Lochinvar AW1000, AW1300, AW1500 Installation Manual

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property damage,

personal injury or loss of life.

-- This water heater MUST NOT be installed in

any location where gasoline or flammable vapors

are likely to be present.

-- WHAT TO DO IF YOU SMELL GAS

AWX2-I-O Rev B

Installation & Operation

Manual

Models: 1000 - 1500

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a near by

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

WARNING

Save this manual for future reference.

This manual must only be used

by a qualified heating installer

/ service technician. Read all

instructions, including this manual

and the Armor X2 Water Heater

Service Manual, before installing.

Perform steps in the order given.

Failure to comply could result in

severe personal injury, death, or

substantial property damage.

Contents

HAZARD DEFINITIONS................................................................. 2

PLEASE READ BEFORE PROCEEDING .............................. 3

THE ARMOR X2 WATER HEATER -- HOW IT WORKS 4-5

RATINGS ............................................................................................ 6

1. DETERMINE WATER HEATER LOCATION

Provide Clearances .............................................................................. 7

Provide Air Openings to Room ......................................................... 9

Flooring and Foundation................................................................... 9

Vent and Air Piping ............................................................................ 9

Prevent Combustion Air Contamination ........................................ 9

Corrosive Contaminants and Sources ............................................ 10

Using an Existing Vent System to Install a New Water

Heater .................................................................................................. 10

Removing a Water Heater from Existing Common Vent ........... 11

Combustion and Ventilation Air Requirements ..................... 12-13

2. PREPARE WATER HEATER

Remove Water Heater from Wood Pallet ...................................... 14

3. GENERAL VENTING

Direct Venting Options .................................................................... 15

Install Vent and Combustion Air Piping ....................................... 16

Requirements for Installation in Canada ....................................... 17

Sizing .................................................................................................. 17

Materials ............................................................................................... 18

Optional Room Air ............................................................................ 19

PVC/CPVC ......................................................................................... 20

Polypropylene ..................................................................................... 21

Stainless Steel Vent ............................................................................ 22

4. SIDEWALL DIRECT VENTING

Vent/Air Termination - Sidewall .............................................. 23-26

Determine Location ............................................................... 23-25

Prepare Wall Penetrations .................................................... 25-26

Multiple Vent/Air Terminations ..................................................... 26

5. VERTICAL DIRECT VENTING

Vent/Air Termination - Vertical ............................................... 27-28

Determine Location ..................................................................... 27

Prepare Roof Penetrations .......................................................... 27

Multiple Vent/Air Terminations ............................................... 28

6. SYSTEM PIPING

System Water Piping Methods ........................................................ 29

General Piping Information ............................................................. 29

Scalding ............................................................................................... 29

Water Chemistry ................................................................................ 30

Piping Components ........................................................................... 30

7. GAS CONNECTIONS

Connecting Gas Supply Piping ........................................................ 36

Natural Gas ......................................................................................... 37

Pipe Sizing for Natural Gas ........................................................ 37

Natural Gas Supply Pressure Requirements ............................ 37

Propane Gas ........................................................................................ 37

Pipe Sizing for Propane Gas ....................................................... 37

Propane Supply Pressure Requirements ................................... 37

Check Inlet Gas Supply ............................................................... 38-39

Gas Pressure ....................................................................................... 39

Gas Valve Replacement .................................................................... 39

8. FIELD WIRING

Line Voltage Connections ................................................................ 40

Low Voltage Connections ................................................................ 41

Wiring of the Cascade ....................................................................... 41

9. CONDENSATE DISPOSAL

Condensate Drain .............................................................................. 44

10. STARTUP ............................................................................ 45-49

11. OPERATING INFORMATION

General ................................................................................................ 50

Cascade ................................................................................................ 52

Sequence of Operation ...................................................................... 53

Armor X2 Water Heater Control Module ..................................... 54

Status Screen .......................................................................... 54-55

Main Menu Screen ...................................................................... 56

12. MAINTENANCE

Maintenance & Annual Startup ................................................. 57-62

13. DIAGRAMS

Ladder Diagram ........................................................................... 63-64

Wiring Diagram ................................................................................. 65

Revision Notes .................................................................... Back Cover

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or

to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

2

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

Please read before proceeding

Installation & Operation Manual

WARNING

NOTICE

Installer – Read all instructions, including

this manual and the Armor X2 Water

Heater Service Manual, before installing.

Perform steps in the order given.

Have this water heater serviced/inspected

by a qualified service technician, at least

annually.

Failure to comply with the above could

result in severe personal injury, death or

substantial property damage.

When calling or writing about the water

heater – Please have the water heater

model and serial number from the water

heater rating plate.

Consider piping and installation when

determining water heater location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with unit) does

not apply to units improperly installed or

improperly operated.

When servicing the water heater –

• To avoid electric shock, disconnect electrical supply

before performing maintenance.

• To avoid severe burns, allow the water heater to cool

before performing maintenance.

Water heater operation –

• Do not block flow of combustion or ventilation air to

the water heater.

• Should overheating occur or gas supply fail to shut off,

do not turn off or disconnect electrical supply to

circulator. Instead, shut off the gas supply at a location

external to the appliance.

• Do not use this water heater if any part has been under

water. The possible damage to a flooded appliance can

be extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

WARNING

WARNING

Failure to adhere to the guidelines on this

page can result in severe personal injury,

death, or substantial property damage.

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

-- This water heater MUST NOT be

installed in any location where gasoline or

flammable vapors are likely to be present.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a near by phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier,

call the fire department.

• Installation and service must be

performed by a qualified installer,

service agency, or the gas supplier.

3

Installation & Operation Manual

The Armor X2 Water Heater - How it works...

1. Access cover - front

Provides access to the gas train and the heat exchanger.

2. Air intake adapter

Allows for the connection of the PVC air intake pipe to the

water heater.

3. Air pressure switches

The air pressure switches detect blocked flue/vent conditions.

4. Air shrouds (1.0 Model only)

The air shrouds control air and gas flow into the burners.

5. Automatic air vents

Designed to remove trapped air from the heat exchanger

coils.

6. Blowers

The blowers pull in air and gas through the venturis (item

36). Air and gas mix inside the blowers and are pushed into the

burners, where they burn inside the combustion chamber.

7. Water heater drain port

Location from which the heat exchangers can be drained.

8. Water heater inlet temperature sensors

These sensors monitor inlet water temperature.

9. Water heater outlet temperature sensors

These sensors monitor water heater outlet water temperature.

10. Burners (not shown)

Made with metal fiber and stainless steel construction,

the burners use pre-mixed air and gas and provide a

wide range of firing rates.

11. Condensate drain connection

Connects the condensate drain line to a 1/2" PVC union.

12. Control modules

The control modules respond to internal and external signals

and control the blowers, gas valves, and pumps to meet the

heating demand.

13. Electronic display

Digital controls with touch screen technology and full color

display.

14. Flame inspection windows

The quartz glass windows provide a view of the burner

surfaces and flames.

15. Flame sensors

Used by the control module to detect the presence of burner

flame.

16. Flap valves

Prevents recirculation of flue products when only one burner is

running.

17. Flue gas sensors

These sensors monitor the flue gas exit temperature. The

control modules will modulate and shut down the water heater

if the flue gas temperature gets too hot. This protects the flue

pipe from overheating.

18. Flue pipe adapter

Allows for the connection of the PVC vent pipe system to the

water heater.

19. Gas connection pipe

Threaded 1½" pipe connection. This pipe should be

connected to the incoming gas supply for the purpose of

delivering gas to the water heater.

20. Gas shutoff valves (inside unit)

Manual valves used to isolate the gas valves from the burners.

21. Gas shutoff valve (outside unit)

Manual valve used to isolate the gas valve from the gas supply.

