LR810

WEIGHING

SYSTEM

Operating

Manual

LR810

Distributed Worldwide by:

Loadrite Ltd

93 First Avenue

P.O. Box 13-115, Tauranga,

New Zealand

Facsimile: INTL-64-7-5776034

Phone: INTL-64-7-5782820

For: LOADRITE model LR 810

Software # 60042. Version: 3.20

Issue Date: December, 1996

Designed and Manufactured by:

A MEMBER OF THE LOADRITE GROUP OF COMPANIES

Actronic New Zealand Ltd reserves the right to make changes to the Loadrite range of products without prior notice

and assumes no liability in connection with the use of any Loadrite branded product.

© 1996, ACTRONIC NEW ZEALAND LTD

When re-ordering this manual, quote Doc number 80085-05.MAN

i

Contents

1 About This Manual.................................................................1

2 The Loadrite LR810 Weighing System................................ 2

Main Parts of the LR810 System.......................................................... 2

Weight Measurement............................................................................ 3

Displays................................................................................................ 3

Indicator Lights..................................................................................... 4

Optical Trigger ..................................................................................... 4

3 Getting Started........................................................................5

Switching On........................................................................................ 5

Warming Up......................................................................................... 5

Weight Display Modes......................................................................... 5

Multiple Products ................................................................................. 6

4 Weighing - Overview..............................................................7

Before Weighing a Load....................................................................... 7

Weighing a Load .................................................................................. 7

Multiple Scales..................................................................................... 8

5 Total Mode............................................................................... 9

Short Total............................................................................................ 9

Long Total.......................................................................................... 10

Clearing Totals for all Products.......................................................... 10

6 Target Mode..........................................................................11

7 Product Names......................................................................13

Identification/Tracking....................................................................... 13

One Product Only............................................................................... 13

Multiple Products ............................................................................... 13

8 Zeroing the LR810................................................................15

9 Automatic Zero Prompt....................................................... 17

10 Adding, Subtracting and Recalling...................................18

Adding a Weight................................................................................. 18

Subtracting a Weight.......................................................................... 19

Recalling Last Weight........................................................................ 21

11 Batch Weighing Mode........................................................22

12 Weighing with Tare............................................................23

13 Operating with Interlock...................................................25

14 Additional Data................................................................... 26

15 Operator Menu Options.....................................................28

Menu Keys.......................................................................................... 28

Change Scale...................................................................................... 28

Batch Mode On / Off.......................................................................... 29

Setting the Time and Date.................................................................. 29

ii

Clearing Long Totals.......................................................................... 30

Menu Map .......................................................................................... 32

16 Using the LD640 Data Logger...........................................33

Displays.............................................................................................. 33

17 Print Functions....................................................................34

18 Obtaining the Best Accuracy............................................. 36

Lifting Speed...................................................................................... 36

Trigger Point....................................................................................... 36

Bounce................................................................................................ 36

Centre of Gravity................................................................................ 36

Uneven Ground .................................................................................. 36

Temperature........................................................................................ 37

19 Span Calibration Correction.............................................38

20 Changing the Backup Battery ...........................................40

21 Error Messages ...................................................................41

Lift Speed Changed? .......................................................................... 41

Bouncing Load ................................................................................... 41

Error Close to Tolerance Limit........................................................... 42

Trigger Fault....................................................................................... 42

22 Keys......................................................................................43

23 Specifications.......................................................................45

24 Output/Input Connections................................................. 47

25 Index.....................................................................................49

1 About This Manual

1

1 About This Manual

This manual describes the day to day operation of the Loadrite LR810

weighing system.

Other Manuals

For information on ... See...

Installation of the system Installation Manual

Calibration of the system Setup and Calibration Manual

Printing weight data LP750 Data Printer Manual

Storing data LD640 Data Capture Manual

Parts list LR810 / LP750 Spare Parts Manual

2 The Loadrite LR810 Weighing System

2

2 The Loadrite LR810 Weighing System

The Loadrite LR810 weighing system measures the weight of loads lifted by

front end loaders, log loaders, fork lift trucks and similar machines which

use hydraulic rams to lift the load.

The heart of the system is the LR810 indicator which provides a keypad for

entering instructions and LCD screens to display readings and messages.

The indicator has internal memory which stores settings and production data

even when switched off.

The LR810 is installed in the cab of the loading machine and is connected to

sensors on the lifting arms.

Main Parts of the LR810 System

The main parts of the controller are shown in the diagram below.

2 The Loadrite LR810 Weighing System

3

Weight Measurement

The LR810 measures the hydraulic pressure in the lift cylinders as the

machine raises the load. The indicator converts pressure into a weight

reading and displays the value.

An electronic trigger device mounted on the lift arms ensures that the

pressure readings are always taken at the same position on every lift.

The weight of the bucket or forks and associated structures is zeroed out

when the system is calibrated so that only the weight of the payload is

displayed.

When a weight is displayed, the driver can add it to a total or use one of the

other functions described later in this manual.

Displays

The LR810 provides two displays.

The top display gives instructions and information to the operator, including

product names and weight data.

The bottom display shows the current weight as it is lifted, then shows the

total weight loaded or weight required to reach a target, depending on the

mode of operation currently selected.

Both displays on the LR810 can be backlit for ease of operation in low light

conditions.

>>>>

To turn on or off the display lighting

• Press the LIGHT key.

2 The Loadrite LR810 Weighing System

4

Indicator Lights

The LR810 provides three indicator lights (positioned between the two

displays).

TRIG Light

This light comes on when the lifting arms have passed the trigger point.

This indicates that the displays now show the currently lifted weight.

Interlock Light (middle light

If the interlock feature is enabled, this light comes on when the bucket is in

the correct weighing position (not used with a standard LR810 installation).

TARE Light

This light is on when a tare has been entered. This means that the LR810 is

subtracting the tare weight from the lifted weight and is displaying the net

weight.

Optical Trigger

To ensure consistent and accurate measurement, the LR810 system

incorporates an optical trigger which initiates the weight measurement as the

lifting arms pass a certain point.

3 Getting Started

5

3 Getting Started

Switching On

The on / off switch is on the right hand side of the casing, just below the

rubber mounting bush.

On power up, the upper display shows a sequence of check messages and

then the Ready message (or Warm Up message - see below).

The lower display shows the total weight recorded when the LR810 was last

turned off.

Warming Up

For best weighing accuracy, the hydraulic fluid in the lift cylinders should be

at normal operating temperature.

If the machine has been standing idle or used only occasionally during the

last 30 minutes, the empty bucket should be lifted a few times. A zero

check should be performed before weighing.

You can ignore the readings on the weight displays as you warm up the

machine.

Initial Warm up Message

If your LR810 has been set up to display an initial warm up message and has

been off for two hours or more, it prompts you to warm up the machine

before starting weighing.

