LMI Liquitron DC4500 Series Instruction Manual

InstructionInstruction

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

Instruction

InstructionInstruction

Liquitron™ DC4500 Series

ManualManual

Manual

ManualManual

For file reference, please record the following data:

Model No:

Serial No:

Installation Date:

Installation Location:

When ordering replacement parts for your LMI Controller or accessory, please include

the complete Model Number and Serial Number of your unit.

Replaces same of Rev. C 7/97

1780.D 7/00

Contents

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

1.0 Introduction ........................................................................................................................... 4

2.0 Installation .............................................................................................................................. 6

2.1 Mounting the Controller Enclosure ........................................................................ 6

2.2 Enclosure Mounting Dimensions ........................................................................... 7

2.3 Electrical Wiring Information ................................................................................... 8

2.4 Terminal Strip Layout .............................................................................................. 9

3.0 Operating the Controller ...................................................................................................... 13

3.1 Menu Overview ..................................................................................................... 14

3.2 Conductivity .......................................................................................................... 15

3.3 Set Point ................................................................................................................ 16

3.4 ∆ Differential .......................................................................................................... 17

3.5 Low Alarm ............................................................................................................. 18

3.6 High Alarm ............................................................................................................ 19

3.7 Feed ...................................................................................................................... 20

3.8 Clock ..................................................................................................................... 21

3.9 View Biocide.......................................................................................................... 22

3.10 Add Biocide .......................................................................................................... 23

3.11 Biocide Lockout .................................................................................................... 24

3.12 Biocide Prebleed .................................................................................................. 25

3.13 Manual Outputs .................................................................................................... 26

3.14 Advanced Setup ................................................................................................... 27

3.15 Temperature ......................................................................................................... 28

3.16 H

O Meter ............................................................................................................. 29

2

4.0 Start-Up .............................................................................................................................. 30

4.1 Cooling Tower Installation .................................................................................... 30

4.2 Cooling Tower Start-Up ........................................................................................ 31

4.3 Bleed Sampling Option ........................................................................................ 34

5.0 Calibration ............................................................................................................................ 35

6.0 Maintenance ........................................................................................................................ 36

7.0 Troubleshooting................................................................................................................... 37

8.0 Factory Settings ................................................................................................................... 38

9.0 Product Specifications ......................................................................................................... 39

10.0 Product Exploded View .......................................................................................................40

11.0 Product Parts List ................................................................................................................ 41

3

1.0 Introduction

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

The DC4500 is a microprocessor-based conductivity controller. It is designed for use in a variety of water

treatment applications requiring precise control of totally dissolved solids and chemical feed. Among its many

uses, the DC4500 will control conductivity and chemical feed in cooling towers and closed loop systems.

LMI’s DC4500 Series of conductivity controllers allows the greatest programming flexibility for cooling tower

system applications. This is accomplished through the use of an extensive options menu that is easy to use.

BLEED or BLOWDOWN of system water by valve control can be based on several setpoint options:

• Conductivity setpoint

• Hysteresis delay (lower than setpoint) to avoid valve operation chattering

• Rising or Falling conductivity trip points

FEED of chemical (inhibitor) can be based on four (4) different methods and the pump control can be either

On/Off or externally-triggered Variable Speed.

• FEED at the same time system BLEEDS (lockout timer limits maximum FEED time)

• FEED time calculated as a percentage of total BLEED time

• FEED based on a timed cycle (pump is on for a percentage of this timed cycle)

• FEED based on flow meter input

DUAL BIOCIDE chemical addition may be accomplished by the use of two (2) individually programmable

relays or optocoupler outputs. These outputs provide control of two individual chemical addition pumps based

on the following options:

• On/Off or externally-triggered Variable Speed pump control or BOTH for two pump/TIMER operation

• 28-DAY programmable timer (1, 2, 3, or 4 week selectable cycle)

ALARM indicators and relay outputs are energized based on the following conditions:

• HIGH conductivity set point is reached

• LOW conductivity se tpoint is reached

• NO FLOW condition exists (flow switch must be installed)

The display is a 16-character backlit LCD (liquid crystal display) which is visible in all light conditions.