22. Gas valves

The gas valves sense the negative pressure created by the

blowers, allowing gas to flow only if the gas valves are

powered and combustion air is flowing.

23. Heat exchanger access covers

Allows access to the combustion side of the heat

exchanger coils.

24. High limits

Devices used to monitor the outlet water temperature. If the

temperature exceeds its setting, they will break the control

circuit, shutting the water heater down.

25. Ignition electrodes

Provides direct spark for igniting the burners.

26. Line voltage junction box

The junction box contains the connection points for the line

voltage power and all pumps.

27. Line voltage wiring connections (knockouts)

Conduit connection points for the high voltage junction box.

28. Low voltage connection board

The connection board is used to connect external low voltage

devices.

29. Low voltage wiring connections (knockouts)

Conduit connection points for the low voltage connection board.

30. Power switch

Turns 120 VAC ON/OFF to the heater.

31. Pump relay board

The pump relay board is used to control the HW pumps.

32. Relief valve

Protects the heat exchangers from an over pressure condition.

The relief valve will be set at 150 PSI and 210°F.

33. Stainless steel heat exchangers

Allows system water to flow through specially designed coils for

maximum heat transfer, while providing protection against flue

gas corrosion. The coils are encased in a jacket that contains the

combustion process.

34. Temperature and pressure gauge

Monitors the outlet temperature of the water heater as well as the

system water pressure.

35. Top panel

Removable panel to gain access to the internal components.

36. Venturis

The venturis control air and gas flow into the burners.

37. Water inlets

Two 2" NPT water connections that return water from the

system to the heat exchangers.

38. Water outlets

A 3" NPT stainless steel water connection that supplies hot water to

the system.

39. O-temp switch (located underneath access cover)

An electrical switch designed to shut down water heater operation in

the event the outer back of the heat exchanger, directly above the

flue connection does not exceed 604°F (318°C). This is a one time

switch and could warrant a heat exchanger replacement. Check

the integrity of the rear refractory at the back of the upper coil if

the switch opens.

40. Flow switch

The flow switch is a safety device that ensures flow through the

heat exchanger during operation. This appliance is low mass

and should never be operated without flow. The flow switch makes

contact when flow is detected and allows the unit to operate. If flow

is discontinued during operation for any reason the flow switch will

break the control circuit and the unit will shut down.

41. Limiting thermostat

The limiting thermostat is used to prevent the outlet water of the

heat exchangers from exceeding 190°F.

4

23

2

33

Installation & Operation Manual

The Armor X2 Water Heater - How it works... (continued)

Models 1.0 - 1.3 - 1.5

3

18

35

21

13

1

IMG00133

29

28

27

26

19

39

17

11

31

12

IMG00134

37

Front View

32

38

7

1.0 MODEL ONLY

41

34 16

8

24

9

Rear View

4

22

2

IMG00135A

14

30

40

24

36

6

20

15

25

5

Left Side (inside unit)

IMG00135

22

Right Side (inside unit)