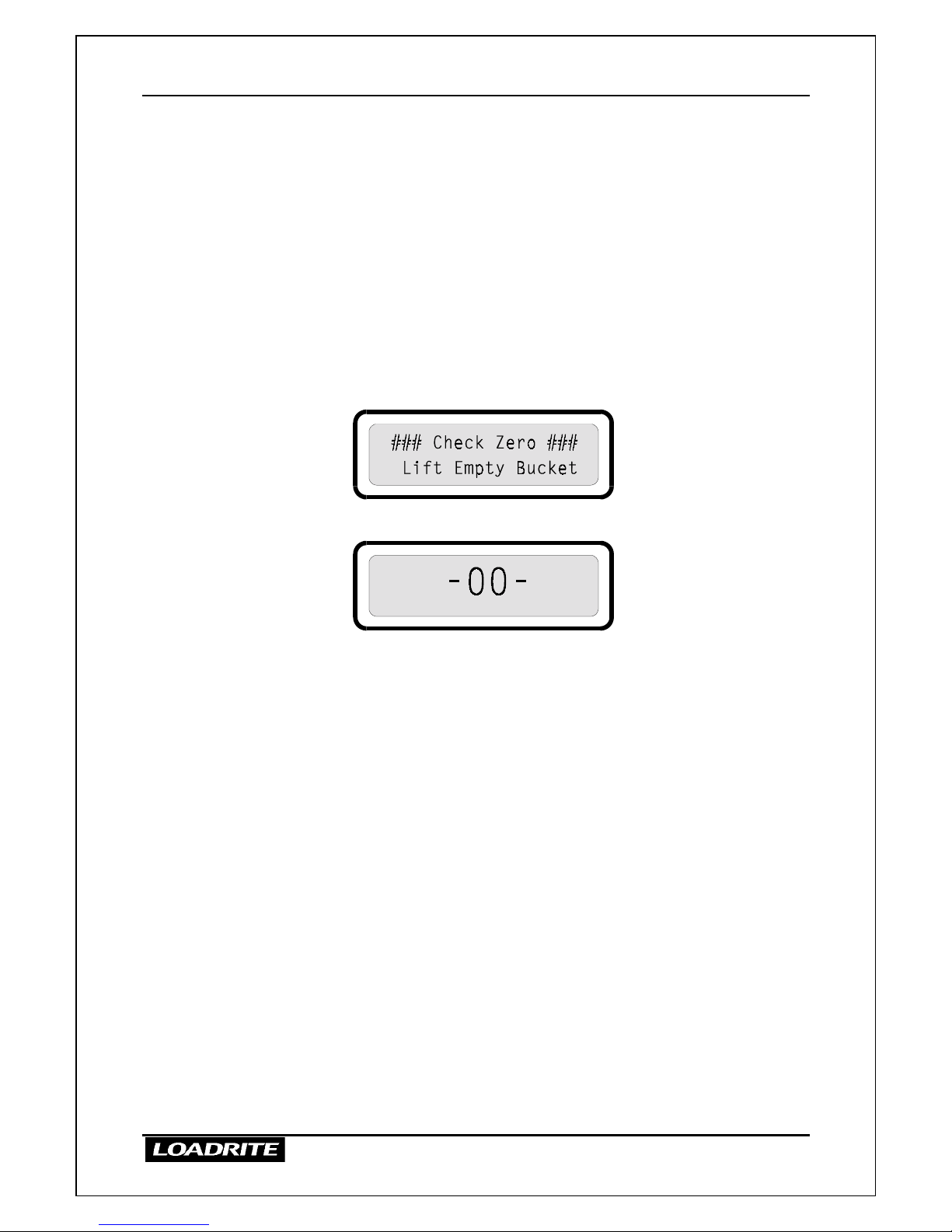

You need to do three lifts before the display shows Check -00-.

Refer to section 8 on how to zero the LR810.

Weight Display Modes

The LR810 provides two modes for displaying weight data:

• Total mode

• Target mode.

3 Getting Started

6

In total mode the LR810 displays each weight lifted and the running total as

you add weights.

In target mode the LR810 displays each weight lifted and the amount to go

to reach a specified target.

Details of total mode and target mode are given on pages 9 and 11

respectively.

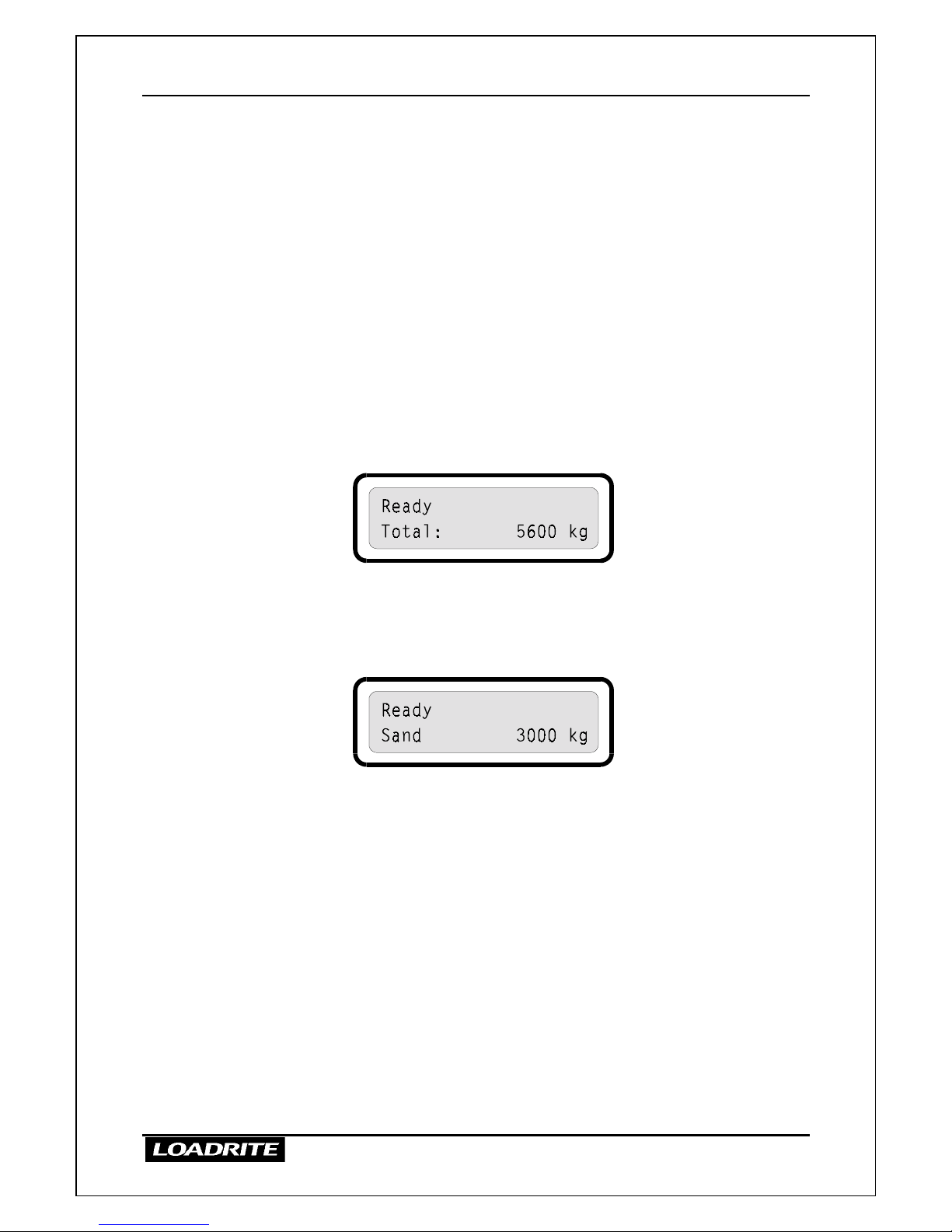

Multiple Products

The LR810 allows you to weigh and store totals for up to sixteen different

products. The selected number of products are enabled when the LR810 is

installed.

The top display shows the name (number) of the currently selected product.

If your LR810 is set up for one product only, the display simply shows Total

instead of a product name.

Further information about product names is given on page 13.

4 Weighing - Overview

7

4 Weighing - Overview

When ready to weigh, the LR810 displays Ready on the top display.

There may be other information on the top display, depending on the mode

of operation.

The total (or target) weight is shown on the second line of the top display

and on the large bottom display.

Before Weighing a Load

Before weighing, make sure that:

• The bucket or forks are rolled fully back for each lift.

• The loader is on level ground.

• The loader is stationary (for best accuracy).

• The lift arms start well below the trigger point. This ensures that all

aceleration and load bounce has been eliminated well before the

trigger sequence begins.

• The LR810 is correctly zeroed.

Weighing a Load

>>>>

To weigh a load

Raise the load smoothly through the trigger point, using normal engine revs.

For best results, operate the lift lever before accelerating the engine so that

the machine does not rock as it lifts.

As you raise the load past the trigger point, the LR810 beeps and the TRIG

light comes on to show that the weight has been measured.

The lifted weight is briefly displayed on the top line of the top display and

on the bottom (large number) display.

