LMI Technologies Gocator 2330, Gocator 2320, Gocator 2342, Gocator 2150, Gocator 2170 User Manual

...

Gocator Line Profile Sensors

USER MANUAL

Gocator 2100, 2300, 2400 Series; Gocator 2880

Firmware version:4.7.x.xx

Document revision:D

Copyright

Copyright © 2017 by LMI Technologies, Inc. All rights reserved.

Proprietary

This document, submitted in confidence, contains proprietary information which shall not be

reproduced or transferred to other documents or disclosed to others or used for manufacturing or any

other purpose without prior written permission of LMI Technologies Inc.

No part of this publication may be copied, photocopied, reproduced, transmitted, transcribed, or

reduced to any electronic medium or machine readable form without prior written consent of LMI

Technologies, Inc.

Trademarks and Restrictions

Gocator™ is a registered trademark of LMI Technologies, Inc. Any other company or product names

mentioned herein may be trademarks of their respective owners.

Information contained within this manual is subject to change.

This product is designated for use solely as a component and as such it does not comply with the

standards relating to laser products specified in U.S. FDA CFR Title 21 Part 1040.

Contact Information

LMI Technologies, Inc.

9200 Glenlyon Parkway

Burnaby BCV5J 5J8

Canada

Telephone: +1 604-636-1011

Fax: +1 604-516-8368

www.lmi3D.com

Gocator Line Profile Sensors: User Manual

2

Table of Contents

Copyright 2

Table of Contents 3

Introduction 12

Gocator Overview 13

Safety and Maintenance 14

Laser Safety 14

Laser Classes 15

Precautions and Responsibilities 15

Class 3B Responsibilities 16

Nominal Ocular Hazard Distance (NOHD) 17

Systems Sold or Used in the USA 18

Electrical Safety 18

Handling, Clean ing, and Maintenance 19

Environment and Lighting 19

Getting Started 21

Hardware Overview 22

Gocator Sensor 22

Gocator Cordsets 22

Master 100 23

Master 400 / 800 / 1200 / 2400 24

Master 810 / 2410 25

Calibration Targets 27

System Overview 27

Standalone System 27

Dual-Sensor System 28

Multi-Sensor System 29

Installation 30

Mounting 30

Orientations 31

Grounding 33

Gocator 33

Recommended Practices for Cordsets 33

Master Network Controllers 34

Grounding When Using a DIN Rail (Master

810/2410) 35

Installing DIN Rail Clips: Master 810 or 2410 35

Configuring Master 810 36

Setting the Divider 37

Encoder Quadrature Frequency 37

Setting the Debounce Period 38

Rut-Scanning System Setup 38

Layout 38

System Setup 39

Software Configuration 40

System Operation 40

Network Setup 41

Client Setup 41

Gocator Setup 44

Running a Standalone Sensor System 44

Running a Dual-Sensor System 45

Next Steps 48

How Gocator Works 49

3D Acquisition 49

Clearance Distance, Field of Viewand

Measurement Range 50

Resolution and Accuracy 51

X Resolution 51

Z Resolution 52

Z Linearity 52

Profile Output 54

Coordinate Systems 54

Sensor Coordinates 54

System Coordinates 55

Part and Section Coordinates 58

Switching between Coordinate Systems 58

Spacing (Data Resampling) 59

Data Generation and Processing 60

Surface Generation 60

Part Detection 60

Sectioning 61

Part Matching 61

Measurement and Anchoring 62

Output and Digital Tracking 62

Gocator Web Interface 64

Unblocking Flash 64

Google Chrome 64

Internet Explorer 65

Firefox 66

Microsoft Edge 67

User Interface Overview 69

Toolbar 70

Creating, Saving and Loading Jobs (Settings) 71

Gocator Line Profile Sensors: User Manual

3

Recording, Playback, and Measurement

Simulation 72

Recording Filtering 74

Downloading, Uploading, and Exporting

Replay Data 75

Metrics Area 78

Data Viewer 78

Status Bar 78

Log 79

Frame Information 79

Interface Language 80

Quick Edit Mode 80

Management and Maintenance 81

Manage Page Overview 81

Sensor System 82

Dual- and Multi-sensor Systems 82

Buddy Assignment 83

Over Temperature Protection 84

Sensor Autostart 84

Layout 84

Device Exp osure Multiplexing 91

Networking 92

Motion and Alignment 93

Alignment Reference 93

Encoder Resolution 94

Encoder Value and Frequency 94

Travel Speed 94

Jobs 95

Security 96

Maintenance 97

Sensor Backups and Factory Reset 98

Firmware Upgrade 99

Support 100

Support Files 101

Manual Access 101

Software Development Kit 102

Scan Setup and Alignment 103

Scan Page Overview 103

Scan Modes 104

Triggers 105

Trigger Examples 109

Trigger Settings 110

Maximum Input Trigger Rate 112

Maximum Encoder Rate 112

Sensor 112

Active Area 112

Tracking Window 114

Transformations 115

Exposure 117

Single Exposure 118

Dynamic Exposure 118

Multiple Exposure 119

Spacing 121

Sub-Sampling 121

Spacing In terval 122

Advanced 123

Material 124

Camera Gain and Dynamic Exposure 125

Alignment 125

Alignment States 125

Alignment Types 126

Alignment: with and without Encoder

Calibration 126

Aligning Sensors 126

Clearing Alignment 130

Filters 130

Gap Fillin g 131

Median 132

Smoothing 132

Decimation 133

Surface Generation 134

Part Detection 137

Part Detection Status 141

Edge Filtering 143

Data Viewer 144

Data Viewer Controls 144

Video Mode 147

Exposure Information 147

Exposures 147

Overexposure and Underexposure 148

Spots and Dropouts 149

Profile Mode 150

Surface Mode 152

Height Map Color Scale 155

Sections 155

Gocator Line Profile Sensors: User Manual

4

Region Definition 157

Intensity Output 158

Models 159

Model Page Overview 159

Part Matching 160

Using Edge Detection 161

Creating a Model 164

Modifying a Model's Edge Points 166

Adjusting Target Sensitivity 169

Setting the Match Acceptance Criteria 170

Running Part Matching 170

Using Bounding Box and Ellipse 170

Configuring a Bounding Box or an Ellip se172

Running Part Matching 173

Using Part Matching to Accept or Reject a

Part 174

Sections 174

Creating a Section 177

Deleting a Section 179

Measurement 180

Measure Page Overview 180

Data Viewer 181

Tools Panel 182

Adding and Configuring a Measurement

Tool 182

Source 183

Streams (Sections) 184

Regions 184

Feature Points 187

Fit Lines 189

Geometric Features 190

Decisions 191

Filters 192

Measurement Anchoring 194

Enabling and Disabling Measurements 199

Editing a Tool or Measurement Name 200

Changing a Measurement ID 200

Duplicating a Tool 201

Removing a Tool 201

Reordering Tools 202

Profile Measurement 202

Area 202

Measurements, F eatures, and Settings 204

Bounding Box 206

Measurements, F eatures, and Settings 207

Bridge Value 209

Understanding the Window and Skip

Settings 210

Measurements and Settings 211

Using Window and StdDev as Metrics

Measurements 213

Circle 214

Measurements, F eatures, and Settings 215

Dimension 216

Groove 219

Intersect 223

Measurements, F eatures, and Settings 223

Line 225

Measurements, F eatures, and Settings 226

Panel 229

Position 232

Measurements, F eatures, and Settings 233

Round Corner 235

Strip 238

Script 242

Surface Measurement 244

Bounding Box 245

Measurements, F eatures, and Settings 246

Countersunk Hole 249

Measurements, F eatures, and Settings 252

Dimension 258

Edge 262

Paths and Path Profiles 265

Measurements, F eatures, and Settings 266

Ellipse 276

Measurements, F eatures, and Settings 277

Hole 279

Measurements, F eatures, and Settings 281

Measurement Region 283

Opening 284

Measurements, F eatures, and Settings 287

Measurement Region 291

Plane 291

Measurements, F eatures, and Settingss 294

Position 295

Measurements, F eatures, and Settingss 296

Gocator Line Profile Sensors: User Manual

5

Stud 298

Measurements, F eatures, and Settings 300

Measurement Region 302

Volume 302

Script 304

Feature Measurement 305

Dimension 305

Intersect 309

Scripts 313

Built-in Functions 313

Output 318

Output Page Overview 318

Ethernet Output 319

Digital Output 323

Analog Output 326

Serial Output 327

Dashboard 330

Dashboard Page Overview 330

State and Health Information 330

Statistics 332

Measurements 332

Performance 332

Gocator Emulator 334

System Requirements 334

Limitations 335

Downloading a Support File 335

Running the Emulator 336

Adding a Scenario to the Emulator 337

Running a Scenario 337

Removing a Scenario from the Emulator 338

Using Replay Protection 339

Stopping and Restarting the Emulator 339

Running the Emulator in Default Browser 339

Working with Jobs and Data 340