IMG00136

5

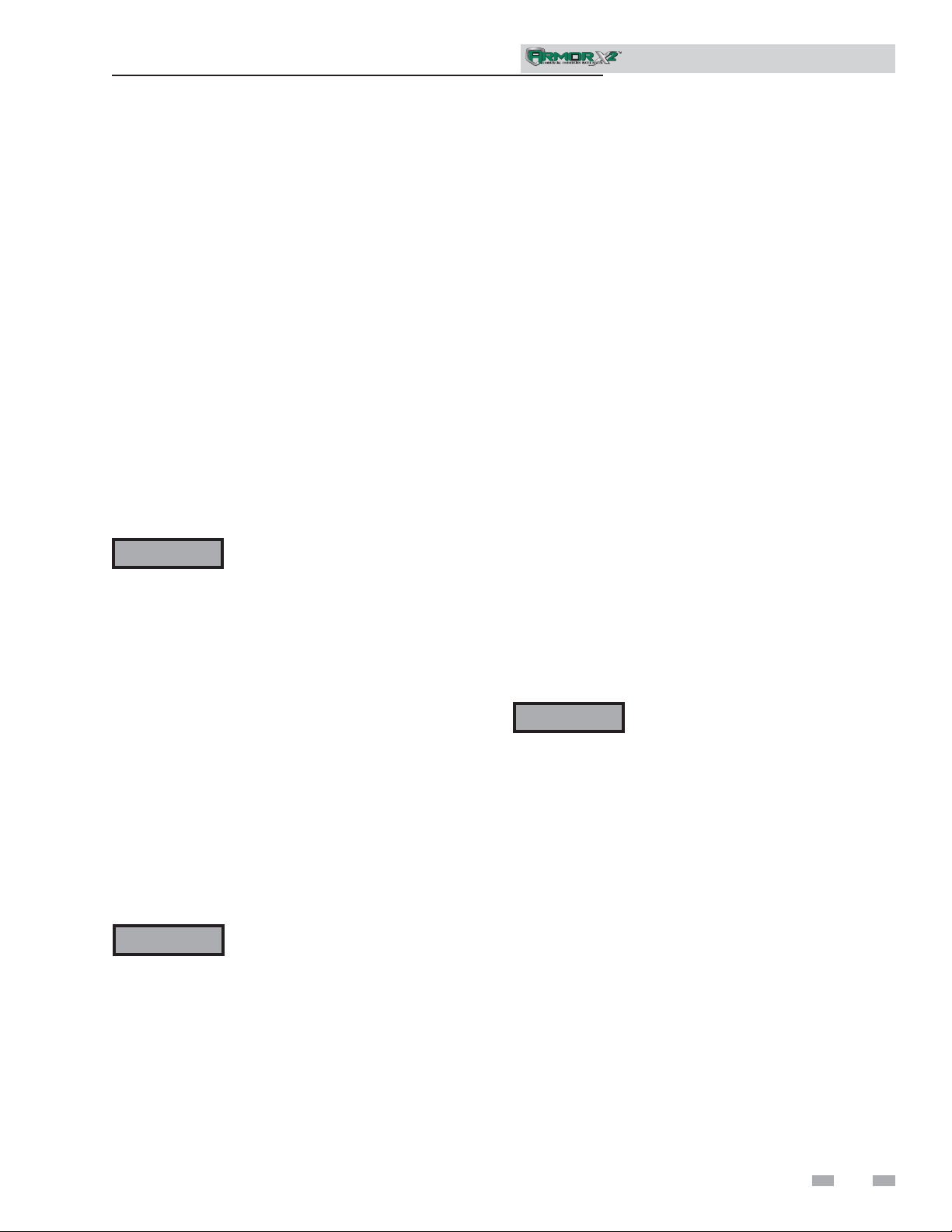

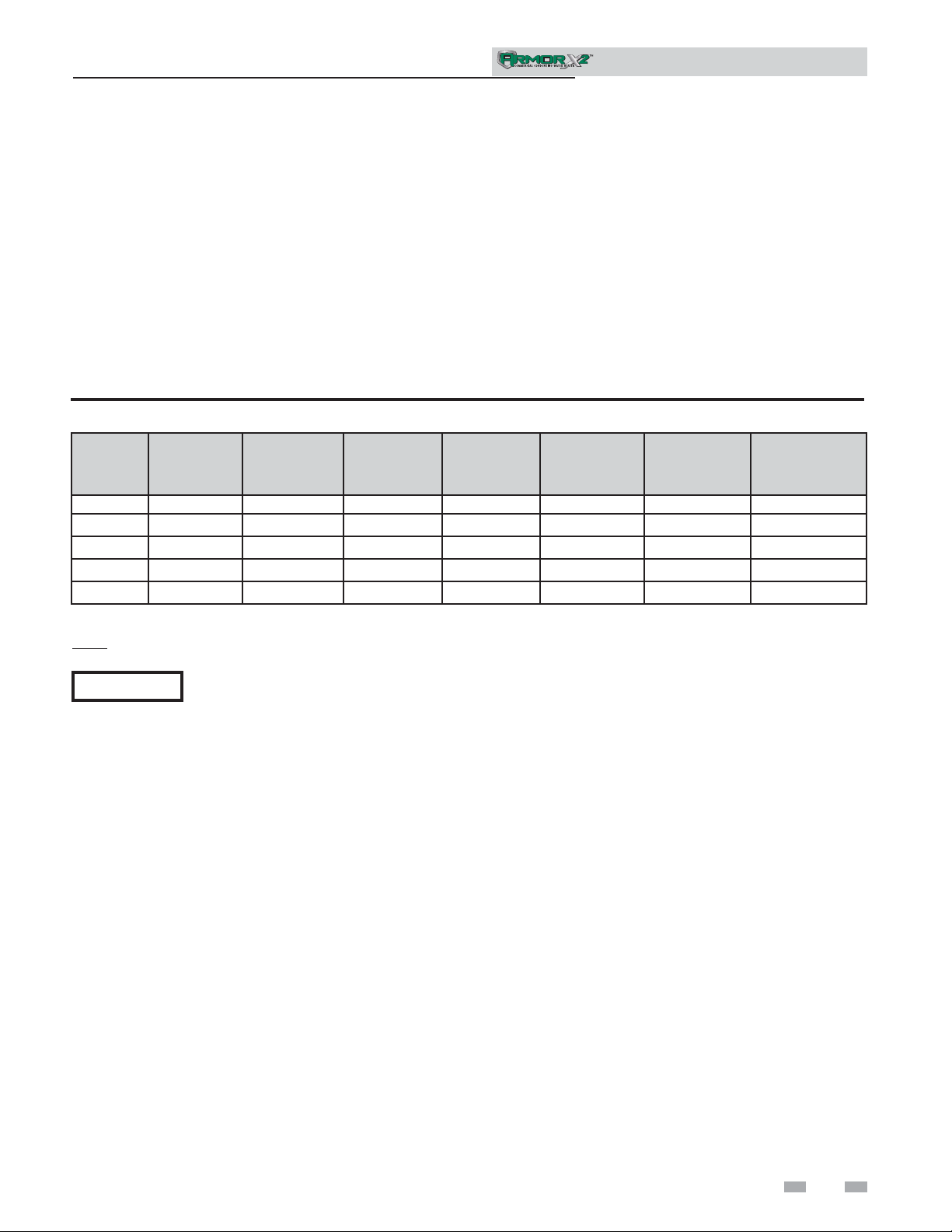

Ratings

HLW

Installation & Operation Manual

Model Number

Note: Change “N” to “L” for

L.P. gas models.

AWN1000 100,000 - 1,000,000 8.4 2" 3" 1 1/2" 6"

AWN1300 130,000 - 1,300,000 10.0 2" 3" 1 1/2" 6"

AWN1500 150,000 - 1,500,000 11.4 2" 3" 1 1/2" 6"

NOTICE

Maximum allowed working pressure is located on the rating plate.

Input Modulation Btu/hr

CSA

(Note 2, 3) (Note 1)

Notes:

1. Armor X2 water heaters require special gas venting. Use

only the vent materials and methods specified in the

Armor X2 Installation and Operation Manual.

2. Standard Armor X2 water heaters are equipped to

operate from sea level to 4,500 feet only with no

adjustments. The water heater will de-rate by 4% for

each 1,000 feet above sea level up to 4,500 feet.

3. High altitude Armor X2 water heaters are equipped to

operate from 3,000 to 12,000 feet only with no field

adjustments. The water heater will de-rate by 2% for

each 1,000 feet above 3,000 feet. High altitude models

are manufactured with a different control module for

altitude operation, but the operation given in this manual

remains the same as the standard water heaters. A high

altitude label (as shown in FIG. A) is also affixed to the

unit.

4. The manual reset high limit provided with the Armor X2

is listed to UL353.

Water

Content

Gallons

Water Connections

Gas Connections

Inlet Outlet

Figure A High Altitude Label Location

Vent/Air Size

UNIT EQUIPPED FOR

HIGH ALTITUDE

3,000 FT. TO 12,000 FT.

6

1 Determine water heater location

Installation & Operation Manual

Installation must comply with:

• Local, state, provincial, and national codes, laws, regulations,

and ordinances.

• National Fuel Gas Code, ANSI Z223.1 – latest edition.

• National Electrical Code.

• For Canada only: B149.1 Installation Code, CSA C22.1

Canadian Electrical Code Part 1 and any local codes.

NOTICE

The Armor X2 water heater gas manifold

and controls met safe lighting and other

performance under tests specified in ANSI

Z21.10.3 – latest edition.

Before locating the water heater, check:

1. Check for nearby connection to:

• Water piping

• Venting connections

• Gas supply piping

• Electrical power

2. Locate the appliance so that if water connections should

leak, water damage will not occur. When such locations

cannot be avoided, it is recommended that a suitable

drain pan, adequately drained, be installed under the

appliance. The pan must not restrict combustion air

flow. Under no circumstances is the manufacturer to be

held responsible for water damage in connection with

this appliance, or any of its components.

3. Check area around the water heater. Remove any

combustible materials, gasoline and other flammable

liquids.

WARNING

4. The Armor X2 water heater must be installed so that gas

control system components are protected from dripping or

spraying water or rain during operation or service.

5. If a new water heater will replace an existing water heater,

check for and correct system problems, such as:

• System leaks causing oxygen corrosion or heat exchanger

cracks from hard water deposits.

WARNING

Failure to keep water heater area clear and

free of combustible materials, gasoline, and

other flammable liquids and vapors can

result in severe personal injury, death, or

substantial property damage.

This appliance is certified as an indoor

appliance. Do not install the appliance

outdoors or locate where the appliance will

be exposed to freezing temperatures or to

temperatures that exceed 100°F.

Do not install the appliance where the

relative humidity may exceed 93%. Do not

install the appliance where condensation

may form on the inside or outside of the

appliance, or where condensation may fall

onto the appliance.

Failure to install the appliance indoors could

result in severe personal injury, death, or

substantial property damage.

WARNING

This appliance requires a special

venting system. Use only the vent

materials, primer and cement

specified in this manual to make the

vent connections. Failure to follow

this warning could result in fire,

personal injury, or death.

Closet and alcove installations

A closet is any room the water heater is installed in which

is less than 778 cubic feet for AW1000 models, 847 cubic

feet for AW1300 models, and 914 cubic feet for AW1500

models.

An alcove is any room which meets the criteria for a

closet with the exception that it does not have a door.

Example: Room dimensions = 9 feet long, 9 feet wide,

and 9 foot ceiling = 9 x 9 x 9 = 729 cubic feet. This would

be considered a closet for a Armor X2 water heater.

WARNING

For closet and alcove installations as

shown in FIG.’s 1-1 and 1-2, CPVC,

polypropylene, and stainless steel

vent material must be used inside the

structure. The ventilating air openings

shown in FIG.’s 1-1 and 1-2 are

required for this arrangement. Failure

to follow this warning could result in

fire, personal injury, or death.

Provide clearances:

Clearances from combustible materials

1. Hot water pipes—at least 1/4" from combustible

materials.

2. Vent pipe – at least 1" from combustible materials.

3. See FIG.’s 1-1 and 1-2 on page 8 for other clearance

minimums.

Clearances for service access

1. See FIG.’s 1-1 and 1-2 on page 8 for recommended

service clearances. If you do not provide the

minimum clearances shown, it may not be possible

to service the water heater without removing it from

the space.

