USERMANUAL

Gocator 2300 & 2880 Series

Document revision:C

Copyright

Copyright © 2015 by LMI Technologies, Inc. All rights reserved.

Proprietary

This document, submitted in confidence, contains proprietary information which shall not be

reproduced or transferred to other documents or disclosed to others or used for manufacturing or any

other purpose without prior written permission of LMI Technologies Inc.

No part of this publication may be copied, photocopied, reproduced, transmitted, transcribed, or

reduced to any electronic medium or machine readable form without prior written consent of LMI

Technologies, Inc.

Trademarks and Restrictions

Gocator™ is a registered trademark of LMI Technologies, Inc. Any other company or product names

mentioned herein may be trademarks of their respective owners.

Information contained within this manual is subject to change.

This product is designated for use solely as a component and as such it does not comply with the

standards relating to laser products specified in U.S. FDA CFR Title 21 Part 1040.

Contact Information

For more information, please contact LMI Technologies.

LMI Technologies, Inc. 1673 Cliveden Ave.

Delta, BC V3M 6V5

Canada

Telephone: +1 604 636 1011

Facsimile: +1 604 516 8368

www.lmi3D.com

Gocator 2300 & 2880 Series

2

Table of Contents

Copyright 2

Table of Contents 3

Introduction 9

Safety and Maintenance 10

Laser Safety 10

Laser Classes 11

Precautions and Responsibilities 12

Class 3B Responsibilities 12

Nominal Ocular Hazard Distance (NOHD) 13

Systems Sold or Used in the USA 14

Electrical Safety 14

Environment and Lighting 15

Sensor Maintenance 16

Getting Started 17

System Overview 17

Standalone System 17

Dual-Sensor System 17

Multi-Sensor System 18

Hardware Overview 20

Gocator 2300 &2880 Sensor 20

Gocator 2300 &2880 Cordsets 20

Master 100 21

Master 400/800 22

Master 1200/2400 22

Calibration Targets 23

Installation 25

Grounding - Gocator 25

Recommended Grounding Practices - Cordsets 25

Grounding - Master 400/800/1200/2400 26

Mounting 26

Orientations 27

Network Setup 30

Client Setup 30

Gocator Setup 32

Running a Standalone Sensor System 32

Running a Dual-Sensor System 33

Next Steps 36

Theory of Operation 38

3D Acquisition 38

Principle of 3D Acquisition 38

Resolution and Accuracy 39

X Resolution 39

Z Resolution 40

Z Linearity 40

Profile Output 41

Coordinate Systems 41

Sensor Coordinates 41

System Coordin ates 41

Resampled and Uniform Spacing Profile

Format 42

Gocator Web Interface 43

User Interface Overview 43

Common Elements 44

Toolbar 44

Saving and Loading Settings 44

Managing Multiple Settings 45

Recording, Playback, and Measurement

Simulation 46

Downloading, Exporting, and Uploading

Recorded Data 48

Log 49

Metrics Area 50

Data Viewer 50

System Management and Maintenance 51

Manage Page Overview 51

Sensor System 52

Sensor Autostart 52

Dual-Sensor System Layout 52

Buddy Assignment 54

Exposure Multiplexing 55

Networking 55

Motion and Alignment 56

Alignment Reference 57

Encoder Resolution 57

Encoder Value and Frequency 58

Travel Speed 58

Jobs 58

Security 60

Maintenance 61

Sensor Backups and Factory Reset 62

Firmware Upgrade 63

Scan Setup and Alignment 65

Scan Page Overview 65

Gocator 2300 & 2880 Series

3

Scan Modes 66

Triggers 67

Trigger Examples 70

Trigger Settings 71

Sensor 72

Active Area 73

Tracking Window 74

Transformations 76

Exposure 76

Single Exposure 77

Dynamic Exposure 78

Multiple Exposure 79

Spacing 81

Sub-Sampling 82

Spacing Interval 82

Material 83

Alignment 85

Alignment States 85

Alignment Types 86

Alignment: With and Without Encoder

Calibration 86

Aligning Sensors 87

Clearing Alignment 89

Filters 90

Gap Filling 90

Median 91

Smoothing 92

Decimation 93

Surface Generation 93

Part Detection 95

Edge Filtering 98

Data Viewer 99

Data Viewer Controls 100

Video Mode 100

Exposure View 100

Spots and Dropouts 102

Profile Mode 103

Surface Mode 105

Height Map Color Scale 107

Region Definition 108

Intensity Output 109

Measurement 111

Measure Page Overview 111

Data Viewer 112

Tools Panel 112

Measurement Tool Management 112

Adding and Removing Tools 112

Enabling and Disabling Measurements 113

Editing a Tool or Measurement Name 115

Changing a Measurement ID 115

Common Measurement Settings 116

Source 116

Regions 117

Decisions 117

Filters 119

Measurement Anchoring 120

Profile Measurement 122

Feature Points 122

Fit Lines 124

Measurement Tools 125

Area 125

Circle 127

Dimension 128

Groove 130

Intersect 133

Line 135

Position 136

Panel 138

Gap 138

Flush 139

Strip 141

Tilt 146

Script 146

Surface Measurement 147

Measurement Tools 148

Bounding Box 148

Countersunk Hole 152

Ellipse 158

Hole 160

Measurement Region 164

Opening 165

Measurement Region 171

Plane 172

Position 174

Gocator 2300 & 2880 Series

4

Stud 176

Measurement Region 179

Volume 179

Script 181

Script Measurement 182

Built-in Functions 183

Output 187

Output Page Overview 187

Ethernet Output 188

Digital Output 192

Analog Output 194

Serial Output 196

Dashboard 198

Dashboard Page Overview 198

System Panel 198

Measurements 199

Gocator Device Files 201

Job Files 201

Configuration (Root) 201

Setup 201

Filters 202

XSmoothing 202

YSmoothing 203

XGapFilling 203

YGapFilling 203

XMedian 203

YMedian 203

XDecimation 204

YDecimation 204

Layout 204

Alignment 205

Disk 205

Bar 205

Plate 206

Devices / Device 206

Tracking 207

Material 207

SurfaceGeneration 209

FixedLength 209

VariableLength 210

Rotational 210

PartDetection 210

EdgeFiltering 211

Triggers 211

Tools 212

Profile Types 212

ProfileRegion2D 212

ProfileFeature 213

ProfileLine 213

SurfaceTypes 213

Region3D 213

SurfaceRegion2D 214

SurfaceFeature 214

ProfileArea 214

ProfileCircle 216

ProfileDimension 216

ProfileGroove 218

ProfileIntersect 219

ProfileLine 220

ProfilePanel 221

ProfilePosition 223

ProfileStrip 224

Script 226

SurfaceBoundingBox 226

SurfaceEllipse 227

SurfaceHole 228

SurfaceCsHole 230

SurfaceOpening 232

SurfacePlane 234

SurfacePosition 235

SurfaceStud 235

SurfaceVolume 237

SurfaceCsHole 238

Output 240

Ethernet 240

ASCII 242

EIP 242

Modbu s 243

Digital0 and Digital1 243

Analog 243

Serial 244

Selcom 245

ASCII 245

Transformation File 246

Gocator 2300 & 2880 Series

5

Transform 247

Device 247

Protocols 248

Gocator Protocol 248

General 248

Modes 248

Buddy Communication Channels 248

States 249

Data Types 249

Status Codes 250

Discovery Commands 250

Get Address 250

Set Address 251

Control Commands 252

Protocol Version 252

Get Address 253

Set Address 253

Get System Info 254

Get States 255

Log In/Out 256

Change Password 256

Set Bud dy 257

List Files 257

Copy File 258

Read F ile 258

Write File 258

Delete File 259

Get Default Job 259

Set Default Job 260

Get Loaded Job 260

Set Alignment Reference 260

Get Alignment Reference 261

Clear Alignment 261

Get Timestamp 261

Get Encoder 262

Reset Encoder 262

Start 262

Scheduled Start 263

Stop 263

Start Alignment 264

Start Exposure Auto-set 264

Software Trigger 264

Schedule Digital Output 265

Schedule Analog Output 265

Ping 266

Reset 266

Backup 267

Restore 267

Restore Factory 268

Set Recording Enabled 268

Get Recording Enabled 269

Clear Replay Data 269

Set Playback Source 269

Get Playback Source 270

Simulate 270

Seek Playback 271

Step Playback 271

Playback Position 272

Clear Measurement Stats 272

Simulate Unaligned 272

Acquire 273

Acquire Unaligned 273

Read F ile (Progressive) 273

Export CSV (Progressive) 274

Export Bitmap (Progressive) 274

Upgrade Commands 275

Get Protocol Version 275

Start Upgrade 276

Get Upgrade Status 276

Get Upgrade Log 277

Data Results 277

Stamp 278

Video 278

Profile 279

Resampled Profile 280

Profile Intensity 280

Surface 281

Surface Intensity 281

Measurement 282

Alignment Result 283

Exposure Calibration Result 283

Health Results 283

Modbu s TCP Protocol 288

Concepts 288

Gocator 2300 & 2880 Series

6

Messages 288

Registers 289

Control Registers 290

Output Registers 291

State 291

Stamp 291

Measurement Registers 292

EtherNet/IP Protocol 294

Concepts 294

Basic Object 294

Identity Object (Class 0x01) 294

TCP/IP Object (Class 0xF5) 295

Ethernet Link Object (Class 0xF6) 295

Assembly Object (Class 0x04) 295

Command Assembly 296

Sensor State Assembly 296

Sample State Assembly 297

ASCII Protocol 300

Ethernet Communication 300

Asynchronous and Polling Operation 300

Command and Reply Format 300

Special Characters 301

Standard Result Format 301

Custom Result Format 302

Control Commands 302

Start 303

Stop 303

Trigger 303

Load Job 304

Stamp 304

Stationary Alignment 305

Moving Alignment 305

Clear Alignment 306

Data Commands 306

Get Result 306

Get Value 307

Get Decision 308

Health Commands 308

Get Health 308

Software Development Kit 310

Setup and Locations 310

Class Reference 310

Examples 310

Sample Project Environment Variable 311

Header Files 311

Class Hierarchy 311

GoSystem 311

GoSensor 312

GoSetup 312

GoLayout 312

GoTools 312

GoTransform 312

GoOutput 312

Data Types 312

Value Types 312

Output Types 313

GoDataSet Type 313

MeasurementValues and Decisions 314

Operation Workflow 314

Initialize GoSdk APIObject 315

Discover Sensors 316

Connect Sensors 316

Configure Sensors 316

Enable Data Channels 316

Perform Operations 316

Limiting Flash Memory Write Operations 318

Tools and Native Drivers 319

