

6.27

7.53

8.79

10.05

11.16

13.91

Burner Pressure - mbar

8.7

8.7

8.7

8.7

8.7

8.7

8.7

8.7

8.7

Minimum Gas Inlet Pressure mbar

Maximum Gas Inlet Pressure -

GAS DATA (G31)

Gas inlet connection – “BSP

¾”

¾”

¾”

¾”

¾”

¾”

¾”

¾”

1”

Gas Flow Rate - m3/hr

0.99

1.49

1.98

2.48

2.97

3.47

3.97

4.41

5.51

Burner Pressure - mbar

26.0

26.0

26.0

26.0

26.0

26.0

26.0

26.0

26.0

Minimum Gas Inlet Pressure mbar

Maximum Gas Inlet Pressure mbar

FLUE DATA

Flue spigot diameter - mm

126

152

178

178

200

200

228

250

250

Flue gas volume - m3/min

0.79

1.25

1.64

2.07

2.52

2.92

3.39

3.79

4.73

Maximum flue gas temp. - ⁰C

140

140

130

130

160

160

160

160

160

2 2 2 2 2 2 2 2 2

(water heaters) - °C

mbar

90 90

105 105 105 105 105 105 105 105 105

17.5 17.5 17.5 17.5 17.5 17.5 17.5 17.5 17.5

25 25 25 25 25 25 25 25 25

27 27 27 27 27 27 27 27 27

45 45 45 45 45 45 45 45 45

90 90 90 90 90 90 90

TABLE 3.1: TECHNICAL DATA

Page 8

8

Dimension

Description

MC91CE

MC136CE

MC181CE

MC226CE

MC271CE

MC316CE

MC361CE

MC401CE

MC501CE

A

Overall height of heater

750

750

750

750

750

750

750

750

876

B

Overall width of heater

394

495

597

673

749

825

902

1130

1334

C

Overall depth of heater

546

546

546

546

546

546

546

559

559

D

Centreline of flue

197

248

298

337

375

413

451

565

667

E

Flue diameter

126

152

178

178

203

203

228

254

254

F

Height of ga s inlet

171

171

171

171

171

171

171

171

321

G

Centreline of gas inlet

475

475

475

475

475

475

475

475

493

H

Service clearance above

355

355

355

737

737

737

737

737

737

152

H

A

432

260

OUTLET

C

INLET

610

GAS CONNECTION

RECOMMENDED CLEARANCES

F

E DIA

D

178 159

G

(TO CENTRE OF GAS INLET)

RECOMMENDED CLEARANCES

263

610

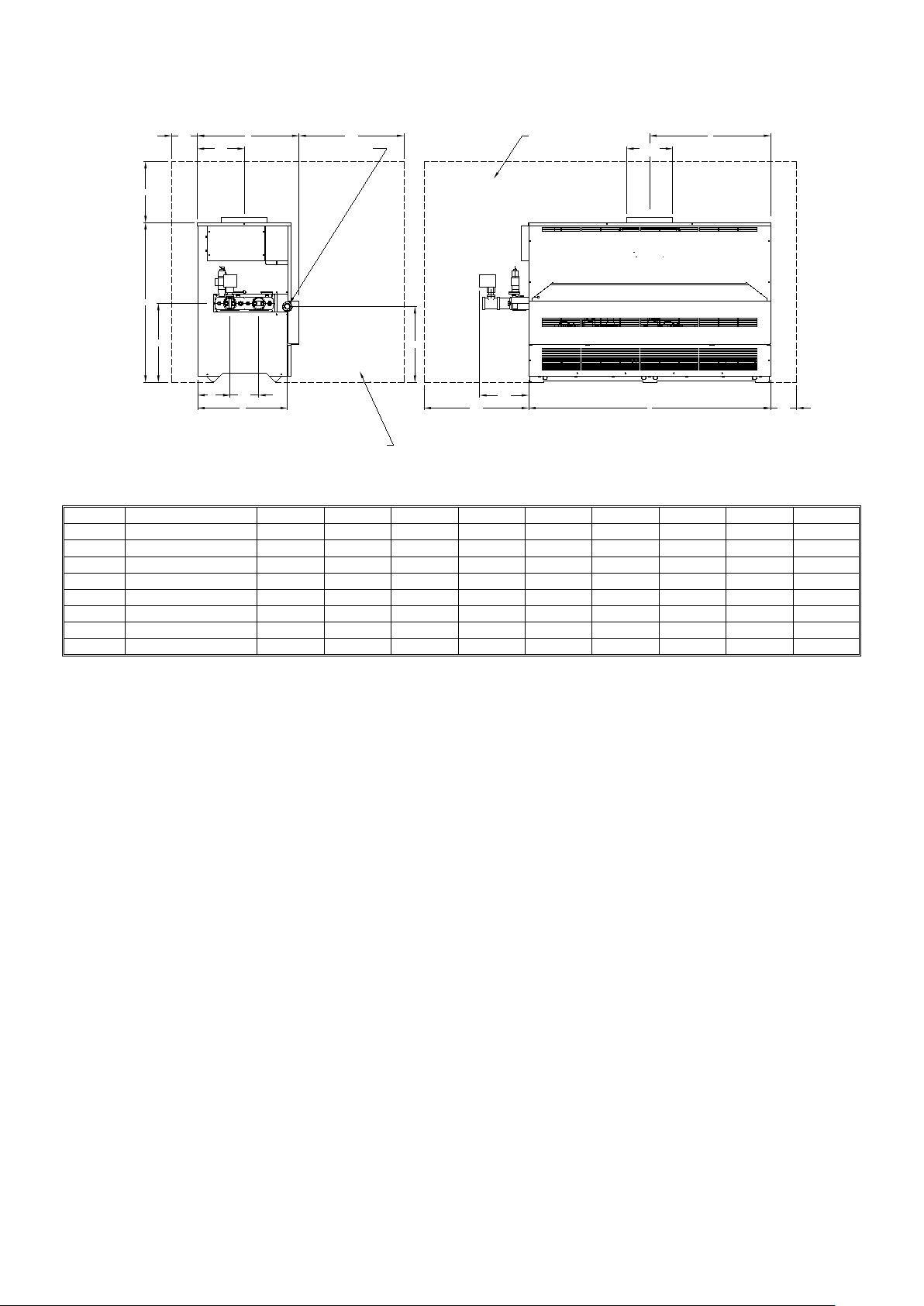

FIGURE 3.1: DIMENSIONS

TABLE 3.1: DIMENSIONS

B

152

Page 9

9

4.0 GENER AL REQUIREMENTS

The Lochinvar Mini Copper-Fin has been designed to operate trouble free for many years. These instructions

should be followed closely to obtain the maximum usage and efficiency of the equipment. PLEASE read the

instructions fully before installing or using the appliance.