7

A

A

A

A

1 Determine water heater location

Installation & Operation Manual

Figure 1-1 Closet Installation - Minimum Required Clearances

1/4” (6 MM) MINIMUM CLEARANCE

ROUND HOT WATER PIPES

1” (25 MM) MINIMUM CLEARANCE

ROUND VENT PIPES

0"

LEFT

24" (610 MM)

REAR

RECOMMENDED SERVICE

CLEARANCES:

Front - 30" (762 mm)

Top - 24" (610 mm)

Left Side - 24" (610 mm)

Rear - 24" (610 mm)

WARNING

For closet installations, CPVC,

polypropylene or stainless steel

vent material MUST BE used in

a closet structure due to elevated

temperatures. Failure to follow this

warning could result in fire, personal

injury, or death.

4" (330 MM)

TOP

VENTILATING*

AIR OPENING

CLOSED DOOR

VENTILATING*

AIR OPENING

6" (152 MM)

0"

RIGHT

6" (152 MM)

FRONT

*AREA OF EACH OPENING:

1 SQ. INCH PER 1000 BTU PER HOUR INPUT

WITH A MINIMUM OF 100 SQ. INCHES

Figure 1-2 Alcove Installation - Minimum Required Clearances

1/4” (6 MM) MINIMUM CLEARANCE

ROUND HOT WATER PIPES

1” (25 MM) MINIMUM CLEARANCE

ROUND VENT PIPES

WARNING

For alcove installations, CPVC,

polypropylene or stainless steel

vent material MUST BE used in

an alcove structure due to elevated

0"

LEFT

24" (610 MM)

REAR

RECOMMENDED SERVICE

CLEARANCES:

Front - 30" (762 mm)

Top - 24" (610 mm)

6" (152.40 MM)

FRONT

temperatures. Failure to follow

this warning could result in fire,

personal injury, or death.

13" (330 MM)

TOP

OPEN FRONT

0"

RIGHT

Left Side - 24" (610 mm)

Rear - 24" (610 mm)

8

Installation & Operation Manual

1 Determine water heater location (continued)

Provide air openings to room:

The Armor X2 alone in boiler room

1. No air ventilation openings into the boiler room are

needed when clearances around the Armor X2 are at least

equal to the SERVICE clearances shown in FIG.’s 1-1

and 1-2. For spaces that do NOT supply this clearance,

provide two openings as shown in FIG. 1-1. Each

opening must provide one square inch free area per 1,000

Btu/hr of water heater input.

2. Combustion air openings are required when using the

Room Air Option on page 19 of this manual.

The Armor X2 in same space with other gas or oilfired appliances

1. Follow the National Fuel Gas Code (U.S.) or CSA B149.1

(Canada) to size/verify size of the combustion/ventilation

air openings into the space.

WARNING

2. Size openings only on the basis of the other appliances in

the space. No additional air opening free area is needed

for the Armor X2 because it takes its combustion air from

outside (direct vent installation).

The space must be provided with

combustion/ventilation air openings

correctly sized for all other appliances

located in the same space as the Armor X2.

Do not install the water heater in an attic.

Failure to comply with the above warnings

could result in severe personal injury,

death, or substantial property damage.

Flooring and foundation

Flooring

The Armor X2 is approved for installation on combustible

flooring, but must never be installed on carpeting.

WARNING

If flooding is possible, elevate the water heater sufficiently to

prevent water from reaching the water heater.

Do not install the water heater on carpeting

even if foundation is used. Fire can result,

causing severe personal injury, death, or

substantial property damage.

Vent and air piping

The Armor X2 requires a special vent system, designed for

pressurized venting.

The water heater is to be used for either direct vent installation

or for installation using indoor combustion air. When room

air is considered, see Section 5, Vertical Direct Venting. Note

prevention of combustion air contamination below when

considering vent/air termination.

Vent and air must terminate near one another and may be

vented vertically through the roof or out a side wall, unless

otherwise specified. You may use any of the vent/air piping

methods covered in this manual. Do not attempt to install

the Armor X2 using any other means.

Be sure to locate the water heater such that the vent

and air piping can be routed through the building and

properly terminated. The vent/air piping lengths, routing

and termination method must all comply with the methods

and limits given in this manual.

Prevent combustion air contamination

Install air inlet piping for the Armor X2 as described in this

manual. Do not terminate vent/air in locations that can allow

contamination of combustion air. Refer to Table 1A, page

10 for products and areas which may cause contaminated

combustion air.

WARNING

Ensure that the combustion air will not

contain any of the contaminants in Table

1A, page 10. Contaminated combustion

air will damage the water heater, resulting

in possible severe personal injury, death

or substantial property damage. Do not

pipe combustion air near a swimming

pool, for example. Also, avoid areas

subject to exhaust fumes from laundry

facilities. These areas will always contain

contaminants.

9

1 Determine water heater location

Installation & Operation Manual

Table 1A Corrosive Contaminants and Sources

Products to avoid:

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents

found in household laundry rooms

Adhesives used to fasten building products and other similar

products

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

When using an existing vent system to

install a new water heater:

WARNING

Check the following venting components before installing:

• Material - For materials listed for use with this appliance,

see Section 3 - General Venting. For polypropylene or

stainless steel venting, an adapter of the same

manufacturer must be used at the flue collar connection.

• Size - To ensure proper pipe size is in place, see Table 3A.

Check to see that this size is used throughout the vent

system.

• Manufacturer - For a stainless steel or polypropylene

application, you must use only the listed manufacturers

and their type product listed in Tables 3E and 3F for CAT

IV positive pressure venting with flue producing

condensate.

• Supports - Non-combustible supports must be in place

allowing a minimum 1/4" rise per foot. The supports

should adequately prevent sagging and vertical slippage,

by distributing the vent system weight. For additional

information, consult the vent manufacturer’s

instructions for installation.

Failure to follow all instructions can result

in flue gas spillage and carbon monoxide

emissions, causing severe personal injury

or death.

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

• Terminations - Carefully review Sections 3 through 5 to

ensure requirements for the location of the vent and air

terminations are met and orientation of these fit the

appropriate image from the Horizontal or Vertical

options listed in the General Venting Section. For

stainless steel vent, only use terminations listed in Table

3F for the manufacturer of the installed vent.

• Seal - With prior requirements met, the system should be

tested to the procedure listed in parts (c) through (f) of

the Removal of an Existing Water Heater Section on

page 11.

With polypropylene and stainless steel vent, seal and connect

all pipe and components as specified by the vent manufacturer

used; with PVC/CPVC vent, see the Installing Vent or Air

Piping Section on page 20.

WARNING

If any of these conditions are not met,

the existing system must be updated

or replaced for that concern. Failure to

follow all instructions can result in flue gas

spillage and carbon monoxide emissions,

causing severe personal injury or death.

10

Installation & Operation Manual

1 Determine water heater location (continued)

When removing a water heater from

existing common vent system:

DANGER

Do not install the Armor X2 into a

common vent with any other appliance.

This will cause flue gas spillage or

appliance malfunction, resulting in

possible severe personal injury, death, or

substantial property damage.

WARNING

At the time of removal of an existing water heater, the

following steps shall be followed with each appliance

remaining connected to the common venting system placed

in operation, while the other appliances remaining connected

to the common venting system are not in operation.

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage

or restriction, leakage, corrosion, or other deficiencies,

which could cause an unsafe condition.

c. Test vent system – Insofar as is practical, close all building

doors and windows and all doors between the space

in which the appliances remaining connected to the

common venting system are located and other spaces of

the building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn on

any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

d. Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

e. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or pipe.

f. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined herein, return

doors, windows, exhaust fans, fireplace dampers, and any

other gas-burning appliance to their previous conditions

of use.

g. Any improper operation of the common venting system

should be corrected so the installation conforms with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CAN/CSA B149.1, Natural Gas and Propane Installation

Code. When resizing any portion of the common venting

system, the common venting system should be resized

to approach the minimum size as determined using the

appropriate tables in Part 11 of the National Fuel Gas

Code, ANSI Z223.1/NFPA and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code.