Sensor Recovery Tool 319

GenTL Driver 321

16-bit RGB Image 322

16-bit Grey Scale Image 323

Registers 324

XMLSettings File 326

CSV Converter Tool 326

Troubleshooting 328

Specifications 330

Gocator 2300 Series 331

Gocator 2320 333

Gocator 2330 334

Gocator 2340 336

Gocator 2350 337

Gocator 2370 339

Gocator 2375 342

Gocator 2380 345

Gocator 2300 & 2880 Series

7

Gocator 2880 Sensor 348

Gocator 2880 349

Gocator Power/LAN Connector 352

Grounding Shield 352

Power 353

Laser Safety Input 353

Gocator 2300 &2880 I/O Connector 354

Grounding Shield 354

Digital Outputs 355

Inverting Outputs 355

Digital Inputs 355

Encoder Input 356

Serial Output 357

Analog Output 357

Master 100 359

Master 100 Dimensions 360

Master 400/800 361

Master 400/800 Electrical Specifications 362

Master 400/800 Dimensions 363

Master 1200/2400 364

Master 1200/2400 Electrical Specifications 365

Master 1200/2400 Dimensions 366

Parts and Accessories 367

Return Policy 369

Software Licenses 370

Support 376

Contact 377

Gocator 2300 & 2880 Series

8

Introduction

The Gocator 2300 series of laser profiling sensors is designed for 3D measurement and control

applications. Gocator sensors are configured using a web browser and can be connected to a variety of

input and output devices.

This documentation describes how to connect, configure, and use a Gocator. It also contains reference

information on the device's protocols and job files.

Notational Conventions

This guide uses the following notational conventions:

Follow these safety guidelines to avoid potential injury or property damage.

Consider this information in order to make best use of the product.

Gocator 2300 & 2880 Series

9

Safety and Maintenance

The following sections describe the safe use and maintenance of Gocator sensors.

Laser Safety

Gocator sensors contain

semiconductor lasers that emit visible

or invisible light and are designated as

Class 2M, Class 3R, or Class 3B,

depending on the chosen laser option.

Gocator sensors are referred to as

components, indicating that they are

sold only to qualified customers for

incorporation into their own

equipment. These sensors do not

incorporate safety items that the

customer may be required to provide

in their own equipment (e.g., remote

interlocks, key control; refer to

references for detailed information).

As such, these sensors do not fully

comply with the standards relating to

laser products specified in IEC 60825-1

and FDA CFR Title 21 Part 1040.

Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

References

1. International standard IEC 60825-1 (2001-08) consolidated edition, Safety of laser products – Part 1:

Equipment classification, requirements and user's guide.

2. Technical report 60825-10, Safety of laser products – Part 10. Application guidelines and explanatory

notes to IEC 60825-1.

3. Laser Notice No. 50, FDA and CDRH http://www.fda.gov/cdrh/rad-health.html

Gocator 2300 & 2880 Series

10

Laser Classes

Class 2M laser components

Class 2M laser components would not cause

permanent damage to the eye under

reasonably foreseeable conditions of operation,

provided that any exposure can be terminated

by the blink reflex (assumed to take 0.25

seconds). Because classification assumes the

blink reflex, the wavelength of light must be in

the visible range (400 nm to 700 nm). The

Maximum PermissibleExposure (MPE) for

visible radiation for 0.25 seconds is 25 watts per

square meter, which is equivalent to 1 mW

entering an aperture of 7 mm diameter (the

assumed size of the pupil).

Class 3R laser components

Class 3R laser products emit radiation where

direct intrabeam viewing is potentially

hazardous, but the risk is lower with 3R lasers

than for 3B lasers. Fewer manufacturing

requirements and control measures for 3R laser

users apply than for 3B lasers.

Class 3B laser components

Class 3B components are unsafe for eye

exposure. Usually only ocular protection will be

required. Diffuse reflections are safe if viewed

for less than 10 seconds.

Labels reprinted here are examples only. For accurate specifications, refer to the label on your

sensor.

Gocator 2300 & 2880 Series

Safety and Maintenance • Laser Safety • 11

Precautions and Responsibilities

Precautions specified in IEC 60825-1 and FDA CFR Title 21 Part 1040 are as follows:

Requirement Class 2M Class 3R Class 3B

Remote interlock Not required Not required Required*

Key control Not required Not required Required – cannot remove

key when in use*

Power-on delays Not required Not required Required*

Beam attenuator Not required Not required Required*

Emission indicator Not required Not required Required*

Warning signs Not required Not required Required*

Beam path Not required Terminate beam at useful

length

Specular reflection Not required Prevent unintentional

reflections

Eye protection Not required Not required Required under special

Laser safety officer Not required Not required Required

Training Not required Required for operator and

maintenance personnel

*LMI Class 3B laser components do not incorporate these laser safety items. These items must be added and completed by customers

in their system design.

Terminate beam at useful

length

Prevent unintentional

reflections

conditions

Required for operator and

maintenance personnel

Class 3B Responsibilities

LMI Technologies has filed reports with the FDA to assist customers in achieving certification of laser

products. These reports can be referenced by an accession number, provided upon request. Detailed

descriptions of the safety items that must be added to the system design are listed below.

Remote Interlock

A remote interlock connection must be present in Class 3B laser systems. This permits remote switches

to be attached in serial with the keylock switch on the controls. The deactivation of any remote switches

must prevent power from being supplied to any lasers.

Key Control

A key operated master control to the lasers is required that prevents any power from being supplied to

the lasers while in the OFF position. The key can be removed in the OFF position but the switch must not

allow the key to be removed from the lock while in the ON position.

Power-On Delays

A delay circuit is required that illuminates warning indicators for a short period of time before supplying

power to the lasers.

Gocator 2300 & 2880 Series

Safety and Maintenance • Laser Safety • 12

Beam Attenuators

A permanently attached method of preventing human access to laser radiation other than switches,

power connectors or key control must be employed. On some LMI laser sensors, the beam attenuator is

supplied with the sensor as an integrated mechanical shutter.

Emission Indicator

It is required that the controls that operate the sensors incorporate a visible or audible indicator when

power is applied and the lasers are operating. If the distance between the sensor and controls is more

than 2 meters, or mounting of sensors intervenes with observation of these indicators, then a second

power-on indicator should be mounted at some readily-observable position. When mounting the

warning indicators, it is important not to mount them in a location that would require human exposure

to the laser emissions. User must ensure that the emission indicator, if supplied by OEM, is visible when

viewed through protective eyewear.

Warning Signs

Laser warning signs must be located in the vicinity of the sensor such that they will be readily observed.

Examples of laser warning signs are as follows:

FDA warning sign example IEC warning sign example

Nominal Ocular Hazard Distance (NOHD)

This is the distance from the source at which the intensity or the energy per surface unit becomes lower

than the Maximum Permissible Exposure (MPE) on the cornea and on the skin. The laser beam is

considered dangerous if the operator is closer from the source than the NOHD.

The following table shows the estimated NOHD for each Gocator model and laser class, assuming

continuous operation of the laser. As a configurable device the Gocator allows the user to set the laser

exposure (laser on-time) independently of the frame period (total cycle time for data acquisition).

Continuous operation of the laser means that the laser exposure is configured to be identical to the

frame period, which is also referred to as 100% duty cycle. However, in many applications the laser

exposure can be smaller than the frame period (less than 100% duty cycle) thereby reducing the NOHD.

The table therefore shows the worst-case NOHD.

Gocator 2300 & 2880 Series

Safety and Maintenance • Laser Safety • 13

Model Laser Class Line Fan Angle NOHD (mm)

2x20 2M 28 259

2x30 2M 28 259

3R 28 900

3B 28 5759

2x40 2M 28 259

3R 28 900

3B 28 5759

2x50 2M 28 259

3R 28 900

3B 28 5759

2x70 2M 43 251

3R 43 875

3B 43 3645

2x80 2M 57 245

3R 57 859

3B 57 2645

Systems Sold or Used in the USA

Systems that incorporate laser components or laser products manufactured by LMI Technologies

require certification by the FDA.

Customers are responsible for achieving and maintaining this certification.

Customers are advised to obtain the information booklet Regulations for the Administration and

Enforcement of the Radiation Control for Health and Safety Act of 1968: HHS Publication FDA 88-8035.

This publication, containing the full details of laser safety requirements, can be obtained directly from

the FDA, or downloaded from their web site at http://www.fda.gov/cdrh.

