Pro

Weighing System

MANUAL

OPERATORS

Pro Weighing System

Model LR918

Document No. MAN-80664-00

Software No. 60270 Version 1.0

Issue Date: October 2002

Distributed Worldwide by:

93 First Avenue, PO Box 13-115, Tauranga, New Zealand

+64-7-5776034

℡ +64-7-5782820

info@loadrite.co.nz

www.loadritescales.com

Designed & Manufactured by:

8 Walls Road, PO Box 12-607, Penrose, Auckland, New Zealand

www.actronic.com

This manual is copyrighted with all rights reserved. Under copyright laws, this manual may not be

copied in whole or in part or reproduced in any other media without the express written permission

of Actronic Ltd. Permitted copies must carry the same proprietary and copyright notices as were

affixed to the original. Under the law, copying includes translation into another language.

Please note that while every effort has been made to ensure that the data given in this document is

accurate, the information, figures, illustrations, tables, specifications, and schematics contained

herein are subject to change without notice.

Actronic Ltd assumes no liability in connection with the use of any Loadrite branded product.

© 2002 ACTRONIC LIMITED

i

Contents

1 Introduction .........................................................................................................................1

Indicator Lights .............................................................................................................................................. 2

Keypad ............................................................................................................................................................ 2

2 Quick Start Guide ...............................................................................................................5

Switching On ................................................................................................................................................. 5

Standby............................................................................................................................................................ 5

The Warm Up Screen .................................................................................................................................. 5

The Ready Screen ......................................................................................................................................... 6

Weighing a Load ........................................................................................................................................... 6

Static Weigh function................................................................................................................................... 7

Adding a Load ............................................................................................................................................... 7

Clearing the Short Total............................................................................................................................... 8

Zeroing............................................................................................................................................................ 8

3 Weighing Overview........................................................................................................... 10

Weighing Modes......................................................................................................................................... 10

Short and Long Totals ................................................................................................................................11

Accurate Weighing..................................................................................................................................... 11

General Method of Weighing..................................................................................................................12

4 Weighing Procedures ........................................................................................................ 13

Adding a Load .............................................................................................................................................13

Auto Add....................................................................................................................................................... 14

Subtracting a Load...................................................................................................................................... 14

Zeroing.......................................................................................................................................................... 15

Recalling Last Load ..................................................................................................................................... 18

Viewing Long Total..................................................................................................................................... 19

Clearing Totals ............................................................................................................................................. 19

Tare Function ............................................................................................................................................... 21

5 Product Management .......................................................................................................23

6 Data ....................................................................................................................................25

Data Edit........................................................................................................................................................ 25

Automatic Data Prompt ............................................................................................................................ 30

Data Suspend............................................................................................................................................... 30

7 Target Mode.......................................................................................................................32

8 Batch Mode........................................................................................................................ 35

The Batch Screen ........................................................................................................................................ 36

Viewing the Current Recipe ..................................................................................................................... 37

Changing the Recipe.................................................................................................................................. 38

Entering the Batch Total ............................................................................................................................ 39

Batch Weighing ........................................................................................................................................... 40

Clearing the Batch Totals .......................................................................................................................... 41

Returning to Total Mode........................................................................................................................... 41

9 Mix Mode...........................................................................................................................42

The Mix Screen............................................................................................................................................ 43

Mix Weighing ..............................................................................................................................................43

Clearing the Mix Totals.............................................................................................................................. 45

Returning to Total Mode........................................................................................................................... 45

10 Blend Mode........................................................................................................................46

The Blend Screen........................................................................................................................................ 46

ii

Blend Weighing ...........................................................................................................................................47

11 Split Mode ..........................................................................................................................49

12 Tip Off.................................................................................................................................52

13 Menu Options....................................................................................................................56

Setup ..............................................................................................................................................................57

Clock Setting (Clock) ................................................................................................................................57

Changing Scale Number (Scale#) .......................................................................................................... 57

Clear All Long Totals (ClearAll) ................................................................................................................58

Auto Add On/Off Setting (Auto Add)....................................................................................................58

Rotary Trigger Position Screen (TrigScrn)..............................................................................................58

LD941 Data Module Properties (Module)...........................................................................................59

Data Edit (DataEdit) ....................................................................................................................................59

Data List (DataList)...................................................................................................................................... 60

Alarm Clock On/Off...................................................................................................................................61

Alarm Time Set ............................................................................................................................................61

Self Test (Selftest) ....................................................................................................................................... 62

Uplink (Uplink).............................................................................................................................................62

14 Print Functions...................................................................................................................63

Printed Data ................................................................................................................................................. 64

Print Menu ....................................................................................................................................................64

15 Obtaining the Best Accuracy............................................................................................70

Lifting Speed.................................................................................................................................................70

Trigger Point ................................................................................................................................................. 70

Bounce...........................................................................................................................................................70

Centre of Gravity.........................................................................................................................................70

16 Error Messages...................................................................................................................71

Bouncing Load.............................................................................................................................................71

Check Power................................................................................................................................................71

Check Transducer .......................................................................................................................................71

Check Trigger...............................................................................................................................................71

Check Zero................................................................................................................................................... 71

Lift Under Range ......................................................................................................................................... 72

Module Data Lost ....................................................................................................................................... 72

Module Error ................................................................................................................................................72

Module Full................................................................................................................................................... 72

No Lock.........................................................................................................................................................72

Over Target ..................................................................................................................................................72

Overload .......................................................................................................................................................73

Poor Lift .........................................................................................................................................................73

Printer Disabled ........................................................................................................................................... 73

Printer Error ..................................................................................................................................................73

Return Under Range...................................................................................................................................73

Speed Changed ...........................................................................................................................................74

Too Heavy, Zero Aborted......................................................................................................................... 74

Warm Up Lift................................................................................................................................................74

17 Specifications .....................................................................................................................75

18 Output / Input Connections.............................................................................................77

Appendix i Time and Date...........................................................................................................78

Appendix ii Span Calibration Adjustment..................................................................................81

LOADRITE PRO OPERATING MANUAL

1

1 Introduction

The Loadrite Weighing System measures the weight of loads lifted by frontend loaders, log loaders, forklift trucks and similar machines that use

hydraulic rams to lift the load. The Loadrite is installed in the cab of the

loading machine and is connected to sensors on the lifting arms.

As the machine raises the load, the Loadrite measures the hydraulic

pressure in the lift cylinders, converts pressure into a weight reading and

displays the result. An electronic trigger device mounted on the lift arms

ensures that the pressure readings are always taken at the same position

on every lift.

The weight of the bucket or forks and associated structures is zeroed out

when the system is calibrated so that only the weight of the payload is

displayed. While operating the loader, the driver can add each weight lifted

to a running total.

LCD display

Indicator lights

Keypad

Main Operating Keys

LOADRITE PRO OPERATING MANUAL

2

The Loadrite has internal memory which stores settings and production data

even when switched off.

Indicator Lights

Four indicator lights are provided below the LCD screen.

Trigger

Check

Auto-Add

Tip-Off

Trigger Illuminates when a load is lifted past the

trigger point. When this light is on, the lifted

weight may be added.

Pages 7

and 12

Check

Function

Illuminates when the Loadrite is in the userselected function. Possible options are

Interlock, Tare mode, and Safe-to-weigh

mode for rotary trigger. Configuration is set

during installation.

-

Auto-Add Illuminates when the Loadrite is in Auto-Add

mode. In this mode, the Loadrite will

automatically add the lifted weight.

Page 14

Tip-Off Illuminates when the Tip-Off function is

operating.