Creating, Saving, and Loading Jobs 340

Playback and Measurement Simulation 341

Downloading, Uploading, and Exporting

Replay Data 342

Downloading and Uploading Jobs 345

Scan, Model, and Measurement Settings 346

Calculating Potential Maximum Frame Rate 346

Protocol Output 347

Remote Operation 347

Gocator Accelerator 349

System Requirements 350

Benefits 350

Installation 350

Gocator Accelerator Utility 350

Dashboard and Health Indicators 353

SDK Application Integration 353

Gocator Device Files 355

Live Files 355

Log File 355

Job File Structure 356

Job File Components 356

Accessing Files and Components 357

Configuration 357

Setup 358

Filters 359

XSmoothing 359

YSmoothing 359

XGapFilling 360

YGapFilling 360

XMedian 360

YMedian 360

XDecimation 361

YDecimation 361

XSlope 361

YSlope 361

Trigger 362

Layout 363

Alignment 364

Disk 365

Bar 365

Plate 366

Devices / Device 366

Tracking 369

Material 369

IndependentExposures 371

SurfaceGeneration 371

FixedLength 372

VariableLength 372

Rotational 372

SurfaceSections 373

Gocator Line Profile Sensors: User Manual

6

ProfileGeneration 373

FixedLength 374

VariableLength 374

Rotational 374

PartDetection 374

EdgeFiltering 376

PartMatching 376

Edge 376

BoundingBox 376

Ellipse 377

Replay 378

RecordingFiltering 378

Conditions/AnyMeasurement 378

Conditions/AnyData 379

Conditions/Measurement 379

Streams/Stream (Read-only) 379

ToolOptions 380

MeasurementOptions 381

FeatureOptions 381

StreamOptions 382

Tools 382

Profile Types 382

ProfileFeature 382

ProfileLine 383

ProfileRegion2d 383

SurfaceTypes 383

Region3D 383

SurfaceFeature 383

SurfaceRegion2d 384

Geometric Feature Types 384

Parameter Types 384

ProfileArea 386

ProfileBoundingBox 388

ProfileBridgeValue 389

ProfileCircle 391

ProfileDimension 392

ProfileGroove 394

ProfileIntersect 396

ProfileLine 397

ProfilePanel 399

ProfilePosition 402

ProfileRoundCorner 403

ProfileStrip 405

Script 407

SurfaceBoundingBox 407

SurfaceCsHole 409

SurfaceDimension 412

Tool 414

SurfaceEllipse 417

SurfaceHole 418

SurfaceOpening 421

SurfacePlane 423

SurfacePosition 425

SurfaceStud 426

SurfaceVolume 429

Tool 431

Tool 432

Custom 433

Output 434

Ethernet 434

Ascii 437

EIP 437

Modbus 437

Digital0 and Digital1 438

Analog 438

Serial 439

Selcom 440

Ascii 440

Transform 440

Device 441

Part Models 442

Edge Points 443

Configuration 443

Protocols 445

Gocator Protocol 445

Data Types 446

Commands 446

Discovery Commands 447

Get Address 447

Set Address 448

Get Info 449

Control Commands 450

Protocol Version 451

Get Address 451

Gocator Line Profile Sensors: User Manual

7

Set Address 452

Get System Info V2 452

Get System Info 455

Get States 456

Log In/Out 457

Change Password 457

Assign Bud dies 458

Remove Buddies 459

Set Buddy 459

List Files 459

Copy File 460

Read File 460

Write File 461

Delete File 462

User Storage Used 462

User Storage Free 462

Get Default Job 463

Set Default Job 463

Get Loaded Job 463

Get Alignment Reference 464

Set Alignment Reference 464

Clear Alignment 465

Get Timestamp 465

Get Encoder 465

Reset En coder 466

Start 466

Scheduled Start 467

Stop 467

Get Auto Start Enabled 467

Set Auto Start Enabled 468

Get Voltage Settings 468

Set Voltage Settings 469

Get Quick Edit Enab led 469

Set Quick Edit Enabled 469

Start Alignment 470

Start Exposure Auto-set 470

Software Trigger 471

Schedule Digital Output 471

Schedule Analog Output 472

Ping 472

Reset 473

Backup 473

Restore 474

Restore Factory 474

Get Recording Enabled 475

Set Recording Enabled 475

Clear Replay Data 476

Get Playback Source 476

Set Playback Source 476

Simulate 477

Seek Playback 477

Step Playback 478

Playback Position 478

Clear Measurement Stats 479

Read Live Log 479

Clear Log 479

Simulate Unaligned 480

Acquire 480

Acquire Unaligned 480

Create Model 481

Detect Edges 481

Add Tool 482

Add Measurement 482

Read File (Progressive) 483

Export CSV (Progressive) 483

Export Bitmap (Progressive) 484

Get Runtime Variable Count 485

Set Runtime Variables 485

GetRuntimeVariables 486

Upgrade Commands 486

Start Upgrade 487

Start Upgrade Extended 487

Get Upgrade Status 487

Get Upgrade Log 488

Results 488

Data Results 488

Stamp 489

Video 490

Profile 490

Resampled Profile 491

Profile Inten sity 492

Resampled Profile Intensity 492

Surface 493

Surface Intensity 494

Gocator Line Profile Sensors: User Manual

8

Surface Section 494

Surface Section Intensity 495

Measurement 496

Operation Result 496

Exposure Calibration Result 497

Edge Match Result 497

Bounding Box Match Result 498

Ellipse Match Result 498

Event 498

Feature Point 499

Feature Line 499

Health Results 499

Modbus Protocol 505

Concepts 505

Messages 505

Registers 506

Control Registers 507

Output Registers 508

State 508

Stamp 509

Measurement Registers 510

EtherNet/IP Protocol 512

Concepts 512

Basic Object 513

Identity Object (Class 0x01) 513

TCP/IP Object (Class 0xF5) 513

Ethernet Link Object (Class 0xF6) 513

Assembly Object (Class 0x04) 514

Command Assembly 514

Runtime Variable Configuration Assembly 515

Sensor State Assembly 516

Sample State Assembly 517

Implicit Messaging Command Assembly 518

Implicit Messaging Output Assembly 519

ASCIIProtocol 521

Connection Settings 521

Ethernet Communication 521

Serial Communication 522

Polling Operation Commands (Ethernet Only) 522

Command and Reply Format 523

Special Characters 523

Command Channel 523

Start 524

Stop 524

Trigger 524

LoadJob 525

Stamp 525

Clear Alignment 526

Moving Align ment 526

Stationary Alignment 526

Set Runtime Variables 527

Get Runtime Variables 527

Data Channel 527

Result 527

Value 528

Decision 529

Health Channel 529

Health 530

Standard Result Format 530

Custom Result Format 531

Selcom Protocol 532

Serial Communication 532

Connection Settings 532

Message Format 532

Development Kits 534

GoSDK 534

Setup and Locations 535

Class Reference 535

Examples 535

Sample Project Environment Variable 535

Header Files 535

Class Hierarchy 535

GoSystem 536

GoSensor 536

GoSetup 536

GoLayout 536

GoTools 537

GoTransform 537

GoOutput 537

Data Types 537

Value Types 537

Output Types 537

GoDataSet Type 538

MeasurementValues and Decisions 539

Gocator Line Profile Sensors: User Manual

9

Operation Workflow 539

Initialize GoSdk APIObject 540

Discover Sensors 541

Connect Sensors 541

Configure Sensors 541

Enable Data Channels 541

Perform Operations 541

Limiting Flash Memory Write Operations 543

GDK 544

Benefits 544

Supported Sensors 544

Typical Workflow 545

Installation and Class Reference 545

Required Tools 545

Getting Started with the Example Code 546

Building the Sample Code 546

Tool Registration 546

Tool Definitions 547

Entry Functions 547

Parameter Configurations 548

Graphics Visualization 549

Debuggin g Your Measurement Tools 551

Debuggin g Entry Functions 552

Tips 552

Backward Compatibility with Older Versions

of Tools 552

Define new parameters as optional 552

Configuration Versioning 552

Version 554

Common Programming Operations 554

Input Data Objects 554

Setup and Region Info during Tool

Initialization 555

Computing Region Based on the Offset

from an Anchor Source 555

Part Matching 556

Accessing Sensor Local Storage 556

Print Output 556

Tools and Native Drivers 557

Sensor Discovery Tool 557

GenTL Driver 558

16-bit RGB Image 562

16-bit Grey Scale Image 563

Registers 565

XMLSettings File 566

Interfacing with Halcon 566

Setting Up Halcon 567

Halcon Procedures 570

Generating Halcon Acquisition Code 574

CSV Converter Tool 575

MountainsMap Transfer Tool 577

Configuring Gocator to Work with the Transfer

Tool 578

Using the Mountains Map Transfer Tool 578

Troubleshooting 581

Specifications 583

Sensors 583

Gocator 2100 & 2300 Series 583

Gocator 2320 586

Gocator 2130 and 2330 588

Gocator 2140 and 2340 590

Gocator 2342 592

Gocator 2150 and 2350 594

Gocator 2170 and 2370 597

Gocator 2375 600

Gocator 2180 and 2380 603

Gocator 2400 Series 606

Gocator 2410 608

Gocator 2420 611

Gocator 2880 Sensor 614

Gocator 2880 615

Sensor Connectors 618

Gocator Power/LAN Connector 618

Grounding Shield 618

Power 619

Laser Safety Input 619

Gocator I/O Connector 620

Grounding Shield 620

Digital Outputs 620

Inverting Outputs 621

Digital Input 621