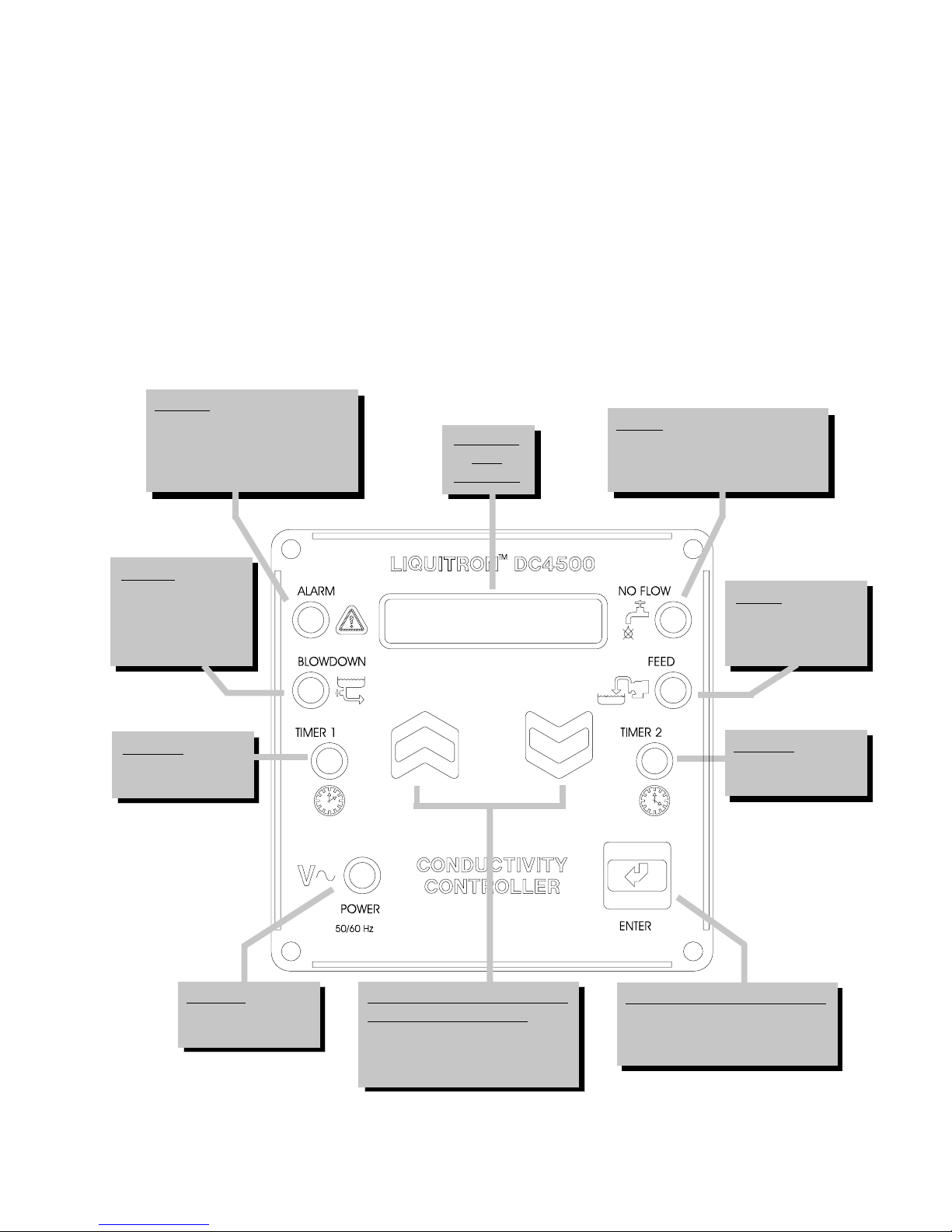

A three-key position membrane is used to enter data and settings (see Figure 1).

The conductivity range is 0 - 20,000 µSiemens. The units can be either µSiemens or PPM/TDS (total disolved

solids).

4

All setpoints and parameter settings are retained permanently in a special nonvolatile computer chip memory,

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

preventing their loss due to a power outage. This nonvolatile memory chip allows the unit to be programmed

before installation. No battery powered backup is required.

Built in test circuits are provided to test each individual relay output wiring and to allow for quick field

service isolation of faulty probe, circuit cards, pumps, or solenoids for ease of troubleshooting.

A display for temperature is also provided. The range is 32° F to 158° F [0° C to 68° C]. The display can be

either fahrenheit or centigrade. This reading also provides the basis for temperature compensation which is

performed in all modes.

ALARMALARM

ALARM indicator lights when

ALARMALARM

a warning condition occurs:

* high alarm set point

* low alarm set point

* loss of flow

BACKLITBACKLIT

BACKLIT

BACKLITBACKLIT

LCDLCD

LCD

LCDLCD

DISPLAYDISPLAY

DISPLAY

DISPLAYDISPLAY

FLOWFLOW

FLOW indicator lights when

FLOWFLOW

there is a loss of system flow.