Page 52

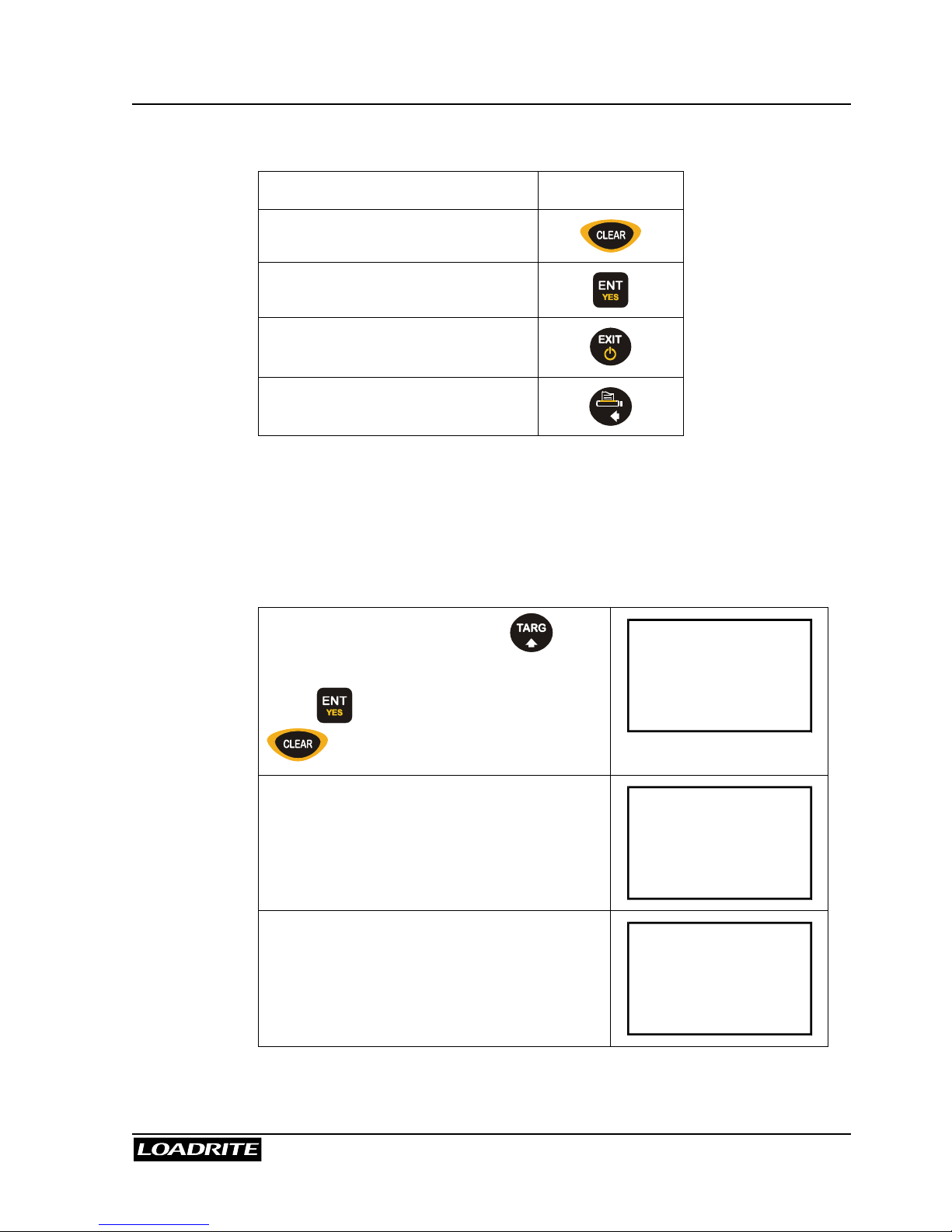

Keypad

The table below shows the special functions that the keys have in addition

to their numeric values used for entering data.

Adjusts the brightness of the screen back light.

-

A B C

Displays time and date. -

+

L

D E F

Displays the long total for the current product. Page 19

G H I

Recalls the previous load. Page 18

LOADRITE PRO OPERATING MANUAL

3

J K L

Allows you to enter a tare weight. Page 21

M N O

Accesses the menu Page 56

P Q R S

Subtracts the current load from the total. Page 15

T U V

Toggle language. -

W X Y Z

Accesses conversion. -

View alarm settings. -

i

Decimal point. Also view system information. -

Enter key for accepting data or changes. -

Exits an operation without changing the data.

When pressed on the Ready screen, puts the

Loadrite into standby mode. To return to the

Ready screen, press any key.

-

Allows you to enter additional Data. Page 25

Scroll down. Also enter Total mode. Page 10

Scroll up. Also enter Target mode. Page 32

Scroll left. Also selects the Print functions. Page 64

Scroll right. Also change Product. Page 23

Tip-off weighing. Page 52

LOADRITE PRO OPERATING MANUAL

4

Adds the current load to the total. Also toggles

into Auto Add mode.

Page 13

Clears the short total for the current product. Page 19

Zeroes out the current load. Page 15

LOADRITE PRO OPERATING MANUAL

5

2 Quick Start Guide

This section summarises the common Loadrite procedures. For full details

of weighing methods, see Weighing Overview on page 10 and Weighing

Procedures on page 13.

Switching On

The Loadrite powers up automatically when you switch on the ignition of the

loading machine.

If the Loadrite has been switched off for more than 1 hour, it displays the

Warm Up screen when powered up.

Standby

The Loadrite has a ‘standby’ mode which is similar to turning the Loadrite

off.

To put the Loadrite into standby press

, the EXIT key, when in the Ready

mode.

To restart the Loadrite, press any key.

Standby

The Warm Up Screen

For best weighing accuracy, the hydraulic fluid in the lift cylinders should be

at normal operating temperature. This is achieved by raising and lowering

the empty bucket or forks a few times.

The Warm up screen is displayed if the machine has been turned off over

an hour.

Raise the empty bucket or forks past the

trigger point three times.

Warm up

Lift 3

The Loadrite beeps at each lift and

displays the count down from 3. After the

third lift, the Ready screen is displayed

and the screen may look like this.

Ready

Sand

0

LOADRITE PRO OPERATING MANUAL

6

If it is time to check zero, the Loadrite will

display the Check Zero message to

remind you.

More information about Ready screen and

Check Zero screen will be covered later

in this manual.

Check

Zero

The Ready Screen

The Ready screen shows the product name and the short total for that

product. The short total is simply the sum of loads since you last cleared

the total.

When the Ready screen is displayed, the Loadrite is in Total mode and is

ready to weigh. Note that Sand in the below example represents the

current product of choice. Your Loadrite may be configured differently, and

hence, a different product name may appear on the screen.

Ready

Sand

3400

The Loadrite is ready to weigh

Current product to be loaded

Current total loaded

Weighing a Load

(Weights shown are examples only)

Loadrite is ready to

weigh sand.

(Current total 3400)

Ready

Sand

3400

Raise the load

smoothly past the

trigger point using

normal engine revs.

The bucket must be

fully rolled back

during weighing.

Weighing

3400

LOADRITE PRO OPERATING MANUAL

7

A short time later,

the Loadrite beeps,

turns the TRIG

indicator light on

and displays the

load lifted (2200).

Sand

3400

2200

The trigger point is where the metal plate passes the body of the trigger.

Static Weigh function

The Loadrite has an option known as ‘Static Weigh’. When this is used, the

weight display is always ‘live’ and no trigger is used.

The ‘Trigger’ light is used to indicate that the weight being measured is

‘stable’ (not changing too much) and therefore can be Added, Subtracted or

Zeroed.

Your Loadrite dealer will have configured the Static Weigh function if

required. Other functions described in this manual operate in a similar

manner, regardless of whether Static Weigh is being used.

Adding a Load

(Weights shown are examples only)

Before lifting:

(Current total 5600)

Ready

Sand

5600

Raise the load smoothly past the trigger

point using normal engine revs.

The Loadrite beeps and displays the load.