Encoder Input 622

Serial Output 623

Selcom Serial Output 623

Analog Output 623

Gocator Line Profile Sensors: User Manual

10

Master Network Controllers 625

Master 100 625

Master 100 Dimensions 626

Master 400/800 627

Master 400/800 Electrical Specifications 628

Master 400/800 Dimensions 630

Master 810/2410 631

Electrical Specifications 633

Encoder 634

Input 636

Master 810 Dimensions 638

Master 2410 Dimensions 639

Master 1200/2400 640

Master 1200/2400 Electrical Specifications 641

Master 1200/2400 Dimensions 642

Accessories 643

Return Policy 645

Software Licenses 646

Support 652

Contact 653

Gocator Line Profile Sensors: User Manual

11

Introduction

This documentation describes how to connect, configure, and use a Gocator. It also contains reference

information on the device's protocols and job files, as well as an overview of the development kits you

can use with Gocator. Finally, the documentation describes the Gocator emulator and accelerator

applications.

The documentation applies to the following sensors:

l Gocator 2100 series

l Gocator 2300 series

l Gocator 2400 series

l Gocator 2880

B revision Gocator sensors are only supported by firmware version 4.3 or later. These sensors

are compatible with SDKapplications built with version 4.x of the SDK. The sensors are also

compatible with jobs created on sensors running firmware 4.3.

C revision Gocator sensors are only supported by firmware version 4.5 SR1 or later. These

sensors are compatible with SDKapplications built with version 4.x of the SDK. The sensors are

also compatible with jobs created on sensors running firmware 4.x.

Notational Conventions

This documentation uses the following notational conventions:

Follow these safety guidelines to avoid potential injury or property damage.

Consider this information in order to make best use of the product.

Gocator Line Profile Sensors: User Manual

12

Gocator Overview

Gocator laser profile sensors are designed for 3D measurement and control applications. Gocator

sensors are configured using a web browser and can be connected to a variety of input and output

devices. Gocator sensors can also be configured using the provided development kits.

Gocator Line Profile Sensors: User Manual

13

Safety and Maintenance

The following sections describe the safe use and maintenance of Gocator sensors.

Laser Safety

Gocator sensors contain semiconductor lasers that emit visible or invisible light and are designated as

Class 2M, Class 3R, or Class 3B, depending on the chosen laser option. For more information on the laser

classes used in Gocator sensors, Laser Classes on the next page.

Gocator sensors are referred to as components, indicating that they are sold only to qualified customers

for incorporation into their own equipment. These sensors do not incorporate safety items that the

customer may be required to provide in their own equipment (e.g., remote interlocks, key control; refer

to the references below for detailed information). As such, these sensors do not fully comply with the

standards relating to laser products specified in IEC 60825-1 and FDA CFR Title 21 Part 1040.

Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

References

1. International standard IEC 60825-1 (2001-08) consolidated edition, Safety of laser products – Part 1:

Equipment classification, requirements and user's guide.

2. Technical report 60825-10, Safety of laser products – Part 10. Application guidelines and explanatory

notes to IEC 60825-1.

3. Laser Notice No. 50, FDA and CDRH (https://www.fda.gov/Radiation-Emit-

tingProducts/ElectronicProductRadiationControlProgram/default.htm)

Gocator Line Profile Sensors: User Manual

14

Laser Classes

Class 3R laser components

Class 3R laser products emit radiation where direct

intrabeam viewing is potentially hazardous, but the

risk is lower with 3R lasers than for 3B lasers. Fewer

manufacturing requirements and control measures

for 3R laser users apply than for 3B lasers. Eye

protection and protective clothing are not required.

The laser beam must be terminated at the end of

an appropriate path. Avoid unintentional

reflections. Personnel must be trained in working

with laser equipment.

Class 3B laser components

Class 3B components are unsafe for eye exposure.

Usually only eye protection is required. Protective

gloves may also beused. Diffuse reflections are

safe if viewed for less than 10 seconds at a

minimum distance of 13 cm. There is a risk of fireif

the beam encounters flammable materials. The

laser area must be clearly identified. Use a key

switch or other mechanism to prevent

unauthorized use. Usea clearly visible indicator to

show that a laser is in use, such as “Laser in

operation.” Restrict the laser beam to the working

area. Ensure that there are no reflective surfaces in

this area.

Labels reprinted here are examples only. For accurate specifications, refer to the label on your

sensor.

For more information, see Precautions and Responsibilities below.

Precautions and Responsibilities

Precautions specified in IEC 60825-1 and FDA CFR Title 21 Part 1040 are as follows:

Requirement Class 2M Class 3R Class 3B

Remote interlock Not required Not required Required*

Key control Not required Not required Required – cannot remove

key when in use*

Power-on delays Not required Not required Required*

Beam attenuator Not required Not required Required*

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 15

Requirement Class 2M Class 3R Class 3B

Emission indicator Not required Not required Required*

Warning signs Not required Not required Required*

Beam path Not required Terminate beam at useful

length

Specular reflection Not required Prevent unintentional

reflections

Eye protection Not required Not required Required under special

Laser safety officer Not required Not required Required

Training Not required Required for operator and

maintenance personnel

*LMI Class 3B laser components do not incorporate these laser safety items. These items must be added and completed by customers

in their system design. For more information, see Class 3B Responsibilities below.

Terminate beam at useful

length

Prevent unintentional

reflections

conditions

Required for operator and

maintenance personnel

Class 3B Responsibilities

LMI Technologies has filed reports with the FDA to assist customers in achieving certification of laser

products. These reports can be referenced by an accession number, provided upon request. Detailed

descriptions of the safety items that must beadded to the system design are listed below.

Remote Interlock

A remote interlock connection must be present in Class 3B laser systems. This permits remote switches

to be attached in serial with the keylock switch on the controls. The deactivation of any remote switches

must prevent power from being supplied to any lasers.

Key Control

A key operated master control to the lasers is required that prevents any power from being supplied to

the lasers while in the OFF position. The key can be removed in the OFF position but the switch must not

allow the key to be removed from the lock while in the ON position.

Power-On Delays

A delay circuit is required that illuminates warning indicators for a short period of time before supplying

power to the lasers.

Beam Attenuators

A permanently attached method of preventing human access to laser radiation other than switches,

power connectors or key control must be employed.

Emission Indicator

It is required that the controls that operate the sensors incorporate a visible or audible indicator when

power is applied and the lasers are operating. If the distance between the sensor and controls is more

than 2 meters, or mounting of sensors intervenes with observation of these indicators, then a second

power-on indicator should be mounted at some readily-observable position. When mounting the

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 16

warning indicators, it is important not to mount them in a location that would requirehuman exposure

to the laser emissions. User must ensure that the emission indicator, if supplied by OEM, is visible when

viewed through protective eyewear.

Warning Signs

Laser warning signs must be located in the vicinity of the sensor such that they will be readily observed.