4.1 RELATED DOCUMENTS

It is law that all gas appliances are installed by competent persons, in accordance with The Gas Safety

(Installation and Use) Regulations 1998. Failure to install appliances correctly could lead to prosecution. It is in

your own interest, and that of safety, to ensure that this law is complied with.

The installation of the equipment MUST be in accordance with the relevant requirements of the Gas Safety

Regulations, Building Regulations, I.E.E. Regulations and the bylaws of the local water undertaking. The

installation should also be in accordance with any relevant requirements of the local gas distributor and local

authority.

In addition the installation should follow the relevant guidance offered in the following documents. It is not

practical to list all relevant information but emphasis is placed on the following documents, as failure to comply

with the guidance given will almost certainly result in an unsatisfactory installation:

BS EN 1858: 2003 Chimneys. Components. Concrete flue blocks

BS 5440-1: 2008 Installation and maintenance of flues and ventilation for gas appliances of rated input

not exceeding 70kW net (1st, 2nd and 3rd family gases)

Part 1: Specification for installation and maintenance of flues

BS 5440-2: 2009 Installation and maintenance of flues and ventilation for gas appliances of rated input

not exceeding 70kW net (1st, 2nd and 3rd family gases)

Part 2: Specification for installation and maintenance of ventilation for gas

appliances

BS 6644: 2005 Specification for Installation of g as fired hot water boilers of rated inputs between

70kW

nd

+ A1: 2008 (net) and 1.8MW (net) (2

and 3rd family gasses)

BS 6700: 1997 Design, installation, testing and maintenance of services supplying water for

domestic use within buildings and their curtilages

BS 6880: 1988 Code of practice for low temperature hot water systems of output greater than 45kW

Parts 1, 2 and 3

BS 7074: 1989 Application, selection and installation of expansion vessels and ancillary equipment

Parts 1and 2 for sealed systems

BS 7671: 2008 Requirements for electrical installations, I.E.E. wiring regulations seventeenth edition

CP 342: Code of practice for centralised hot water supply-buildings other than dwellings

Part 2 1974

IGE/UP/1: Installation pipework on industrial and commercial premises

Edition 2

IGE/UP/2: Gas installation pipework, boosters and compressors on industrial and commercial

Edition 2 premises

Page 10

10

IGE/UP/4: Commissioning of gas fired plant on industrial and commercial premises

Edition 2

IGE/UP/10: Installation of flued gas appliances in industrial and commercial premises

Edition 3

Gas Safety (Installation and Use) Regulations 1998 (England, Scotland & Wales)

CIBSE: Guide parts A, B and C

H.S.E. guidance Automatically controlled steam and hot water boilers

note PM5:

Third edition of the 1956 Clean Air Act Memorandum on Chimney Heights

Manufacturer's notes must not be taken in any way as overriding statutory obligations.

5.0 WATER QUALITY

Water supply quality may adversely affect the efficiency and performance of water heaters and hot water systems.

The situation can intensify where higher temperatures or demands exist.

Water hardness should not exceed 205ppm CaCO

and TDS (Total Dissolved Solids) of untreate d water should

3

not exceed 350ppm. If these values are exceeded, contact Lochinvar Limited for further guidance.

6.0 LOCATION

6.1 PLANT ROOM VENTILATION

The Lochinvar Mini Copper-Fin may only be installed in a room that complies with the appropriate ventilation

requirements. For further details, please refer to Section 9: AIR SUPPLY or to BS5440-2 or BS6644 as

appropriate.

6.2 GENERAL REQUIREMENTS

Corrosion of the heat exchanger and flue system may occur if air for combustion contains certain chemical

vapours. Such corrosion may result in poor combustion and create a risk of asphyxiation. Aerosol propellants,

cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes and process chemicals are corrosive. Products of this sort should not be stored near the water

heater or outside by the air intake (if applicable). The fitting of this equipment in a situation where aerosols or

other chemicals may be entrained into the combustion air will invalidate the warranty.

The equipment must be installed on a level, non-combustible surface that is capable of adequately supporting its

weight (when filled with water) and any ancillary equipment. The operation of the equipment must not cause the

temperature of any combustible material in the vicinity of the equipment and its flue to exceed 65 °C. If such a

situation is unavoidable, appropriate insulation should be provided.

Locate the equipment so that if the appliance or any connecting pipework should leak, water damage will not

occur. When such locations cannot be avoided it is recommended that a suitable drain pan be installed under the

equipment. The pan should be adequately drained but must not restrict the combustion or ventilation airflow.

6.3 CLEARANCES

The location chosen for the equipment must permit the provision for a satisfactory flue system and an adequate air

supply. The location must also provide adequate space for servicing and air circulation around each unit. This

includes any electrical trunking laid across the floor and to the appliance.

See Figure 3.1 and Table 3.1 for dimensions and clearances. Further details regarding locations are given in

BS5440 or BS6644 as appropriate.

Page 11

11

7.0 GAS SU PPLY

The Lochinvar Mini Copper-Fin range is suitable for use on second and third family gasses 2H - G20 - 20mbar and

3P - G31 - 37mbar. Details relating to Natural Gas (2H) appear below; for details relating to Propane (3P)

please refer to Section 13: LPG FUEL.

7.1 SERVICE PIPES

The local gas distributor must be consulted at the installation planning stage in order to establish the availability of

an adequate supply of gas. An existing service pipe must not be used without prior consultation with the local gas

distributor.

