Page 1

LTV VALVE APPLICATION INSTRUCTIONS FOR

LOW TEMPERATURE PROTECTION

COPPER-FIN AND POWER-FIN MODELS

CB 495 - 2066 / CH 401 - 2071 AND PB 501 - 2000

INS7238 Rev C

Kit components:

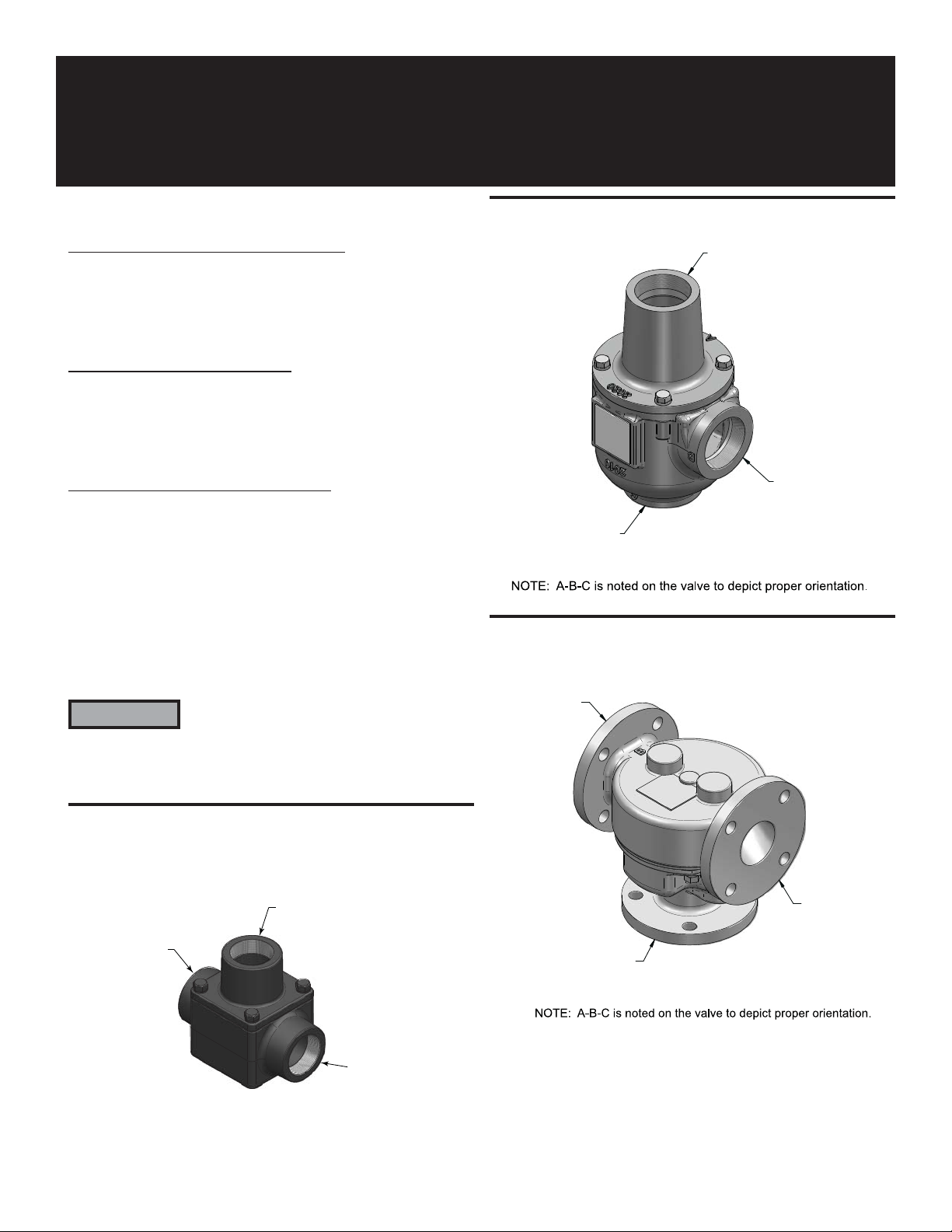

VAL30000 - 1 1/2" VALVE

Models: CB 45 - 500

• VAL20000 1 1/2" LTV Valve

• INS7238 Instruction Sheet

VAL3048 - 2" VALVE

Models: CB 495 - 745 and CH 401 - 751

• VAL2123 2" LTV Valve

• INS7238 Instruction Sheet

VAL3047 - 2 1/2" VALVE

Models: CB 986 - 2066, CH 991 - 2071, and PB 501 - 2000

• VAL2124 2 1/2" LTV Valve

• BLT2118 Bolt (12)