Examples of laser warning signs are as follows:

FDA warning sign example IEC warning sign example

Nominal Ocular Hazard Distance (NOHD)

Nominal Ocular Hazard Distance (NOHD)is the distance from the source at which the intensity or the

energy per surface unit becomes lower than the Maximum Permissible Exposure (MPE) on the cornea

and on the skin.

The laser beam is considered dangerous if the operator is closer to the source than the NOHD.

The following table shows example calculations of the NOHDvalues for each Gocator model and laser

class, assuming continuous operation of the laser. As a configurable device the Gocator, lets you set the

laser exposure (laser on-time) independently of the frame period (total cycle time for data acquisition).

Continuous operation of the laser means that the laser exposure is configured to be identical to the

frame period, which is also referred to as 100% duty cycle. However, in many applications the laser

exposure can be smaller than the frame period (less than 100% duty cycle) thereby reducing the NOHD.

The table therefore shows the worst-case NOHD.

Model Laser Class Model Constant Class IMPE(mW) Class IIMPE(mw) Class INOHD(mm)

2x20 2M

2x30 2M

3R

3B

2x40 2M

3R

3B

101 0.39 0.98 259 103

101 0.39 0.98 259 103

351 0.39 0.98 900 358

2246 0.39 0.98 5759 2292

101 0.39 0.98 259 103

351 0.39 0.98 900 358

2246 0.39 0.98 5759 2292

Class IINOHD

(mm)

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 17

Model Laser Class Model Constant Class IMPE(mW) Class IIMPE(mw) Class INOHD(mm)

2x50 2M

3R

3B

2x70 2M

3R

3B

2x75 3B-N

2x80 2M

3R

3B

101 0.39 0.98 259 103

351 0.39 0.98 900 358

2246 0.39 0.98 5759 2292

98 0.39 0.98 251 100

341 0.39 0.98 875 348

1422 0.39 0.98 3645 1451

8817 0.64 13777

95 0.39 0.98 245 97

335 0.39 0.98 859 342

1031 0.39 0.98 2645 1052

To calculate the NOHDvalue for a specific laser class, use the following formula:

NOHD= Model Constant / MPE

Model Constant includes a consideration of the fan angle for the individual models.

Systems Sold or Used in the USA

Class IINOHD

(mm)

Systems that incorporate laser components or laser products manufactured by LMI Technologies

require certification by the FDA.

Customers are responsible for achieving and maintaining this certification.

Customers are advised to obtain the information booklet Regulations for the Administration and

Enforcement of the Radiation Control for Health and Safety Act of 1968: HHS Publication FDA 88-8035.

This publication, containing the full details of laser safety requirements, can be obtained directly from

the FDA, or downloaded from their web site at https://www.fda.gov/Radiation-

EmittingProducts/ElectronicProductRadiationControlProgram/default.htm.

Electrical Safety

Failure to follow the guidelines described in this section may result in electrical shock or equipment

damage.

Sensors should be connected to earth ground

All sensors should beconnected to earth ground through their housing. All sensors should be mounted

on an earth grounded frame using electrically conductive hardware to ensure the housing of the sensor

is connected to earth ground. Use a multi-meter to check the continuity between the sensor connector

and earth ground to ensure a proper connection.

Minimize voltage potential between system ground and sensor ground

Care should be taken to minimize the voltage potential between system ground (ground reference for

I/O signals) and sensor ground. This voltage potential can be determined by measuring the voltage

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 18

between Analog_out- and system ground. The maximum permissible voltagepotential is 12 V but should

be kept below 10 V to avoid damage to the serial and encoder connections.

For a description of the connector pins, see Gocator I/O Connector on page 620.

Use a suitable power supply

The +24 to +48 VDC power supply used with Gocator sensors should be an isolated supply with inrush

current protection or be able to handle a high capacitive load.

Use care when handling powered devices

Wires connecting to the sensor should not be handled while the sensor is powered. Doing so may cause

electrical shock to the user or damage to the equipment.

Handling, Cleaning, and Maintenance

Dirty or damaged sensor windows (emitter or camera) can affect accuracy. Use caution when

handling the sensor or cleaning the sensor's windows.

Keep sensor windows clean

Use dry, clean air to remove dust or other dirt particles. If dirt remains, clean the windows carefully with

a soft, lint-free cloth and non-streaking glass cleaner or isopropyl alcohol. Ensure that no residue is left

on the windows after cleaning.

Turn off lasers when not in use

LMI Technologies uses semiconductor lasers in Gocator sensors. To maximize the lifespan of the sensor,

turn off the laser when not in use.

Avoid excessive modifications to files stored on the sensor

Settings for Gocator sensors are stored in flash memory inside the sensor. Flash memory has an

expected lifetime of 100,000 writes. To maximize lifetime, avoid frequent or unnecessary file save

operations.

Environment and Lighting

Avoid strong ambient light sources

The imager used in this product is highly sensitive to ambient light hence stray light may have adverse

effects on measurement. Do not operate this device near windows or lighting fixtures that could

influence measurement. If the unit must be installed in an environment with high ambient light levels, a

lighting shield or similar device may need to beinstalled to prevent light from affecting measurement.

Avoid installing sensors in hazardous environments

To ensure reliable operation and to prevent damage to Gocator sensors, avoid installing the sensor in

locations

l that are humid, dusty, or poorly ventilated;

l with a high temperature, such as places exposed to direct sunlight;

l where there are flammable or corrosive gases;

l where the unit may be directly subjected to harsh vibration or impact;

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 19

l where water, oil, or chemicals may splash onto the unit;

l where static electricity is easily generated.

Ensure that ambient conditions are within specifications

Gocator sensors are suitable for operation between 0–50° C and 25–85% relative humidity (noncondensing). Measurement error due to temperature is limited to 0.015% of full scale per degree C. The

storage temperature is -30–70° C.

The Master network controllers are similarly rated for operation between 0–50° C.

The sensor must be heat-sunk through the frame it is mounted to. When a sensor is properly heat

sunk, the difference between ambient temperature and the temperature reported in the sensor's

health channel is less

than 15° C.

Gocator sensors are high-accuracy devices, and the temperature of all of its components must

therefore be in equilibrium. When the sensor is powered up, a warm-up time of at least one hour is

required to reach a consistent spread of temperature in the sensor.

Gocator Line Profile Sensors: User Manual

Safety and Maintenance • 20

Getting Started

The following sections provide system and hardware overviews, in addition to installation and setup

procedures.

Gocator Line Profile Sensors: User Manual

21

Hardware Overview

The following sections describe Gocator and its associated hardware.

Gocator Sensor

Gocator 2140 / 2340

Item Description

Camera Observes laser light reflected from target surfaces.

Laser Emitter Emits structured light for laser profiling.

I/O Connector Accepts input and output signals.

Power / LAN Connector Accepts power and laser safety signals and connects to 1000 Mbit/s Ethernet network.

Power Indicator Illuminates when power is applied (blue).

Range Indicator Illuminates when camera detects laser light and is within the target range (green).

Laser Indicator Illuminates when laser safety input is active (amber).

Serial Number Unique sensor serial number.

