Page 1

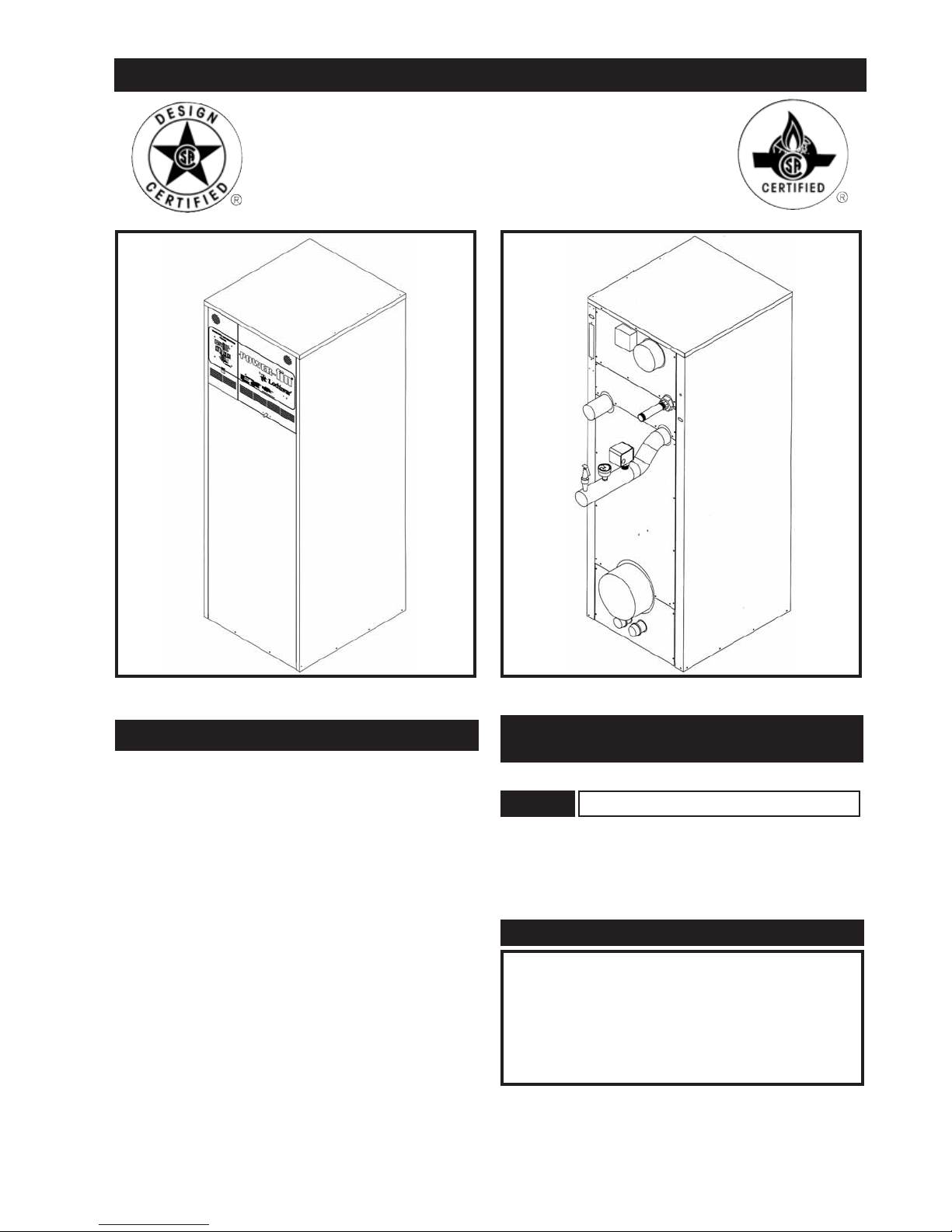

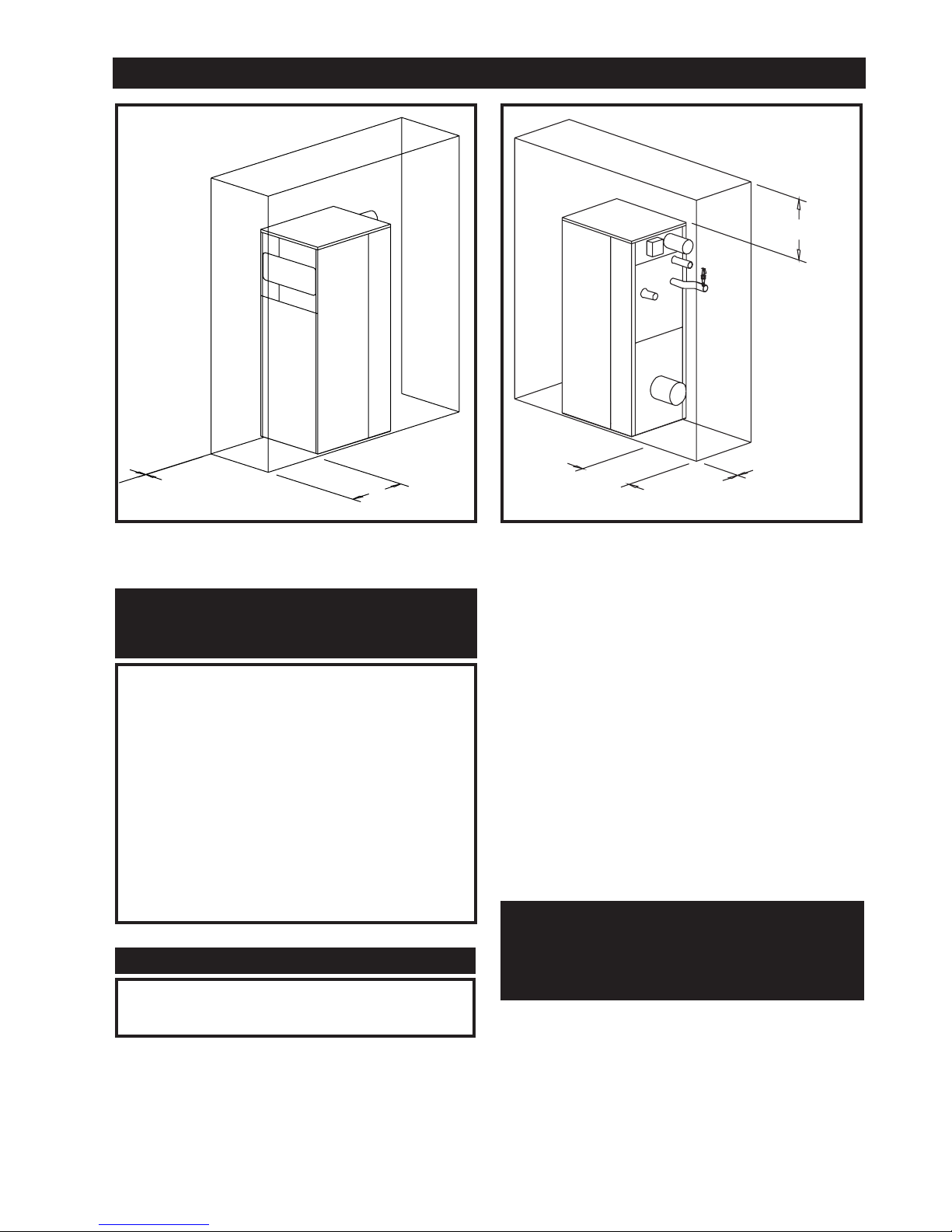

FIG. 1 Front View 1,500,000 - 2,000,000 Btu/hr Models

Installation and service must be performed by a qualified

service installer, service agency or the gas supplier.

Factory warranty (shipped with unit) does not apply to

units improperly installed or improperly operated.

Experience has shown that improper installation or system

design, rather than faulty equipment, is the cause of most

operating problems.

1. Excessive water hardness causing a lime/scale build-up

in the copper tube is not the fault of the equipment and

is not covered under the manufacturer's warranty (See

Water Treatment and Water Chemistry).

2. Excessive pitting and erosion on the inside of the

copper tube may be caused by too much water velocity

through the tubes and is not covered by the

manufacturer's warranty (See Boiler Flow Rates and

Temperature Rise for flow requirements).

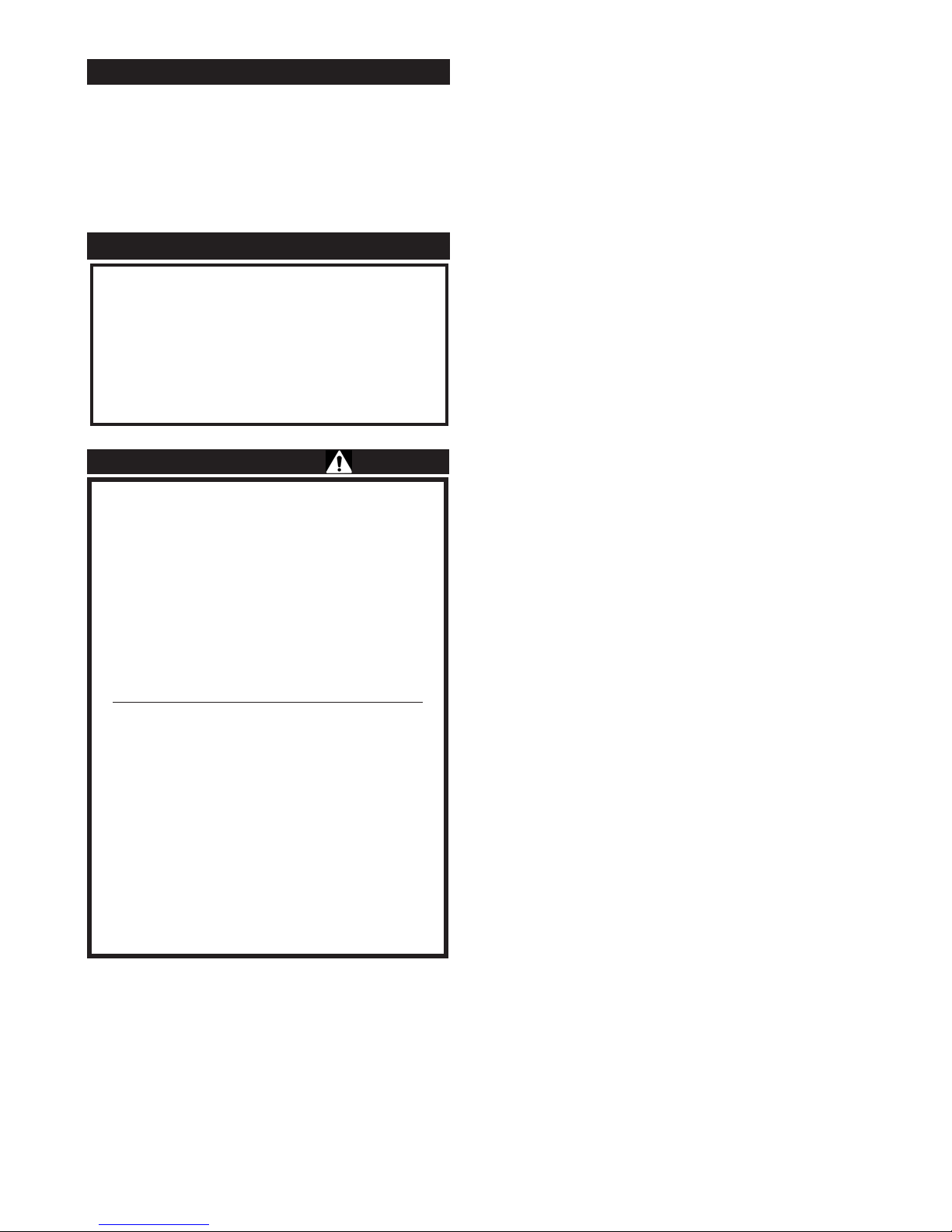

FIG. 2 Rear View 1,500,000 - 2,000,000 Btu/hr Models

This manual supplies information for the installation,

operation and servicing of the appliance. It is strongly

recommended that this manual be reviewed completely

before proceeding with an installation.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

can cause injury or property damage. Refer to this

manual. For assistance or additional information,

consult a qualified installer, service agency or the gas

supplier.

WARNING:

Retain this manual for future reference.

NOTE:

SPECIAL INSTRUCTIONS

TO OWNER

WARRANTY

INSTALLATION AND SERVICE MANUAL

Power-Fin® 4:1

HOT WATER HEATING BOILERS

DOMESTIC HOT WATER SUPPLY BOILERS

1,500,000, 1,700,000 and 2,000,000 Btu/hr MODELS

PBE/PFE-i&s-03

Page 2

Upon receiving equipment, check for signs of shipping

damage. Pay particular attention to parts accompanying

the boiler, which may show signs of being hit or otherwise

being mishandled. Verify total number of pieces shown on

packing slip with those actually received. In case there is

damage or a shortage, immediately notify carrier.

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

This appliance MUST NOT be installed in any

location where gasoline or flammable vapors

are likely to be present, unless the installation is

such to eliminate the probable ignition of

gasoline or flammable vapors.

WHA

T TO DO IF Y

OU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electric switch; do not use

any phone in your building.

•Immediately call your gas supplier from a

neighbors phone. Follow the gas supplier's

instructions.

•If you cannot reach your gas supplier, call

the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING:

DO NOT USE THIS APPLIANCE IF ANY

PART HAS BEEN UNDER WATER. THE

POSSIBLE DAMAGE TO A FLOODED

APPLIANCE CAN BE EXTENSIVE AND

PRESENT NUMEROUS SAFETY HAZARDS.

ANY APPLIANCE THAT HAS BEEN UNDER

WATER MUST BE REPLACED.