Failure to follow all instructions can result

in flue gas spillage and carbon monoxide

emissions, causing severe personal injury

or death.

11

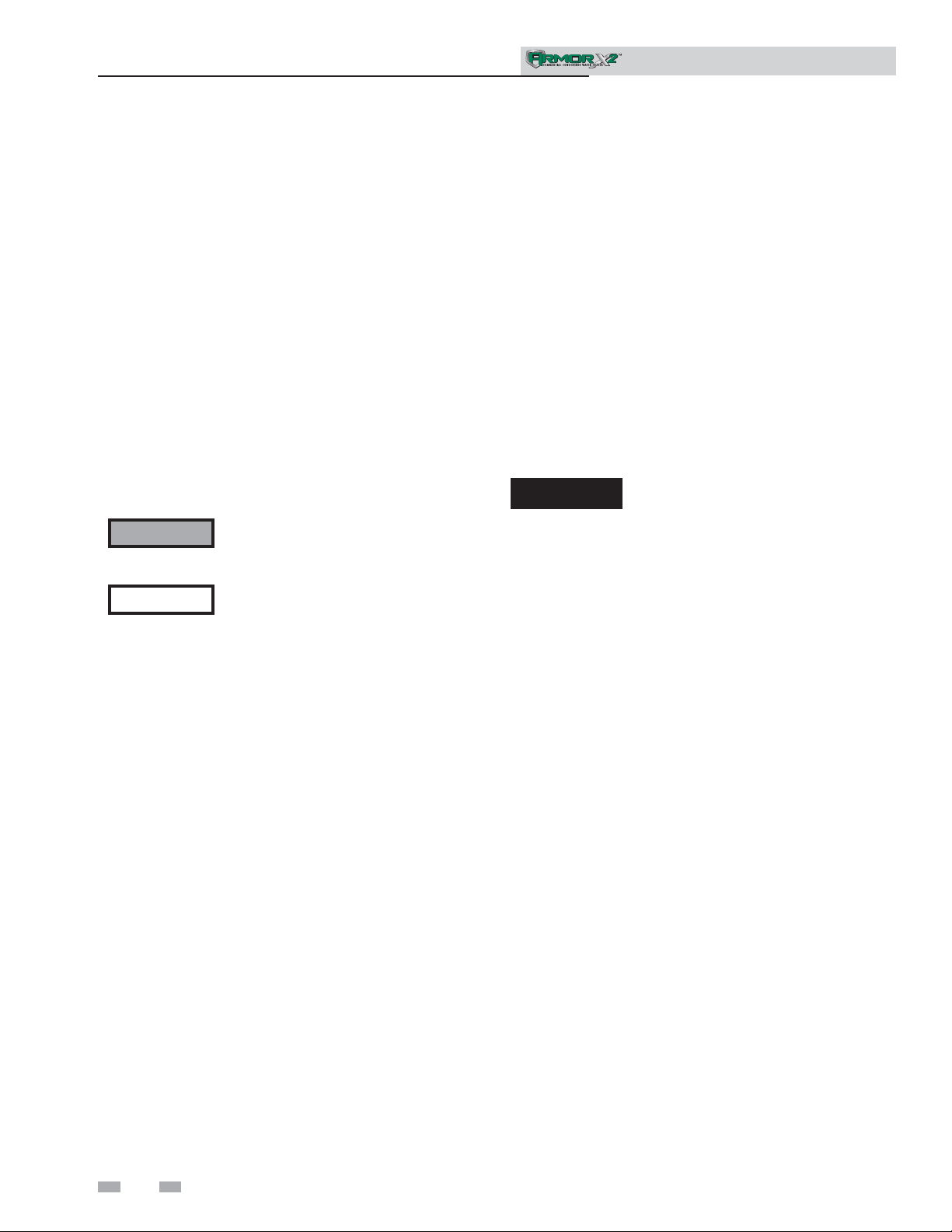

1 Determine water heater location

Combustion and ventilation air

requirements for appliances drawing air

from the equipment room

Provisions for combustion and ventilation air must be in

accordance with Air for Combustion and Ventilation, of

the latest edition of the National Fuel Gas Code, ANSI

Z223.1, in Canada, the latest edition of CGA Standard B149

Installation Code for Gas Burning Appliances and Equipment,

or applicable provisions of the local building codes.

The equipment room MUST be provided with properly sized

openings to assure adequate combustion air and proper

ventilation.

Figure 1-4_Combustion Air Through Ducts

2. If combustion and ventilation air is taken from the

outdoors using a duct to deliver the air to the equipment

room, each of the two openings should be sized based on a

minimum free area of one square inch per 2000 Btu/hr

(11 cm2 per kW) of input (see FIG. 1-4).

Installation & Operation Manual

Figure 1-3_Combustion Air Direct from Outside

1. If air is taken directly from outside the building

with no duct, provide two permanent openings to

the equipment room (see FIG. 1-3):

(a) Combustion air opening, with a minimum free

area of one square inch per 4000 Btu/hr input

2

(5.5 cm

per kW). This opening must be located

within 12" (30 cm) of the bottom of the enclosure.

(b) Ventilation air opening, with a minimum free

area of one square inch per 4000 Btu/hr input

(5.5 cm

2

per kW). This opening must be located

within 12" (30 cm) of the top of the enclosure.

IF NECESSARY

FOR TIGHT

CONSTRUCTION

Figure 1-5_Combustion Air from Interior Space

3. If air is taken from another interior space, each of the

two openings specified above should have a net free

area of one square inch for each 1000 Btu/hr (22 cm2

per kW) of input, but not less than 100 square inches

(645 cm2) (see FIG. 1-5).

12

1 Determine water heater location (continued)

Where two openings are provided, one must be within 12"

(30cm) of the ceiling and one must be within 12" (30cm) of the

floor of the equipment room. Each opening must have net free

area as specified in the chart below (Table 1B). Single openings

shall commence within 12" (30cm) of the ceiling.

Under no circumstances should the

equipment room ever be under negative

pressure. Particular care should be taken

where exhaust fans, attic fans, clothes dryers,

compressors, air handling units, etc., may

take away air from the unit.

Figure 1-6_Combustion Air from Outside - Single

Opening

4. If a single combustion air opening is provided to bring

combustion air in directly from the outdoors, the opening

must be sized based on a minimum free area of one

square inch per 3000 Btu/hr (7 cm2 per kW). This

opening must be located within 12" (30 cm) of the top of

the enclosure (see FIG. 1-6).

Combustion air requirements are based on the latest edition

of the National Fuel Gas Code, ANSI Z223.1; in Canada refer

to the latest edition of CGA Standard CAN B149.1. Check all

local code requirements for combustion air.

All dimensions based on net free area in square inches. Metal

louvers or screens reduce the free area of a combustion air

opening a minimum of approximately 25%. Check with

louver manufacturers for exact net free area of louvers.

CAUTION

The combustion air supply must be completely free of any

flammable vapors that may ignite or chemical fumes which may

be corrosive to the appliance. Common corrosive chemical

fumes which must be avoided are fluorocarbons and other

halogenated compounds, most commonly present as refrigerants

or solvents, such as Freon, trichlorethylene, perchlorethylene,

chlorine, etc. These chemicals, when burned, form acids which

quickly attack the stainless steel heat exchanger, headers, flue

collectors, and the vent system.

The result is improper combustion and a non-warrantable,

premature appliance failure.

EXHAUST FANS: Any fan or equipment which exhausts air

from the equipment room may deplete the combustion air

supply and/or cause a downdraft in the venting system. Spillage

of flue products from the venting system into an occupied

living space can cause a very hazardous condition that must be

corrected immediately.