Operates only if flow switch is

installed

BLEEDBLEED

BLEED indicator

BLEEDBLEED

lights when the

BLEED OFF or

BLOWNDOWN

output is energized

TIMER 1TIMER 1

TIMER 1 indicator

TIMER 1TIMER 1

lights when timer 1

output is energized

POWERPOWER

POWER indicator

POWERPOWER

lights when power

is supplied to unit

PUSH BUTTON UP ANDPUSH BUTTON UP AND

PUSH BUTTON UP AND

PUSH BUTTON UP ANDPUSH BUTTON UP AND

DOWN ARROW KEYSDOWN ARROW KEYS

DOWN ARROW KEYS allow

DOWN ARROW KEYSDOWN ARROW KEYS

scrolling through menu and

selection or changing of set

point values

FEEDFEED

FEED indicator

FEEDFEED

lights when feed

(inhibitor) output is

energized

TIMER 2TIMER 2

TIMER 2 indicator

TIMER 2TIMER 2

lights when timer 2

output is energized

PUSH BUTTON ENTER KEYPUSH BUTTON ENTER KEY

PUSH BUTTON ENTER KEY

PUSH BUTTON ENTER KEYPUSH BUTTON ENTER KEY

provides for menu selection

and/or acceptance of selected

values

Figure 1Figure 1

Figure 1

Figure 1Figure 1

5

An analog data (or control) output is provided. This is a non-isolated 4 - 20 mA signal. The conductivity

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

reading that corresponds to minimum and maximum analog signals is fully adjustable. This signal can be used

to power chart recorders or other pumps and devices.

The controller operates in two (2) distinct modes, ‘SYSTEM RUN’ and ‘SYSTEM START-UP’ or 'PROGRAMMING MODE'. The unit will be in the ‘SYSTEM RUN’ mode when it is first turned on. The various

program screen menus are used to calibrate the unit, set the control and alarm points, set the inhibitor feed

operating parameters, program the biocide [two (2) chemical addition] pumps, and manually test the relays

and wiring connections.

In the ‘SYSTEM RUN’ mode the DC4500 monitors the conductivity and activates the appropriate control or

alarm relay as necessary based on the set points entered in the ‘SYSTEM START-UP’ mode.

The DC4500 is packaged in a NEMA 12X, flame-retardant, molded TPE enclosure. When ordered, 115 VAC

units come fully wired to include input power cord and relay output pigtails to allow for simple installation.

The unit can be hardwired through conduit to the lower junction box portion of the enclosure when required.

Hard wiring makes the unit suitable for NEMA 4X applications.

2.0 Installation

2.1 Mounting the Controller Enclosure

The DC4500 conductivity controller is supplied with integral wall-mounting flanges. It should be mounted

with the display at eye level on a vibration free surface. All accessible mounting holes should be utilized. The

maximum allowable temperature is 122° F [50° C]. This should be considered if installation is in a hightemperature location. Once the DC4500 is wall mounted, the metering pumps may be located at any distance

from the controller. The conductivity probe should be placed as close to the controller as possible, to a

maximum distance of 300 ft [91 m]. Under 25 ft [7.6 m] is recommended. Over 25 ft [7.6 m], the cable may

need to be isolated or shielded from background electrical noise.