DO NOT:

CHECKING EQUIPMENT

2

Page 3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation Requirements

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Combustion/Ventilation Air Requirements . . . . . . . . . . .5

Construction Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . .8

V

enting Options

Category IV Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Flue Pipe Sizes . . . . . . . . . . . . . . . . . . . . . . . . .9

Flue Pipe Materials . . . . . . . . . . . . . . . . . . . . .10

Vent Length Requirements . . . . . . . . . . . . . . .10

Masonry Chimneys . . . . . . . . . . . . . . . . . . . . .11

Vertical Terminations . . . . . . . . . . . . . . . . . . .12

Horizontal Terminations . . . . . . . . . . . . . . . . .12

Direct Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Vertical Direct Vent . . . . . . . . . . . . . . . . . . . . . . . .15

Air Inlet Pipe Materials . . . . . . . . . . . . . . . . .15

Combined Air Inlets . . . . . . . . . . . . . . . . . . . .15

Air Inlet Pipe Length Requirements . . . . . . .16

Location Requirements . . . . . . . . . . . . . . . . . .16

Multiple Vertical Direct Vent Installations . . .17

Horizontal Direct Vent . . . . . . . . . . . . . . . . . . . . . .17

Air Inlet Pipe Materials . . . . . . . . . . . . . . . . .17

Air Inlet Pipe Length Requirements . . . . . . .17

Location Requirements . . . . . . . . . . . . . . . . . .18

Multiple Horizontal Direct Vent Installations 18

DirectAire Vent Systems . . . . . . . . . . . . . . . . . . . . .19

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Vertical Flue - Sidewall Air . . . . . . . . . . . . . .19

Sidewall Flue - Rooftop Air . . . . . . . . . . . . . .20

Sidewall Flue - Sidewall Air . . . . . . . . . . . . .21

Gas Supply

Gas Supply Pressures . . . . . . . . . . . . . . . . . . .23

Manifold Pressure . . . . . . . . . . . . . . . . . . . . .23

Gas Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . .24

Supply Pressure Measurement . . . . . . . . . . . .25

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Minimum

Water Temperatures . . . . . . . . . . . . . . . . .28

Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Low Water Cut-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Gas Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Ratio Gas Valve . . . . . . . . . . . . . . . . . . . . . . .29

Diaphragm Gas Valve . . . . . . . . . . . . . . . . . .30

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . .30

Jacket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Components and Contr

ols

Component Location Drawings . . . . . . . . . . .32

Variable Frequency Drive . . . . . . . . . . . . . . . .33

Low Air Pressure Switch . . . . . . . . . . . . . . . .33

Gas Pressure Switches . . . . . . . . . . . . . . . . . .34

Electronic Temperature Controller . . . . . . . . .34

Location . . . . . . . . . . . . . . . . . .34

Diagnostic Information Center.. 35

Changeable Data Points . . . . . .35

Operation Status LED's . . . . . . .36

Fault Status LED's . . . . . . . . . .36

Temperature Adjustment . . . . . .37

Outdoor Reset Function . . . . . .37

Lockout Procedure . . . . . . . . . .38

Limited Access Features . . . . . .38

Error Displays . . . . . . . . . . . . . .39

Temperature Limit Control . . . . . . . . . . . . . . .39

Condensate Trap Installation . . . . . . . . . . . . .40

Hot Surface Ignition Control . . . . . . . . . . . . .41

Igniter . . . . . . . . . . . . . . . . . . . .41

Diagnostic Status . . . . . . . . . . .42

Ignition and Control Timings . . . . . . . . . . . . .42

Burner Assembly . . . . . . . . . . . . . . . . . . . . . .42

Combustion Air Blower . . . . . . . . . . . . . . . . .43

Cleaning Air Inlet Filter . . . . . . . . . . . . . . . . .43

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . .44

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . .45

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .46

Vent System . . . . . . . . . . . . . . . . . . . . . . . . . .46

Flame Patterns . . . . . . . . . . . . . . . . . . . . . . . .47

Cleaning Flue Gas Passageways . . . . . . . . . .47

Burner Cleaning . . . . . . . . . . . . . . . . . . . . . . .47

Changing the HSI . . . . . . . . . . . . . . . . . . . . . .48

Heat Exchanger Inspection . . . . . . . . . . . . . . .49

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . .50

Control Circuit Voltage . . . . . . . . . . . . . . . . . .50

Condensate Trap . . . . . . . . . . . . . . . . . . . . . . .50

Combustion Blower Measurements . . . . . . . .50

Freeze Protection . . . . . . . . . . . . . . . . . . . . . .51

Heating Boiler

Typical Piping . . . . . . . . . . . . . . . . . . . . . . . . .52

Boiler Pump Operation . . . . . . . . . . . . . . . . . .53

Intermittent Pump . . . . . . . . . . . . . . . . . . . . . .53

Primary/Secondary Piping . . . . . . . . . . . . . . .53

Minimum Water Temperatures . . . . . . . . . . . .54

Low Water Temperature Bypass . . . . . . . . . . .54

Three Way Valves . . . . . . . . . . . . . . . . . . . . . .55

High Flow Bypass . . . . . . . . . . . . . . . . . . . . .56

Boiler Flow Rates . . . . . . . . . . . . . . . . . . . . . .56

Placing the Boiler in Operation . . . . . . . . . . .57

Boiler Temperature Control . . . . . . . . . . . . . .58

W

ater Heater/Domestic Hot Water Supply Boiler

Typical Piping . . . . . . . . . . . . . . . . . . . . . . . . .60

Maximum Flow Rate . . . . . . . . . . . . . . . . . . .60

Water Velocity Control . . . . . . . . . . . . . . . . . .60

Temperature Rise . . . . . . . . . . . . . . . . . . . . . .61

Water Chemistry . . . . . . . . . . . . . . . . . . . . . . .61

Piping Requirements . . . . . . . . . . . . . . . . . . .62

Pump Operation . . . . . . . . . . . . . . . . . . . . . . .63

Temperature Adjustment . . . . . . . . . . . . . . . . .64

Minimum Water Temperatures . . . . . . . . . . . .64

Risk of Scald Warnings . . . . . . . . . . . . . . . . .65

Temperature Limit Control . . . . . . . . . . . . . . .66

Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . .66

Thermal Expansion . . . . . . . . . . . . . . . . . . . . .66

3

CONTENTS

Page 4

The information contained in this manual is intended

for use by qualified professional installers, service

technicians or gas suppliers. Consult your local expert

for proper installation or service procedures.

A gas appliance that draws combustion air from the

equipment room where it is installed must have a supply of

fresh air circulating around it during burner operation for

proper gas combustion and proper venting.

1. Boilers and water heaters are heat producing

appliances. To avoid damage or injury, do not store

materials against the appliance or the vent-air intake

system. Use proper care to avoid unnecessary

contact (especially children) with the appliance and

vent-air intake components.

2. Never cover your appliance, lean anything against it,

store trash or debris near it, stand on it or in any way

block the flow of fresh air to your appliance.

3. UNDER NO CIRCUMSTANCES must flammable

materials such as gasoline or paint thinner be used or

stored in the vicinity of this appliance, vent-air intake

system or any location from which fumes could reach

the appliance or vent-air intake system.

The equipment shall be installed in accordance with those

installation regulations in force in the local area where the

installation is to be made. These shall be carefully

followed in all cases. Authorities having jurisdiction shall

be consulted before installations are made. In the absence

of such requirements, the installation shall conform to the

latest edition of the National Fuel Gas Code, ANSI Z223.1.

Where required by the authority having jurisdiction, the

installation must conform to American Society of

Mechanical Engineers Safety Code for Controls and Safety

Devices for Automatically Fired Boilers, ASME CSD-1.

All boilers conform to the latest edition of the ASME

Boiler and Pressure Vessel Code, Section IV. Where

required by the authority having jurisdiction, the

installation must comply with the Canadian Gas

Association Code, CAN/CGA-B149.1 and/or B149.2

and/or local codes. This appliance meets the safe lighting

performance criteria with the gas manifold and control

assembly provided, as specified in the ANSI standards for

gas-fired units, ANSI Z21.13.

1. Locate the appliance so that if water connections

should leak, water damage will not occur. When such

locations cannot be avoided, it is recommended that a

suitable drain pan, adequately drained, be installed

under the unit. The pan must not restrict combustion

airflow. Under no circumstances is the manufacturer to

be held responsible for water damage in connection

with this unit, or any of its components.

2. The appliance must be installed so that the ignition

system components are protected from water (dripping,

spraying, etc.) during appliance operation and service

(circulator replacement, control replacement, etc.).

3. Appliances located in a residential garage and in

adjacent spaces that open to the garage and are not part

of the living space of a dwelling unit must be installed

so that all burners and burner ignition devices have a

minimum clearance of not less than 18" (46cm) above

the floor. The appliance must be located or protected so

that it is not subject to physical damage by a moving

vehicle.

4. DO NOT install this appliance in any location where

gasoline or flammable vapors are likely to be present.

5. The appliance must be installed on a level floor.

Combustible floor locations may be used. Maintain

required clearances from combustible surfaces.

6. The appliance must not be installed on carpet.

7. The appliance must be installed indoors where it is

protected from exposure to wind, rain and weather.

8. This appliance may condense the products of

combustion when operating at water temperatures

below 140°F (60°C). Ensure that the appliance is

located near an acceptable drain where condensate that

may form in the venting system may be properly

collected and disposed.

INSTALLATION PROCEDURE

LOCATION OF UNIT

CODES

To minimize the possibility of serious personal

injury, fire or damage to your appliance, never

violate the following safety rules.

WARNING:

Should overheating occur or the gas supply fail

to shut off, DO NOT turn off or disconnect the

electrical supply to the pump. Instead, shut off

the gas supply at a location external to the

appliance.

WARNING:

Consult and follow local Building and Fire

Regulations and other Safety Codes that apply to

this installation. Consult local gas utility company

to authorize and inspect all gas and flue

connections.

IMPORTANT:

OWNER WARNING:

4

Page 5

FIG. 3 Clearances from Combustible Construction Front

Maintain minimum specified clearances for adequate

operation. All installations must allow sufficient space for

servicing the vent connections, water pipe connections,

piping and other auxiliary equipment, as well as the

FIG. 4 Clearances from Combustible Construction Rear

appliance. The clearance labels on each appliance note the

same service and combustible clearance requirements as

shown above.

Multiple appliances may be installed in a modular boiler or

water heater installation. Multiple appliances may be

installed side by side with no clearance between adjacent

appliances because this appliance is approved for zero

clearance from combustible surfaces and no service access

is required from the sides.

Consult the venting section of the manual for specific

installation instructions for appropriate type of venting

system that you will be using. Direct Vent and DirectAire

venting systems require installation with Category IV flue

pipe, sealed air inlet pipe and air inlet caps, which must

meet the manufacturer's specifications.

Provisions for combustion and ventilation air must be in

accordance with Section 5.3, Air for Combustion and

Ventilation, of the latest edition of the National Fuel Gas

Code, ANSI Z223.1, in Canada, the latest edition of CGA

Standard B149 Installation Code for Gas Burning

Appliances and Equipment, or applicable provisions of the

local building codes.

COMBUSTION AND VENTILATION

AIR REQUIREMENTS FOR

APPLIANCES DRAWING AIR

FROM THE EQUIPMENT ROOM

Clearances from combustible construction are

noted on the appliance rating plate.

NOTE:

Right Side - 0"

Rear - 6" (15cm) (Minimum 24" (0.61m) suggested

for service to pump and components)

Left Side - 0"

Front - ALCOVE* (Minimum 24" (0.61m)

suggested for service)

Top - 6" (15cm) (Minimum 24" (0.61m) suggested

for service)

Flue - 2" (51mm)

Hot Water Pipes - 1" (25.4mm)

*An ALCOVE is a closet without a door.

TABLE — A

Clearances from Combustible

Construction:

5

CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

24" TOP MIN.

0" LEFT SIDE

24" FRONT MIN.

24" REAR MIN.

0" RIGHT SIDE

FROM PIPING

Page 6

6

The equipment room MUST be provided with properly

sized openings to assure adequate combustion air and

proper ventilation when the unit is installed with a basic

Category IV venting system.

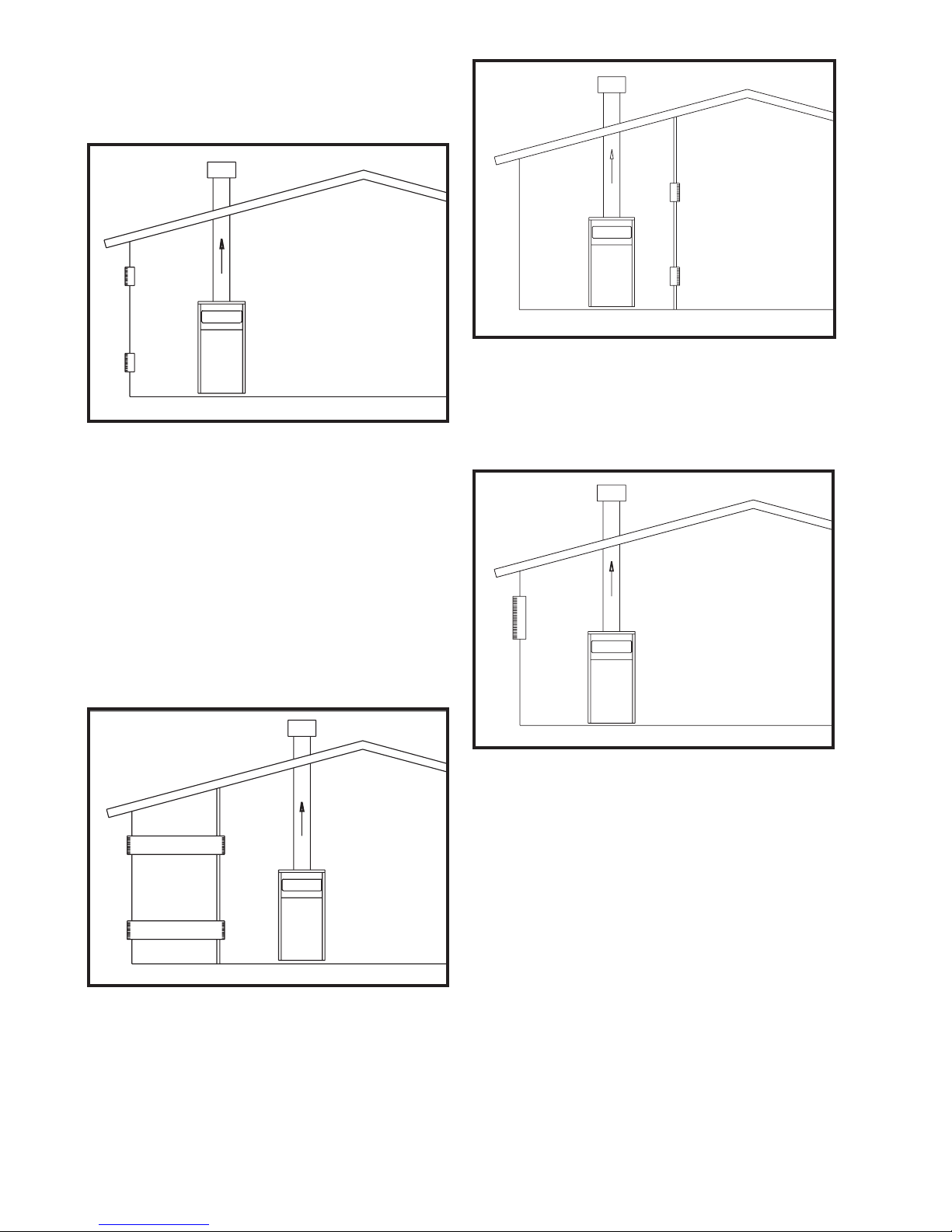

FIG. 5 Combustion Air Direct from Outside

1. If air is taken directly from outside the building with no

duct, provide two permanent openings:

a. Combustion air opening, with a minimum free

area of one square inch per 4000 Btu input (5.5 cm

2

per kW). This opening must be located within 12"

(30 cm) of the bottom of the enclosure.

b. Ventilation air opening, with a minimum free area

of one square inch per 4000 Btu input (5.5 cm

2

per

kW). This opening must be located within

12 inches (30 cm) of the top of the enclosure.