• BLT2119 Nut (12)

• BLT2026 Flat Washer (24)

• BLT2120 Star Washer (12)

• GKT2055 Gasket (3)

• TFL2092 Flange (3)

• INS7238 Instruction Sheet

CAUTION

Pump and motor unit are designed to be

supported by the inline piping only. Do not

support in any other manner. When placing

pump between flanges, tighten flange bolts

evenly and do not tighten excessively.

Figure 2_ 2" Valve

Figure 3_ 2 1/2" Valve

Figure 1_ 1 1/2" Valve

C = SYSTEM

RETURN

WATER

B = FROM BOILER

OUTLET

A = BLENDED

WATER

B = FROM

BOILER

OUTLET

A = BLENDED

WATER

C = SYSTEM

RETURN

WATER

B = FROM BOILER

OUTLET

NOTE: A-B-C is noted on the valve to depict proper orientation.

C = SYSTEM

RETURN

WATER

A = BLENDED

WATER

Page 2

2 of 8

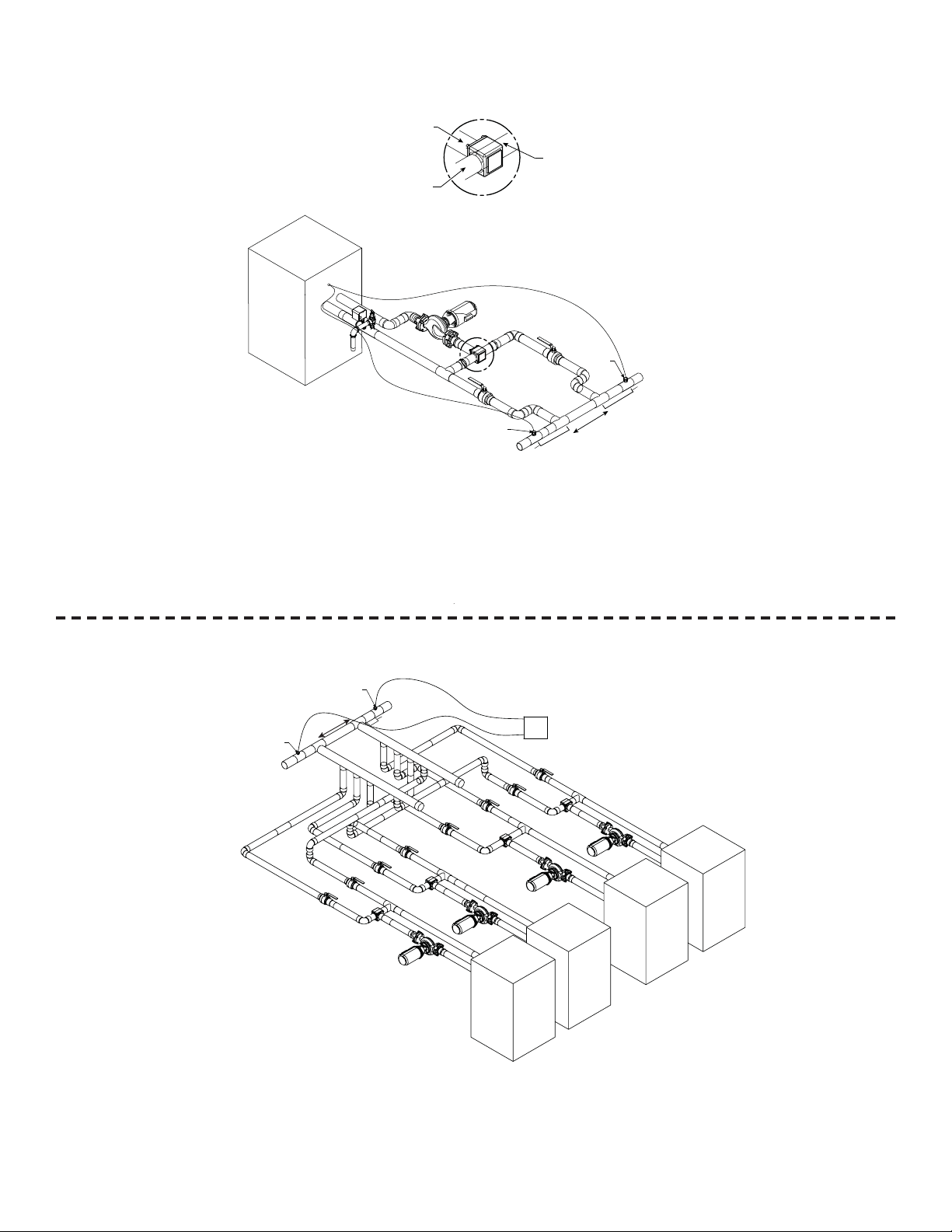

Typical piping applications:

Figure 4_Primary/Secondary Piping of a Single Boiler - 1 1/2" Valve

Figure 5_Primary /Secondary Piping of Multiple Boilers - 1 1/2" Valve for each boiler

INS7238 Rev C

A = BLENDED

WATER

C = SYSTEM

RETURN

B = FROM

BOILER

OUTLET

DETAIL

Note: Valve must be installed with proper port orientation.

Failure to observe port markings on the valve body prior to

installing the valve could result in damage to the unit.

WATER

*Best practice for Indoor/Outdoor reset.

**Best practice for set point operation.

DETAIL

*REMOTE

SENSOR

REQUIRED

MIN. 10 PIPE DIA.

**REMOTE

SENSOR

REQUIRED

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

MIN. 10 PIPE DIA.

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only.

Actual connections may vary from those represented here. Consult the

Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

REMOTE

SENSOR

REQUIRED

REMOTE

SENSOR

REQUIRED

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

MIN. 10 PIPE DIA.

REMOTE

SEQUENCER

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only.