6

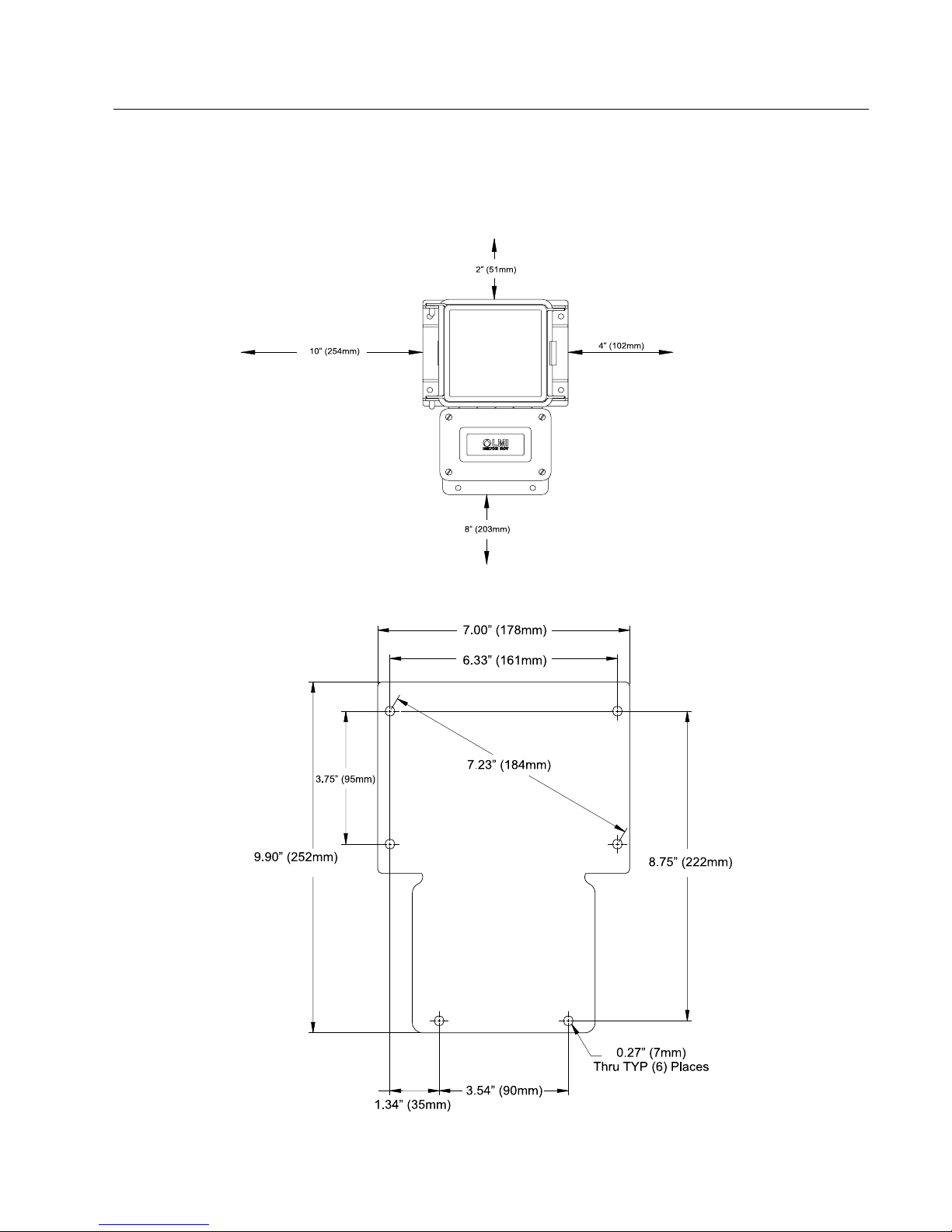

2.2 Enclosure Mounting Dimensions

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

When using the prewired unit, the enclosure is configured as NEMA 12X. If the unit is connected through

watertight conduit, the enclosure is configured as NEMA 4X.

The following clearances should be observed for proper mounting (see Figures 2 and 3).

Figure 2Figure 2

Figure 2

Figure 2Figure 2

Figure 3Figure 3

Figure 3

Figure 3Figure 3

7

2.3 Electrical Wiring Information

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

To reduce the risk of electrical shock, the controller must be plugged into a grounded outlet with ratings

conforming to the specifications on the data nameplate. It must be connected to a viable ground circuit. DO

NOT USE ADAPTERS (see Figure 4)! All wiring must conform to required electrical codes.

Figure 4Figure 4

Figure 4

Figure 4Figure 4

The DC4500 conductivity controller is available in either 115 or 230 VAC 50/60 Hz. The 115 VAC version

is supplied with one (1) 6-foot grounded AC power cord and four (4) 12-inch output pigtails for plug-in connection of controlled devices.

A four-pin connector is provided for the conductivity probe and temperature compensation probe.

The DC4500 controller is provided with a voltage selector switch to allow the unit to be used with a 115 VAC

or 230 VAC power source. To change the voltage selection, disconnect the unit from the power source and

remove the front keypad panel. The selector switch is located on the circuit board attached to the back panel.

When switching voltages ensure that power cord and pigtails are appropriately changed.