7.2 METERS

A new gas meter will be connected to the service pipe by the local gas distributor contractor. An existing gas

meter should be checked, preferably by the gas distributor, to ensure that it is adequate to deal with the rate of gas

supply required.

7.3 GAS SUPPLY PIPES

Supply pipes must be fitted in accordance with IGE/UP/2. Pipework from the meter to the equipment must be of

adequate size. The complete installation must be purged and tested as described in IGE/UP/1. Refer to Section

13: LPG FUEL for information on LPG pipework installation guidance.

7.4 BOOSTED SUP PLIES

Where it is necessary to employ a gas pressure booster, the controls must include a low-pressure cut-off switch at

the booster inlet. The local gas distributor must be consulted before a gas pressure booster is fitted. For details of

how to connect a low-pressure cut-off switch, please refer to Section 11: ELECTRICAL SUPPLY.

7.5 PLANT-ROOM CONTROL VALVE

A manual valve for plant-room isolation must be fitted in the gas supply line. It must be clearly identified and

readily accessible for operation, preferably by an exit.

7.6 EQUIPMENT G AS SYSTEM LEAK CHECK

An approved isolating valve and union should be installed for each unit in a convenient and safe position

and be clearly marked. Ensure that the manual gas service valve is in the OFF position. Although the

equipment receives a gas leak check and gas train component integrity check prior to leaving the factory, transit

and installation may cause disturbance to unions, fittings and components. During commissioning a further test

for tightness should be carried out on the equipment gas pipework and components.

Care must be taken not to allow leak detection fluid on or near any electrical parts or connections.

Page 12

12

8.0 FLUE SYSTEM

8.1 FLUE SYSTEM GENERAL REQUIREMENTS

Detailed recommendations for the flue system are given in BS5440-1 for equipment of rated input not exceeding

70kW net, BS6644 for equipment above 70k W net and IGE/UP/10 for equipment of rated input above 54kW net.

The following notes are intended to give general guidance only.

8.2 FLUE SYSTEM S

Any flue termination must be in such a position as will not cause a hazard to the health of persons who may be

nearby or a nuisance to other persons beyond the curtilage. The flue terminal must be positioned externally such

as to allow the dispersal of products of combustion and air intake. The terminal should be installed in a location

where it will not easily flood or be blocked by snow.

The flue terminal position is very important and must be 1000mm above the roof surfaces or at least 600mm

above any parapet and clear of all adjacent obstructions. It must also be clear of any openable windows,

ventilators or entries that would let flue products from re-entering the building. Recommendations can be found in

BS6644 or BS5440 Part 1 as appropriate.

A minimum of 600mm of vertical flue directly above the draught diverter should be provided where possible on all

draught flue installations. If this dimension cannot be achieved please contact Lochinvar Limited for further

guidance. The weight of the flue must be adequately supported by securing clips and not by the appliance.

The flue system should be designed to maintain atmospheric pressure or a slight suction at the equipment flue

connection at all times within the range of 0.08 to 0.10 mbar (8 to 10 Pascals).

Due to the high thermal efficiency of the equipment, the flue gas temperature is approximately 130°C - 160°C.

Condensation in the flue is thus more likely to occur than with lower efficiency equipment. It is strongly

recommended that twin-wall or insulated flue pipe is used on all in sta llations . Care should be taken to ensure that

the flue is installed such that any condensation is continuously drained. All f lues should have a minimum slope of

2° upwards in the direction of the exhaust gas flow. All joints should be such that any condensat ion is directed

back down the slope to an open drain connection in the flue. The drain pipe must be manufactured from a

corrosion resistant material and be at least 15mm diameter. It must also have a fall of at least 2 to 3° (approx. 3-5

cm per metre) and connect to a drain via a waste trap.

8.3 FLUE MATERIALS – CONVENTI ONAL FLUE INSTALLATIONS

• Flue materials, including all jointing materials and fittings should be free from asbestos, durable,

resistant to corrosion and non-combustible.

• When passing up through or adjacent to combustible materials measures need to be taken to prevent

the temperature of the combustible material from exceeding 60°C. The flue must be at least 50mm from

any combustible material unless shielded by a non-combustible sleeve with an air gap of at least 25mm

• Flues shall be of a size not less than specified in Table 3.1. They should be fitted so there is no risk to

anybody in the building and no risk of accidental damage.

• If using an existing brick chimney, a suitable liner should be installed before connecting to the appliance.

The flue should take the shortest possible route and rise continuously to the terminal avoiding the use of

o

bends when there is a change in direction. Horizontal and very shallow runs of flue should be

90

avoided since they impede the flow of gases and increase local cooling.

Page 13

13

8.4 MULTIPLE FLUE INSTALLATION

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

MC91CE

23.8

26.4

106

132

264

264

528

MC181CE

• Common flues may be used on multiple installations only if all the heaters are of the same burner

system and fuel type and should be sized to ensure complete evacuation of the flue products from the

installation.

• Where one appliance is to be used more regularly or for longer periods than the others in the group, it

should be connected at the point nearest the main flue. Please refer to BS6644 for further information

and recommendations.

• A split collar should be fitted above the draught diverter so that the flue is secure but can be

disconnected for servicing. The weight of the flue must be adequately supported by securing clips and

not by the heater.

• If a 600mm vertical rise before connection to the common header is not possible, the common header

should be sized to ensure adequate evacuation of all products of combustion.

8.5 FAN DILUTION SYSTEMS

An alternative to a natural draught flue system is a Flue dilution system, which is suitable for connection to the Mini

Copper-Fin’s but must be properly designed by a specialist flue company.

8.6 BALANCED COMPARTMENTS

The equipment is suitable for siting within a balanced compartment. This compartment must be designed by a

specialist company.

9.0 AIR SUPPLY

The following information is based on single appliance installations only. If more than one appliance is being

used, BS5440-2 or BS6644 (as appropriate) should be consulted to calculate the necessary requirements.

This is a Type B

appliance and must be installed outside or in a room separated from inhabited rooms

11

with suitable ventilation directly to the outside.