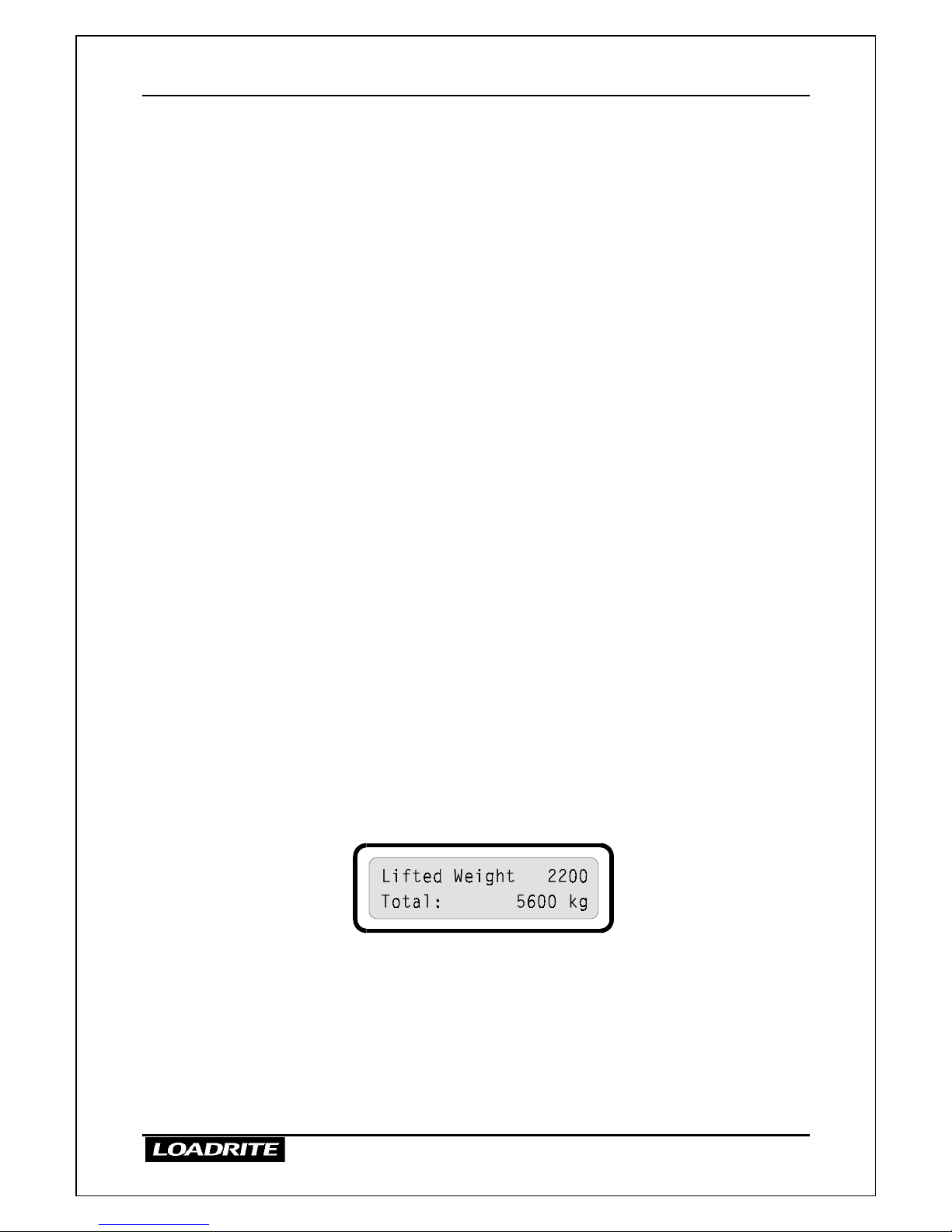

In the diagram above, the lifted weight is 2200kg and the total so far is

5600kg.

While the TRIG light remains on (few seconds), you can:

• Press ADD, to add the displayed weight to the running totals.

• Press SUB, to reduce the running totals by the displayed weight.

• Press ZERO to zero the measuring system.

4 Weighing - Overview

8

These functions are described seperately in this manual.

If you don’t press a key, the LR810 beeps and prompts you to take action. If

after a further delay, you do not press a key, the LR810 discards the just

measured weight and goes back to the Ready state.

Multiple Scales

If the multiple scale option is enabled in your LR810, you can measure

weights using Scale 1 or Scale 2.

Scale 1 and Scale 2 allow two different load bearing implements to be used

for lifting. For example, two different types of bucket/fork attachments.

The scale currently in use is displayed on the top line of the display.

To change the scale, see page 28.

5 Total Mode

9

5 Total Mode

In total mode the LR810 displays each weight lifted and the running total as

you add weights.

Total mode provides two running totals for each product:

• Short total

• Long total

•

When a load is added, both the short and long totals are updated.

The short and long totals are independent and are individually cleared and

restarted as necessary.

Selecting Total Mode

The LR810 starts up in Total mode when switched on.

You can return to total mode from Target mode by pressing TOTAL.

Short Total

The short total is typically used to display the total weight lifted onto a

truck.

As you add successive loads, the LR810 displays the weight of the current

load and the updated short total (sum of the loads so far).

The LR810 displays short totals on the second line of the top display and on

the lower (large) display.

>>>>

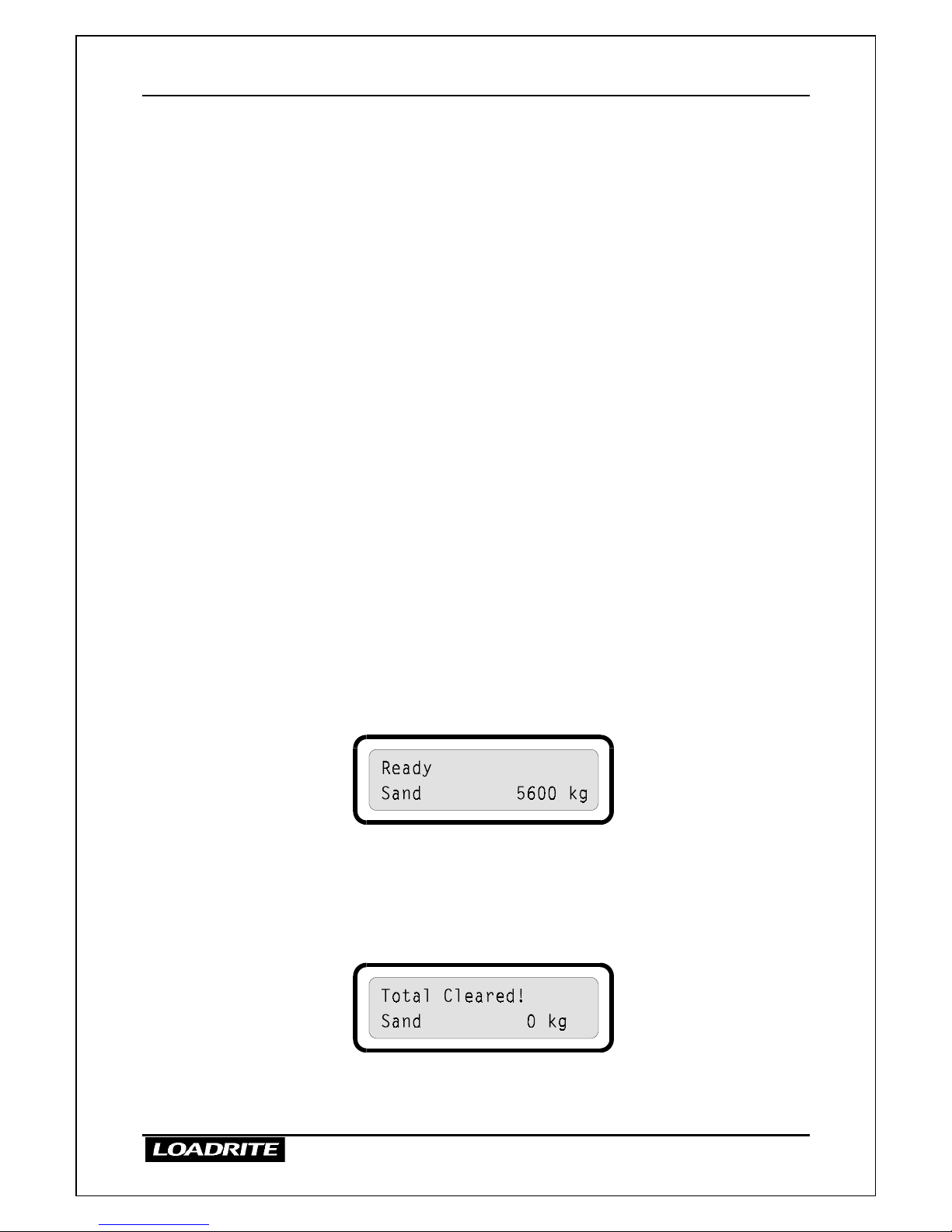

To clear the short total

Press CLEAR.

The indicator clears the short total for the current product and then displays

the following message.

The next ADD operation starts a new short total for this product.

5 Total Mode

10

Long Total

The long total is typically used for accumulating the weights lifted over a

longer period; for example a shift or a day.

>>>>

To display the long total

• Press LONG.

The long total is displayed while the LONG key is held down and for

3 seconds after it is released.

>>>>

To clear the long total

1. While the long total is displayed, press ENT.

The LR810 prompts you to confirm:

2. To clear, press ENT.

The indicator clears the long total for the current product and then

displays the following message.

(In this example, the long total for product number 1 was cleared.)

The next ADD operation starts a new long total for the current

product.

Clearing Totals for all Products

To clear the short totals for all products, you need to select each product in

turn and clear the short total as described above.

You can clear the long totals in the same way, or use the MENU option

Clear All Long. See page 30.

Multiple products are described on page 13.

6 Target Mode

11

6 Target Mode

Target mode allows you to enter a target weight and then load up to that

weight in a series of lifts.

Each time you lift and add a weight, the LR810 displays the remaining

amount to reach the target.

Target mode is used typically when loading a truck to its optimum payload.

Target mode is an optional feature which can be enabled when the LR810 is

installed.

>>>>

To select target mode and enter the target weight

1. Make sure the LR810 is Ready and you have finished (cleared) the last

target operation.

2. Press TARG.

The indicator prompts you to enter a new target weight.

3. Enter the new target using the number keys 0 to 9, or simply press

ENT to select the displayed target weight again.

You can use the CLEAR ENTRY key to correct any errors made while

entering the number.

The indicator displays the amount “To Load” to reach the target and

goes to the Ready state.

>>>>

To reset to the target weight

When you have completed a load, you need to clear the “To Load” amount

for the current product before starting another target operation.

