Lochinvar EcoShield SHW116-410CE, EcoShield SHW46-325CE, EcoShield SHW146-410CE, EcoShield SHW61-325CE, EcoShield SHW86-410CE Installation, Commissioning & Maintenance Instructions

Page 1

1

Installation Manual_EcoShield_October 2018

EcoShield™

Gas Fired Condensing

Water Heaters

MODELS

SHW35-245CE

SHW46-325CE

SHW61-325CE

SHW86-410CE

SHW116-410CE

SHW146-410CE

Installation, Commissioning, &

Maintenance instructions

Page 2

2

Page 3

3

Table of Contents

1.0 INTRODUCTION ....................................................................................................................................................................................................................................................................... 5

2.0 SAFETY GUIDELINES ............................................................................................................................................................................................................................................................. 6

2.1 GENERAL DESCRIPTION OF SAFETY SYMBOLS USED .................................................................................................................................................................................................................. 6

2.2 WHAT TO DO IF YOU SMELL GAS ...................................................................................................................................................................................................................................................... 7

3.0 PRINCIPLE PARTS .................................................................................................................................................................................................................................................................. 8

4.0 TECHNICAL DATA ................................................................................................................................................................................................................................................................ 10

5.0 DIMENSIONS AND CLEARANCE ........................................................................................................................................................................................................................................ 11

5.1 DIMENSIONS ........................................................................................................................................................................................................................................................................................ 11

5.2 CLEARANCES ...................................................................................................................................................................................................................................................................................... 12

6.0 GENERAL REQUIREMENTS ................................................................................................................................................................................................................................................ 13

6.1 RELATED DOCUMENTS ..................................................................................................................................................................................................................................................................... 13

7.0 WATER QUALITY .................................................................................................................................................................................................................................................................. 14

8.0 LOCATION .............................................................................................................................................................................................................................................................................. 14

8.1 PLANT ROOM REQUIREMENTS ........................................................................................................................................................................................................................................................ 14

8.2 GENERAL REQUIREMENTS ............................................................................................................................................................................................................................................................... 14

8.3 CONDENSATE DRAIN ......................................................................................................................................................................................................................................................................... 14

9.0 GAS SUPPLY ......................................................................................................................................................................................................................................................................... 15

9.1 SERVICE PIPES ................................................................................................................................................................................................................................................................................... 15

9.2 METERS ................................................................................................................................................................................................................................................................................................ 15

9.3 GAS SUPPLY PIPES ............................................................................................................................................................................................................................................................................ 15

9.4 BOOSTED SUPPLIES .......................................................................................................................................................................................................................................................................... 15

9.5 PLANT-ROOM CONTROL VALVE ....................................................................................................................................................................................................................................................... 15

9.6 EQUIPMENT GAS SYSTEM LEAK CHECK ........................................................................................................................................................................................................................................ 15

10.0 FLUE SYSTEM ....................................................................................................................................................................................................................................................................... 16

10.1 FLUE SYSTEM GENERAL REQUIREMENTS .................................................................................................................................................................................................................................... 16

10.2 FLUE DISCHARGE ............................................................................................................................................................................................................................................................................... 18

10.3 CONDENSATE DRAIN ......................................................................................................................................................................................................................................................................... 18

10.4 FLUE SYSTEM GENERAL REQUIREMENTS .................................................................................................................................................................................................................................... 19

10.5 APPROVED FLUE SYSTEM ................................................................................................................................................................................................................................................................ 19

10.6 INSTALLATION PRECAUTIONS ......................................................................................................................................................................................................................................................... 19

10.7 CONDENSATE DRAIN ......................................................................................................................................................................................................................................................................... 19

10.8 TYPE B

23

CONVENTIONAL FANNED FLUE ....................................................................................................................................................................................................................................... 19

10.9 ROOM SEALED (TYPE C) FLUE ASSEMBLY .................................................................................................................................................................................................................................... 20

10.10 C13 CONCENTRIC HORIZONTAL FLUE SYSTEMS ................................................................................................................................................................................................................. 22

10.11 HORIZONTAL FLUE TERMINAL INSTALLATION ...................................................................................................................................................................................................................... 23

10.12 FLUE TERMINAL GUARDING ...................................................................................................................................................................................................................................................... 23

10.13 C33 CONCENTRIC VERTICAL FLUE SYSTEMS ....................................................................................................................................................................................................................... 24

10.14 VERTICAL FLUE TERMINAL INSTALLATION ............................................................................................................................................................................................................................ 24

10.15 C43 COMMON VENTED FLUE SYSTEMS IN MULTI FLOOR BUILDINGS ................................................................................................................................................................................ 30

10.16 C

53

(TWIN PIPE) FLUE SYSTEMS ............................................................................................................................................................................................................................................... 31

10.17 FLUE TERMINAL GUARDING ...................................................................................................................................................................................................................................................... 35

10.18 TYPE B23 (CONVENTIONAL FLUE WITH FAN ASSISTANCE) .................................................................................................................................................................................................. 36

10.19 C63 CERTIFIED FLUE SYSTEMS ................................................................................................................................................................................................................................................. 37

11.0 AIR SUPPLY ........................................................................................................................................................................................................................................................................... 38

11.1 COMBUSTION VENTILATION ............................................................................................................................................................................................................................................................. 38

11.2 COOLING VENTILATION ..................................................................................................................................................................................................................................................................... 38

12.0 WATER CONNECTIONS ....................................................................................................................................................................................................................................................... 39

12.1 GENERAL.............................................................................................................................................................................................................................................................................................. 39

12.2 OPEN VENTED SYSTEM ARRANGEMENT ....................................................................................................................................................................................................................................... 39

12.3 UNVENTED SYSTEM ARRANGEMENT ............................................................................................................................................................................................................................................. 40

13.0 ELECTRICAL SUPPLY .......................................................................................................................................................................................................................................................... 42

13.2 EXTERNAL CONTROLS ...................................................................................................................................................................................................................................................................... 43

13.3 MAINS POWER SUPPLY ..................................................................................................................................................................................................................................................................... 43

13.4 LOW VOLTAGE CONNECTOR STRIP ................................................................................................................................................................................................................................................ 44

13.5 ELECTRICAL CONNECTIONS ............................................................................................................................................................................................................................................................ 45

13.6 FUSES ................................................................................................................................................................................................................................................................................................... 45

13.7 ARC WELDING PRECAUTIONS .......................................................................................................................................................................................................................................................... 45

13.8 WIRING DIAGRAM ............................................................................................................................................................................................................................................................................... 46

13.9 LADDER DIAGRAM .............................................................................................................................................................................................................................................................................. 47

14.0 USER CONTROL INTERFACE ............................................................................................................................................................................................................................................. 48

14.1 GENERAL.............................................................................................................................................................................................................................................................................................. 48

14.2 USER CONTROL INTERFACE PANEL ............................................................................................................................................................................................................................................... 48

14.3 SEQUENCE OF OPERATION .............................................................................................................................................................................................................................................................. 49

15.0 COMMISSIONING AND TESTING ........................................................................................................................................................................................................................................ 51

15.1 ELECTRICAL INSTALLATION ............................................................................................................................................................................................................................................................. 51

15.2 GAS INSTALLATION ............................................................................................................................................................................................................................................................................ 51

15.3 WATER CONNECTIONS ...................................................................................................................................................................................................................................................................... 51

15.4 COMMISSIONING THE EQUIPMENT ................................................................................................................................................................................................................................................. 51

15.5 TEMPERATURE ADJUSTMENT PROCEDURE ................................................................................................................................................................................................................................. 52

15.6 INSTALLATION NOISE......................................................................................................................................................................................................................................................................... 52

16.0 LPG FUEL ............................................................................................................................................................................................................................................................................... 53

16.1 RELATED DOCUMENTS ..................................................................................................................................................................................................................................................................... 53

16.2 CONVERSION TO LPG ........................................................................................................................................................................................................................................................................ 53

16.3 LPG COMMISSIONING AND TESTING .............................................................................................................................................................................................................................................. 56

17.0 MAINTENANCE ...................................................................................................................................................................................................................................................................... 57

17.1 GENERAL.............................................................................................................................................................................................................................................................................................. 57

17.2 BURNER INSPECTION ........................................................................................................................................................................................................................................................................ 57

17.3 BURNER REMOVAL ............................................................................................................................................................................................................................................................................. 57

17.4 CLEANING THE HEAT EXCHANGER ................................................................................................................................................................................................................................................. 58

17.5 DRAINING THE WATER HEATER SYSTEM ...................................................................................................................................................................................................................................... 58

17.6 STORAGE VESSEL: INSPECTION AND CLEANING ......................................................................................................................................................................................................................... 58

17.7 SACRIFICIAL ANODES: INSPECTION AND REPLACEMENT .......................................................................................................................................................................................................... 59

17.8 REFILLING THE SYSTEM .................................................................................................................................................................................................................................................................... 59

Page 4

4

17.9 OTHER CHECKS .................................................................................................................................................................................................................................................................................. 59

18.0 USER CONTROL INTERFACE SETTINGS .......................................................................................................................................................................................................................... 61

18.1 TIME AND DATE ................................................................................................................................................................................................................................................................................... 61

18.2 USER ADJUSTABLE PARAMETERS SCREEN ................................................................................................................................................................................................................................. 61

18.3 INSTALLER ADJUSTABLE PARAMETERS SCREEN ........................................................................................................................................................................................................................ 62

18.4 PASTEURISATION FUNCTION (USING NIGHT SET BACK FACILITY) ........................................................................................................................................................................................... 63

18.5 NIGHT SETBACK SCREEN ................................................................................................................................................................................................................................................................. 65

18.6 SERVICE MODE SCREEN ................................................................................................................................................................................................................................................................... 65

18.7 ERROR LOG SCREEN ......................................................................................................................................................................................................................................................................... 65

19.0 TROUBLESHOOTING ........................................................................................................................................................................................................................................................... 66

19.1 CHECKING TEMPERATURE SENSORS ............................................................................................................................................................................................................................................ 66

19.2 TROUBLESHOOTING CHART ............................................................................................................................................................................................................................................................ 66

19.3 ERROR CODES .................................................................................................................................................................................................................................................................................... 67

20.0 ErP SPECIFICATION DATA SHEET..................................................................................................................................................................................................................................... 70

21.0 USER INSTRUCTIONS .......................................................................................................................................................................................................................................................... 70

Page 5

5

1.0 INTRODUCTION

The Lochinvar EcoShield™ range is a floor standing direct gas-fired condensing storage water heater. The equipment comprises a

stainless steel mesh radial burner assembly; a heat exchanger that permits fully condensing operation, a vitreous enamel lined steel

storage vessel, a Stainless Steel circulating pump and interconnecting pipework between the storage vessel and heat exchanger.

The burner is initiated by a full electronic ignition sequence control that incorporates a spark ignition and a flame rectification device

for supervision of the flame.

The output from the water heater is regulated by a variable speed combustion fan and gas/air ratio controls to maintain the correct

combustion at all levels of modulation. This configuration allows modulation down to 20% of the rated output.

This equipment is intended for use on Group H Natural Gas (2

nd

Family) and LPG propane (3rd Family). The information relating to

propane firing is to be found in Section 16.0: LPG FUEL.

This equipment MUST NOT use gas other than that for which it has been designed and adjusted.

This equipment must be installed by a competent person, registered with a HSE approved body. All installations must conform to the

relevant Gas Safety and Building Regulations. Health & Safety requirements must also be taken into account when installing any

equipment. Failure to comply with the above may lead to prosecution.

If the equipment is to be connected to an unvented (pressurised) system, care must be taken to ensure all extra safety requirements

are satisfied should a high or low-pressure condition occur in the system.