Electrical Safety

Failure to follow the guidelines described in this section may result in electrical shock or

equipment damage.

Sensors should be connected to earth ground

All sensors should be connected to earth ground through their housing. All sensors should be mounted

on an earth grounded frame using electrically conductive hardware to ensure the housing of the sensor

is connected to earth ground. Use a multi-meter to check the continuity between the sensor connector

and earth ground to ensure a proper connection.

Gocator 2300 & 2880 Series

Safety and Maintenance • ElectricalSafety • 14

Minimize voltage potential between system ground and sensor ground

Care should be taken to minimize the voltage potential between system ground (ground reference for

I/O signals) and sensor ground. This voltage potential can be determined by measuring the voltage

between Analog_out- and system ground. The maximum permissible voltage potential is 12 V but should

be kept below 10 V to avoid damage to the serial and encoder connections.

See Gocator 2300 &2880 I/O Connector (page 354) for a description of connector pins used with Gocator

2300 series sensors.

Use a suitable power supply

The +24 to +48 VDC power supply used with Gocator sensors should be an isolated supply with inrush

current protection or be able to handle a high capacitive load.

Use care when handling powered devices

Wires connecting to the sensor should not be handled while the sensor is powered. Doing so may cause

electrical shock to the user or damage to the equipment.

Environment and Lighting

Avoid strong ambient light sources

The imager used in this product is highly sensitive to ambient light hence stray light may have adverse

effects on measurement. Do not operate this device near windows or lighting fixtures that could

influence measurement. If the unit must be installed in an environment with high ambient light levels, a

lighting shield or similar device may need to be installed to prevent light from affecting measurement.

Avoid installing sensors in hazardous environments

To ensure reliable operation and to prevent damage to Gocator sensors, avoid installing the sensor in

locations

l

that are humid, dusty, or poorly ventilated;

l

with a high temperature, such as places exposed to direct sunlight;

l

where there are flammable or corrosive gases;

l

where the unit may be directly subjected to harsh vibration or impact;

l

where water, oil, or chemicals may splash onto the unit;

l

where static electricity is easily generated.

Ensure that ambient conditions are within specifications

Gocator sensors are suitable for operation between 0–50° C and 25–85% relative humidity (noncondensing). Measurement error due to temperature is limited to 0.015% of full scale per degree C.

The Master 400/800/1200/2400 is similarly rated for operation between 0–50° C.

The storage temperature is -30–70° C.

The sensor must be heat-sunk through the frame it is mounted to. When a sensor is properly

heat sunk, the difference between ambient temperature and the temperature reported in the

sensor's health channel is less

than 15° C.

Gocator 2300 & 2880 Series

Safety and Maintenance • Environment and Lighting • 15

Gocator sensors are high-accuracy devices, and the temperature of all of its components must

therefore be in equilibrium. When the sensor is powered up, a warm-up time of at least one

hour is required to reach a consistent spread of temperature in the sensor.

Sensor Maintenance

Keep sensor windows clean

Gocator sensors are high-precision optical instruments. To ensure the highest accuracy is achieved in all

measurements, the windows on the front of the sensor should be kept clean and clear of debris.

Use care when cleaning sensor windows

Use dry, clean air to remove dust or other dirt particles. If dirt remains, clean the windows carefully with

a soft, lint-freecloth and non-streaking glass cleaner or isopropyl alcohol. Ensure that no residue is left

on the windows after cleaning.

Turn off lasers when not in use

LMI Technologies uses semiconductor lasers in 3D measurement sensors. To maximize the lifespan of

the sensor, turn off the laser when not in use.

Avoid excessive modifications to files stored on the sensor

Settings for Gocator sensors are stored in flash memory inside the sensor. Flash memory has an

expected lifetime of 100,000 writes. To maximize lifetime, avoid frequent or unnecessary file save

operations.

Gocator 2300 & 2880 Series

Safety and Maintenance • Sensor Maintenance • 16

Getting Started

The following sections provide system and hardware overviews, in addition to installation and setup

procedures.

System Overview

Gocator sensors can be installed and used in a variety of scenarios. Sensors can be connected as

standalone devices, dual-sensor systems, or multi-sensor systems.

Standalone System

Standalone systems are typically used when only a single Gocator sensor is required. The sensor can be

connected to a computer's Ethernet port for setup and can also be connected to devices such as

encoders, photocells, or PLCs.

Dual-Sensor System

In a dual-sensor system, two Gocator sensors work together to perform profiling and output the

combined results. The controlling sensor is referred to as the Main sensor, and the other sensor is

referred to as the Buddy sensor. Gocator's software recognizes three installation orientations: Opposite,

Wide, and Reverse.

Gocator 2300 & 2880 Series

17

A Master 400/800/1200/2400 must be used to connect two sensors in a dual-sensor system. Gocator

Power and Ethernet to Master cordsets are used to connect sensors to the Master.

Multi-Sensor System

Master 400/800/1200/2400 networking hardware can be used to connect two or more sensors into a

multi-sensor system. Gocator Master cordsets are used to connect the sensors to a Master. The Master

provides a single point of connection for power, safety, encoder, and digital inputs. A Master

400/800/1200/2400 can be used to ensure that the scan timing is precisely synchronized across

sensors. Sensors and client computers communicate viaan Ethernet switch (1 Gigabit/s recommended).

Master 400/800/1200/2400 networking hardware does not support digital, serial, or analog output.

Gocator 2300 & 2880 Series

Getting Started • System Overview • 18

Gocator 2300 & 2880 Series

Getting Started • System Overview • 19

Hardware Overview

The following sections describe Gocator and its associated hardware.

Gocator 2300 &2880 Sensor

Gocator 2330

Item Description

Camera Observes laser light reflected from target surfaces.

Laser Emitter Emits structured light for laser profiling.

I/O Connector Accepts input and output signals.

Power / LAN Connector Accepts power and laser safety signals and connects to 1000 Mbit/s Ethernet network.

Power Indicator Illuminates when power is applied (blue).

Range Indicator Illuminates when camera detects laser light and is within the target range (green).

Laser Indicator Illuminates when laser safety input is active (amber).

Serial Number Unique sensor serial number.

Gocator 2300 &2880 Cordsets

Gocator 2300 and 2880 sensors use two types of cordsets.

The Power & Ethernet cordset provides power, laser safety interlock to the sensor. It is also used for

sensor communication via 1000 Mbit/s Ethernet with a standard RJ45 connector. The Master version of

the Power & Ethernet cordset provides direct connection between the sensor and a Master

400/800/1200/2400.

The Gocator I/O cordset provides digital I/O connections, an encoder interface, RS-485 serial connection,

and an analog output.

Gocator 2300 & 2880 Series

Getting Started • Har dware Overview • 20

The maximum cordset length is 60 m. See Gocator 2300 &2880 I/O Connector (page 354) and for pinout

details.

See Parts and Accessories (page 367) for cordset lengths and part numbers. Contact LMI for information

on creating cordsets with customized lengths and connector orientations.

Master 100

The Master 100 is used by the Gocator 2300 series for standalone system setup.

Item Description

Master Ethernet Port Connects to the RJ45 connector labeled Ethernet on the Power/LAN to Master cordset.

Master Power Port Connects to the RJ45 connector labeled Power/Sync on the Power/LAN to Master

cordset. Provides power and laser safety to the Gocator.

Sensor I/O Port Connects to the Gocator I/O cordset.

Master Host Port Connects to the host PC's Ethernet port.

Power Accepts power (+48 V).

Power Switch Toggles sensor power.

Laser Safety Switch Toggles laser safety signal provided to the sensors [O= laser off, I= laser on].

Trigger Signals a digital input trigger to the Gocator.

Encoder Accepts encoder A, B and Z signals.

Digital Output Provides digital output.

Gocator 2300 & 2880 Series

Getting Started • Har dware Overview • 21

See Master 100 (page 359) for pinout details.

Master 400/800

The Master 400 and the Master 800 allow you to connect more than two sensors. The Master 400

accepts four sensors, and the Master 800 accepts eight sensors.

Item Description

Sensor Ports Master connection for Gocator sensors (no specific order required).

Ground Connection Earth ground connection point.

Laser Safety Laser safety connection.

Encoder Accepts encoder signal.

Input Accepts digital input.

See Master 400/800 (page 361) for pinout details.

Master 1200/2400

The Master 1200 and the Master 2400 allow you to connect more than two sensors. The Master 1200

accepts twelve sensors, and the Master 2400 accepts twenty-four sensors.

Gocator 2300 & 2880 Series

Getting Started • Har dware Overview • 22

Item Description

Sensor Ports Master connection for Gocator sensors (no specific order required).

Ground Connection Earth ground connection point.

Laser Safety Laser safety connection.

Encoder Accepts encoder signal.

Input Accepts digital input.

See Master 1200/2400 (page 364) for pinout details.

Calibration Targets

Targets are used for alignment and calibrating encoder systems.

Disks are typically used with systems containing a single sensor and can be ordered from LMI

Technologies. When choosing a disk for your application, select the largest disk that fits entirely within

the required field of view. See Parts and Accessories (page 367) for disk part numbers.

Gocator 2300 & 2880 Series

Getting Started • Har dware Overview • 23

For wide, multi-sensor systems, bars are required to match the length of the system by following the

guidelines illustrated below. (LMI Technologies does not manufacture or sell bars.)

See Aligning Sensors (page 87) for more information on alignment.

Gocator 2300 & 2880 Series

Getting Started • Har dware Overview • 24

Installation

The following sections provide grounding, mounting, and orientation information.