8

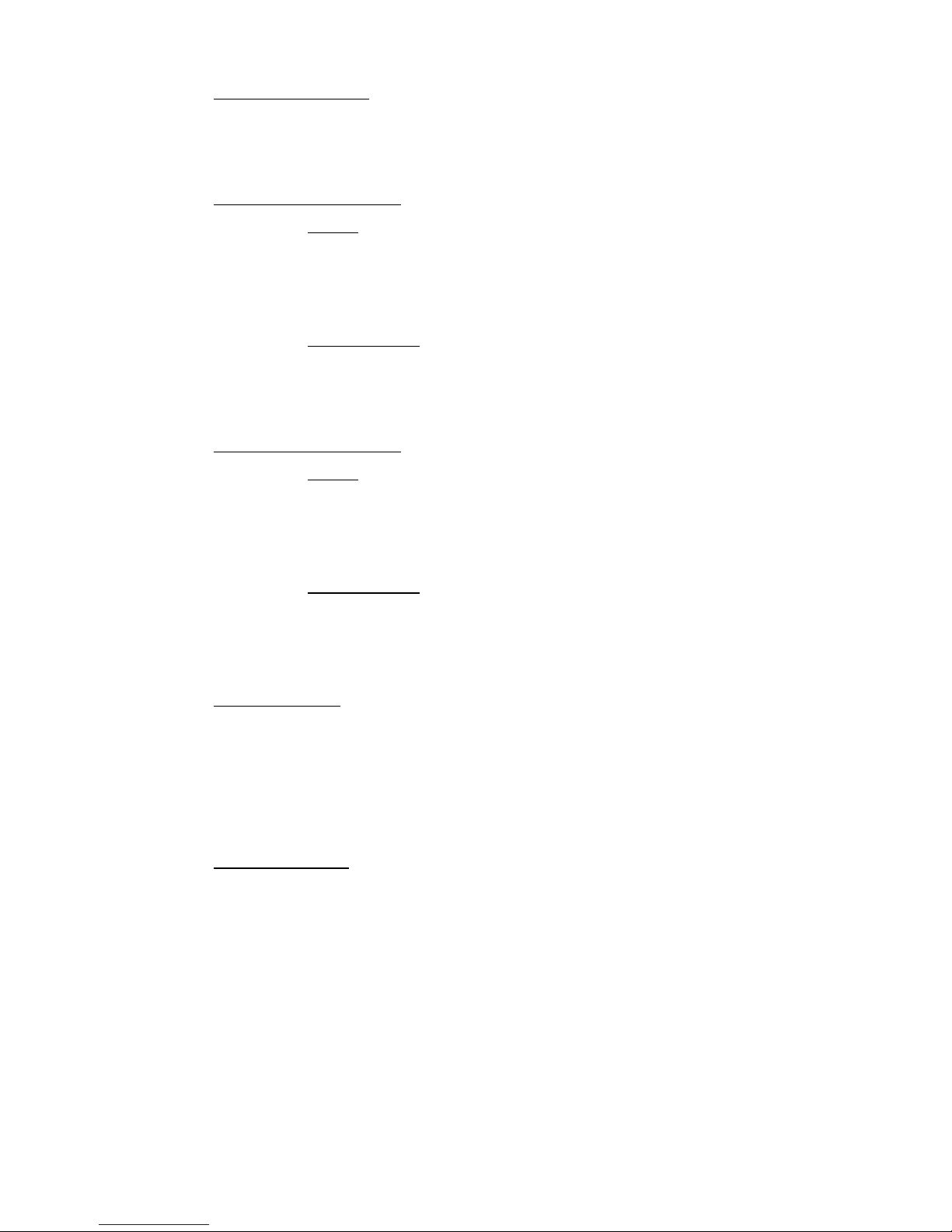

2.4 Terminal Strip Layout

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

To access the wiring connections inside of the conductivity controller:

1. Disconnect the unit from electrical power.

2. Remove the four (4) screws and the junction box cover on the lower half of the unit.

3. Consult the specific instructions below for the connections required.

AC Power InputAC Power Input

AC Power Input

AC Power InputAC Power Input

Hot: TB2-1

Neutral: TB1-4

Ground: TB4-4

Bleed Blowdown Control Relay OutputBleed Blowdown Control Relay Output

Bleed Blowdown Control Relay Output

Bleed Blowdown Control Relay OutputBleed Blowdown Control Relay Output

Hot (N.O.): TB5-1

Hot (N.C.): TB5-2

Neutral: TB1-3

Feed OutputFeed Output

Feed Output

Feed OutputFeed Output

Alarm OutputAlarm Output

Alarm Output

Alarm OutputAlarm Output

Ground: TB4-3

On/Off

Hot: TB6-1

Neutral: TB1-2

Ground: TB4-2

External Trigger

High: TB9-3

Low: TB9-4

Hot: TB6-2

Neutral: TB1-1

Ground: TB4-1

9

4 - 20 mAmp Output4 - 20 mAmp Output

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

4 - 20 mAmp Output

4 - 20 mAmp Output4 - 20 mAmp Output

( + ) TB9-1

( - ) TB9-2

Biocide #1 Pump OutputBiocide #1 Pump Output

Biocide #1 Pump Output

Biocide #1 Pump OutputBiocide #1 Pump Output

On/Off

Hot: TB6-3

Neutral:TB2-4

Ground: TB3-4

External Trigger

High: TB8-1

Low: TB8-2

Biocide #2 Pump OutputBiocide #2 Pump Output

Biocide #2 Pump Output

Biocide #2 Pump OutputBiocide #2 Pump Output

On/Off

Hot: TB6-4

Neutral:TB2-3

Ground: TB3-3

External Trigger

High: TB8-3

Low: TB8-4

Flowmeter InputFlowmeter Input

Flowmeter Input

Flowmeter InputFlowmeter Input

The inputs are reversible when the flowmeter connection is a relay and has no

polarity

TB10-1

TB10-2

Flow Switch InputFlow Switch Input

Flow Switch Input

Flow Switch InputFlow Switch Input

This input can be used to connect a flow switch or other device providing a switch