The equipment is designed for direct connection to a flue system.

Ancillary Options:

Unvented Water System Kits SHW35-SHW61 WH19

Unvented Water System Kits SHW86-SHW146 WH21

De-stratification Pump Kit WH9

Condensate Neutralisation Kit KIT2000

Flue System Components See section 10.0

Page 6

6

2.0 SAFETY GUIDELINES

READ AND UNDERSTAND THE INSTRUCTIONS

Read and fully understand all instructions before attempting to operate maintain or install the unit.

Keep these instructions near the water heater for quick reference.

This equipment must be installed by a competent person, registered with the H.S.E. approved body. All installations must conform to the

relevant Gas Safety and Building Regulations. Health & Safety requirements must also be taken into account when installing any equipment.

Failure to comply with the above may lead to prosecution

Without written approval of the manufacturer the internals of the water heater may not be changed. When changes are executed without approval,

the water heater certification becomes invalid.

Commissioning, maintenance and repair must be done by a skilled installer/engineer, according to all applicable standards and regulations.

2.1 GENERAL DESCRIPTION OF SAFETY SYMBOLS USED

BANNED

A black symbol inside a red circle with a red diagonal indicates an action that should not be performed

WARNING

A black symbol added to a yellow triangle with black edges indicates danger

ACTION REQUIRED

A white symbol inserted in a blue circle indicates an action that must be taken to avoid risk

ELECTRICAL HAZARD

Observe all signs placed next to the pictogram. The symbol indicates components of the unit and

actions described in this manual that could create an electrical hazard.

HOT SURFACES

The symbol indicates those components with a high surface temperature that could create a risk.

This symbol shows essential information which is not safety related

Recover or recycle material

Page 7

7

2.2 WHAT TO DO IF YOU SMELL GAS

Warning if you smell gas

No naked flames, no smoking!

Avoid causing sparks, do not switch on or off electrical equipment or lights

Open windows and doors

Shut off the main gas supply

Warn occupants and leave the building

After leaving the building alert the local gas supply company

Do not re-enter the building until it is safe to do so

Lochinvar Limited is not liable for any damage caused by inaccurately following these installation instructions. Only

original parts may be used when carrying out any repair or service work.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children MUST be supervised to ensure that they do not

play with the appliance.

Page 8

8

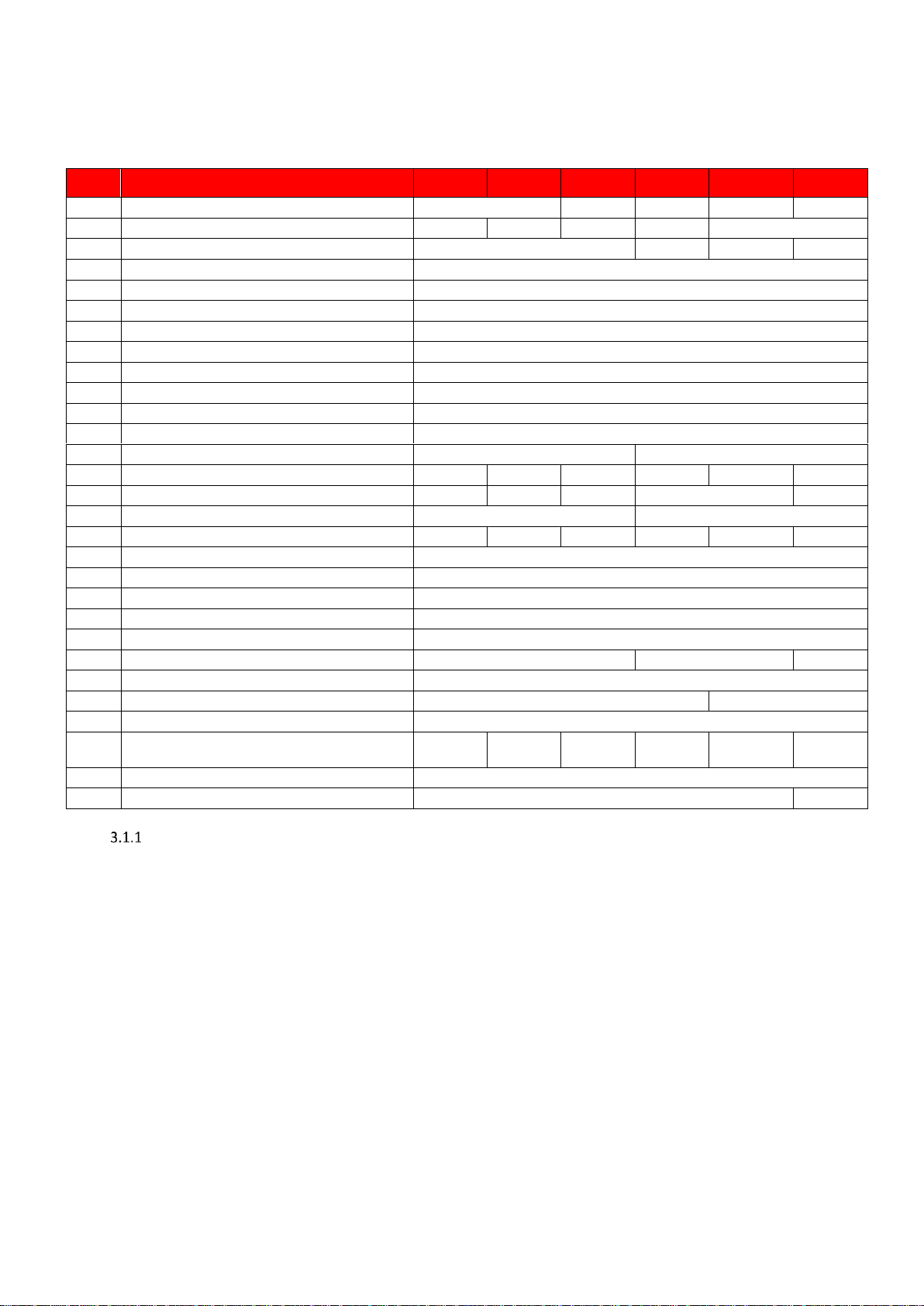

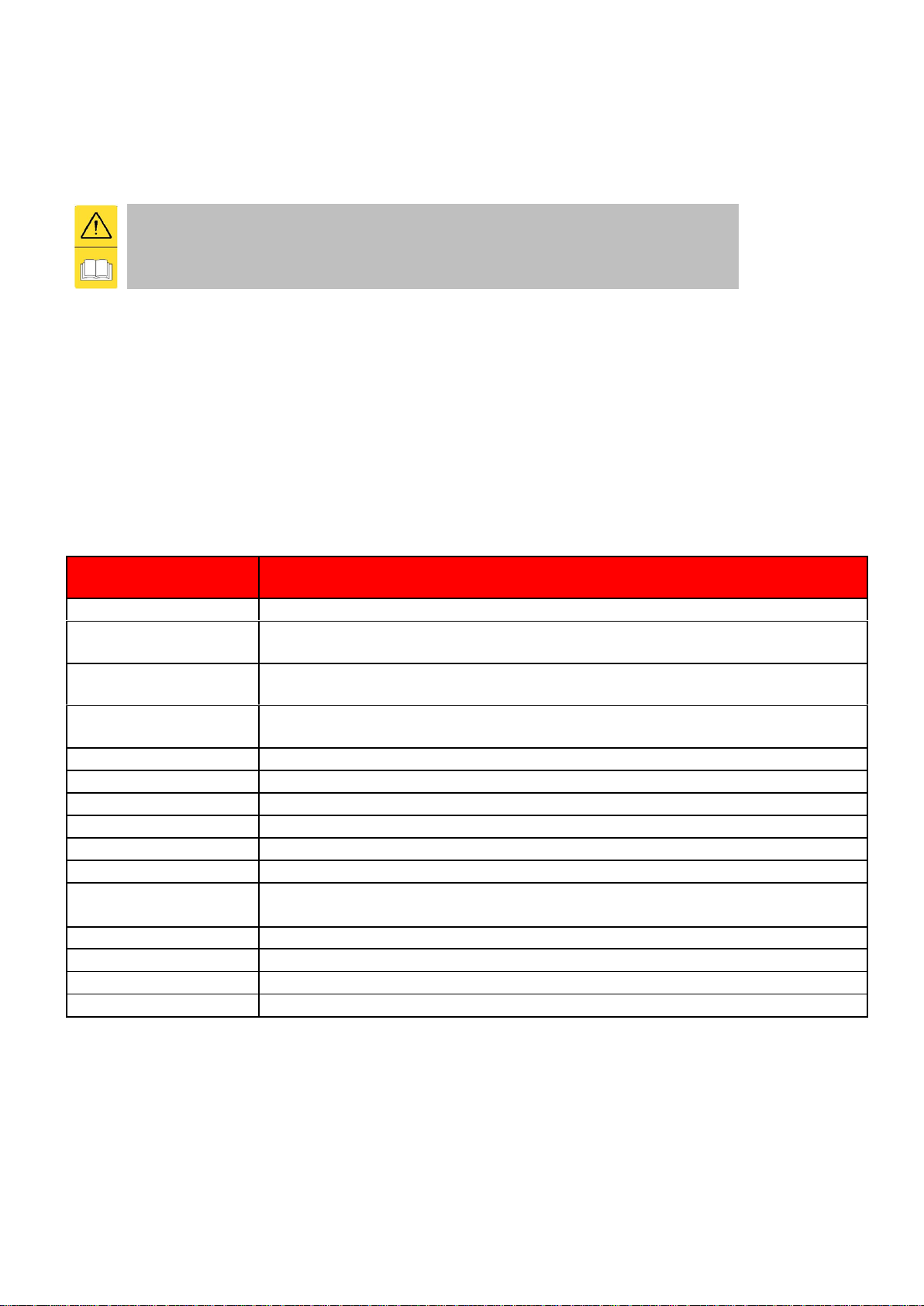

3.0 PRINCIPLE PARTS

Item No

Description of item

SHW35-245

SHW46-325

SHW61-325

SHW86-410

SHW116-410

SHW146-410

1.

AIR PRESSURE SWITCH

PRS20016

PRS20017

PRS20001

PRS20002

PRS20022

2.

BURNER C/W GASKET

BNR30019

BNR3426

BNR3427

BNR3428

BNR3429

3.

BURNER CONTROL

RLY40116

RLY40117

RLY40118

RLY40117

4.

BURNER DOOR GASKET - ROPE

GKT2452

5.

BURNER DOOR GASKET - RUBBER

GKT2455

6.

BURNER DOOR INSULATION

FIB2291

CLEAN OUT DOOR GASKET

GKT2101 NOT SHOWN ON DRAWING

7.

HEAT EXCHANGER REAR WALL INSULATION

FIB2167

8.

CONDENSATE TRAP

MSC20260

FLAME SENSE PROBE CABLE

WRE2211 NOT SHOWN ON DRAWING

9.

FLAME SENSE PROBE C/W GASKET

PLT3022

10.

DISPLAY PCB

RLY20120

11.

FLUE TEMPERATURE SENSOR GROMMET

N/A

MSC2200

12.

FAN ASSEMBLY

FAN2050

FAN2051

FAN2052

FAN2053

FAN2054

FAN2055

13.

FAN GASKET

GKT2456

GKT2436

GKT2456

GKT2436

-

14.

FLUE TEMPERATURE SENSOR

TST20007

TST30011

15.

GAS VALVE ASSEMBLY

VAL30071

VAL30072

VAL30073

VAL30074

VAL30075

VAL30076

16.

IGNITION CABLE

WRE2209

17.

IGNITION ELECTRODE C/W GASKET

PLT3021

18.

