Instruction

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

Liquitron™ DP5000 Series

Manual Manual

Manual

Manual Manual

pH Controller

For file reference, please record the following data:

Model No:

Serial No:

Installation Date:

Installation Location:

When ordering replacement parts for your LMI Controller or accessory, please include

the complete Model Number and Serial Number of your unit.

201 Ivyland Road

Ivyland, PA 18974 USA

TEL: (215) 293-0401

FAX: (215) 293-0445

http://www.Imipumps.com

Replaces same of Rev. F 4/01

1756.G 2/06

1

Contents

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

1.0 Introduction ..................................................................................................................................................... 3

2.0 Unpacking ........................................................................................................................................................ 3

3.0 Installation ........................................................................................................................................................ 4

3.1 Mounting the Electronic Enclosure ................................................................................................... 4

3.2 Electrical Installation ........................................................................................................................ 6

3.2.1 Terminal Board Signal Description........................................................................................ 7

3.2.2 Field Wiring Instructions (Optional 4-20 mA Output) .......................................................... 8

3.3 pH Adjustment Pump(s) .................................................................................................................... 9

3.4 Keypad and Display .......................................................................................................................... 9

4.0 Operation........................................................................................................................................................ 10

4.1 Default Settings ............................................................................................................................... 10

4.1.1 Proportional Mode ............................................................................................................... 11

4.1.2 On/Off Mode ........................................................................................................................ 12

4.2 Alarms ............................................................................................................................................. 13

4.3 Calibration (Viewing Last Calibration Data) ..................................................................................15

4.4 New Calibration .............................................................................................................................. 15

4.5 Pump Timers and Solenoid Valve Control ..................................................................................... 17

4.6 Advanced Menu .............................................................................................................................. 20

5.0 Maintenance .................................................................................................................................................... 21

5.1 pH Electrode and Cable .................................................................................................................. 21

6.0 Troubleshooting .............................................................................................................................................. 21

6.1 Error Messages ................................................................................................................................ 22

7.0 DP5000 Specifications.................................................................................................................................... 23

8.0 Program Log ................................................................................................................................................... 25

9.0 Parts List ....................................................................................................................................................... 26

10.0 Exploded View ............................................................................................................................................... 27

2

1.0 Introduction

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

The Liquitron™ DP5000 Series pH Controllers are designed for a variety of industrial pH applications including metal

finishing, water treatment, printed circuit board manufacturing and waste treatment.

The DP5000 is a microprocessor-based pH controller with a backlit customized display and tactile keypad for ease of

programming. The DP5000 allows independent programming of control methods (‘ON/OFF’ or ‘PROPORTIONAL’) for

acid (Pump A) or base (Pump B) dosage. Independent high and low pH alarms may be set with activation of the ‘Alarm

relays.’ A third relay output is available for activating a solenoid valve or other devices.

The controller is compatible with any pH electrode that generates a mV signal and allows incorporation of platinum 1000 W

automatic temperature compensation (ATC) elements. Two point or single point pH calibrations may be performed. Timer

functions for pump ‘Run’ time and solenoid ‘Delay’ times can be programmed to operate a solenoid pump valve. An

‘Advanced Menu’ allows selection of special features such as a ‘Point 3’ (inflection point) for the control profiles of the

acid or alkali pumps for finer control. The DP5000 features continuous non-volatile memory back-up, voltage selection,

pre-amplifier outputs, flow and level switch inputs as standard. 4-20 mA recorder output is optional.

2.0 Unpacking

Your carton will contain the items shown in Figure 1. Please notify the carrier immediately if there are any signs of damage

to the controller or its parts. Contact your LMI Distributor if any of the parts are missing.

There is a number label on the inside cover of the unit; for easy reference, you should note the model and serial numbers

on the front cover of this instruction manual.