(Weight of load 2200)

Sand

5600

2200

Press .

The Loadrite updates the total and returns

to the Ready state.

(New total 7800)

Ready

Sand

7800

LOADRITE PRO OPERATING MANUAL

8

Clearing the Short Total

(Weights shown are examples only)

When you want to reset the short total to

zero (e.g. after loading a truck) ready for

another loading operation,

Press .

Ready

Sand

7800

The Loadrite displays Total Cleared for

a few seconds, clears the short total for the

current product and then …

Total

Cleared

7800

…returns to the Ready screen.

Ready

Sand

0

Zeroing

It is required to zero the Loadrite from time to time. This is to avoid

inaccurate readings due to build up of material in the bucket.

(Weights shown are examples only)

Before lifting:

Make sure that the bucket is empty and

fully rolled back.

Ready

Sand

0

Raise the bucket smoothly past the trigger

point.

The Loadrite beeps and displays the load.

Sand

0

20

LOADRITE PRO OPERATING MANUAL

9

Press .

The Loadrite performs the zero adjustment

and returns to the Ready state.

Ready

Sand

0

More detailed information about Zeroing can be found on page 15.

LOADRITE PRO OPERATING MANUAL

10

3 Weighing Overview

Weighing Modes

While individual bucket weight can be measured, the Loadrite also has an

ability to accumulate how much weight you have loaded on to a truck. The

main weighing modes are shown in the following table. The modes that are

available in a particular Loadrite depend on the installation.

Mode Description

Total As you add bucket loads, the weights are added to the totals.

The short total is displayed.

Target A target weight is entered into the Loadrite. As you add bucket

loads, the remaining value to reach the target is displayed.

Batch Allows you to weigh and load different products according to a

predefined recipe that specifies the required proportions. You

enter the grand batch target. Loadrite will work out individual

product weights needed.

Mix Similar to Batch mode except that the grand target is not

required. You load the first product to a certain amount.

Loadrite will work out how much you need for the other

products in the mix, based on the predefined recipe.

Blend Allows you to load fixed numbers of bucketful's of different

products according to a predefined recipe.

The normal mode of operation is Total mode, which uses the Ready

screen. To return to Total mode from any of the other modes, press

.

For Batch/Mix/Blend mode, you will return to Total mode when you clear the

grand total, or when you select a product that is not in the recipe.

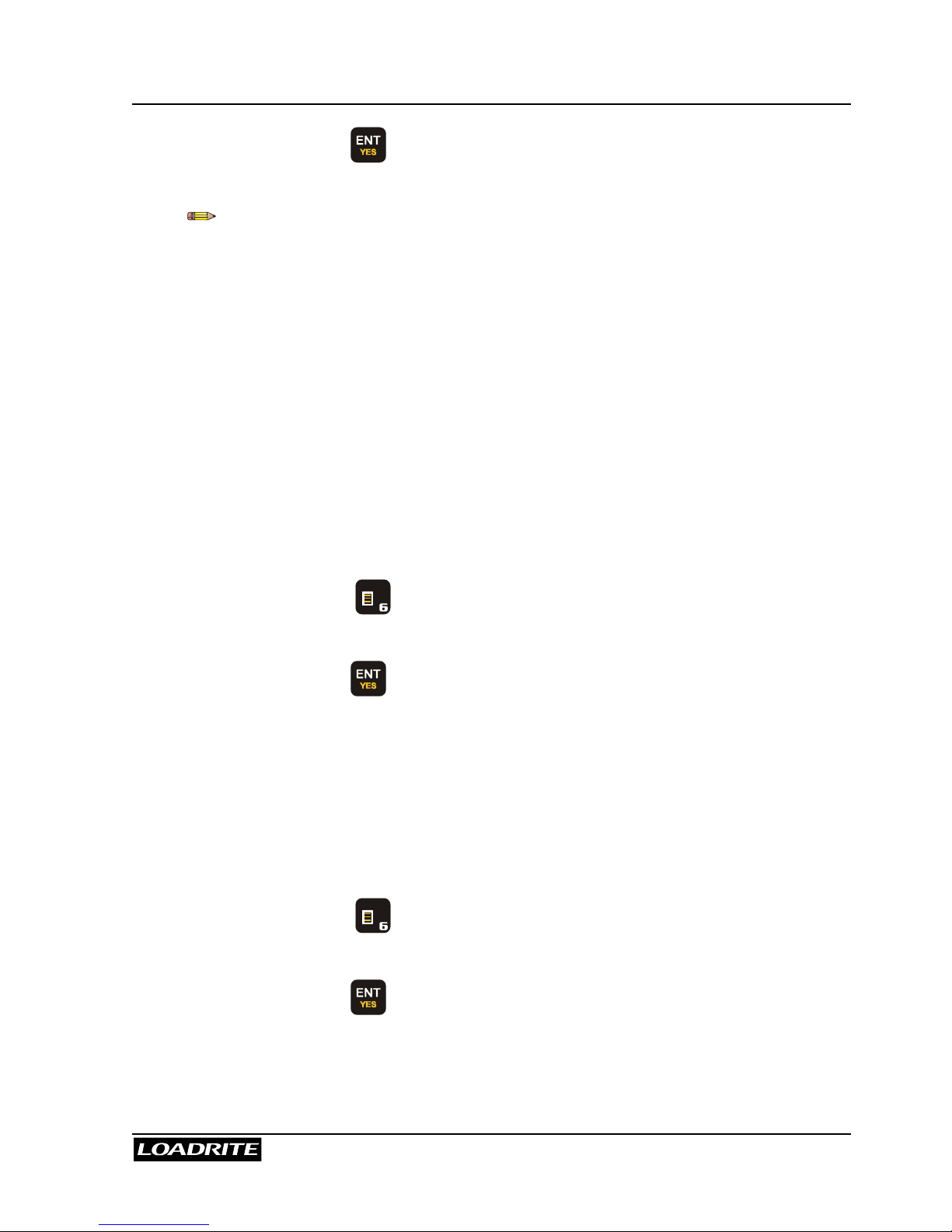

Changing to Target, Batch, Mix or Blend mode

If more than one of the above modes are enabled, you must first select the

mode you want to enter.

LOADRITE PRO OPERATING MANUAL

11

From the Ready screen, press .

Press 5 6 to scroll to the required mode

and then …

Target

Mode?

… press to accept.

Note: if your Loadrite has only one of

Target, Batch or Blend mode, there is no

need to scroll - simply press to

access the required mode.

Batch

Mode?

Short and Long Totals

The Loadrite keeps a total of the bucket weights that you add. For each

product, two independent totals are stored.

Short Total

Typically used to display the total weight lifted

onto a truck.

As you add successive loads, the Loadrite

displays the updated Short Total (sum of the

loads so far) on the Ready screen.

Long Total

Typically used to accumulate the weights lifted

over a longer period, for example a shift or a

day.

To view the Long Total, press

+

L

D E F

.

(See page 19.)

Accurate Weighing

For accurate weighing, make sure that:

• The bucket or forks are fully rolled back for each lift.

• The loader is stationary (for best accuracy).

• The lift arms start well below the trigger point. This ensures that all

acceleration and load bounce has been eliminated well before the

weighing sequence begins.

• The Loadrite is correctly zeroed. (Zeroing is described on page 15).

LOADRITE PRO OPERATING MANUAL

12

General Method of Weighing

1. BUCKET BACK. After picking up material into the bucket, roll the

bucket back.

2. LIFT. Raise the load smoothly past the trigger point using normal

engine revs. (The trigger point is where the metal plate passes the

body of the trigger). For best results, operate the lift lever before

accelerating the engine so that the machine does not rock as it lifts.

The Loadrite beeps, turns the TRIG light on and displays the load.

(See also page 6).

