Page 1

Installation and Operating Manual

POWER VENTED GAS WATER HEATERS

NOT FOR USE IN MANUFACTURED (MOBILE) HOMES

300 Maddox Simpson Parkway

Lebanon, TN 37090

Phone: 615-889-8900 • Fax: 615-547-1000

Technical Services email: 2tech@lochinvar.com

www.lochinvar.com

POWER VENTED GAS MODELS

WITH HOT SURFACE IGNITION

MODELS PVN/PVL 07575 and

CVN075075/CVL075075 SERIES 210/211

WARNING: If the information in these instructions is not followed exactly, a fire or explosion

may result causing property damage, personal

injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed by

a qualified installer, service agency or the

gas supplier.

WARNING

Read and understand instruction

manual and safety messages

before installing, operating or

servicing this water heater.

Failure to follow instructions and

safety messages could result in

death or serious injury.

Instruction manual must remain

with water heater.

• For Your Safety •

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

ALL TECHNICAL AND WARRANTY QUESTIONS: SHOULD BE DIRECTED TO THE LOCAL DEALER FROM WHOM THE WATER HEATER WAS

PURCHASED. IF YOU ARE UNSUCCESSFUL, PLEASE CONTACT THE COMPANY LISTED ON THE RATING PLATE ON THE WATER HEATER.

KEEP THIS MANUAL IN THE POCKET ON HEATER FOR FUTURE REFERENCE

WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

1808 100221773_2000189439_Rev. 01

Page 2

TABLE OF CONTENTS

Safe Installation, Use And Service . . . . . . . . . . . . . . . . 3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Qualified Installer Or Service Agency . . . . . . . . . . . . 6

Preparing For The Installation. . . . . . . . . . . . . . . . . . 6

Installation Requirements For The

Commonwealth Of Massachusetts. . . . . . . . . . . . . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Get To Know Your Water Heater - Gas Models

(List Referencing Figures 1-7). . . . . . . . . . . . . . . . . . 9

Replacement Parts And Deliming Products . . . . . . 10

Combo Heating Inlet And Outlet Side Taps . . . . . . . 10

Water Piping - Mixing Valve Usage . . . . . . . . . . . . . .11

Mixing Valves

Water Heater Operation . . . . . . . . . . . . . . . . . . . . . 12

Electrical Requirements & Wiring Diagram . . . . . . . 13

Safety Lockouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

High Limit Controls (Energy Cut Off). . . . . . . . . . . . 14

Thermostat/Water Temperature

Blower High Limit Switch

Blower Air Pressure Switch. . . . . . . . . . . . . . . . . . . 14

Flammable Vapor Sensor . . . . . . . . . . . . . . . . . . . . 14

Locating The New Water Heater . . . . . . . . . . . . . . . . 15

Facts To Consider About The Location . . . . . . . . . . 15

Storage Of Flammable Liquids . . . . . . . . . . . . . . . . 15

Clearances to combustibles

Floors with carpeting

Clearance for servicing

Insulation jackets and Blankets. . . . . . . . . . . . . . . . 17

Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unconfined Space. . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unusually Tight Construction . . . . . . . . . . . . . . . . . 17

Confined Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Direct Vent Appliances . . . . . . . . . . . . . . . . . . . . . . 18

Exhaust Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fresh Air Openings For Confined Spaces. . . . . . . . 18

Chemical Vapor Corrosion . . . . . . . . . . . . . . . . . . . 19

Installing The New Water Heater . . . . . . . . . . . . . . . . 20

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Space Heating And Potable Water Systems . . . . . . 20

Combo Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Requirements

Installation

Closed Water Systems . . . . . . . . . . . . . . . . . . . . . . 22

Recirculation Loops. . . . . . . . . . . . . . . . . . . . . . . . . 22

Thermal Expansion . . . . . . . . . . . . . . . . . . . . . . . . . 22

Temperature-Pressure Relief Valve. . . . . . . . . . . . . 23

T&P valve discharge pipe requirements:

Temperature-Pressure Relief Valve and Pipe

Insulation

High Altitude Installation . . . . . . . . . . . . . . . . . . . . . 24

Gas Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sediment Traps. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Filling The Water Heater . . . . . . . . . . . . . . . . . . . . . 26

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Termination Clearances Sidewall Power Vent. . . . . 27

Blower Assembly Installation. . . . . . . . . . . . . . . . . . 28

Installation Of Vent System. . . . . . . . . . . . . . . . . . . 28

Planning The Vent System . . . . . . . . . . . . . . . . . . . 28

Polypropylene Vent Systems . . . . . . . . . . . . . . . . . 29

Condensate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Exhaust Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Important Notes and Warnings

Venting terminations and sizing

Vent screen installation

Calculating Equivalent Feet

Venting instructions

Vent pipe connection to blower

Coupling installations according to vent sizes

Blower Exhaust Direction . . . . . . . . . . . . . . . . . . . . 34

Vent Pipe Preparation . . . . . . . . . . . . . . . . . . . . . . . 34

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . 37

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Operating The Temperature Control System . . . . . . . 39

Gas Control Valve/Thermostat (160°) . . . . . . . . . . . 40

Gas Control Valve/Thermostat (181°) . . . . . . . . . . . 40

For Your Information. . . . . . . . . . . . . . . . . . . . . . . . . . 41

Start Up Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 41

Condensate

Smoke/Odor

Strange sounds

Operational Conditions . . . . . . . . . . . . . . . . . . . . . . 41

Smelly water

“Air” In Hot-Water Faucets . . . . . . . . . . . . . . . . . . . 41

Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 42

General Upkeep . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Venting System Inspection . . . . . . . . . . . . . . . . . .

Blower Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 42

Cleaning The Blower. . . . . . . . . . . . . . . . . . . . . . . . 42

Burner Operation And Inspection . . . . . . . . . . . . . . 43

Combustion Chamber And Burner Cleaning. . . . . . 44

Housekeeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Anode Rod Maintenance. . . . . . . . . . . . . . . . . . . . . 44

Temperature-Pressure Relief Valve Test . . . . . . . . . 45

Draining And Flushing. . . . . . . . . . . . . . . . . . . . . . . 46

To Drain The Water Heater Storage Tank

To Flush The Water Heater Storage Tank

Leakage Checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . 47

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Reference Parts Listing . . . . . . . . . . . . . . . . . . . . . . . 48

Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . 50

Resetting The Heater Control . . . . . . . . . . . . . . . . . 52

Lockouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Soft Lockout

Hard Lockout

Ignition State And Timing . . . . . . . . . . . . . . . . . . . . 53

System Status And Error Codes . . . . . . . . . . . . . . . 53

Reading The LED Flash Sequence. . . . . . . . . . . . . 54

. 42

2 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 3

SAFE INSTALLATION, USE AND SERVICE

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you

and others of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very

important that the meaning of each safety message is understood by you and others who install, use or service this water heater.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

CAUTION

hazardous situation which, if not avoided,

will result in death or injury.

WARNING indicates a potentially

hazardous situation which, if not avoided,

could result in death or injury.

CAUTION indicates a potentially

hazardous situation which, if not avoided,

could result in minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, could

result in property damage

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message

and how to avoid the risk of injury.

This product is certified to comply with a maximum weighted average of 0.25% lead content as required in some areas.

IMPORTANT DEFINITIONS

Qualified Installer: A qualified installer must have ability equivalent to a licensed tradesman in the fields of plumbing,

air supply, venting and gas supply, including a thorough understanding of the requirements of the ”National Fuel Gas

Code” as it relates to the installation of gas fired water heaters. The qualified installer must also be familiar with the

design features and use of flammable vapor ignition resistant water heaters and have a thorough understanding of this

Installation and Operating manual.

Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the fields of plumbing,

air supply, venting and gas supply, including a thorough understanding of the requirements of the ”National Fuel

Gas Code” as it relates to the installation of gas fired water heaters. The service agency must also have a thorough

understanding of this Installation and Operating manual, and be able to perform repairs strictly in accordance with the

service guidelines provided by the manufacturer.

Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning appliances

within this application. The gas supplier typically has responsibility for the inspection and code approval of gas piping

up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also offer service

and inspection of appliances within the building.

100221773_2000189439_Rev. 01 www. lochinvar .com 3

Page 4

GENERAL SAFETY

Read and understand instruction

manual and safety messages

before installing, operating or

servicing this water heater.

Failure to follow instructions and

safety messages could result in

death or serious injury.

Instruction manual must remain

with water heater.

DANGER

WARNING

Water temperature over

125°F can cause severe

burns instantly resulting in

severe injury or death.

Children, the elderly and the

disabled and are at highest

risk of scald injury.

Feel water before bathing or

showering.

WARNING

Fire Hazard

For continued protection against

risk of fire:

• Do not install water heater on

carpeted floor.

• Do not operate water heater if

flood damaged.

WARNING

Explosion Hazard

•

Overheated water can cause

water tank explosion.

•

Properly sized temperature and

pressure relief valve must be

installed in opening provided.

HOT

HOT

BURN

Temperature limiting valves

are available.

Read instruction manual for

safe temperature setting.

WARNING

Fire or Explosion Hazard

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

• Avoid all ignition sources if you smell gas.

• Do not expose water heater control to excessive

gas pressure.

• Use only gas shown on rating plate.

• Maintain required clearances to combustibles.

• Keep ignition sources away from faucets after

extended period of non-use.

Read instruction manual before

installing, using or servicing

water heater.

4 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 5

GENERAL SAFETY

CAUTION

Improper Installation, use and service may result

in property damage.

• Do not operate water heater if flood damaged.

• Inspect anode rods regularly, replace when significantly

depleted.

• Install in location with drainage.

• Fill tank with water before operation.

• Properly sized thermal expansion tanks are required on all

closed water systems.

Refer to this manual for installation and service.