Quick Reference Guide

DP5000 pH Controller

User Manual

Figure 1: Unpacking Items

3

3.0 Installation

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

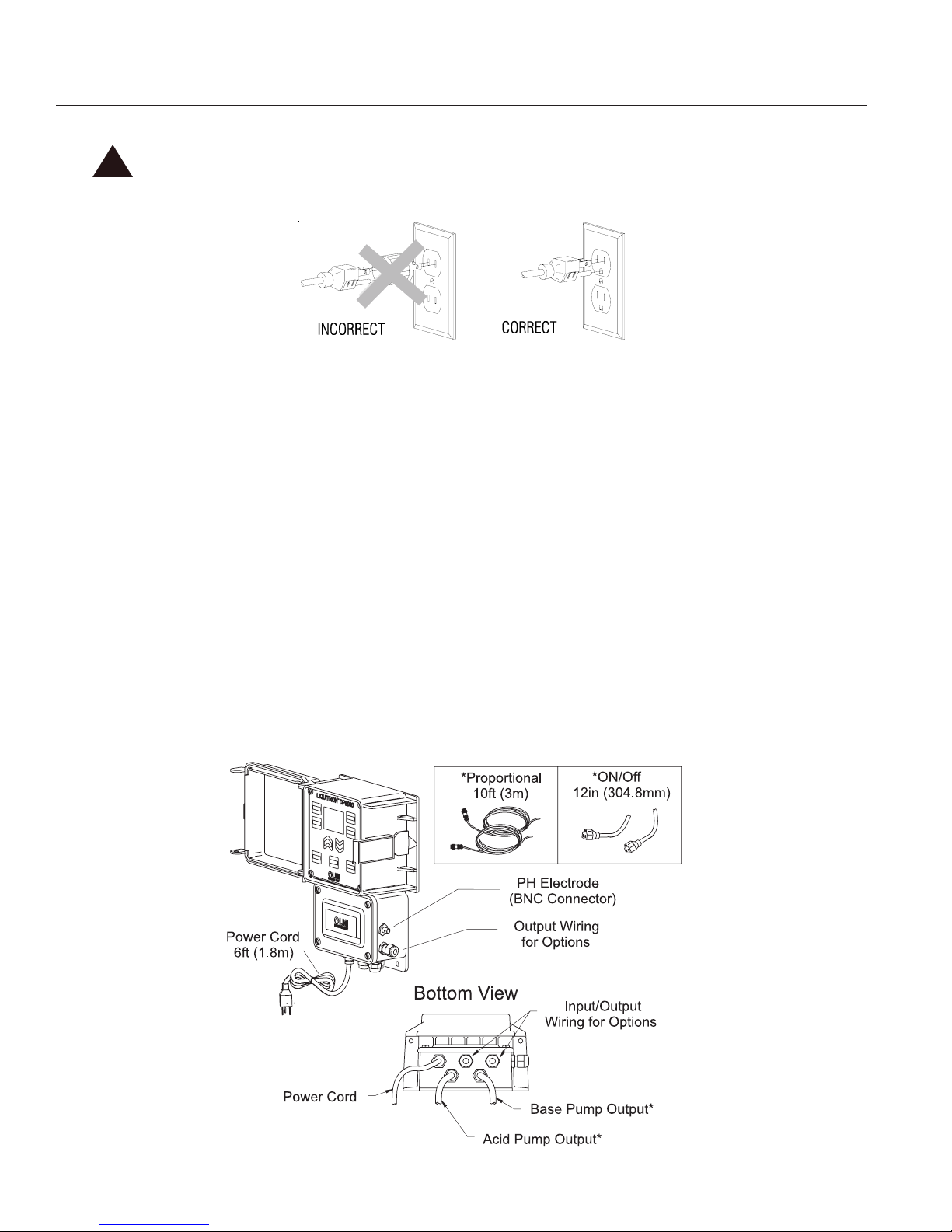

Pre-Installation

!

Be sure that the unit has a plug and voltage code compatible with the power source that you intend to use.

CAUTION

Environment

The housing is corrosion and spray resistant but should not be subjected to excessive spray or ambient temperature over

122° F (50° C). Never immerse the unit.