9.1 NATURAL VENTILATION

The combustion air requirements are as follows:

Compartment Compartment

(Direct to Outside) (To Internal S pace)

Model

Gross

Input

(kW)

Net

Input

(kW)

Ventilation

(Room)

2

(cm

)

MC136CE 35.6 39.6 160 199 396 396 792

47.0 52.8 212 264 528 528 1056

MC226CE 59.4 65.9 264 330 659 659 1318

TABLE 9.1 COMBUSTION VENTILATION REQUIREMENTS MC91CE – MC226CE

Page 14

14

Low

Summer Use

Medium

Summer Use

High

Summer Use

Low

Summer Use

Medium

Summer Use

High

Summer Use

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

MC271CE

79.1

71.3

143

286

214

357

286

428

357

713

428

785

500

856

MC361CE

105.5

95.1

190

380

285

475

380

570

475

951

570

1045

665

1140

MC501CE

Flow rate per kW total rated net input (m3/h)

Minimum Inlet Air

Difference between Inlet and Ext ract Air

With draught diverters

2.80

2.07 ± 0.18

Without draught diverters.

Heat input (net):

=

95.1 kW

Minimum combustion air flow rate:

=

95.1 x 2.8 m3/h

=

266.28 m3/h

Ventilation grille size (high level):

=

192 cm2

Plant Room Enclosure

Input

(kW)

Net

Input

(kW)

Model

Gross

MC316CE 92.3 83.1 167 333 250 416 333 500 416 831 500 916 583 999

MC401CE 117.2 105.6 212 423 317 528 423 634 528 1056 634 1162 740 1268

146.5 132.0 264 528 396 660 528 792 660 1320 792 1452 924 1584

TABLE 9.2 COMBUSTION VENTILATION REQUIREMENTS MC271CE – MC501CE

9.2 MECHANICAL VENTILATION

To comply with the relevant installation standards, (BS5440-2:2009 for appliances with net heat inputs below

70kW and BS6644:2005 for appliances with net heat inputs between 70kW and 1.8MW) combustion ventilation

must be provided for all open flued appliances. In situations where this cannot be provided by the means of

ventilation grilles, combustion air can be supplied by a fan. The minimum flow rate for the fan should be in

accordance with Table 9.3.

If required, extract air can also be through the use of a fan. When sizing the extract fan, the extract flow rate

should be calculated by subtracting the difference volume (from Table 9.3) from the actual supplied volume of inlet

air. If therefore, a larger than required inlet volume is provided, the extract flow rate will need to be increased

accordingly.

If the ventilation discharge from the plant room is through the means of simple openings relying on thermal effects,

the minimum free areas of the openings and any associated grilles should be as specified for natural ventilation

(see separate “Free Area Requirements – Combustion” specification sheet). The ventilation openings shall be at

high level and the air supply shall be at low level.

Ventilation must not be provided through natural inlet and mechanical extract as this will cause a negative

pressure within the plant room and may lead to the products of combustion being drawn into the plant room.

When using mechanical ventilation systems, an automatic control should be used to cause a safety shut-down of

the burner in the event of failure of air-flow either inlet or extract ducts.

NOTE: VENTILATION MUST NOT BE PROVIDED THROUGH NATURAL INLET AND

MECHANICAL EXTRACT AS THIS WILL CAU SE A NEGATIVE PRESSURE WITHIN TH E PLANT ROOM AND

MAY LEAD TO THE PRODUCTS OF COMBUSTION BEING DRAWN INTO THE PLANT ROOM.

Appliance Type

(with or without draught stabilisers)

TABLE 9.3 MECHANICAL VENTILATION FLOW RATES

Worked Example – Mechanical inlet/natural discharge:

Lochinvar MC361CE

(Combustion, Ventilation)

2.60 1.35 ± 0.18

(Inlet minus Extract Ventilation)

Page 15

15

Worked Example – Mechanical inlet/mechanical discharge (minimum combustion air flow rate):

Heat input (net):

=

95.1 kW

Minimum combustion air flow rate:

=

95.1 x 2.8 m3/h

=

266.28 m3/h

Difference between inlet and extract air

(maximum value):

=

95.1 x (2.07 + 0.18) m3/h

=

213.98 m3/h

Difference between inlet and extract air

(minimum value):

=

95.1 x (2.07 - 0.18) m3/h

=

179.74 m3/h

Extract air (maximum value):

=

266.28 m3/h – 179.74 m3/h

=

86.54 m3/h

Extract air (minimum value):

=

266.28 m3/h – 213.98 m3/h

=

52.30 m3/h

Heat input (net):

=

95.1 kW

Minimum combustion air flow rate:

=

95.1 x 2.8 m3/h

=

266.28 m3/h

Actual combustion air flow rate:

=

95.1 x 3.15 m3/h

=

299.57 m3/h

Difference between inlet and extract air:

(maximum value)

=

95.1 x (2.07 + 0.18) m3/h

=

213.98 m3/h

Difference between inlet and extract air:

(minimum value)

=

95.1 x (2.07 - 0.18) m3/h

=

179.74 m3/h

Extract air (maximum value):

=

299.57 m3/h – 179.74 m3/h

=

119.83 m3/h

Extract air (minimum value):

=

299.57 m3/h – 213.98 m3/h

=

85.59 m3/h

Lochinvar MC361CE

Worked Example – Mechanical inlet/mechanical discharge (alternate combustion air flow rate):

Lochinvar MC361CE

Page 16

16

10.0 WATER CONNECTIONS

10.1 WATER HEATERS

10.1.1 GENERAL

Mini Copper-Fin water heaters require a minimum flow rate and should also be supplied with separate storage

vessels. Suitably sized pumps and separate storage vessels are available from Lochinvar Limited as ancillary

options.

Note: Lochinvar Limited recommends the use of glanded bronze pumps.

Recommended pipework layouts are available for different water heater and storage vessel combinations. Please

contact Lochinvar Limited for details. When multiple units are connected using common pipework, it is

recommended that a reverse-return arrangement is used to ensure equal flow through each unit.

The requirements of minimum water flow are given in Table 10.2. Recommendations for the water circulation

system are given in BS6644 and CP 342. The following notes are of particular importance.