Gocator Cordsets

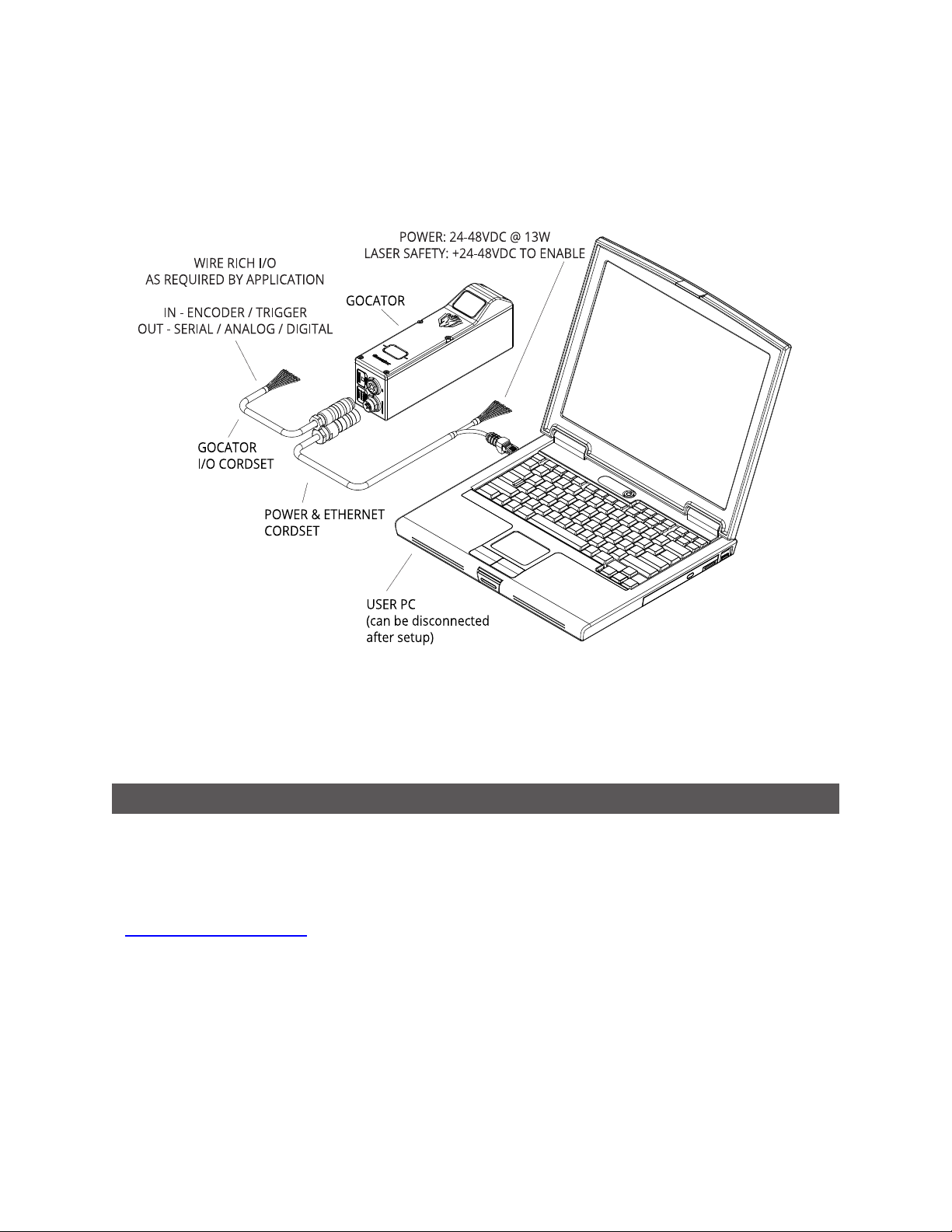

Gocator sensors use two types of cordsets:the Power & Ethernet cordset and the I/Ocordset.

The Power & Ethernet cordset provides power, laser safety interlock to the sensor. It is also used for

sensor communication via 1000 Mbit/s Ethernet with a standard RJ45 connector. The Master version of

the Power & Ethernet cordset provides direct connection between the sensor and a Master network

controller (excluding Master 100).

The Gocator I/O cordset provides digital I/O connections, an encoder interface, RS-485 serial connection,

and an analog output.

Gocator Line Profile Sensors: User Manual

Getting Started • 22

The maximum cordset length is 60 m.

See Gocator I/O Connector on page 620 and Gocator Power/LAN Connector on page 618 for pinout

details.

See Accessories on page 643 for cordset lengths and part numbers. Contact LMI for information on

creating cordsets with customized lengths and connector orientations.

Master 100

The Master 100 is used by Gocator sensors for standalone system setup (that is, a single sensor).

Item Description

Master Ethernet Port Connects to the RJ45 connector labeled Ethernet on the Power/LAN to Master cordset.

Master Power Port Connects to the RJ45 connector labeled Power/Sync on the Power/LAN to Master

cordset. Provides power and laser safety to the Gocator.

Sensor I/O Port Connects to the Gocator I/O cordset.

Master Host Port Connects to the host PC's Ethernet port.

Power Accepts power (+48 V).

Power Switch Toggles sensor power.

Laser Safety Switch Toggles laser safety signal provided to the sensors [O= laser off, I= laser on].

Trigger Signals a digital input trigger to the Gocator.

Encoder Accepts encoder A, B and Z signals.

Digital Output Provides digital output.

Gocator Line Profile Sensors: User Manual

Getting Started • 23

See Master 100 on page 625 for pinout details.

Master 400 / 800 / 1200 / 2400

The Master 400, 800, 1200, and 2400 network controllers let you connect more than two sensors:

l Master 400: accepts four sensors

l Master 800 accepts eight sensors

l Master 1200:accepts twelve sensors

l Master 2400:accepts twenty-four sensors

Master 400 and 800

Gocator Line Profile Sensors: User Manual

Getting Started • 24

Master 1200 and 2400

Item Description

Sensor Ports Master connection for Gocator sensors (no specific order required).

Ground Connection Earth ground connection point.

Power and Safety Power and laser safety connection.

Encoder Accepts encoder signal.

Input Accepts digital input.

For pinout details for Master 400 or 800, see Master 400/800 on page 627.

For pinout details for Master 1200 or 2400, see Master 1200/2400 on page 640.

Master 810 / 2410

The Master 810 and 2410 network controllers let you connect multiple sensors to create a multi-sensor

system:

l Master 810 accepts up to eight sensors

l Master 2410 accepts up to twenty-four sensors

Both models let you divide the quadrature frequency of a connected encoder to make the frequency

compatible with the Master, and also set the debounce period to accommodate faster encoders. For

more information, see Configuring Master 810 on page 36. (Earlier revisions of these models lack the

DIPswitches.)

Gocator Line Profile Sensors: User Manual

Getting Started • 25

Item Description

Master 810

Master 2410

Sensor Ports Master connection for Gocator sensors (no specific order required).

Power and Safety Power and laser safety connection.

Encoder Accepts encoder signal.

Input Accepts digital input.

DIPSwitches Configures the Master (for example, allowing the device to work with faster encoders).

For information on configuring Master 810 and 2410 using the DIPswitches, see

Configuring Master 810 on page 36.

For pinout details, see Master 810/2410 on page631.

Gocator Line Profile Sensors: User Manual

Getting Started • 26

Calibration Targets

Targets are used for alignment and calibrating encoder systems.

Disks are typically used with systems containing a single sensor and can be ordered from LMI

Technologies. When choosing a disk for your application, select the largest disk that fits entirely within

the required field of view. See Accessories on page 643 for disk part numbers.

For dual- and multi-sensor systems, bars are required to match the length of the system by following the

guidelines illustrated below. (LMI Technologies does not manufacture or sell bars.)

See Aligning Sensors on page 126 for more information on alignment.

System Overview

Gocator sensors can be installed and used in a variety of scenarios. Sensors can be connected as

standalone devices, dual-sensor systems, or multi-sensor systems.

Standalone System

Standalone systems are typically used when only a single Gocator sensorscanner is required. The

sensorscanner can be connected to a computer's Ethernet port for setup and can also be connected to

devices such as encoders, photocells, or PLCs.

Gocator Line Profile Sensors: User Manual

Getting Started • 27

Dual-Sensor System

In a dual-sensor system, two Gocator sensors work together to perform profiling and output the

combined results. The controlling sensor is referred to as the Main sensor, and the other sensor is

referred to as the Buddy sensor. Gocator's software recognizes three installation orientations: Opposite,

Wide, and Reverse.

A Master network controller (excluding Master 100) must be used to connect two sensors in a dual-

sensor system. Gocator Power and Ethernet to Master cordsets areused to connect sensors to the

Master.

Gocator Line Profile Sensors: User Manual

Getting Started • 28

Multi-Sensor System

A Master network controller (excluding Master 100) can be used to connect two or more sensors into a

multi-sensor system. Gocator Master cordsets are used to connect the sensors to a Master. The Master

provides a single point of connection for power, safety, encoder, and digital inputs. A Master

400/800/1200/2400 can beused to ensure that the scan timing is precisely synchronized across

sensors. Sensors and client computers communicate viaan Ethernet switch (1 Gigabit/s recommended).

Master networking hardware does not support digital, serial, or analog output.

Gocator Line Profile Sensors: User Manual

Getting Started • 29

Installation

The following sections provide grounding, mounting, and orientation information.

Mounting

Sensors should be mounted using a model-dependent number of screws. Some models also provide the

option to mount using bolts in through-body holes. Refer to the dimension drawings of the sensors in

Specifications on page 583 for the appropriate screw diameter, pitch, and length, and bolt hole diameter.

Proper care should be taken in order to ensure that the internal threads are not damaged from

cross-threading or improper insertion of screws.

With the exception of Gocator 2880, sensors should not be installed near objects that might occlude a

camera's view of the laser. (Gocator 2880 is specifically designed to compensate for occlusions.)