closure output. If a device such as this is connected to the DC4500, it will serve

to disable the controller outputs when this switch is in the “OPEN” position.

This function can be used as a safety override to prevent controller/pump

operation during loss of flow.

The inputs are reversible since the flow switch connection has no polarity.

TB10-3

TB10-4

10

Thermistor Probe Output (Hardwire Only)Thermistor Probe Output (Hardwire Only)

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Thermistor Probe Output (Hardwire Only)

Thermistor Probe Output (Hardwire Only)Thermistor Probe Output (Hardwire Only)

Run the thermistor probe wiring through the PG9 connector on the right side of

the DC4500 controller junction box keeping the wires away from any

115/230 VAC cables that may cause electrical interference.

Signal Output: TB11-1

Signal Return: TB11-2

Conductivity Probe (Hardwire Only)Conductivity Probe (Hardwire Only)

Conductivity Probe (Hardwire Only)

Conductivity Probe (Hardwire Only)Conductivity Probe (Hardwire Only)

Run the conductivity probe wiring through the PG9 connector on the right side of

the DC4500 controller junction box keeping the wires away from any 115/230 VAC cables that

may cause electrical interference.

Signal Output: TB11-3

Signal Return: TB11-4

11

Figure 5: Bottom of controller with cover open.Figure 5: Bottom of controller with cover open.

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Figure 5: Bottom of controller with cover open.

Figure 5: Bottom of controller with cover open.Figure 5: Bottom of controller with cover open.