Grounding - Gocator

Gocators should be grounded to the earth/chassis through their housings and through the grounding

shield of the Power I/O cordset. Gocator sensors have been designed to provide adequate grounding

through the use of M5 x 0.8 pitch mounting screws. Always check grounding with a multi-meter to

ensure electrical continuity between the mounting frame and the Gocator's connectors.

The frame or electrical cabinet that the Gocator is mounted to must be connected to earth

ground.

Recommended Grounding Practices - Cordsets

If you need to minimize interference with other equipment, you can ground the Power & Ethernet or the

Power & Ethernet to Master cordset (depending on which cordset you are using) by terminating the

shield of the cordset before the split. The most effective grounding method is to use a 360-degree

clamp.

To terminate the cordset's shield:

1. Expose the cordset's braided shield by cutting

the plastic jacket before the point where the

cordset splits.

Gocator 2300 & 2880 Series

Getting Started • Installation • 25

2. Install a 360-degree ground clamp.

Grounding - Master 400/800/1200/2400

The mounting brackets of all Masters have been designed to provide adequate grounding through the

use of star washers. Always check grounding with a multi-meter by ensuring electrical continuity

between the mounting frame and RJ45 connectors on the front.

The frame or electrical cabinet that the Master is mounted to must be connected to earth

ground.

Mounting

Sensors should be mounted using four or six (depending on the model)M5 x 0.8 pitch screws of suitable

length. The recommended thread engagement into the housing is 8 - 10 mm. Proper care should be

taken in order to ensure that the internal threads are not damaged from cross-threading or improper

insertion of screws.

With the exception of Gocator 2880, sensors should not be installed near objects that might occlude a

camera's view of the laser. (Gocator 2880 is specifically designed to compensate for occlusions.)

Sensors should not be installed near surfaces that might create unanticipated laser reflections.

Gocator 2300 & 2880 Series

Getting Started • Installation • 26

The sensor must be heat sunk through the frame it is mounted to. When a sensor is properly

heat sunk, the difference between ambient temperature and the temperature reported in the

sensor's health channel is less than 15° C.

Gocator sensors are high-accuracy devices. The temperature of all of its components must be

in equilibrium. When the sensor is powered up, a warm-up time of at least one hour is required

to reach a consistent spread of temperature within the sensor.

Orientations

The examples below illustrate the possible mounting orientations for standalone and dual-sensor

systems.

See Dual-Sensor System Layout (page 52) for moreinformation on orientations.

Standalone Orientations

Gocator 2300 & 2880 Series

Single sensor above conveyor

Getting Started • Installation • 27

Single sensor on robot arm

Dual-Sensor System Orientations:

Side-by-side for wide-area measurement (Wide) Main must be on the left side (when

looking into the connector)

of the Buddy (Wide)

Gocator 2300 & 2880 Series

Getting Started • Installation • 28

Above/below for two-sided measurement (Opposite) Main must be on the top

with Buddy on the bottom (Opposite)

Gocator 2300 & 2880 Series

Getting Started • Installation • 29

Network Setup

The following sections provide procedures for client PCand Gocator network setup.

Client Setup

Sensors are shipped with the following default network configuration:

Setting Default

DHCP Disabled

IP Address 192.168.1.10

Subnet Mask 255.255.255.0

Gateway 0.0.0.0

All Gocator sensors are configured to 192.168.1.10 as the default IP address. For a dual-sensor

system, the Main and Buddy sensors must be assigned unique addresses before they can be

used on the same network. Before proceeding, connect the Main and Buddy sensors one at a

time (to avoid an address conflict) and use the steps in Running a Dual-Sensor System on page 33

to assign each sensor a unique address.

To connect to a sensor for the first time:

1. Connect cables and apply power.

Sensor cabling is illustrated in

System Overview on page 17.

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 30

2. Change the client PC's network

settings.

Windows 7

a. Open the Control Panel, select

Network and Sharing

Center, and then click Change

Adapter Settings.

b. Right-click the network

connection you want to

modify, and then click

Properties.

c. On the Networking tab, click

Internet Protocol Version 4

(TCP/IPv4), and then click

Properties.

d. Select the Use the following

IP address option.

e. Enter IP Address "192.168.1.5"

and Subnet Mask

"255.255.255.0", then click OK.

Mac OS X v10.6

a. Open the Network pane in

System Preferences and

select Ethernet.

b. Set Configure to Manually.

c. Enter IP Address "192.168.1.5"

and Subnet Mask

"255.255.255.0", then click

Apply.

See Troubleshooting (page 328) if you experience any problems while attempting to establish a

connection to the sensor.

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 31

Gocator Setup

The Gocator is shipped with a default configuration that will produce laser profiles on most targets.

The following sections walk you through the steps required to set up a standalone sensor system and a

dual-sensor system for operations. After you have completed the setup, you can perform laser profiling

to verify basic sensor operation.

Running a Standalone Sensor System

To configure a standalone sensor system:

1. Power up the sensor.

The power indicator (blue) should turn on immediately.

2. Enter the sensor's IP address (192.168.1.10) in a web

browser.

3. Log in as Administrator with no password.

The interface display language can be changed using the

language option. After selecting the language, the

browser will refresh and the web interface will display in

the selected language.

4. Go to the Manage page.

5. Ensure that Replay mode is off (the slider is set to the

left).

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 32

6. Ensure that the Laser Safety Switch is enabled or the

Laser Safety input is high.

7. Go to the Scan page.

8. Press the Start button or the Snapshot on the Toolbar to

start the sensor.

The Start button is used to run sensors continuously,

whereas the Snapshot button is used to trigger a single

capture.

9. Move a target into the laser plane.

If a target object is within the sensor's measurement

range, the data viewer will display the shape of the target,

and the sensor's range indicator will illuminate.

If you cannot see the laser, or if a profile is not displayed

in the Data Viewer, see Troubleshooting (page 328).

Master 200

Standalone

Master 400/800/1200/2400

10. Press the Stop button.

The laser should turn off.

Running a Dual-Sensor System

All sensors are shipped with a default IP address of 192.168.1.10. Ethernet networks require a unique IP

address for each device, so you must set up a unique address for each sensor.

To configure a dual-sensor system:

1. Turn off the sensors and unplug the Ethernet network

connection of the Main sensor.

All sensors are shipped with a default IP address of

192.168.1.10. Ethernet networks require a unique IP

address for each device. Skip step 1 to 3 if the Buddy

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 33

sensor's IP address is already set up with an unique

address.

2. Power up the Buddy sensor.

The power LED (blue) of the Buddy sensor should turn on

immediately.

3. Enter the sensor's IP address 192.168.1.10 in a web

browser.

This will log into the Buddy sensor.

4. Log in as Administrator with no password.

5. Go to the Manage Page.

6. Modify the IP address to 192.168.1.11 in the Networking

category and click the Save button.

When you click the Save button, you will be prompted to

confirm your selection.

7. Turn off the sensors, re-connect the Main sensor's

Ethernet connection and power-cycle the sensors.

After changing network configuration, the sensors must

be reset or power-cycled before the change will take

effect.

8. Enter the sensor's IP address 192.168.1.10 in a web

browser.

This will log into the Main sensor.

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 34

9. Log in as Administrator with no password.

The interface display language can be changed using the

language option. After selecting the language, the

browser will refresh and the web interface will display in

the selected language.

10. Select the Manage page.

11. Go to Manage page, Sensor System panel, and select the

Visible Sensors panel.

The serial number of the Buddy sensor is listed in the

Available Sensors panel.

12. Select the Buddy sensor and click the Assign button.

The Buddy sensor will be assigned to the Main sensor and

its status will be updated in the System panel.

The firmware on Main and Buddy sensors must be the

same for Buddy assignment to be successful. If the

firmware is different, connect the Main and Buddy sensor

one at a time and follow the steps in Firmware Upgrade on

Gocator 2300 & 2880 Series

Getting Started • Network Setup • 35

page 63 to upgrade the sensors.

13. Ensure that the Laser Safety Switch is enabled or the

Laser Safety input is high.

14. Ensure that Replay mode is off (the slider is set to the

left).

15. Go to the the Scan page.

16. Press the Start or the Snapshot button on the Toolbarto

start the sensors.

The Start button is used to run sensors continuously,

while the Snapshot button is used to trigger a single

profile.

17. Move a target into the laser plane.

If a target object is within the sensor's measurement

range, the data viewer will display the shape of the target,

and the sensor's range indicator will illuminate.

If you cannot see the laser, or if a profile is not displayed

in the Data Viewer, see Troubleshooting (page 328).

Master 400/800/1200/2400

18. Press the Stop button if you used the Start button to start

the sensors.

The laser should turn off.

Next Steps

After you complete the steps in this section, the Gocator measurement system is ready to be configured

for an application using the software interface. The interface is explained in the following sections:

System Management and Maintenance (page 51)

Contains settings for sensor system layout, network, motion and alignment, handling jobs, and sensor

maintenance.

Scan Setup and Alignment (page 65)

Contains settings for scan mode, trigger source, detailed sensor configuration, and performing

alignment.

Measurement (page 111)

Contains built-in measurement tools and their settings.

Gocator 2300 & 2880 Series

Getting Started • Next Steps • 36

Output (page 187)

Contains settings for configuring output protocols used to communicate measurements to external

devices.

Dashboard (page 198)

Provides monitoring of measurement statistics and sensor health.

Toolbar (page 44)

Controls sensor operation, manages jobs, and replays recorded measurement data.

