Page 1

Boiler

Product Line

Brochure

Page 2

Lochinvar Corporation

300 Maddox Simpson Pkwy

Lebanon, TN 37090

615-889-8900 / Fax: 615-547-1000

www.Lochinvar.com

Page 3

From the SolutionTM to the SYNC®, Lochinvar Boilers are noted for their

range of benefits and application flexibility. Collectively, they represent the most

complete product line in the industry. From a company with a long history of

innovation and a reputation for excellence.

You’ll find there’s a Lochinvar product for any application imaginable – from

standard residential units to the advanced Intelli-Fin

®

. And with selection, comes

opportunity.

In fact, the diversity and performance of our product line is surpassed only by

it’s quality–in design, construction, and training. A commitment that is reinforced

by the Lochinvar Tech Center, a state-of-the-art testing and training facility

equipped with the very latest in CAD/CAM technology and a comprehensive

R&D lab.

Quality, efficiency, features, service, and selection. For more than 90 years,

these have been the hallmarks of Lochinvar products.

Contents

CREST 1

SYNC® 3

Power-Fin

KNIGHT XL 7

Copper-Fin II

Copper-Fin

Copper-Fin

®

5

®

9

®

11

®

Atmospheric 13

Lochinvar...the innovator in boiler technology.

This emblem means a product has a NOx

rating which exceeds the requirements of

the South Coast Air Quality Management

District and Texas Commission of

Environmental Quality.

This emblem means the Stack Frame is

available for use with that product. See page

27 for details.

This catalog is designed to provide a convenient, condensed overview of the entire Lochinvar boiler product

line. For a complete list of features, specifications and technical data on a particular product, see the full line

catalog, your local distributor or contact Lochinvar. Every Lochinvar product is designed and built to meet

or exceed the fuel efficiency and safety standards of one or more of these agencies, wherever applicable.

KNIGHTTM 15

Efficiency+

Solution

®

19

TM

21

Buffer Tanks 23

Squire Buffer Tank 24

Squire Stainless Steel 25

Stack Frame 27

Low Temperature Valve 29

Electric Boilers 30

Page 4

99

CREST allows system designers tremendous flexibility to vary the flow rate through the boiler. It can service systems that operate

with widely fluctuating flow rates depending on demand. CREST can be installed with primary/secondary piping or in a full-flow

arrangement. Typical design techniques include full-flow systems or variable flow systems using variable frequency drives on the

heating water pumps. In either case, CREST excels in these applications and allows the flow through the boiler to vary based on

system demand. * 35 GPM min. flow on FB1500 model, 80 GPM on FB3500 model.

Sequences up to an 8-boiler system using simple 2-wire daisy-chain

connection, eliminating cost and uncertainty of separate “third party”

sequencer. On demand, one boiler functions as the leader and modulates

to capacity. Increasing load then “cascades” to additional “lag” boilers

in sequence as needed. Lead-lag rotation shifts “first on” boiler role

every 24 hours, distributing equal lead-lag runtimes to each unit.

CREST’s ability to sequence up to eight units that each have as much

as 25:1 turndown means that the combined system has the potential of

operating with modulation of up to 200:1 turndown. A bank of eight

2.0M Btu CRESTs would be able to provide as little as 80,000 Btu/hr and as much as 16,000,000 Btu/hr of heating output. In addition,

the CREST Cascade can be set for “Efficiency Optimization” with each boiler firing at the same low BTU/hr input rates to receive

the benefits of the highest thermal efficiency.

CR

CR

asas(N(Nsy

s

sy

s

pr

e

pr

e

con

con

for

for

u

25

25

a 2

a 2

dem

demdede

sys

sys

ret

retofof

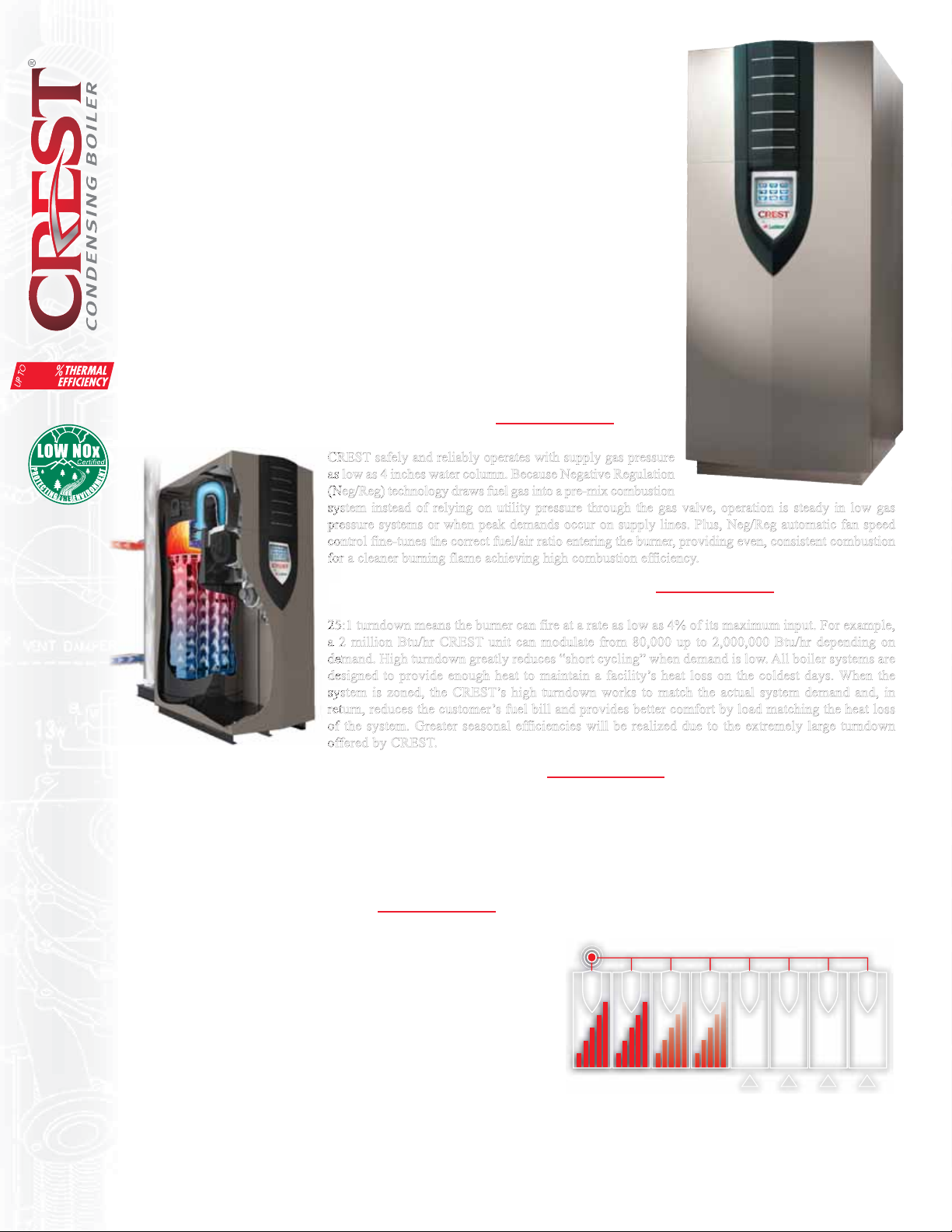

Fire Tube Innovation up to 3.5 Million BTU

Lochinvar® has taken the fire-tube concept in an innovative new direction with the

CREST® modulating-condensing boiler. With sizes that range from 1.5 to 3.5 million

Btu/hr, you finally have the opportunity to utilize Lochinvar leading-edge technology

in your largest applications. W ith thermal efficiencies up to 99% in low water temperature

applications, CREST is positioned to provide exceptional energy-saving performance.

The advanced CREST introduces a combustion system with a unique burner design with

up to 25:1 turndown. The burner fires into an array of 316L stainless steel fire-tubes that

transfer the heat to the surrounding water with exceptionally high efficiency.

CREST communicates seamlessly and in real time with building management systems

by utilizing an on-board Modbus protocol. The SMART TOUCH™ control has a builtin cascading feature that communicates with up to eight units, providing total command

without an external control or complex and expensive control logic programming by the

BMS integrator.

Yes, innovative fire-tube boiler technology integrated with our SMART TOUCH™

operating control makes the CREST a genuine game-changer among commercial boilers.

Advanced Negative Regulation Technology

CREST safely and reliably operates with supply gas pressure

as low as 4 inches water column. Because Negative Regulation

(Neg/Reg) technology draws fuel gas into a pre-mix combustion

system instead of relying on utility pressure through the gas valve, operation is steady in low gas

pressure systems or when peak demands occur on supply lines. Plus, Neg/Reg automatic fan speed

control fine-tunes the correct fuel/air ratio entering the burner, providing even, consistent combustion

for a cleaner burning flame achieving high combustion efficiency.

Fully Modulating up to 25:1 Turndown

F

25:1 turndown means the burner can fire at a rate as low as 4% of its maximum input. For example,

a 2 million Btu/hr CREST unit can modulate from 80,000 up to 2,000,000 Btu/hr depending on

demand. High turndown greatly reduces “short cycling” when demand is low. All boiler systems are

designed to provide enough heat to maintain a facility’s heat loss on the coldest days. When the

system is zoned, the CREST’s high turndown works to match the actual system demand and, in

return, reduces the customer’s fuel bill and provides better comfort by load matching the heat loss

of the system. Greater seasonal efficiencies will be realized due to the extremely large turndown

offered by CREST.

As Low As 35 GPM* to Full 350 GPM Flow Rates

CREST allows system designers tremendous flexibility to vary the flow rate through the boiler. It can service systems that operate

with widely fluctuating flow rates depending on demand. CREST can be installed with primary/secondary piping or in a full-flow

arrangement. Typical design techniques include full-flow systems or variable flow systems using variable frequency drives on the

heating water pumps. In either case, CREST excels in these applications and allows the flow through the boiler to vary based on

system demand. * 35 GPM min. flow on FB1500 model, 80 GPM on FB3500 model.

Built-in Cascading Sequencer

Sequences up to an 8-boiler system using simple 2-wire daisy-chain

connection, eliminating cost and uncertainty of separate “third party”

sequencer. On demand, one boiler functions as the leader and modulates

to capacity. Increasing load then “cascades” to additional “lag” boilers

in sequence as needed. Lead-lag rotation shifts “first on” boiler role

every 24 hours, distributing equal lead-lag runtimes to each unit.

CREST’s ability to sequence up to eight units that each have as much

as 25:1 turndown means that the combined system has the potential of

operating with modulation of up to 200:1 turndown. A bank of eight

2.0M Btu CRESTs would be able to provide as little as 80,000 Btu/hr and as much as 16,000,000 Btu/hr of heating output. In addition,

the CREST Cascade can be set for “Efficiency Optimization” with each boiler firing at the same low BTU/hr input rates to receive

the benefits of the highest thermal efficiency.