Actual connections may vary from those represented here. Consult the

Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

Page 3

3 of 8

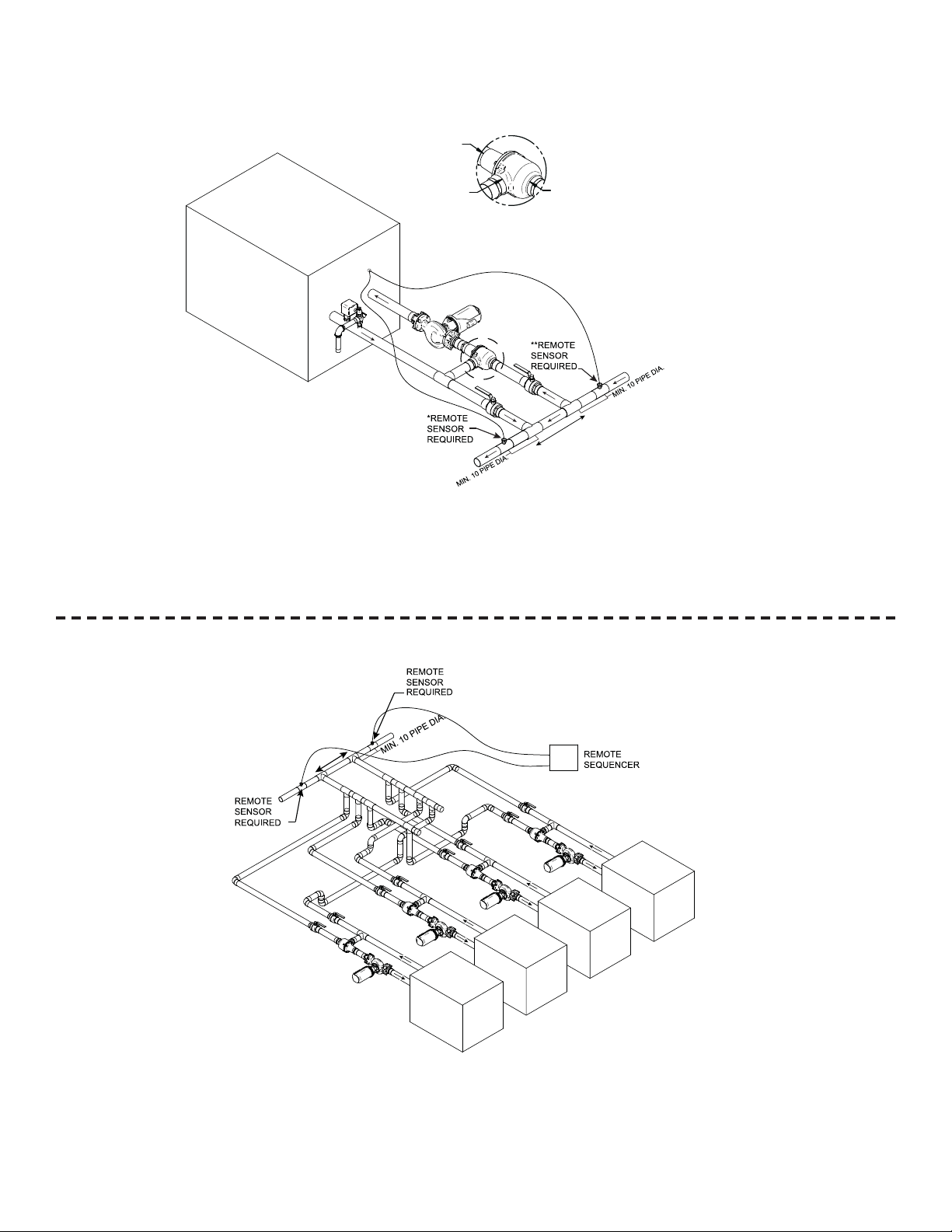

Typical piping applications (cont.):

Figure 6_Primary /Secondary Piping of a Single Boiler - 2" Valve

Figure 7_Primary/Secondary Piping of Multiple Boilers - 2" Valve for each boiler

INS7238 Rev C

A = BLENDED

WATER

C = SYSTEM

RETURN

WATER

Note: Valve must be installed with proper port orientation.

Failure to observe port markings on the valve body prior to

installing the valve could result in damage to the unit.

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

*Best practice for Indoor/Outdoor reset.

**Best practice for set point operation.

B = FROM

BOILER

OUTLET

DETAIL

DETAIL

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only. Actual connections may vary

from those represented here. Consult the Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only. Actual connections may vary

from those represented here. Consult the Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