INLET TEMPERATURE SENSOR

TST20037

19.

OUTLET TEMPERATURE SENSOR/HIGH LIMIT

TST20038

20.

STEP DOWN POWER TRANSFORMER

LL100170179

21.

PUMP

PUM20081

PUM20082

PUM20083

22.

PUMP RELAY

RLY2610

23.

VENTURI GASKET

GKT2443

GKT2444

24.

MAGNESIUM ANODE

WTR2500

25.

HEAT EXCHANGER C/W GASKETS/FITTINGS

RECOMMEND LOCHINVAR FIT THIS ITEM

LL200030P

LL200031P

LL200032P

LL200033P

LL200034P

LL200035P

26.

LOW VOLTAGE CONNECTION BOARD

LL100167623

27.

AIR SHROUD GASKET

N/A

GKT2080

PRINCIPLE PARTS-USE IN CONJUNCTION WITH 3.1.2

Page 9

9

EXPLODED VIEW DRAWINGS

Page 10

10

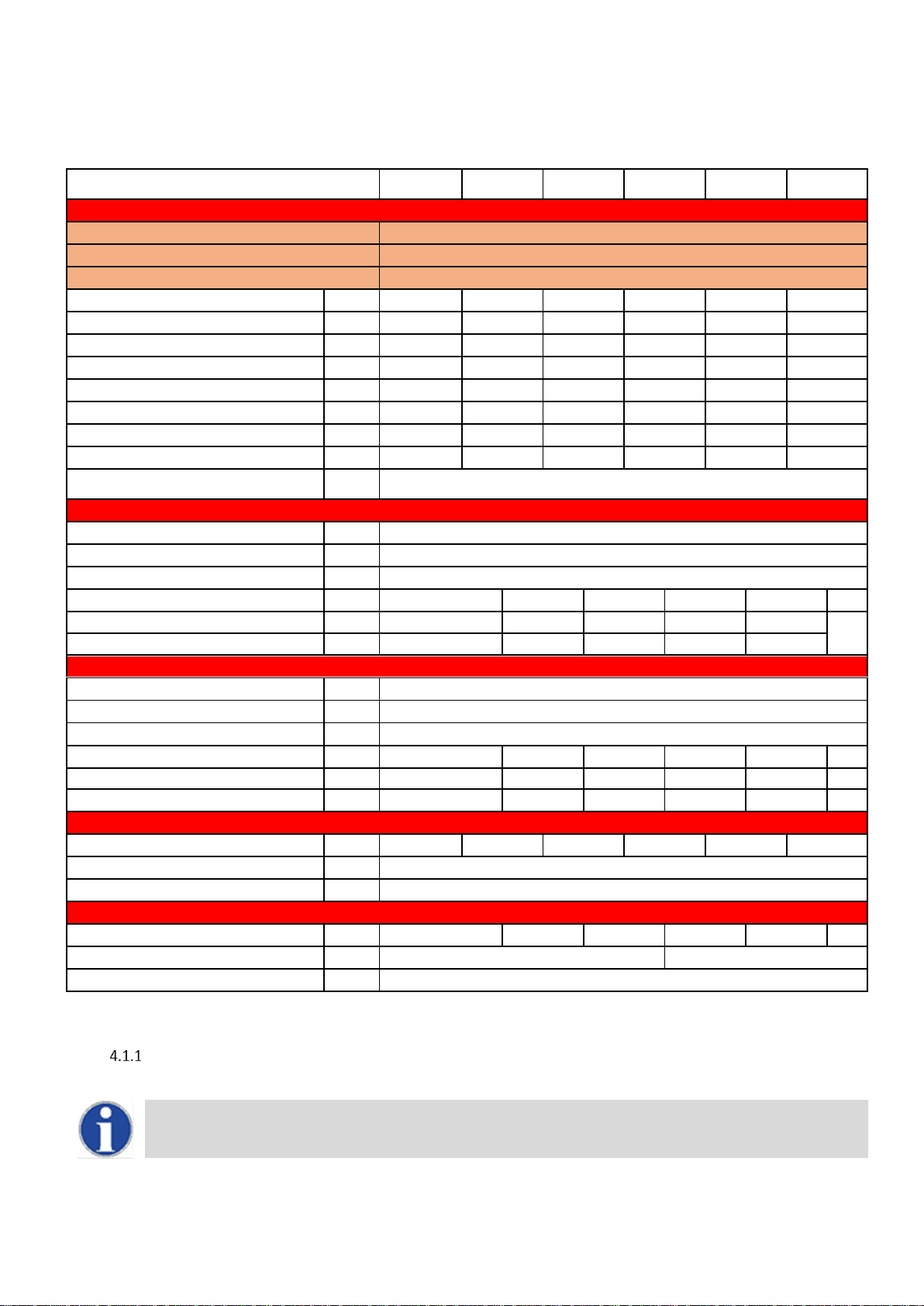

4.0 TECHNICAL DATA

Model Number

SHW35-

245CE

SHW46-

325CE

SHW61-

325CE

SHW86-

410CE

SHW116-

410CE

SHW146-

410CE

GENERAL DATA

Product I.D Number

CE0063

Catergory(ies)

II2H3B/P

Countries of Destination

GB/IE

Input (gross)

kW

36.6

44

61.5

83.5

116.9

146.5

Input (net)

kW

33.3

39.6

55.4

75.2

105.3

132

Output (PMMin-PNMax)

kW

7.03-35.2

8.49-41.2

11.79-58.7

16-79.7

22.13-110.6

28.2-141.2

Recovery Rate (44°)

l/hr

695

806

1153

1567

2164

2768

Recovery Rate (50°)

l/hr

612

709

1014

1379

1904

2436

Shipping Weight

kg

136

281

290

379

388

406

Full Weight

kg

384

614

625

825

838

860

NOX @0%o2 According to EU regulation 812/2013

mg/kw

25.3

33

27.3

33.1

40

38

Maximum allowable temperature of the combustion

air

°C

40

GAS DATA – G20

Nominal gas inlet pressure

mbar

20

Maximum gas inlet pressure

mbar

25

Minimum gas inlet pressure

mbar

17.5

Gas flow rate

m3/hr

3.5

4.2

5.7 8 11.1

14

Flue gas mass rate (@ 9.0% CO2)

g/sec

13.6

16

22.3

30.4

42.5

53.2

Gas inlet connection size

B.S.P ½ ½ ½ ¾ 1 1

GAS DATA – G31

Nominal gas inlet pressure

mbar

37

Maximum gas inlet pressure

mbar

45

Minimum gas inlet pressure

mbar

27

Gas flow rate

m3/hr

1.4

1.7

2.3

3.1

4.4

5.5

Flue gas mass rate (@ 10.5% CO2)

g/sec

14

16.7

23.2

31.6

44.2

55.4

Gas inlet connection size

B.S.P

R½

R½

R½

R¾

R1

R1

ELECTRICAL DATA

Power consumption

W

361

431

459

646

932

961

Power supply

Single phase/230v/50HZ

Protection class

IP00

WATER DATA

Water content

litres

248

331

332

420

423

424

Water connections (F & R)

B.S.P

1 ½

2

Maximum water pressure

bar

10

TECHNICAL DATA

The Installer much check that the information given on the data plate or supplementary plate is compatible with local

supply conditions before installing the appliance.