FIG. 6 Combustion Air Through Ducts

2. If combustion and ventilation air is taken from the

outdoors using a duct to deliver the air to the

mechanical room, each of the two openings should be

sized based on a minimum free area of one square inch

per 2000 Btu (11 cm

2

per kW) of input.

FIG. 7 Combustion Air from Interior Space

3. If air is taken from another interior space, each of the

two openings specified above should have a net free area

of one square inch for each 1000 Btu (22 cm

2

per kW) of

input, but not less than 100 square inches (645 cm2).

FIG. 8 Combustion Air from Outside - Single

Opening

4. If a single combustion air opening is provided to bring

combustion air in directly from the outdoors, the

opening must be sized based on a minimum free area of

one square inch per 3000 Btu (7 cm

2

per kW). This

opening must be located within 12 inches (30 cm) of

the top of the enclosure.

Page 7

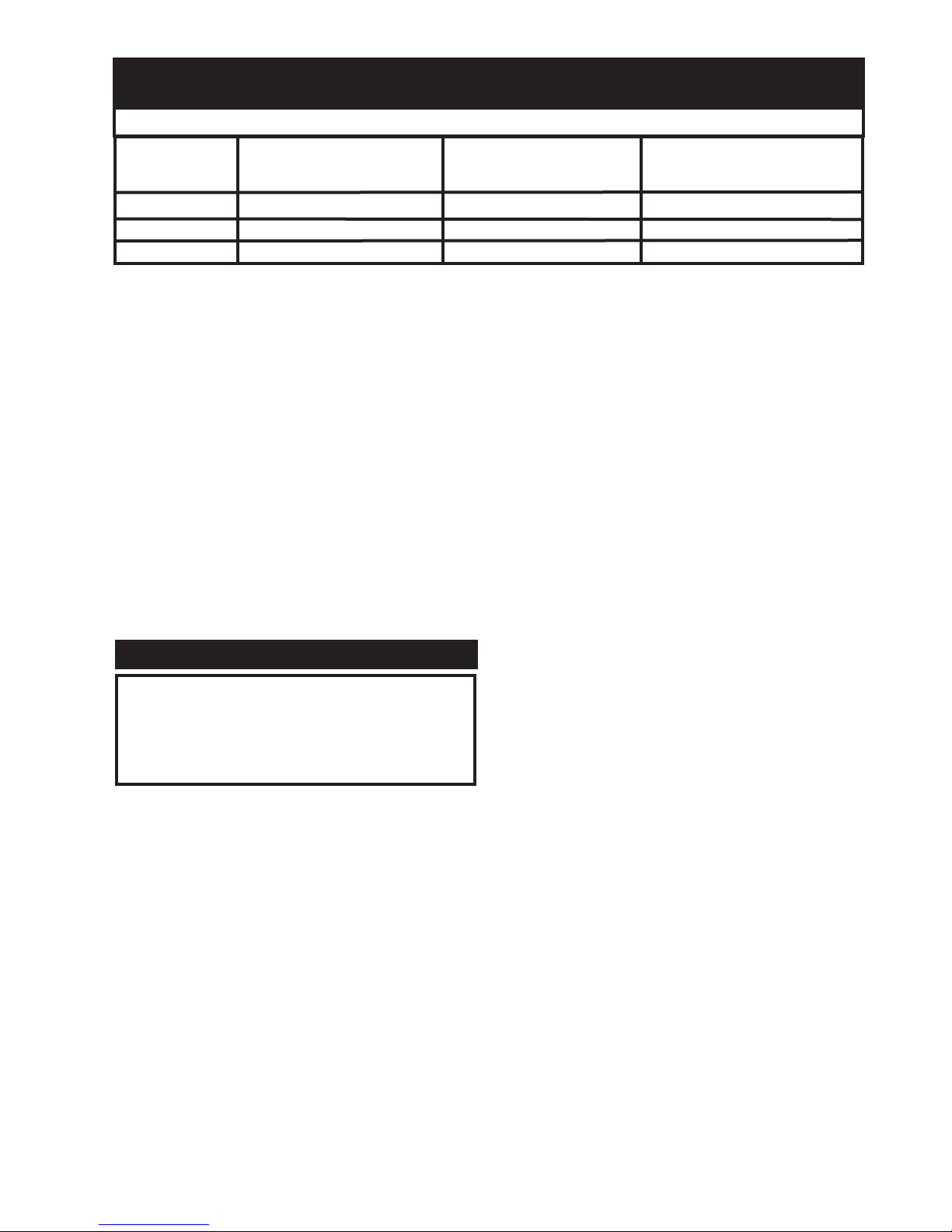

All dimensions based on net free area in square inches.

Metal louvers or screens reduce the free area of a

combustion air opening a minimum of approximately 25%.

Check with louver manufacturers for exact net free area of

louvers. Where two openings are provided, one must be

within 12 inches (30 cm) of the ceiling and one must be

within 12 inches (30 cm) of the floor of the mechanical

room. Each opening must have net free area as specified in

the chart above. Single openings shall commence within

12 inches (30 cm) of the ceiling.

The combustion air supply must be completely free of any

flammable vapors that may ignite or chemical fumes which

may be corrosive to the appliance. Common corrosive

chemical fumes which must be avoided are fluorocarbons

and other halogenated compounds, most commonly present

as refrigerants or solvents, such as Freon, trichlorethylene,

perchlorethylene, chlorine, etc. These chemicals, when

burned, form acids which quickly attack the heat exchanger

finned tubes, headers, flue collectors, and the vent system.

The result is improper combustion and a non-warrantable,

premature appliance failure.

EXHAUST FANS: Any fan or equipment which exhausts

air from the equipment room may deplete the combustion

air supply and/or cause a down draft in the venting system.

Spillage of flue products from the venting system into an

occupied living space can cause a very hazardous condition

that must be immediately corrected. If a fan is used to

supply combustion air to the equipment room, the installer

must make sure that it does not cause drafts that could lead

to nuisance operational problems with the appliance.

Under no circumstances should the mechanical

room ever be under a negative pressure. Particular

care should be taken where exhaust fans, attic fans,

clothes dryers, compressors, air handling units,

etc., may take away air from the unit.

CAUTION

7

TABLE — B

Minimum Recommended Combustion Air Supply to Equipment Room

Boiler

Input

1,500,000

1,700,000

2,000,000

Outside Air*

2 - Openings

375 in

2

(2,419 cm2)

425 in2(2,742 cm2)

500 in2(3,226 cm2)

Outside Air*

1 - Opening

500 in

2

(3,226 cm2)

567 in2(3,658 cm2)

667 in2(4,303 cm2)

Inside Air

2 - Openings

1500 in

2

(9,677 cm2)

1700 in2(10,968 cm2)

2000 in2(12,903 cm2)

COMBUSTION AIR SOURCE

*Outside air openings shall directly communicate with the outdoors. When combustion air is drawn from the outside

through a duct, the net free area of each of the two openings must have twice (2 times) the free area required for Outside

Air/2 Openings. The above requirements are for the boiler only; additional gas fired appliances in the equipment room

will require an increase in the net free area to supply adequate combustion air for all appliances. Combustion air

requirements are based on the latest edition of the National Fuel Gas Code, ANSI Z223.1; in Canada refer to the latest

edition of CGA Standard CAN B149.1 or .2. Check all local code requirements for combustion air.

Page 8

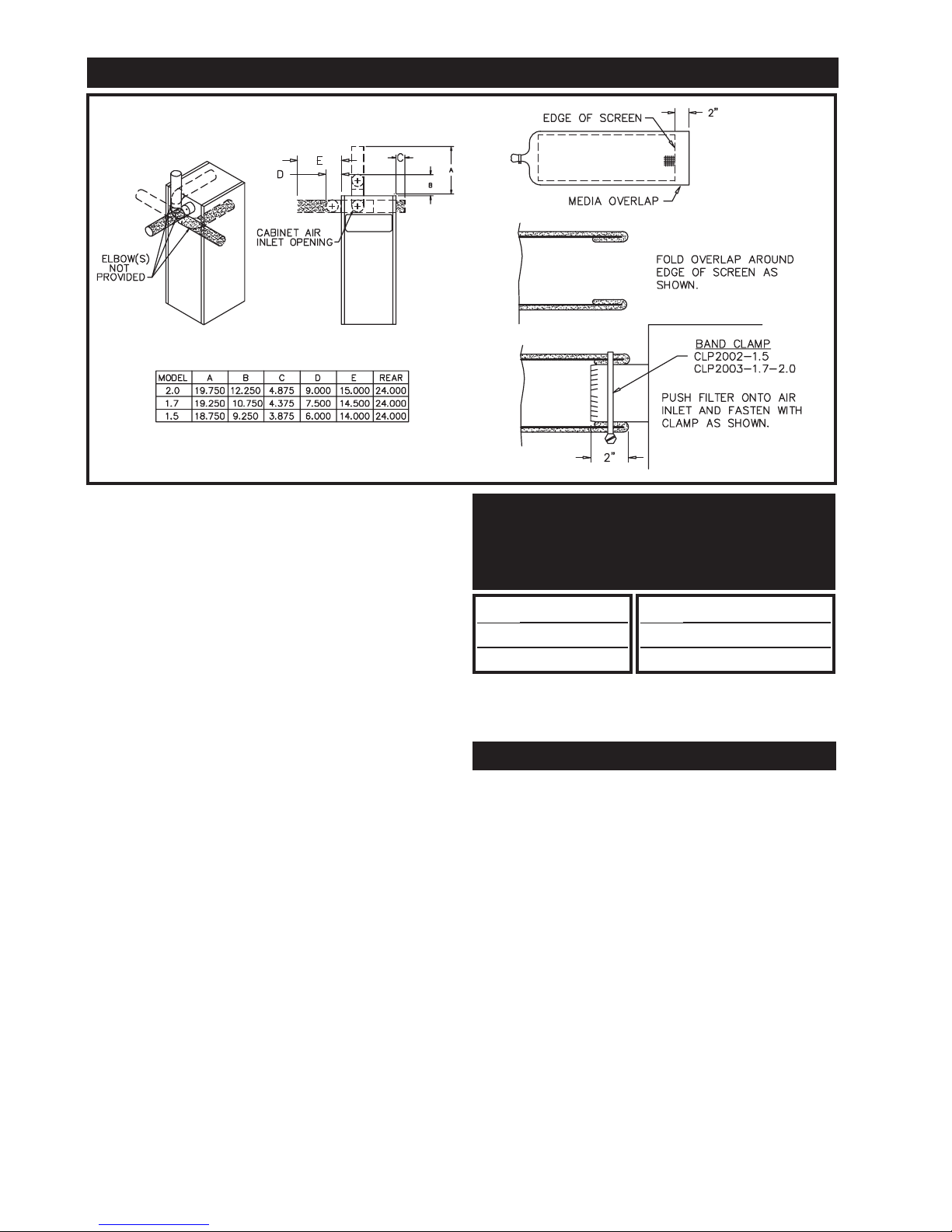

A construction air filter is provided with the appliance as

shipped. An air filter is provided for installation on the

combustion air inlet located at the rear of the appliance.

This filter is For Temporary Use Only on an appliance that

must be operated for temporary heat or hot water when a

building is under construction. The filter will provide a

temporary means to remove airborne dust, dirt and

particulate matter generated by construction. The filter

prevents air borne particulate contaminants from being

drawn into the burner with the combustion air. The filter can

be cleaned routinely during construction if necessary.

Remove the filter to clean. Wash the filter with water. A

flow of water from the inside to the outside should remove

most particulate mater. Allow the filter to dry before

reinstalling. Unfiltered combustion air from a construction

site can contain contaminants that will collect in the burner

reducing the firing rate. A burner that becomes clogged with

air borne particulate contaminants must be removed and

cleaned to restore proper operation to the burner. Sustained

operation of an appliance with a clogged burner may result

in nuisance operational problems, bad combustion and

non-warrantable component failures. The combustion air

filter MUST be removed from the appliance's air inlet before

the appliance is placed in normal operation. Once the

construction air filter is removed, ensure that either the

equipment room is supplied with combustion air from

properly sized combustion and ventilation air openings or a

combustion air duct from a Direct Vent or DirectAire system

is connected to the appliance.

The optional Direct Vent and DirectAire venting systems

have specific requirements for a special combustion air duct

from the outside that is directly connected to the appliance.

See the requirements for this combustion air duct in the

venting section for each specialized vent system.

Vent Systems Options

This appliance has three venting system options. They are:

(A) Category IV Venting system with vertical roof top

termination or sidewall termination of the flue and

combustion air supplied from the mechanical room. (B)

Direct Vent with a Category IV flue and a separate

combustion air pipe to the outdoors. The Direct Vent

system terminates both the flue and air inlet in the same

pressure zone. The flue outlet and combustion air intake

may terminate on either the sidewall or with a rooftop

termination. (C) DirectAire with a Category IV flue and

a separate combustion air pipe to the outdoors. The

DirectAire vent system terminates the flue and the

combustion air inlet pipe in different pressure zones. The

DirectAire vent system may terminate the flue on the roof

top and combustion air intake on the sidewall, the flue on

the sidewall and combustion air from the rooftop or the flue

on the sidewall and combustion air from a different

VENTING

KIT4000

KIT4001

KIT4002

1,500,000

1,700,000

2,000,000

TABLE — C

Construction Air Filter Kits

Construction

Input Btu/hr Air Filter Kit

8

CONSTRUCTION AIR FILTER

FIG. 9 Construction Air Filter

Page 9

sidewall. All appliances are shipped from the factory

equipped for Category IV venting. The optional Direct

Vent and DirectAire venting systems will require the

installation of specific vent kits and venting materials. The

following is a detailed explanation of the installation

requirements for each venting system, components used

and part numbers of vent kits for each model.

General

Vent installations for connection to gas vents or chimneys

must be in accordance with Part 7, "Venting of

Equipment," of the latest edition of the National Fuel Gas

Code, ANSI Z223.1, in Canada, the latest edition of CGA

Standard B149 Installation Codes for Gas Burning

Appliances and Equipment or applicable provisions of the

local building codes.

Adequate combustion and ventilation air must be supplied

to the equipment room in accordance with the latest edition

of the National Fuel Gas Code, ANSI Z223.1, in Canada,

the latest edition of CGA Standard B149 Installation Codes

for Gas Burning Appliances and Equipment, or applicable

provisions of the local building codes.

The distance of the vent terminal from adjacent buildings,

windows that open and building openings MUST comply

with the latest edition of the National Fuel Gas Code, ANSI

Z223.1, in Canada, the latest edition of CGA Standard

B149 Installation Codes for Gas Burning Appliances and

Equipment.

Vent connection is made directly to flue outlet opening on

the back of the unit. The connection from the appliance

vent to the stack must be made as direct as possible.

IMPORTANT

Examine the venting system at least once a year.

Check all joints and vent pipe connections for tightness.

Also check for corrosion or deterioration. Immediately

correct any problems observed in the venting system.