1. When the unit is being utilised as a direct-fired water heater it is designed for use with a direct type

storage vessel. Contact Lochinvar Limited for help in sizing the storage vessel

2. Circulating pipework not forming part of the useful heating surface should be insulated. Cisterns,

expansion vessels and pipework situated in areas exposed to freezing conditions should also be

insulated.

3. Drain valves must be located in accessible positions that will permit draining of the entire system

including the unit and the storage vessel.

4. Tapping sizes for connection to the water system are detailed in Table 3.1.

5. Ideally, individual valves should be fitted to each unit to enable isolation from the system. The

arrangement must comply with the requirements of BS6644.

6. Every system should be provided with a water gauge complete with isolating valve so that the pressure

of the system may be displayed for commissioning and maintenance purposes.

10.1.2 OPEN VENTED SYSTEM ARRANGEMENT

The Lochinvar Mini Copper-Fin can be used in an open vented arrangement provided that a vent pipe in

accordance with CP342, BS6644 or BS6700 as appropriate is fitted. T he minimum static head requ irement for an

open vented system is 0.5 bar.

10.1.3 UNVENTED SYSTEM ARRANGEMENT

NOTE: IT IS STRONGLY RECOMMENDED THAT UNVENTED HOT WATER SYSTEMS BE

INSTALLED BY AN APPROVED INSTALLER.

If the Lochinvar Mini Copper-Fin is to be used in an unvented arrangement, the system should follow the guidance

given in BS6700 and must comply with The Building Regulations: Part G3. A kit of components that have been

suitably sized for the unvented operation of the appliance is available from Lochinvar Limited. For further

information, contact Lochinvar Limited.

10.1.4 WATER PRESSURE GAUG E

Every system should be provided with a gauge complete with isolating valve so that the pressure of the system

may be displayed for commissioning and maintenance purposes.

10.1.5 DRAIN VALVES

Each unit should be provided with a 15mm drain valve fitted into the return to enable the heat exchanger to be

drained without draining the entire system.

Page 17

17

10.1.6 EXPANSION VESSEL SIZ IN G

Stored

C

Stored

C

The following information is based on an inlet pressure of 3.5 bar. If a different inlet pr essure is to be used, please

consult BS6700.

S V * e

V V =

0.45

Where:

V V = Vessel Volume

S V = System Volume

e = Coefficient of Expansion (See Table 10.1)

Temp.

°

e 0.005 0.006 0.008 0.010 0.012 0.015 0.017

Temp.

°

e 0.020 0.023 0.026 0.030 0.031 0.033 0.037

30 35 40 45 50 55 60

65 70 75 80 82 85 90

TABLE 10.1 COEFFICIENT OF EXPANSION OF WATER AT 3.5 BAR INLET PRESSURE

10.1.7 DE-STRATIFICATION

If the hot water system does not include a constantly circulated building return, it is recommended that a destratification pump be fitted, between the flow connection and the circulation connection on the right hand side of

the storage vessel, to ensure an even temperature distribution throughout the stored water. De-stratification pump

kits are available as ancillary items; please contact Lochinvar Limited for details.

10.1.8 CIRCULATING PUMPS

In order to ensure the correct flow rates through the water heater, the unit requires a bronze glanded pump sized

to overcome the resistance of the heat exchanger and a primary pipework loop. The primary loop should be no

longer than 14 metres plus the following fittings:

6 x 90° Elbows

2 x Unions

2 x Full bore lever ball valves

2 x Tee fittings (cold feed & HWS return)

For longer distances or a greater number of fittings, the pump may have to be resized.

The specification of this type of pump ensures that the bronze body and associated parts in contact with water are

suitable for potable use. A "glanded" construction is required to ensure that any scale in the system does not build

up within the pump and cause a resistance that can lead to a loss of water flow. Glandless (canned rotor) pumps

are not recommended by Lochinvar Limited due to the fact that in hard water areas, scale can build up within the

rotor and failure can occur, not only of the pump but also the heater itself. The warranty will be void if a failure of

the heat exchanger occurs due to a "glandless" pump.

Page 18

18

Total System P ressure

Loss - Metre H20

2.44

2.44

2.44

2.44

2.44

2.44

2.44

2.44

Model Differential - K Flow – l/s

MCW91CE 3 1.9 2.44

MCW136CE 4 1.9

MCW181CE 5 1.9

MCW226CE 6 1.9

MCW271CE 8 1.9

MCW316CE 9 1.9

MCW361CE 11 1.9

MCW401CE 12 1.9

MCW501CE 15 1.9

TABLE 10.2 WATER HEATER FLOW RATES

To ensure proper velocity through the heat exchanger, it is necessary to balance the temperature rise across the

heat exchanger from inlet to outlet. Excessive scale build up in th e tubes is a result of too little velocity; excessive

pitting or erosion on the inside of the tubes is caused by too much velocity. Care should be taken to measure the

temperature rise and maintain a constant velocity as follows:

1. Thermometers are installed on the inlet and outlet of the equipment to measure water temperature

entering and leaving.

2. The pump should run continuously.

3. With the pump in operation and the burner “off”, both thermometers should read the same temperature.

4. Switch the burner on and allow the temperature to stabilise. Record the difference between the inlet and

outlet temperature. The difference will be the “temperature rise”.

5. Compare the temperature rise with the required figure shown in Table 10.2.

A. If the temperature rise is too high, water velocity is too low. Check the following:

1. No restrictions in the outlet of the heater.

2. All valves are open between the heater and the storage vessel.

3. Pump is running in the proper direction.

4. Pump size is correct.

5. Pipework size is correct.

B. If the temperature rise is too low, water velocity is too high. Adjust accordingly.

1. Throttle the valve on the outlet side of the heater, until temperature rise is steady and at correct

value shown in Table 10.2.

2. Periodically check the temperature rise to ensure proper operation.

10.1.9 PIPEWORK SIZE

The pipework for the primary circulating loop should be in accordance with the following table. If more than one

water heater is to be connected to common circulating pipework, the common sections need to be sized in

accordance with the following table:

1 x MCW 2 x MCW 3 x MCW

Pipe Size 54mm 67mm 76mm

TABLE 10.3 PIPE SIZES

Page 19

19

10.2 HEATING BOILERS

10.2.1 GENERAL

The Mini Copper-Fin boiler requires a minimum water flow rate through the heat exchanger. A suitably sized

primary circulating pump is available from Lochinvar Limited as an ancillary option.