1

Page 5

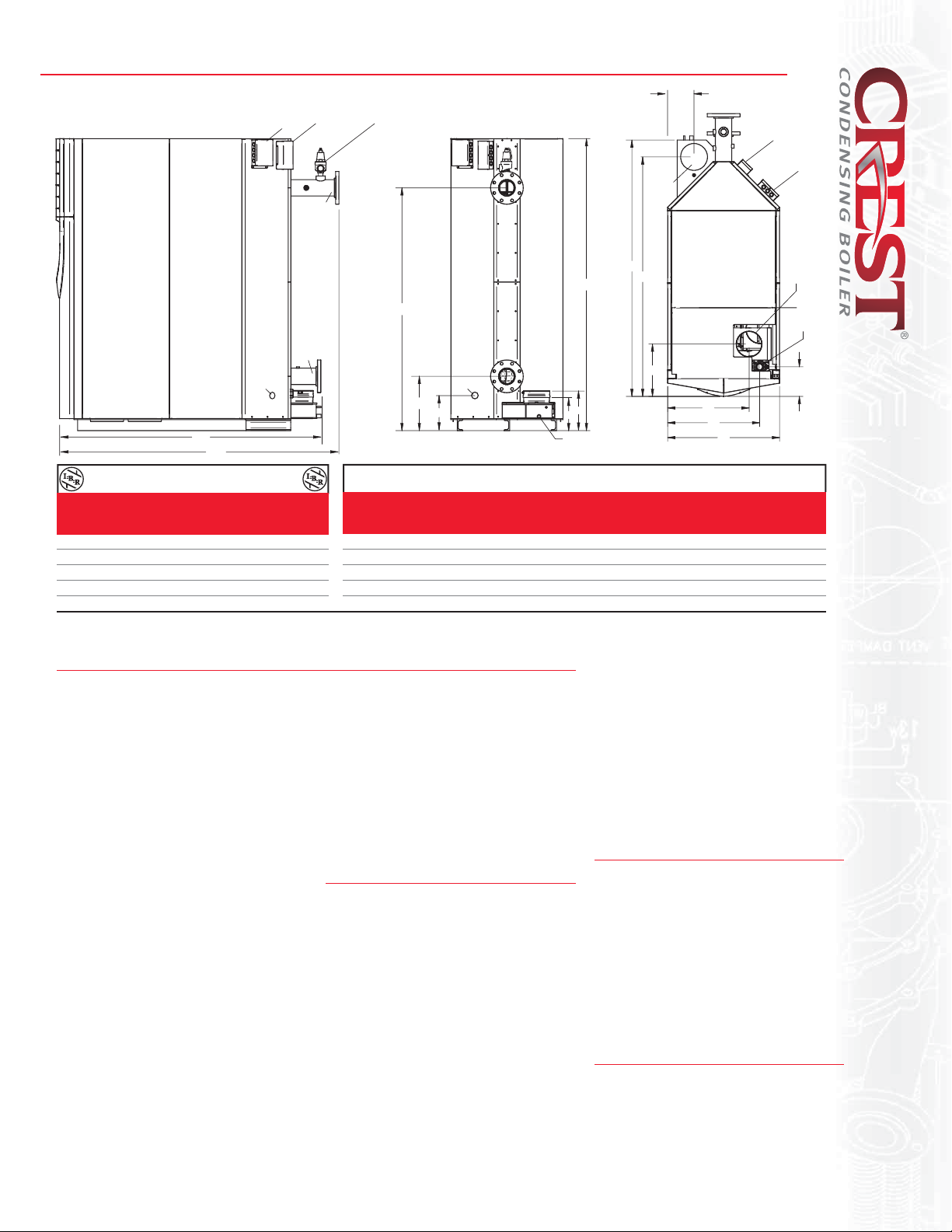

CREST® Boiler Dimensions & Specifications

H

HIGH

VOLTAGE

DRAIN

J

K

WATER

OUTLET

WATER

INLET

LOW

VOLTAGE

Crest Heating Boiler Dimensions and Specifications

Model Input Input NET

Number MBH MBH Thermal Output I=B=R Turndown

Min. Max. Efficiency MBH MBH

FBN1500 60 1,500 92.0% 1,380 1,200 25:1

FBN2000 80 2,000 92.0% 1,840 1,600 25:1

FBN2500 125 2,500 92.0% 2,300 2,000 20:1

FBN3000 150 3,000 92.0% 2,760 2,400 20:1

FBN3500 200 3,500 92.0% 3,220 2,800 18:1

Notes: Indoor installation only. All information subject to change. Change "N" to "L" for LP gas models. Low NOx on FB2500 - FB3500 models, consult factory.

*Turndown rate reduced on LP gas models.

*

Smart Touch™ Features

• SMART TOUCH™ Touchscreen Operating Control

• Full-Color 8” Touchscreen LCD Display

• Built-in Cascading Sequencer for up to 8 Boilers

• Building Management System Integration with

0-10 VDC Input

• Modbus Communications

• Outdoor Reset Control with Outdoor Air Sensor

• Password Security

• Domestic Hot Water Prioritization

• Low Water Flow Safety Control & Indication

• Inlet & Outlet Temperature Readout

• Freeze Protection

•

Service Reminder

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Programmable System Efficiency Optimizers

• Night Setback

• Anti-Cycling

•

Outdoor Air Reset Curve

• Ramp Delay

• Boost Temperature & Time

• Three Pump Control

• System Pump

• Boiler Pump

• Domestic Hot Water Pump

• High-Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1 Phase Power Supply

• System and Boiler Pump Contacts

• Low-Voltage Terminal Strip

• 24 VAC Auxiliary Device Relay

• Auxiliary Proving Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• Unit Enable/Disable Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

• 0-10 VDC BMS External Control Contact

Standard Features

• 92% Thermal Efficiency (AHRI)

• Up to 99% Thermal Efficiency in Low

• Modulating Burner with up to 25:1

• Low-NOx Operation

• Sealed Combustion

• Vertical or Horizontal Venting

• Category IV Venting up to 100 Feet

• ASME “H” Stamped Heat Exchanger

• 316L Stainless Steel Fire Tubes

• 160 psi Working Pressure

• Adjustable High Limit with Manual Reset

• Low Water Cutoff with Manual Reset & Test

• High & Low Gas Pressure Switches w/

• Low Air Pressure Switches

RELIEF

VALVE

4" FLG

OUTLET

80"

66-5/8"

4" FLG

DRAIN

14-7/8"

10 -1/4"

Gas Air Vent Operating Shipping

A B C D E F G H Conn. Inlet Size Wt. (lbs.) Wt. (lbs.)

INLET

11"

8"

CONDENSATE

DRAIN

VENT

B

C

D

E

G

A

30-3/4" 71-1/2" 65-3/4" 14-3/8" 22-3/8" 8-1/2" 25-1/4" 8-1/8" 1-1/2" 7" 7" 2,496 1,900

30-3/4" 71-1/8" 65-1/8" 14-7/8" 22-3/8" 8-1/4" 25-3/8" 9-5/8" 1-1/2" 8" 8" 3,054 2,150

34-1/4" 76-3/8" 70-1/4" 17-3/4" 26-1/8" 9-3/4" 27-3/8" 11-3/8" 2" 8" 9" 3,652 2,560

40-1/2" 83-5/8" 76-3/8" 17-3/8" 31-3/8" 9-7/8" 34-3/4" 11-1/2" 2" 10" 10" 4,126 2,920

40-1/2" 83-1/4" 75-5/8" 17-1/4" 31-3/8" 9-7/8" 34-3/4" 12-7/8" 2" 10" 10" 4,744 3,225

• System Sensor Outdoor Air Sensor

• Inlet & Outlet Temperature Sensors

•

High Voltage Terminal Strip

• Low Voltage Terminal Strip

• Downstream Gas Test Cocks

• 50 psi ASME Relief Valve

•

DHW Thermostat Contacts

• Temperature & Pressure Gauge

•

Zero Clearances to Combustible Materials

• 10-Year Limited Warranty

(See Warranty for Details)

• 1-Year Warranty on Parts

(See Warranty for Details)

Optional Equipment

• Alarm Bell

• BMS Gateway - BACnet or LonWorks

• Condensate Neutralization Kit

•

•

Temperature Applications

Turndown

•

Direct-Spark Ignition

SMART TOUCH PC Software

• Common Vent Kits

• Vent Termination Kits

• Dual Fuel Gas Train - Consult factory

• Electrical Options:

208V/3Ø/60Hz

•

Low Gas Pressure Operation

240V/1Ø/50Hz

480V/3Ø/60Hz

600V/3Ø/60Hz

Codes & Registrations

• ANSI Z21.13/CSA Certified

•

•

On/Off Switch

Manual Reset

ASME certified, “H” Stamp / National Board

• California Code Compliant

• CSD1 / Factory Mutual / GE Gap Compliant

• South Coast Air Quality Management

District Qualified

• Canadian Registration Number (CRN)

•

AHRI Certified

LOW

VOLTAGE

HIGH

VOLTAGE

AIR

GAS

F

2

Page 6

Building on a Tradition of Innovation

s t

.

Lochinvar’s commitment to research and development once again brings

innovation to the industry! The SYNC™ Commercial Boiler combines stainless

steel heat exchanger technology with Modulating Condensing combustion to

deliver thermal efficiencies as high as 98% in low-temperature applications.

With models at 1.0, 1.3 and 1.5 million BTU/hr inputs, SYNC will serve a

large range of commercial applications and add the “green” touch that building

owners and facility managers desire.

SYNC also reaches new levels of innovation with SMART TOUCH™…

touchscreen technology that puts total operational control at your fingertips!

With SMART TOUCH, it’s easier than ever to set up a perfectly synchronized

“green” system, and access a complete onboard database of real-time operational

data and performance history.

Other features in SYNC include space-saving footprints, direct-vent design with

intake and exhaust runs up to 100 feet, and a built-in cascading sequencer for up

to 8 boilers, delivering up to 12 million BTU/hr heating capacity.

Total Control, at Your Fingertips

The full-color SMART TOUCH Main Menu screen is your gateway to

complete control of all SYNC functions, and total access to system performance data and

history. Do it all and see it all right here, using our SMART TOUCH software.

Direct-Venting up to 100 Feet

SYNC offers tremendous flexibility for building plan placement because it permits direct-vent air intake

and exhaust runs up to 100 equivalent feet using PVC, CPVC or AL29-4C stainless steel vent pipe. Intake

and exhaust runs can terminate horizontally through a sidewall or vertically through the roof

Advanced Negative Regulation Technology

SYNC safely and reliably operates with supply gas pressure as low as 4 inches water column, because Negative Regulation (Neg/Reg)

technology automatically adjusts fan speed to ensure the correct volume of fuel and air entering the burner.

“Fail-Safe” Direct-Spark Ignition

With each call for heat, two electrodes ignite the fuel/gas mixture. A third electrode then senses for flame. SMART TOUCH will lock

out and display the fault if ignition does not occur.

Two-in-One Stainless Steel Heat Exchanger

A primary heat exchanger combined with a secondary exchanger captures flue gas heat and allows

very low return water temperatures and does not require a low-temperature bypass. The stainless

steel, pH-tolerant design features a weld-sealed assembly with no O-rings or gaskets, and does not

require special glycol. ASME Section IV approved and stamped.

Fully Modulating Burner

SMART TOUCH allows fully modulating combustion with 10:1 turndown. The combustion system can operate as low as 10% of

maximum input, and modulates the firing rate up to 100% as demand increases. The burner design incorporates a woven steel mesh

sleeve over a stainless steel burner tube and fires in a 360° pattern along the entire length of the primary heat exchanger. These together

allow SYNC’s compact size to excel compared to units with larger multiple burners.

Built-in Cascading Sequencer

Sequences up to an 8-boiler system using simple 2-wire daisy-chain connection,

eliminating cost and uncertainty of separate “third party” sequencer. On demand,

one boiler functions as the “leader”, and modulates to capacity. Increasing load

then “cascades” to additional “lag” boilers in sequence as needed. Lead-lag

rotation shifts “first on” boiler role every 24 hours, distributing equal lead-lag

runtimes to each unit.