Category IV Venting

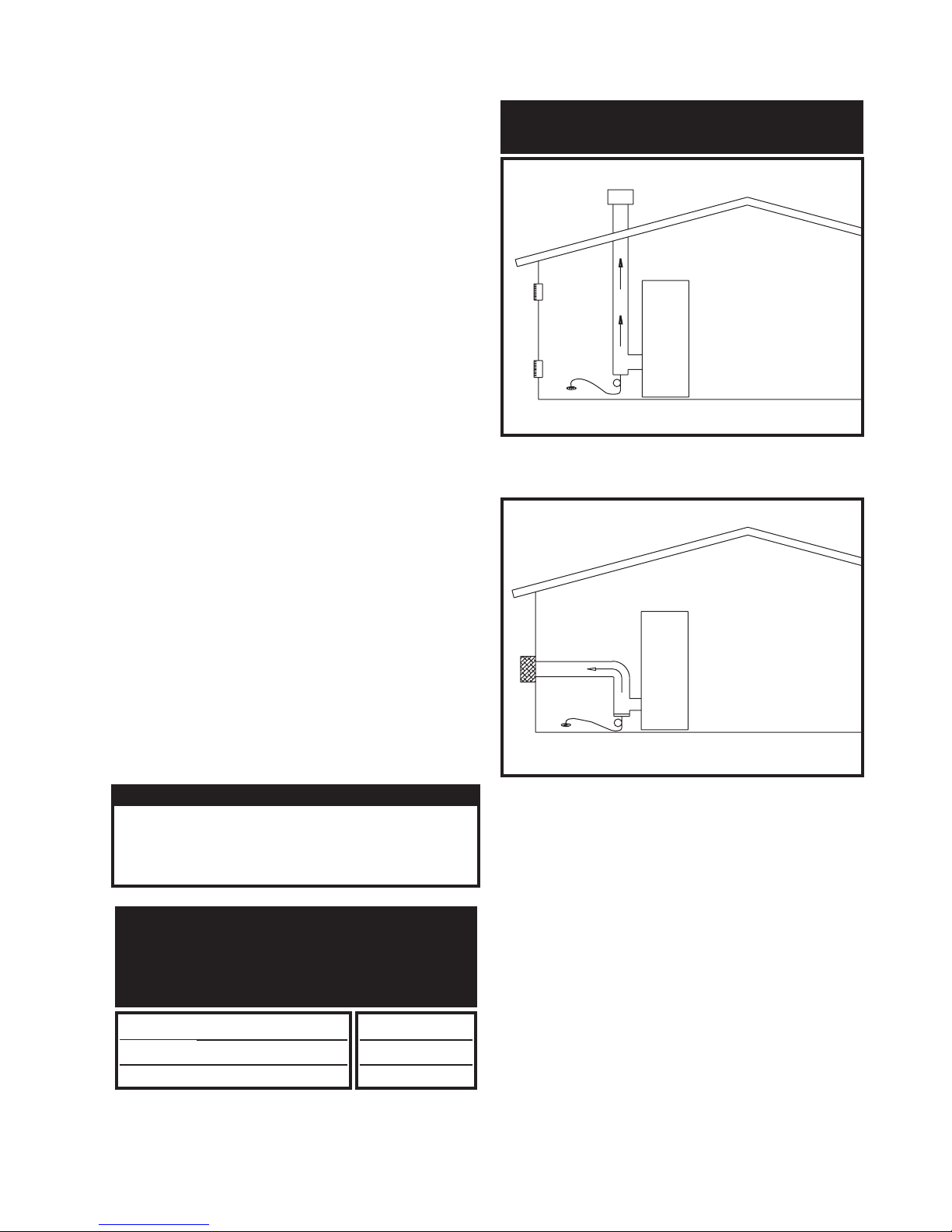

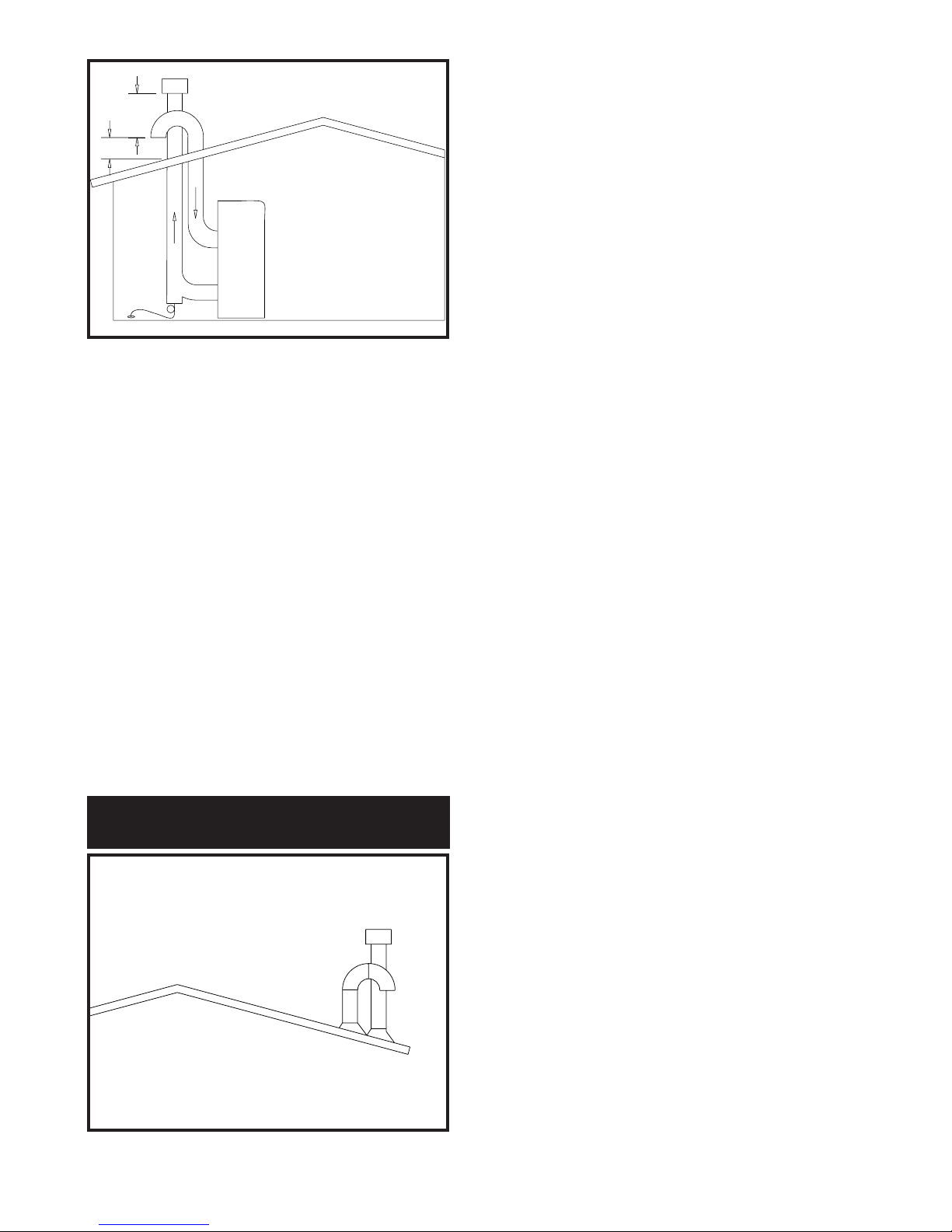

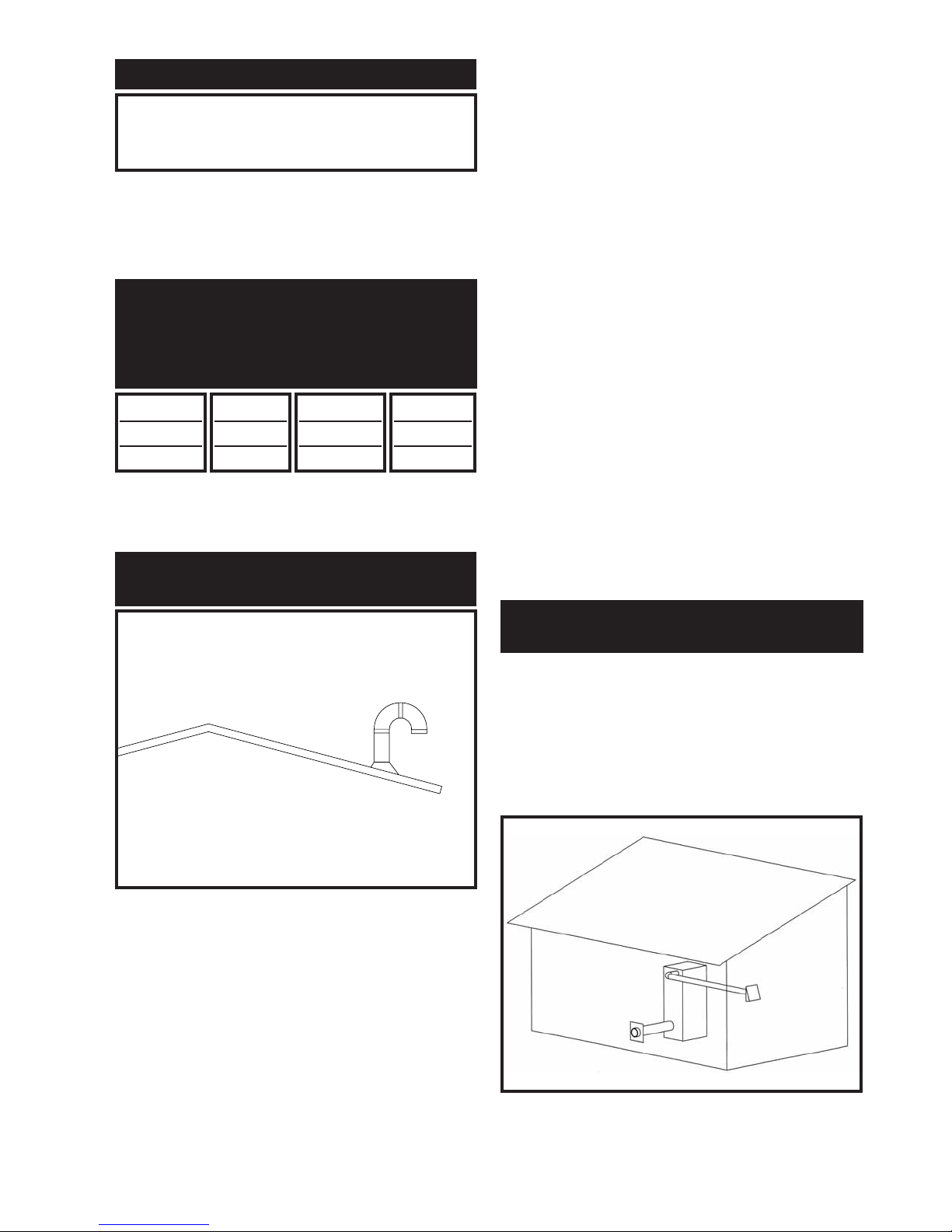

FIG. 10 Basic Category IV Venting - Vertical

Termination with Combustion Air Louvers

FIG. 11 Basic Category IV Venting - Horizontal

Termination with Combustion Air Louvers

A Category IV venting system for the flue products is

required on all models of this appliance. A Category IV

venting system operates with a positive pressure in the

vent. This positive pressure is generated by the internal

combustion air blower which operates the combustion

process and also exhausts the flue products from the

building. The Category IV flue from this appliance can

NOT be combined with the vent from any other appliance.

The Category IV flues from multiple appliances can NOT

be combined into a common vent. The Category IV flue

from this appliance must be a dedicated stack, there is one

exception however. The flues from multiple Power-Fin

appliances may only be combined when using an

engineered vent system incorporating an induced draft fan

to ensure that flue products will be properly exhausted

from the building at all times. Failure to use a properly

sized induced draft fan on a combined vent installation may

A CATEGORY IV POSITIVE

PRESSURE VENTING SYSTEM

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — D

The Category IV Flue

Pipe Sizes Are:

Input Btu/hr Flue Size

9

Page 10

result in a hazardous condition where flue gases spill into

an occupied living space. Consult the induced draft fan

manufacturer to size the induced draft fan and to determine

the diameter of the common vent pipe required for a

combined vent installation. The flue from this Category

IV appliance must have all vent joints and seams sealed

gas-tight. A Category IV vent system has specific vent

material and installation requirements.

The flue products in the vent system may be cooled below

their dew point and form condensate in the flue. The

materials used for a Category IV vent must be resistant to

any corrosive damage from flue gas condensate. The flue

from a Category IV vent system must have a condensate

drain with provisions to properly collect and dispose of any

condensate that may occur in the venting system.

Category IV Flue Pipe Materials

Select venting material from the following specified vent

materials:

Heat-Fab Inc. Saf-T CI Vent with AL29-4C stainless steel

(Call 1-800-772-0739 for nearest distributor)

Protech Systems Inc. Fas N Seal Vent with AL29-4C

stainless steel (Call 1-800-766-3473 for nearest distributor)

Metal-Fab Inc. Corr/Guard Vent with AL29-4C stainless

steel (Call 1-800-835-2830 for nearest distributor)

Z-Flex Z-Vent with AL29-4C stainless steel

(Call 1-800-654-5600 for nearest distributor)

Or other listed Category IV vent systems suitable for a

condensing, positive pressure gas fired appliance.

Venting Guidelines for a Category IV Vent

The connection from the appliance vent to the stack or vent

termination outside the building MUST be made with

listed Category IV vent system and must be direct as

possible with no reduction in diameter. The Category IV

vent and accessories, such as firestop spacers, thimbles,

caps, etc., MUST be installed in accordance with the vent

manufacturers instructions. The vent connector and

firestop must provide correct spacing to combustible

surfaces and seal to the vent connector on the upper and

lower sides of each floor or ceiling through which the vent

connector passes.

Each appliance must have a dedicated flue with no other

appliance interconnected to any part of the dedicated flue.

Each appliance MUST also connect to the dedicated flue

stack using a properly sealed vent adapter provided by the

vent manufacturer.

Any vent materials specified must be listed by a nationally

recognized test agency for use as a Category IV vent

material.

The venting system must be planned so as to avoid possible

contact with concealed plumbing or electrical wiring inside

walls, floors or ceilings.

Locate the appliance as close as possible to chimney or gas

vent.

There shall be no reductions in vent diameter.

Horizontal portions of the venting system shall be

supported to prevent sagging. Horizontal runs should slope

upwards not less than 1/4 inch per foot (21 mm/m) from the

drain tee installed in the flue to the vertical portion of the

flue or to the vent terminal on sidewall venting

installations. This ensures proper removal of any

condensate that may form in the flue. Follow the

installation instructions from the vent material

manufacturer.

Do not use an existing chimney as a raceway if another

appliance or fireplace is vented through the chimney.

The weight of the venting system must not rest on the unit.

Adequate support of the venting system must be provided

in compliance with local codes and other applicable codes.