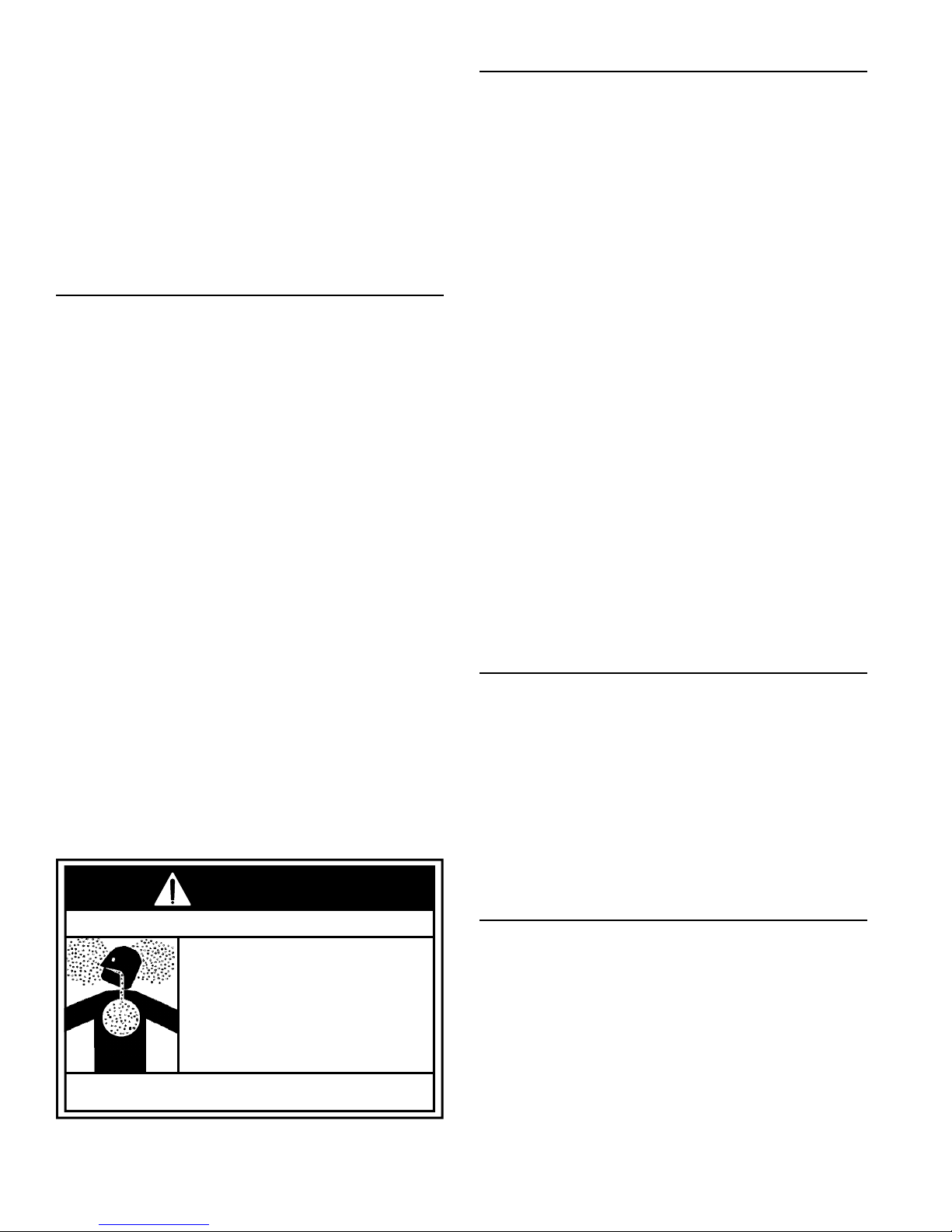

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Install vent system in accordance with codes.

• Do not operate water heater if flood damaged.

• For operation above 10,100’, a high altitude

orifice must be installed.

• Do not operate if soot buildup is present.

• Do not obstruct water heater air intake with

insulating jacket or blanket.

• Do not obstruct blower air intake.

• Do not place chemical vapor emitting products

near water heater.

• Gas and carbon monoxide detectors are

available.

• No vent damper installation is compatible with

this power vented water heater.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

WARNING

• Before servicing the water heater, make

sure the blower assembly is unplugged

or the electrical supply to the water

heater is tumed "OFF".

• Label all wires prior to disconnection

when servicing controls. Wiring error can

cause improper and dangerous operation. Verify proper operation after

servicing.

• Failure to do this could result in death,

serious bodily injury, or property

damage.

WARNING

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Storage or

use of gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance can result in serious injury

or death.

Flammable Vapors

100221773_2000189439_Rev. 01 www. lochinvar .com 5

Page 6

INTRODUCTION

Thank You for purchasing this water heater. Properly

installed and maintained, it should give you years of trouble

free service.

Abbreviations found in this Installation and Operating

manual:

• CSA - Canadian Standards Association

• ANSI - American National Standards Institute

• NFPA - National Fire Protection Association

• ASME - American Society of Mechanical Engineers

• UL - Underwriters Laboratories Inc.

• AHRI - Air Conditioning, Heating and Refrigeration

Institute.

This gas-fired water heater is design certified by CSA

International as a Category IV vented heater, under Water

Heater Standard ANSI Z21.10.3 • CSA 4.3 (current

edition).

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this water heater requires ability

equivalent to that of a Qualified Agency (as defined by

ANSI below) in the field involved. Installation skills such

as plumbing, air supply, venting, gas supply and electrical

supply are required in addition to electrical testing skills

when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualified Agency” - “Any

individual, firm, corporation or company that either in

person or through a representative is engaged in and is

responsible for (a) the installation, testing or replacement

of gas piping or (b) the connection, installation, testing,

repair or servicing of appliances and equipment; that

is experienced in such work; that is familiar with all

precautions required and that has complied with all the

requirements of the authority having jurisdiction.”

If you are not qualified (as defined by ANSI above) and

licensed or certified as required by authority having

jurisdiction to perform a given task, do not attempt to

perform any of the procedures described in this manual.

If you do not understand the instructions given in this

manual do not attempt to perform any procedures outlined

in this manual.

PREPARING FOR THE INSTALLATION

1. Read the “General Safety” section of this manual

first and then entire manual carefully. If you don’t

follow safety rules, the water heater will not operate

properly. It could cause DEATH, SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE. This manual

contains instructions for installation, operation,

and maintenance of the gas-fired water heater. It

also contains warnings throughout the manual that

you must read and be aware of. All warnings and

instructions are essential to proper operation of the

water heater and your safety. Since we cannot put

everything on the first few pages, READ ENTIRE

MANUAL BEFORE ATTEMPTING TO INSTALL OR

OPERATE THE WATER HEATER.

2. The installation must conform with these instructions

and local code authority having jurisdiction. In absence

of local codes, installation must comply with current

editions of the “National Fuel Gas Code”, ANSI

Z223.1/NFPA 54 and “National Electrical Code”,

NFPA 70. All documents are available from:

CSA International,

8501 East Pleasant Valley Road,

Cleveland, Ohio, United States

44131-5575.

NFPA documents are also available from:

National Fire Protection Association,

1 Batterymarch Park,

Quincy, MA 02269.

3. The water heater, when installed, must be electrically

grounded in accordance with the local codes or in

the absence of local codes: current edition of the

“National Electrical Code”, NFPA 70.

4. If after reading this manual you have any questions or

do not understand any portion of the instructions, call

the local gas utility or the manufacturer whose name

appears on the rating plate.

5. Carefully plan the place where you are going to put

the water heater. Correct air supply for combustion

and blower operation, vent action, and vent pipe

installation are very important in preventing death

from possible carbon monoxide poisoning and

fires (see Figure 15 & Figure 16). Examine the

location to ensure the water heater complies with

the “Locating The New Water Heater” section in this

manual.

6. For installation in areas subject to earthquakes, this

water heater must be braced, anchored, or strapped

to avoid falling or moving during an earthquake.

See instructions for correct installation procedures.

Instructions may be obtained from:

California Office of the State Architect,

400 P Street,

Sacramento, CA 95814.

7. Massachusetts Code requires this water heater to be

installed In accordance with Massachusetts 248-CMR

2.00: State Plumbing Code and 248-CMR 5.00.

8. Complies with California Health and Safety code

116875 (known as AB-1953) and with weighted

average maximum of 0.25% lead.

6 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 7

INSTALLATION REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

COMMONWEALTH OF MASSACHUSETTS

For all side wall terminated, horizontally vented power vent, direct vent and power direct vent gas fueled water heaters

installed in every dwelling, building or structure used in whole or in part for residential purposes, including those owned

or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet above

finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall

be satisfied:

INSTALLATION OF CARBON MONOXIDE DETECTORS

At the time of installation of the side wall horizontal vented gas fueled equipment, the installing plumber or gasfitter shall

observe that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the floor level where

the gas equipment is to be installed. In addition, the installing plumber or gasfitter shall observe that a battery operated

or hard wired carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or

structure served by the sidewall horizontal vented gas fueled equipment. It shall be the responsibility of the property owner

to secure the services of qualified licensed professionals for the installation of hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard

wired carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner

shall have a period of thirty (30) days to comply with the above requirements provided that during said thirty (30) day

period, a battery operated carbon monoxide detector with an alarm shall be installed.

APPROVED CARBON MONOXIDE DETECTORS

Each carbon monoxide detector as required in accordance with the above provisions shall comply with NFPA 720 and

be ANSI/ UL 2034 listed and CSA certified.

SIGNAGE

A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height

of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in print size no less than one- half (1/2) inch in size, “GAS VENT DIRECTLY

BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.”

INSPECTION

The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation

unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with

the provisions of 248 CMR 5.08(2)(a) 1 through 4.

EXEMPTIONS

The following equipment is exempt from 248 CMR 5.08(2) (a) 1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current edition of

NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from

the dwelling, building, or structure used in whole or in part for residential purposes.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED

When the manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system

design or venting system components with the equipment, the instructions provided by the manufacturer for installation

of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED

When the manufacturer of Product Approved side wall horizontally vented gas fueled equipment does not provide the

parts for venting the flue gases, but identifies “special venting systems,” the following requirements shall be satisfied by

the manufacturer:

1. The referenced “special venting system” instructions shall be included with the appliance or equipment installation

instructions; and

2. The “special venting systems” shall be Product Approved by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all

venting instructions, all parts lists for venting instructions, and/or all venting design instructions shall remain with the

appliance or equipment at the completion of the installation.