Page 11

11

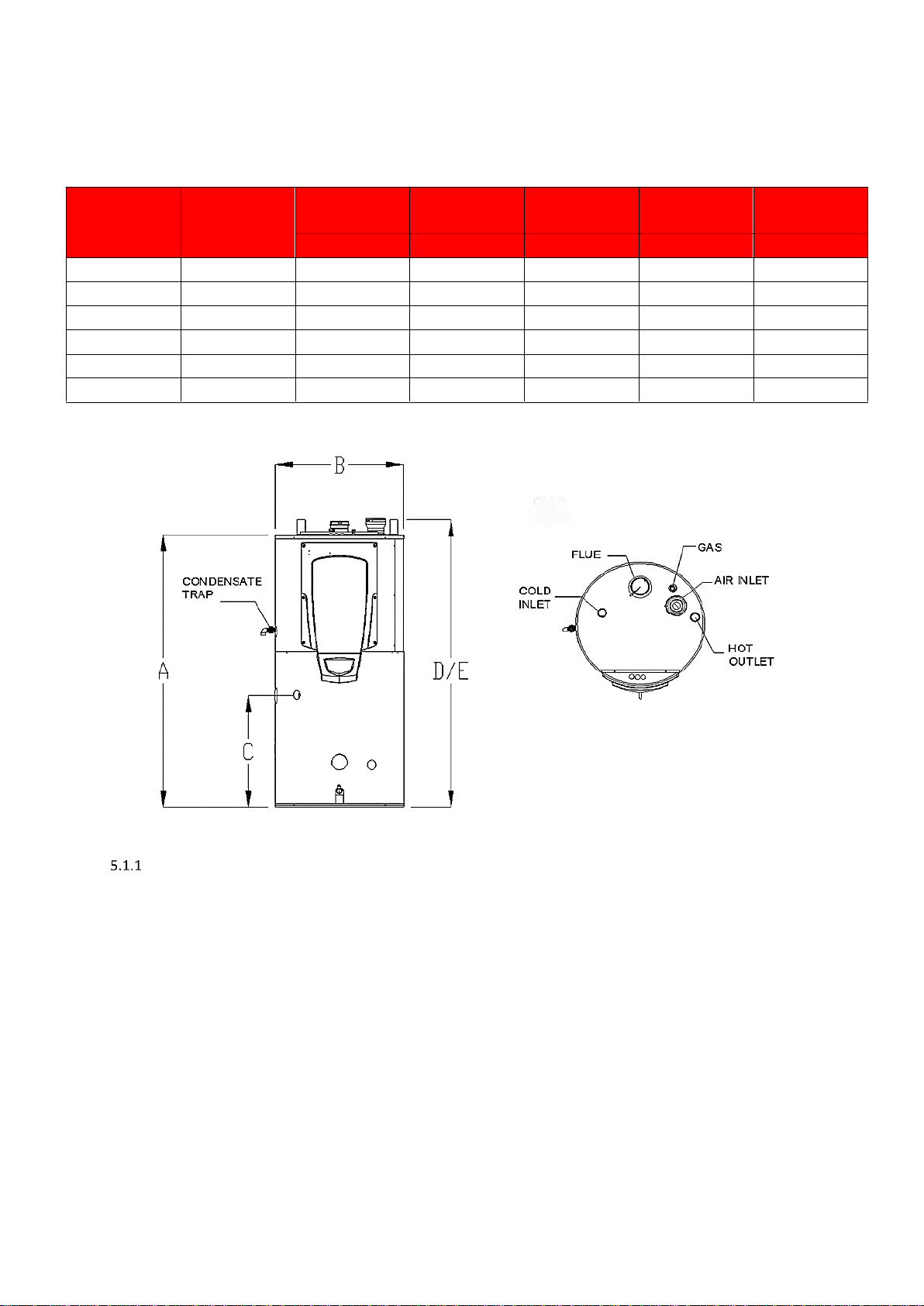

5.0 DIMENSIONS AND CLEARANCE

5.1 DIMENSIONS

MODEL

TANK VOLUME

HEIGHT

WIDTH

T&P VALVE

COLD FEED

HOT OUTLET

A B C D E

SHW35-245

244

1530

715

755

1610

1610

SHW46-325

325

1920

715

1117

2005

2005

SHW61-325

325

1920

715

1126

2005

2005

SHW86-410

410

1920

865

786

2020

2020

SHW116-410

410

1920

865

786

2020

2020

SHW146-410

410

1920

865

786

2020

2020

DIMENSIONAL DRAWING ECOSHIELD™

Page 12

12

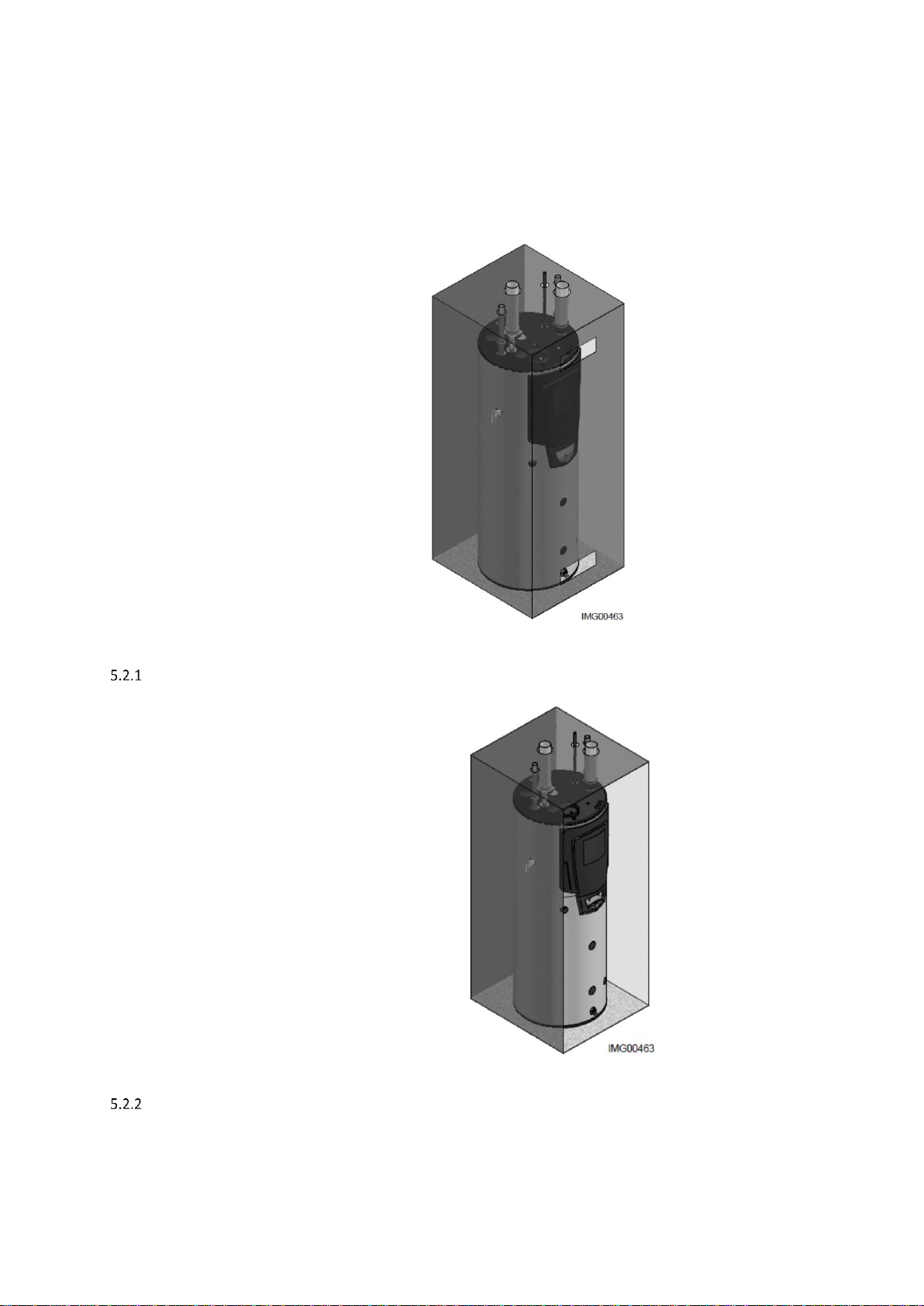

5.2 CLEARANCES

The location chosen for the equipment must permit the provision for a satisfactory flue system and, where necessary, an adequate air supply.

The location must also provide adequate space for servicing and air circulation around each unit. This includes any electrical trunking laid across

the floor and to the appliance.

RECOMMENDED SERVICE CLEARANCES:

TOP - 450mm

LEFT - 600mm

RIGHT - 100mm

FRONT - 600mm

REAR - ZERO

FLUE - 25mm

ENCLOSURE INSTALLATION CLEARANCES (MM)

RECOMMENDED SERVICE CLEARANCES:

TOP - 450mm

LEFT - 600mm

RIGHT - 100mm

FRONT - 600mm

REAR - ZERO

FLUE - 25mm

PLANT-ROOM INSTALLATION CLEARANCES (MM)

Further details regarding locations are given in BS5440 or BS6644 as appropriate.

Page 13

13

6.0 GENERAL REQUIREMENTS

The Lochinvar EcoShield™ condensing water heater has been designed to operate trouble free for many years. These instructions should be

followed closely to obtain the maximum usage and efficiency of the equipment.

READ AND UNDERSTAND THE INSTRUCTIONS

Read and fully understand all instructions before attempting to operate maintain or install the unit.

6.1 RELATED DOCUMENTS

It is law that all gas appliances are installed by competent persons, in accordance with The Gas Safety (Installation and Use) Regulations 1998.

Failure to install appliances correctly could lead to prosecution. It is in your own interest, and that of safety, to ensure that this law is complied

with.

The installation of the equipment MUST be in accordance with the relevant requirements of the Gas Safety Regulations, Building Regulations,

I.E.E. Regulations and the bylaws of the local water undertaking. The installation should also be in accordance with any relevant requirements

of the local gas distributor and local authority.

In addition the installation should follow the relevant guidance offered in the following documents. It is not practical to list all relevant information

but emphasis is placed on the following documents, as failure to comply with the guidance given will almost certainly result in an unsatisfactory

installation:

Regulation

Description

BS EN 1858: 2008 + A1: 2011

Chimneys, Components. Concrete flue blocks.

BS 5440-1: 2008

Flueing and ventilation for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd family gases). Specification for

installation of gas appliances to chimneys and for maintenance of chimneys.

BS 5440-2: 2009

Installation and maintenance of flues and ventilation for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd

family gases). Specification for installation and maintenance of ventilation for gas appliances.

BS 6644: 2011

Specification for Installation of gas-fired hot water Heaters of rated inputs between 70 kW (net) and 1.8 MW (net) (2nd and 3rd

family gases).

BS EN 806 1-5

Specifications for installations inside buildings conveying water for human consumption.

BS 7671 :2008 + A3:2015

Code of practice for low temperature hot water systems of output greater than 45 kW.

BS 7074: 1989 Parts 1 and 2

Application, selection and installation of expansion vessels and ancillary equipment for sealed systems.

BS 7671: 2008 + A1: 2011

Requirements for electrical installations, I.E.E. wiring regulations seventeenth edition.

BS 7671: Amendment 2: August 2013

BS EN 12828:2012+A1:2014

Heating systems in buildings. Design for water-based heating systems.

CP 342 (Part 2 1974):

Code of practice for centralised hot water supply-buildings other than dwellings.

Institute of Gas Engineers and Managers (IGEM) Publications

IGE/UP/1 - Edition 2:

Installation pipework on industrial and commercial premises.

IGE/UP/2 – Edition 3

Gas installation pipework, boosters and compressors on industrial and commercial premises.

IGE/UP/4 - Edition 4

Commissioning of gas-fired plant on industrial and commercial premises.

IGE/UP/10 - Edition 4

Installation of flued gas appliances in industrial and commercial premises.

Gas Safety (Installation and Use) Regulations 1998

CIBSE: Guides

Part A Environmental Design

Part G Public health engineering

H.S.E. guidance

INDG 436 Safe management of industrial steam & hot water Heaters

SAFED BG01Guidance on safe operation of Water Heaters

Third edition of the 1956 Clean Air Act Memorandum on Chimney Heights

Manufacturer's notes must not be taken in any way as overriding statutory obligations.

Page 14

14

7.0 WATER QUALITY

Water supply quality may adversely affect the efficiency performance and longevity of Water Heaters and Hot Water systems. Hard water may

cause the formation of limescale which will reduce operating efficiency and may cause early product failure. Please note the following:-

Water Hardness – should not exceed 205ppm CaCO3 and Total Dissolved Solids (TDS) of untreated water should not exceed

350ppm.

If these values are exceeded a water treatment specialist should be consulted. Water Softeners and Water Conditioners may be

considered, but whichever method is selected, it should be suitable for installation with Direct Gas-fired Water Heaters. A maintenance

regime will also be required for such systems

High hot water temperature and high demand for hot water is likely to cause quicker limescale formation

The formation of limescale or other solids can cause a blockage within the heat exchanger, which in turn may cause

premature failure. Such instances are not regarded as defects in manufacture and will not be covered under the

product warranty.

8.0 LOCATION

8.1 PLANT ROOM REQUIREMENTS

The Lochinvar EcoShield™ may only be installed in a room that complies with the appropriate ventilation requirements.

The Lochinvar EcoShield™ can be used as a type C13, C33, or C53 appliance. Due to its room sealed design, ventilation allowances for

combustion air are not necessary, provided the minimum clearances and service clearances as detailed in 5.2 are observed. If the appliance is

to be installed in a compartment or a hot environment, the minimum clearances detailed in 5.2.1 should be observed. In addition to this or to

comply with the recommendations in BS6644, ventilation for cooling purposes must be fitted. For further guidance, please refer to Section 11.0

or to BS5440-2 or BS6644 as appropriate.

The Lochinvar EcoShield™ can also be used as a type B23 appliance. If such a configuration is to be used, then appropriate ventilation for

cooling and combustion must be provided. For further details, please refer to Section 9 AIR SUPPLY or to BS5440-2 or BS6644 as appropriate.

8.2 GENERAL REQUIREMENTS

Corrosion of the heat exchanger and flue system may occur if air for combustion contains certain chemical vapours. Such corrosion may result

in poor combustion and create a risk of asphyxiation. Aerosol propellants, cleaning solvents, refrigerator and air condition ing refrigerants,

swimming pool chemicals, calcium and sodium chloride, waxes and process chemicals are corrosive. Products of this sort should not be stored

near the water heater or outside by the air intake (if applicable). The fitting of this equipment in a situation where aeros ols or other chemicals

may be entrained into the combustion air will invalidate the warranty.

The equipment must be installed on a level surface that is capable of adequately supporting its weight (when filled with water) and any ancillary

equipment. The operation of the equipment must not cause the temperature of any combustible material in the vicinity of the equipment and its

flue to exceed 65°C. If such a situation is unavoidable, appropriate insulation should be provided.

Locate the equipment so that if the appliance or any connecting pipework should leak, water damage will not occur.

When such locations cannot be avoided a suitable drain pan should be installed under the equipment. The pan should

be adequately drained but must not restrict the combustion or ventilation airflow.

8.3 CONDENSATE DRAIN

The condensate drain is located on the left hand side of the water heater. It is fitted with a ½” PVC tee and union, this should be connected to

an appropriate condensate drain, sloping continuously away from the water heater at an angle of at least 3 (50mm per metre).

The Water Resources Act requires that trade effluent is discharged to municipal sewers between pH 6.5 and 10.0. If it is determined that these

levels cannot be achieved, an in-line condensate neutralisation kit is available from Lochinvar Limited. This unit is capable of neutralising 4000

litres of condensate to a pH of 7.0 before releasing it to a drain.

Page 15

15

9.0 GAS SUPPLY

The Lochinvar EcoShield™ range is suitable for use on second and third family gasses 2H - G20 - 20mbar and 3P - G31 - 37mbar. Details

relating to Natural Gas (2H) appear below; for details relating to Propane (3P) please refer to Section 16.0 LPG FUEL.