Recommended pipework layouts are available; please contact Lochinvar Limited for details. When multiple units

are connected using common pipework, it is recommended that a reverse-return arrangement is used to ensure

equal flow through each unit.

The requirements of minimum water flow are given in Table 10.4. Recommendations for the water circulation

system are given in BS6644 and CP 342. The following notes are of particular importance.

1. Circulating pipework not forming part of the useful heating surface should be insulated. Cisterns,

expansion vessels and pipework situated in areas exposed to freezing conditions should also be

insulated.

2. When the unit is being utilised as a combined central heating and domestic hot water boiler the hot water

vessel must be of the indirect type.

3. Drain valves must be located in accessible positions that will permit draining of the entire system

including the unit.

4. Tapping sizes for connection to the heating system are detailed in Table 3.1.

5. Ideally, individual valves should be fitted to each unit to enable isolation from the system. The

arrangement must comply with the requirements of BS6644.

6. Every system should be provided with a water gauge complete with isolating valve so that the pressure

of the system may be displayed for commissioning and maintenance purposes.

10.2.2 OPEN VENTED SYSTEM ARRANGEMENT

The Lochinvar Mini Copper-Fin can be used in an open vented arrangement provided that a vent pipe in

accordance with CP342 or BS6644 as appropriate is fitted. The minimum static head requirement for an open

vented system is 0.5 bar.

10.2.3 SEALED SYSTEM ARRANGEMENT

If a sealed system arrangement is required, a suitable pressurisation unit is available from Lochinvar Limited on

request. Sealed systems should incorporate a safety valve with a lift pressure no greater than the maximum

pressure rating of any component in the heating system. The maximum working pressure of the boiler is 11.0 bar.

A suitably sized expansion vessel should also be fitted to the system.

10.2.4 DRAIN VALVES

Each unit should be provided with a 15mm drain valve fitted into the return to enable the heat exchanger to be

drained without draining the entire system.

Page 20

20

10.2.5 EXPANSION VESSEL SIZ IN G

Total System P ressure

MCB91CE

20

0.12

0.06

MCB136CE

20

0.20

0.06

MCB181CE

20

0.24

0.06

MCB226CE

20

0.36

0.09

MCB271CE

20

0.48

0.12

MCB316CE

20

0.58

0.12

MCB361CE

20

0.70

0.15

MCB401CE

20

0.85

0.40

MCB501CE

20

0.97

0.46

The following information is based on a static head of 35 metres and a cold fill pressure of 3.8 bar:

S V * e

V V =

0.45

Where:

V V = Vessel Volume

S V = System Volume

e = Coefficient of Expansion (See Table 10.1)

10.2.6 PRIMARY CIRCULATING PUMPS

The Lochinvar Mini Copper-Fin boiler may need a primary pump to ensure correct flow through the boiler and a

secondary pump to circulate water around the heating system. Pump selection must ensure that the flow rate

through the unit is in accordance with that stated in Table 10.4. The pump should be sited to facilitate servicing. It

is important that the existing pump size is checked when the boiler is being used for a refurbishment project, to

ensure that the minimum flow rate can be achieved.

Model Differential - K Flow – l/s

Loss - Metre H20

TABLE 10.4 SYSTEM HEAD LOSS

Primary circulating pumps are available as ancillary items; please contact Lochinvar Limited for details

FIGURE 10.1 BOILER PRIMARY/SECONDARY ARRANGEMENT

Page 21

21

10.3 POOL HEATING

rmal Supply

MC91CE

19 W

MC136CE

19 W

MC181CE

19 W

MC226CE

19 W

MC271CE

19 W

MC316CE

19 W

MC361CE

19 W

MC401CE

19 W

MC501CE

38 W

The Mini Copper-Fin is also suitable for directly heating pool water without a secondary heat exchanger. The

design of the interconnecting pipework must incorporate a bypass to ensure that the return water temperature

does not remain below 50°C for long periods of time. This b ypass arrangement is also needed for low system

temperature circuits. Contact Lochinvar Limited for further information

10.4 FLOW SWITCH

The Lochinvar Mini Copper-Fin range of equipment is based on a low water content copper heat exchanger. In

order to ensure a long life expectancy it is important that the burner does not fire if the main circu lating pump fails.

This is more important in the water heater specification due to the fact that in hard water areas if the heater fires

up without adequate water flow, then lime scale will be deposited in a very short space of time and will cause nonwarrantable failure. In both boilers and water heaters it is detrimental to the heater to be fired without adequate

water flow, as localised over-heating will occur.

In order to overcome this problem the units are supplied complete with a flow switch to ensure that the heater will

not fire unless the pump is operational. It should be noted that the flow switch is not an accurate flow-measuring

device and only proves that the pump is operational.

11.0 ELECTRICAL SUPPLY

Wiring external to the equipment must be installed in accordance with the I.E.E. Regulations and any local

regulations that apply.

Model

No

Voltage

230V AC

50 Hz

1 PH

External Fuse

Rating

6.0 A

Power Consumption

TABLE 11.1 ELECTRICAL SUPPLY REQUIREMENTS

WARNING: THIS APPLIANCE MUST BE EARTHED

A suitably competent person MUST check wiring. Normal supply required is 230 volts AC, single phase,

50 Hz. An isolator with a contact separation of at least 3mm in all poles should be sited close to the

equipment and must only serve that equipment. The double pole switch must be readily ac cessible und er

all conditions.

Page 22

22

11.1 ELECTRICAL CONNECTIONS

Access to the electrical connections is achieved by taking off the removable panel next to the controls positioned

on the left hand side of the equipment. Connections to the equipment should pass through one of the 20mm

knock out wiring gland covers provided.

FIGURE 11.1 CONTROL PANEL

11.2 EXTERNAL CONTROLS

The circulating pump should have a separate power source with a suitably sized overload protection device.