12

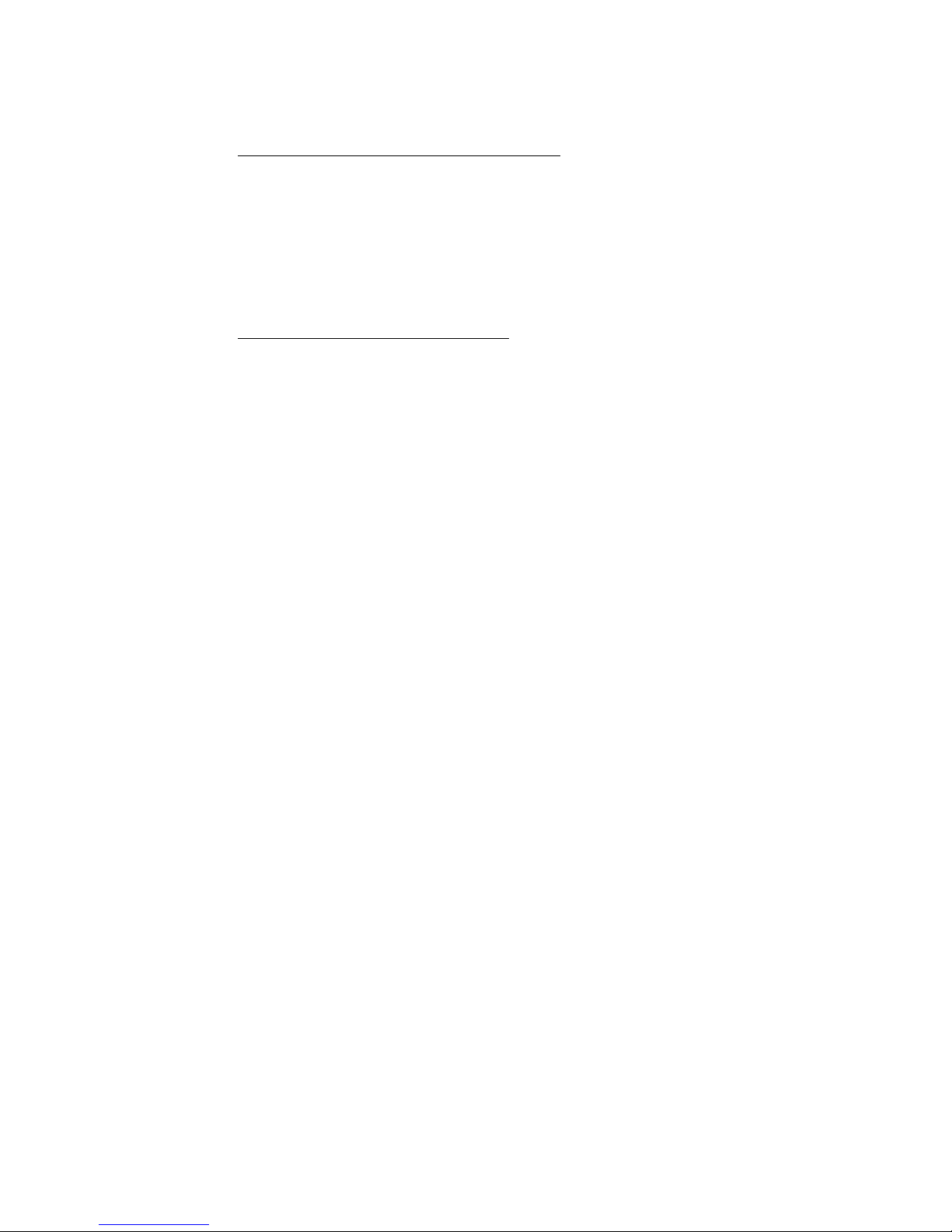

ALARM

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

AC POWER

MOTORIZED

VALV E

SOLENOID VALVE

LINE(N.O.)

LINE(N.C.)

NEUTRAL

TB6

TB5

TB4

MAIN

POWER

INPUT

TEST SWITCH

RUN

TEST

1

TB2

2

3

4

1

2

3

4

1

2

3

4

FUSE

1

2

3

4

1

2

3

4

1

2

3

4

TB1

TB3

1

2

3

4

1

2

3

4

TB7

TB8

1

2

TB9

3

4

1

2

TBIO

3

4

RED

1

GREY

2

ORG

VIO

3

TB11

4

CHART RECORDER

4-20

MILLIAMP

OUTPUT

FLOWMETER

FLOW SWITCH

WHITE

GRAY

RED

BLACK

PROBE

FEED

BIO 1

BIO 2

DC4500

RUN

TEST

1

2

3

4

1

2

3

4

TB9

TB10 TB11

4-20mA

4-20mA

PLS1

PLS1

F/MTR

F/MTR

F/SW

F/SW

TEMP

TEMP

PROBE

PROBE

1

+

2

-

3

+

4

-

1

+

2

-

3

+

4

-

1

2

3

4

TB6

ALARM

TMR 1

TMR 2

BLD(NO)

TB5

BLD(NC)

not used

TB4

Wiring diagram for ON/OFF output control.Wiring diagram for ON/OFF output control.

Wiring diagram for ON/OFF output control.

Wiring diagram for ON/OFF output control.Wiring diagram for ON/OFF output control.