Gocator 2300 & 2880 Series

Getting Started • Next Steps • 37

Theory of Operation

The following sections describe the theory of operation of Gocator sensors.

3D Acquisition

Principle of 3D Acquisition

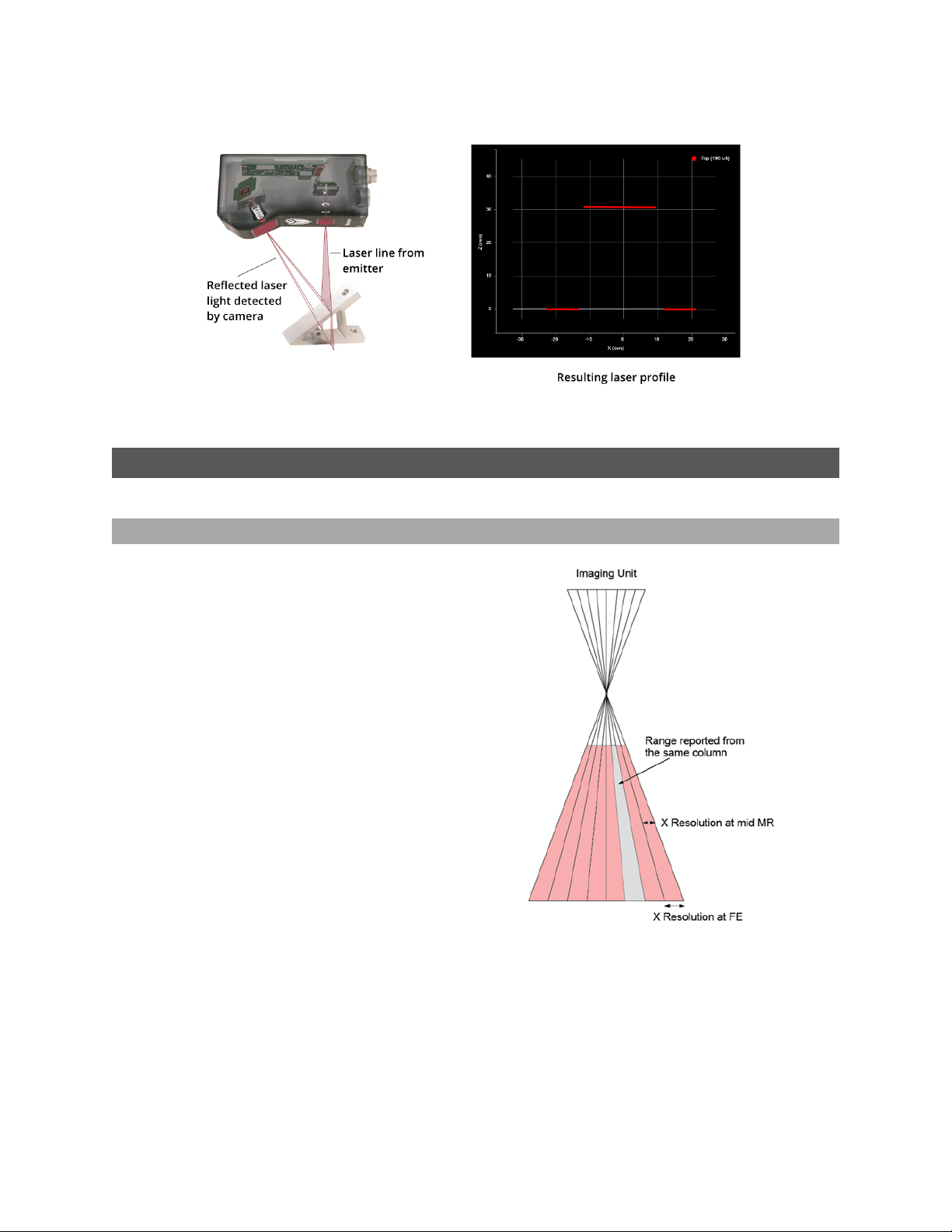

The Gocator 2300 series sensors are line

profiler sensors, meaning that they capture a

single 3D profile for each camera exposure. The

sensor projects a laser line onto the target. The

sensor's camera views the laser from an angle,

and captures the reflection of the light off the

target. Because of this triangulation angle, the

laser line appears in different positions on the

camera depending on the 3D shape of the

target. Gocator sensors are always precalibrated to deliver 3D data in engineering

units throughout the specified measurement

range.

Target objects are typically moved under the sensor on a transportation mechanism, such as a conveyor

belt. The sensor captures a series of 3D slices, building up the full scan of the object. Sensor speed and

required exposure time to measure the target are typically critical factors in applications with line profiler

sensors.

Gocator 2300 & 2880 Series

38

Resolution and Accuracy

Delete this text and replace it with your own content.

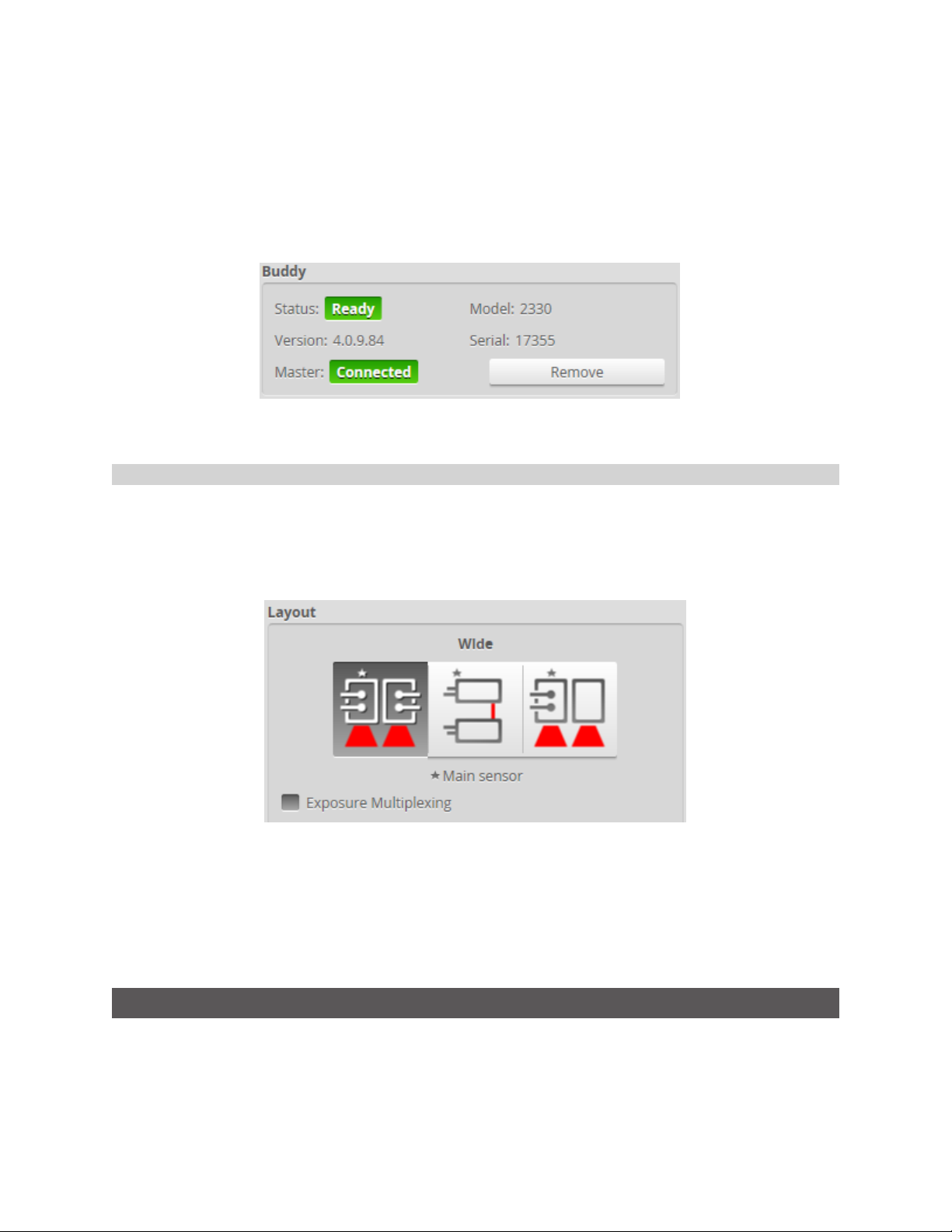

X Resolution

X resolution is the horizontal distance between

each measurement point along the laser line.

This specification is essentially based on the

number of camera columns used to cover the

field of view (FOV) at a particular measurement

range .

Since the FOV is trapezoidal, the distance

between points is closer at the near range than

at the far range. This is reflected in the Gocator

data sheet as the two numbers quoted for X

resolution.

X resolution is important for how accuratel the

width of a target can be measured.

NOTE: When the Gocator runs in Profile mode

and Uniform Spacing is enabled, the 3D data

is resampled to an X interval that is different

from the raw camera resolution.

Gocator 2300 & 2880 Series

Theory of Operation • 3D Acquisition • 39

Z Resolution

Z resolution is the variability of the height

measurement, in each individual 3D point, with

the target at a fixed position. This variability is

caused by camera imager and sensor

electronics.

Like X resolution, the Z resolution is better at

the close range and worse at the far range. This

is reflected in the Gocator data sheet as the two

numbers quoted for Z resolution.

Z Resolution gives an indication of the smallest

detectable height difference.

Z Linearity

Z Linearity is the difference between the actual

distance to the target and the measured

distance to the target, throughout the

measurement range.