Page 4

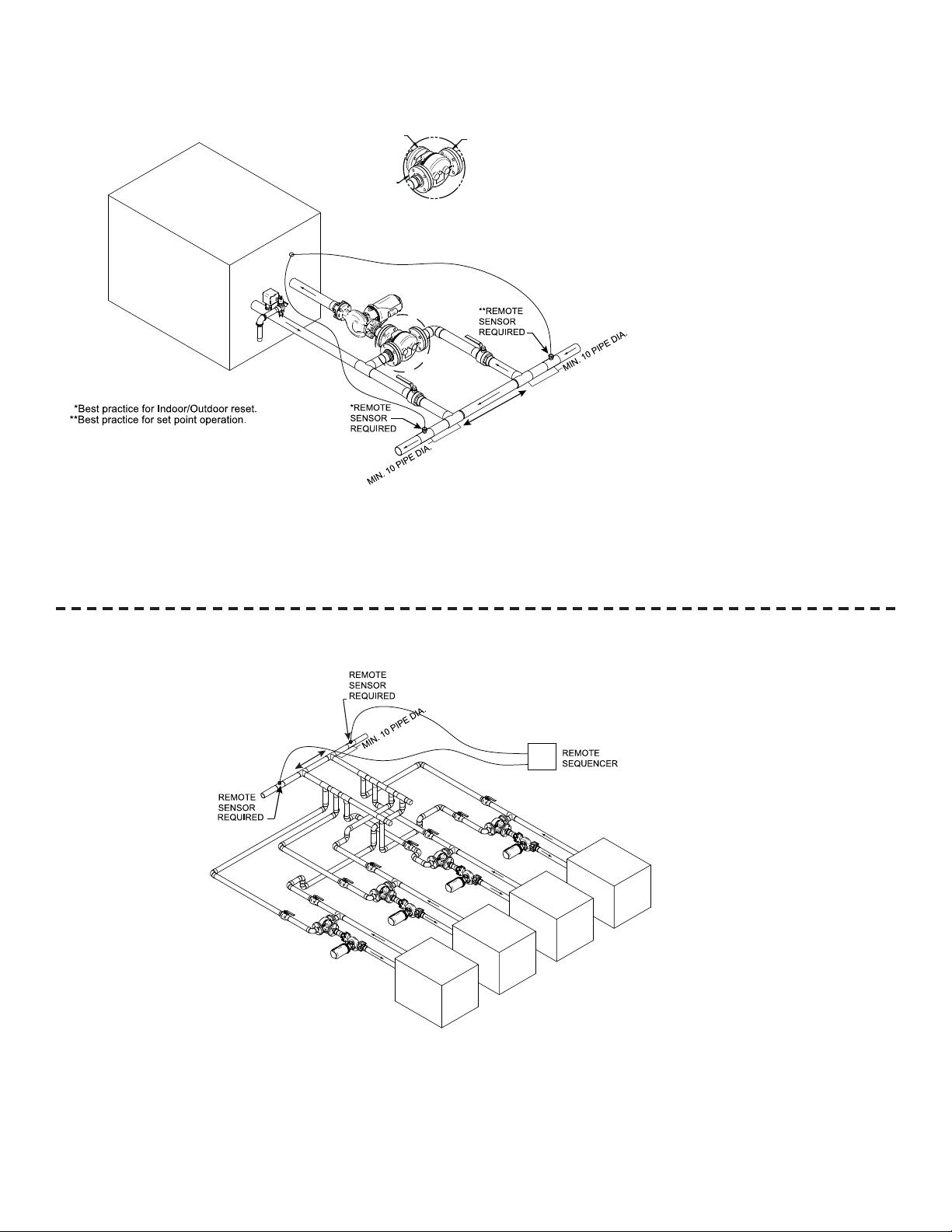

Typical piping applications (cont.):

Figure 8_Primary/Secondary Piping of a Single Boiler - 2 1/2" Valve

Figure 9_Primary/Secondary Piping of Multiple Boilers - 2 1/2" Valve for each boiler

4 of 8

INS7238 Rev C

A = BLENDED

WATER

B = FROM

BOILER

OUTLET

DETAIL

C = SYSTEM

RETURN

WATER

Note: Valve must be installed

with proper port orientation. Failure to

observe port markings on the valve

body prior to installing the valve could

result in damage to the unit.

DETAIL

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only. Actual connections may vary

from those represented here. Consult the Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

NOT TO EXCEED 4 PIPE DIA.

OR A MAX. OF 12” APART

NOTES: 1) Unit(s) high limit must be set at max.

2) Inlet and outlet connections to the boiler are shown for reference only. Actual connections may vary

from those represented here. Consult the Installation and Service Manual for actual locations.

3) Unit(s) pump should operate only during firing periods.

Page 5

Figure 11_2" LTV Valve - Up to 750,000 Btu/hr

Figure 12_2 1/2" LTV Valve - 990,000 Btu/hr and up

Figure 10_1 1/2" LTV Valve - 45,000 - 500,000 Btu/hr

5 of 8

INS7238 Rev C

A

C

5.250

B

3.750

TOP

PORT "C"

PORT "A"

PORT "B"