3. ADD. The Loadrite waits for a few seconds for you to take one of the

following actions:

• Press to add the weight to the long and short totals, or

• Press

P Q R S

to subtract the load from the totals, or

• Press to zero the measuring system.

If you don’t press a key, the Loadrite beeps and prompts you to take

action. The Loadrite then counts down and if you still don't press a

key, it discards the weight and goes back to the Ready state.

LOADRITE PRO OPERATING MANUAL

13

4 Weighing Procedures

Adding a Load

This function adds the lifted weight to the short and long totals for the

current product.

To Add a load

(Weights shown are examples only)

Before the load is lifted:

(Current total 5600)

Ready

Sand

5600

Raise the load smoothly past the trigger

point.

The Loadrite beeps and displays the load.

(Weight of load 2200)

Sand

5600

2200

Press .

The Loadrite updates the total and returns

to the Ready state.

(New total 7800)

Ready

Sand

7800

The Loadrite has an option to use a remote add button. If fitted, the remote

add button is normally mounted on the lift lever.

In Target mode, the display is different. For details, see Target Mode on

page 32.

LOADRITE PRO OPERATING MANUAL

14

Auto Add

Auto Add is an optional feature that is selected during installation. If Auto

Add is enabled, the Loadrite can automatically operate the ADD function

every time a load is lifted past the trigger point.

The Auto Add indicator light illuminates

when the Loadrite is in Auto-Add mode.

Ready

Sand

5600

To turn on/off auto add function

1. Press

M N O

to access user menu.

2. Use 5 6 to scroll to Auto Add.

3. Press to select.

4. Use 5 6 to adjust the setting.

5. Press to accept the setting.

If Auto Add is on:

• The procedure for zeroing is different. See page 17.

Subtracting a Load

This function can be useful when only part of a final bucket load of loose

material is required. You can add the full bucket load and then re-weigh

and subtract the amount remaining in the bucket.

Another example is when a log has been added and then removed from a

truck.

LOADRITE PRO OPERATING MANUAL

15

To subtract a Load

(Weights shown are examples only)

Before the load Is lifted:

(Current total 5600)

Ready

Sand

5600

Raise the load smoothly past the trigger

point.

The Loadrite beeps and displays the load.

(Weight of load 2200)

Sand

5600

2200

Press

P Q R S

.

The Loadrite updates the total and returns

to the Ready state.

(New total 3400)

Ready

Sand

3400

In Target mode, the display is different. For details, see Target Mode on

page 32.

Zeroing

When you raise an empty bucket past the trigger point, the display should

read zero. However, due to build up of material in the bucket, a small zero

error may occur.

Zero error affects the accuracy of lifted weights.

To zero the Loadrite

Before lifting:

Make sure that the bucket is empty and

fully rolled back.

The loader must be on level ground.

Ready

Sand

0

LOADRITE PRO OPERATING MANUAL

16

Raise the bucket smoothly past the trigger

point using normal engine revs.

The Loadrite beeps and displays the load.

(Example weight 20)

Sand

0

20

Press the key.

The Loadrite performs the zero adjustment

and returns to the Ready state.

Ready

Sand

0

Large ZERO Error

If the weight is greater than 5% of full scale, when you press , the

Loadrite prompts Bucket Empty? If it is, press ENT which will zero the

empty bucket. Pressing EXIT will not zero the scale

If the weight is greater than 10% of full scale, when you press , the

Loadrite displays Too heavy, zero aborted and does not alter any

settings.

This prevents any accidental zeroing of valid weights.

If the bucket is empty and this message still occurs, there may be a fault in

the system. The Loadrite should be checked and, if necessary, recalibrated.

Check Zero Prompt

Check

Zero

This function automatically reminds the operator to check ZERO

occasionally. Changes in the ZERO occur more often while the machine is

warming up.

When first turned on, after having been off for more than one hour, the

Loadrite will remind the operator to do a ZERO check:

• Every 15 minutes for the first hour

• Every 30 minutes thereafter

LOADRITE PRO OPERATING MANUAL

17

At this point a ZERO check lift should be carried out as described in the

previous section.

The reminder can be cleared without doing a ZERO check, by simply

continuing with normal operation. However, a ZERO error can affect the

accuracy of lifted weights so it is important to do a ZERO check regularly.

The automatic CHECK ZERO reminder will not occur if the operator is

checking the ZERO often enough.

The automatic CHECK ZERO prompt is an optional function that is selected

during installation.

Zeroing when Auto Add is On

The procedure to zero may be different when Auto Add is on and Auto Add

Time is set to 0. If this is how your Loadrite is configured, you will need to

carry out the following procedure:

Before lifting:

Press the key.

Zero

Lift

Raise the empty bucket smoothly past the

trigger point. The Loadrite beeps and

performs the zero adjustment.

Zero

Updated

If Auto Add is not on, or Auto Add Time is not set to 0, follow the standard

procedure to zero (page 15).

Auto-Add is described on page 14.

LOADRITE PRO OPERATING MANUAL

18

Recalling Last Load

The Recall function is equivalent to lifting the same load again and can be

used to correct mistakes.

You can recall and display the last load if it has been:

• Added

• Subtracted, or

• Timed out (ignored).

To Recall the previously lifted weight

(Weights shown are examples only)

Current total 5600.

Press

G H I

.

Ready

Sand

5600

The Loadrite beeps and displays the last

load.

(Weight of last load 2200)

Sand

5600

2200

If the last action was an “add”, you can

subtract.

If the last action was a “subtract”, you can

add.

(Example: subtracting a load that was

previously added, new total 3400)

Ready

Sand

3400

If you press a key that is not allowed in the circumstances, such as

when the recalled load was previously added, the Loadrite ignores the key

press.

LOADRITE PRO OPERATING MANUAL

19

Viewing Long Total

To view the Long Total for the current product

(Weights shown are examples only)

In Ready screen, press

+

L

D E F

.

After a few seconds, the Loadrite

automatically returns to the Ready screen.

Long Tot

23400

Clearing Totals

To clear the Short Total for the current product

(Weights shown are examples only)

In the Ready mode,

press .

Ready

Sand

7800

The Loadrite displays Total Cleared for

a few seconds, clears the Short Total for

the current product and then …

Total

Cleared

7800

… returns to the Ready screen.

The next ADD operation starts a new Short

Total for this product.

Ready

Sand

0

LOADRITE PRO OPERATING MANUAL

20

To clear the Long Total for the current product

(Weights shown are examples only)

In the Ready mode,

Press

+

L

D E F

.

The Loadrite displays the Long Total.

Long Tot

23400

Press .

The Loadrite asks you to confirm the clear

Long Tot

Clear?

23400

Press to confirm.

The Loadrite displays Long Tot

Cleared for a few seconds and then

returns to the Ready screen.

Note that the Short Total is also cleared for

consistency.

Ready

Sand

0

To clear all Long Totals in one go

Press

M N O

to display the menu and use

5 6

to scroll to the Clear All screen.

Press .

Menu

ClearAll

The Loadrite displays a prompt for you to

confirm the clear operation.

Press

again to clear all totals or

to return to the menu without clearing.

ClearAll

ENT/EXIT

If the Loadrite has a printer connected, the Long Totals are printed together

with a grand total before being cleared.

LOADRITE PRO OPERATING MANUAL

21

Tare Function

The Loadrite has two ways of using Tare and this is selected at time of

installation. The Tare can work either with the lifted weight, or the total

weight. This is explained in more detail below.

Your Loadrite dealer will set up how Tare is to operate with your machine.

Tare on Lifted weight

In this mode, the Tare function can be used, for example, to allow for the

weight of a pallet. When weighing, the Loadrite automatically deducts the

tare from the lifted weight and displays the net weight of the load.

Tare on Total weight

In this mode the entered Tare value is applied to the displayed Total value.