All connections should be secured and sealed per the vent

manufacturers specifications.

Vent connectors serving appliances vented by natural draft

shall not be connected to any portion of the Category IV

positive pressure vent system used by this appliance.

Connection of a negative draft flue into the positive

pressure stack from this appliance may cause flue products

to be discharged into an occupied living space causing

serious health injury.

When a Category IV vent system is disconnected for any

reason, the flue must be reassembled and resealed

according to the vent manufacturer's instructions.

The installed length of the Category IV flue from the

appliance to the point of termination, outside of the

building, must not exceed a maximum of 50 equivalent

feet (15.2 m) in length. Subtract 5 feet (1.5 m) of

equivalent length for each 90° elbow installed in the vent.

Subtract 2-1/2 feet (0.7 m) of equivalent length for each

45° elbow installed in the vent.

The flue may terminate either vertically at the roof top or

horizontally on a sidewall. See the information about the

specific vent termination location for recommended

location and clearances.

General Category IV Vent Termination

Clearances

The vent cap should have a minimum clearance of 4 feet

(1.2 m) horizontally from and in no case above or below,

unless a 4 foot (1.2 m) horizontal distance is maintained

from electric meters, gas meters, regulators and relief

equipment.

The venting system shall terminate at least 3 feet (0.9 m)

above any forced air inlet within 10 feet (3.05 m).

10

Page 11

The venting system shall terminate at least 4 feet (1.2 m)

below, 4 feet (1.2 m) horizontally from, or 1 foot (30 cm)

above any door, window or gravity air inlet into any

building.

Do not terminate the vent in a window well, stairwell,

alcove, courtyard or other recessed area. The vent can not

terminate below grade. The bottom of the vent terminal

shall be located at least 12 inches (30 cm) above grade and

above normal snow levels.

To avoid a blocked flue condition, keep the vent cap clear

of snow, ice, leaves, debris, etc.

Flue gases from this appliance may contain large amounts

of water vapor that will form a white plume in winter.

Plume could obstruct a window view.

Flue gas condensate can freeze on exterior surfaces or on

the vent cap. Frozen condensate on the vent cap can result

in a blocked flue condition. Flue gas condensate can cause

discoloration of exterior building surfaces. Adjacent brick

or masonry surfaces should be protected with a rust

resistant sheet metal plate.

The manufacturer shall NOT be held liable for any

personal injury or property damage due to ice formation or

the dislodging of ice from the vent system or the vent

termination.

Drain Tee Installation

FIG. 12 Drain Tee Installed In Category IV Venting

A drain tee MUST be installed in the Category IV vent

pipe to collect and dispose of any condensate that may

occur in the vent system. The drain tee should be installed

at the point where the flue turns vertical for a roof top

termination or as one of the first fitting in a horizontal flue

that will terminate on a sidewall. Ensure that horizontal

portions of the vent are properly sloped to allow

condensate to be evacuated at the drain tee. See the typical

vent installation drawings. Plastic drain tubing, sized per

the vent manufacturer's instructions, shall be provided as a

drain line from the tee. The drain tubing must have a trap

provided by a 4 inches (10.2 cm) diameter circular trap

loop in the drain tubing. Prime the trap loop by pouring a

small quantity of water into the drain hose before assembly

to the vent. Secure the trap loop in position with nylon

wire ties. Use caution not to collapse or restrict the

condensate drain line with the nylon wire ties. The

condensate drain must be routed to the condensate

neutralization system or a suitable drain for disposal of

condensate that may occur in the Category IV vent

system. Refer to the condensate drain installation

instructions as supplied by the manufacturer of the vent

material. Ensure that the drain from the condensate tee is

not exposed to freezing temperatures. See “Freeze

Protection” for more information.

A standard masonry chimney must NOT be used to vent

the products of combustion from the flue of a Category IV,

positive pressure appliance. If a masonry chimney is to

be used, the chimney MUST use a sealed, metallic,

corrosion resistant liner system to vent flue products

from this high efficiency appliance. Sealed, metallic,

corrosion resistant liner systems (single wall, doublewall, or flexible or rigid metallic liners) must be rated

for use with a high efficiency, Category IV, positive

pressure vent system. Corrosion resistant chimney liner

systems are typically made from a high grade of corrosion

resistant stainless steel such as AL29-4C. The corrosion

resistant liner must be properly sized and fully sealed

throughout the entire length if the flue is contained within

the masonry chimney. Both the top and the bottom of the

masonry chimney must be capped and sealed to provide a

dead air space around the sealed corrosion resistant

metallic liner. Consult with local code officials to

determine code requirements or the advisability of

using a masonry chimney with a sealed corrosion

resistant liner system.

Venting of a high efficiency Category IV

appliance into a masonry chimney without a sealed

stainless steel liner can result in operational and

safety problems. Any breaks, leaks or damage to

the masonry flue/tile will allow spillage of the

positive pressure flue products from the chimney.

These flue products can easily escape into an

occupied living space causing a health hazard. If

there is any doubt about the condition of a masonry

chimney, or its acceptability for use after insertion

of a corrosion resistant liner system, consult with

local code officials.

CAUTION:

MASONRY CHIMNEY

INSTALLATIONS

11

WIRE TIE

4" Ø

CIRCULAR TRAP

TO SUITABLE DRAIN

Page 12

Follow all General Category IV Vent Termination

Clearances.

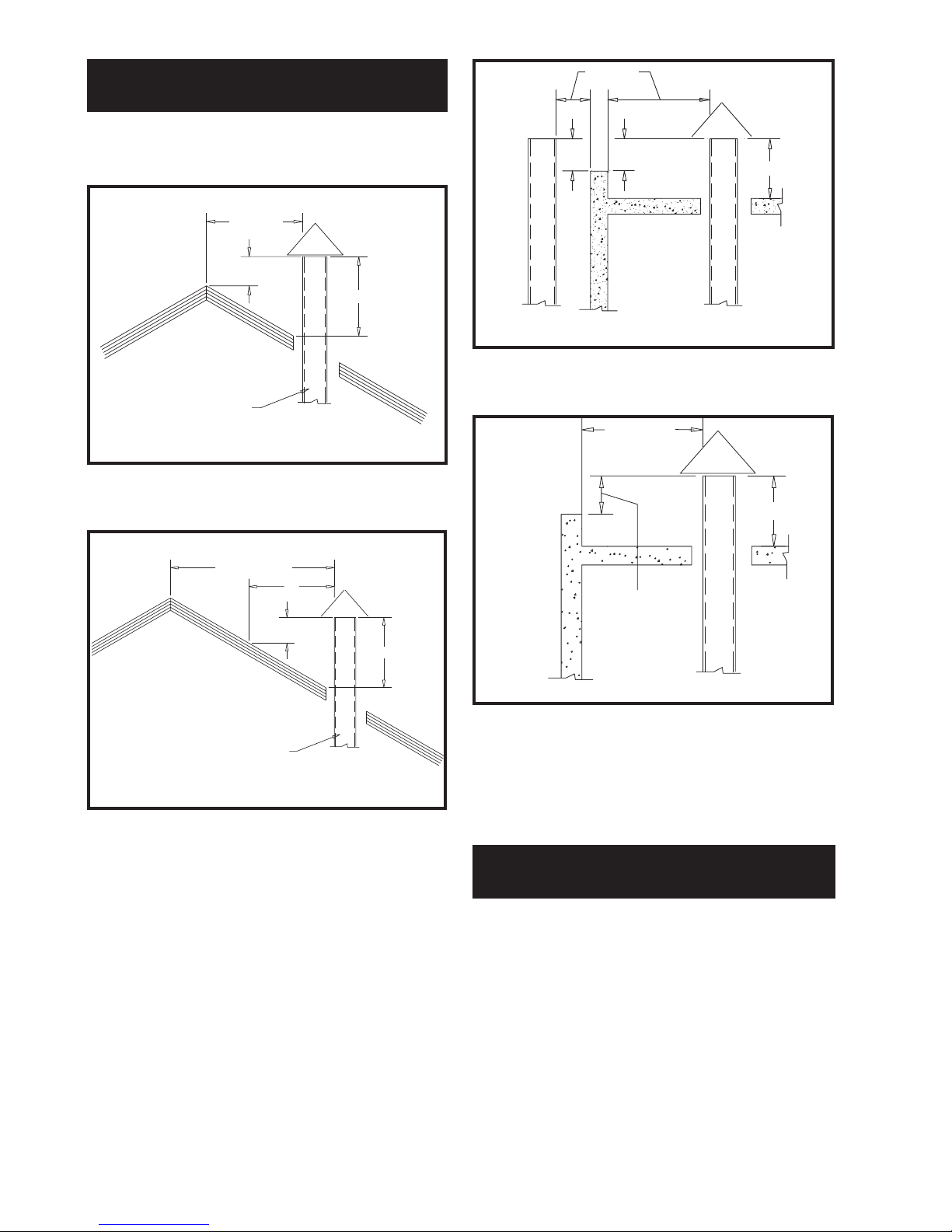

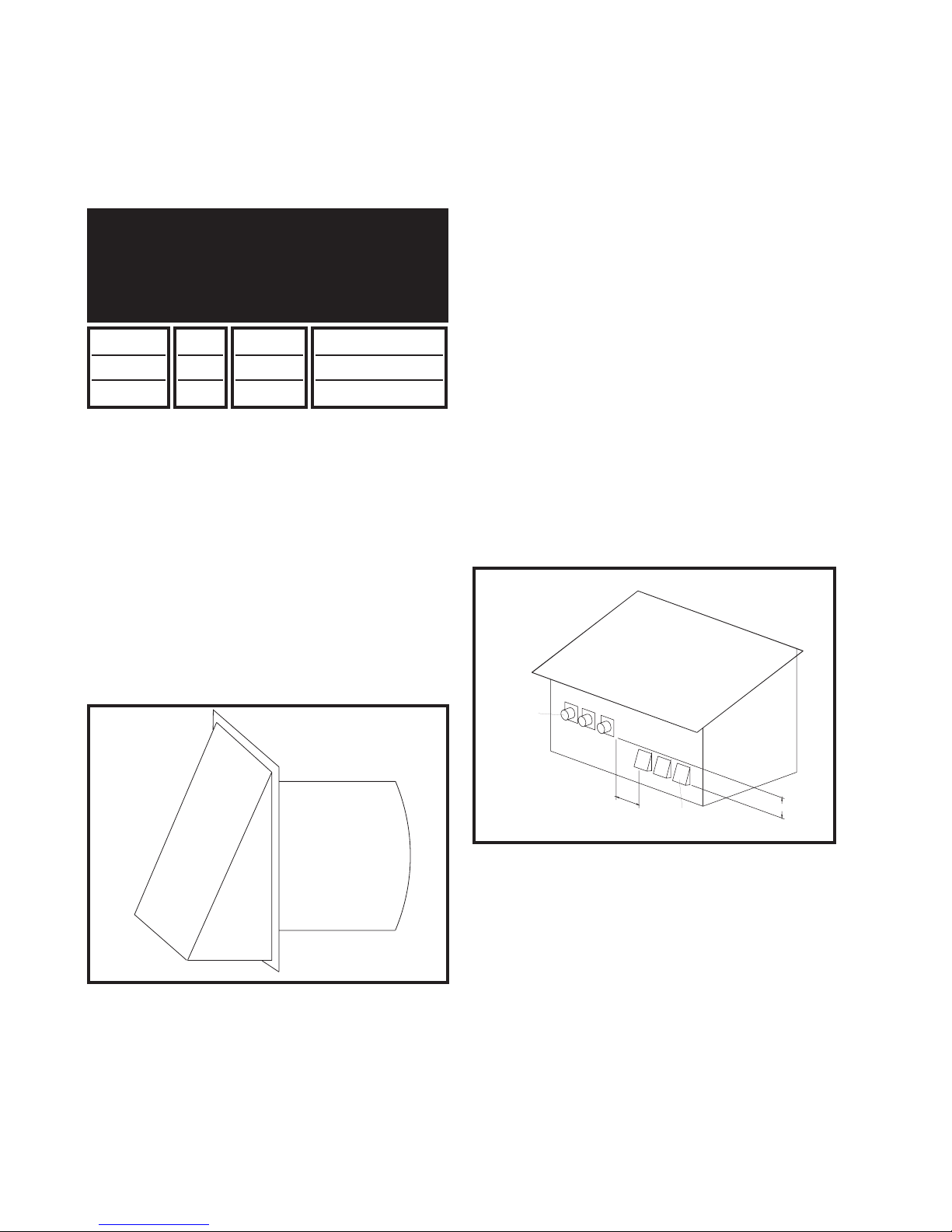

FIG. 13 Vent Termination from Peaked Roof - 10' or

Less From Ridge

FIG. 14 Vent Termination from Peaked Roof More

Than 10' From Ridge

The vent terminal should be vertical and exhaust outside

the building at least 2 feet (0.61 m) above the highest point

of the roof within a 10 foot (3.05 m) radius of the

termination.

The vertical termination must be a minimum of 3 feet

(0.91 m) above the point of exit.

FIG. 15 Vent Termination from Flat Roof 10' or Less

from Parapet Wall

FIG. 16 Vent Termination from Flat Roof More Than

10' from Parapet Wall

A vertical termination less than 10 feet (3.05 m) from a

parapet wall must be a minimum of 2 feet (0.61 m) higher

than the parapet wall.

This venting system uses the appliance's internal

combustion air blower to force the flue products out of a

horizontally-terminated flue. This blower generates a

positive pressure in the flue. Combustion air is drawn from

the equipment room (see Combustion and Ventilation Air

Requirements) unless the appliance is equipped with an

optional Direct Vent or DirectAire vent system.