The power supply to the Mini Copper-Fin should not be switched by a time clock; the equipment has a remote

stop/start circuit across terminals R and W. Any safety interlocks should be wired in series with the integral flow

switch across terminals X and B. Power is supplied from the equipment for these functions and will be the same

as the equipment’s power supply.

Volt free terminals for a fault alarm condition are marked VFA. Additionally the equipment puts a 230 volt signal

on to the brown wire in the ALM terminal when in a fault condition; the blue wire in the ALM terminal can be used

for a neutral.

Volt free terminals for burner on indication are marked RUN.

11.3 ARC WELDING PRECAUTIONS

The appliance must be isolated from the mains electricity supply in the event of electric arc welding being carried

out on any interconnecting pipework.

Page 23

11.4 WIRING DIAGRAM

1

2

3

4

5

12

11

10

13

14

16

C 1 221C

21 3

L

N

R

W

X

B

C

VFA

VFA

ALM

ALM

RUN

RUN

5

2

1

3

6

4

1

BL

BR/W

BK/W BK

BK

W

OR

BK

W

OR

R

BR

R

W

G

OR

R

RBRBLY/GR

Y/GR

Y/GR

BR

BR

BL

BL

BR

BR

BL

BL

BL

R

R

OR

OR

BR

BL

I O

NOC

8

+

-

72

63

54

+

-

1

2

3

4 5

6

7

8

10

9

11

12

1 TERMINAL STRIP

2 ROCKER SWITCH

TTB DEVICE6

FLAME FAILURE RESET7

8 IGNITION SEQUENCE CONTROLLER

12 FAULT RELAY (TIME DELAY)

11 RUN RELAY

9 PILOT ASSY.

GAS VALVE10

OVERHEAT LIMIT RESET3

OPERATING THERMOSTAT5

4 LIMIT THERMOSTAT

FIGURE 11.2 WIRING DIAGRAM MC91CE – MC401CE

Page 24

24

1

2

3

4

5

12

11

10

13

14

16

C 1 2

21C

21 3

L

N

R1

W1

X

B

C

VFA

VFA

ALM

ALM

RUN

RUN

BL

BR

BK/W BK

W

OR

BK

W

OR

R

BR

R

W

G

OR

BR

RBRBLY/GR

Y/GR

Y/GR

BR/W

BR

BL

BR

BR

BL

BL

BL

R

R

OR

OR

I O

NOC

R2

W2

R/BK Y/GR BL

Y/GR

BL

BK

R/BK

R/BK

R/BK

BK

BL

BK

11

-

+

BL

4

6

3

1

2

5

1 8

+

-

72

63

54

12

54

3

2

1

7

6

8

9

10

LIMIT THERMOSTAT4

5 OPERATING THERMOSTAT

3 OVERHEAT LIMIT RESET

10 GAS VALVES

PILOT ASSY.9

RUN RELAY11

FAULT RELAY (TIME DELAY)12

IGNITION SEQUENCE CONTROLLER8

7 FLAME FAILURE RESET

6 TTB DEVICE

ROCKER SWITCH2

TERMINAL STRIP

1

10

BR

FIGURE 11.3 WIRING DIAGRAM MC501CE

Page 25

12.0 COMMISSIONING AND TESTING

12.1 ELECTRICAL INSTALLATION

Notes on the requirements for electrical installation are provided in Section 11: ELECTRICAL SUPPLY.

Schematic drawings of the control circuit are shown in Figure 11.2 and 11.3.

12.2 GAS INSTALLATION

For design see Section 7: GAS SUPPLY. See Figure 3.1 for details on the position of the gas connection.

12.3 WATER CONNECTIONS

For design see Section 10: WATER CONNECTIONS

The system should be thoroughly flushed out with cold water without any circulating pump in position.

Ensure all the valves are open.

If a secondary pump is to be fitted, it should be fitted before the system is filled and air locks cleared. Check the

system for leaks and repair as necessary. If the system is configured in an unvented arrangement, check the

expansion vessel cushion pressure.

12.4 COMMISSIONING THE EQUIPMENT

12.4.1 GENERAL CHECKS PRIOR TO LIGHTING

A person deemed competent MUST be responsible for the commissioning of this equipment. Before

attempting to commission any equipment, ensure that personnel involved are aware of what action is

about to be taken and begin by making the following checks:

1. Flueway passages to chimney are clear.

2. Adequate ventilation exists in the plant room.

3. The system is fully charged with water, ready to receive heat. All necessary valves are open and the

secondary pump (if fitted) is circulating water.

4. The gas supply pipework is clear of any loose matter, tested for soundness and purged.

5. Any condensate drain fitted to the flue system is installed correctly and the condensate trap is filled with

water.

NOTE: If a condensate trap is not filled before use, products of combustion may escape and can lea d t o

severe personal injury or death

12.4.2 EQUIPMENT CHECKS PRIOR TO LIGHTING

This unit has been designed for a nominal gas inlet pressure of 20 mbar when used on natural gas.

Information relating to propane firing can be found in Section 13: LPG FUEL.

1. Gas supply is connected but turned to the “off” position. Any unions or fittings are correctly tightened,

test points are closed and the flame rectification probe lead is connected correctly. Ensure the ceramic

sheath around the flame rectification probe is not cracked or broken.

2. Ensure electricity supply is connected.

3. Check that the circulating pumps are fully bled.

4. Remove the temperature overheat limit switch bulb from the pocket and by carefully applying a heat

source to the bulb the reset pin should operate. If satisfactory cool the bulb, reset the thermostat and

refit the bulb in its pocket.

5. Check that the combustion products discharge safety device (TTB) is correctly fitted to the appliance

draught diverter.

Page 26

26

12.4.3 PROCEDURE FOR INITIAL LIGHTING

IF THE UNIT IS T O OPERATE ON LPG REFER TO SECTION 13: LPG FUEL BEFORE PROCEEDING

1. Ensure that the gas inlet appliance isolating valve, provided by the installer, is in the ‘off’ position.

2. Remove the control cover (located above the water flow and return header). Set the thermostat to a

temperature above that of the system water.