The Loadrite automatically adds the total for the currently product to the

Tare value and displays this value.

This mode if useful when loading vehicles which display their Tare weight

and maximum weight. The operator enters the Tare value into the Loadrite,

then loads the vehicle until the displayed total is equal to the vehicles

maximum loaded weight.

Entering a Tare weight using the keypad

You can enter a tare using the keypad or by measuring the weight. To enter

a Tare with the keypad, do the following steps. (When Tare is set to work on

the Total, the Tare value is normally entered with the keypad).

Press

J K L

.

Tare?

0

Key in the tare weight and press to

accept.

Tare?

50

LOADRITE PRO OPERATING MANUAL

22

Measuring a Tare weight

A Tare weight can be measured by the Loadrite. This is common when

finding the Tare weight of a pallet on the forks of a loader. (It is not normal

to measure the Tare weight when the Tare value is set to work on the

Total).

Lift the empty pallet past the trigger point.

The Loadrite beeps and displays the

weight.

Sand

0

50

Press

J K L

.

The Loadrite displays the measured weight

on the Tare screen.

Tare?

50

If necessary, edit the weight using the

keypad. Press to accept.

To turn on the function, enter a tare weight. To turn it off, enter a tare of

zero.

LOADRITE PRO OPERATING MANUAL

23

5 Product Management

Loadrite supports up to 30 products. Each product is associated with a

product number, product name, short total, long total and add bucket

counter. The product info screen enables you to manage your products.

The product info screen not only allows you to select a different product, but

also displays information about the product before you select it.

To select a different product

(Weights and product names are examples only.)

Ready screen:

Press .

Ready

Sand

3400

The Loadrite will first display the product

number along with the product name.

Then, the Short Total and the number of

buckets added will follow.

Product index = 1

Product name = Sand

Bucket added = 4

Short total = 3400

PROD01

Sand

Sand

Add# 4

3400

Press

56

to scroll through the products,

or key in a product number directly.

PROD02

Gravel

Gravel

Add# 0

0

LOADRITE PRO OPERATING MANUAL

24

Press to select the product and return

to the Ready screen.

Ready

Gravel

0

LOADRITE PRO OPERATING MANUAL

25

6 Data

If this feature is enabled, the Loadrite allows you to enter five data fields (up

to eight characters) that provide additional information to the weight data.

Each field has a label to identify it and can be configured as a specific data

type (e.g. alphanumeric, numeric or auto-increment). The specific labels

and data type for your Loadrite are set up at installation time.

Typical labels might be, for example:

Customer for Data 1

Docket for Data 2

Truck for Data 3

If you have the appropriate equipment installed, this information can be

stored in the LD940 MMS data logger and/or printed with the weight data.

Data Edit

Before loading a truck, for example, you can enter the data as follows.

In Ready mode,

press . The Loadrite displays the first

field and prompts you to enter a value.

Customer

0

Suppose the customer is 1234

A B C

+

L

D E F

G H I

Note that pressing means accepting

the displayed value for the data field.

Customer

The Loadrite automatically displays the

next data field and prompts you to enter a

value.

Docket

0

Loadrite will automatically return to the

Ready screen, as soon as all data fields

have been accepted.

LOADRITE PRO OPERATING MANUAL

26

You may have up to five data fields available, depending on how the

Loadrite has been set up at installation time.

Alphanumeric Data

The Loadrite has an option to enter Alphanumeric (Alpha) data. This option

is enabled at installation time. The Loadrite uses its telephone style keypad

to allow letters to be entered.

When a number key is pressed, a digit is displayed. If the same number key

is pressed again, the first letter on that key is displayed. If the key is

pressed again the second letter is displayed and so on. For example, if the

A B C

key is pressed repeatedly, the characters displayed in sequence are

‘2’, ‘A’, ‘B’, ‘C’, ‘a’, ‘b’, ‘c’, ‘2’, ‘A’ and so on.

In this way names can be entered for customers, trucks etc.

Sometimes a name will have two sequential letters on the same key. For

example the letters ‘D’ and ‘E’ in the word ‘DEAKON. After the ‘D’ has been

entered (by pressing the

+

L

D E F

key twice), wait a second or two. The cursor

will automatically shift and be ready for your next character. You can then

enter 'E' by pressing the

+

L

D E F

key again.

Name Speed Dial and Scrolling

The Loadrite keeps a list of names for the data fields i.e. Customer List.

You can either use 5 6 keys to scroll through the list, or dial the index to

the list to recall the name.

Suppose we have a customer list as follows:

Joe

Deakon

Smith

Johnson

Adams

Use scrolling to recall Smith:

• Press

• Press

56

until you see Smith on the screen, then press

LOADRITE PRO OPERATING MANUAL

27

Use speed dial to recall Smith:

• Press

• You can press

+

L

D E F

(the 3rd name on the list), then

The data list can be printed out via Print Function: Print Data List as

described on page 68.

Name speed dial requires the Data Index option to be enabled at

installation.

Data List (name list) will not store names starting with numbers, if name

speed dial function is in active (Data Index option is enabled).

Auto target value look up

This function enables you to store a list of target values (for different trucks).

You can recall the target value from memory by either entering a number or

scrolling through a list of truck names.

Use scrolling to recall truck target value:

Suppose we have a truck and target list as follows. We configure Data 3 to

store truck plate numbers and Data 4 to store the corresponding target

values. Data 3 itself is an alphanumeric field and is set up as target

reference. Data 4 is set up as target list.

Data 3: Truck Data 4: Target

AGT175 15000

AUQ887 16500

BQ1001 15500

BQ1002 15500

YA8855 12000

LOADRITE PRO OPERATING MANUAL

28

Suppose we want to recall the target value for Truck AUQ887.

In Ready mode,

press . You will be prompted for the

first data field (Data 1: Customer). Since

we use Data 3 for Truck number, you must

first enter data for Data 1 and Data 2.

Customer

Smith

When you get to Data 3 (Truck number),

the last truck will be displayed.

Press

56

until you see AUQ887 on the

screen, then press to select the truck.

Truck

YA8855

Loadrite will then automatically use

AUQ887 as reference and look up the

corresponding target value.

When prompted to confirm, press to

accept it.

You may enter a new target value. If

changed, the new value will be saved.

Target?

16500

You will then return to the To Load

screen.

To Load

Sand

16500

Use indexing to recall truck target value:

Suppose we have a truck target list as follows. We configure Data 4 as

target list with index function enabled. The order of the list is important as

we use the index numbers to represent the trucks.

Index Data 4: Target

1 (AGT175) 15000

2 (AUQ887) 16500

3 (BQ1001) 15500

4 (BQ1002) 15500

5 (YA8855) 12000

LOADRITE PRO OPERATING MANUAL

29

Suppose we want to recall the target value for Truck AUQ887. This truck is

the second item on the list. It makes it Truck #2.

In Ready mode,

press . You will be prompted for the

first data field (Data 1: Customer). Since

we use Data 4 for Target list, you must first

enter data for Data 1, Data 2, and Data 3.

Customer

Smith

When you get to Data 4 (Target), the last

target value and the last index number will

be displayed.

Target

12000

Target

Index

5

Enter the index (2 for this example, as

Truck AUQ887 is Truck #2), and then

press .

Target

Index

2

Loadrite will use the index 2 and look up

the corresponding target value.

Target

16500

You will then return to the To Load

screen.

To Load

Sand

16500

LOADRITE PRO OPERATING MANUAL

30

Auto tare value look up

This function is similar to Auto target value look up, except that it handles

tare values obviously. You can recall the tare value from memory by either

entering a number or scrolling through a list of truck names. The

procedures are the same as the Auto target value look up.