3

Page 7

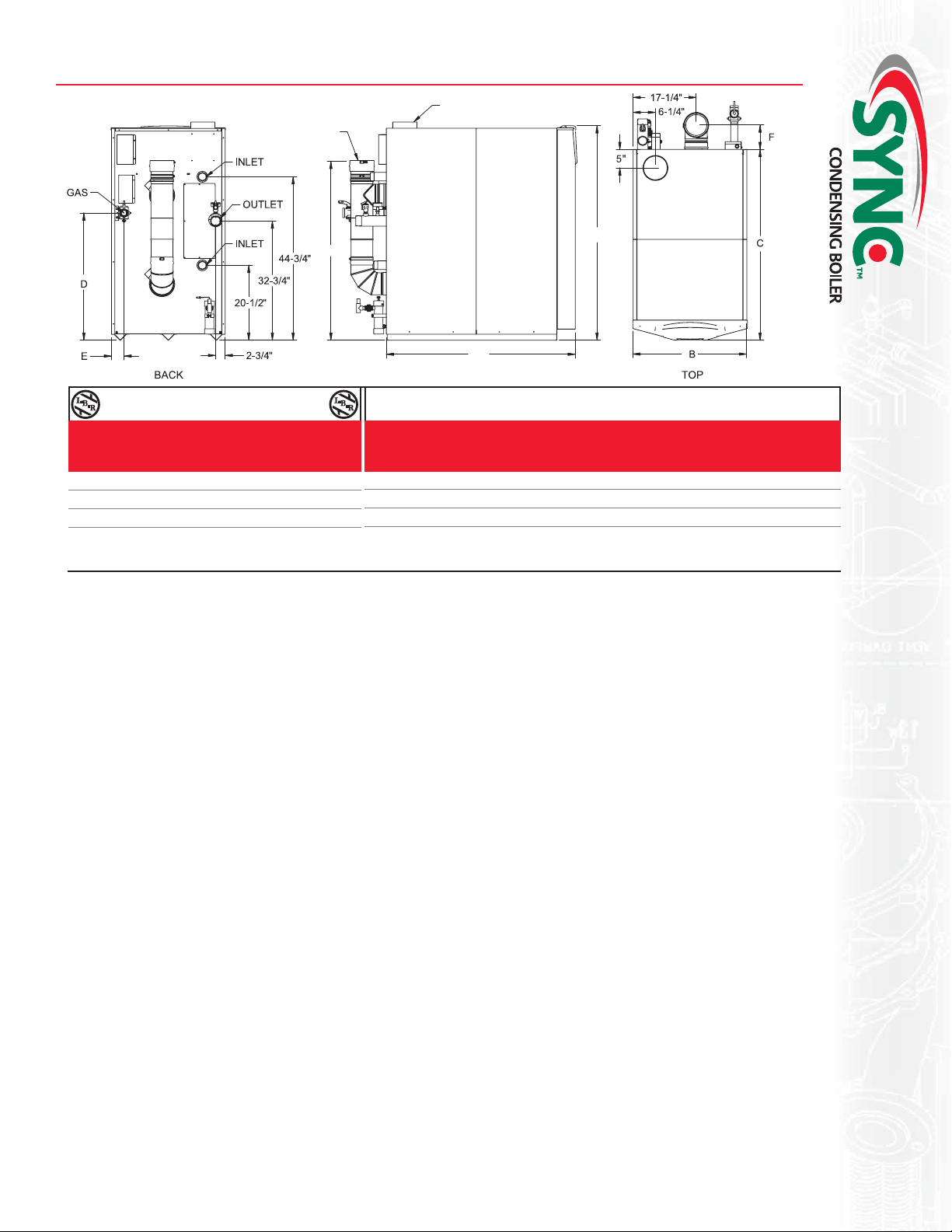

SYNCTM Boiler Dimensions & Specifications

FLUE

AIR INTAKE

49"

C

LEFT

Sync Heating Boiler

Input Net

Model Min. Max. Thermal Output I=B=R

Number MBH MBH Efficiency MBH MBH

SBN1000 100 1,000 94.1% 941 818

SBN1300 130 1,300 95.4% 1,240 1,078

SBN1500 150 1,500 96.2% 1,443 1,255

Notes: Change ‘N’ to ‘L’ for L.P. Gas Model. No deration on L.P. models. Performance data based on manufacturer test results. 120 VAC /15 AMP circuit required.

All dimensions shown in inches.

Standard Features

• Up to 96.2% Thermal Efficiency

• Modulating Burner with 10:1 Turndown

• Direct-Spark Ignition

• Low NOx Operation

• Sealed Combustion

• Low Gas Pressure Operation

• Vertical & Horizontal Venting

• Category IV Venting up to 100 Feet

• PVC, CPVC or AL29-4C Vent Material

• Sidewall Vent Terminations Provided

• ASME Stainless Steel Heat Exchanger

• ASME Certified, “H” Stamped

• Gasketless Design

• 160 psi Working Pressure

• On/Off Switch

• Adjustable High Limit with Manual Reset

• Low Water Cutoff with Manual Reset & Test

• Low Air Pressure Switch

• High & Low Gas Pressure Switches

with Manual Reset

• Inlet & Outlet Temperature Sensors

• Two Easy Access Terminal Strips

• Downstream Test Cocks

• 50 psi ASME Relief Valve

• Temperature & Pressure Gauge

• Zero Clearance to Combustible Material

• Approved for Combustible Floor Installation

• 1 Year Warranty on Parts

• 10 Year Limited Warranty

(see warranties for details)

Inlet Outlet

Gas Water Water Air Vent Shipping

A B C D E F Conn. Conn. Conn. Inlet Size Wt. (lbs.)

58-3/4" 31" 48" 35" 4-1/2" 15" 1-1/2" 2" x 2" 3" 6" 6" 786

58-3/4" 31" 52-1/4" 34-3/4" 3-1/2" 6-3/4" 1-1/2" 2" x 2" 3" 6" 6" 856

58-3/4" 31" 56-1/2" 34-3/4" 3-1/2" 6-3/4" 1-1/2" 2" x 2" 3" 6" 6" 926

SMART TOUCH™ Features

• SMART TOUCH™ Touchscreen Operating Control

• Full-Color Touchscreen LCD Display

• Built-in Cascading Sequencer for up to 8 Boilers

• Building Management System Integration with

0-10 VDC Input

• Outdoor Reset Control with Outdoor Air Sensor

• Dual Level Password Security

• Domestic Hot Water Prioritization

• Low Water Flow Safety Control & Indication

• Inlet & Outlet Temperature Readout

• Freeze Protection

• Service Reminder

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Programmable System Efficiency Optimizers

• Night Setback

• Anti-Cycling

• Outdoor Air Reset Curve

• Boost Temperature & Time

• Three Pump Control

• System Pump

• Boiler Pump

• Domestic Hot Water Pump

Dimensions and Specifications

A

• High Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1-Phase

Power Supply

• Three Sets of Pump Contacts

• Low Voltage Terminal Strip

• 24 VAC Auxiliary Device Relay

• Auxiliary Proving Switch Contacts

• Flow Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• Unit Enable/Disable Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

Optional Equipment

• Alarm Bell

• Condensate Neutralization Kit

• SMART SYSTEM PC Software

• Modbus Communications

• Stainless Steel Vent Kits

Codes & Registrations

• ANSI Z21.13a-2010 certified

• ASME certified, “H” stamp

• California Code compliant

• CSD1 / FM / GE Gap

• Massachusetts Code compliant

• South Coast Air Quality Management

District registered

Registered under U.S. Patent # 7,506,617

4

Page 8

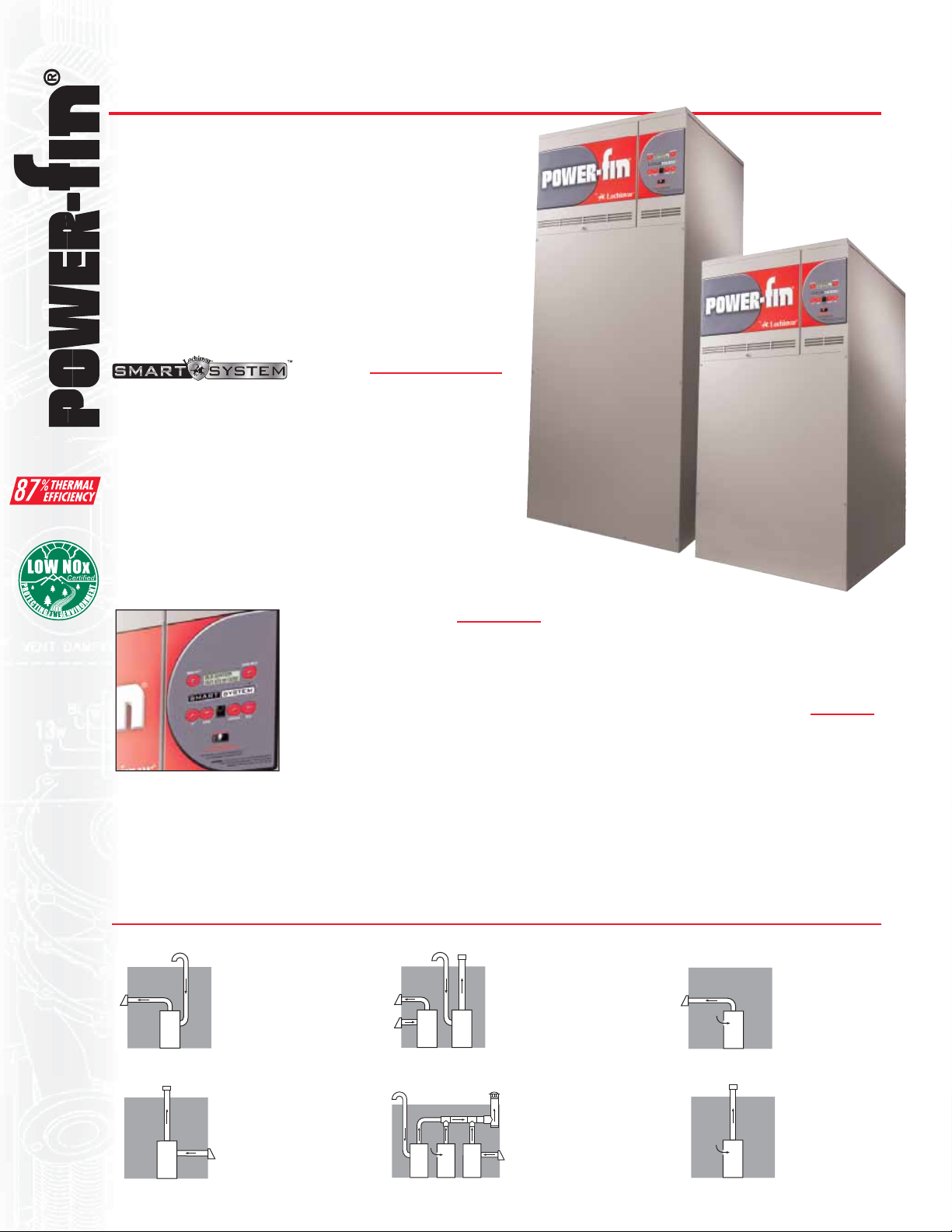

500,000 to 2,000,000 Btu/hr models

The Next Generation

The latest generation of Power-Fin continues to evolve, with

new “Built-in Advantages” from Lochinvar Corporation

These include expanded burner modulation and the advanced

SMART SYSTEM™ operating control, including a builtin cascading sequencer for up to eight boilers. It has been

designed to operate more efficiently at lower inputs, which

can add up to big savings. Plus, with numerous venting

capabilities, the Power-Fin is even more flexible to install.

And it’s easy to see how the Power-Fin is performing thanks

to a digital control panel. Take a look at what the next

generation of Power-Fin has to offer

.

Control

• Built-in cascading sequencer controls up to 8 units

• 2-line 16-character LCD readout of setup, system status

and diagnostic data in words, not codes.

• Password security

• Pump control for operation of water heater pump

• Pump delay w/freeze protection

• Low NOx operation

• 0-10 Vdc BMS input for easy integration into Building

Management Systems

• Optional SMART SYSTEM PC software for advanced

setup and diagnostics

®

.