9.1 SERVICE PIPES

The local gas distributor must be consulted at the installation planning stage in order to establish the availability of an adequate supply of gas.

An existing service pipe must not be used without prior consultation with the local gas distributor.

9.2 METERS

A new gas meter will be connected to the service pipe by the local gas distributor contractor. An existing gas meter should be checked, preferably

by the gas distributor, to ensure that it is adequate to deal with the rate of gas supply required.

9.3 GAS SUPPLY PIPES

Supply pipes must be fitted in accordance with IGE/UP/2. Pipework from the meter to the equipment must be of adequate size. The complete

installation must be purged and tested as described in IGE/UP/1. Refer to Section 16.0 LPG Fuel for information on LPG pipework installation

guidance.

9.4 BOOSTED SUPPLIES

Where it is necessary to employ a gas pressure booster, the controls must include a low-pressure cut-off switch at the booster inlet. The local

gas distributor must be consulted before a gas pressure booster is fitted. For details of how to connect a low-pressure cut-off switch, please

refer to Section 11 Electrical Supply

9.5 PLANT-ROOM CONTROL VALVE

A manual valve for plant-room isolation must be fitted in the gas supply line. It must be clearly identified and readily accessible for operation,

preferably by an exit.

9.6 EQUIPMENT GAS SYSTEM LEAK CHECK

An approved gas-inlet appliance isolating valve and union should be installed for each unit in a

convenient and safe position and be clearly marked.

Ensure that the gas-inlet appliance isolating valve is in the OFF position. Although the equipment receives a gas leak check and gas train

component integrity check prior to leaving the factory, transit and installation may cause disturbance to unions, fittings and components. During

commissioning a further test for tightness should be carried out on the equipment gas pipework and components.

Care must be taken not to allow leak detection fluid on or near any electrical parts or

connections.

Page 16

16

10.0 FLUE SYSTEM

All versions of the EcoShield™ Condensing water heater can be installed as either type B23 (fan assisted open flue) or C13, C33, C43,C53,C63

(room sealed) appliances. Only C13,C33,C53 Flue systems are covered in any detail within this document, further information can be found in

the EcoShield™ Flue assemblies and ancillaries guide available at www.lochinvar.ltd.uk See the relevant section for details of each flue type

and requirements.

10.1 FLUE SYSTEM GENERAL REQUIREMENTS

Install the horizontal flue components with an angle of 3° back in the direction of the boiler (roughly equal to five

centimetres for every linear meter). Failure to install the flue correctly will result in a build-up of condense within the

flue pipework that will cause early component failure.

When using a wall terminal, there is the possible risk of ice building-up on surrounding parts/structures, because the

condensate will freeze. This risk should be taken into account during the design phase of the heating installation.

EcoShield™ Water heaters will produce large condense clouds especially during cold weather, consideration must be

taken as to whether this will cause a nuisance to neighbouring properties and if so alternative flue arrangements used.

EcoShield™ Water heaters can operate with very low flue temperatures; as such the flue system used must be suitable

for use with condensing appliances made from either Polypropylene or stainless steel and have a temperature class

of T120.

Aluminium flue pipe must not be used on this appliance as it may lead to premature failure of the heat exchanger and

will invalidate the warranty.

Before installation of any flue system read the installation manual carefully for both the appliance and flue system to

be used. Information on the flue system Supplied by Lochinvar can be found within this manual.

Page 17

17

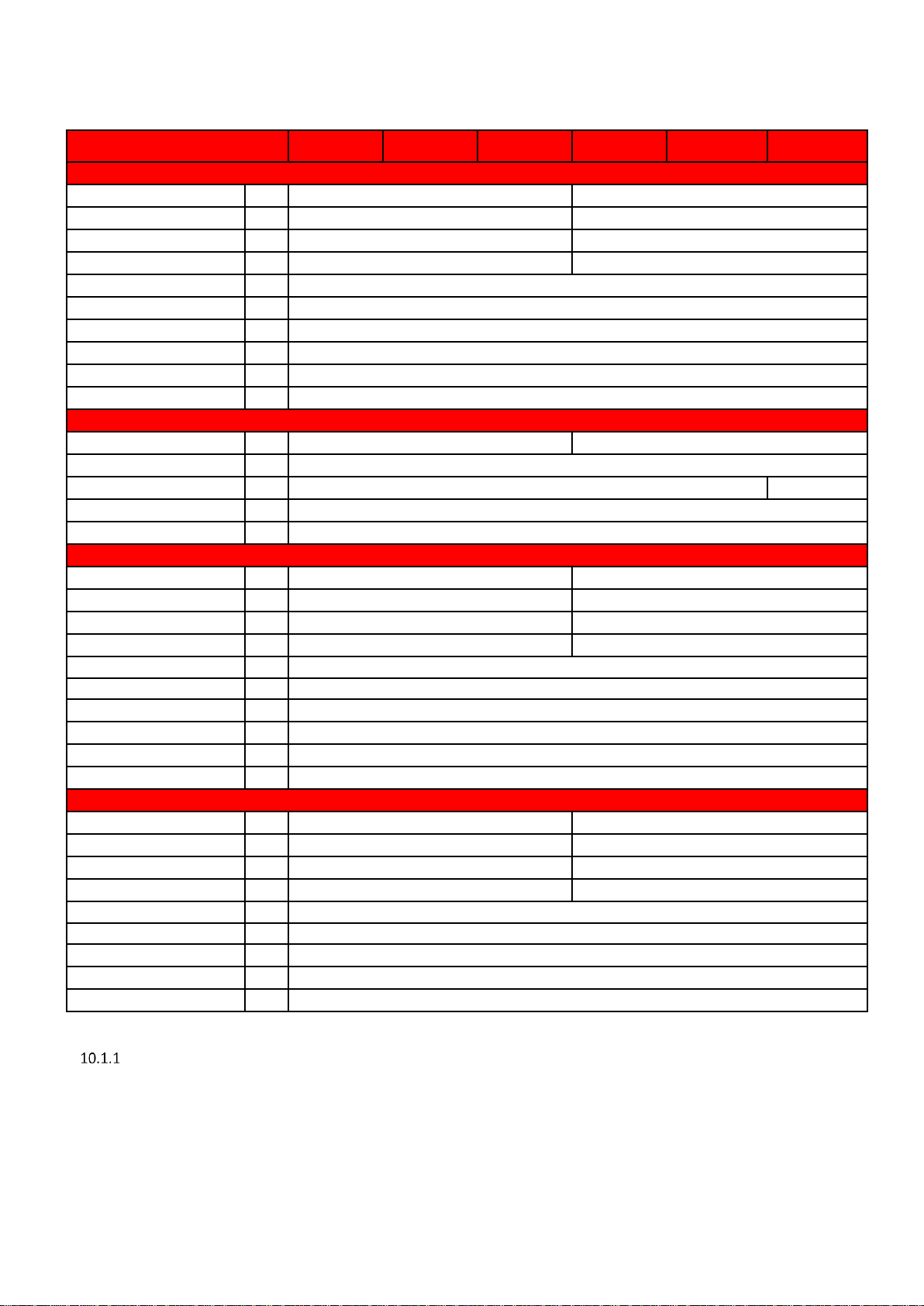

Model Number

SHW35-245CE

SHW46-325CE

SHW61-325CE

SHW86-410CE

SHW116-410CE

SHW146-410CE

FLUE DATA TYPE B23

Nominal flue diameter (d

nom

)

mm

80

100

Nominal flue diameter (d

outside

)

mm

80 +/-0.3

100 +/-0.3

Nominal flue diameter (d

inside

)

mm

81 +/-0.6

101+/-0.6

Nominal flue diameter (L

insert

)

mm

50 +20/ -2

50 +20/ -2

Maximum flue gas temp.

°C

120

Maximum equivalent length

m

60

Equivalent length 90 bend

mm

1000

Equivalent length 45 bend

mm

500

Flue gas temperature

°C

70

Flue draught requirements

mbar

-0.03 to -0.1

FLUE DATA TYPE C13 & C33

Nominal flue diameter

mm

80/125

100/150

Maximum flue gas temp.

°C

120

Maximum equivalent length

m

30

13

Equivalent length 90 bend

mm

1000

Equivalent length 45 bend

mm

500

FLUE DATA TYPE C43 & C53

Nominal flue diameter (d

nom

)

mm

80

100

Nominal flue diameter (d

outside

)

mm

80 +/-0.3

100 +/-0.3

Nominal flue diameter (d

inside

)

mm

81 +/-0.6

101+/-0.6

Nominal flue diameter (L

insert

)

mm

50 +20/ -2

50 +20/ -2

Minimum flue gas temp

°C

35

Average flue gas temp

°C

70

Maximum flue gas temp.

°C

120

Maximum equivalent length

m

60*

Equivalent length 90 bend

mm

1000

Equivalent length 45 bend

mm

500

FLUE DATA TYPE C63

Nominal flue diameter (d

nom

)

mm

80

100

Nominal flue diameter (d

outside

)

mm

80 +/-0.3

100 +/-0.3

Nominal flue diameter (d

inside

)

mm

81 +/-0.6

101+/-0.6

Nominal flue diameter (L

insert

)

mm

50 +20/ -2

50 +20/ -2

Minimum flue gas temp

°C

35

Average flue gas temp

°C

70

Maximum flue gas temp.

°C

120

Max combustion air temperature

°C

40

Maximum equivalent length

m

48

FLUE SYSTEM TECHNICAL DATA TABLE

* On twin pipe systems, the maximum equivalent length is the sum of the air inlet components and the exhaust components.

Page 18

18

10.2 FLUE DISCHARGE

The flue system must ensure safe and efficient operation of the equipment to which it is attached, protect the combustion process from wind

effects and disperse the products of combustion to open external air.

The flue must terminate in a freely exposed position and be so situated as to prevent the products of combustion entering any opening in a

building. For installations with a total output above 333kW nett, the clean air act should be consulted and complied with.

Under certain operating and weather conditions, the EcoShield™ water heater may generate a plume at the terminal. Consideration should be

given to the nuisance this may cause and the terminal should be sited accordingly.

For further information on terminal locations, please refer to Section 10.3.1 FLUE TERMINAL POSITIONS.

10.3 CONDENSATE DRAIN

If the flue system rises at an angle of at least 3 (50mm per metre), no additional condensate drain will be required. Failure to provide an

adequate rise in the flue system may lead to pooling of condensate which may lead to premature failure of the flue system.

FLUE TERMINAL POSITIONS

Location

Description

SHW35-245CE

SHW46-325CE

SHW61-325CE

SHW86-410CE

SHW116-410CE

SHW146-410CE

A

Directly below an opening, air brick, opening windows etc.

300

2000

B

Above an opening, air brick, opening windows etc.

300

1000

C

Horizontally to an opening, air brick, opening windows etc.

300

1000

D

Below a gutter or sanitary pipework

75

75

E

Below the eaves

200

200

F

Below a balcony or car port roof

200

200

G

From a vertical drain or soil pipe

150

150

H

From an internal or external corner

300

300

I

Above ground, roof or balcony level

300

300

J

From a surface facing the terminal

600

1000

K

From a terminal facing the terminal

1200

2000

L

From an opening in the car port (e.g. door, window) into the

dwelling

1200

1200

M

Vertically from a terminal on the same wall

1500

1500

N

Horizontally from a terminal on the same wall

300

600

P

From a vertical structure on the roof

300

300

Q

Above intersection with the roof

300

300

FLUE TERMINAL MINIMUM DISTANCES

Page 19

19

10.4 FLUE SYSTEM GENERAL REQUIREMENTS

Detailed recommendations for the flue system are given in BS5440-1 for equipment of rated input not exceeding 70kW net, BS6644 for

equipment above 70kW net and IGE/UP/10 for equipment of rated input above 54kW net. The following notes are intended to give general

guidance only.