1. Press CLEAR.

The LR810 resets to the last entered target weight and resets the short

total for the current product to zero.

6 Target Mode

12

2. The LR810 returns to the Ready state with the new “To Load” amount

displayed.

At this stage you can press TARG to enter a new target weight or continue

weighing with the current target weight.

Target Mode Notes

• If you have lifted and added any weights, you must clear the totals

before you can reset or change the target weight.

• During a target weight operation, you can check the amount added so

far by pressing TOTAL to switch to total mode. You can then return

to target mode by pressing TARG.

• During a target weight session, you can review the target weight and

the weight still to go by pressing and holding down TARG.

• If the total of the weights added exceeds the target by a certain

percentage, the LR810 beeps and displays a negative weight to load.

You can still add the weight to the totals in the normal way.

7 Product Names

13

7 Product Names

Identification/Tracking

The LR810 allows you to weigh and store separate short and long totals for

up to sixteen different products.

The number of products and names for them can be entered when the LR810

is installed.

When used with an LD640 data logger, the LR810 can track up to 999

different products, but these can only be identified by number.

One Product Only

If your LR810 is set up for one product only, the display simply shows Total

instead of a product name.

Multiple Products

If your LR810 is set up for multiple products, the display shows the name of

the currently selected product.

The LR810 maintains a separate short and long total for each product. The

ADD and SUB functions only affect the totals for the current product.

7 Product Names

14

>>>>

To select a different product

1. Press PROD.

2. Enter the number or press

≤

or to display the product required.

3. When the required product is displayed, press ENT.

The LR810 displays the product name corresponding to the number

you entered and is ready to weigh.

Notes

• If you do not select a new product within a few seconds, the LR810

reverts to the original product.

• You can select a different product in the middle of a total or target

operation and return to the original at any time without losing the data.

8 Zeroing the LR810

15

8 Zeroing the LR810

When you raise an empty bucket past the trigger point, the indicator should

display zero. However, due to build up of material in the bucket or changes

in the oil temperature, a small zero error may occur.

Zero error affects the accuracy of lifted weights.

Remember the following requirements for accurate measurements:

• The bucket or forks must be fully rolled back.

• The loader must be stationary.

• The loader must be on level ground.

• Raise the lifting arms smoothly past the trigger point.

>>>>

To zero the LR810

1. Raise the empty bucket smoothly until the LR810 beeps and the TRIG

light comes on.

2. While the TRIG light is on, press ZERO.

3. The LR810 performs the zero adjustment and displays a confirmation

message.

4. The LR810 then returns to the Ready to weigh state.

Large Zero Error

If, while zeroing, there is a large zero error (displayed weight greater than

5% of full scale), the LR810 asks you to confirm that the bucket is empty.

Depending on your response, the indicator displays “Zeroed” or “Not

Zeroed”.

If the bucket is empty and this message still occurs, there may be a fault in

the system. The LR810 should be checked and, if necessary, re-calibrated.

8 Zeroing the LR810

16

Bucket Too Heavy Message

If, while zeroing, the weight is greater than 10% of full scale, the indicator

displays the following message and does not carry out any adjustment.

This prevents any accidental zeroing of valid weights.

9 Automatic Zero Prompt

17

9 Automatic Zero Prompt

Because zero errors affect the accuracy of lifted weights, it is important to

do zero checks regularly. Changes in zero occur more often while the

machine is warming up.

The automatic zero prompt is an optional feature which can be enabled

when the LR810 is installed.

The automatic zero prompt reminds the operator to do a zero check:

• Every 15 minutes for the first hour.

• Every 30 minutes thereafter.

The reminder consists of a series of short beeps and the following display.

You should then carry out the zeroing operation described on page 15.

Note

The automatic zero prompt does not appear if you have recently checked

zero.

10 Adding, Subtracting and Recalling

18

10 Adding, Subtracting and Recalling

Adding a Weight

The ADD function adds the lifted weight to the short and long totals for the

current product.

>>>>

To add a new load

1. Lift the load smoothly until the LR810 beeps and the TRIG light

comes on. (The lower display shows the lifted weight.)

2. While the TRIG light is on, press ADD.

The LR810 updates the long and short totals for the current product

and displays the result.

The displays depend on whether you are in Total mode or Target mode

as shown below.

Total mode

When the weight is added the

upper display briefly shows the

number of lifts and then the short

total for the product.

Lifted Weight 1000

Sand 1500 kg

Then

2 Added

Sand 2500 kg

Then

Ready

Sand 4000 kg

Target mode

The upper display briefly shows

“Reduced amount” and then the

amount still required to reach the

target.

Ready

To Load 12000 kg

Then

Lifted Weight 2500

To Load 12000 kg

Then

Reduced Amount

To Load 9500 kg

Then

Ready

To Load 9500 kg

The lower display shows the current short total or the amount to reach

the target according to the mode selected.

10 Adding, Subtracting and Recalling

19

Subtracting a Weight

The subtract function subtracts the lifted weight from the short and long

totals for the current product.

This can be used, for example, when a log has been added and then removed

from a truck.

Another example is when only part of a final bucket load of loose material is

required. You can add the full bucket weight and then re-weigh and subtract

the amount remaining in the bucket.

>>>>

To subtract a weight

1. Lift the load smoothly until the LR810 beeps and the TRIG light

comes on. (The lower display shows the lifted weight.)

2. While the TRIG light is on, press SUB.

The LR810 subtracts the weight from the long and short totals for the

current product and displays the result.

The information given in the upper display depends on whether you

are in Total mode or Target mode as shown below.

10 Adding, Subtracting and Recalling

20

Total mode

The upper display briefly shows

“Subtracted!” and then the

reduced short total.

Lifted Weight 2500

Sand 9650 kg

Then

Subtracted! 2500

Sand 7150 kg

Then

Ready

Sand 7150 kg

Target mode

The upper display briefly shows

“Increased amount” and then the

amount required to reach the

target (which has been

increased).

Ready

To Load 12000 kg

Then

Lifted Weight 2500

To Load 12000 kg

Then

Increase Amount

To Load 14500 kg

Then

Ready

To Load 14500 kg

The lower display shows the current short total or the amount to reach

the target according to the mode selected.

NOTE:

The LR810 treats SUB as a similar action to ADD. If you add three

weights and then subtract one, on the next ADD the indicator briefly

displays 5 added, not 3.

10 Adding, Subtracting and Recalling

21

Recalling Last Weight

The recall function is a feature which recalls and displays the last weight

lifted. This allows you to correct mistakes in adding or subtracting weights

to the totals.

Recalling is equivalent to lifting the same weight again, but there are some

limitations.

You can only recall the last weight if it has been:

• Added

• Subtracted, or

• Timed out (ignored)

>>>>

To recall the previously lifted weight

1. Press RECALL.

The LR810 displays the previous weight and the TRIG light comes on.

2. While the TRIG light is on, you can:

• ADD (unless the previous action was an ADD)

• SUB (unless the previous action was a SUB)

• TARE

• Ignore (allow to time out).

11 Batch Weighing Mode

22

11 Batch Weighing Mode

Batch weighing allows you to add the weights of different products together

to obtain the total weight of a mix.

Batch weighing mode is an optional feature which can be enabled when the

LR810 is installed.

If it is available in your installation, you can switch batch mode on or off

from the MENU options (see page 29).

When batch mode is on, the functions of the weight displays change as

follows:

Top display

While the TRIG light is on, shows the lifted weight.

While the TRIG light is off, shows the short total for this product.

Bottom (large) display

While the TRIG light is on, shows the lifted weight.

While the TRIG light is off, shows the sum of the short totals for all

the products.

>>>>

To clear batch totals

In batch mode, the CLEAR key clears all short totals including the batch

total.

12 Weighing with Tare

23

12 Weighing with Tare

A tare is a weight that is lifted but is not part of the payload. (For example,

the weight of a wooden pallet). If only the weight of the product is required,

the weight of the pallet can be automatically subtracted from the total

weight. This is performed by the tare function.

The tare function is an optional feature which can be enabled when the

LR810 is installed.

The LR810 provides two methods of entering a tare:

1. Push button tare

The LR810 is used to weigh the unwanted weight (eg. pallet)

separately. The LR810 then automatically subtracts this tare weight

from all subsequently measured weights.

2. Keyboard tare

The unwanted weight is already known and is entered using the

keyboard. The LR810 then automatically subtracts this tare weight

from all subsequently measured weights.

>>>>

To enter a push button tare

(Use this method if you do not know the tare weight.)

1. Lift the empty container or pallet until the LR810 beeps and the TRIG

light comes on.

2. Press TARE.

3. To accept the tare weight, press ENT.

The LR810 briefly displays the following

4. The TARE light comes on and the LR810 returns to Ready.

You can now commence weighing with the tare applied to all lifted weights.