100221773_2000189439_Rev. 01 www. lochinvar .com 7

Page 8

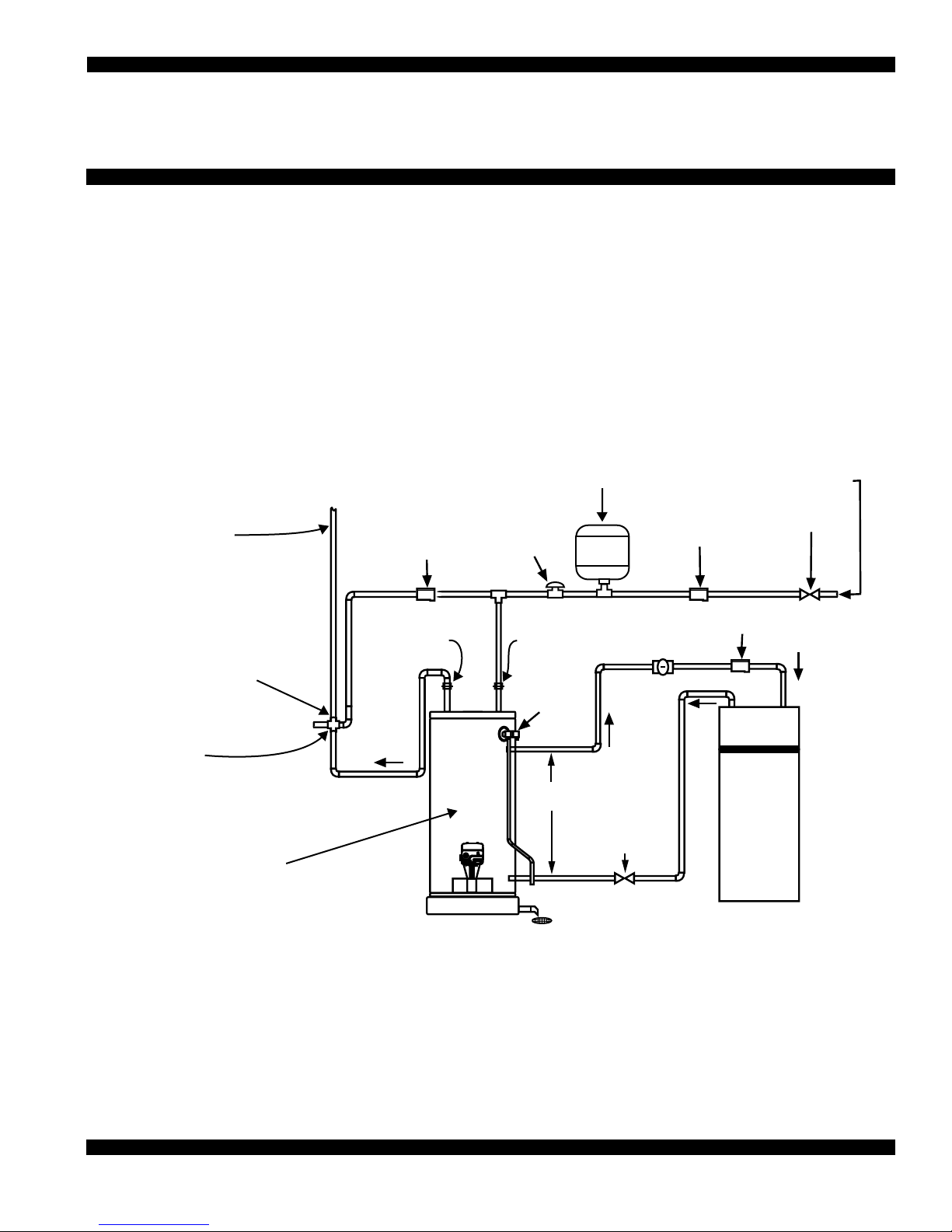

INSTALLATION GRAPHIC: GAS-FIRED POTABLE

WATER HEATING/SPACE HEATING SYSTEM

• If your water heater will be installed in the Commonwealth of Massachusetts, refer to the following

graphic during installation and during modifications to the water supply system.

COMBINATION SPACE HEATING / POTABLE WATER HEATING SYSTEM

TEMPERED WATER

TO FIXTURES

(MUST MEET TEMPS LISTED

IN MASS. CODE 248 CMR

MUST BE VERTICAL TO

REMOVE A

MIXING VALVE

(MUST BE INSTALLED BELOW

TOP OF WATER HEATER

AS PER MANUFACTURER’S

RECOMMENDATIONS)

WATER HEATER ACCEPTED

BY THE BOARD FOR

INSTALLATION IN

MASSACHUSETTS.

MASSACHUSETTS INSTALLATION REQUIREMENTS:

*

1.) CONNECT ELECTRONICALLY-CONTROLLED TIMER TO AN ALL-BRONZE PUMP. PUMP MUST ACTIVATE EVERY 6 HOURS

2.) ALL WATER PIPING MUST BE INSTALLED AND INSULATED IN ACCORDANCE WITH MASSACHUSETTS CODE (248 CMR

3.) PIPING LOOP BETWEEN WATER HEATER AND AIR HANDLER MUST BE INSTALLED IN COMPLIANCE WITH 248 CMR.

† REQUIRED FOR MASSACHUSETTS.

‡ PIPING FROM THE TOP OF THE WATER HEATER WITH TEES IS ACCEPTABLE.

IR BUBBLES

FOR 60 SECONDS. TURN PUMP TIMER OFF BEFORE CLOSING PIPING LOOP SHUT-OFF VALVE.

& 780 CMR).

†

)

†

TYPICAL MIXING VALVE INSTALLATION

EXPANSION TANK

CHECK

VALVE

UNION

HOT

WATER

OUT

VACUUM

†

RELIEF

VALVE

UNION

TEMP/

PRESSURE

RELIEF

VALV E

SEE

NOTE ‡

100’-0” MAXIMUM DISTANCE

FROM WATER HEATER TO FAN

COIL AND BACK. (DEVELOPED

LENGTH) NOT INCLUDING COIL

CHECK VALVE

(1/8” HOLE

DRILLED IN CLAPPER)

PUMP

TO

AIR

HANDLER

SHUT-OFF

VALV E

*

IN HEATING UNIT

COLD WATER INLET

†

FLOW CONTROL

VA

LV

E

*

OUT

COIL

AIR

HANDLER

†

SHUT-OFF

VALVE

IN

8 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 9

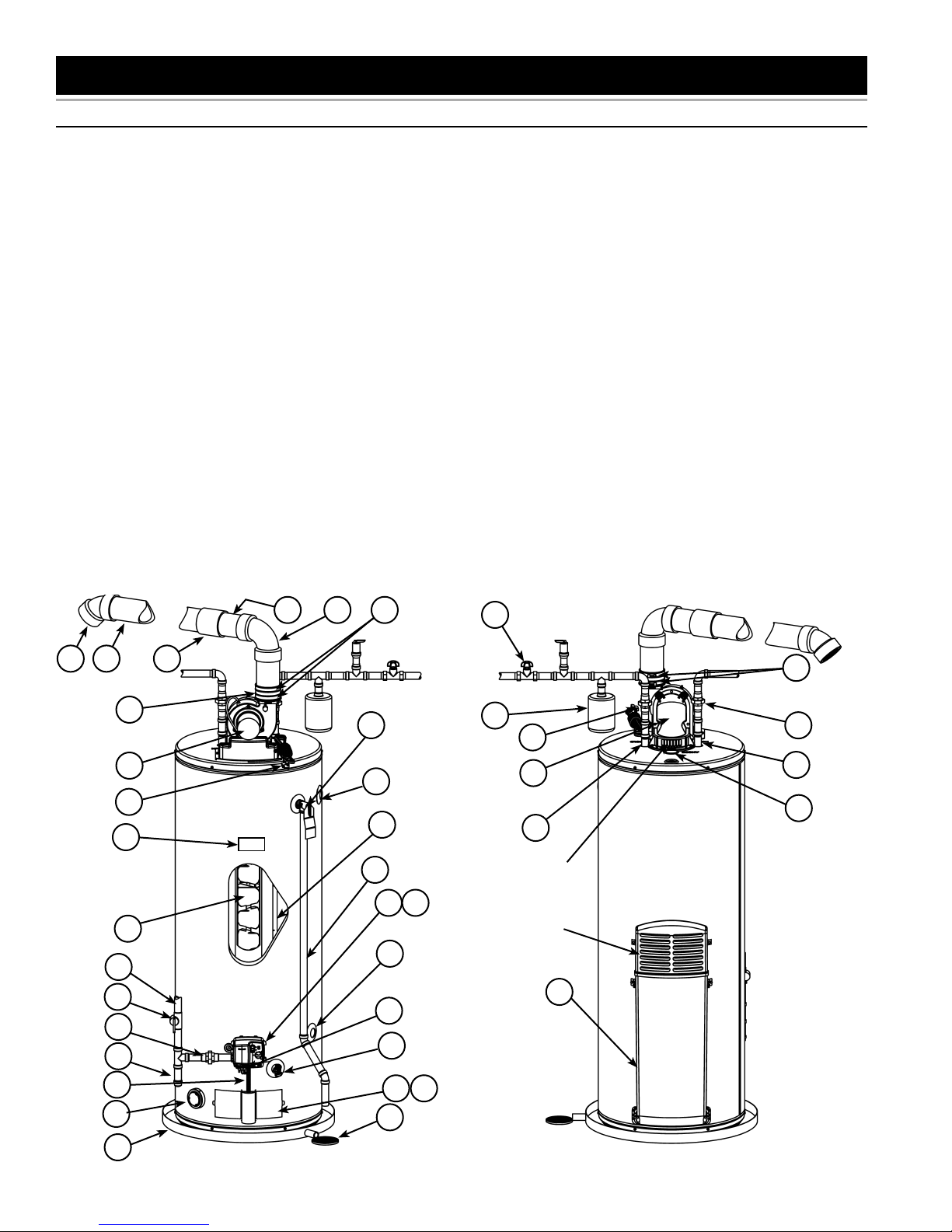

TYPICAL INSTALLATION

GET TO KNOW YOUR WATER HEATER - GAS MODELS (LIST REFERENCING FIGURES 1-7)

1 Vent Termination Elbow with Rodent

Screen

2 *Vent Pipe

3 *Vent Pipe Coupling (if required)

4 CPVC Vent Pipe ( 5 ft. supplied)

5 *CPVC Vent Pipe Elbow (long

radius)

6 Gear Clamp (see Figure 6)

7 T&P Valve

8 **Combo Heating System Supply

Outlet (Optional)

9 Cold-Water Inlet Nipple/Diptube

10 * Discharge Pipe

11 Gas Control Valve/Thermostat

(Honeywell)

12 Gas Valve Electronic Control Module

And Cover (Honeywell)

13 **Combo Heating System Return

Inlet (Optional)

14 ***Control Harness

15 Drain Valve

16 Outer Gas Door

17 Manifold Door Assembly

(behind outer door) (see

Figure 3 (NG) or Figure 4 (LP))

18 *Floor Drain

19 *Metal Drain Pan

20 Flammable Vapor Sensor (under

cover) (see Figure 5)

21 Flexible Manifold Tube (see

Figure 3)

22 *Sediment Trap

23 *Ground Joint Union (gas

connection)

24 *Main Manual Gas Shut-off Valve

25 *Gas Supply*

26 Baffle Assembly

27 Rating Plate

28 Blower with Power Cord (see

Figure 6)

29 *Rubber Coupling (see Figure 6)

30 *Inlet Water Shut-off Valve

31 *Union (water connection)

32 Hot-Water Outlet Nipple

33 Anode (under cap)

34 Air Inlet Snorkel

35 Flue Collector

36 *Thermal Expansion Tank (required

for all closed systems)

37 Aluminum Burner (see Figure 3)

38 Gas Orifice (see Figure 3)

39 Gas Manifold (see Figure 3)

40 Hot-Surface Igniter (see Figure 3)

41 Manifold Door Gasket (see

Figure 3)

42 Manifold Door (see Figure 3)

43 Two Piece Grommet With Clip (see

Figure 3)

44 Viewport (see Figure 3)

45 Flame Sensor Rod (see Figure 3)

46 Stainless Steel Burner (see

Figure 4)

47 Air Switch (inside box) (see

Figure 6)

48 Air Tubing (see Figure 6)

49 Blower High Limit Switch (see

Figure 6)

50 Junction Box Cover (see Figure 6)

51 Junction Box (see Figure 6)

*, **, ***, **** see notes on following

page

1 2

27

25

24

23

22

29

28

28

26

6

4

3

5

30

6

7

8

36

31

35

31

32

33

10

9

11

12

9

Blower

Dilution Air

Inlets

Combustion

Air Inlets

13

34

14

15

21

20

19

100221773_2000189439_Rev. 01 www. lochinvar .com 9

Front View

Figure 1.