Auto-increment

Auto-increment function is an optional that is selected during installation. If

auto-increment is enabled, data value will be made to increment

automatically when Short Total is cleared. The data value can only be

viewed but cannot be edited.

Odometer (Distance/Mileage Recorder)

Odometer function is an option that is selected during installation. With

properly installed and configured hardware, the data field can be used to

display the odometer/distance/mileage value. If enabled, the data field will

be updated regularly with the current odometer/distance/mileage value. The

data value can only be viewed but cannot be edited.

Automatic Data Prompt

Automatic Data Prompt is an optional function that is selected during

installation. If enabled, the Loadrite automatically prompt for data field

entries when a new product is selected.

Data Suspend

Data Suspend is a feature that allows operator to temporarily suspend all

data values (except odometer/distance/mileage value) and set them to 0

(zero). Data Suspend is an optional function that is selected during

installation.

To suspend data

When the Loadrite is in Ready mode, press

. The Loadrite displays the current

setting.

Customer

Joe

LOADRITE PRO OPERATING MANUAL

31

Press CLEAR key and then enter 0.

Loadrite will then display a message to

confirm that the Data Suspend has been

activated.

Customer

0

During the suspension period, the Loadrite will:

exclude all data fields in printing, if printer is enabled

override all data fields to 0 in data logging, if MMS data logger feature is

enabled.

To resume data (turn off suspend mode)

When the Loadrite is in Ready mode, press

. The Loadrite displays the last

setting.

Customer

Joe

Press to accept it. Or, enter a new

name, if desired.

Loadrite will then display a message to

confirm that the Data Suspend has been

de-activated.

Customer

Joe

As soon as the Data Suspend function is de-activated, the Loadrite will

resume normal operation.

LOADRITE PRO OPERATING MANUAL

32

7 Target Mode

Target mode is an optional feature that is selected during installation. This

feature provides an easy way to load up to a target weight for a product in a

series of lifts. In Target mode, the Loadrite displays the “To Load” value,

which is the remaining amount to reach the target.

Before loading, the operator enters a target weight. Each time you add a

weight, the “To Load” value is reduced by that weight.

Target mode is used typically when loading a truck to its optimum payload.

To enter Target mode (and enter a new target)

You can also change the current target when entering target mode. This is

explained below.

(Weights shown are examples only)

First clear the previous total.

(Clearing Totals is described on page 19.)

The Loadrite is in Total mode at this point.

Ready

Sand

0

Press .

The Loadrite displays the last target value

used.

Target?

8500

Suppose the new target is 9000.

Use the numeric keys to enter 9000, and

press

to accept it.

Target?

9000

The Loadrite displays Target Updated

for a few seconds and then returns to the

To Load screen. You are now in Target

mode.

To Load

Sand

9000

LOADRITE PRO OPERATING MANUAL

33

As your “To Load” value approaches to zero, you are getting close to

finishing loading a truck. It does not have to be exactly zero, as long as it is

close. For example, if you have To Load value 20, it means that you are 20

under the target. If you have To Load value -20 (negative), it means that

you are 20 over the target.

To reset to Target

When you are finished loading a truck, you need to clear the total or reset

the target.

(Weights shown are examples only)

Press .

To Load

Sand

20

The Loadrite displays Target Reset for

a few seconds and then …

Target

Reset

9000

… resets the display to the current target.

To Load

Sand

9000

LOADRITE PRO OPERATING MANUAL

34

To return to Total mode

(Weights shown are examples only)

To Load message indicates that we are in

target mode.

To Load

Sand

9000

Press to go to total mode.

The Loadrite displays Total Mode for a

few seconds and then …

Total

Mode

… return to total mode. The message

Ready is shown along with the current

total.

Ready

Sand

0

LOADRITE PRO OPERATING MANUAL

35

8 Batch Mode

Batch mode allows you to weigh and load products according to a

predefined recipe. You enter the target weight of the batch, the Loadrite will

work out exactly what you need for each product.

The recipe can contain up to ten products. It specifies the relative amount of

each product in a batch.

When in Batch mode, the Loadrite displays the To Load value for each

product as you weigh them.

Example

Suppose that a recipe of three products has been entered as follows:

Product Proportion

Sand 4

Gravel 2

Pumice 1

When loading the three products, you specify the total load required. An

example might be 7000kg. The Loadrite automatically calculates the

amount of each product required, which in this case would be:

Sand 4000kg

Gravel 2000kg

Pumice 1000kg

As you weigh and load the products, the Loadrite maintains the To Load

amount for each product in a similar way to target mode. You can change

from one product to another at any time during weighing in order to mix the

products.

LOADRITE PRO OPERATING MANUAL

36

The Batch Screen

All Batch weighing operations are started from the Batch screen.

From the Ready screen, press .

Note: if Target or Blend modes are also

available, you may need to scroll to Batch

mode and then press to select it.

Recipe

ENT:OK

From the Batch screen, the following operations are available.

To … Press … See page …

Change the recipe.

38

Accept the recipe. Enter the

batch total.

39

Start weighing.

40

Return to the Ready or To Load

screen.

Print the current recipe.

LOADRITE PRO OPERATING MANUAL

37

Viewing the Current Recipe

The Loadrite automatically scrolls through

the recipe details after you have entered

the Recipe confirm screen.

Recipe

ENT:OK

The Loadrite briefly displays the proportion

of each product in turn.

(Example display: 4 units of sand, 2 units

of gravel and 1 unit of pumice)

Batch

Sand

4

Batch

Gravel

2

Batch

Pumice

1

LOADRITE PRO OPERATING MANUAL

38

Changing the Recipe

Except for the very first time that a recipe is entered, the current recipe must

be cleared before you can enter a new one.

Press and if necessary, scroll to

display the Batch screen.

Recipe

ENT:OK

Press followed by to confirm.

Recipe

Clear?

The Loadrite briefly displays Recipe

Empty and then….

Recipe

Empty

… displays the screen where you select

the products to make up the recipe

Use 5 6 keys, or key in a product

number, and press to select the first

product.

Prod#?

Sand

Key in the required proportion of this

product and press .

In this example, 4 units of product 3 (sand)

have been keyed in.

Sand

4.0

The Loadrite automatically moves on to the

next product number in sequence.

If this is not the next product required,

select the correct one and press .

Prod#?

Gravel

LOADRITE PRO OPERATING MANUAL

39

Repeat the procedure of selecting a product and entering the proportion

required until the recipe is complete. Then press to return to the

Batch screen.

Entering the Batch Total

Press and if necessary, scroll to

display the Batch screen, then press

.

Recipe

ENT:OK

The Loadrite displays the last Batch target

value.

Target?

10000

If necessary, key in a new Target value.

Press to accept.

Target?

7000

The Loadrite beeps and returns to the To

Load screen with the target value for the

first product displayed.

To Load

Sand

4000

LOADRITE PRO OPERATING MANUAL

40

Batch Weighing

To start a Batch weighing operation, you need to access Batch mode and

enter or accept the batch total. See Entering the Batch Total above.

During Batch weighing, the Loadrite maintains a "To Load" target for each

product in the recipe. Each time that you add a weight, the “To Load” value

is reduced by that weight.

You can load the products in any order and switch between products during

weighing.

The Loadrite displays the To Load screen

with the target value for the first product.

To Load

Sand

4000

Raise the load smoothly past the trigger

point.

The Loadrite beeps and displays the load.

(Weight of load 2200)

Sand

4000

2200

Press .

The Loadrite briefly displays the number of

buckets loaded for this product and then …

Bucket 1

Added

2200

… updates the total and returns to the

To Load screen.

(Target now 1800)

To Load

Sand

1800

LOADRITE PRO OPERATING MANUAL

41

Changing Product

You can change product at any time (the Loadrite maintains the individual

totals for each product).

Press .