Z Linearity is expressed in the Gocator data

sheet as a percentage of the total

measurement range.

Z Linearity gives an indication of the sensor's

ability to measure absolute distance

Gocator 2300 & 2880 Series

Theory of Operation • 3D Acquisition • 40

Profile Output

Gocator measures the height of the object calculated from laser triangulation. The Gocator reports a

series of ranges along the laser line, with each range representing the distance from the sensor's origin

plane. Each range contains a height and a position in the sensor's field of view.

Coordinate Systems

Range data is reported in sensor or system coordinates depending on the alignment state. The

coordinate systems are described below.

Sensor Coordinates

Before alignment, individual sensors use the

coordinate system shown here.

The Z axis represents the sensor's measurement

range (MR), with the values increasing towards the

sensor.

The X axis represents the sensor's field of view

(FOV).

The origin is at the center of the MR and FOV.

In Surfacedata, the Y axis represents the relative

position of the part in the direction of travel.

Y position increases as the object moves forward

(increasing encoder position).

System Coordinates

Alignment is used with a single sensor to

compensate for mounting misalignment and to

set a zero reference, such as a conveyor belt

surface. Alignment is also used to set a

common coordinate system for dual-sensor

systems. In both cases, alignment determines

the adjustments to X, Z, and tilt (rotation in the

X–Z plane) needed to align the data from each

sensor. The adjustments resulting from

alignment are called transformations. See

Alignment (page 85) for more information on

alignment.

System coordinates are aligned so that the

system X axis is parallel to the alignment target

surface. The system Z origin is set to the base of

the alignment target object. The tilt angle is

positive when rotating from the X to the Z axis.

Similar to the sensor coordinates, Y positions

increase when the encoder increases.

Gocator 2300 & 2880 Series

Theory of Operation • Profile Output • 41

For Wide and Opposite layouts, profiles and

measurements from the Main and Buddy

sensors are expressed in a unified coordinate

system. Isolated layouts express results using a

separate coordinate system for each sensor.

Resampled and Uniform Spacing Profile Format

Profile data produced in Profile mode is available in two formats: with and without uniform spacing.

Uniform spacing is enabled in the Scan Mode panel, on the Scan page.

With uniform spacing enabled, the ranges that make up a profile are resampled so that the spacing is

uniform along the laser line (X axis). The resampling divides the X axis into fixed size "bins." Profile points

that fall into the same bin are combined into a single range value (Z). The size of the spacing interval can

be set under the Spacing tab in the Sensor panel on Scan page.

As a result, in the Ethernet data channel, only the range values (Z) are reported and the X positions can

be reconstructed through the array index at the receiving end (the client).

Resampling to uniform spacing reduces the complexity for downstream algorithms to process the profile

data from the Gocator, but places a higher processing load on the sensor's CPU.

In contrast, the profile format without uniform spacing set requires no processing on the sensor. Ranges

arereported in (X, Z) coordinate pairs. This frees up processing resources in the Gocator, but usually

requires more complicated processing on the client side.

All built-in measurement tools in the Gocator operate on profiles with uniform spacing in both Profile

and Surface mode.

Gocator 2300 & 2880 Series

Theory of Operation • Profile Output • 42

Gocator Web Interface

The following sections describe the Gocator web interface.

User Interface Overview

Gocator sensors are configured by connecting to a Main sensor with a web browser. The Gocator web

interface is illustrated below.

Element Description

1 Manage page Contains settings for sensor system layout, network, motion and alignment,

handling jobs, and sensor maintenance. See System Management and

Maintenance (page 51).

2 Scan page Contains settings for scan mode, trigger source, detailed sensor configuration,

and performing alignment. See Scan Setup and Alignment (page 65).

3 Measure page

Gocator 2300 & 2880 Series

Contains built-in measurement tools and their settings. See Measurement

(page 111).

43

Element Description

4 Output page Contains settings for configuring output protocols used to communicate

measurements to external devices. See Output (page 187).

5 Dashboard page

Provides monitoring of measurement statistics and sensor health. See

Dashboard (page 198).

6 CPULoad and Speed

7 Help Provides links to the user manual and SDK.

8 Toolbar Controls sensor operation, manages jobs, and replays recorded measurement

9 Configuration area Provides controls to configure scan and measurement tool settings.

10 Data viewer

11 Log

Provides important sensor performance metrics. See Metrics Area (page 50).

data. See Toolbar (below).

Displays sensor data, tool setup controls, and measurements. See Data Viewer

on page 99 for its use when the Scan page is active and on page 112 for its use

when the Measure page is active.

Displays messages from the sensor (errors, warnings, and other information).

See Log (page 49).

Common Elements

Toolbar

The toolbar is used for performing common operations. This section explains how to use the toolbar to

manage jobs and to operate the sensor.

Element Description

1 Job controls For saving and loading different jobs.

2 Recorded data controls For downloading, uploading, and exporting recorded data.

3 Sensor operation / replay control Use the sensor operation controls to start sensors, enable

recording, and control recorded data.

4 Replay switch Toggles the sensor data source between live and replay.

Saving and Loading Settings

When you change sensor settings using the Gocator web interface, some changes are saved

automatically, whileother changes are temporary until you save them manually. The following table lists

the types of information that can be saved in a sensor.

Setting Type Behavior

Network Address

Gocator 2300 & 2880 Series

Network address changes are saved when you click the Save button in Networking on

Gocator Web Inter face • User Interface Overview • 44

Setting Type Behavior

the Manage page. The sensor must be reset before changes take effect.

Job Most of the settings that can be changed in the Gocator's web interface, such as the ones

in the Manage, Measure, and Output pages, are temporary until saved in a job file.

Each sensor can have multiple job files. If there is a job file that is designated as the

default, it will be loaded automatically when the sensor is reset.

Alignment

Alignment can either be fixed or dynamic, as controlled by the Alignment Reference

setting in Motion and Alignment in the Manage page.

Alignment is saved automatically at the end of the alignment procedure when

Alignment Reference is set to Fixed. When Alignment Reference is set to

Dynamic, however, you must manually save the job to save alignment.

The job drop-down list shows the list of jobs stored in the sensor. The job that is currently active is listed

at the top. The job name will be marked with "[unsaved]" to indicate any unsaved changes.

To save a job:

1. Select a job in the job drop-down list.

l

If you are creating a new job, choose [New] in the job drop-down list and enter a name for the job.

l

If you are saving changes to an existing job, choose the job in the job drop-down list.

2. Press the Enter key or click the Save button .

The job will be saved to sensor storage using the name you provided. Saving a job automatically sets it

as the default, that is, the job loaded when then sensor is restarted.

To activate an existing job:

1. Select an existing file name in the job drop-down list.

The job will be activated from sensor storage. If there are any unsaved changes to the current job, you

will be asked whether you want to discard those changes.

Detailed management of jobs is handled in the Jobs panel in the Manage page. See Jobs (page 58) for

more information.

Managing Multiple Settings

A Gocator can store several hundred jobs. Being ableto switch between different jobs is useful when a

Gocator is used with different constraints during separate production runs (for example, width decision

constraints might be loose during one production run and tight during another depending on the

desired grade of the part).

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 45

Switching active jobs can be done manually through the web interface as described under To activate an

existing job in Saving and Loading Settings on page 44. Switching active jobs can also be done

programmatically using the supported industrial protocols (Modbus, EtherNet/IP, and ASCII), the

Gocator’s native Ethernet protocol, and through the SDK.