Infinite Modulation

With thermal efficiencies up to 87%,

Power-Fin boilers feature infinitely

modulating burner firing rates

(turndown), precisely matching the

firing rate to domestic water load

requirements. The result is better overall

efficiency and less cycling. Power-Fin

boilers may be specified as either 5:1

turndown (502 - 2001), 2:1 turndown (1501 - 2001), or 100% ON/

OFF (502 - 1302). With 5:1 turndown the burner fires as low as

20% of maximum input when demand is lowest and increases

the firing rate up to 100% as demand increases. Models with 2:1

turndown modulate from 50% to 100% of maximum input.

Venting Options

DirectAire Horizontal

Vents horizontally up to 50

equivalent feet using Category IV

vent materials. Draws combustion

air up to 50 ft. from a different

pressure zone.

DirectAire Vertical

Vertical venting up to 50 equivalent

feet using Category I or IV vent

materials. Draws combustion air up

to 50 ft. from a different pressure

5

zone.

Direct Vent

Horizontal or vertical venting up to 50

equivalent feet using Category IV vent

materials. Draws combustion air from

the same pressure zone. This option

only available with 5:1 (M) firing

code models.

Common Venting

Vents multiple units vertically

through one vent termination with

Category II vent materials and draws

combustion air from the room, roof

or sidewall. Vent kit and Category IV

to II conversion kit required.

Gasketless Heat Exchanger

The Power-Fin heat exchanger features an array

of 20 or 24 copper-finned tubes surrounding the

burner for maximum heat transfer. Lochinvar also

pioneered the “gasketless” heat exchanger, which

eliminates the use of O-rings and gaskets. Because

of the time-proven reliability of this design, the

Power-Fin heat exchanger is backed by a 5 year

limited warranty.

Sidewall

Horizontal venting up to 50

equivalent feet using Category

IV vent materials. Draws

combustion air from the room.

Vertical

Vertical venting using

Category I or Category IV

vent materials. Draws

combustion air from

the room.

Page 9

Power-Fin® Boiler Dimensions & Specifications

J

K

M

B

G

P

L

N

C

Power-Fin Boiler Dimensions and Specifications

B9/F9 Net M9 Net

Model Input Thermal Output I=B=R Thermal Output I=B=R B9/F9 M9

Number MBH Efficiency MBH MBH Efficiency MBH MBH A B C D E E F G

PBN0502 500 85.0% 425 370 85.0% 425 370 44-1/2” 28-1/2” 23-1/4” 34” 17-3/4” 19-1/2” 6-1/2” 6”

PBN0752 750 85.0% 638 554 85.0% 638 554 52” 28-1/2” 23-1/4” 41-1/2” 17-3/4” 19-1/2” 6-3/4” 6”

PBN1002 999 85.0% 850 739 85.0% 850 739 59-1/4” 28-1/2” 23-1/4” 48-3/4” 17-3/4” 19-1/2” 7-1/4” 6”

PBN1302 1,300 85.0% 1,105 961 85.0% 1,105 961 67-3/4” 28-1/2” 23-1/4” 57-1/4” 17-3/4” 19-1/2” 8-1/4” 6”

PBN1501 1,500 84.0% 1,260 1,096 85.0% 1,275 1,109 65-1/2” 29-3/4” 27-1/4” 58-3/4” 21” 21” 13-1/2” 8”

PBN1701 1,700 84.0% 1,428 1,242 85.0% 1,445 1,257 70” 29-3/4” 27-1/4” 63-1/4” 21” 21” 13-1/2” 8”

PBN2001 2,000 84.0% 1,680 1,461 85.0% 1,700 1,478 76-3/4” 29-3/4” 27-1/4” 70” 21” 21” 13-1/2” 8”

Vent Sizes Shipping

Model B9/F9 M9 Gas Air B9/F9 M9* M9 Wt.

Number H J K L M N P P Conn. Inlet Cat I Cat II Cat IV (lbs)

PBN0502 8” 7-3/4” 23” 11-1/2” 11-1/4” 17-1/2” 15-1/4” 15-1/4” 1” 5” 7” 7” 4” 505

PBN0752 8” 7-3/4” 30-1/2” 11-1/2” 11-1/4” 17-1/2” 15-1/4” 15-1/4” 1-1/4” 5” 9” 9” 5” 554

PBN1002 8” 7-3/4” 37-3/4” 11-1/2” 11-1/4” 17-1/2” 15-1/4” 15-1/4” 1-1/4” 6” 10” 10” 6” 603

PBN1302 8” 7-3/4” 46-1/4” 11-1/2” 19-1/2” 17-1/2” 15-1/4” 15-1/4” 1-1/4” 6” 12” 12” 8” 652

PBN1501 10” 9-1/2” 43-1/2” 5-3/4” 22-1/4” 21-1/2” 24-1/2” 19-1/2” 1-1/2” 6” 12” 8” 6” 1,065

PBN1701 10” 9-1/2” 48” 5-3/4” 25” 21-1/2” 24-1/2” 19-1/2” 1-1/2” 7” 14” 9” 7” 1,100

PBN2001 10” 9-1/2” 54-3/4” 5-3/4” 27-1/2” 21-1/2” 24-1/2” 19-1/2” 1-1/2” 8” 14” 10” 8” 1,127

Notes: Change ‘N’ to ‘L’ for LP Gas Model. No deration on LP models. All water connections are 2-1/2” *w/CAT II conversion kit

Standard Features

• Up to 87% Thermal Efficiency (M)

• Up to 85% Thermal Efficiency (B/F)

• Modulating Burner with 5:1 Turndown

• Hot Surface Ignition

• Low NOx Operation

• Sealed Combustion

• Low Gas Pressure Operation

• Vertical & Horizontal Venting

• Venting up to 50 Feet

• Category I or Category IV Venting

• Cat IV converts to Cat II

w/ optional vent kit

• ASME Copper-Finned Tube

Heat Exchanger

• ASME Certified, “H” Stamped

• Gasketless design

• 160 psi working pressure

• On/Off Switch

• Adjustable High Limit w/ Manual Reset

• Flow Switch

• Low Air Pressure Switch

• Downstream Test Cocks

• 50 psi ASME Relief Valve

• Combustion Air Filtration

• Temperature & Pressure Gauge

• Zero Clearances to Combustible Material

• 1 Year Warranty on Parts

• 10 Year Limited Warranty

(See Warranties for Details)

Smart System Features

• SMART SYSTEM Operating Control

• 2 line, 16 Character Display

• Dual Level Password Security

• Domestic Hot Water Prioritization

• Built in Cascading Sequencer

for up to 8 Boilers

• Building Management System

Integration with 0-10 VDC Input

• Outdoor Reset Control

with Outdoor Air Sensor

• Low Water Flow Safety Control & Indication

• Inlet & Outlet Temperature Readout

• Freeze Protection

• Service Reminder

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Programmable System Efficiency

Optimizers

• Night Setback

• Anti-Cycling

• Outdoor Air Reset Curve

• Ramp Delay

• Boost Temperature & Time

• Three Pump Control

• System Pump

• Boiler Pump

• Domestic Hot Water Pump

• High Voltage Terminal Strip

• 120 VAC / 50-60 Hertz /

1 Phase Power Supply

• Three sets of Pump Contacts

with Pump Relays

• Low Voltage Terminal Strip

• 24 VAC Auxiliary Device Relay

• Auxiliary Proving Switch

Contacts

• Flow Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• Room Thermostat Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

• 0-10 VDC BMS External

Control Contact

Firing Control Systems

• M Indicates 5:1 Turndown, Category IV

• B Indicates 2:1 Turndown, Category I

• F Indicates 100% On/Off Fire, Category I

• M9 Standard

• B9 or F9 Special Order,

Factory Trimmed

• M7, B7 or F7 California Code

• M13, B13 or F13 CSD1/FM/GE Gap

Optional Equipment

• Alarm Bell

• Cupro-Nickel Heat Exchanger

• High & Low Gas Pressure Switches

w/ Manual Reset

• Low Water Cutoff

w/ Manual Reset & Test

• SMART SYSTEM PC Software

• Vent Kits:

- Horizontal Exhaust Cap

- Horizontal Air Intake Cap

- Horizontal Direct Vent Kit

- Category IV to Category II

Conversion Kit

Registered under U.S. Patent # 7,506,617

500,000 - 2,000,000 Btu/hr models

6

Page 10

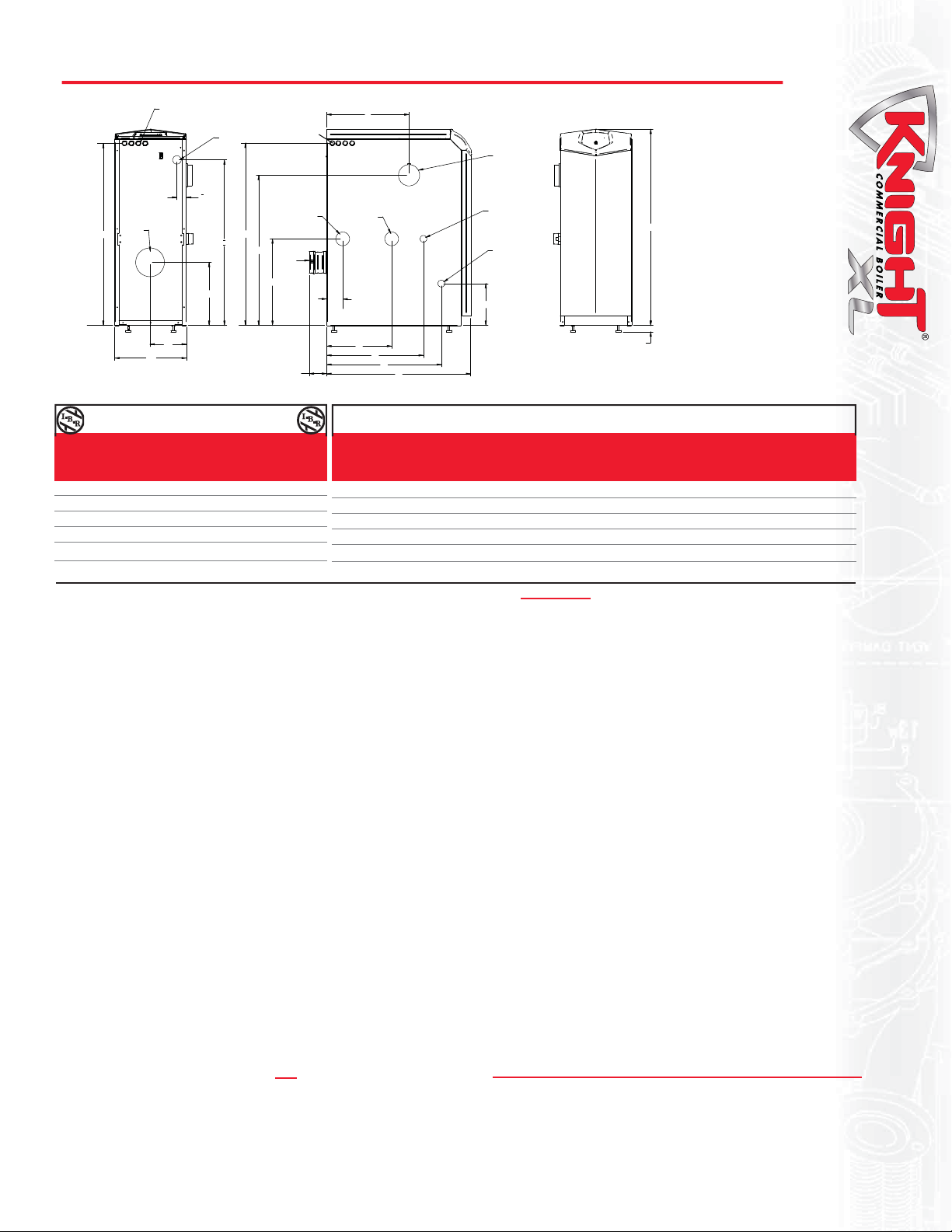

The Smartest Choice for Condensing Boiler Performance

The KNIGHT® XL, engineered with Lochinvar’s exclusive SMART SYSTEM™ control

and an array of other innovative features, places it far ahead of any commercial heating

boiler in its class. It promises and delivers ultimate ease of installation and maintenance.