10.5 APPROVED FLUE SYSTEM

For Concentric and Twin pipe flue systems only the Lochinvar supplied M&G flue system must be used

The approved flue system is not suitable for use external to the building. If external routes cannot be avoided, a flue

system manufacturer should be consulted to supply a suitable alternative.

10.6 INSTALLATION PRECAUTIONS

The approved flue system is rated to 120C max. To prevent the exhaust temperature exceeding this, the appliance is supplied with

a flue gas temperature sensor.

This must be fitted during the installation of the flue system. Failure to do so may lead to severe

personal injury, death or substantial property damage.

The water heater must not be operated unless the complete flue system is installed. This includes the water heater connections,

concentric adaptor (if required) flue pipes, air ducts (if required) and terminals. If discharging at low level, a suitable flue guard must

be installed.

During assembly precaution should be taken to ensure that the internal sealing ring is seated correctly.

Due to the close tolerances in the flue system, it may be necessary to use a twisting action to fit the joints together. No lubrication

other than water should be used.

10.7 CONDENSATE DRAIN

Condensate can flow back to the appliance, this will travel through the heat exchanger into the condensate drain via the trap.

If the flue system rises at an angle of at least 3 (50mm per metre), no additional condensate drain will be required. Failure to provide an

adequate rise in the flue system may lead to pooling of condensate which may lead to premature failure of the flue system.

10.8 TYPE B

23

CONVENTIONAL FANNED FLUE

When the heater is installed as a Type B23 appliance, the flue system should be installed in accordance with the flue manufacturer’s specific

instructions. A kit of components is available to facilitate conventional flueing of the EcoShield™ water heater;

This must be fitted prior to any other flue pipework.

SHW35-245CE –SHW61-325CE kit number SHCF003

SHW86-410CE –SHW145-410CE kit number SHCF004

Page 20

20

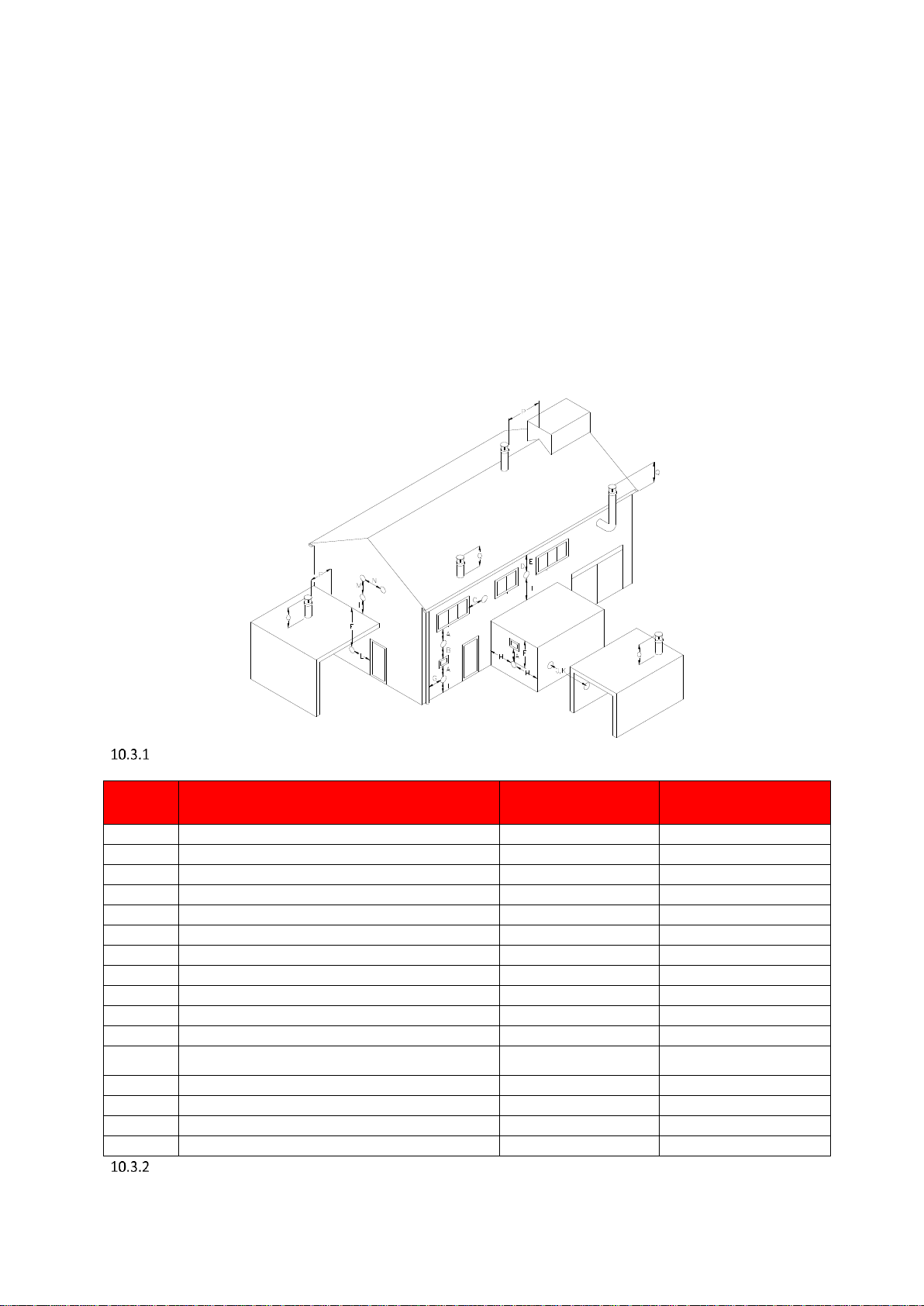

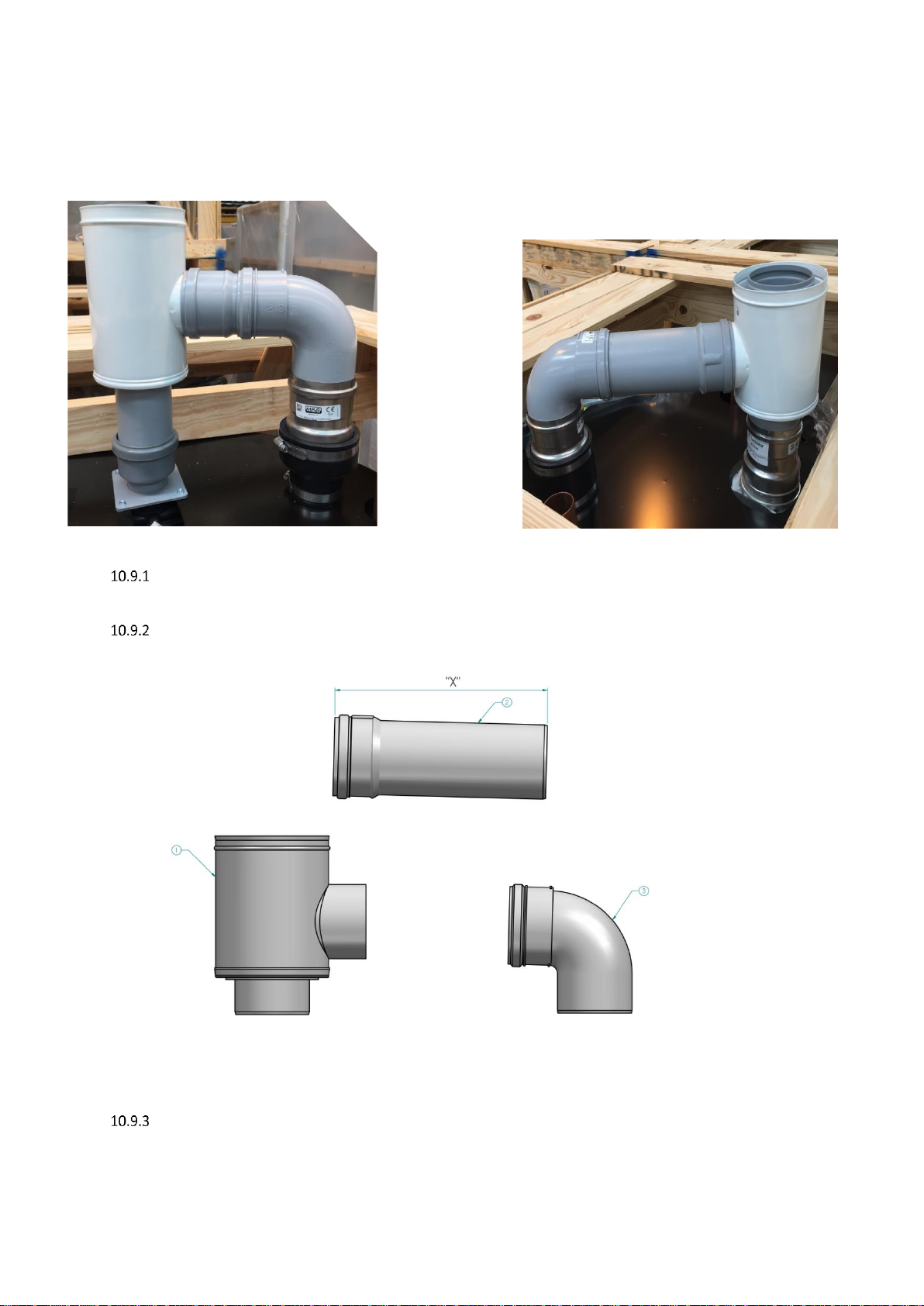

10.9 ROOM SEALED (TYPE C) FLUE ASSEMBLY

Before fitting the flue system for either type C13 Horizontal or C53 Vertical Concentric flue the flue transition kit should be installed to the top of

the heater as per 10.9.3 and 10.9.7

SHW35-245,SHW46-325,SHW61-325

SHW86-410,SHW116-410,SHW146-410

ECOSHIELD™ SHOWING TRANSITION KIT FITTED

TRANSITION KIT SHW35-245CE – SHW61-325CE

FLUE TRANSITION DETAILS SHW35-245CE – SHW61-325CE

Page 21

21

ITEM

DESCRIPTION

1

CONCENTRIC ADAPTER

2

EXTENSION

3

ELBOW

FLUE CONNECTION DETAILS SHW35-245CE - SHW61-325CE

MODEL

“X” DIMENSION

SHW35-245 NG CE

115mm

SHW46-325 NG CE

195mm

SHW61-325 NG CE

No cut required

EXTENSION LENGTH SHW35-245 CE - SHW61-325 CE

To install the flue connection to the SHW35-245CE - SHW61-325CE water heaters the following procedure should be followed:

1. Insert the air intake transition into the intake connection reducer and tighten the worm drive clip.

2. Fit 80mm elbow (Item 3 in Table) to cut end of extension.

3. To the side (intake) connection of the concentric adaptor (Item 1 in Table), fit the other end of the 80mm dia. Extension.

4. Fit the bottom (flue) connection of the concentric adapter to the flue connection on the heater.

.