6.125

SIDE

Page 6

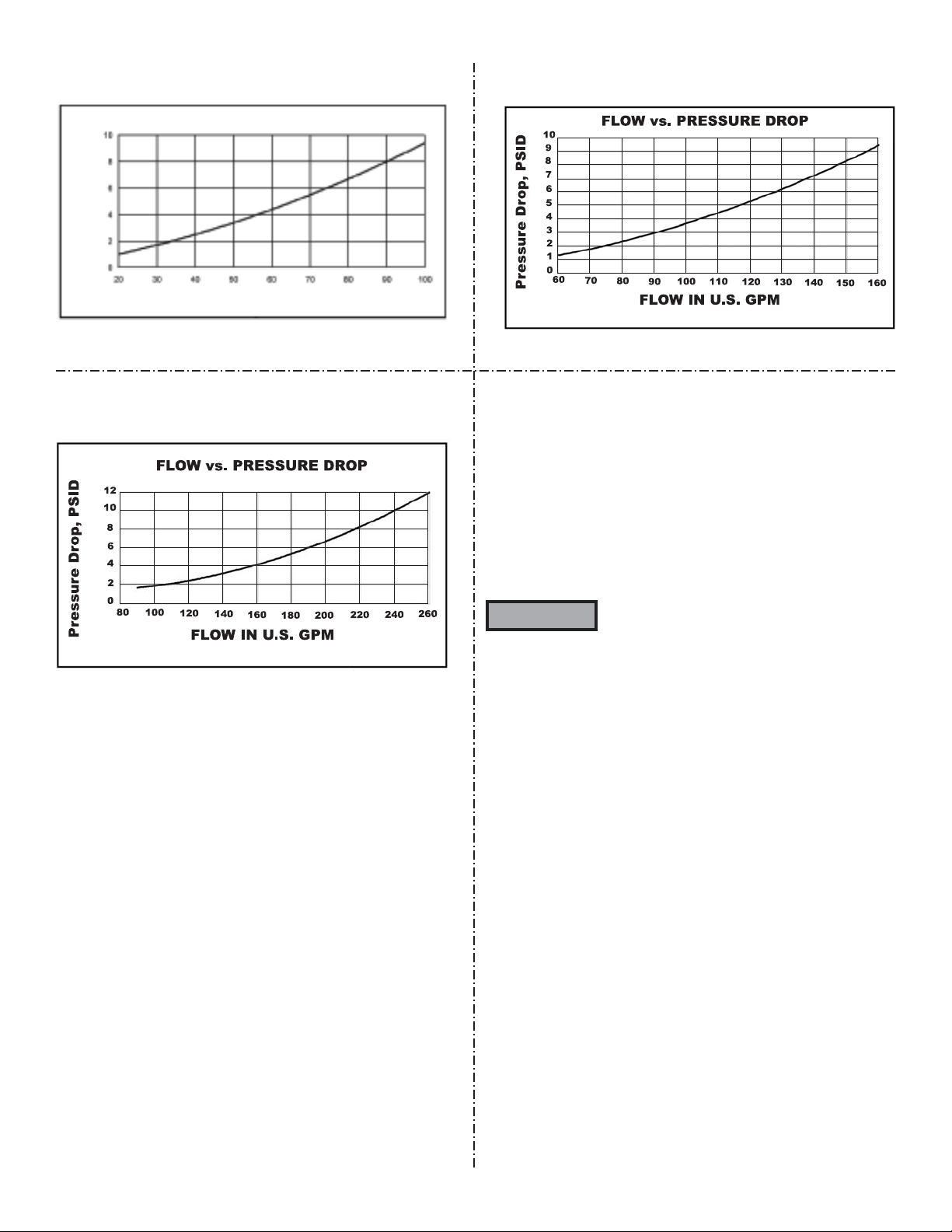

Figure 14_2" - Flow vs. Pressure Drop

Figure 15_2 1/2" - Flow vs. Pressure Drop

Figure 13_1 1/2" - Flow vs. Pressure Drop

6 of 8

INS7238 Rev C

Maintenance instructions

The LTV valve is maintenance free. It does not require regular

cleaning or calibration. In most installations, the 1-1/2" and 2"

valves are hard piped into place and do not afford access. The

2-1/2" valve has flanged connects which allows removal.

If the valve becomes unable to maintain a consistent inlet water

temperature of 125°F during steady state firing conditions, replace

the valve or the wax element inside the valve.

The recommended maximum high

temperature to the valve should be 175°F; the

absolute maximum is 195°F.

WARNING

FLOW vs. PRESSURE DROP

Pressure Drop, PSID

FLOW IN U.S. GPM

Page 7

7 of 8

INS7238 Rev C

Notes

Page 8

Revision Notes: Revision A (INS7238 Rev A)

reflects the addition of the 1 1/2" valve.

Revision B (INS7238 Rev B) reflects the

addition of the maintenance instructions.

Revision C (ECO C02335) reflects the revision

of FIG.’s. 1, 2, 3, 4, 6 & 8.

10/08 - Printed in U.S.A.

Loading...

Loading...