3. Press the power rocker switch located below the thermostat dials to bring the equipment on.

4. The burner should try to fire and a spark should be visible by looking at the pilot assembly. As the gas

inlet appliance isolating valve is closed, the controls should go to a flame failure condition.

5. If the above occurs correctly, open the gas inlet appliance isolating valve and press the flame failure

reset button, positioned above the rocker switch.

6. After a short delay, the pilot should ignite and the main gas valve should energise lighting the main

burners.

NOTE: During initial warm-up, condensation may drop onto the burners. This will continue until the system

water reaches a temperature above 50°C.

7. Allow the system to reach temperature to check operation of the control thermostat.

8. Once the thermostat has been satisfied, check that the main burner and pilot burner flames have

extinguished.

12.4.4 GAS PRESSURE ADJUSTMENT AND COMBUSTION CHECKS

1. After the burner has operated for approximately 10 minutes, switch off the equipment.

2. Open the pressure test point on the inlet side of the gas valve, attach a manometer and check the

standing gas-inlet pressure.

3. Relight the appliance and check the operating gas-inlet pressure

NOTE: The equipment has been designed to conform to the requirements of the Gas Appliance (Safety)

Regulations (1992). For Natural Gas the gas pressure governor control system is configured for a

nominal gas inlet pressure of 20 mbar, with a maximum inlet pressure of 25 mbar. Information relating

to propane firing can be found in Section 13: LPG FUEL.

4. Switch off the appliance, remove manometer and close pressure test point.

5. Open the pressure test point on the outlet side of the gas valve and attach a manometer.

6. Relight the appliance and check the burner pressure.

7. If required, the burner pressure can be corrected by removing the dust cap with a large slotted

screwdriver and the adjusting screw turned clockwise to increase burner pressure or counter-clockwise

to decrease burner pressure. Details of the correct burner pressure can be found in Table 3.1

NOTE: A second gas control valve is fitted to the MC501CE model, this must also be adjusted in accordance

with the procedure taken for the first valve. Remember to shut all test points after removing the

manometer.

NOTE: If the dust cap is removed, once reinstalled it should be marked with an anti-tamper indicator.

8. Carry out a spillage test in accordance with BS5440-1.

9. Carry out a combustion analysis. Record all readings for future reference on a relevant

commissioning sheet.

Page 27

27

12.5 WATER HEATER TEMPERATURE ADJUSTMENT PROCEDURE

The temperature selector knob of the operator thermostat will be adjusted to its lowest setting when dispatched

from the factory. The operating thermostat setting should be adjusted to ensure that the water is stored at 60°C

and distributed at 50°C within 1 (one) minute at all outlets. Care is needed to avoid much higher temperatures

because of the risk of scalding. At 50°C the risk of scalding is small for most people, but the risk increases rapidly

with higher temperatures and for longer exposure times. The risk to young children and to those with a sensory or

mobility loss will be greater. Where a significant scalding risk has been identified, the use of thermostatic mixing

valves on baths and showers should be considered to reduce temperature, these need to be placed as close to

the point of use as possible.

The operating temperature of the water heater can be adjusted as follows:

1. Locate the control cover and remove.

2. Adjust the dial on the operating thermostat to give the desired water temperature.

3. Adjust the limit thermostat to 10°C above the operating thermostat setting.

4. Re-fit the control cover.

12.6 BOILER TEMPERATURE ADJUSTMENT PROCEDURE

The operating temperature of the boiler can be adjusted as follows:

1. Locate the control cover and remove.

2. Adjust the dial on the operating thermostat to give the desired water temperature.

3. Adjust the limit thermostat to 10°C above the operating thermostat setting.

4. Re-fit the control cover.

12.7 INSTALLATION NOISE

If care has been taken to follow the manufacturer’s instructions there should be no discernible noise from the

equipment. The allied pump motor may have a level of sound that could lead to consideration for acoustic

insulation, but care must be taken not to impede ventilation or airflow to the pump motor.

13.0 LPG FUEL NOTE! IT IS STRONGLY RECO MM ENDED THAT, ON LPG I NST ALL ATIONS, GA S DET ECTIO N EQUI PME NT

IS FITTED. THI S EQUI PMENT SHOULD BE POSI TIONE D NEA R THE APPL IANC E AND AT LOW LE VEL. I T

IS ALSO IMPORTANT THAT THE SPACE HOUSING TH E APPLIANCE IS ADEQUATELY VENTILATED AT

HIGH AND LOW LEVEL. THIS APPLI ANCE MUST NOT BE LOCATED BELOW GROUND E.G. IN A CELLAR

13.1 RELATED DOCUMENTS

In addition to those documents listed in Section 4.1: RELATED DOCUMENTS within the main body of the

installer’s guide the gas installation should also comply with the guidance offered in the following documents.

BS 5482-1: 2005 Code of practice for domestic butane and propane gas burning installations.

Part 1: Installations at permanent dwellings, residential park homes and commercial

premises, with installation pipework sizes not exceeding dn25 for steel and dn28 for

corrugated stainless steel or copper.

rd

The operation of the Mini Copper-Fin range on LPG-Propane (3

Family) 3P is similar to that on Natural Gas (2nd

Family) 2H and the design and installation details described in the main body of the installer’s guide should be

followed.

Page 28

28

13.2 PROPANE INJ ECTORS

Injector

Size

Marking

Pilot Burner

n/a

2304

Main Burner

2.0mm

2402

When converting to propane, the pilot and main burner injectors should be checked to ensure that they are

correctly sized. For further information, please refer to Table 13.1.

TABLE 13.1 LPG INJECTOR SIZES

13.3 CONVERSION TO LPG

This process must be carried out in the order stated. Failure to follow the following procedure may lead to

non-warrantable damage to the water heater. The conversion MUST be carried out be a competent person

certified for work on LPG fuel.

1. Turn power and gas off.

2. Remove middle and lower door panels.

3. Remove pilot assembly and fit LPG pilot orifice (ORF2614).

4. Remove the Natural Gas burner injectors and fit LPG injectors (ORF2402).

5. Re-fit middle and lower door panels.

6. Attach the LPG warning label and rating plate overlay.

13.4 LPG COMMISSIONING AND TESTING