Page 1

DD-SUP-01

INSTALLATION INSTRUCTION - SUPPLEMENT SHEET

HYDRONIC HEATING WITH DOUBLE DUTY

POTABLE AND SPACE HEATING CONNECTIONS

The heat exchanger interior has been designed for non-potable water, such as in a hydronic

heating system. If replacing an existing water heating appliance, be sure to turn off electrical

power, heating fluid and / or gas supply to the existing appliance.

The return and supply heating system connections are identified on the side of the appliance. The

use of shut off valves and unions are recommended for future service convenience. A suitable

expansion tank must be installed in the space heating circuit. Consult local codes for proper use,

sizing and installation of an expansion tank. DO NOT operate this water heater in a closed

system without provisions for controlling thermal expansion.

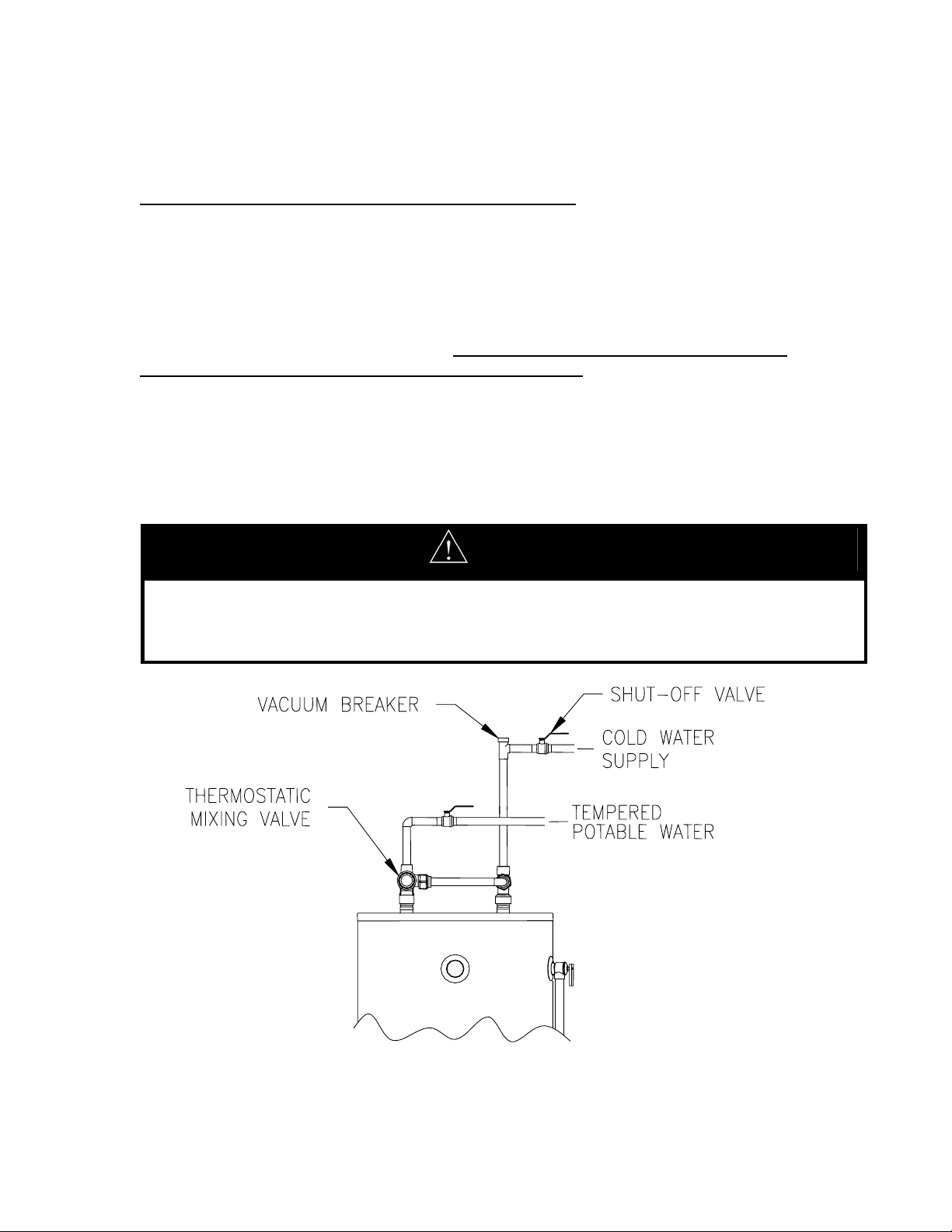

Due to the elevated operating temperature needed to supply adequate hot water for space heating,

an ASSE approved thermostatic mixing valve has been provided and must be installed in the

potable water piping as shown in Figure 1. Directions for proper installation and adjustment are

provided with the integrated mixing system.