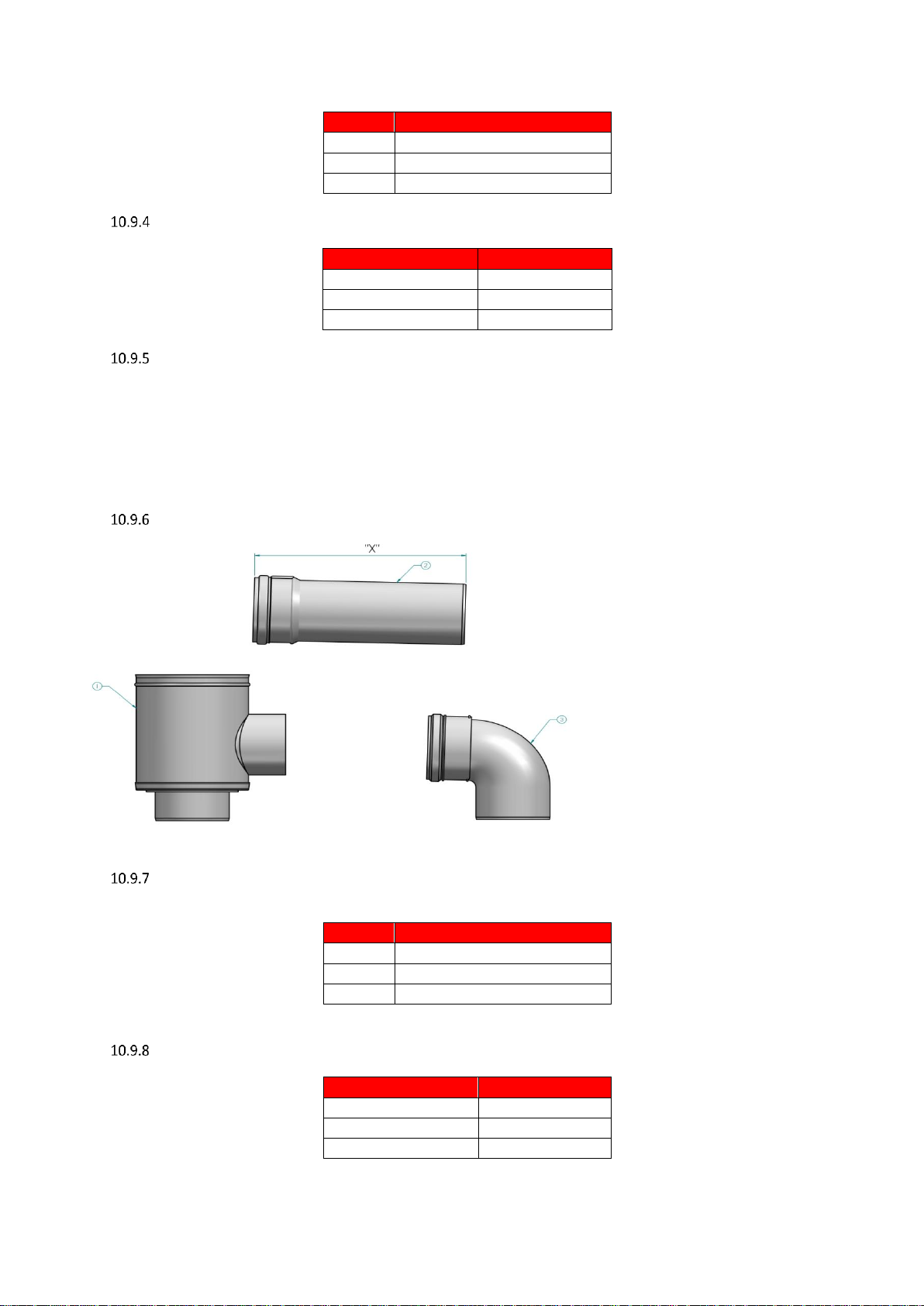

TRANSITION KIT SHW86-410CE, SHW116-410CE & SHW146-410CE

FLUE TRANSITION DETAILS SHW86-410CE - SHW146-410CE

ITEM

DESCRIPTION

1

CONCENTRIC ADAPTER

2

EXTENSION

3

ELBOW

FLUE CONNECTION DETAILS SHW86-410CE - SHW146-410CE

MODEL

“X” DIMENSION

SHW86-410 NG CE

135mm

SHW116-410 NG CE

No cut required

SHW146-410 NG CE

No cut required

Page 22

22

To install the flue connection to the SHW86-410 CE – SHW146-410 CE water heaters the following procedure should be followed:

1. Insert the air intake transition into the intake connection reducer and tighten the worm drive clip.

2. Fit 100mm elbow (Item 3 in 10.9.7) to cut end of extension.

3. To the side (intake) connection of the concentric adaptor (Item 1 in 10.9.7), fit the other end of the 100mm dia. Extension.

4. Fit the bottom (flue) connection of the concentric adapter to the flue connection on the heater.

10.10 C13 CONCENTRIC HORIZONTAL FLUE SYSTEMS

Flue system specifications

MANUFACTURER MUELINK AND GROL (M&G)

TEMPERATURE CLASS T120

FLUE GAS MATERIAL PP

Each concentric horizontal flue kit includes the items shown in the tables below

Item No SHHF003

CONCENTRIC HORIZONTAL FLUE ASSEMBLY MODELS

SHW35-245,SHW46-325,SHW61-325

COMPONENTS INCLUDED

Item No.

Description

Included

M86934

CONCENTRIC HORIZONTAL TERM Ø80/125mm PP (NO WALL PLATES)

1

M28925

TERMINAL WALL PLATES (PAIR)

1

M121602

TWIN PIPE TO CONCENTRIC ADAPTOR Ø80/80mm TO Ø80/125mm PP

1

M75256

AIR INLET TRANSITION Ø80mm ALU

1

M84471

SAMPLING POINT Ø80/125mm PP

1

M84460

CONCENTRIC BEND 90° Ø80/125mm PP

1

Item No SHHF004

CONCENTRIC HORIZONTAL FLUE ASSEMBLY MODELS

SHW86-410,SHW116-410,SHW146-410

COMPONENTS INCLUDED

Item No.

Description

Included

LV310758

CONCENTRIC HORIZONTAL TERMINAL Ø100/150mm PP

1

M75257

AIR INLET TRANSITION Ø100mm ALU

1

M121605

TWIN PIPE TO CONCENTRIC ADAPTOR Ø100/100mm TO Ø100/150mm PP

1

M84421

SAMPLING POINT Ø100/150mm PP

1

M84412

CONCENTRIC BEND 90° Ø100/150mm PP

1

Page 23

23

10.11 HORIZONTAL FLUE TERMINAL INSTALLATION

When the Water Heater is installed as a Type C13 (Horizontal concentric) appliance, the flue system should be installed as follows:

1. Determine the location of the flue terminal, taking into account minimum distances as detailed in 10.3.1 and the relevant British

Standards.

2. Taking care to protect the appliance from debris and dust, drill a hole in the desired location. The diameter of the hole should be no

more than 10mm greater than the diameter of the air supply pipe of the terminal.

3. Determine the required length of the terminal and cut as necessary.

When determining the required length for the flue terminal, the outer wall plate or rosette should be flush to the wall.

(see 10.11.1 )

Once cut; remove all burrs and sharp edges

4. Insert the terminal into the drilled hole. The terminal section should be installed level or with a fall to outside (Max. 10mm per metre)

to prevent the ingress of water.

When inserting the terminal, ensure the air intake section is at the bottom.

5. Fill the void between the terminal and wall with water resistant sealant.

6. Fit the wall plates or rosette using appropriate fixings.

7. Install the remainder of the flue system working progressively away from the Water Heater supporting the pipes as necessary.

HORIZONTAL TERMINAL INSTALLATION

10.12 FLUE TERMINAL GUARDING

If a horizontal flue terminal is to be fitted less than 2 metres from ground level or in a location where it can be touched from a window, door or

balcony, a terminal guard must be fitted.

Page 24

24

10.13 C33 CONCENTRIC VERTICAL FLUE SYSTEMS

Flue system specifications

MANUFACTURER MUELINK AND GROL (M&G)

TEMPERATURE CLASS T120

FLUE GAS MATERIAL PP

Each concentric Vertical flue kit includes the items shown in the tables below

Item No SHVF003

CONCENTRIC VERTICAL FLUE ASSEMBLY MODELS

SHW35-245,SHW46-325,SHW61-325

COMPONENTS INCLUDED

Item No.

Description

Included

M75256

AIR INLET TRANSITION Ø80mm ALU

1

M121602

TWIN PIPE TO CONCENTRIC ADAPTOR Ø80/80mm TO Ø80/125mm PP

1

M84471

SAMPLING POINT Ø80/125mm PP

1

M86864

CONCENTRIC VERTICAL TERMINAL Ø80/125mm PP

1

Item No SHVF004

CONCENTRIC HORIZONTAL FLUE ASSEMBLY MODELS

SHW86-410,SHW116-410,SHW146-410

COMPONENTS INCLUDED

Item No.

Description

Included

M75257

AIR INLET TRANSITION Ø100mm ALU

1

M121605

TWIN PIPE TO CONCENTRIC ADAPTOR Ø100/100mm TO Ø100/150mm PP

1

M84421

SAMPLING POINT Ø100/150mm PP

1

LV310754

CONCENTRIC VERTICAL TERMINAL Ø100/150mm PP

1

10.14 VERTICAL FLUE TERMINAL INSTALLATION

When the water heater is installed as a Type C33 appliance, the flue system should be installed as follows:

1. Confirm that the roof flashing is correct for the type of roof through which the terminal is to be installed. Section 10.14.1

2. Determine the desired location for the flue terminal, taking into account minimum distances as detailed in Section 10.3.1 TERMINAL

POSITIONS and the relevant British Standards.

3. Taking care to protect the appliance from debris and dust, drill a hole in the desired location. The diameter of the hole should be no

more than 10mm greater than the diameter of the air supply pipe of the terminal.

The hole should be drilled from the outside to ensure that no damage is done to the roofing material. Extra care

should be taken to ensure that the hole is drilled vertically.

4. Install the roof flashing and secure as appropriate.

5. Carefully insert the roof terminal through the roof flashing and hole in the roof.

Page 25

25

When inserting the roof terminal do not support or turn the terminal using the cap.

6. Ensure the terminal is vertical using a spirit level.

7. Fit the support bracket around the terminal and secure using appropriate fixings. Do not tighten the support bracket

8. Install the remainder of the flue system working progressively away from the water heater supporting the pipes as necessary.

9. Once the flue system is fully installed, tighten the clamp to secure the terminal in place.

VERTICAL TERMINAL ROOF FLASHINGS FOR SYNTHETIC, FLAT AND TILED ROOFS

INSTALLING TERMINAL THROUGH ROOF FLASHING

Page 26

26

GENERAL CONCENTRIC FLUE SYSTEM INSTALLATION GUIDELINES

The information in this section is for General guidance only and may not fully represent the installation on site

Do not drill and screw

into flue system

Page 27

27

Max distance between

brackets

Page 28

28

Page 29

29

Page 30

30

10.15 C

43

COMMON VENTED FLUE SYSTEMS IN MULTI FLOOR BUILDINGS

In C43 systems water heaters are fitted on common air inlet and flue gas outlet (either concentric or parallel) systems in multiple floor buildings.

Only use a C43 venting system when the common duct is a natural draught chimney. The

common duct is part of the building, not a part of the system.

CONDENSATE DRAIN

Condensate can flow back to the appliance, this will travel through the heat exchanger into the condensate drain via the trap.

If the flue system rises at an angle of at least 3 (50mm per metre), no additional condensate drain will be required. Failure to provide an

adequate rise in the flue system may lead to pooling of condensate which may lead to premature failure of the flue system.

Page 31

31

10.16 C

53

(TWIN PIPE) FLUE SYSTEMS

Flue system specifications

MANUFACTURER MUELINK AND GROL (M&G)

TEMPERATURE CLASS T120

FLUE GAS MATERIAL PP

Each Twin-Pipe starter assembly includes the items shown in the tables below, you then add either the Vertical or Horizontal terminal and air

inlet.