12 Weighing with Tare

24

>>>>

To enter a keyboard tare

(Use this method if you already know the tare weight.)

1. Before lifting any load, press the TARE key.

2. Enter the tare weight using the number keys 0 to 9 and press ENT.

(You can use the CLEAR ENTRY key to correct any mistakes.)

3. The LR810 briefly confirms the tare entered.

4. The tare light comes on and the LR810 returns to Ready.

You can now commence weighing with the tare applied to all lifted weights.

Note

The LR810 rounds the tare weight to the weighing resolution of your

installation. If the weighing resolution is set to 100kg and you enter a tare

of 260kg, the LR810 rounds the tare weight to 300kg.

>>>>

To clear the tare

To clear a tare, use the keyboard as described above to enter a tare of zero.

The LR810 turns off the tare light and briefly displays a confirmation

message.

Notes on tare

• Whenever the tare light is on, the LR810 displays the net weight of the

product.

• You cannot tare out negative weights.

• If you enter a tare for a container or pallet and then lift the forks

empty, the LR810 displays the negative of the tare weight.

13 Operating with Interlock (not part of standard LR810 installation kit)

25

13 Operating with Interlock

(not part of standard

LR810 installation kit)

The interlock feature is used to ensure that the bucket or forks are in the

correct position for weighing.

Interlocking is an optional feature which can be enabled when the LR810 is

installed.

When working with interlock enabled, you carry out weighing in the normal

way, except that the bucket or forks of the machine must be in the correct

position before a weight can be measured.

The correct position is indicated when the interlock light (centre light on the

LR810) is on.

>>>>

To weigh with interlocking

1. Make sure the LR810 is Ready.

2. Operate the bucket to pick up the load.

3. Move the bucket to the correct lifting position.

The interlock light comes on.

4. Lift the load smoothly until the LR810 beeps and the TRIG light

comes on.

5. You can then add or subtract the load as normal.

If you attempt to weigh when the interlock light is not on, the LR810

displays a message and no weight is measured.

.

14 Additional Data

26

14 Additional Data

If this feature is enabled, the LR810 allows you to enter three numbers

which provide additional information to the weight data.

Each number has a label to identify it. The specific labels for your LR810

are set up at installation time.

Typical labels might be, for example:

Customer number

Truck number

Docket Number

When you press the DATA key, the LR810 displays the three labels in

sequence and you can enter the relevant numbers for the current load. The

numbers can be up to 8 digits long.

If you have the appropriate equipment installed, this information can be

stored in the data logger and / or printed with the weight data.

>>>>

To enter additional data numbers

(This explanation uses the example labels above)

1. When the LR810 is Ready, press DATA.

The LR810 displays the first label and prompts you to enter a number.

2. Enter a number (up to eight digits) and press ENT.

The LR810 displays the second label and prompts you to enter a

number.

3. Enter a number and press ENT.

4. Enter the third number in the same way.

The LR810 returns to the Ready state.

Note

If you have an on-board computer, the third number can be altered remotely

from the computer or made to increment automatically when the CLEAR

key is pressed.

Note

14 Additional Data

27

You may have either one, two or three numbers available depending on how

the LR810 is set up at installation time.

15 Operator Menu Options

28

15 Operator Menu Options

The operator menu provides options for you to change some of the settings

of the LR810.

The settings you can change are:

• Switch between scale 1 and scale 2.

• Switch batch mode on or off.

• Set the clock.

• Clear all long totals.

These functions are described below. A diagram showing the menu options

(menu map) is given on page 32.

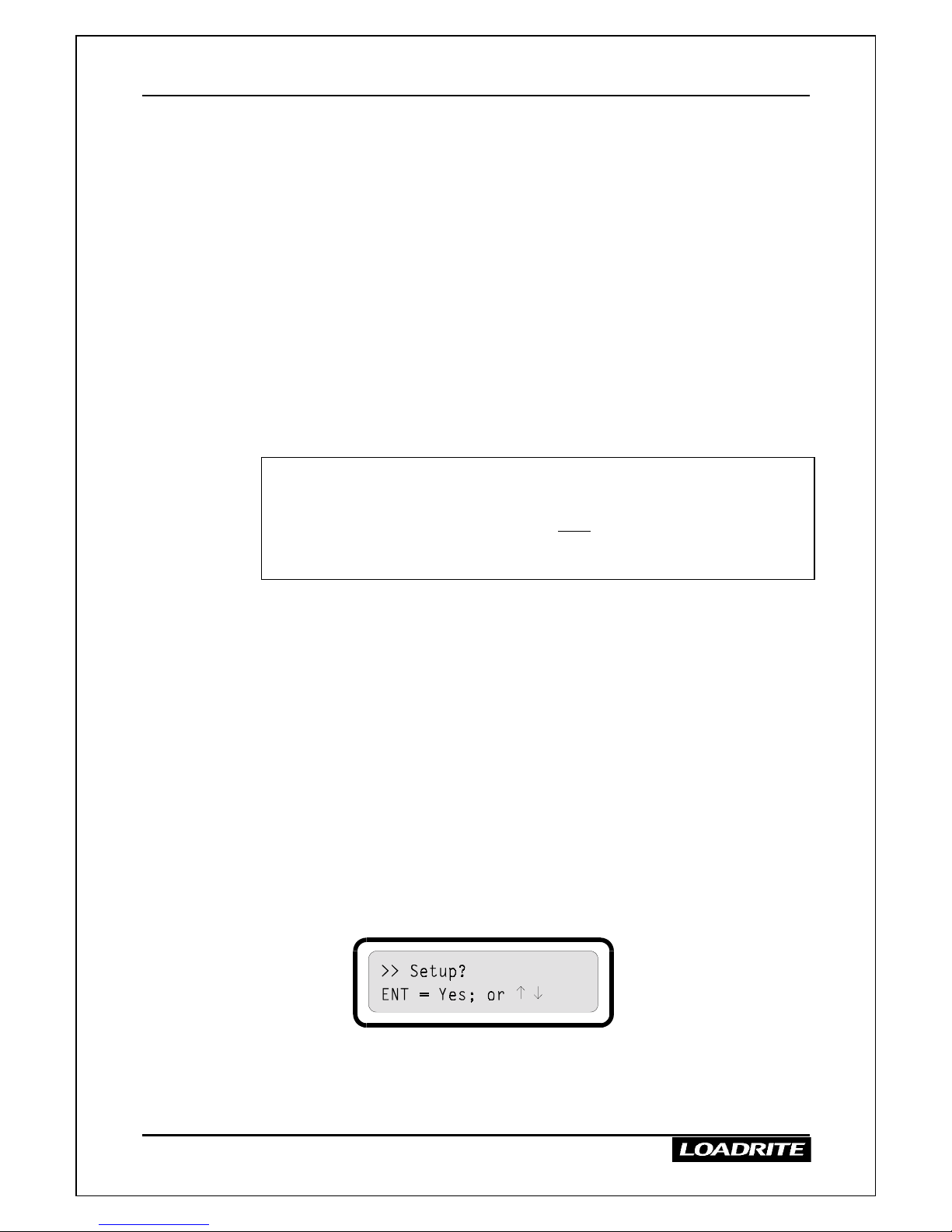

(Another option on the menu is Setup, which provides further functions used

at installation time. Setup requires a security code to allow access to these

functions.)

Menu Keys

The same keys are used for all menu options as follows:

• To access the menu, press MENU.

• To accept an option, press ENT.

• To obtain the next menu option, press

≤

or

(shown as ↑↓ on the display).

• To exit the menu, press EXIT then ENT.

• If you do not press a key, the LR810 returns to the Ready state after a

short delay.

Change Scale

If the multiple scale option is enabled in the LR810, you can select Scale 1

or Scale 2.

Scale 1 and Scale 2 allow two different load bearing implements to be used

for lifting (for example, two different types of bucket).

>>>>

To change scale

1. When the LR810 is Ready, press MENU.

2. Press

≤

or to reach the Change Scale option.

15 Operator Menu Options

29

3. To change the scale, press ENT.

The LR810 displays the new scale for a few seconds and then returns

to the Ready state with the new scale selected.

The LR810 then prompts you to check zero.

Batch Mode On / Off

If batch mode is enabled in the LR810, you can switch batch mode on or off.

Operating with batch mode is described on page 22.

>>>>

To switch batch mode on / off

1. When the LR810 is Ready, press MENU.

2. Press

≤

or to reach the Change Batch Mode option.

3. To change the mode, press ENT.

The LR810 displays the new setting of batch mode for a few seconds

and then returns to the Ready state.

Setting the Time and Date

The LR810 has an internal clock which can used for inserting the time and

date into recorded and printed data. You can also display the time and date

on the upper display by pressing the TIME key.

The LR810 has a backup battery which maintains the clock and memory

when main power is off.

>>>>

To set the time and date

1. When the LR810 is Ready, press MENU.

2. Press

≤

or to reach the Set Clock option.