2

L

3

L

4

L

1

L

2

L

3

4

1

2

3

4

TB2

DC4500

TB1

TB3

1

L

FEED

AC LIVE

not used

AC NEUT

AC NEUT

AC NEUT

AC NEUT

AC NEUT

AC NEUT

not used

not used

1

2

3

4

1

2

3

4

1

2

3

4

FUSE

TEST

SWITCH

RS485

+

TB7 TB8

RS485

-

DGND

LEVEL

+

PLS2

+

PLS2

-

PLS3

+

PLS3

-

13

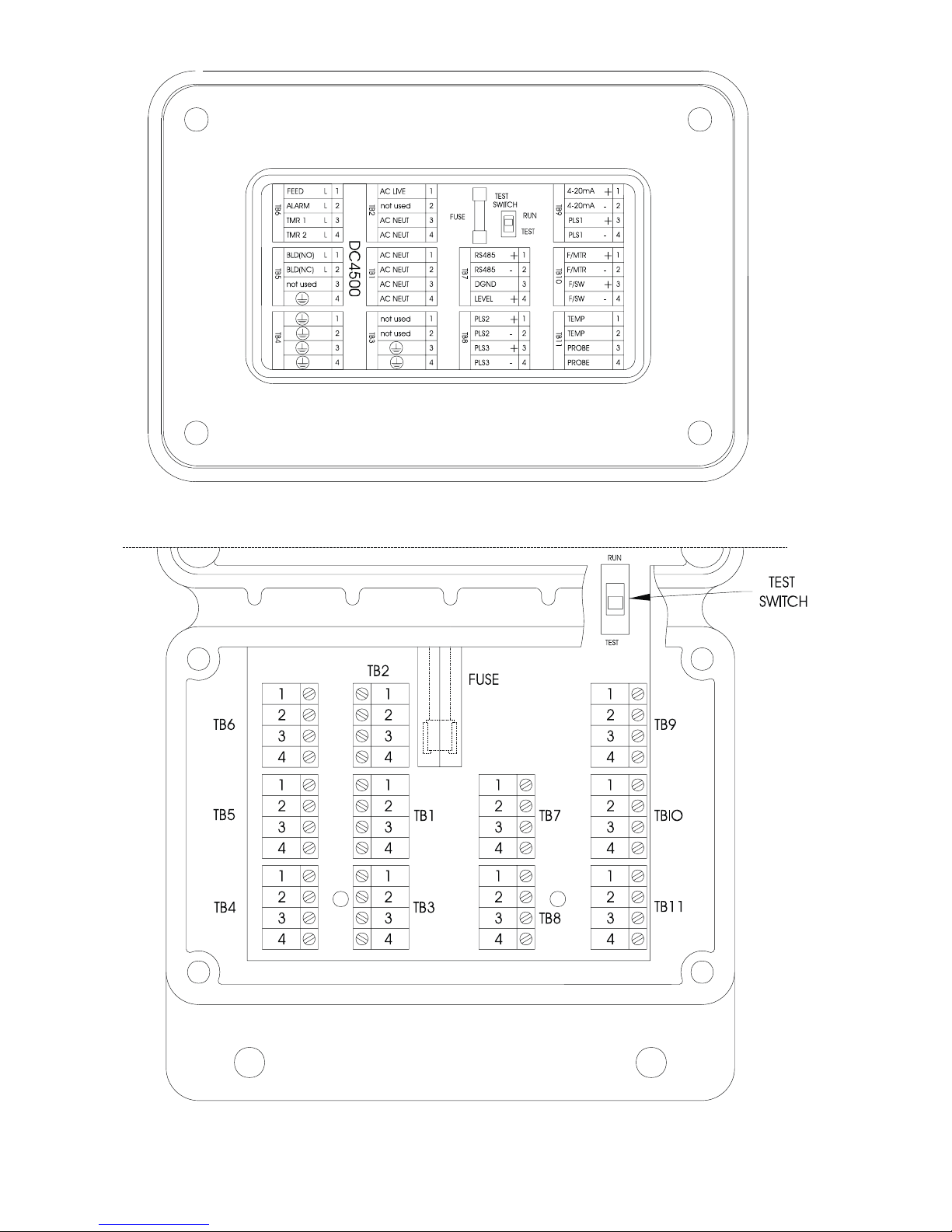

ALARM

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

SOLENOID

VALVE

MOTORIZED

VALV E

AC POWER

AC POWER

LINE(N.O.)

LINE(N.C.)

NEUTRAL

TB6

TB5

TB4

MAIN

POWER

INPUT

FEED

TEST SWITCH

RUN

TEST

TB2

1

2

3

4

1

2

3

4

1

2

3

4

FUSE

1

2

3

4

1

2

3

4

1

2

3

4

TB1

TB3

1

2

3

4

1

2

3

4

TB7

TB8

1

2

TB9

3

4

1

2

TBIO

3

4

RED

1

GREY

2

ORG

VIO

3

TB11

4

CHART RECORDER

4-20

MILLIAMP

OUTPUT

FLOWMETER

FLOW SWITCH

WHITE

GRAY

RED

BIO 1

BLACK

BIO 2

PROBE

14

DC4500

RUN

TEST

1

2

3

4

1

2

3

4

4-20mA

1

+

TB9 TB10 TB11

4-20mA

2

-

3

PLS1

+

4

PLS1

-

1

F/MTR

+

2

F/MTR

-

3

F/SW

+

4

F/SW

-

1

TEMP

2

TEMP

3

PROBE

4

PROBE

TB6

ALARM

TMR 1

TMR 2

BLD(NO)

TB5

BLD(NC)

not used

TB4

Wiring diagram for external pulse output control.Wiring diagram for external pulse output control.

Wiring diagram for external pulse output control.

Wiring diagram for external pulse output control.Wiring diagram for external pulse output control.

2

L

3

L

4

L

1

L

2

L

3

4

1

2

3

4

TB2

DC4500

TB1

TB3

1

L

FEED

AC LIVE

not used

AC NEUT

AC NEUT

AC NEUT

AC NEUT

AC NEUT

AC NEUT

not used

not used

1

2

3

4

1

2

3

4

1

2

3

4

FUSE

TEST

SWITCH

RS485

+

TB7 TB8

RS485

-

DGND

LEVEL

+

PLS2

+

PLS2

-

PLS3

+

PLS3

-

Loading...

Loading...