16

18

17

Rear View

Figure 2.

Page 10

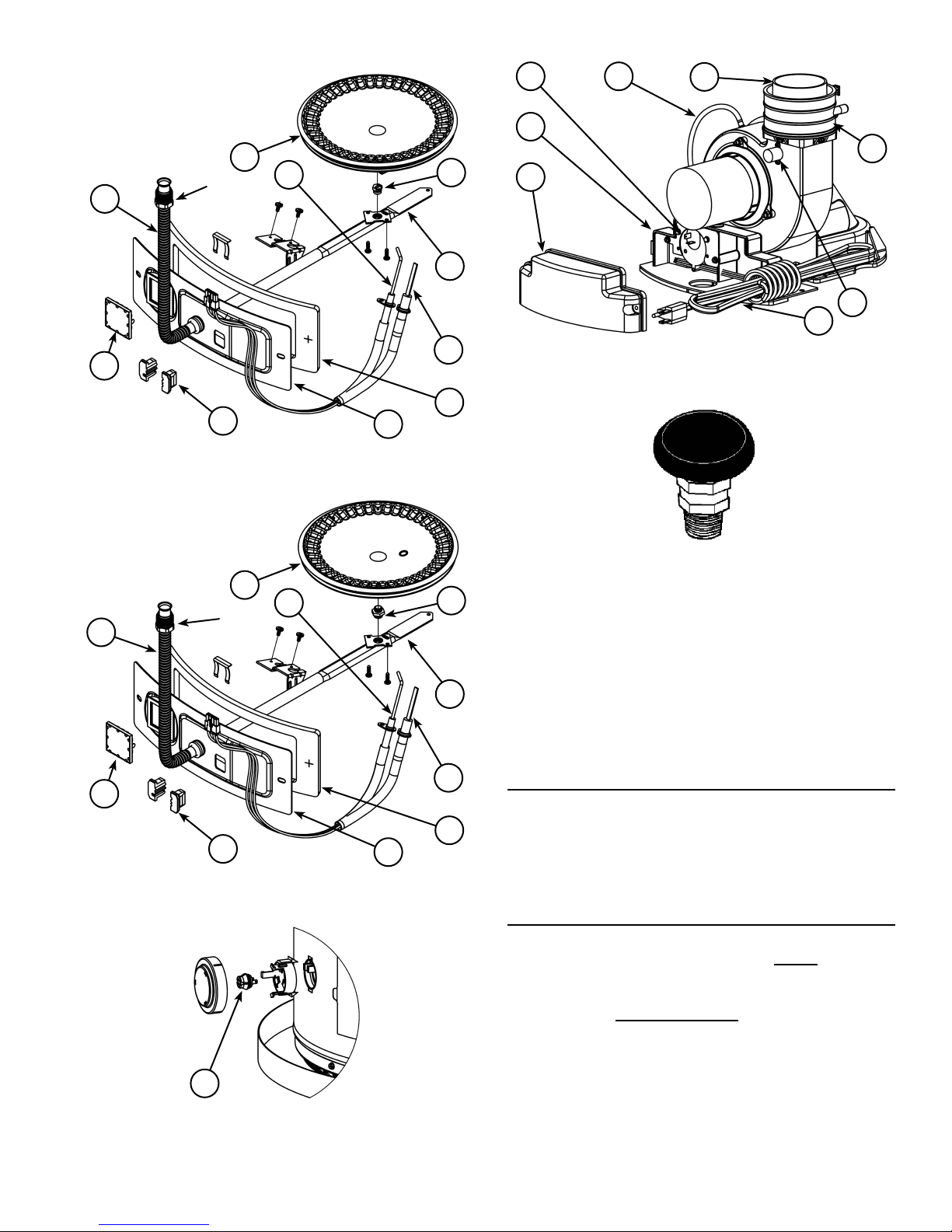

Natural gas main burner

with igniter assembly

(item 17 in Figure 1).

37

Flare

21

Nut

45

38

39

51

50

4847

29

6

49

28

44

43

Figure 3.

Propane (LP) main burner

with igniter assembly

(item 17 in Figure 1).

46

Flare

21

Nut

44

43

Figure 4.

45

42

42

40

41

38

39

40

41

Figure 6.

Vacuum relief valve

install per local

codes (not supplied

with heater).

Figure 7.

Notes:

* Items not supplied with the water heater.

** The side recirculation loop connections may not be

used as the primary water inlet and outlet connections.

See “Combo Heating Inlet And Outlet Side Taps”.

*** Caution: harness has 120 VAC In operation.

**** See “Planning The Vent System”, “Condensate” and

“Blower Assembly Installation” for more information.

REPLACEMENT PARTS AND DELIMING PRODUCTS

Replacement parts and recommended delimer may be

ordered through authorized servicers or distributors. When

ordering parts, provide complete model and serial numbers

(see rating plate), quantity and name of part desired.

Standard hardware items may be purchased locally.

20

Figure 5.

10 www. lochinvar .com 100221773_2000189439_Rev. 01

COMBO HEATING INLET AND OUTLET SIDE TAPS

Models equipped with Combo Heating capabilities are

shipped with the two side plumbing taps OPEN (item 8 and

item 13 in Figure 1 and see also Figure 8 & Figure 28). If

the heater is to be operated without using the side taps

these openings must be plugged with the two pipe plugs

supplied with the heaters.

Page 11

WATER PIPING - MIXING VALVE USAGE

Mixing Valves

Water temperature over

DANGER

125°F can cause severe

burns instantly resulting in

severe injury or death.

Children, the elderly and the

disabled and are at highest

risk of scald injury.

Feel water before bathing or

showering.

HOT

HOT

Temperature limiting devices

such as mixing valves must

be installed when required

BURN

by codes and to ensure safe

temperatures at fixtures.

Water heated to a temperature which satisfies space

heating, clothes washing, dish washing, and other

sanitizing needs can scald and cause permanent injury

upon contact. Short repeated heating cycles caused by

small hot-water uses can cause a temperature increase of

the hot water by 20F° higher than the heater’s temperature

settings.

SUGGESTED PIPING

ARRANGEMENT FOR

SIDE CONNECTIONS

COLD-WATER

INLET

TEMPERATURE-

PRESSURE

RELIEF VALVE

DISCHARGE

PIPE (DO NOT

CAP OR PLUG)

SHUT-OFF

VALV E

TEMPERED

POTABLE WATER

MIXING VALVE

CERTAIN

MODELS ARE

EQUIPPED WITH

SIDE PLUMBING

CONNECTIONS

FOR SPACE

HEATING.

* NOTE: THE

T&P VALVE

DISCHARGE

PIPE SHALL

BE PIPED

DIRECTLY TO

THE DRAIN

OR EXTERNAL

TO THE

BUILDING

METAL DRAIN

PAN 1.75 in.

MAX. DEPTH.

AT LEAST 2 in.

GREATER THAN

THE DIAMETER

OF THE WATER

HEATER.

This appliance has been design certified as complying

with American National Standard/CSA Standard for water

heaters and certain models with side plumbing connections

are considered suitable for Water (Potable) Heating and

Space Heating.

Note: Do not use in space heating only applications.

The water supply pressure should not exceed 80 psi. If this

occurs, a pressure reducing valve with a bypass should be

installed in the cold water inlet line. This should be placed

on the supply to the entire house in order to maintain equal

hot and cold water pressures.

SUGGESTED PIPING

ARRANGEMENT FOR

TOP CONNECTIONS

COLD-WATER

INLET

NON-TEMPERED

WATER RETURN

TEMPERATUREPRESSURE

RELIEF VALVE

* NOTE: THE

T&P VALVE

DISCHARGE

PIPE SHALL

BE PIPED

DIRECTLY TO

THE DRAIN

OR EXTERNAL

TO THE

BUILDING

DISCHARGE

PIPE (DO NOT

CAP OR PLUG)

DRAIN

VALV E

SHUT-OFF

VALV E

TEMPERED

POTABLE WATER

NON-TEMPERED

WATER SUPPLY

MIXING VALVE

MASSACHUSETTS:

INSTALL A VACUUM

RELIEF IN COLD

WATER LINE PER

SECTION 19 MGL

142.

METAL DRAIN

PAN 1.75 in.

MAX. DEPTH.

AT LEAST 2 in.

GREATER THAN

THE DIAMETER

OF THE WATER

HEATER.

6 in. MAX.

AIR GAP*

Figure 9.

TEMPERED

POTABLE

WATER

SHUT-OFF

VALV E

COLD-

WATER

SUPPLY

DRAIN

VALV E

MASSACHUSETTS: INSTALL A VACUUM RELIEF IN COLD WATER LINE

PER SECTION 19 MGL 142.

Figure 8.

100221773_2000189439_Rev. 01 www. lochinvar .com 11

6 in. MAX.

AIR GAP*

NON-

TEMPERED

WATER

SUPPLY

TO HOT

OUTLET

MIXING

VALV E

Figure 10.