With up to 94.6% thermal efficiency, low-NOx emissions and a fully modulating burner,

it is the best ”green choice” for today’s environmentally focused market.

Five modulating/condensing stainless steel KNIGHT XL boilers are available with

399,999–800,000 Btu/hr inputs and remarkably small space-saving footprints. All are

equipped for direct-vent installation with air intake and exhaust runs up to 100 feet

using PVC, CPVC or AL29-4C vent materials. This range of choices is ideal for lightduty applications such as small hotels, schools and office buildings. For higher-demand

applications, up to eight KNIGHT XL units can be installed utilizing the built-in cascading

sequencer to deliver up to 6.4 million Btu/hr heating capacity.

Control

SMART SYSTEM provides unequalled control and monitoring functions that are easy to

understand and use.

• Multi-Color Graphic LCD Display

• Navigation Dial

• USB Port

• Modbus Capability (Optional)

• DHW Modulation Limiting

• DHW Night Setback*

• Controls up to three different setpoint temperatures

• 0-10 V Boiler Rate Output

• 0-10V Signal to control variable speed boiler pump*

• 0-10V System Pump Signal Input*

• Heat Demand from 0-10V Input

• Installer to Program Name and Number into the Boiler

• Freeze Protection Parameters Installer Adjustable

• Separately adjustable SH/DHW Switching times*

• Installer access to BMS and ramp delay settings

*Exclusive to Lochinvar Smart System

Advanced Negative Regulation Technology

KNIGHT XL safely and reliably operates with supply gas pressure as low as 4

inches water column. Negative Regulation (Neg/Reg) technology automatically

adjusts fan speed that ensures the correct volume and mix of fuel and air

throughout the firing range.

Two-in-One Stainless Steel Heat Exchanger

A primary heat exchanger combined with a secondary heat exchanger captures

flue gas heat and condenses to utilize available latent energy. The stainless steel,

pH-tolerant design features a weld-sealed assembly with no O-rings or gaskets

and does not require special glycol. ASME Section IV approved and stamped.

Fully Modulating Burner

The SMART SYSTEM allows fully modulating combustion with 5:1 turndown.

The burner can fire as low as 20% of maximum input and modulates the firing

rate up to 100% as demand increases. The burner is a single stainless steel

assembly covered with woven steel mesh and fires in a 360° pattern along the entire length of the primary heat exchanger. This

allows the compact KNIGHT XL to exceed the capacity of units with larger multiple burners.

Direct Venting up to 100 Feet

KNIGHT XL offers 7 venting options and tremendous flexibility for placement of units within

the building, because it permits direct-vent air intake and exhaust runs up to 100 equivalent feet

using either PVC, CPVC or AL29-4C stainless steel vent pipe. A sidewall vent termination kit is

shipped standard with every KNIGHT boiler.

7

Page 11

KNIGHT XL® Boiler Dimensions & Specifications

A

LOW VOLTAGE

ELECTRICAL

CONNECTIONS

GAS

HIGH VOLTAGE

ELECTRICAL

CONNECTIONS

K

AIR INLET

39-1/2"

FLUE

B

BACK

J

INLET

38-3/4"

I

H

FLUE

13-3/4"

8"

18-3/4"

D

3-1/2"

OUTLET

G

F

E

C

LEFT SIDE

HEAT

EXCHANGER

DRAIN

3/4" NPT

CONDENSATE

DRAIN

9"

Knight XL Heating Boiler Dimensions and Specifications

Input Net

Model Min Max Thermal Output I=B=R

Number MBH MBH Efficiency MBH MBH

KBN400 80 399 93.3% 373 324

KBN501 100 500 93.3% 467 406

KBN601 120 600 94.6% 567 493

KBN701 140 700 94.3% 660 574

KBN801 160 800 94.0% 752 654

Notes: Indoor installation only. All information subject to change. Change “N” to “L” for LP gas models.

Standard Features

• Up to 94.6% Thermal Efficiency

• Modulating Burner with 5:1 Turndown

• Direct-Spark Ignition

• Low NOx Operation

• Sealed Combustion

• Low Gas Pressure Operation

• ASME Stainless Steel Heat Exchanger

• ASME Certified, ”H” Stamped

Gasketless Heat Exchanger

• 160 psi Working Pressure

• 50 psi ASME Relief Valve

• Highly efficient, condensing design

• Vertical & Horizontal Direct-Vent

• Category IV venting up to 100 feet

• PVC, CPVC or AL29-4C Venting up to 100 Feet

• Factory Supplied Sidewall Vent Termination

• Smart System Control

• Other Features

• On/Off Switch

• Adjustable High Limit w/ Manual Reset

• Automatic Reset High Limit

• Flow Switch

• Flue Temperature Sensor

• Low Air Pressure Switch

• Temperature & Pressure Gauge

• Adjustable Leveling Legs

• Condensate Trap

• Zero Clearances to Combustible Material

• 10 Year Limited Warranty (See Warranty)

Firing Control Systems

• M9 Standard Construction

• M7 California Code

• M13 CSD1 / FM / GE Gap (KB501-KB801)

A B C D E F G H I J K Gas Water Air Vent Shipping

Conn. Conn. Inlet Size Wt. (lbs.)

42-1/2” 15-1/2” 27-3/4” 3-3/4” 20-3/4” 21” 14” 34” 34” 2” 18-3/4” 1” 1-1/2” 4” 4” 280

42-1/2” 15-1/2” 31-1/2” 3-3/4” 25-1/2” 21” 14” 32-1/2” 36” 2” 18” 1” 1-1/2” 4” 4” 310

42-1/2” 15-1/2” 36-1/4” 3-3/4” 25” 21” 14” 36” 32-3/4” 5-1/2” 19-1/2” 1” 2” 4” 4” 340

42-1/2” 15-1/2” 40-1/4” 3-3/4” 29” 23” 17” 36” 32-3/4” 3-1/4” 23-1/2” 1” 2” 4” 6” 370

42-1/2” 15-1/2” 45-1/4” 3-3/4” 33-1/4” 23” 17” 36” 32-3/4” 3-1/4” 27-3/4” 1” 2” 4” 6” 405

Smart System Features

• SMART SYSTEM Digital Operating Control

• Multi-Colored Graphic LCD Display w/ Navigation Dial

• Three Reset Temperature Inputs

with curves for three set point temperature inputs

• Built in Cascading Sequencer for up to 8 Boilers

• Lead Lag

• Efficiency Optimization

• Outdoor Reset Control with Outdoor Air Sensor

• Programmable System Efficiency Optimizers

• Night Setback

• DHW Night Setback

• Anti-Cycling

• Outdoor Air Reset Curve

• Ramp Delay

• Boost Temperature & Time

• Three Pump Control

System Pump With Parameter for Continuous Operation

•

• Boiler Pump With Variable Speed Pump Control*

• Domestic Hot Water Pump

• Domestic Hot Water Prioritization

• DHW tank piped with priority in the boiler loop

• DHW tank piped as a zone in the system with

the pumps controlled by the Smart System

• DHW Modulation Limiting

• Separately Adjustable SH/DHW Switching Times*

• Building Management System Integration

• 0-10VDC Input to Control Modulation or Set Point

• 0-10VDC Input Signal from Variable Speed

System Pump*

• 0-10VDC Modulation Rate Output

• 0-10VDC Input to Enable/Disable call for heat

• Access to BMS Settings through Display

Optional Equipment

• Alarm Bell

• Condensate Neutralization Kit)

• Concentric Vent Kit (KB400-KB601)

• High & Low Gas Pressure Switches

w/ Manual Reset (KB501-KB801)

1-1/4"1/4" -

ADJUSTABLE

FRONT

• High Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1 Phase Power Supply

• Three sets of Pump Contacts with Pump Relays

• Low Voltage Terminal Strip

• 24 VAC Device Relay

• Proving Switch Contacts

• Flow Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• 3 Space Heat Thermostat Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

• 0-10 VDC BMS External Control Contact

• 0-10VDC Boiler Rate Output Contacts

•

0-10VDC Variable Speed System Pump Signal Input

• 0-10VDC Signal to Control Variable Speed Boiler Pump

• Modbus Contacts

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Other Features

• Low Water Flow Safety Control & Indication

• Password Security

• Inlet & Outlet Temperature Readout

• Customizable Freeze Protection Parameters

• Custom Maintenance Reminder with Contractor Info

*Exclusive feature, available only from Lochinvar

• Modbus Communication

• Low Water Cutoff w/Manual Reset & Test

• SMART SYSTEM PC Software

• Stainless Steel Vent Kits (KB701-KB801)

• Stack Frame

8

Page 12

®

The Foundation of Lochinvar Becomes Stronger

Copper-finned tube, non-condensing appliances are the

foundation of Lochinvar’s success. In 1993, Lochinvar

introduced the Copper-Fin II, the first horizontal chassis,

copper-finned tube boiler to operate with fan-assisted

combustion. Now, the Copper-fin II is even better.

Along with high thermal efficiency, gasketless heat

exchangers and multiple venting options we have added

Lochinvar’s exclusive SMART SYSTEM™ control.

Nine models from 399,999 to 2,070,000 Btu/hr input

provide you with exceptional products with a long

list of new features in addition to the established features which redefined the industry. The Copper-fin II was the first

proportional fired, fan-assisted boiler on the market. Every model features a small footprint for easy passage through a

36” door, low NOx – third party tested to less than 20 PPM, Stack Frames that can put twice the Btu/hr input in the same

space and vent diameters up to 8” smaller than conventional atmospheric boilers.

SMART SYSTEM Puts More Control and Information at your Fingertips

The most exciting addition to the Copper-Fin II is the SMART SYSTEMTM control. The SMART SYSTEM is an advanced,

state of the art integrated operating control. We introduced the SMART SYSTEM control in 2005 and it has delivered proven

operation in thousands of demanding commercial applications. The control provides the installer, owners and operators with

precise temperature control and diagnostic information.

Advanced features include:

• 2-Line, 16 Character LCD display of Setup, System Status and Diagnostic Data in Words, not codes

• Built-in Cascade sequencer controlling up to 8 Boilers

• Outdoor Reset adjusts setpoint based on reset curve

• Domestic hot water prioritization allows the boiler to provide space heating and produce domestic hot

water all in one system

• 0-10 VDC BMS Input to control boiler operation

• Modbus protocol - optional

Proportional Firing

Proportional firing divides a single manifold of multiple burners into smaller, independent stages.

With up to four stages of individual operation, the Smart System control can reduce the firing rate down to approximately 25%

Btu/hr input. This simple but effective design matches the boiler’s firing capacity to the constantly changing system demand.

Full Fire or On/Off combustion systems often fire the entire gas train in short, inefficient bursts. Stage firing delivers the Btu’s

required in smoother and longer burn cycles which will improve operation and reduce component fatigue.

Gasketless Heat Exchanger

In 1989, Lochinvar was the first water heater manufacturer to offer gasketless cast iron & copper-finned tube heat

exchangers. Our unique gasketless design enhances reliability by eliminating o-rings and gaskets found on other brands.

The heat exchanger features glass lined headers and copper-finned tubes with extruded integral fins spaced 7-fins per inch

for exceptional heat transfer. The heat exchanger is built to ASME construction standards for 160 psi working pressure

and is backed by a ten year limited warranty.