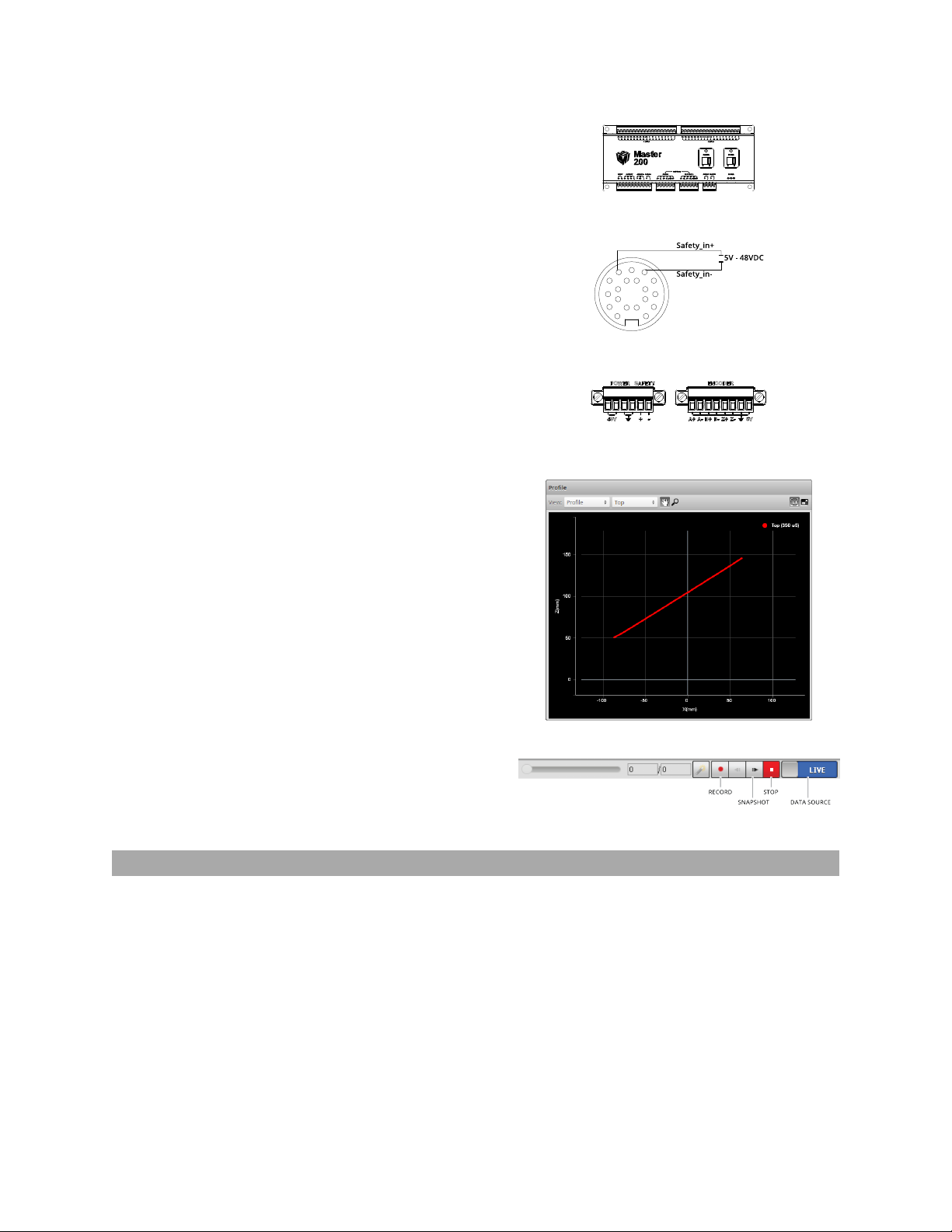

Recording, Playback, and Measurement Simulation

Gocator sensors can record and replay data, and can also simulate measurement tools on recorded data.

This feature is most often used for troubleshooting and fine-tuning measurements, but can also be

helpful during setup.

Recording and playback are controlled by using the toolbar controls.

Recording and playback controls when replay is off

To record live data:

1. Toggle Replay mode off by setting the slider to the left in the Toolbar.

2. Press the Record button to enable recording.

When replay is off and recording is enabled, the sensor will store the most recent data as it runs.

Remember to disable recording if you no longer wish to record live data (press the Record button again

to disable recording).

3. Press the Snapshot button or Start button.

The Snapshot records a single frame. The Start button will run the sensor continuously and all frames

will be recorded, up to available memory. When the memory limit is reached, the oldest data will be

discarded.

Newly recorded data is appended to existing replay data unless the sensor job has been

modified.

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 46

Recording and playback controls when replay is on

To replay recorded data:

1. Toggle Replay mode on by setting the slider to the right in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Use the Replay slider or the Step Forward, Step Back, or Play buttons to review data.

The Step Forward and Step Back buttons move and the current replay location backward and forward

by a single frame, respectively.

The Play button advances the replay location continuously, animating the playback.

The Stop button (replaces the Play button while playing) can be used to pause the replay at a particular

location.

The Replay slider (or Replay Position box) can be used to go to a specific replay frame.

To simulate measurements on recorded data:

1. Toggle Replay mode on by setting the slider to the right in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Go to the Measure page.

Modify settings for existing measurements, add new measurement tools, or delete measurement tools

as desired.

3. Use the Replay Slider, Step Forward, Step Back, or Play button to simulate measurements.

Step or play through recorded data to execute the measurement tools on the recording.

Individual measurement values can be viewed directly in the data viewer. Statistics on the

measurements that have been simulated can be viewed in the Dashboard page; see Dashboard (page

198).

To clear recorded data:

1. Stop the sensor if it is running by clicking on the Stop button.

2. Click on the Clear Replay Data button .

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 47

Downloading, Exporting, and Uploading Recorded Data

Recorded data can be downloaded or exported to the client computer or uploaded to the Gocator.

Export is often used for processing the recorded data using third-party tools. Recorded data can also be

downloaded in a binary format, which is used to back up the data for reviewing in the future.

Recorded data is not saved or loaded when you save or activate jobs in the toolbar.

To download recorded data:

1. Toggle Replay mode on by setting the slider to the right in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Click the Download button .

To upload recorded data:

1. Toggle Replay mode on by setting the slider to the left in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Click the Upload button .

3. Select the directory and the file name to upload from the client computer and click on OK.

Recorded data can be exported using the CSVformat. If Acquire Intensity has been enabled in the

Scan Mode panel on the Scan page, intensity data will be included in the exported CSVfile.

To export recorded data to CSV:

1. Toggle Replay mode on by setting the slider to the right in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Click the Export button and select Export Range Data as CSV.

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 48

In Profile mode, all data in the record buffer is exported. In Surface mode, only data at the current

replay location is exported.

Use the playback control buttons to move to a different replay location; see To replay recorded data in

Recording, Playback, and Measurement Simulation on page 46 for more information on playback.

3. Optionally, convert exported data to another format using the CSV Converter Tool on page 326.

Recorded intensity data can be exported to a bitmap (.BMP format). Acquire Intensity must be

checked in the Scan Mode panel while data was being recorded in order to export intensity data.

To export recorded intensity data to BMP:

1. Toggle Replay mode on by setting the slider to the right in the Toolbar.

The slider's background will turn blue and a Replay Mode Enabled message will be displayed.

2. Click the Export button and select Intensity data as BMP.

Only the intensity data in the current replay location is exported.

Use the playback control buttons to move to a different replay location; see To replay recorded data in

Recording, Playback, and Measurement Simulation on page 46 for more information on playback.

Log

The log, located at the bottom of the web interface, is a centralized location for all messages that the

Gocator displays, including warnings and errors.

To use the log:

1. Click on the Log open button at the bottom of the web interface.

2. Click on the appropriate tab for the information you need.

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 49

Metrics Area

The Metrics area displays two important sensor performance metrics: CPU load and speed (current

frame rate).

The CPU bar in the Metrics panel (at the top of the interface) displays how much of the CPU is being

utilized. A warning symbol ( ) will appear next to the CPUbar if the sensor drops profiles because the

CPU is over-loaded.

CPUat 100%

CPUwarning message

The Speed bar displays the frame rate of the sensor. A warning symbol ( ) will appear next to it if

triggers (external input or encoder) are dropped because the external rate exceeds the maximum frame

rate.

In both cases, a warning message will be temporarily displayed in the lower right corner of the web

interface. Click on the warning symbol ( ) to redisplay the warning message.

Open the log for details on the warning. See Log (previous page) for more information.

Data Viewer

The data viewer is displayed in both the Scan and the Measure pages, but displays different

information depending on which page is active.

When the Scan page is active, the data viewer displays sensor data and can be used to adjust regions of

interest. Depending on the selected operation mode (page 66), the data viewer can display video images,

3Dprofiles, or 3D surfaces. For details, see Data Viewer (page 99).

When the Measure page is active, the data viewer displays sensor data onto which representations of

measurement tools and their measurements are superimposed. For details, see Data Viewer (page 112).

Because Gocator 2880 has two cameras, two profiles are displayed in the Gocator web

interface.

Gocator 2300 & 2880 Series

Gocator Web Inter face • User Interface Overview • 50

System Management and Maintenance

The following sections describe how to set up the sensor connections and networking, how to calibrate

encoders and choose alignment reference, and how to perform maintenance tasks.

Manage Page Overview

Gocator's system and maintenance tasks are performed on the Manage page.

Element Description

1 Sensor System

2 Networking

3 Motion and Alignment

4 Jobs

5 Security

6 Maintenance

Gocator 2300 & 2880 Series

Contains settings for configuring sensor system and layout, and boot-up. See

Sensor System (next page).

Contains settings for configuring the network. See Networking (page 55).

Contains settings to configure the encoder. See Motion and Alignment (page

56).

Lets you manage jobs stored on the sensor. See Jobs (page 58).

Lets you change passwords. See Security (page 60).

Lets you upgrade firmware, create/restore backups, and reset sensors. See

Maintenance (page 61).

Gocator Web Inter face • System Management and Maintenance • 51

Sensor System

The following sections describe the Sensor System category on the Manage page. This category lets

you choose the layout standalone or dual-sensor systems, and provides other system settings.

Dual-sensor layouts are only displayed when a Buddy sensor has been assigned.

Sensor Autostart

With the Autostart setting enabled, laser ranging profiling and measurement functions will begin

automatically when the sensor is powered on. Autostart must be enabled if the sensor will be used

without being connected to a computer.