NON-

TEMPERED

WATER

RETURN

TO COLD

INLET

Page 12

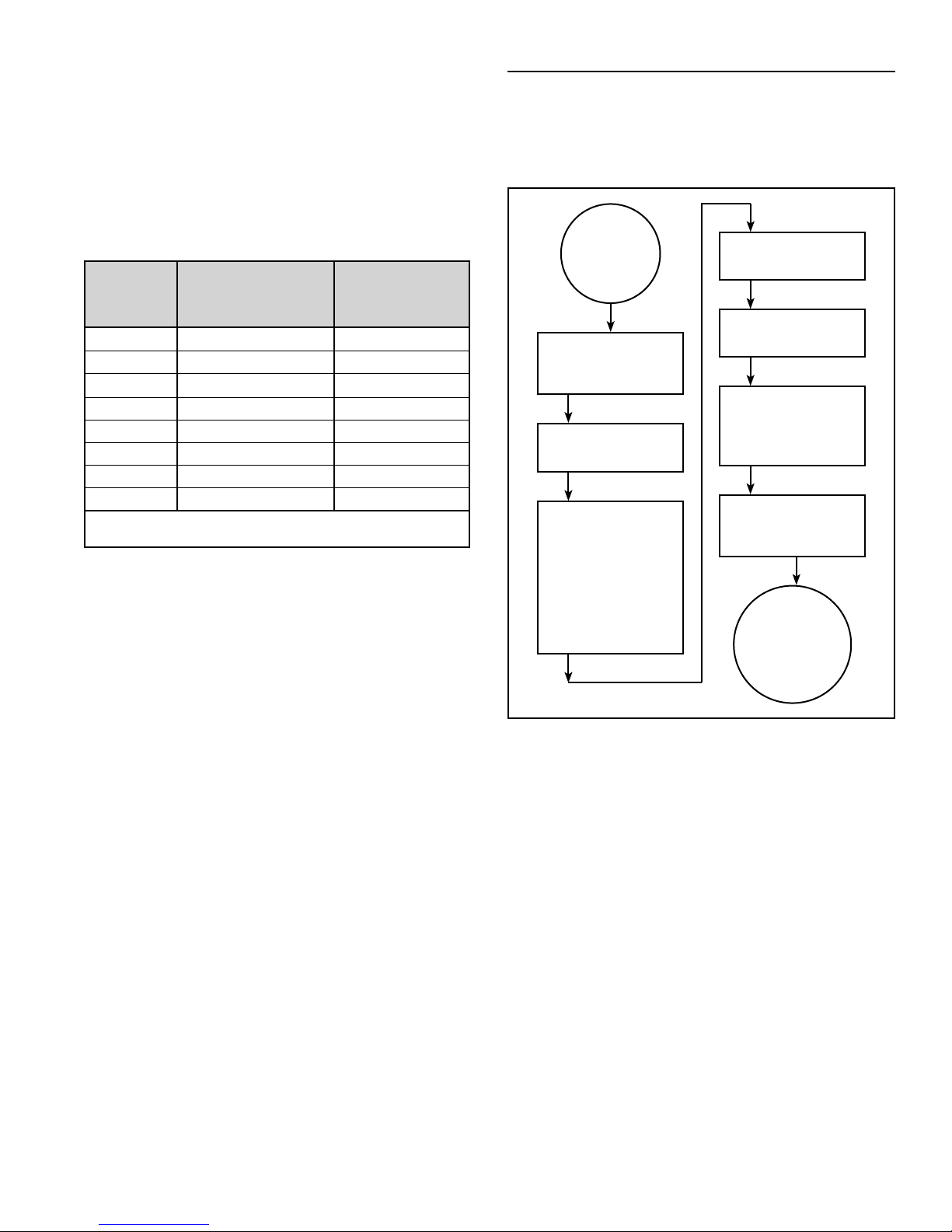

Some people are more likely to be permanently injured

by hot water than others. These include the elderly,

children, the infirm and the physically/mentally disabled.

Table 1 (published by U.S. Government Memorandum,

1978) shows the approximate time-to-burn relationship

for normal adult skin. If anyone using hot water provided

by the water heater being installed fits into one of these

groups or if there is a local code or state law requiring a

certain water temperature at the point of use, then special

precautions must be taken.

Water

Temperature

°F

Time for 1st

Degree Burns

(Less Severe Burns)

110 (normal shower temp.)

116 (pain threshold)

116 35 minutes 45 minutes

122 1 minute 5 minutes

131 5 seconds 25 seconds

140 2 seconds 5 seconds

149 1 second 2 seconds

154 instantaneous 1 seconds

(U.S. Government Memorandum, C.P.S.C., Peter L. Armstrong,

Sept. 15,1978)

Time for Permanent

Burns 2nd & 3rd

Degree (Most

Severe Burns)

Table 1.

In addition to using lowest possible temperature setting

that satisfies demand of application, a mixing valve should

be installed at water heater (see Figure 8 & Figure 9) or at

hot-water taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores.

Consult a Qualified Installer or Service Agency. Follow

mixing valve manufacturer’s instructions for installation

of the valves. Before changing the factory setting on the

thermostat, read the “Operating The Temperature Control

System” section in this manual.

WATER HEATER OPERATION

Figure 11 shows the water heater’s sequence of operation

when a call for heat is initiated. The ignition control module

will attempt to light the burner three times. If the ignition

control does not detect ignition it will enter lockout mode

and flash the corresponding error code.

HEATER

THERMOSTAT

CALLS FOR HEAT

HEATER CONTROL

CHECKS TO ENSURE

BLOWER PRESSURE

SWITCH IS OPEN

BLOWER IS ENERGIZED

CONTROL CHECKS TO

ENSURE PRESSURE

SWITCH CLOSES

INDICATING BLOWER

IS OPERATING AND

THERE ARE NO VENTING

BLOCKAGES (INLET OR

OUTLET)

IGNITER IS ENERGIZED

AND MAIN GAS VALVE IS

OPENED

MAIN BURNER COMES

ON AND THE FLAME IS

SENSED BY CONTROL

MAIN BURNER

CONTINUES UNTIL THE

WATER IN THE TANK

REACHES THERMOSTAT

SETTING

MAIN BURNER

SHUTS OFF. BLOWER

CONTINUES FOR A POST

PURGE TIME

HEATER REMAINS

ON STANDBY UNTIL

NEXT CALL FOR

HEAT

Figure 11.

12 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 13

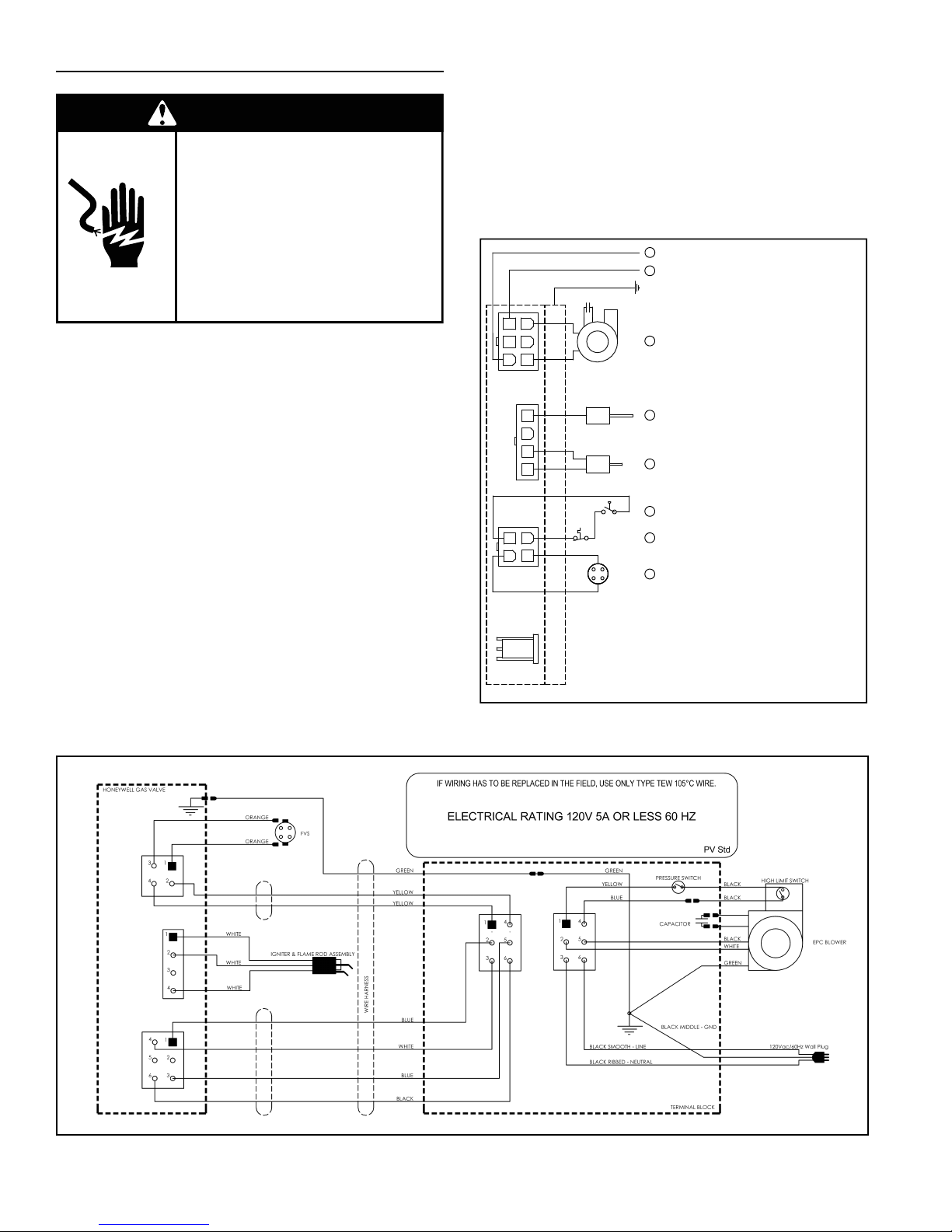

ELECTRICAL REQUIREMENTS & WIRING DIAGRAM

WARNING

Electric Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electrical shock.

Before plugging in the water heater, always make sure:

• The voltage and frequency correspond to that specified

on the water heater wiring diagram.

• The electrical outlet has the proper overload fuse or

breaker protection.

1. The unit must be connected to a 120VAC power

supply. A dedicated circuit is preferred.

2. The water heater must be properly grounded.

3. This water heater is a polarity sensitive appliance and

will not operate properly if the power supply polarity

is reversed.

4. Do not use a GFI outlet.

Note: Always reference the wiring diagram for the correct

electrical connections.

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS. WIRING ERRORS CAN

CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

POWER VENT WIRING SCHEMATIC.

NOTE: REFER TO THE “Installation Checklist”

BEFORE OPERATING THIS HEATER.

N

1

L1

1

EARTH GND

CAPACITOR

3

6

BLOWER

2

5

P1

4

1

4

3

P2

2

1

2

4

P3

1

3

4

7

FLAME SENSOR

6

HOT SURFACE IGNITER

5

PRESSURE SWITCH

HIGH LIMIT SWITCH

3

2

FLAMMABLE VAPOUR SENSOR

After making all electrical connections, completely fill the

tank with water and check all connections for leaks. Open

the nearest hot-water faucet and let it run for 3 minutes to

purge the water lines of air and sediment and to ensure

complete filling of the tank. The electrical power may then

be turned on. Verify proper operation after servicing. See

also “Installation Checklist”.

P4

Circled numbers indicate

sequence of operation.

Figure 13.

Figure 12.

100221773_2000189439_Rev. 01 www. lochinvar .com 13

Page 14

SAFETY LOCKOUTS

This water heater has several lockout features designed

to prevent the heater from operating in unsafe conditions.

HIGH LIMIT CONTROLS (ENERGY CUT OFF)

Thermostat/Water Temperature

This feature is a part of the gas control valve/thermostat

(see Figure 1, item 11) and limits the maximum water

temperature. In the event of the water overheating, this

safety feature shuts off the fuel supply to the burner. This

ECO is not resettable and the gas control valve/thermostat

will need to be replaced by a qualified service technician.