3. To set the clock, press ENT.

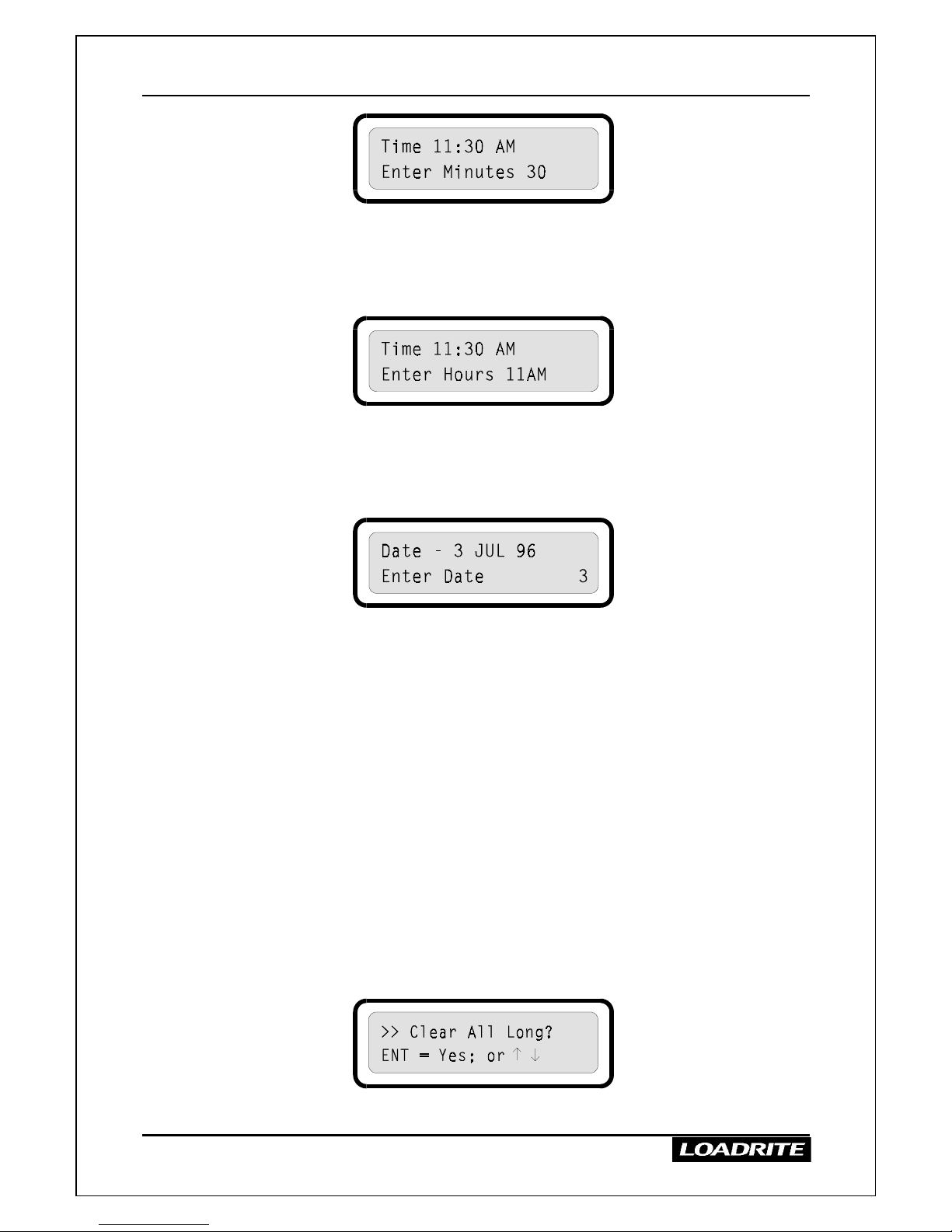

4. The display shows the current time and prompts you to enter the

minutes.

15 Operator Menu Options

30

Enter the correct minutes using the number keys.

(You can clear mistakes using the CLEAR ENTRY key.)

When the minutes are correct, press ENT.

5. The display prompts you to enter the hours.

Enter the correct hours using the number keys.

Toggle between AM and PM using the

≤

and keys

When the hours are correct, press ENT.

6. The LR810 displays the date and prompts you to enter the date.

Enter the date as prompted (day 1-31, month 1-12, year 0-99), pressing

ENT between each part.

7. Finally, the LR810 displays the complete time and date for a few

seconds before returning to the Ready state.

Note: at any time while entering the time and date you can press EXIT to

return the LR810 to the Ready state without altering the current time and

date.

Clearing Long Totals

This option allows you to clear the long totals for all products in one go.

For an explanation of long totals, see page 10.

>>>>

To clear the long totals

1. When the LR810 is Ready, press MENU.

2. Press

≤

or to reach the Clear All Long option.

3. To clear the totals, press ENT.

15 Operator Menu Options

31

4. The LR810 prompts you to confirm the operation.

To clear the totals, press ENT. To exit without clearing, press any

other key.

Note:

If the LR810 has a printer connected, the long totals are printed

together with a grand total before being cleared.

15 Operator Menu Options

32

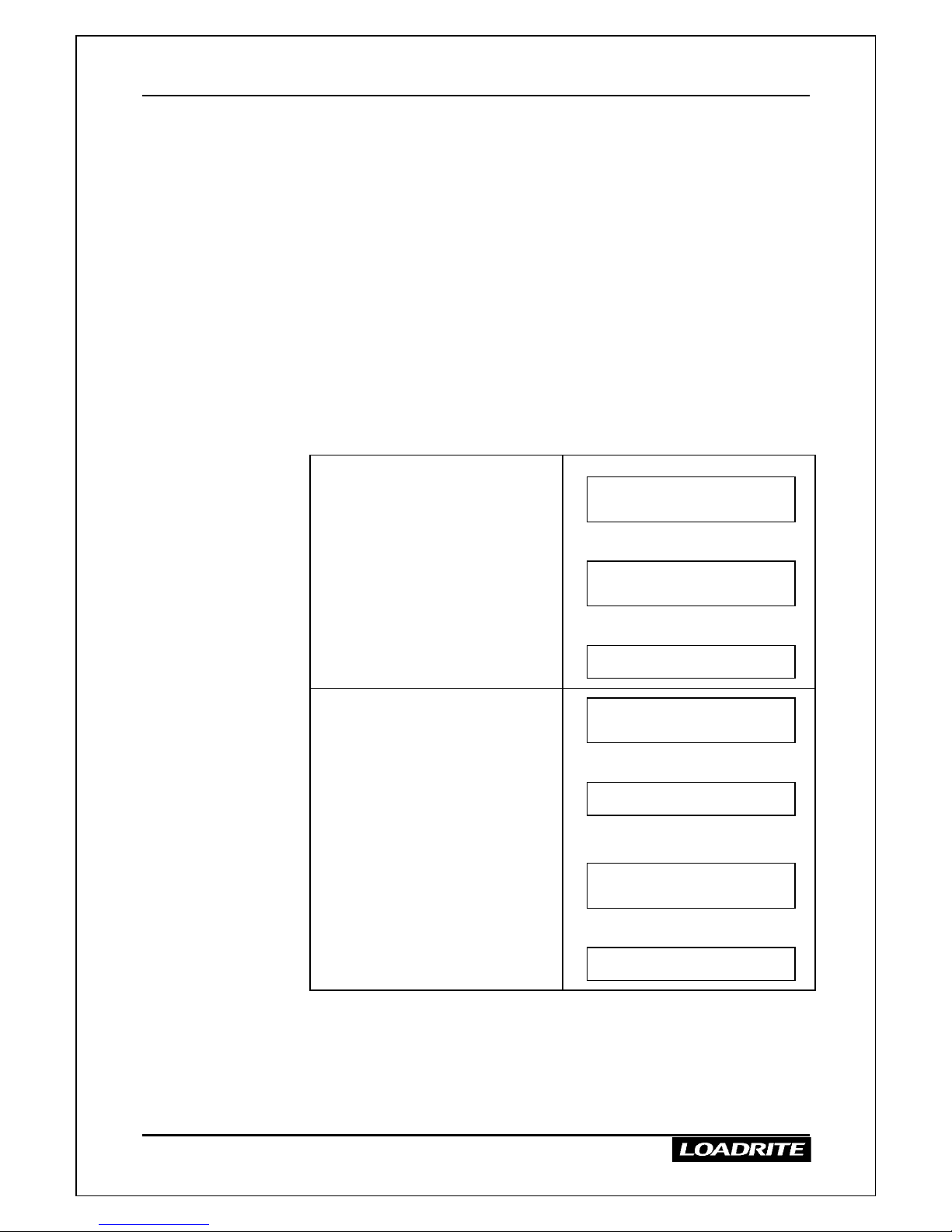

Menu Map

The diagram below shows the menu options available when you press the

MENU key.