Installation & Operation Manual

TABLE - 1B

MINIMUM RECOMMENDED COMBUSTION

AIR SUPPLY TO EQUIPMENT ROOM

FIG. 1-3 FIG. 1-4 FIG. 1-5 FIG. 1-6

Model

Number

1000

1300

1500

*Outside Air from

2 Openings Directly from

Outdoors

Top

Opening, in

250

(1613 cm2)

325

(2097 cm2)

375

(2420 cm2)

Bottom

2

Opening, in

250

(1613 cm2)

325

(2097 cm2)

375

(2420 cm2)

2

*Outside Air from

2 Ducts Delivered from

Outdoors

Top

Opening, in

2

Opening, in

Bottom

500

(3226 cm2)

(3226 cm2)

650

(4194 cm2)

(4194 cm2)

750

(4839 cm2)

(4839 cm2)

500

650

750

**Inside Air from

2 Ducts Delivered from

Interior Space

Top

2

Opening, in

2

1000

(6452 cm2)

1300

(8388 cm2)

1500

(9678 cm2)

Bottom

Opening, in

1000

(6452 cm2)

1300

(8388 cm2)

1500

(9678 cm2)

*Outside Air from

1 Opening Directly

from Outdoors, in

2

333

(2149 cm2)

433

(2794 cm2)

500

(3226 cm2)

2

*Outside air openings shall directly communicate with the outdoors. When combustion air is drawn from the outside through a

duct, the net free area of each of the two openings must have twice (2 times) the free area required for Outside Air/2 Openings.

The above requirements are for the appliance only; additional gas fired appliances in the equipment room will require an increase

in the net free area to supply adequate combustion air for all appliances.

**Combined interior space must be 50 cubic feet per 1,000 Btu/hr input. Buildings MUST NOT be of *“Tight Construction”.

For buildings of *“Tight Construction”, provide air openings into the building from outside.

*No combustion air openings are needed when the appliance is installed in a space with a volume NO LESS than 50 cubic feet per

1,000 Btu/hr of all installed gas fired appliances. Buildings MUST NOT be of *“Tight Construction”.

*”Tight Construction” is defined as a building with less than 0.40 ACH (air changes per hour).

13

2 Prepare water heater

T

Remove water heater from wood pallet

1. After removing the outer shipping carton from the water

heater, remove the parts package (packaged parts inside the

jacket of the water heater).

2. To remove the water heater from the pallet:

a. Remove the front door of the water heater.

b. Remove the two lag bolts from the wood pallet

inside the water heater (FIG. 2-1).

c. Detach the water heater from the lag bolts in the rear of

the unit, see FIG. 2-1.

NOTICE

Figure 2-1 Water heater Mounted on Shipping Pallet

Do not drop the water heater or bump the

jacket on the floor or pallet. Damage to the

water heater can result.

Installation & Operation Manual

LAG BOLTS

(QTY. 3)

REAR

LAG BOLTS

(QTY. 3)

FRON

Maintain minimum specified clearances for adequate operation.

All installations must allow sufficient space for servicing the

vent connections, water pipe connections, piping and other

auxiliary equipment, as well as the appliance. The clearance

labels on each appliance note the same service and combustible

clearance requirements as shown in this manual.

Multiple appliances may be installed in a modular water heater

installation. Multiple appliances may be installed side by side

with no clearance between adjacent appliances because this

appliance is approved for zero clearance from combustible

surfaces and no service access is required from the sides.

Consult the Venting section of this manual for specific

installation instructions for the appropriate type of venting

system that you will be using.

14

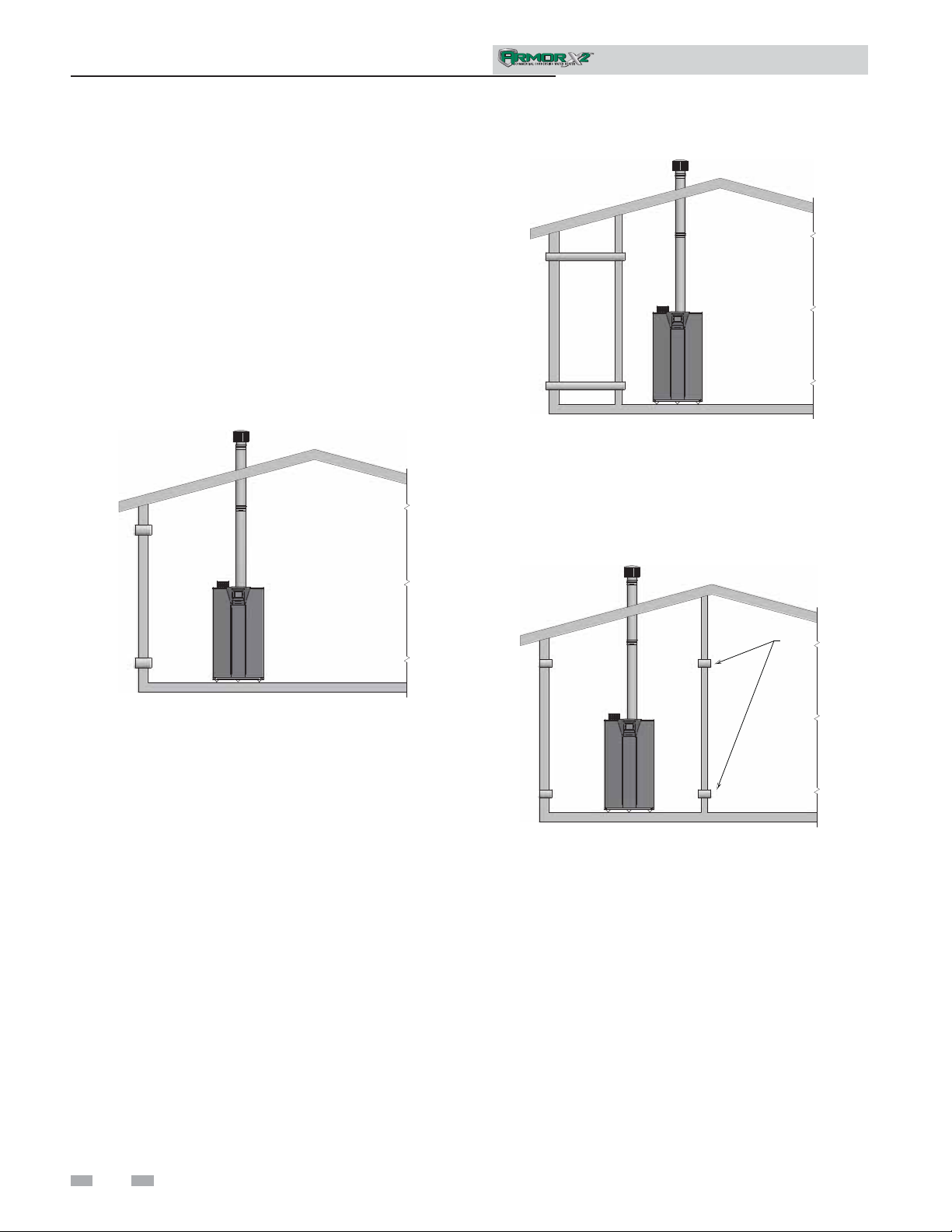

3 General venting

Direct venting options - Sidewall Vent

Installation & Operation Manual

Figure 3-1 Two-Pipe Sidewall Termination - See page

23 for more details

Direct venting options - Vertical Vent

Figure 3-2 Two-Pipe Vertical Termination - See

page 27 for more details

Figure 3-3 Vertical Vent, Sidewall

Air - See page 19 for more details

15

3 General venting

Install vent and combustion air piping

Installation & Operation Manual

DANGER

WARNING

WARNING

NOTICE

WARNING

The Armor X2 water heater must be

vented and supplied with combustion and

ventilation air as described in this section.

Ensure the vent and air piping and the

combustion air supply comply with these

instructions regarding vent system, air

system, and combustion air quality. See

also Section 1 of this manual.