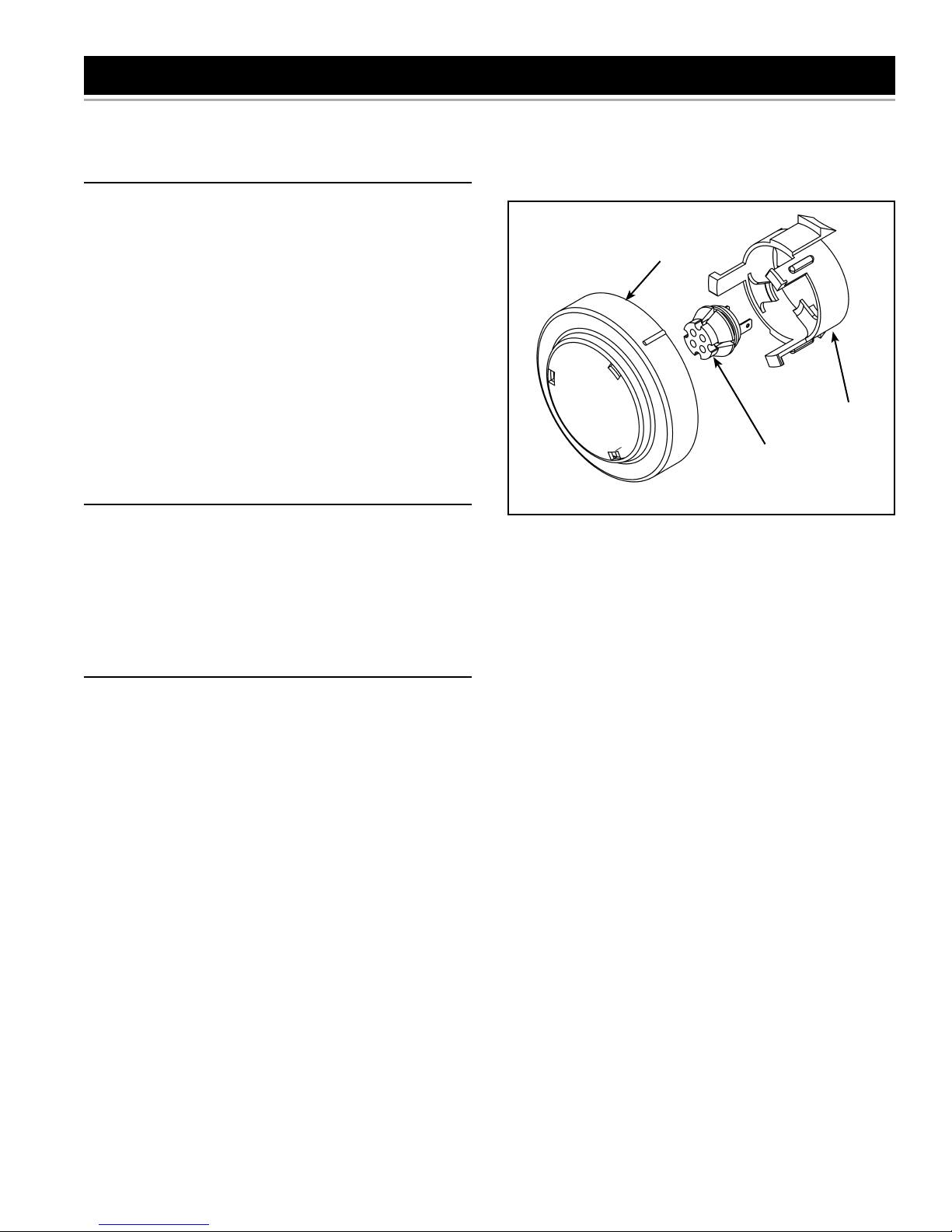

Blower High Limit Switch

This device is located on the blower (see Figure 6, item

49) and limits the maximum temperature of the blower.

If the blower temperature rises above the temperature

setting, the switch opens causing the heater to shut down.

The switch will auto reset once the temperature drops

sufficiently.

BLOWER AIR PRESSURE SWITCH

This device, located in the junction box, monitors the air

pressure produced by the blower. In the event that the

exhaust venting becomes blocked or sufficiently restricted,

the switch will shut the heater down (see Figure 6, item

47). If the water heater has not gone into a soft lockout

condition, the heater will restart after the blockage is

removed (see “Resetting The Heater Control”).

If there is a problem with the wiring of the flammable

vapor sensor or the flammable vapor interface, the LED

will flash the failure status code (see “System Status And

Error Codes”).

* ROTATE LEFT (CCW)

TO REMOVE

COVER*

MOUNTING

BRACKET

FLAMMABLE

VAPOR SENSOR

(PULL TO REMOVE)

Figure 14.

FLAMMABLE VAPOR SENSOR

When using a gas fired water heater there is a risk of

flammable vapors entering the combustion chamber, being

ignited by the burner flame and causing a flashback. In

order to detect such flammable vapors before they enter

the combustion chamber, this water heater is equipped

with a flammable vapor sensor (FVS). It is a chemicalabsorption based sensor that is connected to the gas

control/thermostat (see Figure 14). When exposed to

flammable vapors it will trigger the control to stop the

flow of gas and enter the FVS lockout state. While in the

FVS lockout state the LED on the control will flash the

gas lockout code. (Refer to the “System Status And Error

Codes” section of this manual for an explanation of the

codes applicable to the control installed on your water

heater.) If this error occurs, check around the water heater

for sources of chemical contamination such as: flammable

vapors including gas vapors, solvents, paint and thinners

as well as sources of water and detergents.

Note: Resetting the heater will reset the FVIR circuit if

all sources of contamination have been removed and the

sensor clears. If all sources of contamination have been

removed and the system will not reset, the sensor will

need to be replaced (see “Resetting The Heater Control”).

14 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 15

LOCATING THE NEW WATER HEATER

FACTS TO CONSIDER ABOUT THE LOCATION

Carefully choose an indoor location for the new water

heater because the placement is a very important

consideration for the safety of the occupants in the building

and for the most economical use of the appliance. This

water heater is not for use in manufactured (mobile) homes

or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must

be observed:

1. Select a location indoors as close as practical to

the vent termination or location to which the water

heater vent piping is going to be connected, and as

centralized with the water piping system as possible.

2. Selected location must provide adequate clearances

for servicing and proper operation of the water heater.

3. Ensure the area has a continuous supply of air for

combustion, blower dilution and ventilation.

4. Avoid locations that could cause the water heater to

freeze from outside air.

5. Selected location must provide access to a properly

grounded electrical branch circuit. A dedicated circuit

is preferred. Do not use a GFI outlet.

6. Avoid locations that expose the water heater to direct

sunlight.

7. Keep combustibles such as boxes, magazines,

clothes, etc., away from the water heater area.

Important: Do not use an extension cord to connect the

water heater to an electrical outlet.

Important: this heater has special venting requirements

when installed in areas where the ambient temperatures

exceed 110°F (see “Polypropylene Vent Systems”).

CAUTION

Property Damage Hazard

• All water heaters eventually leak.

• Do not install without adequate drainage.

Installation of the water heater must be accomplished in

such a manner that if the tank or any connections should

leak, the flow of water will not cause damage to the

structure. For this reason it is not advisable to install the

water heater in an attic or upper floor. In all cases, a metal

drain pan should be installed under the water heater. Metal

drain pans are available at your local hardware store. Such

a metal drain pan must have a clearance of at least 1 in.

greater than any point on the water heater’s outer jacket

and must be piped to an adequate drain. The pan must

have a maximum depth of 1.75 in. .

Water heater life depends upon water quality, water

pressure and the environment in which the water heater

is installed. Water heaters are sometimes installed in

locations where leakage may result in property damage,

even with the use of a metal drain pan piped to a drain.

However, unanticipated damage can be reduced or

prevented by a leak detector or water shut-off device used

in conjunction with a piped metal drain pan. These devices

are available from some plumbing supply wholesalers and

retailers, and detect and react to leakage in various ways:

• Sensors mounted in the metal drain pan that trigger an

alarm or turn off the incoming water to the water heater

when leakage is detected.

• Sensors mounted in the metal drain pan that turn off

the water supply to the entire building when water is

detected in the metal drain pan.

• Water supply shut-off devices that activate based on

the water pressure differential between the cold-water

and hot-water pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water

heater while at the same time shutting off its water

supply.

STORAGE OF FLAMMABLE LIQUIDS

Flammable liquids (such as gasoline, solvents, propane

(LP or butane, etc.) and other substances (such as

adhesives, paints, etc.) emit flammable vapors which can

be ignited by a gas water heater’s hot surface igniter (HSI)

or main burner. The resulting flashback and fire can cause

death or serious burns to anyone in the area.

This water heater is equipped with a FV (Flammable Vapor)

sensor for detecting the presence of flammable vapors.

When the sensor detects those vapors, the unit will shut

down and not operate. Should this happen, please refer

to the “Troubleshooting Guidelines” section of this manual.

Even though this water heater is a flammable vapors

ignition resistant (FVIR) water heater and is designed to

reduce the chances of flammable vapors being ignited,

gasoline and other flammable substances should never

be stored or used in the same vicinity or area containing a

gas water heater or other open flame or spark producing

appliance. Examples of such locations are garages,

storage and utility areas.

The water heater must be located and/or protected so it

is not subject to physical damage by a moving vehicle.

100221773_2000189439_Rev. 01 www. lochinvar .com 15

Page 16

WARNING

Fire or Explosion Hazard

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

• Avoid all ignition sources if you smell gas.

• Do not expose water heater control to excessive gas

pressure.

• Use only gas shown on rating plate.

• Maintain required clearances to combustibles.

• Keep ignition sources away from faucets after extended

period of non-use.

Read instruction manual before

installing, using or servicing

water heater.

Clearance for servicing

Adequate clearance of 24 in. for servicing this appliance

should be considered before installation, such as changing

the anodes, etc.

A minimum clearance of 5.5 in. must be allowed for access

to replaceable parts such as thermostats, drain valve and

relief valve.

When installing the heater, consideration must be given to

proper location. Location selected should be as close to

the wall as practicable and as centralized with the water

piping system as possible.