To Load

Sand

1800

The Loadrite displays the number of

buckets loaded, the product name and the

Short Total for that product.

Sand

Bucket 1

2200

Use 5 6 keys, or key in a product

number, and press to select the next

product.

(Only the products in the recipe are

available.)

Gravel

Bucket 0

0

Load this product and continue on to the

next.

Clearing the Batch Totals

To finish a Batch weighing operation, press .

The Loadrite clears the totals for all the products in the recipe and returns to

the Ready screen in Total mode.

Returning to Total Mode

The Loadrite automatically returns to Total mode after a CLEAR operation.

You can also return to Total mode by pressing .

LOADRITE PRO OPERATING MANUAL

42

9 Mix Mode

Mix mode is similar to Batch mode except that target value for the mix is not

required. You load the first product to a certain amount. When you change

to the next product, the Loadrite will work out exactly what you need to load

based on the predefined recipe.

The recipe can contain up to ten products. It specifies the relative amount of

each product in a batch.

When in Mix mode, the Loadrite displays the word Mix to indicate that you

are in Mix mode and loading the primary product. When you change to

other product in the recipe, the Loadrite displays To Load value for the

product.

Example

Suppose that a recipe of three products has been entered as follows:

Product Proportion

Sand

* First item in the recipe is

the primary product.

4

Gravel 2

Pumice 1

Suppose that you have loaded 4000 kg of the primary product sand. The

Loadrite automatically calculates the amount of other product required,

which in this case would be:

Sand 4000kg

Gravel 2000kg

Pumice 1000kg

As you weigh and load the products, the Loadrite maintains the To Load

amount for each product in a similar way to target mode. You can change

from one product to another at any time during weighing in order to mix the

products.

LOADRITE PRO OPERATING MANUAL

43

The Mix Screen

All mix-weighing operations are started from the Mix screen.

From the Ready screen, press .

Note: if Target or Batch modes are also

available, you may need to scroll to Mix

Mode and press to select it.

Recipe

ENT:OK

From the Mix screen, the following operations are available.

To … Press …

Change the recipe

Start weighing

Return to the Ready or To Load

screen

Print the current recipe

Viewing and changing the recipe are explained in Batch Mode on page 35.

Mix Weighing

To start a Mix weighing operation, you need to access Mix mode.

During Mix weighing, the Loadrite maintains a "To Load" target for each

product (except the primary product) in the recipe. Each time that you add

a weight, the “To Load” value is reduced by that weight.

You can load the products in any order and switch between products during

weighing.

LOADRITE PRO OPERATING MANUAL

44

From the Ready screen, press to

access the Mix screen.

Press to accept the recipe (or press

to enter a new recipe).

Recipe

ENT:OK

The Loadrite displays the primary product

and the current total.

For primary product, the Loadrite is in

normal count up mode.

Mix

Sand

0

Suppose that we have loaded 4000 kg of

Sand. We are ready to load another

product in the mix.

Mix

Sand

4000

Changing Product

You can change product at any time (the Loadrite maintains the individual

totals for each product).

Press .

Mix

Sand

4000

The Loadrite displays the number of

buckets loaded, the product name and the

Short Total for that product.

Sand

Add# 4

4000

Use 5 6 keys to select the next product.

Press to accept.

(Only the products in the recipe are

available.)

Gravel

Add# 0

0

LOADRITE PRO OPERATING MANUAL

45

Load this product and continue on to the

next.

To Load

Gravel

2000

Clearing the Mix Totals

To finish a Mix weighing operation, press .

The Loadrite clears the totals for all the products in the recipe and returns to

the Ready screen in Total mode.

Returning to Total Mode

The Loadrite automatically returns to Total mode after a CLEAR operation.

You can also return to Total mode by pressing .

LOADRITE PRO OPERATING MANUAL

46

10 Blend Mode

Blend mode is similar to Batch mode except that the recipe contains the

total number of buckets of each product and you do not enter a target load.

When weighing, the Loadrite tracks the number of lifts of each product and

automatically changes to the next product when the required number of

buckets has been loaded.

Example

Suppose that a recipe of three products has been entered as follows:

Product Buckets

Sand 6

Gravel 10

Pumice 10

During weighing, the Loadrite guides the operator through the process that

will result in a total load of 26 buckets.

The Blend Screen

All blend-weighing operations are started from the Blend screen.

From the Ready screen, press .

Note: if Target or Batch modes are also

available, you may need to scroll to Blend

Mode and press to select it.

Recipe

ENT:OK

LOADRITE PRO OPERATING MANUAL

47

From the Blend screen, the following operations are available.

To … Press …

Change the recipe

Start weighing

Return to the Ready or To Load

screen

Print the current recipe

Viewing and changing the recipe are explained in Batch Mode on page 35.

Remember that the Blend recipe contains the actual number of buckets of

each product rather than a proportion of the whole load.

Blend Weighing

From the Ready screen, press to

access the Blend screen.

Press to accept the recipe (or press

to enter a new recipe).

Recipe

ENT:OK

The Loadrite displays the first product and

how many buckets need to be added.

Blend

Sand

6

Raise the load smoothly past the trigger

point.

The Loadrite beeps and displays the load.

(Weight of load 2200)

Sand

6

2200

LOADRITE PRO OPERATING MANUAL

48

Press .

The Loadrite briefly displays the number of

buckets loaded for this product and then …

Bucket 1

Added

2200

… updates the short total and returns to

the Blend screen.

The To-load bucket count decrements to 5.

Blend

Sand

5

Continue to load buckets of the first

product. After the last bucket the Loadrite

automatically displays the second product

name for you to start loading that product.

After the last bucket of the last product in

the sequence is added, the Loadrite starts

from the beginning of the sequence again.

Blend

Gravel

10

LOADRITE PRO OPERATING MANUAL

49

11 Split Mode

Split Mode is an optional feature that is selected during installation. This

feature provides an easy way to load a truck with a trailer. You can split

the total into multiple sub-totals.

The following example illustrates how to use the split function.

Example: Suppose we are to load a truck with a trailer. The truck can carry 10 000

and the trailer 15 000, the total therefore being 25 000.

(Weights shown are examples only)

EXAMPLE TOTAL MODE TARGET MODE

At start:

Current weight = 0

Weight needed = 10 000

Ready

Sand

0

Ready

Sand

0

To load 10 000 into the truck…

Target = 10 000

To Load

Sand

10000

Add # 1: 5 000:

Ready

Sand

5000

To Load

Sand

5000

15 00010 000

LOADRITE PRO OPERATING MANUAL

50

EXAMPLE (continued) TOTAL MODE TARGET MODE

Add # 2: 5 000

The truck is full with a weight of

10 000.

Ready

Sand

10000

To Load

Sand

0

Go into Split Mode:

Press .

Subtotal

10000

10000

Subtotal

10000

0

At present we have:

Truck Total = 10 000

Trailer Total = 0

Grand Total = 10 000

Ready

10000

0

To Load

10000

10000

To load 15 000 into the trailer…

Target = 15 000

To Load

10000

15000

Add # 3: 5 000

(First add towards the trailer).

This gives us:

Truck Total = 10 000

Trailer Total = 5 000

Grand Total = 15 000

Ready

15000

5000

To Load

15000

10000

Add # 4: 5 000

(Next add towards the trailer).

This gives us:

Truck Total = 10 000

Trailer Total = 10 000

Grand Total = 20 000

Ready

20000

10000

To Load

20000

5000

LOADRITE PRO OPERATING MANUAL

51

EXAMPLE (continued) TOTAL MODE TARGET MODE

Add # 5: 5 000

(Final add towards the trailer).

This gives us:

Truck Total = 10 000

Trailer Total = 15 000

Grand Total = 25 000

Ready

25000

15000

To Load

25000

0

Press to finish loading.