Sensors should not be installed near surfaces that might create unanticipated laser reflections.

Gocator Line Profile Sensors: User Manual

Getting Started • 30

The sensor must be heat sunk through the frame it is mounted to. When a sensor is properly

heat sunk, the difference between ambient temperature and the temperature reported in the

sensor's health channel is less than 15° C.

Gocator sensors are high-accuracy devices. The temperature of all of its components must be

in equilibrium. When the sensor is powered up, a warm-up time of at least one hour is required

to reach a consistent spread of temperature within the sensor.

Orientations

The examples below illustrate the possible mounting orientations for standalone and dual-sensor

systems.

See Layout on page 84 for more information on orientations.

Standalone Orientations

Gocator Line Profile Sensors: User Manual

Single sensor above conveyor

Getting Started • 31

Single sensor on robot arm

Dual-Sensor System Orientations:

Side-by-side for wide-area measurement (Wide) Main must be on the left side (when

looking into the connector)

of the Buddy (Wide)

Gocator Line Profile Sensors: User Manual

Getting Started • 32

Above/below for two-sided measurement (Opposite) Main must be on the top

with Buddy on the bottom (Opposite)

For more information on setting up a dual-sensor system, see

http://lmi3d.com/sites/default/files/APPNOTE_Gocator_2300_Gocator_4.x_Dual_Sensor_Setup_

Guide.pdf.

Grounding

Components of a Gocator system should be properly grounded.

Gocator

Gocators should be grounded to the earth/chassis through their housings and through the grounding

shield of the Power I/O cordset. Gocator sensors have been designed to provide adequate grounding

through the use of M5 x 0.8 pitch mounting screws. Always check grounding with a multi-meter to

ensure electrical continuity between the mounting frame and the Gocator's connectors.

The frame or electrical cabinet that the Gocator is mounted to must be connected to earth ground.

Recommended Practices for Cordsets

If you need to minimize interference with other equipment, you can ground the Power & Ethernet or the

Power & Ethernet to Master cordset (depending on which cordset you are using) by terminating the

shield of the cordset before the split. The most effective grounding method is to use a 360-degree

clamp.

Gocator Line Profile Sensors: User Manual

Getting Started • 33

To terminate the cordset's shield:

1. Expose the cordset's braided shield by cutting

the plastic jacket before the point where the

cordset splits.

2. Install a 360-degree ground clamp.

Master Network Controllers

The rack mount brackets provided with all Masters are designed to provide adequate grounding through

the use of star washers. Always check grounding with a multi-meter by ensuring electrical continuity

between the mounting frame and RJ45 connectors on the front.

When using the rack mount brackets, you must connect the frame or electrical cabinet to which

the Master is mounted to earth ground.

You must check electrical continuity between the mounting frame and RJ45 connectors on the

front using a multi-meter.

If you are mounting Master 810 or 2410 using the provided DIN rail mount adapters, you must ground

the Master directly; for more information, see Grounding When Using a DIN Rail (Master 810/2410) on the

next page.

Gocator Line Profile Sensors: User Manual

Getting Started • 34

Grounding When Using a DIN Rail (Master 810/2410)

If you are using DIN rail adapters instead of the rack mount brackets, you must ensure that the Master is

properly grounded by connecting a ground cable to one of the holes indicated below. The holes accept

M4x5 screws.

Installing DIN Rail Clips: Master 810 or 2410

You can mount the Master 810 and 2410 using the included DINrail mounting clips with M4x8 flat

socket cap screws. The following DINrail clips (DINM12-RC) are included:

To install the DINrail clips:

1. Remove the 1Urack mount brackets.

2. Locate the DINrail mounting holes on the back of the Master (see below).

Master 810:

Gocator Line Profile Sensors: User Manual

Getting Started • 35

Master 2410:

3. Attach each of the two DINrail mount clips to the back of the Master using an M4x8 flat socket cap screw for

each one.

The following illustration shows the installation of clips on a Master 810 for horizontal mounting:

Ensure that there is enough clearance around the Master for cabling.

Configuring Master 810

If you are using Master 810 with an encoder that runs at a quadrature frequency higher than 300 kHz,

you must use the device's divider DIP switches to limit the incoming frequency to 300 kHz.

Master 810 supports up to a maximum incoming encoder quadrature frequency of 6.5 MHz.

The DIP switches are located on the rear of the device.

Gocator Line Profile Sensors: User Manual

Getting Started • 36

Switches 5 to 8 are reserved for future use.

This section describes how to set the DIP switches on Master 810 to do the following:

l Set the divider so that the quadrature frequency of the connected encoder is compatible with the

Master.

l Set the debounce period to accommodate faster encoders.

Setting the Divider

To set the divider, you use switches 1 to 3. To determine which divider to use, use the following formula:

Output Quadrature Frequency = Input Quadrature Frequency / Divider

In the formula, use the quadrature frequency of the encoder (for more information, see Encoder

Quadrature Frequency below) and a divider from the following table so that the Output Quadrature

Frequency is no more than 300 kHz.

Divider Switch 1 Switch 2 Switch 3

1 OFF OFF OFF

2 ON OFF OFF

4 OFF ON OFF

8 ON ON OFF

16 OFF OFF ON

32 ON OFF ON

64 OFF ON ON

128 ON ON ON

The divider works on debounced encoder signals. For more information, see Setting the

Debounce Period on the next page.

Encoder Quadrature Frequency

Encoder quadrature frequency is defined as illustrated in the following diagram. It is the frequency of

encoder ticks. This may also be referred as the native encoder rate.

Gocator Line Profile Sensors: User Manual

Getting Started • 37

You must use a quadrature frequency when determining which divider to use (see Setting the Divider on

the previous page). Consult the datasheet of the encoder you are using to determineits quadrature

frequency.

Some encoders may be specified in terms of encoder signal frequency (or period). In this case,

convert the signal frequency to quadrature frequency by multiplying the signal frequency by 4.

Setting the Debounce Period

If the quadrature frequency of the encoder you are using is greater than 3 MHz, you must set the

debounce period to “short.” Otherwise, set the debounce period to “long.”

You use switch 4 to set the debounce period.

Debounce period Switch 4

short debounce ON

long debounce OFF

Rut-Scanning System Setup

The following sections describe how to set up a Gocator 2375 rut-scanning system.

Layout

The Gocator 2375 sensor is designed to cover a scan width of up to 4.2 m by using 8 sensors mounted

in parallel.

Gocator Line Profile Sensors: User Manual

Getting Started • 38

The diagram above shows the clearance distanceand measurement range required in a typical setup.

Use the specification estimator (Gocator-2375_Specification_Estimator.xlsx) to calculate the X and Z

resolution of the sensors with different combinations of clearance distance and measurement range.

System Setup

A typical Gocator 2375 system is set up as a multi-sensor system. Thesensors are powered using a

Master network controller (excluding Master 100).

To connect a Gocator 2375:

1. Connect the Power and Ethernet to Master cordset to the Power/LAN connector on the sensor.

Gocator Line Profile Sensors: User Manual

Getting Started • 39

2. Connect the RJ45 jack labeled Power to an unused port on the Master.

3. Connect the RJ45 jack labeled Ethernet to an unused port on the Master.

4. Repeat the steps above for each sensor.

See Master 400/800 on page 627 and Master 1200/2400 on page 640 for more information on how to

install a Master.

Software Configuration

Each sensor is shipped with a default IP address of 192.168.1.10. Before you add a sensor to a multisensor system, its firmware version must match that of the other sensors, and its IP address must be

unique.

To configure a Gocator 2375 for the first time:

1. Set up the sensor’s IP address.

a. Follow the steps in Running a Standalone Sensor System on page 44.

b. Make sure that there is no other sensor in the network with the IP address 192.168.1.10.

2. Upgrade the firmware.

a. Follow the steps in Firmware Upgrade on page 99.

3. Set up profiling parameters.

a. Follow the steps in Scan Setup and Alignment on page 103 to set up profiling parameters. Typically,

trigger, active area, and exposure will need to be adjusted.

System Operation

An isolated layout should be used. Under this layout, each sensor can be independently controlled by

the SDK. The following application notes explain how to operate a multi-sensor system using the SDK.

APPNOTE_Gocator_4.x_Multi_Sensor_Guide.zip

Explains how to use the SDK to create a multi-sensor system, and multiplex their timing.

Gocator-2000-2300_appnote_multi-sensor-alignment-calibration.zip

Explains how to use the SDK to perform alignment calibration of a multi-sensor system.