Venting Options

Conventional

Vents into

conventional

flue or vent

breaching using

Type B double

wall vent.

Powered Sidewall DirectAire Vertical

Vents directly

through the outside

wall using an

optional powered

sidewall cap. Ideal

when a vent stack

9

is not practical.

Sidewall DirectAire Vertical w/ Sidewall Outdoor

Draws fresh air from

inside the room. Vents

up to 50 equivalent

feet

directly through

the outside wall

without the need for a

powered sidewall cap.

Draws fresh air

from outside and

vents through

conventional

vertical flue.

Power DirectAire Horizontal

Draws fresh

air from

outside and

vents through

conventional

vertical flue.

Aire-Lock Direct Vent

Draws fresh air

from outside

and vents

through sidewall

using optional

powered vent

cap.

Requires optional

outdoor vent cap.

Use when indoor

space is a problem

or if outdoor

location gives

better access.

Draws fresh air

50 equivalent feet

from a sidewall.

Vents horizontally

up to 50 equivalent

feet through the

sidewall.

Page 13

Copper-Fin II® Boiler Dimensions & Specifications

E

GAS CONNECTION

0402-0752

A

INLET AIR

FILTER

B

G

D

F

OUTLET

H

C

INLET

GAS CONNECTION

0992-2072

G

Copper-Fin II Heating Boiler Dimensions & Spec i fi ca tions

Net

Model Input Thermal Output I=B=R Vent Air Gas Shipping

Number MBH Efficiency MBH MBH A B C D E F G H Size Inlet Conn Weight

CHN0402 399 85% 339 295 31-1/2” 37-3/4” 22-1/4” 12-1/2” 7” 7” 29” 6-1/2” 6” 6” 1-1/4” 378

CHN0502 500 85% 425 370 31-1/2” 45-1/2” 22-1/4” 12-1/2” 7” 7” 29” 6-1/2” 6” 6” 1-1/4” 414

CHN0652 650 85% 553 481 31-1/2” 56-3/4” 22-1/4” 12-1/2” 8-1/2” 8-1/4” 29” 6-1/2” 8” 8” 1-1/4” 500

CHN0752 750 85% 638 555 31-1/2” 64” 22-1/4” 12-1/2” 8-1/2” 8-1/4” 29” 6-1/2” 8” 8” 1-1/4” 543

CHN0992 990 85% 842 732 36” 48-1/4” 33-1/2” 15-3/4” 8-1/2” 8-1/2” 33-3/4” 8-3/4” 10” 10” 2” 773

CHN1262 1,260 85% 1,071 931 36” 58-1/2” 33-1/2” 15-3/4” 10-1/2” 9-1/2” 33-3/4” 8-3/4” 12” 12” 2” 863

CHN1442 1,440 85% 1,224 1,064 36” 68-3/4” 33-1/2” 15-3/4” 10-1/2” 10-1/2” 33-3/4” 8-3/4” 12” 12” 2” 965

CHN1802 1,800 85% 1,530 1,330 36” 82-1/4” 33-1/2” 15-3/4” 11” 11” 33-3/4” 8-3/4” 14” 12” 2” 1,100

CHN2072 2,070 85% 1,760 1,530 36” 92-1/2” 33-1/2” 15-3/4” 11” 11” 33-3/4” 8-3/4” 14” 12” 2” 1,219

Notes: Change ‘N’ to ‘L’ for LP gas models. No deration on LP models Water connections for models CH 0402-0752 are 2” NPT on 6-1/2” centers.

Header increases “B” dimension 3-1/2” for models CH 0402-0752 and 6-1/4” for models CH 0992-2072. Water connections for models CH 0992-2072 are 2-1/2” NPT on 11-1/4” centers.

Performance data is based on manufacturer test results.

®

Standard Features

• 85% Thermal Efficiency (AHRI Certified)

• Proportional Firing up to 4:1 Turndown

• Hot Surface Ignition

• Low NOx Operation

• Sealed Combustion

• Low Gas Pressure Operation

• Vertical & Horizontal Venting

• Category I Venting

• Double Wall “B” Vent Material

• Category IV Venting

• AL29-4C Stainless Steel Vent Material

• ASME Copper Finned Tube Heat Exchanger

• ASME Certified, “H” Stamped

• Gasketless design

• 160 psi working pressure

• On/Off Switch

• Combustible Floor Rated (0992 - 2072)

• Adjustable High Limit w/ Manual Reset

• Flow Switch

• Low Air Pressure Switch

• Inlet & Outlet Temperature Sensors

• Easy Access Terminal Strips

• Downstream Test Cocks

• 50 psi ASME Pressure Relief Valve

• Temperature & Pressure Gauge

• 1 Year Warranty on Parts (See Warranty for Details)

• 10 Year Limited Warranty (See Warranty for Details)

Optional Equipment

• Alarm Bell

• High & Low Gas Pressure Switches w/ Manual Reset

• Cupro-Nickel Heat Exchanger

• Low Water Cut Off, Probe Type w/ Manual Reset &

Test

• Modbus Communications

• Combustible Floor Kit (0402-0752)

• Stack Frame

Smart System™ Features

• SMART SYSTEM™ Operating Control

• 2 Line/16 Character LCD Display

• Built in Cascading Sequencer for up to 8 boilers

• Front End Loading with Crest boilers

• Building Management System Integration

with 0-10 VDC Input

• Outdoor Reset Control with Outdoor Air Sensor

• Password Security

• Domestic Hot Water Prioritization

• Low Water Flow Control & Indication

• Inlet & Outlet Temperature Readout

• Freeze Protection

• Service Reminder

• Time Clock

• 0-10V DC Rate Output

• Condensing Protection

• 0-10V System Pump Speed Input

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Programmable System Efficiency Optimizers

• Night Setback

• Anti-Cycling

• Outdoor Air Reset Curve

• Boost Temperature & Time

Firing Codes

•

M7 Firing Code - California Code

• M9 Firing Code - Hot Surface Ignition

with Electronic Supervision

• M13 Firing Code - CSD1 / Factory Mutual / GE Gap

Certifications

ANSI Z21.13/CSA 4.9 certified

South Coast Air Quality Management District registered

Texas Commission on Environmental Quality

• Three Pump Control

• System Pump

• Boiler Pump

• Domestic Hot Water Pump

• High Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1 Phase Power Supply

• Pump Contacts with Pump Relay

• Low Voltage Terminal Strip

• 24 VAC Auxiliary Device Relay Output - Louvers

• Auxiliary Proving Switch Contacts - Louvers

• 3-way Valve Contacts for Low

Temperature Protection

• Alarm on Any Failure Contacts

• 0-10V System Pump Speed Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• DHW Tank Sensor Contacts

• Unit Enable/Disable Contacts

• System Sensor Contacts - Supply and Return

• Outdoor Air Sensor Contacts

• Contacts for Air Louvers

• Contacts on Any Failure

• Cascade Contacts

• 0-10 VDC BMS External Control Contact

• 0-10 VDC Rate Contacts

• Low Water Temperature Valves

10

Page 14

®

Energy Efficient, Cost Effective Boilers

Lochinvar first introduced Copper-Fin technology to the

boiler industry some 50 years ago. Since then, we’ve

continued to refine and perfect it - adding advanced

fan-assisted combustion, hot surface ignition, a unique

gasketless cop per finned tube heat ex chang er and highly

efficient insulating materials.

Installation Flexibility and Cost-Savings

With compact sizes that use less floor space than ever

before, all Copper-Fin units are narrow enough to fit

through a standard 36” doorway – an ad van tage most

commercial boilers can’t provide. Plus, thanks to special

insulating materials, Copper-Fin units require only 3”

clearance from combustible walls. What’s more, our

Stack Frame allows you to install two units in the area

normally required for one. This makes it easier to fit

Copper-Fin

multiple Copper-Fin boilers into cramped me chan i cal rooms. And you can even use a smaller diameter vent stack - up to 8” smaller

than typically required for comparable atmospheric boilers - so it saves money as well as valuable mechanical room space.

Unique Copper-Fin Heat Ex chang er

The Lochinvar Copper-Fin boiler design uses a two pass heat ex chang er. Water is circulated through a row of

high ly-efficient, finned copper tubes. The high rate of water flow creates a scour ing action that prevents sed i-

ment and lime-scale buildup, common in conventional boilers, and the finned copper tubes allow maximum

heat transfer efficiency.To create this special heat transfer capability, Lochinvar extrudes the fins from

thick wall copper tubing to precise specifications - ex act ly 7 fins per inch. The result is an integrally-

finned tube with a heat transfer ratio 9 times greater than a plain copper tube.

Heavy-Duty Gasketless Design

What’s more, advanced casting processes allowed Lochinvar to develop a unique one-piece

header system. This gasketless design provides enhanced reliability, improved durability and

optimum performance - without the problems or failures common with O-rings and gaskets.

Meets the Toughest Air Quality Standards

Because of our unique fan-assisted combustion process, the Copper-Fin exceeds today’s toughest NOx emissions requirements. An

independent certification laboratory test gave us a rating of less than 20 ppm - corrected to 3% O2. And less NOx means a cleaner

environment.

Enhanced to Provide Performance and Serviceability

Our enhanced Copper-Fin models offer the same reliable operation, and feature a more service friendly

design. The down stream test valves and referenced gas valves are now in the upper deck for easier

access, and the electrical and BMS connections have been repositioned to the front of the unit for easier

installation.

The gas valves, which are referenced to the sealed combustion chamber, improve operational performance

by monitoring the pressure in the sealed combustion chamber and adjusting gas flow to maintain the

optimum air/fuel mixture. And the built-in air inlet filter reduces maintenance and improves performance

by trapping dust and airborne particulates that can foul the burners and blowers.

With dual sight glasses (one on each end), you can easily monitor burner performance and flame

characteristics throughout the entire combustion chamber.

The operator interface panel provides two-stage electronic temperature control and comprehensive

diagnostic status without opening the control panel. Its user friendly design simplifies service while

providing additional diagnostic information through a series of LEDs.

11

Page 15

Copper-Fin® Boiler Dimensions & Specifications

Copper-Fin Heating Boiler Dimensions & Spec i fi ca tions

Input Heating Net

Model Max Thermal Capacity I=B=R Gas Vent Shipping

Number MBH Efficiency MBH MBH A B C D E F G Conn. Size Weight

CBN0497 495 81% 401 349 31-1/2” 45-1/4” 22-1/4” 12-1/2” 9-1/2” 22-3/4” 29-1/2” 1-1/4” 6” 440

CBN0647 645 81% 522 454 31-1/2” 56-3/4” 22-1/4” 12-1/2” 9-1/2” 28-1/2” 29-1/2” 1-1/4” 8” 510

CBN0747 745 81% 603 524 31-1/2” 64” 22-1/4” 12-1/2” 9-1/2” 32” 29-1/2” 1-1/4” 8” 550

CBN0987 985 81% 798 694 36” 48-1/4” 33-1/2” 15-3/4” 8-1/2” 8-1/2” 33-3/4” 2” 10” 845

CBN1257 1255 81% 1,017 884 36” 58-1/2” 33-1/2” 15-3/4” 9-1/2” 10-1/2” 33-3/4” 2” 12” 905

CBN1437 1435 81% 1,162 1,010 36” 68-3/4” 33-1/2” 15-3/4” 10-1/2” 10-1/2” 33-3/4” 2” 12” 1050

CBN1797 1795 81% 1,454 1,264 36” 82-1/4” 33-1/2” 15-3/4” 11” 11” 33-3/4” 2” 14” 1193

CBN2067 2065 81% 1,673 1,455 36” 92-1/2” 33-1/2” 15-3/4” 11” 11” 33-3/4” 2” 14” 1350

Notes: Change ‘N’ to ‘L’ for LP gas models. Water connections for models CB 0497-747 are 2” NPT on 6-1/2” centers.