Installation

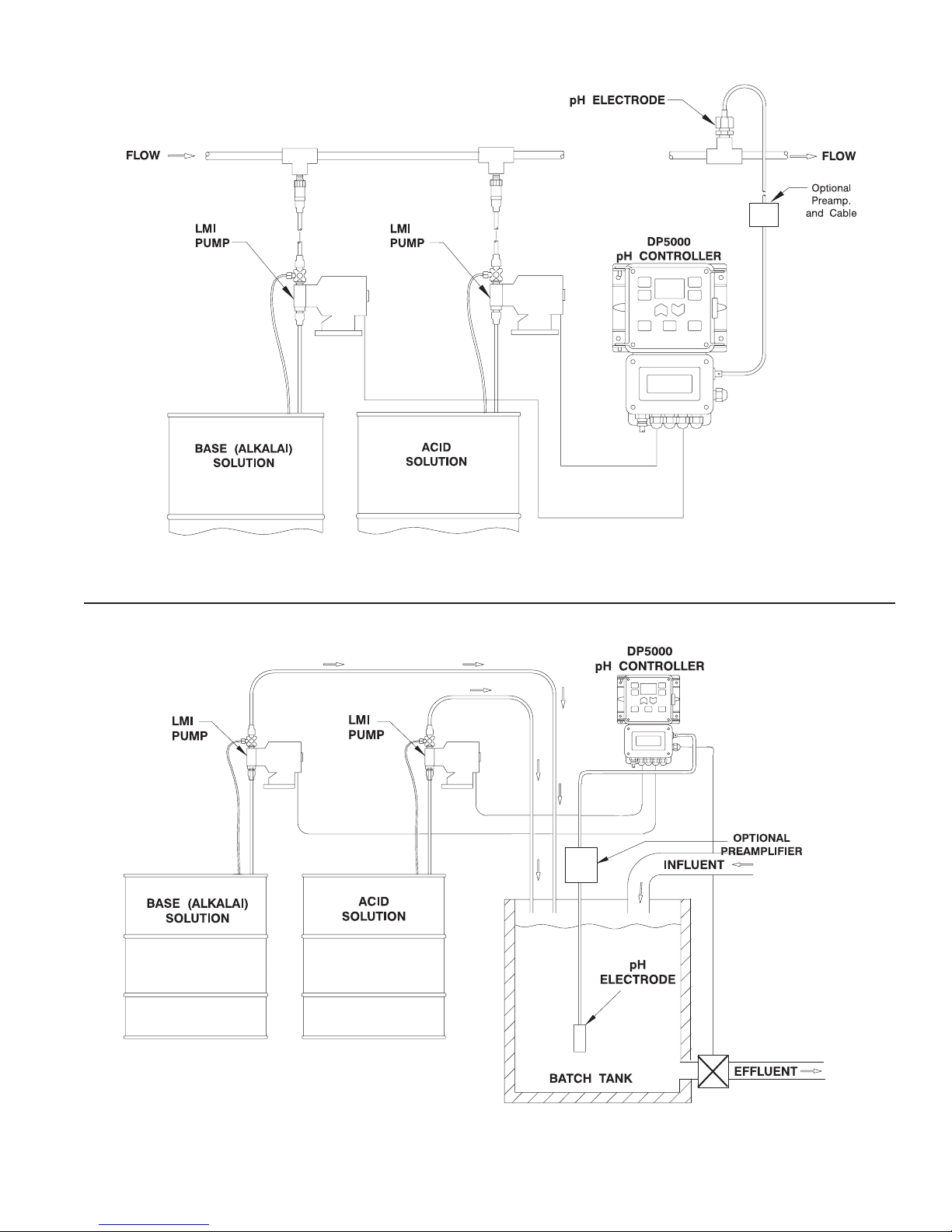

The DP5000 Controller should be mounted on a solid, stable surface. pH adjustment pumps should be installed following

the manufacturer’s recommendations. For installations requiring longer cables, consult your distributor. The electrode

installation will vary, depending on the process used. In general, the temperature electrode and pH electrode should be

mounted together, and placed far enough downstream from the source of pH adjusting solution that sufficient mixing may

occur, but close enough to eliminate hydraulic lag time of response. Refer to the typical installation diagrams on the

following page.