To enable/disable Autostart:

1. Go to the Manage page and click on the Sensor System category.

2. Check/uncheck the Autostart option in the Main section.

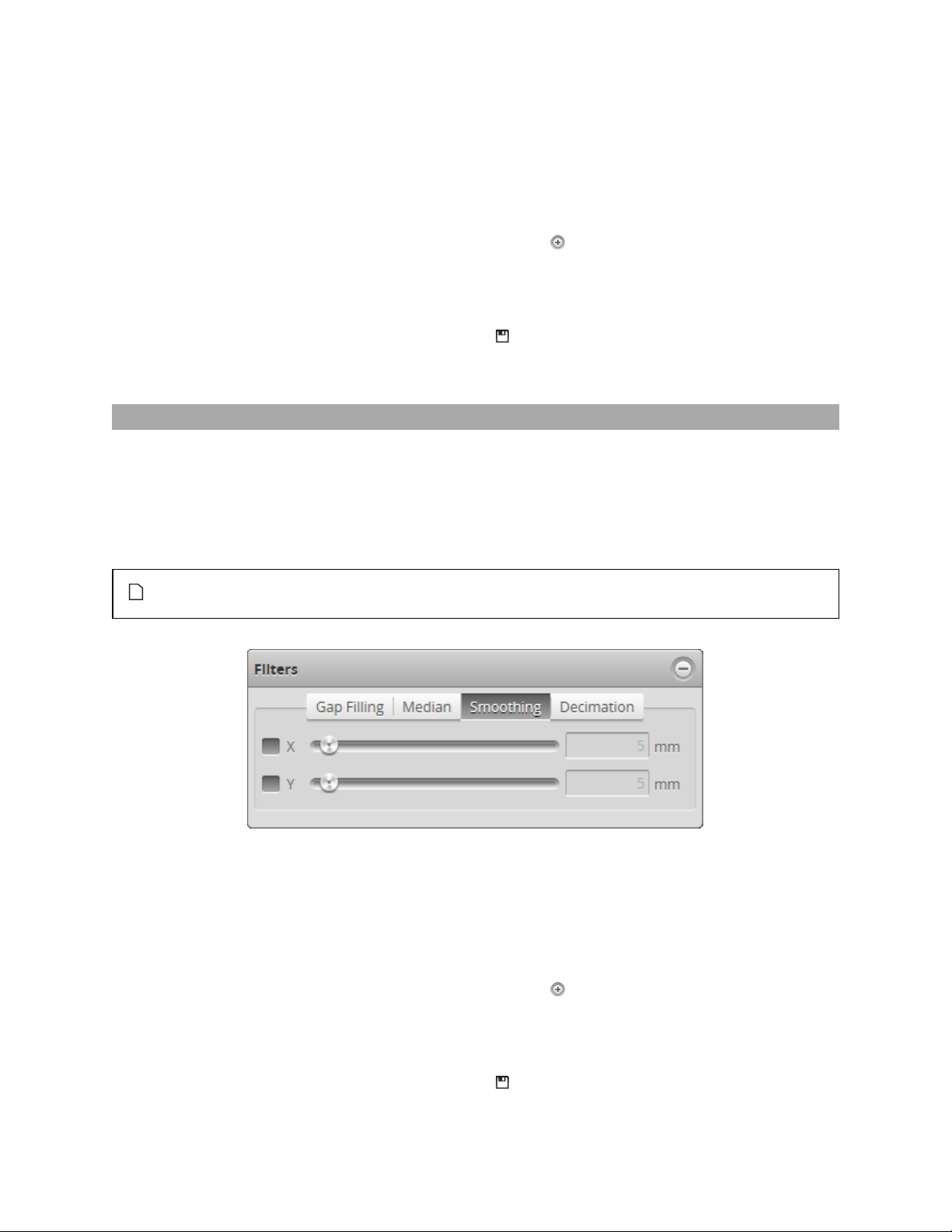

Dual-Sensor System Layout

Mounting orientations must be specified for a dual-sensor system. This information allows the

alignment procedure to determine the correct system-wide coordinates for laser profiling and

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 52

measurements. See Coordinate Systems (page 41) for more information on sensor and system

coordinates.

Supported Layouts

Orientation Example

Standalone

The sensor operates as an isolated device.

Wide

Sensors are mounted in Left (Main) and Right

(Buddy) positions for a larger combined field

of view. Sensors may be angled to avoid

occlusions.

Reverse

Sensors are mounted in a left-right layout as

with the Wide layout, but the Buddy sensor

is mounted such that it is rotated 180

degrees around the Z axis to prevent

occlusion along the Y axis.

Opposite

Sensors are mounted in Top (Main) and

Bottom (Buddy) positions for a larger

combined measurement range and the

ability to perform Top/Bottom differential

measurements.

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 53

To specify the layout:

1. Go to the Manage page and click on the Sensor System category.

2. Select an assigned Buddy sensor in the Visible Sensors list.

See Buddy Assignment (below) for information on assigning a Buddy Sensor.

3. Select a layout by clicking on one of the Layout buttons.

See the table above for information on layouts.

Buddy Assignment

In a dual-sensor system, the Main sensor assumes control of the Buddy sensor after the Buddy sensor is

assigned to the Main sensor. Configuration for both sensors can be performed through the Main

sensor's interface.

Main and Buddy sensors must be assigned unique IP addresses before they can be used on the

same network. Before proceeding, connect the Main and Buddy sensors one at a time (to avoid

an address conflict) and use the steps outline in Running a Dual-Sensor System (page 30) to

assign each sensor a unique address.

When a sensor is acting as a Buddy, it is not discoverable and its web interface is not

accessible.

To assign a Buddy sensor:

1. Go to the Manage page and click on the Sensor System category.

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 54

2. Select a sensor in the Visible Sensors list.

3. Click the Assign button.

A sensor can only be assigned as a Buddy if its firmware and model number match the firmware and

model number of the Main sensor. The Assign button will be greyed out if a sensor cannot be assigned

as a Buddy.

The Buddy sensor will be assigned to the Main sensor and its status will be updated in the System panel.

To remove a Buddy, click on the Remove button.

Exposure Multiplexing

If the Main and Buddy sensors are mounted such that the camera from one sensor can detect the laser

from the other sensor, the Exposure Multiplexing option can be used to eliminate laser interference.

This setting creates a time offset for laser exposures and ensures that interfering lasers are not strobed

at the same time. Using the Exposure Multiplexing option may reduce the maximum frame rate.

To enable/disable exposure multiplexing:

1. Go to the Manage page and click on the Sensor System category.

2. In the Layout section, check/uncheck the Exposure Multiplexing option.

This option is only displayed if a buddy is assigned.

Networking

The Networking category on the Manage page provides network settings. Settings must be configured

to match the network to which the Gocator sensors are connected.

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 55

To configure the network settings:

1. Go to the Manage page.

2. In the Networking category, specify the Type, IP, Subnet Mask, and Gateway settings.

The Gocator sensor can be configured to use DHCP or assigned a static IP address.

3. Click on the Save button.

You will be prompted to confirm your selection.

Motion and Alignment

The Motion and Alignment category on the Manage page lets you configure alignment reference,

encoder resolution, and travel speed.

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 56

Alignment Reference

The Alignment Reference setting can have one of two values: Fixed or Dynamic.

Setting Description

Fixed A single global alignment is used for all jobs. This is typically used when the sensor

mounting is constant over time and between scans, for example, when the sensor is

mounted in a permanent position over a conveyor belt.

Dynamic A separate alignment is used for each job. This is typically used when the sensor’s

position relative to the object scanned is always changing, for example, when the

sensor is mounted on a robot arm moving to different scanning locations.

To configure alignment reference:

1. Go to the Manage page and click on the Motion and Alignment category.

2. In the Alignment section, choose Fixed or Dynamic in the Alignment Reference drop-down.

Encoder Resolution

You can manually enter the encoder resolution in the Resolution setting , or it can be automatically set

by performing an alignment with Type set to Moving. Establishing the correct encoder resolution is

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 57

required for correct scaling of the scan of the target object in the direction of travel.

Encoder resolution is expressed in millimeters per tick.

To configure encoder resolution:

1. Go to the Manage page and click on the Motion and Alignment category.

2. In the Encoder section, enter a value in the Resolution field.

Encoder Value and Frequency

The encoder value and frequency are used to confirm the encoder is correctly wired to the Gocator and

to manually calibrate encoder resolution (that is, by moving the conveyor system a known distance and

making a note of the encoder value at the start and end of movement).

Travel Speed

The Travel Speed setting is used to correctly scale scans in the direction of travel in systems that lack an

encoder but have a conveyor system that is controlled to move at constant speed. Establishing the

correct travel speed is required for correct scaling of the scan in the direction of travel.

Travel speed is expressed in millimeters per second.

To manually configure travel speed:

1. Go to the Manage page and click on the Motion and Alignment category.

2. In the Speed section, enter a value in the Travel Speed field.

Travel speed can also be set automatically by performing an alignment with Type set to Moving (see

page87).

Jobs

The Jobs category on the Manage page lets you manage the jobs stored on the sensor.

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 58

Element Description

Namefield Used to provide a job name when saving files.

Jobs list Displays the jobs that are currently saved in the sensor's flash storage.

Save button Saves current settings to the job using the name in the

Load button Loads the job that is selected in the file list. Reloading the current job discards any unsaved

changes.

Delete button Deletes the job that is selected in the jobs list.

Set as Default

button

Download...

button

Upload... button Uploads a job from the client computer.

Sets the selected job as the default to be loaded at boot time. When the default job is selected, this

button is used to clear the default.

Downloads the selected jobs to the client computer.

Job Name

field.

Jobs can be loaded and set as default independently. For example, Job1 could be loaded, while Job2 is

set as the default. Default jobs load automatically when a sensor is power cycled or reset.

Unsaved jobs are indicated by "[unsaved]".

Gocator 2300 & 2880 Series

Gocator Web Inter face • System Management and Maintenance • 59

To download, load, or delete a job, or to set one as a default or clear a default:

1. Go to the Manage page and click on the Jobs category.

2. Select a job in the Jobs list.

3. Click on the appropriate button for the operation.

To save a job:

1. Go to the Manage page and click on the Jobs category.

2. Provide a name in the Job Name field.

To save an existing job under a different name, click on it in the Jobs list and then modify it in the Job

Name field.

3. Click on the Save button or press Enter.

Saving a job automatically sets it as the default, that is, the job loaded when then sensor is restarted.

Security

Gocator sensors can be secured with passwords to prevent unauthorized access. Each sensor has two

accounts: Administrator and Technician.

Gocator Account Types

Gocator 2300 & 2880 Series