SIDEWALL VENTING

TERMINATIONS

VERTICAL VENTING

TERMINATIONS

12

10' OR LESS

2' MIN

RIDGE

CHIMNEY

3' MIN

10' OR LESS

WALL OR

PARAPET

2' MIN

3' MIN

CHIMNEY

2' MIN

CHIMNEY

10' OR MORE

3' MIN

MORE THAN 10'

10'

RIDGE

2' MIN

3' MIN

CHIMNEY

NOTE: NO HEIGHT

ABOVE PARAPET

REQUIRED WHEN

WALL OR

PARAPET

DISTANCE FOR

WALLS OR PARAPETS

IS MORE THAN 10'>

CHIMNEY

Page 13

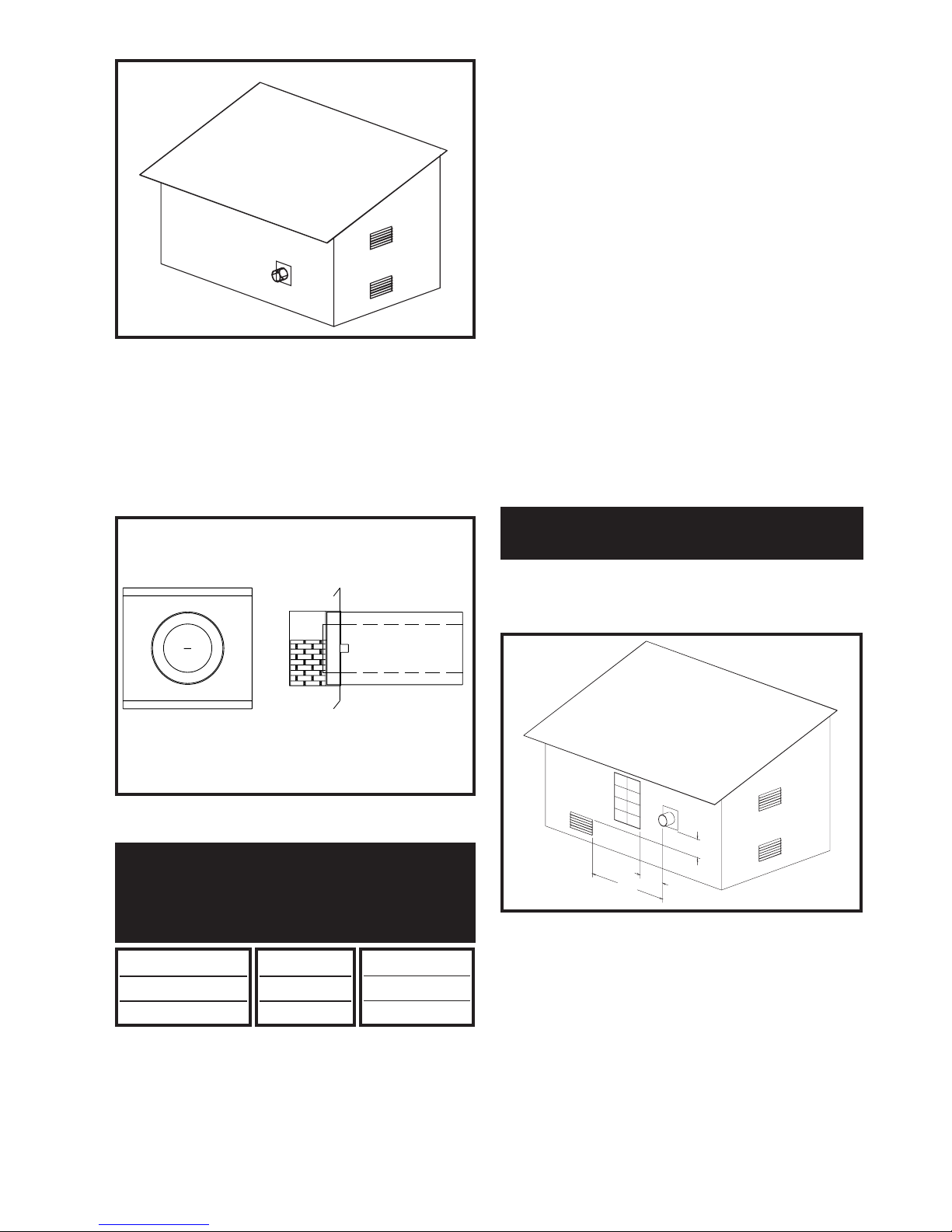

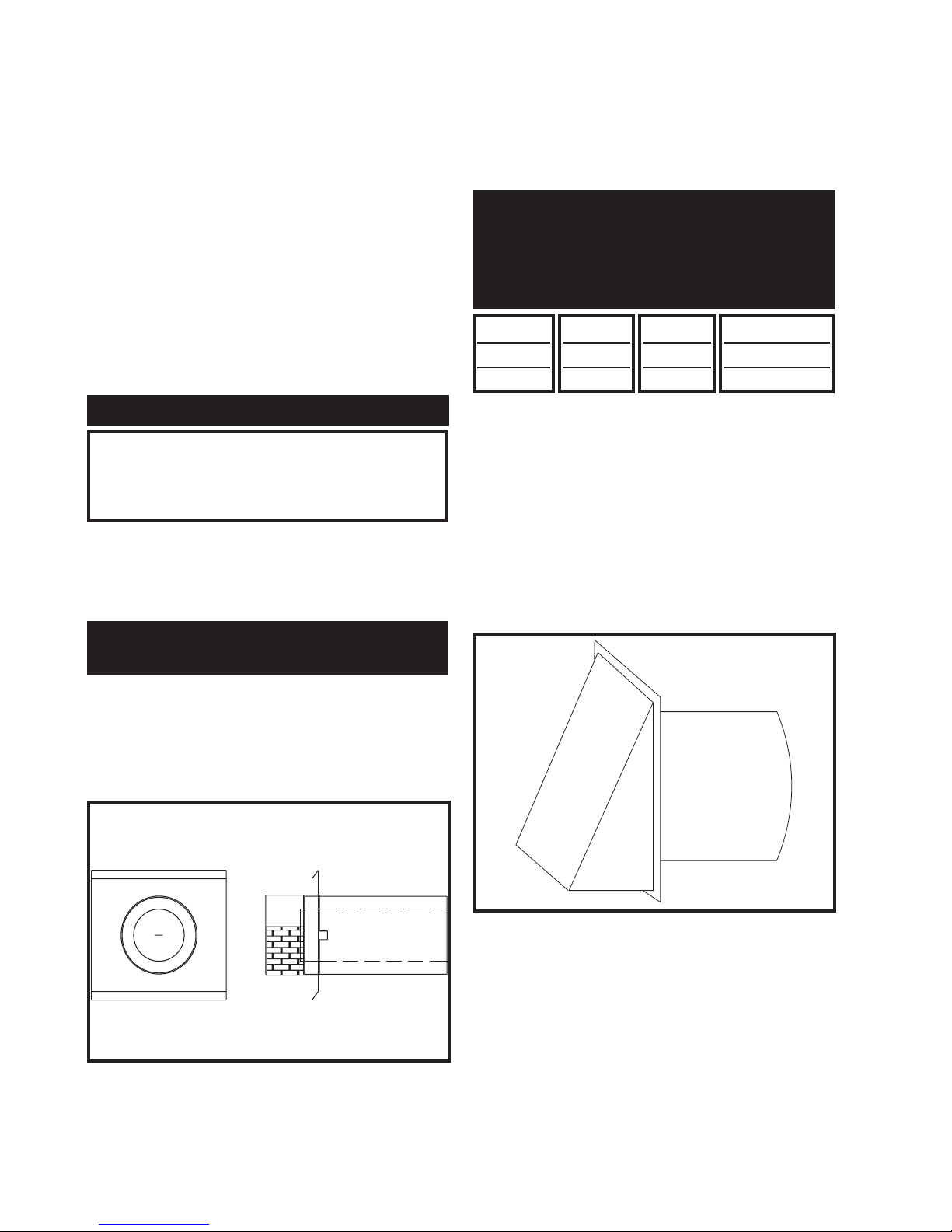

FIG. 17 Sidewall Venting Installation

The connection from the appliance flue outlet to the

sidewall vent cap MUST be made with listed type

Category IV vent materials and accessories. The installer

must supply suitable vent pipe material. The sidewall vent

cap is available from the appliance manufacturer as a vent

kit.

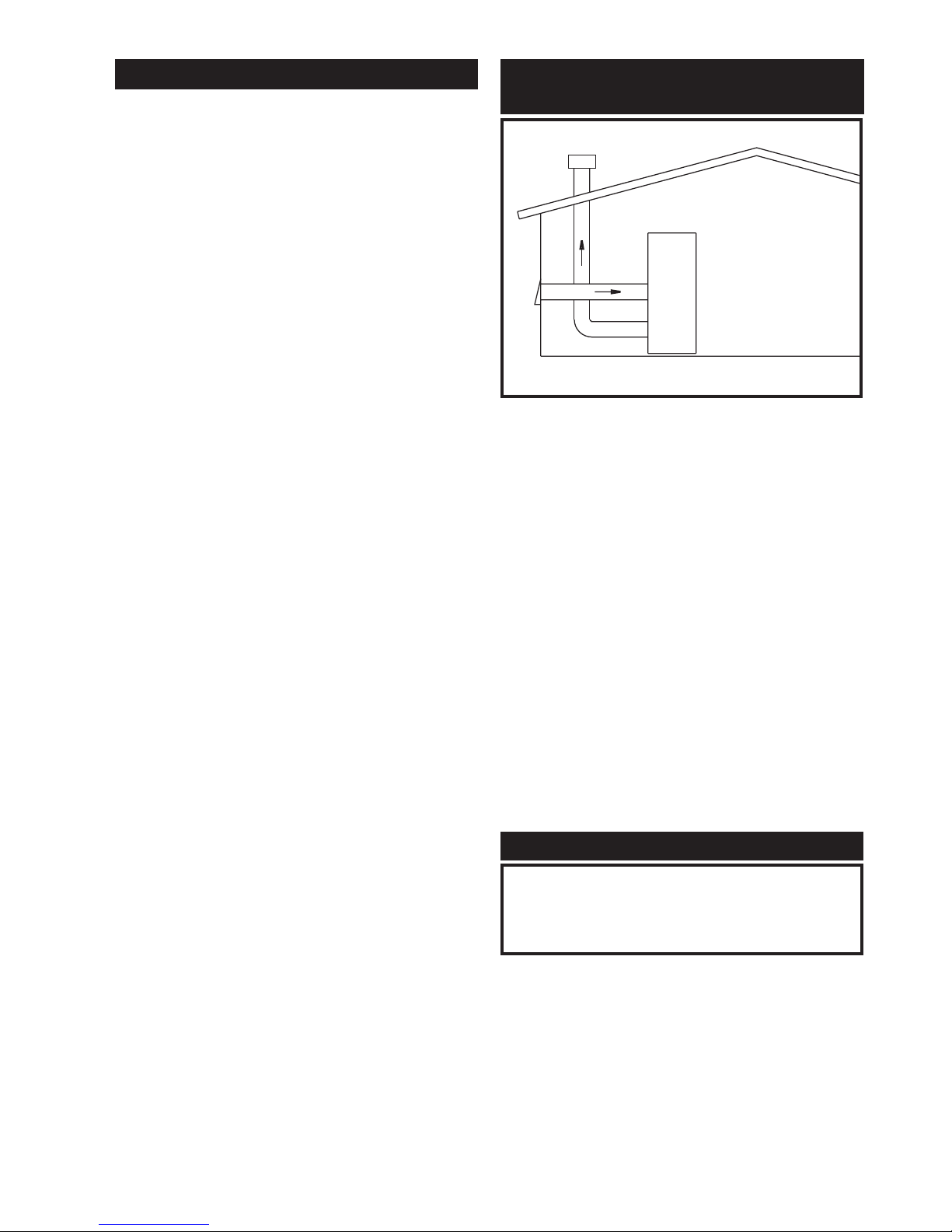

FIG. 18 Sidewall Vent Cap

The sidewall vent cap kit includes the wall penetration

assembly and the discharge screen assembly. All required

Category IV vent pipe and fittings must be purchased

locally. The installed sidewall vent cap assembly may be

painted to match the exterior décor.

The opening through the wall for installation of the

sidewall vent cap must provide an air space clearance of 2

inches (5.1 cm) around the flue pipe. The diameter of the

opening for installation of the sidewall cap will be 4 inches

(10.2 cm) larger (minimum) than the nominal diameter of

the installed vent pipe to the sidewall cap.

The sidewall cap is installed from the outside and mounted

to the wall with four screws or wall anchors. Seal under the

screw heads with caulking. Install the screen assembly

using the stainless steel screws provided in the kit. Install

the Category IV vent pipe from the appliance to the vent

cap. The installed vent pipe must protrude at least 2 inches

(5.1 cm) into the screen area beyond the thimble portion of

the sidewall cap assembly. See detailed instructions

packed with the sidewall vent kit.

Follow all requirements in the General Category IV

Venting sections for venting flue products to the outdoors.

See the Combustion and Ventilation Air Requirements

section to ensure that adequate combustion and ventilation

air is supplied to the equipment room. All other general

installation requirements must be followed.

Follow all General Category IV Vent Termination

Clearances.

FIG. 19 Sidewall Venting Installation with Clearances

From Vent Cap

The vent cap shall terminate at least 3 feet (0.91 m) above

any forced air inlet within 10 feet (3.05 m).

The vent shall terminate at least 4 feet (1.22 m) below,

4 feet (1.22 m) horizontally from or 1 foot (0.30 m) above

and 2 feet (0.60 m) horizontally from any door, window or

gravity air inlet to the building.

LOCATION OF A SIDEWALL VENT

TERMINATION

SVK3028

SVK3028

SVK3029

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — E

Sidewall Vent Cap Kits

Sidewall

Input Btu/hr Flue Size Vent Cap Kit

13

3' MIN.

4' MIN.

10' MIN.

Page 14

The sidewall vent termination must be at least 8 feet

(2.4 m) horizontally from any combustion air intake

located above the sidewall termination cap.

Do not terminate the vent in a window well, stairwell,

alcove, courtyard or other recessed area. The vent can not

terminate below grade.

The vent shall not terminate directly above a public

walkway due to the normal formation of water vapor in the

combustion process. Horizontal terminations must not be

located over areas of pedestrian or vehicular traffic.

The vent system shall terminate at least 1 foot (0.30 m)

above grade, above normal snow levels and at least 7 feet

(2.13 m) above grade when located adjacent to public

walkways.

The vent terminal shall not be installed closer than 3 feet

(0.91m) from an inside corner of an L-shaped structure.

The vent cap should have a minimum clearance of 4 feet

(1.22 m) horizontally from and in no case above or below,

unless a 4-foot (1.22 m) horizontal distance is maintained

from electric meters, gas meters, regulators and relief

equipment.

Flue gas condensate can freeze on exterior walls or on the

vent cap. Frozen condensate on the vent cap can result in

a blocked flue condition. Some discoloration to exterior

building surfaces can be expected. Adjacent brick or

masonry surfaces should be protected with a rust resistant

sheet metal plate.

The sidewall vent system MUST use the sidewall vent cap

kit provided by the appliance manufacturer for installation

on a sidewall termination.

The sidewall vent cap MUST be purchased as a kit from

the appliance manufacturer to ensure proper operation.

Locally purchased or fabricated sidewall vent caps should

not be used

Direct Vent and DirectAire Vent Systems are installed with

a Category IV flue and a separate combustion air pipe to

the outdoors. The Direct Vent System terminates both the

flue and combustion air inlet in the same pressure zone.

The DirectAire Vent System terminates the flue and

combustion air inlet in different pressure zones. The flue

outlet and combustion air intake may terminate with either

a sidewall or a rooftop termination.

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting of

flue products vertically or horizontally to the outdoors. All

other general installation requirements must be followed.

The Direct Vent and Intelli-Vent Systems require the

installation of an additional pipe to supply combustion air

from outdoors directly to the appliance.

In cold climates, the use of type “B” double wall vent pipe

or an insulated single wall pipe for combustion air is

recommended to help prevent moisture in the cool

incoming air from condensing and leaking from the inlet

pipe.