Notice: Failure to properly install and regulate the provided ASSE approved thermostatic mixing

valve may increase the danger of scald injury and nullify the warranty.

Hotter water increases the risk of scald injury. Scalding may occur within 5 seconds at a setting of

140°F (60°C). Water temperature over 125°F (52°C) can cause severe burns or death from scalds.

Children, disabled and the elderly are at the highest risk of being scalded. Please feel the water before

bathing or showering.

DANGER

Figure 1 – Integrated Mixing Valve application for Tempered Water

Page 2

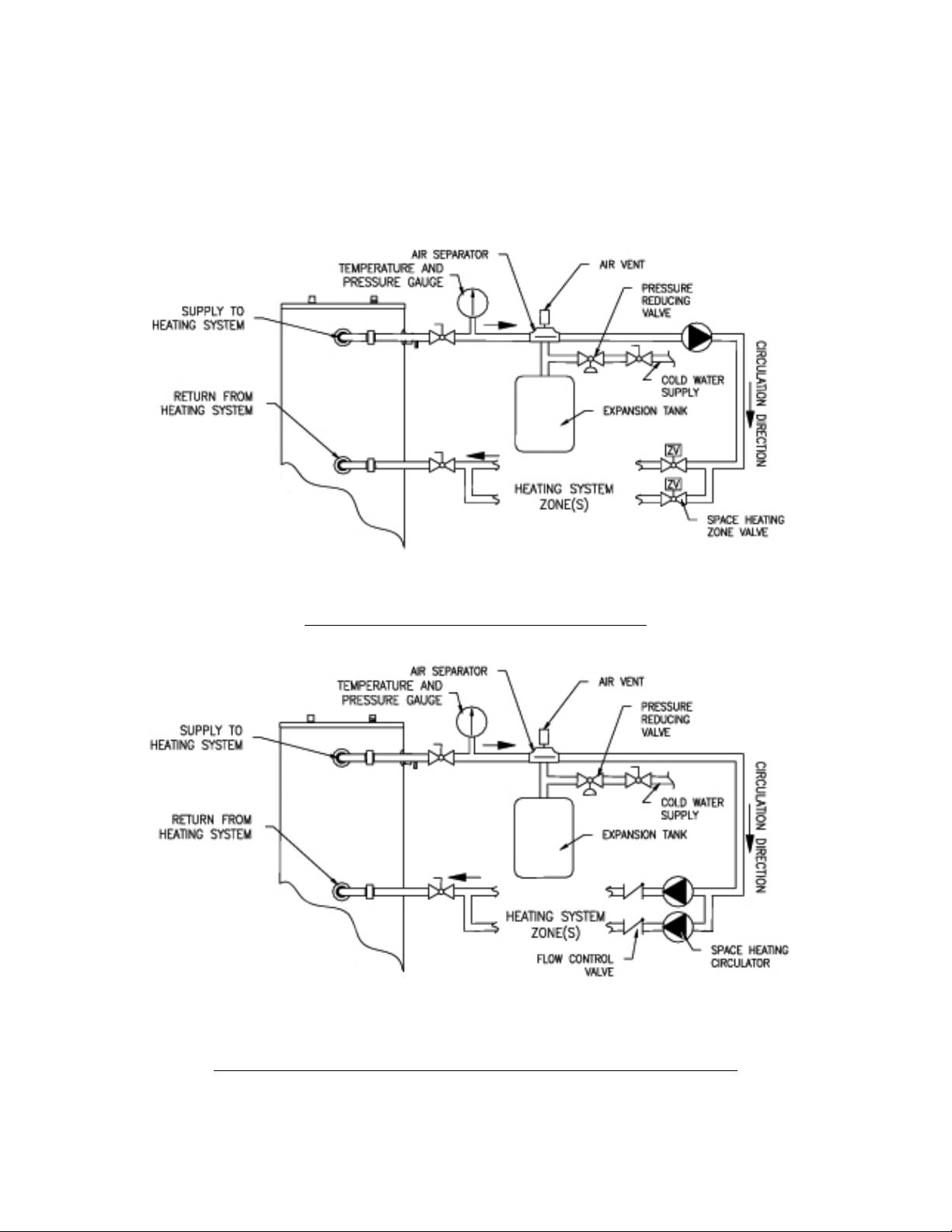

SYSTEM LAYOUT FOR DOUBLE DUTY WATER HEATING SYSTEM (See Figures 2 and 3)

1) Install a properly sized expansion tank. An air separator and vent is recommended to

eliminate air in the system.

2) A pressure reducing valve is recommended for installation to maintain appropriate pressure in

the closed loop system.

3) The circulator should be installed to “pump away” from the expansion tank as shown.

4) Purge all air from the filled, closed system.

Figure 2 – Hydronic Piping with Zone Valves

Figure 3 – Hydronic Piping with Circulators and Flow Control Valves

4/07-Printed in U.S.A.

Loading...

Loading...