You can find the app notes under the How-to category in LMI's online Gocator resources.

Example code is included with both of the application notes above.

Gocator Line Profile Sensors: User Manual

Getting Started • 40

Network Setup

The following sections provide procedures for client PCand Gocator network setup.

DHCP is not recommended for Gocator sensors. If you choose to use DHCP, the DHCPserver

should try to preserve IPaddresses. Ideally, you should use static IP address assignment (by

MAC address) to do this.

Client Setup

To connect to a sensor from a client PC, you must ensure the client's network card is properly

configured.

Sensors are shipped with the following default network configuration:

Setting Default

DHCP Disabled

IP Address 192.168.1.10

Subnet Mask 255.255.255.0

Gateway 0.0.0.0

All Gocator sensors are configured to 192.168.1.10 as the default IP address. For a dual-sensor

system, the Main and Buddy sensors must be assigned unique addresses before they can be used

on the same network. Before proceeding, connect the Main and Buddy sensors one at a time (to

avoid an address conflict) and use the steps in See Running a Dual-Sensor System on page 45 to

assign each sensor a unique address.

Gocator Line Profile Sensors: User Manual

Getting Started • 41

To connect to a sensor for the first time:

1. Connect cables and apply power.

Sensor cabling is illustrated in System

Overview on page 27.

2. Change the client PC's network

settings.

Windows 7

a. Open the Control Panel, select

Network and Sharing Center,

and then click Change Adapter

Settings.

b. Right-click the network connection

you want to modify, and then click

Properties.

c. On the Networking tab, click

Internet Protocol Version 4

(TCP/IPv4), and then click

Properties.

d. Select the Use the following IP

address option.

e. Enter IP Address "192.168.1.5"

and Subnet Mask "255.255.255.0",

then click OK.

Gocator Line Profile Sensors: User Manual

Getting Started • 42

Mac OS X v10.6

a. Open the Network pane in

System Preferences and select

Ethernet.

b. Set Configure to Manually.

c. Enter IP Address "192.168.1.5"

and Subnet Mask "255.255.255.0",

then click Apply.

See Troubleshooting on page 581 if you experience any problems while attempting to establish a

connection to the sensor.

Gocator Line Profile Sensors: User Manual

Getting Started • 43

Gocator Setup

The Gocator is shipped with a default configuration that will produce laser profiles for most targets.

The following sections describe how to set up a standalone sensor system and a dual-sensor system for

operations. After you have completed the setup, you can perform laser profiling to verify basic sensor

operation.

Running a Standalone Sensor System

To configure a standalone sensor system:

1. Power up the sensor.

The power indicator (blue) should turn on immediately.

2. Enter the sensor's IP address (192.168.1.10) in a web

browser.

The Gocator interface loads.

If a password has been set, you will be prompted to

provide it and then log in.

3. Go to the Manage page.

4. Ensure that Replay mode is off (the slider is set to the left).

Replay mode disables measurements.

5. Ensure that the Laser Safety Switch is enabled or the

Laser Safety input is high.

6. Go to the Scan page.

7. Observe the profile in the data viewer

8. Press the Start button or the Snapshot on the Toolbar to

start the sensor.

The Start button is used to run sensors continuously.

The Snapshot button is used to trigger the capture of a

single profile.

Standalone

Master 400/800/1200/2400

Gocator Line Profile Sensors: User Manual

Getting Started • 44

Master 810/2410

9. Move a target into the laser plane.

If a target object is within the sensor's measurement

range, the data viewer will display the shape of the target,

and the sensor's range indicator will illuminate.

If you cannot see the laser, or if a profile is not displayed

in the Data Viewer, see Troubleshooting on page 581.

10. Press the Stop button.

The laser should turn off.

Running a Dual-Sensor System

All sensors areshipped with a default IP address of 192.168.1.10. Ethernet networks require a unique IP

address for each device, so you must set up a unique address for each sensor.

To configure a dual-sensor system:

1. Turn off the sensors and unplug the Ethernet network

connection of the Main sensor.

All sensors are shipped with a default IP address of

192.168.1.10. Ethernet networks require a unique IP

address for each device. Skip step 1 to 3 if the Buddy

sensor's IP address is already set up with an unique

address.

2. Power up the Buddy sensor.

The power LED (blue) of the Buddy sensor should turn on

immediately.

3. Enter the sensor's IP address 192.168.1.10 in a web

browser.

Gocator Line Profile Sensors: User Manual

Getting Started • 45

The Gocator interface loads.

4. Go to the Manage Page.

5. Modify the IP address to 192.168.1.11 in the Networking

category and click the Save button.

When you click the Save button, you will be prompted to

confirm your selection.

6. Turn off the sensors, re-connect the Main sensor's

Ethernet connection and power-cycle the sensors.

After changing network configuration, the sensors must

be reset or power-cycled before the change will take

effect.

7. Enter the sensor's IP address 192.168.1.10 in a web

browser.

The Gocator interface loads.

8. Select the Manage page.

9. Go to Manage page, Sensor System panel, and select the

Visible Sensors panel.

The serial number of the Buddy sensor is listed in the

Available Sensors panel.

10. Select the Buddy sensor and click the Assign button.

The Buddy sensor will be assigned to the Main sensor and

Gocator Line Profile Sensors: User Manual

Getting Started • 46

its status will be updated in the System panel.

The firmware on Main and Buddy sensors must be the

same for Buddy assignment to be successful. If the

firmware is different, connect the Main and Buddy sensor

one at a time and follow the steps in Firmware Upgrade on

page 99 to upgrade the sensors.

11. Ensure that the Laser Safety Switch is enabled or the

Laser Safety input is high.

12. Ensure that Replay mode is off (the slider is set to the

left).

Master 400/800/1200/2400

Master 810/2410

13. Go to the the Scan page.

14. Press the Start or the Snapshot button on the Toolbarto

start the sensors.

The Start button is used to run sensors continuously,

while the Snapshot button is used to trigger a single

profile.

15. Move a target into the laser plane.

If a target object is within the sensor's measurement

range, the data viewer will display the shape of the target,

and the sensor's range indicator will illuminate.

If you cannot see the laser, or if a profile is not displayed

in the Data Viewer, see Troubleshooting on page 581.

16. Press the Stop button if you used the Start button to start

the sensors.

The laser should turn off.

Gocator Line Profile Sensors: User Manual

Getting Started • 47

Next Steps

After you complete the steps in this section, the Gocator measurement system is ready to be configured

for an application using the software interface. The interfaceis explained in the following sections:

Management and Maintenance (page 81)

Contains settings for sensor system layout, network, motion and alignment, handling jobs, and sensor

maintenance.

Scan Setup and Alignment (page 103)

Contains settings for scan mode, trigger source, detailed sensor configuration, and performing

alignment.

Models (page 159)

Contains settings for creating part matching models and sections.

Measurement (page 180)

Contains built-in measurement tools and their settings.

Output (page 318)

Contains settings for configuring output protocols used to communicate measurements to external

devices.

Dashboard (page 330)

Provides monitoring of measurement statistics and sensor health.

Toolbar (page 70)

Controls sensor operation, manages jobs, and replays recorded measurement data.

Gocator Line Profile Sensors: User Manual

Getting Started • 48

How Gocator Works

The following sections provide an overview of how Gocator acquires and produces data, detects and

measures parts, and controls devices such as PLCs. Some of these concepts are important for

understanding how you should mount sensors and configure settings such as active area.

You can use the Gocator Accelerator to speed up processing of data. For more information, see

Gocator Accelerator on page 349.

3D Acquisition

After a Gocator system has been set up and is running, it is ready to start capturing 3D data.

Gocator laser profile sensors project a laser line onto the target.

The sensor's camera views the laser line on the target from an angle and captures the reflection of the

laser light off the target. The camera captures a single 3D profile—a slice, in a sense—for each camera

exposure. The reflected laser light falls on the camera at different positions, depending on the distance

of the target from the sensor. The sensor’s laser emitter, its camera, and the target form a triangle.

Gocator uses the known distance between the laser emitter and the camera, and two known angles—

one of which depends on the position of the laser light on the camera—to calculate the distance from

the sensor to the target. This translates to the height of the target. This method of calculating distance is

called laser triangulation.

Gocator Line Profile Sensors: User Manual

49

Target objects typically move on a conveyor belt or other transportation mechanism under a sensor

mounted in a fixed position. Sensors can also bemounted on robot arms and moved over the target. In

both cases, the sensor captures a series of 3D profiles, building up a full scan of the target. Sensor speed

and required exposure time to measure the target are typically critical factors in applications with line

profilesensors.