Termination point for the flue products must follow the

clearance requirements in the Vertical or Horizontal Vent

Termination sections of the Category IV Venting.

*Piping from the appliance to the air inlet cap may be

either 7" or 8". An 8" diameter sidewall air inlet cap is

provided in the venting kit.

Length of Air Inlet Pipe

The maximum total length of the sidewall or vertical

rooftop combustion air inlet pipe as installed from the

appliance to the air inlet cap must not exceed 50

equivalent feet (15.2 m) in length. Subtract 5 feet

(1.52 m) of equivalent length for each 90° elbow installed

in the air inlet pipe system. Subtract 2 1/2 feet (0.7 m) of

equivalent length for each 45° elbow installed in the air

inlet pipe system.

Do not exceed limits for the combustion air inlet piping

lengths.

Air Inlet Pipe Materials

The air inlet pipe(s) must be sealed. Choose acceptable

combustion air inlet pipe materials from those specified in

this section.

6”

7”*

8”

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — F

Direct Vent and DirectAire Flue

and Air Inlet Pipe Sizes

Air Inlet

Input Btu/hr Flue Size Pipe Size

Appliances that are shut down or will not operate

may experience freezing due to convective airflow

in the air inlet pipe connected to the appliance.

CAUTION:

DIRECT VENT AND

DIRECTAIRE VENT SYSTEMS

14

Page 15

Select air inlet pipe material from the following specified

materials:

PVC, CPVC or ABS (6", 7"or 8" I.D.)*

Dryer Vent or Sealed Flexible Duct (not recommended for

roof top air inlet)

Galvanized steel vent pipe with joints and seams sealed as

specified below.

Type "B" double wall vent with joints and seams sealed as

specified below

* Plastic pipe may require an adapter (not provided) to

transition between the air inlet connection on the appliance

and the plastic air inlet pipe.

Sealing of Type "B" double wall vent material or

galvanized vent pipe material used for air inlet pipe on

a sidewall or vertical roof top Combustion Air Supply

System.

a. Seal all joints and seams of the air inlet pipe using

either Aluminum Foil Duct Tape meeting UL Standard

723 or 181A-P or a high quality UL Listed silicon

sealant such as those manufactured by Dow Corning or

General Electric.

b. Do not install seams of vent pipe on the bottom of

horizontal runs.

c. Secure all joints with a minimum of three sheet metal

screws or pop rivets. Apply aluminum foil duct tape or

silicone sealant to all screws or rivets installed in the

vent pipe.

d. Ensure that the air inlet pipes are properly supported.

The PVC, CPVC or ABS air inlet pipe should be cleaned

and sealed with the pipe manufacturers recommended

solvents and standard commercial pipe cement for the

material used. The PVC, CPVC, ABS, Dryer Vent or Flex

Duct air inlet pipe should use a silicone sealant to ensure a

proper seal at the appliance connection and the air inlet cap

connection. Dryer vent or flex duct should use a screw

type clamp to seal the vent to the appliance air inlet and the

air inlet cap. Proper sealing of the air inlet pipe ensures

that combustion air will be free of contaminants and

supplied in proper volume.

When a sidewall or vertical roof top combustion air supply

system is disconnected for any reason, the air inlet pipe

must be resealed to ensure that combustion air will be free

of contaminants and supplied in proper volume.

Combined Combustion Air Inlet Points

The air inlet pipes from multiple appliances can be

combined to a single common connection if the common

air inlet pipe has a cross sectional area equal to or larger

than the total area of all air inlet pipes connected to the

common air inlet pipe. [Example: two 8" (20.3 cm) air inlet

pipes (50.3 in

2

(324.5 cm2) area each) have a total area of

100.6 in2(645.2 cm2) requires a 12 inches (30.5 cm) (113.1

in

2

area) (729.7 cm2) common air inlet pipe.] The air inlet

point for multiple boiler air inlets must be provided with an

exterior opening which has a free area equal to or greater

than the total area of all air inlet pipes connected to the

common air inlet. This exterior opening for combustion air

must connect directly to the outdoors. The total length of

the combined air inlet pipe must not exceed a maximum of

50 (15.2 m) equivalent feet. You must deduct the restriction

in area provided by any screens, grills or louvers installed

in the common air inlet point. These are common on the

sidewall air inlet openings and some rooftop terminations.

Screens, grills or louvers installed in the common air inlet

can reduce the free area of the opening from 25% to 75%

based on the materials used.

A Vertical Direct Vent System is installed with a Category

IV flue and a separate combustion air pipe to the outdoors.

The Direct Vent system terminates both the flue and air

inlet in the same pressure zone. The flue outlet and

combustion air intake must both terminate on the rooftop.

VERTICAL DIRECT

VENT SYSTEMS

Failure to properly seal all joints and seams as

required in the air inlet piping may result in flue gas

recirculation, spillage of flue products and carbon

monoxide emissions causing severe personal injury

or death.

DANGER:

The use of double wall vent or insulated material

for the combustion air inlet pipe is recommended in

cold climates to prevent the condensation of

airborne moisture in the incoming combustion air.

NOTE:

Using vent or air intake materials other than those

specified, failure to properly seal all seams and

joints or failure to follow vent pipe manufacturer's

instructions can result in personal injury, death or

property damage. Mixing of venting materials will

void the warranty and certification of the

appliance.

WARNING:

15

Page 16

FIG. 20 Vertical Direct Vent Installation with Rooftop

Combustion Air Inlet

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products vertically to the outdoors. All other general

installation requirements must be followed.

The Direct Vent system requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance. The air inlet pipe must use one of

the specified materials.

The maximum installed length of the air inlet pipe from

the appliance to the air inlet cap is 50 equivalent feet

(15.2 m) in length. The maximum installed length of the

flue pipe from the appliance to the termination cap is 50

equivalent feet (15.2 m) in length. Subtract 5 feet (1.52 m)

of equivalent length for each 90° elbow installed in either

the flue pipe or the air inlet pipe.

Termination point for the flue products must follow the

clearance requirements in the Vertical Vent Termination

sections of the Category IV Venting.

FIG. 21 Air Inlet Cap for Rooftop Termination

The air inlet cap for the vertical roof top air inlet is

assembled from components purchased locally. The air

inlet cap consist of two 90° elbows installed at the point of

termination for the air inlet pipe. The first 90° elbow is

installed on the rooftop at the highest vertical point of the

air inlet pipe and turned horizontal, the second 90° elbow

is installed on the horizontal outlet of the first elbow and

turned down. A 90° elbow and a 90° street elbow may be

used to make this assembly. If a straight piece of pipe is

used between the two elbows, it should not exceed 6 inches

(152 mm) in length. The termination elbow on the air inlet

must be located a minimum of 12" (0.30 m) above the roof

or above normal levels of snow accumulation.

The point of termination for the combustion air inlet cap

MUST be at least 3 feet (0.91 m) below the point of flue

gas termination (vent cap) if it is located within a 10 foot

(3.05 m) radius of the flue outlet. Use care to ensure that the

90° elbow assembly is properly installed on the air inlet pipe.

The combustion air inlet cap must not be installed closer

than 10 feet (3.05 m) from an inside corner of an L-shaped

structure.

The termination point of the combustion air inlet cap must

be installed at least one foot (0.30 m) above the rooftop and

above normal snow levels.

The combustion air cap assembly used MUST adequately

protect the combustion air inlet from wind and weather.

The combustion air cap and flue gas outlet MUST be

located on the same roof top surface and in the same

pressure zone.

Combustion air supplied from outdoors must be free of

contaminants (See Combustion and Ventilation Air). To

prevent recirculation of flue products in to the combustion

air inlet, follow all instructions in this section.

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in

incomplete combustion and potentially hazardous levels of

carbon monoxide in the flue products. This will cause

operational problems with the heater and possible spillage

of flue products that can cause personal injury, death or

property damage.

VERTICAL COMBUSTION

AIR INLET

3'

16

12"

Page 17

Multiple Vertical Direct Vent Installations

FIG. 22 Multiple Vertical Direct Vent Installations

The combustion air inlet caps for multiple appliance

installations must maintain the minimum 3 foot (0.91 m)

clearance below the closest vertical flue outlet if within 10

feet (3.05 m). Multiple flue outlet caps may be installed

side by side and multiple air inlet caps may be installed

side by side but the air inlet must always be at least 3 feet

(0.91 m) below the closest flue outlet if the outlet is within

10 feet (3.05 m). All clearance and installation

requirements in this section and the applicable portions of

the general Category IV venting section must be

maintained on multiple appliance installations.

For venting flue products horizontally to the outdoors,

follow all requirements in the installation instructions for

sidewall venting. Termination point for the flue products

must follow the clearance requirements in the Sidewall

Vent Termination section of Category IV Venting.

A Horizontal Direct Vent System is installed with a

Category IV flue and a separate combustion air pipe to the

outdoors. The Direct Vent system terminates both the flue

and air inlet in the same pressure zone. The flue outlet and

combustion air intake must both terminate on the same

sidewall.

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products to the outdoors with a sidewall termination. All

other general installation requirements must be followed.

The Direct Vent system requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance. The air inlet pipe must use one of

the specified materials.

The maximum installed length of the air inlet pipe from

the appliance to the air inlet cap is 50 equivalent feet

(15.2 m) in length. The maximum installed length of the

flue pipe from the appliance to the termination cap is 50

equivalent feet (15.2 m) in length. Subtract 5 feet (1.52 m)

of equivalent length for each 90° elbow installed in either

the flue pipe or the air inlet pipe. Subtract 2 1/2 feet (0.7 m)

of equivalent length for each 45° elbow installed in either

the flue or the air inlet pipe.

Termination point for the flue products must follow the

clearance requirements in the Sidewall Venting

Termination sections of the Category IV Venting.

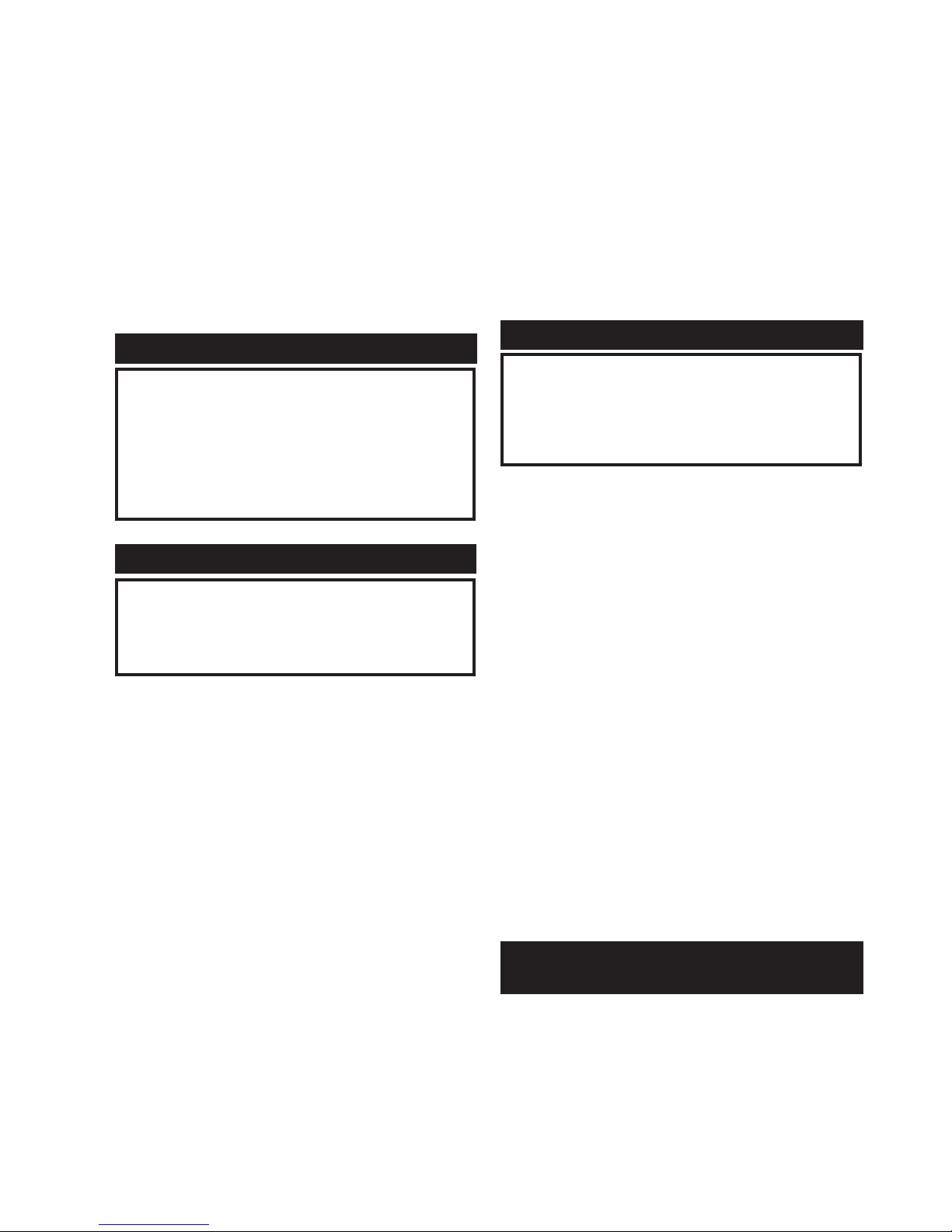

FIG. 23 Horizontal Direct Vent Installation with

Sidewall Combustion Air Inlet

Horizontal Direct Vent systems installed with sidewall

terminations for both combustion air and flue products

must purchase the termination caps from the appliance

manufacturer. The sidewall air inlet cap and sidewall vent

cap for flue products are available as a vent kit.

FIG. 24 Sidewall Vent Cap

SIDEWALL COMBUSTION

AIR INLET

HORIZONTAL DIRECT VENT

17

Page 18

The part numbers for the required sidewall air inlet cap kit

are listed by unit size. The manufacturer, in accordance

with CSA/CGA requirements, must furnish the sidewall air

inlet cap. Each kit includes the special combustion air inlet

cap for installation on an exterior sidewall. The sidewall

air inlet cap supplied in the kit is sized to provide

combustion air for a single appliance only.

*Piping from the appliance to the air inlet cap may be

either 7" or 8" connecting to an 8" sidewall cap

provided in the kit.

Location of a Sidewall Air Inlet Cap

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in

incomplete combustion and potentially hazardous levels of

carbon monoxide in the flue products. This will cause

operational problems with the heater and possible spillage

of flue products that can cause personal injury, death or

property damage

FIG. 25 Air Inlet Cap for Sidewall Termination

The termination point of the sidewall air inlet must be

installed a minimum of 12 inches (0.30 m) above ground

level and above normal levels of snow accumulation.

The point of termination for the sidewall combustion air

inlet cap MUST be located a minimum of 3 feet (0.91 m)

horizontally and 12 inches (0.30 m) below the point of flue

gas termination (vent cap) if it is located within a 10 foot

(3.05 m) radius of the flue outlet.