Inspect finished vent and air piping

thoroughly to ensure all are airtight and

comply with the instructions provided and

with all requirements of applicable codes.

Failure to provide a properly installed vent

and air system will cause severe personal

injury or death.

This appliance requires a special venting

system. Use only approved stainless steel,

PVC, CPVC or polypropylene pipe and

fittings listed in Tables 3C, 3E, and 3F for

vent pipe, and fittings. Failure to comply

could result in severe personal injury,

death, or substantial property damage.

DO NOT mix components from different

systems. The vent system could fail,

causing leakage of flue products into the

living space. Mixing of venting materials

will void the warranty and certification of

the appliance.

Installation must comply with local

requirements and with the National

Fuel Gas Code, ANSI Z223.1 for U.S.

installations or CSA B149.1 for Canadian

installations.

For closet and alcove installations, CPVC,

polypropylene or stainless steel material

MUST BE used in a closet/alcove structure.

Failure to follow this warning could result

in fire, personal injury, or death.

The Armor X2 water heater vent and air piping can be installed

through the roof or through a sidewall. Follow the procedures

in this manual for the method chosen. Refer to the information

in this manual to determine acceptable vent and air piping

length.

You may use any of the vent/air piping methods covered in this

manual. Do not attempt to install the Armor X2 water heater

using any other means.

You must also install air piping from outside to the water

heater air intake adapter unless following the Optional Room

Air instructions on page 19 of this manual. The resultant

installation is direct vent (sealed combustion).

Air intake/vent connections

1. Combustion Air Intake Connector (FIG. 3-4) - Used to

provide combustion air directly to the unit from outdoors. A

fitting is provided with the unit for final connection.

Combustion air piping must be supported per guidelines

listed in the National Mechanical Code, Section 305, Table

305.4 or as local codes dictate.

2. Vent Connector (FIG.'s 3-5 thru 3-8) - Used to provide a

passageway for conveying combustion gases to the

outside. A transition fitting is provided on the unit for

final connection. Vent piping must be supported per the

National Building Code, Section 305, Table 305.4 or as

local codes dictate.

Figure 3-4 Near Water Heater Air Piping

AIR

CAUTION

NOTICE

WARNING

16

Improper installation of venting systems

may result in injury or death.

Follow the instructions in Section 1, page

11 of this manual when removing a water

heater from an existing vent system.

Do not connect any other appliance to

the vent pipe or multiple water heaters to

a common vent pipe. Failure to comply

could result in severe personal injury,

death, or substantial property damage.

3 General venting (continued)

Installation & Operation Manual

Requirements for installation in

Canada

1. Installations must be made with a vent pipe system

certified to ULC-S636.

2. The first three (3) feet of plastic vent pipe from the

appliance flue outlet must be readily accessible for visual

inspection.

3. The components of the certified vent system must not be

interchanged with other vent systems or unlisted

pipe/fittings.

Table 3A Air Intake/Vent Piping Sizes

Model

AW 1000 6" 12' 100' 6" 12' 100' 1.25%*

AW 1300 6" 12' 50' 6" 12' 50' 2.90%

AW 1300 7" 12' 100' 7" 12' 100' 0.95%

AW 1500 6" 12' 50' 6" 12' 50' 3.30%

AW 1500 7" 12' 100' 7" 12' 100' 1.65%

*LP models will derate by 1.5% per 25 feet of vent pipe.

Note: When using a 7" vent or air pipe, a field supplied increaser is required.

Air Intake

Diameter

Air Intake

Min. Length

Air Intake

Max. Length

Sizing

The Armor X2 water heater uses model specific combustion

air intake and vent piping sizes as detailed in Table 3A below.

When determining equivalent combustion air and vent

length, add 5 feet for each 90° elbow and 3 feet for each 45°

elbow.

EXAMPLE: 20 feet of PVC pipe + (4) 90° elbows + (2) 45°

elbows + (1) concentric vent kit (CVK3003) = 49 equivalent

feet of piping.

Vent

Diameter

Vent

Min. Length

Vent

Max. Length

De-Rate per

25 feet of Vent

Input

NOTICE

Increasing or decreasing combustion air or vent piping sizes is not authorized.

17

3 General venting

Materials

Air inlet pipe materials:

The air inlet pipe(s) must be sealed. Choose acceptable

combustion air inlet pipe materials from the following list:

PVC, CPVC, Polypropylene or ABS

Dryer Vent or Sealed Flexible Duct (not recommended

for rooftop air inlet)

Galvanized steel vent pipe with joints and seams sealed as

specified in this section.

Type “B” double-wall vent with joints and seams sealed as

specified in this section.

AL29-4C, stainless steel material to be sealed to

specification of its manufacturer.

*Plastic pipe may require an adapter (not provided) to

transition between the air inlet connection on the appliance

and the plastic air inlet pipe.

WARNING

NOTICE

Using air intake materials other than

those specified can result in personal

injury, death or property damage.

The use of double-wall vent or insulated

material for the combustion air inlet pipe is

recommended in cold climates to prevent

the condensation of airborne moisture in

the incoming combustion air.

Installation & Operation Manual

The PVC, CPVC, or ABS air inlet pipe should be cleaned and

sealed with the pipe manufacturer’s recommended solvents

and standard commercial pipe cement for the material used.

The PVC, CPVC, ABS, Dryer Vent or Flex Duct air inlet pipe

should use a silicone sealant to ensure a proper seal at the

appliance connection and the air inlet cap connection. Dryer

vent or flex duct should use a screw type clamp to seal the vent

to the appliance air inlet and the air inlet cap. Proper sealing

of the air inlet pipe ensures that combustion air will be free of

contaminants and supplied in proper volume.

When a sidewall or vertical rooftop combustion air supply

system is disconnected for any reason, the air inlet pipe must

be resealed to ensure that combustion air will be free of

contaminants and supplied in proper volume.

DANGER

Failure to properly seal all joints and seams

as required in the air inlet piping may

result in flue gas recirculation, spillage

of flue products and carbon monoxide

emissions causing severe personal injury

or death.

Sealing of Type “B” double-wall vent material or galvanized

vent pipe material used for air inlet piping on a sidewall or

vertical rooftop Combustion Air Supply System:

a. Seal all joints and seams of the air inlet pipe using either

Aluminum Foil Duct Tape meeting UL Standard 723 or

181A-P or a high quality UL Listed silicone sealant such as

those manufactured by Dow Corning or General Electric.

b. Do not install seams of vent pipe on the bottom of

horizontal runs.

c. Secure all joints with a minimum of three (3) sheet metal

screws or pop rivets. Apply Aluminum Foil Duct Tape or

silicone sealant to all screws or rivets installed in the vent

pipe.

d. Ensure that the air inlet pipes are properly supported.

18

3 General venting (continued)

Optional room air

Applications utilizing the Armor X2 water heater may be

installed with a single pipe carrying the flue products to the

outside while using combustion air from the equipment

room. In order to use the room air venting option the

following conditions and considerations must be followed.

• The unit MUST be installed with the appropriate

room air kit (Table 3B).

• The equipment room MUST be provided with

properly sized openings to assure adequate

combustion air. Please refer to instructions provided

with the room air kit.

• There will be a noticeable increase in the noise level

during normal operation from the inlet air opening.

• Using the room air kit makes the unit vulnerable to

combustion air contamination from within the

building. Please review Section 1, Prevent

Combustion Air Contamination, to ensure proper

installation.

• Vent system and terminations must comply with the

standard venting instructions set forth in this

manual.

WARNING

Figure 3-5 Room Air Installation

When utilizing the single pipe method,

provisions for combustion and ventilation

air must be in accordance with Air for

Combustion and Ventilation, of the latest

edition of the National Fuel Gas Code,

ANSI Z223.1, in Canada, the latest edition

of CGA Standard B149 Installation

Code for Gas Burning Appliances and

Equipment, or applicable provisions of

the local building codes.