Gocator sensors are always pre-calibrated to deliver 3D data in engineering units throughout

their measurement range.

Clearance Distance, Field of Viewand Measurement Range

Clearance distance (CD), field of view (FOV),and measurement range (MR)are important concepts for

understanding the setup of a Gocator sensor and for understanding results.

Clearance distance – The minimum distance from the sensor that a target can be scanned and

measured. A target closer than this distance will result in invalid data.

Measurement range – The vertical distance, starting at the end of the clearance distance, in which

targets can be scanned and measured. Targets beyond the measurement range will result in invalid data.

Field of view –The width on the X axis along the measurement range. At the far end of the

measurement range, the field of view is wider, but the X resolution and Zresolution are lower. At the

near end, the field of view is narrower, but the X resolution is higher. When resolution is critical, if

possible, place the target closer to the near end. (For more information on the relation between target

distance and resolution, see

Gocator Line Profile Sensors: User Manual

How Gocator Works • 50

Resolution and Accuracy

The following sections describe X Resolution, ZResolution, and ZLinearity. These terms are used in the

Gocator datasheets to describe the measurement capabilities of the sensors.

X Resolution

X resolution is the horizontal distance between each measurement point along the laser line. This

specification is based on the number of camera columns used to cover the field of view (FOV) at a

particular measurement range.

Because the FOV is trapezoidal (shown in red, below), the distance between points is closer at the near

range than at the far range. This is reflected in the Gocator data sheet as the two numbers quoted for X

resolution.

X Resolution is important for understanding how accurately width on a target can be measured.

When the Gocator runs in Profile mode and Uniform Spacing is enabled, the 3D data is

resampled to an X interval that is different from the raw camera resolution. For more

information, see Spacing (Data Resampling) on page 59.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 51

Z Resolution

Z Resolution gives an indication of the smallest detectable height difference at each point, or how

accurately height on a target can be measured. Variability of height measurements at any given moment,

in each individual 3D point, with the target at a fixed position, limits Z resolution. This variability is

caused by camera and sensor electronics.

Like X resolution, Z resolution is better closer to the sensor. This is reflected in the Gocator data sheet as

the two numbers quoted for Z resolution.

Z Linearity

Z linearity is the difference between the actual distance to the target and the measured distance to the

target, throughout the measurement range. Z linearity gives an indication of the sensor's ability to

measure absolute distance.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 52

Z linearity is expressed in the Gocator data sheet as a percentage of the total measurement range.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 53

Profile Output

Gocator represents a profile as a series of ranges, with each range representing the distance from the

origin. Each range contains a height (on the Z axis) and a position (on the X axis) in the sensor's field of

view.

Coordinate Systems

Range data is reported in one of three coordinate systems, which generally depends on the alignment

state of the sensor. Sensor coordinates are used for unaligned sensors, whereas system coordinates are

used for aligned sensors. Part data can optionally be reported using a coordinate system relative to the

part itself. These systems are described below.

Sensor Coordinates

Unaligned sensors use the coordinate system shown below.

The measurement range (MR) is along the Z axis. Values increasetoward the sensor. The sensor’s field of

view (FOV) is along the X axis. The origin is at the center of the MR and FOV.

In Surface data, the Y axis represents the relative position of the part in the direction of travel. Y position

increases as the object moves forward (increasing encoder position). The image below represents a lefthanded coordinate system.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 54

The mounting direction, relative to the direction of travel, can be set in Gocator using either the Normal

or Reverse layout. For more information, see Layout on page 84.

System Coordinates

Aligning sensors adjusts the coordinate system in relation to sensor coordinates using transformations

(offsets along the axes and rotations around the axes).

Alignment is used with a single sensor to compensate for mounting misalignment and to set a zero

reference, such as a conveyor belt surface.

Alignment is also used to set a common coordinate system for multi-sensor systems. That is, scan data

and measurements from the sensors are expressed in a unified coordinate system.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 55

System coordinates are aligned so that the system X axis is parallel to the alignment target surface. The

system Z origin is set to the base of the alignment target object.

In both cases, alignment determines the offsets in X and Z.

Offsets can also be determined along the Yaxis. This allows setting up a staggered layout in multi-sensor

systems. This is especially useful in side-by-side mounting scenarios, as it provides full coverage for

models such as Gocator 2410 and Gocator 2420.

As with sensor coordinates, Y position increases as the object moves forward (increasing encoder

position). Gocator defines the travel direction to be forward when the object travels from the laser’s end

to the camera end of the sensor.

Alignment also determines the Y Angle (angle on the X–Z plane, around the Yaxis) needed to align sensor

data. This is also sometimes called roll correction.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 56

Y Angle

Y angle is positive when rotating from positive X to positive Z axis.

Finally, tilt can be determined around the X and the Zaxis, which compensates for the angle in height

measurements. These are sometimes called pitch correction and yaw correction, respectively. Rotation

around the X axis often used for specular mounting.

X Angle

Z Angle

X angle is positive when rotating from positive Y to positive Z. Z angle is positive when rotating from

positive X to positive Y.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 57

When applying the transformations, the object is first rotated around X, then Y, and then Z, and then the

offsets are applied.

The adjustments resulting from alignment are called transformations and are displayed in Sensor panel

on the Scan page. For more information on transformations in the web interface, see Transformations

on page 115.

For more information on aligning sensors, see Alignment on page 125.

Part and Section Coordinates

When you work with parts or sections extracted from scan data, a different coordinate system is

available.

Part data can be expressed in aligned system coordinates or unaligned sensor coordinates, depending

on the alignment state of the sensor. Part data can also be represented in part coordinates: data and

measurement results are in a coordinate system that places the X and Yorigins at the center of the part.

The Z origin is at the surface surrounding the alignment target.

The Frame of Reference setting, in the Part Detection panel on the Scan page, controls

whether part data is recorded using sensor/system coordinates or part coordinates.

Sections are always represented in a coordinate system similar to part coordinates: the X origin is always

at the center of the extracted profile, and the Z origin is at the bottom of the alignment target (or in the

center of the measurement range if the sensor is unaligned).

Switching between Coordinate Systems

In many situations, when working with part data that has been recorded with Frame of Reference set

to Part or section data, it is useful to have access to the "real-world"coordinates, rather than part- or

section-relative coordinates. Gocator provides special "global"measurements, in the Bounding Box

tools, that you can use in Gocator scripts to convert from part or section coordinates to sensor/system

coordinates.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 58

For more information, see the ProfileBounding Box tool or the Surface Bounding Box tool, and the

Script tool.

Spacing (Data Resampling)

Data produced in Profile mode is available in two formats: with and without uniform spacing. Uniform

spacing is enabled in the Scan Mode panel, on the Scan page.

When uniform spacing is enabled, the ranges that make up a profile are resampled so that the spacing is

uniform along the laser line (X axis). The resampling divides the X axis into fixed size "bins." Profile points

that fall into the same bin are combined into a single range value (Z). The size of the spacing interval is

set under the Spacing tab in the Sensor panel on Scan page.

Resampling to uniform spacing reduces the complexity for downstream algorithms to process the profile

data from the Gocator, but places a higher processing load on the sensor's CPU.

When uniform spacing is not enabled, no processing is required on the sensor. This frees up processing

resources in the Gocator, but usually requires more complicated processing on the client side. Ranges in

this case are reported in (X, Z) coordinate pairs.

Most built-in measurement tools in the Gocator in Profile mode operate on profiles with uniform

spacing. Alimited number of tools can operate on profiles without uniform spacing. For more

information on the profile tools, see Profile Measurement on page 202.

A drawback of uniform spacing is that if sensors are angled to scan the sides of a target, data on the

"verticals"is lost because points falling in the same "bin"are combined. When Uniform Spacing is

disabled, however, all points are preserved on the sides. In this case, the data can be processed by the

subset of tools that work on profiles without uniform spacing. Alternatively, the data can be processed

externally using the SDK.

When uniform spacing is enabled, in the Ethernet output, only the range values (Z) are reported

and the X positions can be reconstructed through the array index at the receiving end (the

client). For more information on Ethernet output, see Ethernet Output on page 319.

For information on enabling uniform spacing, see Scan Modes on page 104.

Gocator Line Profile Sensors: User Manual

How Gocator Works • 59

Data Generation and Processing

After scanning a target, Gocator can process the scan data to allow the use of more sophisticated