The sidewall combustion air inlet cap MUST NOT be

installed above the sidewall flue outlet if it is located within

a 10 foot (3.05 m) radius of the flue outlet.

The sidewall combustion air inlet cap must not be installed

closer than 10 feet (3.05 m) from an inside corner of an

L-shaped structure.

The sidewall combustion air cap assembly used MUST

adequately protect the combustion air inlet from wind and

weather.

The sidewall combustion air inlet cap and flue gas outlet

MUST be located on the same sidewall surface and in the

same pressure zone.

Combustion air supplied from outdoors must be free of

contaminants (See Combustion and Ventilation Air). To

prevent recirculation of flue products in to the combustion

air inlet, follow all instructions in this section.

Multiple Horizontal Direct Vent Installations

FIG. 26 Multiple Horizontal Direct Vent Caps Installed

on a Sidewall

The combustion air inlet caps for multiple appliance

installations must maintain the same minimum clearance

from the closest vent cap installed within a 10 foot radius

of the point of flue gas termination as specified in single

appliance installations. Multiple flue outlet caps may be

installed side by side and multiple air inlet caps may be

installed side by side but, the minimum clearance of a 3

feet (0.91 m) horizontal radius and 12 inches (0.30 m)

below the closest flue outlet to the air inlet cap must be

maintained. All clearance and installation requirements in

this section and the applicable portions of the general

Category IV venting section must be maintained on

multiple appliance installations.

HDK3021

HDK3022

HDK3023

6”

8”*

8”

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — G

Horizontal Direct Vent Kits

Flue Sidewall Air

Input Cap Air Inlet Inlet Flue

Btu/hr Size Cap Size Cap Kit

18

FLUE OUTLETS

3' HORIZONTALLY

AIR INLET CAP

1' BELOW FLUE

Page 19

A DirectAire vent system is a Category IV flue installed

with a separate combustion air pipe to the outdoors. The

DirectAire vent system terminates the flue and the

combustion air inlet pipe in different pressure zones. The

DirectAire vent system may terminate the flue and

combustion air in any one of three configurations. These

are: (1) the flue on the roof top and combustion air intake

on the sidewall; (2) the flue on the sidewall and

combustion air from the rooftop; (3) the flue on the

sidewall and the combustion air on a sidewall other than

the sidewall where the flue is located. All appliances are

shipped from the factory equipped for Category IV

venting system. The optional DirectAire vent systems

require the installation of specific venting materials that are

purchased locally. Sidewall termination caps for flue

products and combustion air must be purchased from the

manufacturer. The sidewall caps for combustion air and

flue products are available as vent kits. The following is a

detailed explanation of the installation requirements for

each venting system, components used and part numbers of

vent kits for each model.

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products to the outdoors with either a rooftop or a sidewall

termination. All other general installation requirements

must be followed.

The DirectAire vent system requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance. The air inlet pipe must use one of

the specified materials.

Combined Air Inlet Points

The air inlet pipes from multiple appliances installed with

a DirectAire vent system can be combined to a single

common connection based on the cross sectional area of

the common pipe as defined in the Direct-Vent basic

information section.

Maximum Length of a DirectAire Vent System

The maximum installed length of the air inlet pipe from

the appliance to the air inlet cap is 50 equivalent feet

(15.2 m) in length. The maximum installed length of the

flue pipe from the appliance to the termination cap is 50

equivalent feet (15.2 m) in length. Subtract 5 feet (1.52 m)

of equivalent length for each 90° elbow installed in either

the flue pipe or the air inlet pipe. Subtract 2 1/2 feet (0.7 m)

of equivalent length for each 45° elbow installed in either

the flue pipe or the air inlet pipe.

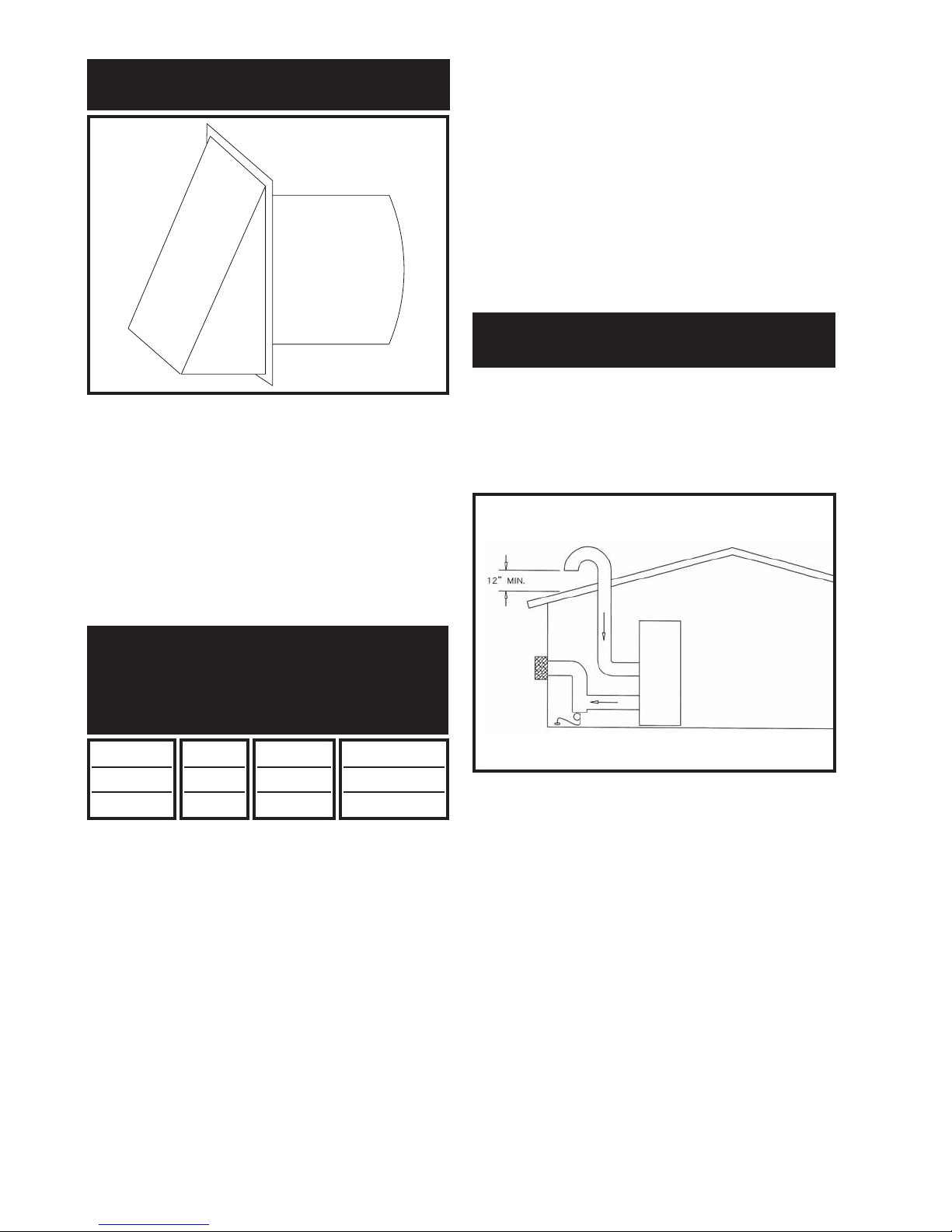

FIG. 27 Vertical DirectAire Installation with Sidewall

Combustion Air Inlet

DirectAire vent systems are installed with a Category IV

flue and a separate combustion air pipe to the outdoors.

The Vertical DirectAire vent system terminates the flue at

the rooftop and air inlet at the sidewall. The flue outlet and

combustion air intake terminate in different pressure zones.

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products vertically to the outdoors. All other general

installation requirements must be followed.

The DirectAire vent system requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance.

Termination point for the flue products must follow the

clearance requirements in the Vertical Vent Termination

section of the Category IV Venting.

Appliances that are shut down or will not

operate may experience freezing due to

convective airflow in the air inlet pipe connected

to the appliance.

CAUTION:

VERTICAL DIRECTAIRE WITH

SIDEWALL COMBUSTION AIR

DIRECTAIRE VENT SYSTEMS

19

Page 20

FIG. 28 Air Inlet Cap for Sidewall Termination

The air inlet cap for the sidewall air inlet must be

purchased from the appliance manufacturer.

The part numbers for the required sidewall air inlet cap kit

are listed by unit size. The appliance manufacturer, in

accordance with CSA/CGA requirements, must furnish the

sidewall air inlet cap. Each kit includes the special

combustion air inlet cap for installation on an exterior

sidewall.

*Piping from the appliance to the air inlet cap may be

either 7" or 8" connecting to an 8" sidewall cap

provided in the kit.

Location of a Sidewall Air Inlet Cap

Installation, location and clearance requirements for the

sidewall air inlet cap in an DirectAire vent application are

the same as the installation, location and clearance

requirements for the sidewall air inlet cap in the Horizontal

Direct Vent section of the venting instructions.

The sidewall combustion air inlet cap and the rooftop flue

gas outlet are located in different pressure zones in a

DirectAire system.

Combustion air supplied from outdoors must be free of

contaminants (See Combustion and Ventilation Air). To

prevent recirculation of flue products in to the combustion

air inlet, follow all instructions in this section.

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in

incomplete combustion and potentially hazardous levels of

carbon monoxide in the flue products. This will cause

operational problems with the heater and possible spillage

of flue products that can cause personal injury, death or

property damage.

DirectAire vent systems are installed with a Category IV

flue and a separate combustion air pipe to the outdoors.

The Horizontal DirectAire system terminates the flue at the

sidewall and air inlet at the rooftop. The flue outlet and

combustion air intake terminate in different pressure zones.

FIG. 29 Horizontal DirectAire Installation with

Rooftop Combustion Air Inlet

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products horizontally to the outdoors. All other general

installation requirements must be followed.

The DirectAire vent system requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance.

In cold climates, the use of type “B” double wall vent pipe

or an insulated single wall pipe is recommended to help

prevent moisture in the cool incoming air from condensing

and leaking from the inlet pipe.

Termination point for the flue products must follow the

clearance requirements in the Horizontal Sidewall Vent

Termination section of the Category IV Venting.

HORIZONTAL DIRECTAIRE WITH

VERTICAL COMBUSTION AIR

SAK3000

SAK3001

SAK3001

6”

7”*

8”

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — H

Sidewall Air Inlet Cap Kits

Air Inlet Sidewall

Input Flue Pipe Air Inlet

Btu/hr Size Size Cap Kit

SIDEWALL COMBUSTION

AIR INLET

20

Page 21

The flue and air inlet duct sizes for a Horizontal DirectAire

Installation with Rooftop Combustion Air Inlet are listed

by unit size. The sidewall vent cap must be purchased from

the appliance manufacturer as a vent kit.

*Piping from the appliance to the air inlet cap may be

either 7" or 8" connecting to an 8" sidewall cap

provided in the kit.

FIG. 30 Air Inlet Cap for Rooftop Termination

The air inlet cap for the vertical roof top air inlet is

assembled from components purchased locally. The air

inlet cap consist of two 90° elbows installed at the point of

termination for the air inlet pipe. The first 90° elbow is

installed on the rooftop at the highest vertical point of the

air inlet pipe and turned horizontal, the second 90° elbow

is installed on the horizontal outlet of the first elbow and

turned down. A 90° elbow and a 90° street elbow may be

used to make this assembly. If a straight piece of pipe is

used between the two elbows, it should not exceed 6 inches

(152 mm) in length. The termination elbow on the air inlet must

be located a minimum of 12 inches (0.30 m) above the roof

or above normal levels of snow accumulation.

Location of a Rooftop Air Inlet Cap

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in

incomplete combustion and potentially hazardous levels of

carbon monoxide in the flue products. This will cause

operational problems with the heater and possible spillage

of flue products that can cause personal injury, death or

property damage

Installation, location and clearance requirements for the

rooftop air inlet cap in an DirectAire application are the

same as the installation, location and clearance

requirements for the rooftop air inlet cap in the Vertical

Direct Vent section of the venting instructions.

The rooftop combustion air inlet cap and the sidewall flue

gas outlet are located in different pressure zones in a

DirectAire vent system.

Combustion air supplied from outdoors must be free of

contaminants (See Combustion and Ventilation Air). To

prevent recirculation of flue products in to the combustion

air inlet, follow all instructions in this section and related

Direct Vent sections.

DirectAire systems are installed with a Category IV flue

and a separate combustion air pipe to the outdoors. The

Horizontal DirectAire system terminates the flue at the

sidewall and the combustion air on a sidewall other than

the sidewall where the flue is located. The sidewall flue

outlet and sidewall combustion air intake must terminate in

different pressure zones.

FIG. 31 Horizontal DirectAire Installation with

Sidewall Combustion Air Inlet in a Different

Pressure Zone

HORIZONTAL DIRECTAIRE WITH

SIDEWALL COMBUSTION AIR

VERTICAL COMBUSTION

AIR INLET

SVK3028

SVK3028

SVK3029

6”

7”*

8”

8”

8”

10”

1,500,000

1,700,000

2,000,000

TABLE — I

Sidewall Vent Cap Kits

Air Inlet Sidewall

Input Flue Pipe Vent

Btu/hr Size Size Cap Kit

Appliances that are shut down or will not operate

may experience freezing due to convective airflow

in the air inlet pipe connected to the appliance.

CAUTION:

21

Page 22

Follow all requirements in the General Category IV

Venting sections for proper installation and of venting flue

products horizontally to the outdoors. All other general

installation requirements must be followed.

The DirectAire System requires the installation of an

additional pipe to supply combustion air from outdoors

directly to the appliance.

In cold climates, the use of type “B” double wall vent pipe

or an insulated single wall pipe is recommended to help

prevent moisture in the cool incoming air from condensing

and leaking from the inlet pipe.

Termination point for the flue products must follow the

clearance requirements in the Horizontal Sidewall Vent

Termination section of the Category IV Venting.

The flue and air inlet duct sizes for a Horizontal DirectAire

Installation with Sidewall Combustion Air Inlet are listed

by unit size.

DirectAire systems installed with sidewall terminations for

both combustion air and flue products must purchase the

termination caps from the appliance manufacturer. The

sidewall air inlet cap and sidewall vent cap for flue

products are available as a vent kit.

FIG. 32 Sidewall Vent Cap

The part numbers for the required sidewall air inlet and flue

cap kit are listed by unit size. The manufacturer, in

accordance with CSA/CGA requirements, must furnish

both the sidewall air inlet and flue cap. Each kit includes

the both the special combustion air inlet cap and the

sidewall flue cap for installation on an exterior sidewall.

The sidewall air inlet cap supplied in the kit is sized to

provide combustion air for a single appliance only.

*Piping from the appliance to the air inlet cap may be

either 7" or 8" connecting to an 8" sidewall cap

provided in the kit.

Location of a Sidewall Air Inlet Cap

Installation, location and clearance requirements for the