NOTICE

FOR DIRECT VENT SYSTEMS

REMOVE AIR INLET COVER AND

INSTALL RUBBER COUPLING FOR

PVC / CPVC VENT SYSTEMS OR

STAINLESS STEEL ADAPTER FOR

STAINLESS STEEL VENT SYSTEMS

Installation & Operation Manual

Table 3B Room Air Minimum / Maximum Allowable Air /

Vent Lengths

Model

AW 1000 6" 12’ 100’ 0.63%*

AW 1300 6" 12’ 100’ 1.45%

AW 1500 6" 12’ 100’ 1.65%

*LP models will derate by .9% per 25 feet of vent pipe.

Air contamination

Pool and laundry products and common household and hobby

products often contain fluorine or chlorine compounds. When

these chemicals pass through the water heater, they can form

strong acids. The acid can eat through the water heater wall,

causing serious damage and presenting a possible threat of flue

gas spillage or water heater water leakage into the building.

Please read the information given in Table 1A, page 10, listing

contaminants and areas likely to contain them. If contaminating

chemicals will be present near the location of the water heater

combustion air inlet, have your installer pipe the water heater

combustion air and vent to another location, per this manual.

WARNING

WARNING

Vent

Diameter

If the water heater combustion air inlet is

located in a laundry room or pool facility,

for example, these areas will always contain

hazardous contaminants.

To prevent the potential of severe personal

injury or death, check for areas and products

listed in Table 1A, page 10 before installing

the water heater or air inlet piping.

If contaminants are found, you MUST:

Vent

Min.

Length

• Remove contaminants permanently.

• Relocate air inlet and vent terminations

Vent

Max.

Length

—OR—

to other areas.

Input

De-Rate per

25 feet of

Vent

19

3 General venting

Installation & Operation Manual

PVC/CPVC

This product has been approved for use with the PVC/CPVC

vent materials listed in Table 3C.

Installing vent and air piping

WARNING

NOTICE

NOTICE

WARNING

WARNING

Table 3C PVC/CPVC Vent Pipe, and Fittings

For all installations, the first ten (10)

equivalent feet of vent must be CPVC or

stainless steel (see FIG. 3-6). The field

provided vent fittings must be cemented

to the CPVC pipe section using an “All

Purpose Cement” suitable for PVC and

CPVC pipe. Use only the vent materials,

primer, and cement specified in Table 3C

to make the vent connections. Failure to

follow this warning could result in fire,

personal injury, or death.

Use only cleaners, primers, and solvents

that are approved for the materials which

are joined together.

All PVC vent pipes must be glued, properly

supported, and the exhaust must be pitched

a minimum of a 1/4 inch per foot back to

the water heater (to allow drainage of

condensate).

Insulation should not be used on PVC

or CPVC venting materials. The use of

insulation will cause increased vent wall

temperatures, which could result in vent

pipe failure.

For all installations, the first ten (10)

equivalent feet of vent must be CPVC or

stainless steel (see FIG. 3-6). Failure to

follow this warning could result in fire,

personal inury, or death.

Approved PVC/CPVC Vent Pipe and Fittings

Item Material Standard

PVC Schedule 40, 80 ANSI/ASTM D1785

Vent pipe

Vent fittings

Pipe Cement /

Primer

NOTICE: DO NOT USE CELLULAR (FOAM) CORE PIPE

PVC - DWV ANSI/ASTM D2665

CPVC Schedule 40, 80 ANSI/ASTM F441

PVC Schedule 40 ANSI/ASTM D2466

PVC Schedule 80 ANSI/ASTM D2467

CPVC Schedule 80 ANSI/ASTM F439

PVC ANSI/ASTM D2564

CPVC ANSI/ASTM F493

1. Work from the water heater to vent or air termination.

Do not exceed the lengths given in this manual for the

air or vent piping.

2. Cut pipe to the required lengths and deburr the inside

and outside of the pipe ends.

3. Chamfer outside of each pipe end to ensure even

cement distribution when joining.

4. Clean all pipe ends and fittings using a clean dry rag.

(Moisture will retard curing and dirt or grease will prevent

adhesion.)

5. Dry fit vent or air piping to ensure proper fit up before

assembling any joint. The pipe should go a third to

two-thirds into the fitting to ensure proper sealing after

cement is applied.

6. Priming and Cementing:

a. Handle fittings and pipes carefully to prevent

contamination of surfaces.

b. Apply a liberal even coat of primer to the fitting

socket and to the pipe end to approximately 1/2"

beyond the socket depth.

c. Apply a second primer coat to the fitting socket.

d. While primer is still wet, apply an even coat of

approved cement to the pipe equal to the depth of

the fitting socket along with an even coat of

approved cement to the fitting socket.

e. Apply a second coat of cement to the pipe.

f. While the cement is still wet, insert the pipe into

the fitting, if possible twist the pipe a 1/4 turn as

you insert it. NOTE: If voids are present,

sufficient cement was not applied and joint could

be defective.

g. Wipe excess cement from the joint removing ring or

beads as it will needlessly soften the pipe.

Figure 3-6 Near Water Heater PVC/CPVC Venting

CPVC ELBOW

5'

CPVC PIPE

NOTE: In Canada, CPVC and PVC vent pipe, fi ttings and cement/

primer must be ULC-S636 certifi ed.

20

3 General venting (continued)

A

Installation & Operation Manual

Polypropylene

This product has been approved for use with polypropylene

vent with the manufacturers listed in Table 3D.

All terminations must comply with listed options in this manual

and be a single-wall vent offering.

For use of flex pipe, it is recommended to have the vent material

in 32°F or higher ambient space before bending at installation.

No bends should be made to greater than 45° and ONLY

installed in vertical or near vertical installations.

For support and special connections required, see the

manufacturer's instructions. All vent is to conform to standard

diameter and equivalent length requirements established.

Table 3D Polypropylene Vent Pipe and Fittings

Approved Polypropylene Vent Manufacturers

Make Model

Centrotherm Eco Systems

Duravent (M & G Group)

NOTICE

PolyPro Single-Wall / PolyPro Flex

The installer must use a specific vent starter

adapter at the flue collar connection,

supplied by the vent manufacturer to

adapt to its vent system. See Table 3E for

approved vent adapters. Discard CPVC

starter piece.

InnoFlue SW/Flex

WARNING

NOTICE

NOTICE

Figure 3-7 Near Water Heater Polypropylene Venting

Use only the adapters and vent system listed

in Tables 3E and 3F. DO NOT mix vent

systems of different types or manufacturers.

Failure to comply could result in severe

personal injury, death, or substantial

property damage.

Installations must comply with applicable

national, state, and local codes. For

Canadian installation, polypropylene vent

must be listed as a ULC-S636 approved

system.

Installation of a polypropylene vent system

should adhere to the vent manufacturer’s

installation instructions supplied with the

vent system.

NOTICE

WARNING

Table 3E Approved PolypropyleneTerminations

Model

1000 -1500

* These parts are only needed if the sidewall termination assembly is used (see FIG. 4-4B on page 25).

All vent connections MUST be secured by

the vent manufacturer's joint connector

(FIG. 3-7).

Insulation should not be used on

polypropylene venting materials. The use

of insulation will cause increased vent wall

temperatures, which could result in vent

pipe failure.

Centrotherm InnoFlue SW

Polypropylene

Adapter

ISAAL0606 Not Required IATP0606 ISTAGL0606 FSA-6PVCM-6PPS N/A 6PPK-HLK

Joint

Connector

Sidewall Retaining

Bracket*

POLYPROPYLENE

DAPTER

Sidewall

Adapter*

Duravent Polypro

Polypropylene

Adapter

Joint

Connector

IMG00024

Sidewall

Adapter*

21

Loading...

Loading...