Item No SHTF003

TWIN-PIPE FLUE STARTER ASSEMBLY MODELS

SHW35-245,SHW46-325,SHW61-325

COMPONENTS INCLUDED WITHIN KIT TO START INSTALLATION

Item No.

Description

Included

M75256

AIR INLET TRANSITION Ø80mm ALU

1

M85279

SAMPLING POINT Ø80mm PP

1

VERTICAL FLUE

M86864

CONCENTRIC VERTICAL TERMINAL Ø80/125mm PP

LV305016

HORIZONTAL AIR INLET Ø80mm

HORIZONTAL FLUE

M86934

CONCENTRIC HORIZONTAL TERMINAL Ø80/125mm PP (NO WALL PLATES)

LV305016

HORIZONTAL AIR INLET Ø80mm

M28925

TERMINAL WALL PLATES (PAIR)

Item No SHTF004

TWIN-PIPE FLUE STARTER ASSEMBLY MODELS

SHW86-410,SHW116-410,SHW146-410

COMPONENTS INCLUDED WITHIN KIT TO START INSTALLATION

Item No.

Description

Included

M75257

AIR INLET TRANSITION Ø100mm ALU

1

M85189

SAMPLING POINT Ø100mm PP

1

VERTICAL FLUE

LV310754

CONCENTRIC VERTICAL TERMINAL Ø100/150mm PP

LV305039

HORIZONTAL AIR INLET Ø100mm ALU

HORIZONTAL FLUE

M86934

CONCENTRIC HORIZONTAL TERMINAL Ø80/125mm PP (NO WALL PLATES)

LV305039

HORIZONTAL AIR INLET Ø100mm ALU

M28925

TERMINAL WALL PLATES (PAIR)

When installing EcoShield™ on a C53 twin pipe flue system, the Lochinvar Twin pipe flue starter assembly must be fitted first.

Page 32

32

When installing the water heater as a Type C53 appliance, it should be noted that the terminals must not be

installed on opposite sides of the building.

If the flue temperature sensor is not fitted, the flue gas temperature may exceed the maximum

temperature rating of the flue and can lead to severe personal injury, death or substantial property

damage.

To install a Type C53 terminal or air inlet, the procedure for either a Type C13 (horizontal) or a Type C33 (vertical) terminal should

be followed noting that the annular space of the terminal should be sealed off.

Page 33

33

GENERAL TWIN-PIPE INSTALLATION GUIDELINES

The information in this section is for General guidance only and may not fully represent the installation on site

Page 34

34

Page 35

35

10.17 FLUE TERMINAL GUARDING

If a horizontal flue terminal is to be fitted less than 2 metres from ground level or in a location where it can be touched from a window, door or

balcony, a terminal guard must be fitted.

The terminal guard is constructed from plastic-coated mild steel and is suitable for use on condensing appliances only. The guard should be

installed centrally around the terminal ensuring a gap of at least 50mm between the guard and terminal is maintained.

Page 36

36

10.18 TYPE B

23

(CONVENTIONAL FLUE WITH FAN ASSISTANCE)

Item No SHCF003

CONVENTIONAL FLUE ASSEMBLY

MODELS SHW35-245,SHW46-325,SHW61-325

COMPONENTS REQUIRED TO START INSTALLATION

Item No.

Description

Included

M75256

AIR INLET TRANSITION Ø80mm ALU

1

M73039

AIR INLET GRILLE Ø80mm ALU

1

M85279

SAMPLING POINT Ø80mm PP

1

Item No SHCF004

CONVENTIONAL FLUE ASSEMBLY MODELS

SHW86-410,SHW116-410,SHW146-410

COMPONENTS REQUIRED TO START INSTALLATION

Item No.

Description

Included

M75257

AIR INLET TRANSITION Ø100mm ALU

1

M86787

APPLIANCE AIR INLET GUARD Ø100mm

1

M85189

SAMPLING POINT Ø100mm PP

1

The above is a kit of components to facilitate conventional flueing of the appliance and must be fitted prior to fitting any other flue components.

Page 37

37

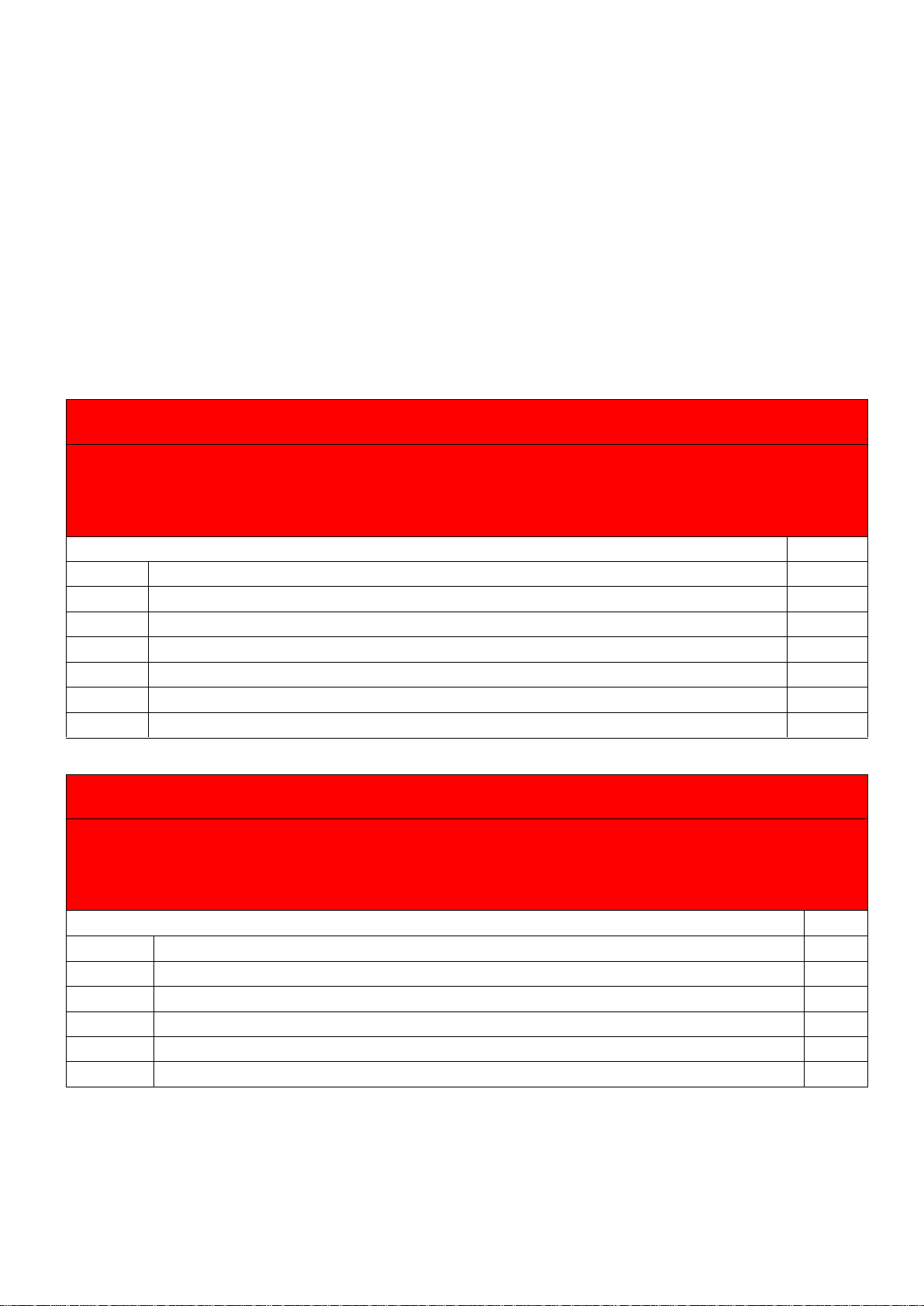

10.19 C

63

CERTIFIED FLUE SYSTEMS

In general, Water heaters are certified with their own purpose supplied Concentric or Twin Pipe flue systems, C63 certified appliances allow the

installer to use other flue systems when installing the Water heater however, they must be of a suitable minimum standard as per Table below.

CE string

flue gas

material

European standard

Tempera

-ture

class

Pressure

class

Resistance to

condensate Corrosion

resistance

class

Metal: liner

specification

s

Soot fire

resistance

class

Distance to

combustible

material

Plastics:

location

Plastics: fire

behaviour

Plastics:

enclosure

Min required PP

EN 14471

T120

P1 W 1 O

30

I of E

C/E

L

Min required

Inox

EN 1856-1

T120

P1 W 1

L20040

O

40

C63 FLUE SYSTEM SPECIFICATION

Twin-pipe Flue Systems

Material

Water heater

d

nom

D

outside

d

inside

L

insert

PP

SHW35-SHW61

80

80 +/-0.3

81 +/-0.6

50 +20/ -2

PP

SHW86-SHW146

100

100 +/-0.3

101+/-0.6

50 +20/ -2

Concentric Flue Systems

Material

Water heater

d

nom

D

outside

d

inside

L

insert

PP

SHW35-SHW61

80/100

80 +/-0.3-124 +0.5/-1

81 +/-0.6-125.5 +1/-0.5

56 +/-3

PP

SHW86-SHW146

100/150

100 +/-0.3 - 148.5 +0.5/-1

101+/-0.5 - 150+1/-0.5

50 +20/ -2

When installing the water heater as a Type C63 appliance, it should be noted that the terminals

must not be installed on opposite sides of the building.

The maximum allowable recirculation rate is 10% under wind conditions

Aluminium flue pipe must not be used on this appliance as it may lead to premature failure of the

heat exchanger and will invalidate the warranty.

CONDENSATE DRAIN

Condensate can flow back to the appliance, this will travel through the heat exchanger into the condensate drain via the trap.

If the flue system rises at an angle of at least 3 (50mm per metre), no additional condensate drain will be required. Failure to provide an

adequate rise in the flue system may lead to pooling of condensate which may lead to premature failure of the flue system.

Model Number

SHW35-245CE

SHW46-325CE

SHW61-325CE

SHW86-410CE

SHW116-410CE

SHW146-410CE

FLUE DATA TYPE C

63 WITH TWIN-PIPE FLUE

Minimum flue gas temp

°C

35

Average flue gas temp

°C

70

Maximum flue gas temp

°C

120

Maximum equivalent length

m

48

Model Number

SHW35-245CE

SHW46-325CE

SHW61-325CE

SHW86-410CE

SHW116-410CE

SHW146-410CE

FLUE DATA TYPE C

63 WITH CONCENTRIC FLUE

Minimum flue gas temp

°C

35

Average flue gas temp

°C

70

Maximum flue gas temp

°C

120

Maximum equivalent length

m

24

10

Page 38

38

11.0 AIR SUPPLY

The following information is based on single water heater installations only. If more than one water heater is being used, BS6644 should be

consulted to calculate the necessary requirements.

11.1 COMBUSTION VENTILATION

When used as a Type C appliance, provided sufficient clearance is provided, ventilation for combustion is not necessary as the combustion air

is ducted directly from outside.

When used as a Type B appliance, the combustion air requirements are as follows:

Model

Gross

Input

(kW)

Net

Input

(kW)

Ventilation

(Room)

(cm2)

Compartment

Compartment

(Direct to Outside)

(To Internal Space)

High

(cm2)

Low

(cm2)

High

(cm2)

Low

(cm2)

SHW35-245CE

36.6

33.3

132

166

332

332

664

SHW46-325CE

43.9

39.6

165

200

400

400

800

SHW61-325CE

58.6

52.8

230

265

530

530

1060

COMBUSTION VENTILATION REQUIREMENTS SHW35-245CE – SHW61-325CE