Subtotal

15000

Subtotal

15000

We now have:

Truck Total = 10 000

Trailer Total = 15 000

Grand Total = 25 000

Total

25000

Total

25000

Sample Printout:

Add(1) 5000

Add(2) 5000

Subtotal 10000

Add(3) 5000

Add(4) 5000

Add(5) 5000

Subtotal 15000

SAND 25000

LOADRITE PRO OPERATING MANUAL

52

12 Tip Off

This feature allows you to load a truck to an exact value by using only part

of the last bucketful.

There are two different methods, depending on the way the Loadrite has

been set up:

• Truck tip-off, or

• Stock Pile tip-off.

Truck Tip-Off

Using this method, you tip a measured amount of product from the bucket

into the truck and dump the rest. The following example illustrates the

weigh screen shots when in Total mode or Target mode.

EXAMPLE TOTAL MODE TARGET MODE

Target weight = 6000kg

Current weight = 5600kg

Weight needed = 400kg

Ready

Sand

5600

To Load

Sand

400

Lift the load in the normal way.

The Loadrite displays the lifted

weight (2200kg)

Lift the bucket to a suitable

height over the truck.

Sand

5600

2200

Sand

400

2200

Press . The Tip-Off

indicator light comes on.

Tipoff

Wait...

2200

Tipoff

Wait...

2200

LOADRITE PRO OPERATING MANUAL

53

To tip off into truck a weight

of 400kg:

Middle number shows weight

tipped off onto the truck.

Lower number shows total

weight as it is being tipped onto

the truck.

Middle number shows weight

tipped off onto the truck.

Lower number shows the weight

still to be tipped onto the truck.

Truck

0

5600

Truck

0

400

Roll the bucket partially forward,

tipping product into the truck:

with 300kg tipped off so far…

Truck

300

5900

Truck

300

100

The Loadrite displays the

amount that has been tipped

from the bucket and the total in

the truck.

The Loadrite displays the

amount that has been tipped

from the bucket and the weight

still to be tipped onto the truck.

Truck

400

6000

Truck

400

0

When the required truck load is reached, press .

Finally, move away from the truck and dump any product remaining in the bucket.

LOADRITE PRO OPERATING MANUAL

54

Stock Pile Tip-off

Using this method, you dump product from the bucket until it contains the

right amount for loading onto the truck. The following example illustrates

the weigh screen shots when in Total Mode or Target Mode.

EXAMPLE TOTAL MODE TARGET MODE

Target weight = 6000kg

Current weight = 5600kg

Weight needed = 400kg

Ready

Sand

5600

To Load

Sand

400

Lift the load in the normal way.

The Loadrite displays the lifted

weight (2200kg)

Lift the bucket to a suitable

height over the truck.

Sand

5600

2200

Sand

400

2200

Press . The Tip-Off

indicator light comes on.

Tip Off

Wait...

2200

Tip Off

Wait...

2200

To adjust weight of last

bucket to 400kg:

Middle number shows total

weight.

Lower number shows ‘live’

weight in the bucket.

Middle number shows target

weight.

Lower number shows ‘live’

weight in the bucket.

Sand

5600

2200

Sand

400

2200

LOADRITE PRO OPERATING MANUAL

55

Roll the bucket partially forward,

dumping product :

with 300kg tipped off so far…

Sand

5600

1900

Sand

400

1900

The Loadrite displays the ‘live’

weight in the bucket.

Sand

5600

400

Sand

400

400

When the required weight is displayed, press .

Finally, tip the product from the bucket into the truck.

Notes on Tip-Off Function

• When tipping product from the bucket, do not raise or lower the lifting

arms as this would adversely affect the live weight reading.

• Tip-Off cannot be used if Auto-Add Time is set to 0 sec. Auto-Add is

described on page 14.

LOADRITE PRO OPERATING MANUAL

56

13 Menu Options

The Menu allows you to change some of the settings of the Loadrite.

The options are as follows:

Setup...

Installation functions (security code required)

Clock

Clock setting

Scale #

Change scale

Clear All

Clear all long totals

Auto Add

Auto add setting

Trigger

Screen

Rotary trigger position screen

Module

LD940 Module properties

Data Edit

Edit data settings. Useful for overriding autoincrement number

Data List

Edit Data1 (Customer) list

Alarm

Turn alarm on or off

Alarm Time

Set alarm time

Selftest

Self test

Uplink

Sets up the Loadrite to communicate with PC-

based “Loadrite Link” application to receive new

configuration

Depending upon the configuration during installation, some options may

not be available.

To access an item on the menu:

1. Press

M N O

.

2. Use 5 6 to scroll to the required option.

3. Press to select the option.

When you have finished with an option, the Loadrite returns to the main

menu. To return to the Ready screen, press .

LOADRITE PRO OPERATING MANUAL

57

Setup

The Setup option enables you to access special functions such as span

calibration. You need a security code to access these functions.

To access the Setup options:

1. Press

M N O

.

2. Use 5 6 to scroll to Setup.

3. Press

to select.

4. The Loadrite prompts you to enter an access code. For special

functions, key in your security code and press

.

Clock Setting (Clock)

Clock Setting editing is an optional function that is selected during

installation. Once enabled, you have access to change the Loadrite internal

clock (date/time) setting.

To set the time and date – refer to page 78.

Changing Scale Number (Scale#)

This function enables different load bearing implements to be used by the

vehicle. It is available only if the multiple scale feature has been enabled

during installation, e.g. bucket or forks. Both should be assigned a number.

Once enabled, the operator needs to select the correct scale for the

attached implement. The Loadrite has two scales.

To change the scale

1. Press

M N O

.

2. Use

5 6

to scroll to Scale#.

3. Press to select.

4. Use 5 6 to scroll to the desired scale number, then press .

It is important to check zero before continuing (page 15).

LOADRITE PRO OPERATING MANUAL

58

Clear All Long Totals (ClearAll)

This function clears all the long totals to zero.

To clear all the long totals – refer to page 20.

Auto Add On/Off Setting (Auto Add)

Auto Add is an optional feature that is selected during installation. If AutoAdd is enabled, the Loadrite can automatically operate the ADD function

every time a load is lifted past the trigger point.

To turn on/off auto add function

1. Press

M N O

. The time is displayed.

2. Use 5 6 to scroll to Auto Add.

3. Press to select.

4. Use 5 6 to adjust the setting.

5. Press to accept the setting.

Rotary Trigger Position Screen (TrigScrn)

This function displays a bar graph that reflects the current position of the

rotary trigger. It is available only if the rotary trigger is installed.

>>>>---+

Sand

0

Bar graph

+ trigger point,

>>> current bucket

position from ground

--- distance away from

trigger point

To turn on/off rotary trigger position screen

1. Press

M N O

.

2. Use 5 6 to scroll to TrigScrn.

3. Press to select.

4. Use 5 6 to adjust the setting.

LOADRITE PRO OPERATING MANUAL

59

5. Press to accept the setting.

This function is only available if the Loadrite is configured to use rotary

trigger.

LD941 Data Module Properties (Module)

This function is available only if the LD940 MMS data logger feature has

been enabled during installation. Data Module Properties function enables

you to examine the properties and the status of the data logger module

connected to the Loadrite.

When activated, this function will do the following:

• Display software and hardware information of the data logger

• Perform self-test

• Display data usage

To access the Data Module Properties function:

1. Press

M N O

.

2. Use 5 6 to scroll to Module.

3. Press to select.

Data Edit (DataEdit)

Data Edit is an optional feature that is selected during installation.

This is the same Data Edit function as described in chapter 6 (page 25),

except that when accessed through the Menu it allows you to over-ride any

data setting, including auto-increment-type data.

To access the Data Edit function:

1. Press

M N O

.

2. Use 5 6 to scroll to DataEdit.

3. Press to select.