16 Using the LD640 Data Logger

33

16 Using the LD640 Data Logger

The LD640 Data Logger is an optional accessory to the LR810 weighing

system. The LD640 consists of a portable capsule which stores the data and

a base unit which is connected to the LR810.

The LD640 records weight data as you operate the LR810. The data can

later be transferred to a computer for analysis. Data is recorded whenever a

weight is added, subtracted, zeroed or tared, or when a total is cleared.

Once installed, the LD640 operates automatically as you weigh loads, it

does not require any action by the operator.

Displays

The LD640 causes the LR810 to display the following messages at certain

times.

When data capsule inserted

When a data capsule is inserted into the base, the LR810 briefly displays the

following message.

(4.2% is replaced by the actual amount of data in the capsule)

When data capsule removed

If the data capsule has been removed from the base and the LR810 attempts

to send data to it, the LR810 briefly displays the following message.

Operation of the LR810 is unaffected.

A warning is also given as the capsule reaches 95% full.

When data capsule is full

When the data capsule has stored data up to its capacity, the LR810 briefly

displays a message to that effect.

You can continue to operate the LR810, but if you want to record the data,

you must insert another data capsule.

17 Print Functions

34

17 Print Functions

When an LP750 printer is connected weight data can be printed as the

LR810 makes measurements. Most print options can be set up at

installation.

The data can be automatically printed when particular functions are

performed as listed below.

On Power Up

LR810 Always printed

ADD performed

Sequence number Optional

Weight Optional

Tare Optional

Gross Optional

Time Optional

User defined number 1 Optional

User defined number 2 Optional

User defined number 3 Optional

SUB performed

Sequence number Optional

Weight Optional

Clear short total

Product number Optional

Total weight Optional

User defined number 1 Optional

User defined number 2 Optional

User defined number 3 Optional

ID number (of loader) Optional

Time and date Optional

User title (company name) Optional

Product name Optional

Scale Number Optional

Clear long total

Product name Printed if more than one product is being used

Long total weight Always printed

ID number (of loader) Always printed

Time and date Always printed

Clear all Long (MENU option)

All long total weights Always printed

Product numbers Always printed

ID number Always printed

17 Print Functions

35

Time and date Always printed

Zero performed

Weight zeroed Always printed

Tare performed

New tare value or tare cleared

Change of scale

New scale number Always printed

18 Obtaining the Best Accuracy

36

18 Obtaining the Best Accuracy

Lifting Speed

The hydraulic pressure required to lift a load varies with the speed of lift.

The LR810 electronically corrects for most variations, but better accuracy is

obtained if you limit the range of lifting speed used.

Keep engine revs consistant

Trigger Point

The hydraulic pressure required to start lifting is much greater than is

required to keep the load moving smoothly upwards. It is important that the

load is moving at a steady speed when it reaches the trigger point.

We recommend that you:

Start the lift well below the trigger point

(In terms of time, at least 2 seconds of lift before the trigger point.)

Bounce

Most loaders have pneumatic tyres which can cause the machine to bounce

when lifting. Any bounce causes variation in the hydraulic pressure and

affects the accuracy of the weight measurement.

To minimise the effect of bounce:

Always operate the lift lever before accelerating the engine and as

recommended above “Start the lift well below the trigger point”

Centre of Gravity

The hydraulic pressure in the lifting cylinders depends on where the centre

of gravity of the load is.

It is important that:

The bucket is always in the same position - fully rolled back

Uneven Ground

Uneven or sloping ground changes the pressure required to lift a load and

hence affects the accuracy of weighing.

Whenever possible:

Avoid weighing on uneven or sloping ground.

18 Obtaining the Best Accuracy

37

Temperature

The temperature of the hydraulic fluid in the lifting cylinders affects

weighing accuracy. If the loader is idle for more than an hour, the oil cools

down.

If practical:

Warm the oil to the normal working temperature before weighing

19 Span Calibration Correction

38

19 Span Calibration Correction

This function allows small changes to be made to the LR810 calibration if

the bucket or forks of the loader are modified or if no accurate test weight is

available when the LR810 is calibrated at installation time.

The adjustment is carried out by entering the total of weights recorded at a

weighbridge (scale house) over a period of time and the corresponding

LR810 total.

If your LR810 is set up to use two measuring scales, both Scale 1 and Scale

2 calibration must be adjusted.

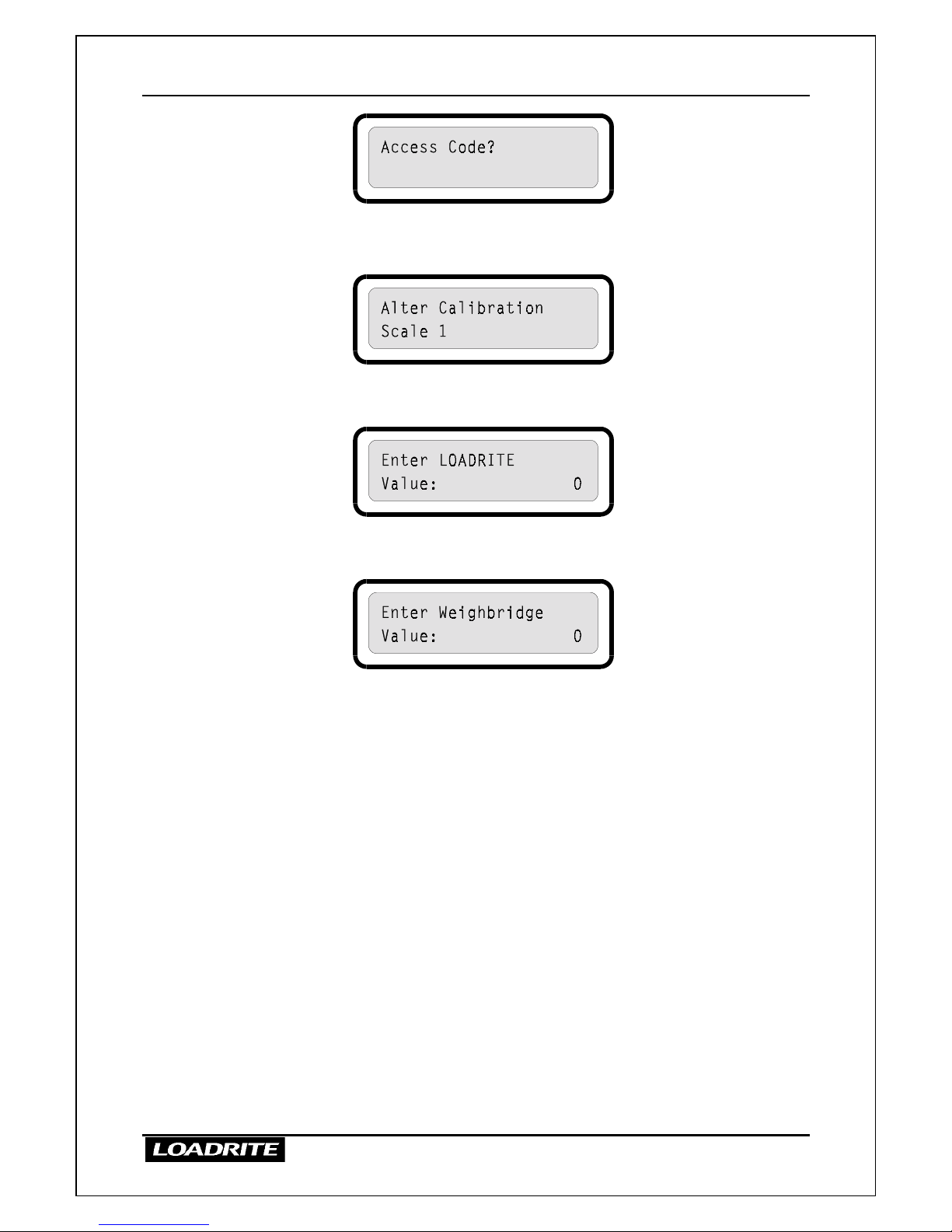

To perform the adjustment you need to obtain a security access code from

your Loadrite installer.

WARNING

The LR810 alters its calibration every time this function is used. It is

important that you only use this function once with a given set of data. If

the same weights are entered again, the LR810 will over correct and its

accuracy will be seriously impaired.

The method is explained below using an example.

Suppose a bucket loader loads aggregate onto trucks which then proceed to a

weighbridge (scale house). The figures of the loads are as follows:

LR810 26.000 tonnes

Weighbridge 26.600 tonnes

>>>>

To correct the calibration of the LR810

1. Select the scale to be corrected (see Change Scale on page 28)

2. Press MENU.

3. Press

≤

or to reach the Setup option.

4. Press ENT. The LR810 prompts you to enter the security access code.

19 Span Calibration Correction

39

5. Enter the access code and press ENT.

6. Press

≤

or to reach the Alter Span option.

7. Press ENT. The LR810 prompts you to enter the Loadrite value for

the weight.