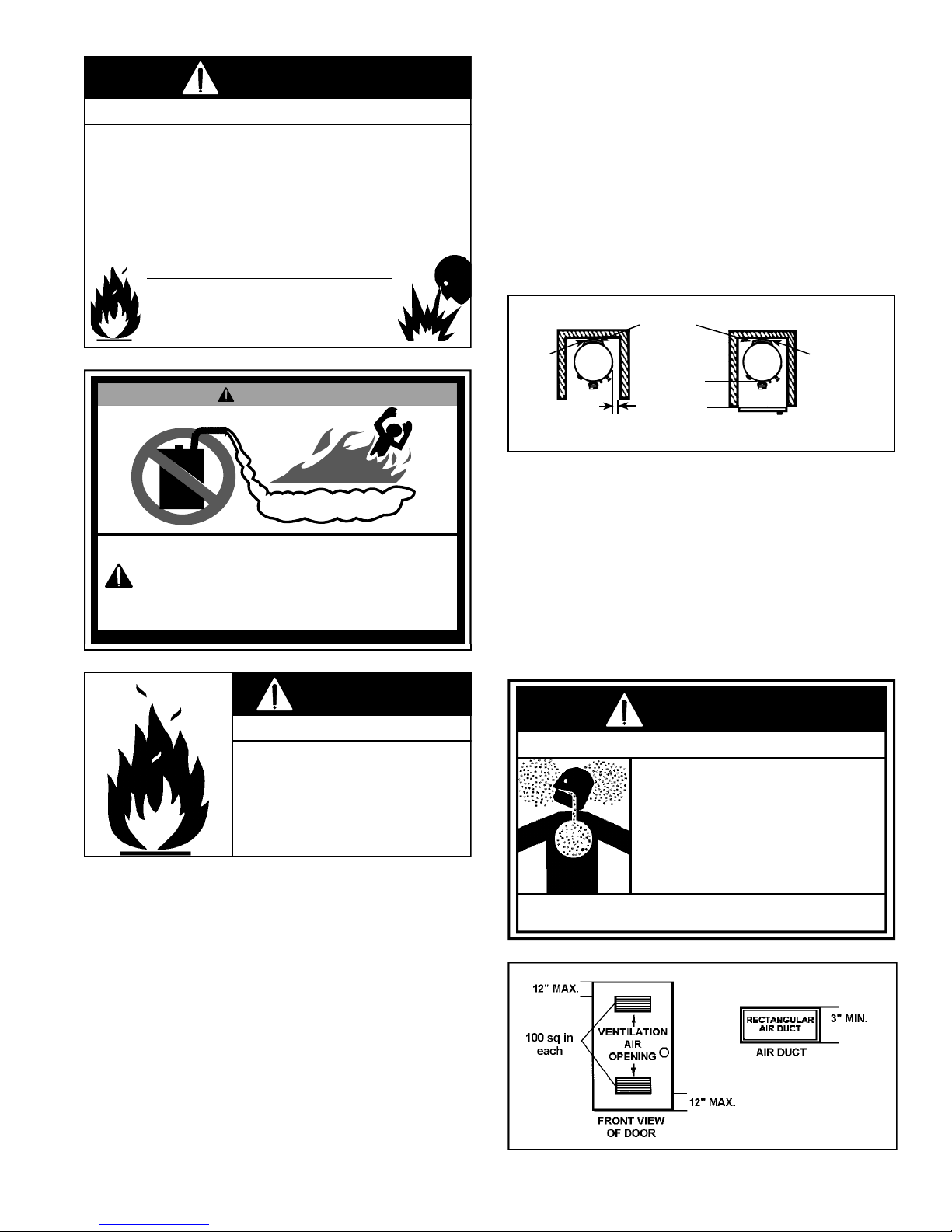

TOP VIEW

OF CLOSET

WITHOUT DOOR

0” MIN. 0” MIN.

AIR INTAKE*

TOP VIEW OF

CLOSET WITH

DOOR

WARNING

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Storage or

use of gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance can result in serious injury

or death.

Flammable Vapors

WARNING

Fire Hazard

For continued protection against

risk of fire:

• Do not install water heater on

carpeted floor.

• Do not operate water heater if

flood damaged.

Clearances to combustibles

Minimum clearances between water heater and

combustibles are 0 in. at the sides and rear, 5.5 in. from the

front and 12 in. from top (standard clearance.) If clearances

stated on the heater differ from standard clearances, install

water heater according to clearances stated on the heater

(see Figure 15).

0” MIN.

* DO NOT BLOCK OR RESTRICT IN ANY MANNER,

THE AIR INTAKES AT THE BACK OF THE WATER HEATER.

5.5” MIN.

Figure 15.

A gas water heater cannot operate properly without the

correct amount of air for combustion and ventilation. Do

not install in a confined area such as a closet unless you

provide air as shown below and described in the ”Air

Requirements” section (see Figure 16). Never obstruct the

flow of ventilation air for dilution and combustion. If you

have any doubts or questions at all, call your gas supplier.

Failure to provide the proper amount of combustion air

can result in a fire or explosion and cause death, serious

bodily injury, or property damage.

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Install water heater in accordance with the

instruction manual and NFPA 54.

• To avoid injury, combustion and ventilation air

must be taken from outdoors.

• Do not place chemical vapor emitting products

near water heater.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

Floors with carpeting

This water heater must not be installed directly on

carpeting. Carpeting must be protected by a metal or

wood panel beneath the appliance extending beyond the

full width and depth of the appliance by at least 3 in. in

every direction, or if the appliance is installed in an alcove

or closet, the entire floor must be covered by the panel.

Failure to heed this warning may result in a fire hazard.

16 www. lochinvar .com 100221773_2000189439_Rev. 01

Figure 16.

Page 17

If this water heater will be used in beauty shops, barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the water

heater or water heaters be installed so that combustion

and ventilation air be taken from outside these areas.

Propellants of aerosol sprays and volatile compounds,

(cleaners, chlorine based chemicals, refrigerants, etc.) in

addition to being highly flammable in many cases, will also

react to form corrosive hydrochloric acid when exposed to

the combustion products of the water heater. The results

can be hazardous, and also cause product failure.

INSULATION JACKETS AND BLANKETS

Insulation blankets are available to the general public for

external use on gas water heaters but are not necessary

with these products. The purpose of an insulation blanket is

to reduce standby heat loss encountered with storage tank

heaters. Your water heater meets or exceeds the current

standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Should you choose to apply an insulation blanket to

this heater, you should follow these instructions (For

identification of components mentioned below, see Figure 1

through Figure 7). Failure to follow these instructions will

restrict the air flow required for proper combustion and

dilution, potentially resulting in fire, asphyxiation, serious

personal injury or death.

AIR REQUIREMENTS

For safe operation an adequate supply of fresh,

uncontaminated air for combustion, dilution and ventilation

must be provided.

Note: Contaminated or dusty air may cause build-up on

the blower wheel resulting in nuisance shut downs.

An insufficient supply of air can cause recirculation of

combustion products resulting in contamination that may

be hazardous to life. Such a condition often will result in

a yellow, luminous burner flame, causing sooting of the

combustion chamber, burners and flue tubes and creates

a risk of asphyxiation.

Do not install the water heater in a confined space unless

an adequate supply of air for combustion, dilution and

ventilation is brought into that space using the methods

described in the “Confined Space” section that follows.

Never obstruct the flow of dilution/ventilation air. If you

have any doubts or questions at all, call your gas supplier.

Failure to provide the proper amounts of air can result in

a fire or explosion and cause property damage, serious

bodily injury or death. The combustion and dilution air

inlets are shown in Figure 2.

Important: Power Vented water heaters require air for

combustion and dilution air for the blower.

• Do not apply insulation to the top of the water heater,

as this will interfere with safe operation of the blower

assembly.

• Do not cover the outer door, thermostat or T&P relief

valve, FV sensor, or Air Intake Snorkel.

• Do not cover the “Installation And Operating manual”.

Keep it on the side of the water heater or nearby for

future reference.

• Do obtain new warning and instruction labels from the

manufacturer for placement on the blanket directly over

the existing labels.

• Do inspect the insulation blanket frequently to make

certain it does not sag, thereby obstructing combustion

air flow.

WARNING

Breathing Hazard - Carbon Monoxide Gas

• Do not obstruct water heater air intake(s) with

insulating jacket or blanket.

• Gas and carbcn monoxide detectors are available.

• Install water heater in accordance with the

instruction manual and NFPA54.

Air supply must be provided as required by the current

edition of “National Fuel Gas Code”, ANSI Z223.1/

NFPA 54.

UNCONFINED SPACE

An Unconfined Space is one whose volume is not less than

50 cubic feet per 1,000 Btu/hr of the total input rating of all

appliances installed in the space. Rooms communicating

directly with the space in which the appliances are

installed, through openings not furnished with doors, are

considered a part of the unconfined space.

Makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and fireplaces

should also be considered in determining the adequacy of

a space to provide combustion, ventilation and dilution air.

UNUSUALLY TIGHT CONSTRUCTION

In unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion, ventilation and

dilution of flue gases. However, in buildings of unusually

tight construction (e.g., weather stripping, heavily

insulated, caulked, vapor barrier, etc.) additional air must

be provided using the methods described in the ”Confined

Space” section that follows.

Breathing carbon monoxide can cause brain damage or death.

Always read and understand instruction manual.

100221773_2000189439_Rev. 01 www. lochinvar .com 17

Page 18

CONFINED SPACE

A Confined Space is one whose volume is less than 50

cubic feet per 1,000 Btu/hr of the total input rating of all

appliances installed in the space.

Openings must be installed to provide fresh air for

combustion, ventilation and dilution in confined spaces.

The required size for the openings is dependent on the

method used to provide fresh air to the confined space

and the total Btu/hr input rating of all appliances installed

in the space.

DIRECT VENT APPLIANCES

Other appliances installed in a Direct Vent configuration

that derive all air for combustion from the outdoor

atmosphere through sealed intake air piping are not

factored in the total appliance input Btu/hr calculations

used to determine the size of openings providing fresh

air into confined spaces.

EXHAUST FANS

Where exhaust fans are installed, additional air should be

provided to replace the exhausted air. When an exhaust

fan is installed in the same space with a water heater,

sufficient openings to provide fresh air must be provided

that accommodate the requirements for all appliances

in the room and the exhaust fan. Undersized openings

will cause air to be drawn into the room through the

water heater’s vent system causing poor combustion.

Sooting, serious damage to the water heater and the risk

of fire or explosion may result. It can also create a risk of

asphyxiation.

FRESH AIR OPENINGS FOR CONFINED SPACES

The following instructions should be used to calculate the

size, number and placement of openings providing fresh air

for combustion, ventilation and dilution in confined spaces.

The illustrations shown in this section of the manual are

a reference for the openings that provide fresh air into

confined spaces only. Do not refer to these illustrations

for the purpose of vent installation. See “Installation Of

Vent System” section for complete venting installation

instructions.

Each opening shall have a minimum free area of

one square inch per 1,000 Btu/hr of the total input

rating of all gas utilization equipment in the confined

space, but not less than 100 square inches. One

opening shall commence within 12 in. of the top and

one commencing within 12 in. of the bottom of the

enclosures.

Figure 17.

B. ALL AIR FROM OUTDOORS: (See Figure 18 through

Figure 20)

The confined space shall be provided with two

permanent openings, one commencing within 12 in.

of the top and one commencing within 12 in. from

the bottom of the enclosure. The openings shall

communicate directly, or by ducts, with the outdoors

or spaces (crawl or attic) that freely communicate with

the outdoors.

1. When directly communicating with the outdoors,

each opening shall have a minimum free area of

1 square inch per 4,000 Btu/hr of total input rating

of all equipment in the enclosure (see Figure 18).

Chemical vapor corrosion of the flue, blower assembly and

vent system may occur if the air supply contains certain

chemical vapors. Spray can propellants, cleaning solvents,

refrigerator and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride (water softener

salt), waxes, bleach and process chemicals are typical

compounds which are potentially corrosive.

A. ALL AIR FROM INSIDE BUILDINGS: (See Figure 17)

The confined space shall be provided with two

permanent openings communicating directly with an

additional room(s) of sufficient volume so that the

combined volume of all spaces meets the criteria

for an unconfined space. The total input of all gas

utilization equipment installed in the combined space

shall be considered in making this determination.

18 www. lochinvar .com 100221773_2000189439_Rev. 01

Figure 18.