No deration on LP models. Water connections for models CB 0987-2067 are 2-1/2” NPT on 11-1/4” centers.

Performance data based on manufacturer test results.

Copper-Fin

®

Standard Features

• 81% Thermal Efficiency

• Electronic Temperature Control

• Fan Assisted Combustion

• Sealed Combustion Chamber

• Stainless Steel Burners

• Low NOx Operation Exceeds the most

Stringent Air Quality Requirements

• ASME Copper Finned Tube

Heat Exchanger

• 160 psi Working Pressure

• Gasketless Heat Exchanger Design

• Pump Relay w/ Delay

• Down Stream Test Valve

• Referenced Gas Valves

• Loch-Heat Ceramic Tile

Combustion Chamber

• Hot Surface Ignition

• Adjustable High Limit w/ Manual Reset

• ASME Pressure Relief Valve

• Temperature & Pressure Gauge

• Flow Switch

• 24 Volt Control System

• BMS Terminal Strip

• Combustion Air Filter

• Freeze Protection

• 10 Year Limited Warranty on Heat

Exchanger (See warranty for details)

Optional Equipment

• Alarm Bell

• Contacts on any Failure & Runtime

• Contacts for Air Louvers

• Cupro-Nickel Heat Exchanger

• High & Low Gas Pressure Switch

w/ Manual Reset

• Outdoor Reset Control

• Manual Reset Low Water Cut-Off

w/ test

• Stack Frame

• MP2 Sequencer

Available Firing Systems

M9 Hot Surface Ignition with

Electronic Supervision (Standard)

M13 GE GAP/FM/CSD1

M7 California Code

Venting

• Outdoor Vent Cap

Registered under U.S. Patent # 5,989,020

12

Page 16

®

Lightweight, Flexible and

Energy Efficient

Copper-Fin gas-fired atmospheric boilers are

high-efficiency boilers that save space, save

money, are lightweight, and are simple to service

and install. Copper-Fin boilers are equipped with

a built-in draft hood, a highly efficient copper

finned tube heat exchanger, our own specially

designed two-stage electronic control system, and

they are approved for installation on combustible

floors. Models are available with inputs from

315,000 to 500,000 Btu/hr.

Two-Stage Control System

The boiler’s two-stage electronic temperature control provides flexibility and saves fuel by

Copper-Fin

closely matching heat output to system demand. On colder days the boiler fires at full output, and

in warmer conditions the boiler reduces heat output to save energy and reduce boiler cycling.

82

%

standard equipment on all Copper-Fin boilers, provides dramatic fuel savings by reducing the firing rate 50%. And the

two-stage firing control is ideal for applications utilizing indoor/outdoor reset.* *I/O reset is available as an option.

During the majority of the heating season, less than full boiler output is required to satisfy the

heat load. For this reason, Lochinvar has developed a two-stage firing system. Two-stage firing -

Copper Finned Tube Heat Transfer

The heart of the Copper-Fin boiler is its copper finned-tube heat exchanger.

With this unique gasketless design, we’ve combined the best of both worlds:

cast iron headers for long-lasting durability, and a copper finned-tube heat

exchanger for high efficiencies and fast heat transfer. The gasketless

heat exchanger design reduces the risk of leaks or system failures that

are common with conventional boilers. Plus, the unit’s low-mass design

means that water gets heated quickly. Not only is heat up time nearly

instantaneous with these boilers, the energy consumption and operating

costs are lower too.

Intermittent Ignition Device

The Intermittent Ignition Device is a solid-state electronic spark-to-pilot ignition system that reduces fuel

consumption. It’s electronic circuitry continuously monitors the system and provides pilot gas only when there

is a call for heat, eliminating the need for a continuously burning pilot, and providing an additional measure of

operational safety.

13

Built-In Draft Hood

The lower overall height of the draft hood makes it easier to install the Copper-Fin boiler in all applications,

especially in those instances where overhead space is limited and headroom restrictions exist.

Serviceability

This boiler is as flexible and convenient to install and service as it is efficient and compact. The heavy-duty stainless

steel burners can easily be adapted for use with either natural or liquefied petroleum (LP) gas, and the boiler’s design

allows for easy access to all major components for servicing. The heat exchanger is designed to slide out the front of

the boiler for faster maintenance, and Lochinvar backs it up with an exclusive 10-year Limited Warranty. For more

information, call your Lochinvar dealer today.

Page 17

Copper-Fin® Boiler Dimensions & Specifications

Copper-Fin Boiler Dimensions & Spec i fi ca tions

Thermal Net

Model Input Efficiency Output I=B=R Gas Vent Ship.

Number MBH % MBH MBH A B C D Conn. Size Weight

CBN315 315 82.0 258 224 29-1/2” 32-1/4” 21-1/2” 16-1/4” 3/4” 8” 245

CBN360 360 82.0 295 257 29-1/2” 35-1/4” 21-1/2” 17-3/4” 1” 9” 255

CBN399 399 82.0 328 285 29-1/2” 44-1/2” 22” 22-1/4” 1” 10” 320

CBN500 500 82.0 410 357 34-1/2” 52-1/2” 22” 26-1/4” 1” 10” 345

Notes: Change ‘N’ to ‘L’ to denote L.P. gas models

No deration for L.P. models.

Water Connections are 2” NPT on 6-1/4” centers.

Performance data is based on manufacturer test results.

Copper-Fin

®

Standard Features

• 82% Thermal Efficiency

• ASME Copper Finned Tube Heat Exchanger

• Gasketless Heat Exchanger Design

• Two Stage Intermittent Electronic Ignition

• 160 PSI Working Pressure

• Pump Relay

• Two Stage Solid State Temperature Control

• Two Stage Gas Valve with Built-In

Manual Shut-Off

• Automatic Reset High Limit

• ASME Pressure Relief Valve

• Temperature & Pressure Gauge

• Diagnostic Flash Codes

• Built-In Draft Diverter

• CSA Design Certified for Alcove Installation

• CSA Design Certified for Installation

on Combustible Floor

• Stainless Steel Burners

• Loch-Heat Ceramic Tile Combustion Chamber

• 24 Volt Control System

• 10 Year Limited Warranty on Heat Exchanger

(See warranty for details)

Optional Equipment

• Adjustable High Limit

w/ Manual Reset

• Contacts on any Failure

• Contacts for Air Louvers

• Flow Switch

• Outdoor Air Reset Control

• Low Water Cut-Off

• Stack Frame

• Pump Delay/Freeze Protection

• MP2 Sequencer

• 3-Way Low Temperature Valve

Firing Controls

• M9 - Two-Stage Intermittent

Spark Ignition (Standard)

• M13 - GE GAP/FM/IRI

• M7 - California Code

14

Page 18

The Best You Can Buy Is Now Even Better!

KNIGHT is recognized for it’s reliable, proven

performance and high quality standards. Its award

winning design assures contractors and home owners

peace of mind and long term savings in operating costs.

Now, Lochinvar has raised the KNIGHT standard to

even greater heights. The dramatically enhanced SMART

SYSTEM™ control with color display gives installers

and maintenance personnel a greater level of control

than ever before. It’s easier to access all the information

they need to setup, troubleshoot and monitor all boiler

functions. Additionally, two new cascading options allow

the installer to fine-tune sequencing of multiple boiler

installations.

More than ever, KNIGHT is the best choice for

traditional hydronic space heating, radiant floor heating and domestic hot water applications.

Control

The new SMART SYSTEM™ is the most advanced integrated boiler control

on the market today.

Larger LCD Screen - Displays more information.

Soft Keys - For simple programming.

Navigation Dial - For fast transitions from screen to screen and easy

adjustment of settings.

USB Port - USB port permits connection to a laptop computer. SMART

SYSTEM PC software may be used to troubleshoot and program KNIGHT

functions, set date and time, monitor historical data, including faults, trends and

energy consumption.

Built-in Cascading Sequencer

When multiple KNIGHT boilers are installed together, the SMART SYSTEM built-in

sequencer can be set for “Lead-Lag” cascade or “Efficiency Optimized” cascade operation.

Advanced Negative Regulation Technology

KNIGHT safely and reliably operates with supply gas pressures as low as 4 inches water

column. Plus “Neg/Reg” technology automatically adjusts gas pressure to ensure the

correct volume of fuel and air entering the burner.

Direct-Spark Ignition

With each call for heat, two electrodes ignite the fuel/air mixture. A third electrode then

senses for flame. The SMART SYSTEM will generate a soft lockout and display a fault if

ignition does not occur after 3 attempts.

®

15

Fully Modulating Burner with 5:1 Turndown

The SMART SYSTEM allows fully modulating combustion with 5:1 turndown. The burner

can fire as low as 20% of maximum input and modulates the firing rate up to 100% as

demand increases. A woven stainless steel mesh enclosed burner tube fires in a 360° pattern

along the entire length of the primary heat exchanger.

Two-in-One Stainless Heat Exchanger

A primary heat exchanger combined with a secondary heat exchanger captures flue gas

heat and condenses to utilize available latent energy. The stainless steel, pH-tolerant design

features a weld-sealed assembly with no O-rings or gaskets and does not require special glycol.

ASME Section IV approved and stamped

Page 19

KNIGHT® Boiler Dimensions & Specifications

Models:

KBN 081-211

Floor-Standing

Models

Model:

KBN286

Knight Heating Boiler Dimensions and Specifications

Input Heating NET

Model Min. Max. AFUE Capacity I=B=R

Number MBH MBH % MBH MBH

WBN051 10 50 95.3 45 39

WBN081 16 80 95.3 72 63

WBN106 21 105 95.4 94 82

WBN151 30 150 95.5 135 119

WBN211 42 210 95.7 190 165

KBN081 16 80 95.3 72 63

KBN106 21 105 95.4 94 82

KBN151 30 150 95.5 135 119

KBN211 42 210 95.7 190 165

KBN286 57 285 96.0 260 226

Notes: Indoor installation only. All information subject to change. Change "N" to "L" for LP gas models.

Smart System™ Features

• SMART SYSTEM Digital Operating Control

• Multi-Colored Graphic LCD Display

with Navigation Dial and Soft Keys

• Three Setpoint Temperature Inputs

• Built-in Cascading Sequencer for up to 8 Boilers

• Lead Lag

• Efficiency Optimization

• Outdoor Reset Control with Outdoor Air Sensor

• Programmable for Three Reset Temperature Inputs

• Programmable System Efficiency Optimizers

• Night Setback

• DHW Night Setback

• Anti-Cycling

• Outdoor Air Reset Curve

• Ramp Delay

• Boost Temperature & Time

• Three Pump Control

• System Pump with Parameter for

Continuous Operation

• Boiler Pump with Variable Speed Pump Control*

• Domestic Hot Water Pump

• Domestic Hot Water Prioritization

• DHW tank piped with priority in the boiler loop

• DHW tank piped as a zone in the system with

the pumps controlled by the Smart System

• DHW Modulation Limiting

• Separately Adjustable SH/DHW Switching Times*

• Building Management System Integration

• 0-10VDC Input to Control Modulation or Set Point

• 0-10VDC Modulation Rate Output

• 0-10VDC Input Signal from Variable

Speed System Pump*

• 0-10VDC Input to Enable/Disable call for heat

A C D E F G H I J K M Gas Water Air Vent Shipping

Conn. Conn. Inlet Size Wt. (lbs.)