8. Enter the Loadrite weight (26.000 in this example) and press ENT.

The LR810 prompts you to enter the weighbridge value.

9. Enter the weighbridge weight (26.600 in this example) and press

ENT.

10. If the adjustment is within limits, the LR810 alters its calibration,

briefly displays a value of scale factor and then returns to the ready

state.

If the required adjustment is too large, the LR810 displays an error

message and does not change its calibration.

Checking the Adjustment

You can check the calibration adjustment by obtaining and comparing new

Loadrite and weighbridge totals. If necessary, the calibration adjustment can

be performed again using the new data.

Notes to remember:

All trucks and trailers should have tare weights checked for all loads to be

checked. This ensures that a true weight can be established. Avoid split

weighing.

20 Changing the Backup Battery

40

20 Changing the Backup Battery

The LR810 has a backup battery which maintains the clock and memory

when main power is off.

When the battery requires changing, the LR810 displays a “Low Battery”

message each time the unit is switched on.

When this message appears, you should install a new battery as soon as

possible.

The battery compartment is at the top of the rear of the LR810 indicator.

All totals + time/date.

WARNING - memory lost if power off and battery out for 30 seconds

>>>>

To replace the battery

1. Make sure the LR810 is switched on to prevent loss of data.

2. Remove the battery cover which is held in place by four screws.

3. Unplug the old battery.

4. Plug in a new 9V alkaline battery (6LR61).

5. Replace the battery cover.

21 Error Messages

41

21 Error Messages

Lift Speed Changed?

For accurate measurement, the speed of raising the lift arms must be smooth,

without acceleration or deceleration.

The LR810 can detect changing speed as the arms go past the trigger point.

If this occurs, the indicator displays the following error message.

Depending on the installation of the LR810, there are two possibilities:

1. No weight is displayed and hence there is no weight to add.

You should repeat the lift. Avoid accelerating and decelerating at or

near the trigger sequence.

2. If weighing error is turned “off” and a weight is displayed.

You can add the weight to the running total (bearing in mind that the

weight measurement is not reliable) or you can ignore this weight and

repeat the lift again avoiding acceleration and deceleration at or near

the trigger sequence.

Bouncing Load

If the lift arms are bouncing significantly while weighing, an error occurs.

This can happen if, for example, the loader is driven over uneven ground

while lifting the load.

The LR810 can detect a bouncing load and if this occurs, the indicator

displays the following message.

No weight is displayed and hence there is no weight to add.

21 Error Messages

42

Error Close to Tolerance Limit

If a weighing error is close to but not greater than the tolerance limit, the

LR810 displays the following warning message.

The weight can be added as usual.

Trigger Fault

The optical trigger uses light beams to sense the position of the lifting arms.

The light beams are quite powerful and pass through normal build up of dirt

or dust. However, a large chunk of dirt or mud may block one of the beams.

If this occurs, the indicator displays the following message.

If this occurs, clean the faces inside the U shaped trigger sensor with a damp

cloth. There are two dark lenses on either side through which the light

beams pass. In most situations, the beams are never blocked. However, in

extremely dusty or damp environments, regular (say weekly) cleaning is

advisable.

Warning

Avoid using abrasive cleaners

22 Keys

43

22 Keys

This section gives brief descriptions of the function(s) of each key.

Adds the measured weight to the short and long totals

Clears the short total to zero, ready to start another truck load

Zeroes the LR810 when an empty bucket is lifted

Switches the LR810 from total to target mode.

Allows you to enter a new target weight

PROD Allows you to select a new product

TOTAL Switches the LR810 from target to total mode

TARE Allows you to enter or acquire a tare weight

≤

Scrolls the menu options.

DATA Allows you to enter additional data

EXIT Exits some menu options

Clears a numeric entry made in error

Accepts data or options entered

4 Enters the number 4

RECALL Recalls the last measured weight

SUB Subtracts the measured weight from the totals.

Scrolls the menu options

LONG Displays the current long total of the product

currently selected

TIME Displays the time and date

LIGHT Toggles the display lighting on / off

22 Keys

44

MENU Displays the operator menu options

Number keys

23 Specifications

45

23 Specifications

Suitable Applications

The LR810 measures weight by sensing the hydraulic pressure required to

lift a load. An optical trigger mechanism senses the position of the lifting

arms.

Typical vehicles using the LR810 system are:

• Front end loaders (bucket and/or fork)

• Fork lift trucks

Weighing Accuracy

Typical accuracy is ±1% for most bucket loaders. This may vary with

different machine types and installation options.

Minimal Weighing Delay

Weighing delay is minimal, because the weighing function is carried out

during a normal lift.

LR810 Power Requirements

Supply Voltage 11.4 to 32 Volts DC

Supply Current LR810 - 120mA typical, 220mA max.

LP750 printer - 50mA standby, 4A peak.

LD640 data logger - 120mA.

Automatic transient suppression exceeds relevant SAE specifications for DC

automotive power supply transients.

Clock and data backup 9V alkaline battery (8µA typical drain).

Typical battery life 2-3 years.

Signal Inputs and Outputs

Pressure transducer inputs 1 - 20mA (0-100%)

Trigger inputs Pull up resistor requiring switch to ground.

Serial communications RS232C protocol to printer and data logger.

Display / Keyboard

Main display 2 line by 20 character backlit LCD.

alphanumeric.

Auxiliary display 6 digit numeric only backlit LCD.

Keyboard 21 keys including numeric and special function

keys.

23 Specifications

46

Clock

Built in clock Provides time and date.

Hours, minutes, AM/PM, day, month, year.

Physical

LR810 indicator Protected to IP54.

Dimensions W 170mm, L 270mm, H 90mm.

Weight - 2kg with mounting frame.

Anti-vibration mounts.

LX400 pressure transducer Protected to IP67

Optical trigger IP67

Available Options

LP750 printer 24 column.

LD640 data logger Provides electronic data collection.

Remote ADD button For operator convenience.

Interlock system To disable weighing under defined machine

conditions.

A large number of additional operating features can be enabled at

installation time.

24 Output/Input Connections

47

24 Output/Input Connections

Transducer 1

1. NC.

2. Auxillary analog input. (LX400)

3. Transducer 1 current input.

4. +10 volt excitation.

5. Auxillary analog input. (LX400)

6. Shield.

7. Ground.

Transducer 2

1. NC.

2. Auxillary analog input.

3. Transducer 2 current input.

4. +10 volt excitation.

5. Auxillary analog input.

6. Shield.

7. Ground.

Power/Control (15 way)

1. -VE SUPPLY

2. +VE SUPPLY

3. INTERLOCK

4. REMOTE ADD

5. AUXILLARY ANALOG 2

6. TRIGGER 1

7. AUXILLARY ANALOG 1

8. AUX INPUT

9. AUXILLARY INDICATOR

10. TRIGGER 2

11. AUX OUTPUT

12. NC.

13. NC.

14. +VE SWITCHED OUTPUT

15. -VE SWITCHED OUTPUT

24 Output/Input Connections

48

Printer/EDP (12 way)

1. -VE

2. +VE

3. +5V OUTPUT

4. AUX RS232 INPUT

5. AUX RS232 OUTPUT

6. PRINTER RS232 OUTPUT

7. PRINTER BUSY

8. EDP RS232 INPUT

9. EDP RS232 OUTPUT

10. -VE

11. NC.

12. NC.

25 Index

49

25 Index

A

Accuracy...........................36, 45

Adding a weight......................18

Additional data........................ 26

B

Batch weighing........................22

switching on/off.................. 29

Battery..................................... 40

Bouncing.................................41

Bucket too heavy message ...... 16

C

Customer number

entering...............................26

D

Data logger.............................. 33

Date

setting................................. 29

time and date key................43

Display

introduction to......................3

lighting ................................. 3

weight display modes...........5

E

Error messages........................41

I

Indicator lights..........................4

Interlock.................................. 25

light ...................................... 4

K

Keys........................................43

L

Long total................................10

clearing all..........................30

M

Menu map ............................... 32

Menu options...........................28

O

Operator menu.........................28

P

Product names.........................13

introduction to......................6

R

Recalling last weight...............21

S

Scale

introduction to.......................8

Scales

changing..............................28

Short total..................................9

Span calibration adjustment.....38

Specifications ..........................45

Subtracting a weight................ 19

Switching on..............................5

T

Tare

clearing ...............................24

entering a tare weight..........23

light.......................................4

Target mode.............................11

Time

key ......................................43

setting..................................29

Total mode.................................9

TRIG light .................................4

Trigger

cleaning...............................42

optical trigger........................4

W

Warming up...............................5

Weighing

adding a weight...................18

error messages ....................41

overview...............................7

subtracting a weight............19

Weighing accuracy..................45

Weight display modes

introduction...........................5

target mode.........................11

total mode.............................9

Z

Zero prompt.............................15

Zeroing....................................15

Loading...

Loading...