2. When communicating with the outdoors through

vertical ducts, each opening shall have a minimum

free area of 1 square inch per 4,000 Btu/hr of total

input rating of all equipment in the enclosure (see

Figure 19).

Page 19

3. When communicating with the outdoors through

horizontal ducts, each opening shall have a

minimum free area of 1 square inch per 2,000

Btu/hr of total input rating of all equipment in the

enclosure (see Figure 20).

Figure 19.

4. When ducts are used, they shall be of the same

cross-sectional area as the free area of the

openings to which they connect. The minimum

short side dimension of rectangular air ducts shall

not be less than 3 in. (see Figure 20).

Figure 20.

5. Alternatively a single permanent opening may

be used when communicating directly with the

outdoors, or with spaces that freely communicate

with the outdoors. The opening shall have a

minimum free area of 1 square inch per 3,000 Btu/

hr of total input rating of all equipment in enclosure

(see Figure 21).

Figure 21.

6. Louvers and Grilles: In calculating free area,

consideration shall be given to the blocking effect

of louvers, grilles or screens protecting openings.

Screens used shall not be smaller than 1/4 in.

mesh. If the free area through a design of louver

or grille is known, it should be used in calculating

the size opening required to provide the free

area specified. If the design and free area is not

known, it may be assumed that wood louvers will

be 20-25 percent free area and metal louvers and

grilles will have 60-75 percent free area. Louvers

and grilles shall be fixed in the open position or

interlocked with the equipment so that they are

opened automatically during equipment operation.

7. Special Conditions Created by Mechanical

Exhausting or Fireplaces: operation of exhaust

fans, ventilation systems, clothes dryers or

fireplaces may create conditions requiring special

attention to avoid unsatisfactory operation of

installed gas utilization equipment.

CHEMICAL VAPOR CORROSION

CORROSION OF THE FLUEWAYS AND VENT SYSTEM

MAY OCCUR IF AIR FOR COMBUSTION CONTAINS

CERTAIN CHEMICAL VAPORS. SUCH CORROSION

MAY RESULT IN FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and

air conditioning refrigerants, swimming pool chemicals,

calcium and sodium chloride (water softener salt), waxes,

and process chemicals are typical compounds which

are potentially corrosive. Do not store products of this

sort near the heater. Also air which is brought in contact

with the heater should not contain any of the chemicals.

If necessary, uncontaminated air should be obtained

from remote or outside sources. The Limited Warranty is

voided when failure of water heater is due to a corrosive

atmosphere. See Limited Warranty for complete terms

and conditions.

100221773_2000189439_Rev. 01 www. lochinvar .com 19

Page 20

INSTALLING THE NEW WATER HEATER

WATER PIPING

Water temperature over

DANGER

HOT

HOT

BURN

The water supply pressure should not exceed 80 psi. If this

occurs, a pressure reducing valve with a bypass should be

installed in the cold water inlet line. This should be placed

on the supply to the entire house in order to maintain equal

hot and cold water pressures.

HOT WATER CAN SCALD:

Water heaters are intended to produce hot water.

Water heated to a temperature which will satisfy space

heating, clothes washing, dish washing, cleaning and

other sanitizing needs can scald and permanently injure

you upon contact. Some people are more likely to be

permanently injured by hot water than others. These

include the elderly, children, the infirm, or physically/

mentally handicapped. If anyone using hot water fits into

one of these groups or if there is a local code or state law

requiring certain temperature water at the hot-water tap,

then you must take special precautions. In addition to

using lowest possible temperature setting that satisfies

your hot water needs, a means such as a mixing valve,

should be used at hot-water taps used by these people

or at the water heater (see Figure 8 & Figure 9). Valves

for reducing point of use temperature by mixing cold and

hot water are also available.

SPACE HEATING AND POTABLE WATER SYSTEMS

This appliance has been design certified as complying

with American National Standard/CSA Standard for water

heaters and are considered suitable for Water (Potable)

Heating and Space Heating. Note: Water heaters used

in combination water/space heating shall not be used in

space heating only applications.

125°F can cause severe

burns instantly resulting in

severe injury or death.

Children, the elderly and the

disabled and are at highest

risk of scald injury.

Feel water before bathing or

showering.

Temperature limiting devices

such as mixing valves must

be installed when required

by codes and to ensure safe

temperatures at fixtures.

WARNING

Toxic Chemical Hazard

• Do not connect to non-potable water system.

Consult a Qualified Installer or Service Agency. Follow

manufacturer’s instructions for installation of valves.

Before changing the factory setting on thermostat, read

“Operating The Temperature Control System” section in

this manual.

• This water heater should not be connected to any

heating systems or components previously used with

a non-potable water heating appliance.

• All piping components connected to this unit for space

heating applications should be suitable for use with

potable water.

• Toxic chemicals, such as those used for boiler treatment

shall not be introduced into the potable water used for

space heating.

• When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a mixing valve must be installed. Please

refer to Figure 8 & Figure 9 for suggested piping

arrangement.

Note: Water piping and vent piping occupy the space

above the water heater. Plan the water piping to ensure

it does not cause interference with the vent piping (see

“Planning The Vent System”).

If this water heater is to be used to supply both space

heating and potable water, the instructions listed below

must be followed:

• Combo heating systems and hot water supply

recirculation loop systems require adequate check

valves in the loop piping to prevent passive circulation

through the water heater when the system pump is

not operating.

• Be sure to follow the manual(s) shipped with the air

handler or other type heating system.

• This water heater is not to be used as a replacement

for an existing boiler installation.

• Do not use with piping that has been treated with

chromates, boiler seal or other chemicals and do not

add any chemicals to the water heater piping.

• If the space heating system requires water temperatures

in excess of 120°F , a mixing valve must be installed,

per the manufacturer’s instructions, in the potable hot-

water supply to limit the risk of scald injury.

• Pumps, valves, piping and fittings must be compatible

with potable water.

• A properly installed flow control valve is required to

prevent thermosiphoning. Thermosiphoning is the

result of a continuous flow of water through the air

handler circuit during the off cycle. Weeping (blow off)

of the temperature-pressure relief valve (T&P) or higher

than normal water temperatures are the first signs of

thermosiphoning.

• The hot-water line from the water heater should be

vertical past any mixing valve or supply line to the

heating system to remove air bubbles from the system.

• Do not connect the water heater to any system or

components previously used with non-potable water

heating appliances when used to supply potable water.

20 www. lochinvar .com 100221773_2000189439_Rev. 01

Page 21

COMBO HEATING

This section serves as a guide for the installation and use

of “Combo” heating systems utilizing a domestic water

heater that has been specifically approved for such use.

It is written for those knowledgeable in the required trades

and professionals involved in the design and installation

of Combo Heating Systems.

It is the responsibility of the installer/designer to follow all

applicable codes to ensure the effectiveness and safety

of the installation.

System Requirements

The following requirements must be met for the installation

of Combo Heating Systems:

1. All components used for the distribution of water in

the heating loop must be suitable for potable water.

These include all piping, fittings, solder and fluxes,

pumps for circulation of water, valves, etc.

2. The water heater must not be connected to a hydronic

heating system that has been used previously. This

heater is not designed to be used in a space heating

only application.

3. No boiler treatment chemicals of any kind shall be

introduced into the system.

4. The Combo System components must be selected

and sized to meet and maintain the total calculated

demands for both domestic service hot water

and space heating requirement. The sizing and

installation must be performed in accordance with

good engineering practice such as “ASHRAE

Handbooks”, HRAI’s Unified Combo Guidelines,

“Hydronics Institute Manuals”, ANSI Z223.1, CSA

F280, National/Provincial Building Codes, ANSI

and/or codes having jurisdiction.

5. The air handler (fan coil) and/or the circulating pump

in a baseboard hydronic loop will require a dedicated

120V circuit. This must be provided and identified for

this purpose.

6. All piping between the water heater and the air handler

or hydronic baseboard loop must be adequately

insulated to reduce heat loss.

7. If the local jurisdiction requires a back-flow preventer

in the cold water line, an expansion tank of adequate

size must be installed.

8. “Combo” Heating Systems require higher water

temperatures than other applications. When the

system is used to supply water for Combo Heating

applications, a means, such as mixing valve, must be

installed to temper the water in order to reduce scald

hazard potential (see Figure 22 & Figure 23).

Installation

The heating mode may be one of the following options:

A. A fan coil/air handler (Figure 22).

B. A hydronic baseboard (finned tube) loop/In floor

heating (Figure 23).

The following is a list of requirements for the installation

of option A or B.

1. Install shut-off valves and unions so that the water

heater can be isolated from the heating module should

servicing of the water heater become necessary.

2. Install a drain valve at the lowest point of the heating

loop so that water can be drained from the heating

module without affecting the water heater.

3. If the air handler does not have a venting means at

the highest point of the piping arrangement, install

an air bleed at the highest point of the plumbing

arrangement.

4. Important: Install a spring loaded check valve in

the side tap return line to prevent cold water from

continuously entering the water heater. Failure to

install such a valve could cause “stacking” and cause

the T&P valve to open.

HOT WATER

TO HOUSE

FIXTURE

C

M

H

MIXING

VALV E

HOT

OUTLET

SPRING

LOADED

CHECK

VALVE

EXPANSION TANK (OPTIONAL)

COLD SUPPLY

CHECK VALVE (IF USED

REQUIRES EXPANSION TANK)

COLD

INLET

FLOW

CONTROL

HOSE BIB

(OPTIONAL)

WATER

HEATER

SUPPLY

code requirements

(see also

Massachusetts

on page 7)

EXTERNAL

CIRCULATOR

RETURN

DRAIN/

PURGE

VALV E

INTERNAL

CIRCULATOR

AIR

HANDLER

Figure 22.

HOT WATER

TO HOUSE

FIXTURE

C

M

H

MIXING

VALV E

HOT

OUTLET

SPRING

LOADED

CHECK

VALVE

EXPANSION TANK (OPTIONAL)

COLD SUPPLY

CHECK VALVE (IF USED

REQUIRES EXPANSION TANK)

COLD

INLET

FLOW

CONTROL

HOSE BIB

(OPTIONAL)

SUPPLY

WATER

HEATER

code requirements

(see also

Massachusetts

on page 7)

EXTERNAL

CIRCULATOR

RETURN

HYDRONIC

BASEBOARDS

(SERIES

CONNECTED

SHOWN)

Figure 23.

100221773_2000189439_Rev. 01 www. lochinvar .com 21

Page 22

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others,

have installed devices such as pressure-reducing valves,

check valves, and back flow preventers. Devices such

as these cause the water system to be a closed system.

RECIRCULATION LOOPS

Combo heating systems and hot water supply recirculation

loop systems require adequate check valves in the loop

piping to prevent passive circulation through the water

heater when the system pump is not operating.

Passive flow, also known as thermo-siphoning, can be

generated when the loop system water is cooler than the

temperature of the water in the heater. This can happen

during long standby periods, during the off heating season

or when the air handler is in air conditioning mode. Passive

flow can cause unwanted firing of the heater resulting in

overheating which can relieve the T&P valve.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a