29-1/4" 15-3/4" NA 10-3/4" 10-3/4" 2" 6-3/4" NA 3-1/4" 4-1/4" 2-3/4" 1/2" 1" 2" 2" 130

29-1/4" 15-3/4" NA 10-3/4" 10-3/4" 2" 6-3/4" NA 3-1/4" 4-1/4" 2-3/4" 1/2" 1" 2" 2" 130

29-1/4" 15-3/4" NA 10-3/4" 10-3/4" 3-1/2" 5-1/2" NA 3-1/4" 4-1/4" 2-3/4" 1/2" 1" 2" 2" 134

29-1/4" 20-3/4" NA 15-3/4" 8-1/2" 3-1/2" 5-1/2" NA 8-3/4" 9-3/4" 1-1/2" 1/2"

29-1/4" 25" NA 20" 12" 3-1/2" 5-1/2" NA 13" 14" 1-1/2" 1/2" 1" 3" 3" 177

33-1/4" 14" 7" 5-3/4" 5" 3" 20-1/2" 22" 1-3/4" 6-1/2" NA 1/2" 1" 3" 3" 125

33-1/4" 14" 6-1/2" 5-3/4" 4-1/2" 1-1/2" 20-1/2" 22" 1-3/4" 6-1/2" NA 1/2" 1" 3" 3" 129

33-1/4" 18" 12-1/4" 11-1/2" 10

" 1-3/8" 21-1/4" 23" 1-3/4" 12" NA 1/2" 1" 3" 3" 157

33-1/4" 22-1/4" 16-1/2" 15-3/4" 14-1/4" 5-1/4" 21-1/4" 23" 1-3/4" 16-1/4" NA 1/2" 1" 3" 3" 172

42-1/4" 19-3/4" 12-3/4" 13-1/2" 6" 2" 34" 31" 11-3/4" 4-1/4" NA 3/4" 1-1/4" 4" 4" 224

• High-Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1 Phase Power Supply

• Three Sets of Pump Contacts

• Low Voltage Terminal Strip

• 24 VAC Device Relay

• Proving Switch Contacts

• Flow Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• 3 Space Heat Thermostat Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

• 0-10VDC BMS External Control Contact

• 0-10VDC Boiler Rate Output Contacts

• 0-10VDC Variable Speed System Pump Signal Input

• 0-10VDC Signal to Control Variable

Speed Boiler Pump

• Modbus Contacts

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Access to BMS Settings through Graphic LCD Display

• Maintenance Reminder

• Custom Maintenance Reminder with Contractor Info

• Installer Ability to De-activate Service Reminder

• Low-Water Flow Safety Control & Indication

• Password Security

• Customizable Freeze Protection Parameters

Wall-Mount

Models

Models:

WBN051-211

1" 3" 3" 162

Standard Features

• Energy Star™ Qualified

• Up to 96% DOE AFUE Efficiency

• Modulating Burner with 5:1 Turndown

• Direct-Spark Ignition

• Low-NOx Operation

• Field Convertible from Natural to LP Gas

• ASME Stainless Steel Heat Exchanger

• 30 psi ASME Relief Valve

• Vertical & Horizontal Direct-Vent

• PVC, CPVC or SS Venting up to 100 feet

• Factory Supplied Sidewall Vent Termination

• Smart System Control

• Condensate Trap

• Other Features

• Automatic Reset High Limit

• Adjustable High Limit w/Manual Reset

• Boiler Circulating Pump

• Adjustable Leveling Legs (KB Models only)

• Wall-Mount Bracket (WB Models only)

• Zero Clearances to Combustible Materials

• 12-Year Limited Warranty (See Warranty for Details)

Optional Equipment

• Modbus Communication

• Condensate Neutralization Kit

• Flow Switch

• Low-Water Cutoff w/Manual Reset & Test

• Alarm Bell

• Concentric Vent Kit

• SMART SYSTEM PC Software

• Stack Frame

Firing Control Systems

• M9 Standard Construction

• M7 California Code

16

Page 20

Stainless Steel Fire Tube Heat Exchanger

The KNIGHT® Wall Mount, engineered with Lochinvar’s exclusive SMART

SYSTEM™ control and an array of other innovative features is far ahead of any

heating boiler in its class. It promises and delivers ultimate ease of installation

and maintenance. With up to 99% thermal efficiency, low-NOx emissions and a

fully modulating burner, it is the best ”green choice” for today’s environmentally

focused market.

Seven modulating/condensing stainless steel KNIGHT Wall Mount boilers are

available with 55,000–399,999 Btu/hr inputs in a space-saving wall-mounted

design. All are equipped for direct-vent installation with air intake and exhaust

runs up to 100 feet using PVC, CPVC or AL29-4C vent materials. This range

of choices is ideal for residential or light-duty applications such as small hotels,

schools and office buildings. For higher-demand applications, up to eight

KNIGHT Wall Mount units can be installed utilizing the built-in cascading

sequencer to deliver up to 3.2 million Btu/hr heating capacity.

The new KNIGHT Wall Mount Boiler reflects Lochinvar’s constant commitment

to providing all the options you need to serve every application.

Advanced Negative Regulation Technology

KNIGHT safely and reliably operates with supply gas pressure as low as 4 inches water column.Negative Regulation (Neg/Reg)

technology automatically adjusts fan speed to ensure the correct volume and mix of fuel and air throughout the firing range.

Fire Tube Design

This fully welded ASME Certified stainless steel heat exchanger uses oval shaped tubes to pass

heat from the products of combustion into the water stored in the vessel. To facilitate heat transfer

the tubes are manufactured with dimples to slow the flue products and extract available latent

energy. With a fire tube design the flue products are inside tapered passage ways and the water

passed through a vessel. Since the flue products pass through tubes and the water is circulated

through a larger diameter vessel a fire tube design allows for minimal head pressure loss through

the boiler which allows the boiler to be installed easily into various hydronic applications.

Water-Backed Combustion Chamber

An outstanding feature of the fire tube design is a water backed combustion chamber. By having

the combustion chamber surrounded by water the Knight Wall Mount has more heating surface

area. This larger heating surface area allows for efficiencies up to 99%.

Fully Modulating Burner

The SMART SYSTEM allows fully modulating combustion with 5:1 turndown. The burner

can fire as low as 20% of maximum input and modulates the firing rate up to 100% as demand

increases. The burner is a single stainless steel assembly covered with woven steel mesh and fires

in a 360° pattern along the entire length of the burner. This allows the compact KNIGHT to exceed

the modulation capacities of units with larger multiple burners.

Fully Modulating Burner with 5:1 Turndown

The SMART SYSTEM allows fully modulating combustion with 5:1 turndown. The burner

can fire as low as 20% of maximum input and modulates the firing rate up to 100% as demand

increases. A woven stainless steel mesh enclosed burner tube fires in a 360° pattern along the entire

length of the primary

heat exchanger.

Direct Venting up to 100 Feet

KNIGHT offers 5 venting options and tremendous

flexibility for placement of units within the building,

because it permits direct-vent air intake and exhaust runs

up to 100 equivalent feet using either PVC, CPVC or AL29-4C

stainless steel vent pipe. A sidewall vent termination kit is standard

equipment with every KNIGHT boiler.

17

Page 21

KNIGHT® Boiler Dimensions & Specifications

Knight Heating Boiler Dimensions and Specifications

Input Heating NET

Model Max. Min. AFUE Capacity I=B=R

Number MBH MBH % MBH MBH

WHN055 55 11 96 51 44

WHN085 85 17 96 79 69

WHN110 110 22 96 102 89

WHN155 155 31 96 144 125

WHN199 199 40 96 186 162

WHN285 285 57 96 265 230

WHN399 399 80 95** 379 330

Notes: Indoor installation only. All information subject to change. Change "N" to "L" for LP gas models. **WHN399 value is Thermal Efficiency

A B C D E F G H I J K L M N O Gas Water Air Vent Shipping

Conn. Conn. Inlet Size Wt. (lbs.)

33-1/4” 18-1/2” 16” 11-3/4” 10-1/2” 6-1/2” 4” 1-1/2” 3” 14-1/2” 5-3/4” 4” 3” 16-1/4” 5” 1/2” 1” 2” 2” 139

33-1/4” 18-1/2” 16” 11-3/4” 10-1/2” 6-1/2” 4” 1-1/2” 3” 14-1/2” 5-3/4” 4” 3” 16-1/4” 5” 1/2” 1” 2” 2” 142

33-1/4” 18-1/2” 19” 14-1/2” 10-3/4” 7-3/4” 7-3/4” 2-1/4” 10” 15-1/2” 5” 3-1/4” 3” 16-1/2” 2-3/4” 1/2” 1” 3” 3” 159

33-1/4” 18-1/2” 19” 14-1/2” 10-3/4” 7-3/4” 7-3/4” 2-1/4” 10” 15-1/2” 5” 3-1/4” 3” 16-1/2” 2-3/4” 1/2” 1” 3” 3” 166

33-1/4” 18-1/2” 19” 14-1/2” 11-3/4” 8” 8” 1-1/4” 10” 16-3/4” 4-3/4” 3-1/4” 2-3/4” 16-1/2” 3” 1/2” 1-1/4” 3” 3” 175

33-1/4” 18-1/2” 19” 14-1/2” 11-3/4” 8” 8” 1-1/4” 10” 16-3/4” 4-3/4” 3-1/4” 2-3/4” 16-1/2” 3” 1/2” 1-1/4” 3” 3” 184

35-1/2” 25” 21-3/4” 17-1/2” 12-1/2” 9-1/4” 9-1/2” 2-1/4” 13-1/4” 21-1/2” 9” 4-3/4” 4” 22-1/2” 3-3/4” 3/4” 1-1/2” 4” 4” 213

Smart System™ Features

• SMART SYSTEM Digital Operating Control

• Multi-Color Graphic LCD Display

with Navigation Dial and Soft Keys

• Three Boiler Setpoint Temperature Inputs

• Plus Domestic Hot Water Prioritization

• Built-in Cascading Sequencer for

up to 8 Boilers

• Lead Lag

• Efficiency Optimization

• Outdoor Reset Control with Outdoor

Air Sensor

• Programmable for Three Reset

Temperature Inputs

• Programmable System Efficiency Optimizers

• Night Setback

• DHW Night Setback*

• Anti-Cycling

• Outdoor Air Reset Curve

• Ramp Delay

• Boost Temperature & Time

• Three Pump Control

• System Pump with Parameter for

Continuous Operation

• Boiler Pump with Variable Speed

Pump Control*

• Domestic Hot Water Pump

• Domestic Hot Water Prioritization

• DHW tank piped with priority in

the boiler loop

• DHW tank piped as a zone in the

system with the pumps controlled

by the Smart System

• DHW Modulation Limiting

• Separately Adjustable Space Heat/DHW

Switching Times*

• Building Management System Integration

• 0-10 VDC Input to Control Modulation

or Set Point

• 0-10 VDC Modulation Rate Output

• 0-10 VDC Input to Enable/Disable

call for heat

• Access to BMS Settings through Graphic

LCD Display

• High-Voltage Terminal Strip

• 120 VAC / 60 Hertz / 1 Phase Power Supply

• Three Sets of Pump Contacts

• Low Voltage Terminal Strip

• 24 VAC Device Relay

• Proving Switch Contacts

• Flow Switch Contacts

• Alarm on Any Failure Contacts

• Runtime Contacts

• DHW Thermostat Contacts

• 3 Space Heat Thermostat Contacts

• System Sensor Contacts

• DHW Tank Sensor Contacts

• Outdoor Air Sensor Contacts

• Cascade Contacts

• 0-10 VDC BMS External Control Contact

• 0-10 VDC Boiler Rate Output Contacts

• 0-10 VDC Variable Speed System Pump

Signal Input*

• 0-10 VDC Signal to Control Variable

Speed Boiler Pump*

• Modbus Contacts

• Time Clock

• Data Logging

• Hours Running, Space Heating

• Hours Running, Domestic Hot Water

• Ignition Attempts

• Last 10 Lockouts

• Maintenance Reminder

• Custom Maintenance Reminder with