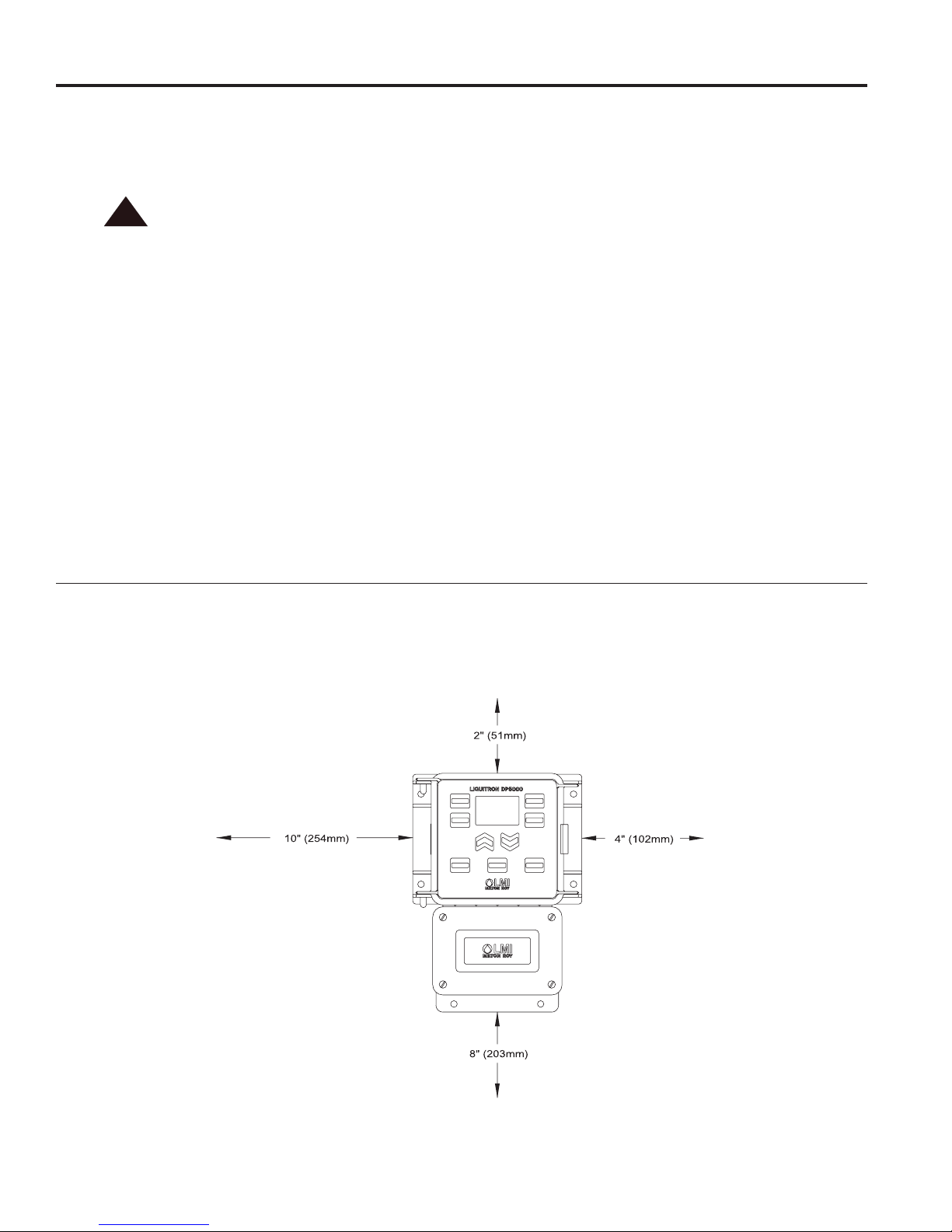

3.1 Mounting the Electronic Enclosure

The DP5000 control module is supplied with integral wall mounting flanges. It should be hung with the display at eye level,

on a vibration-free structure, in a location where liquids will not be splashed on it. All four (4) top-mounting holes should

be used for structural stability. The control module requires the following clearances:

Figure 2: Minimum Clearances

4

Figure 3A: Typical In-Line Installation

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Figure 3B: Typical Batch Installation

5

3.2 Electrical Installation

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Electrical Connections

!

CAUTION

Electrical installation of the DP5000 Series pH Controllers consists of plugging the control module into a proper line outlet.

Based on model number, the following voltages and receptacles are required:

To reduce the risk of electrical shock, the control or metering pump must be plugged into a ground outlet with

ratings conforming to the data on the control panel. It must be connected to a good ground. DO NOT USE

ADAPTERS! All wiring must conform to local electrical codes.

DP5000-1A DP5000-3A DP5000-6A DP5000-01A

DP5000-1B, DP5000-3B DP5000-6B DP5000-01B

115 V, 60 Hz 230 V, 50 Hz, 230 V, 50 Hz 115 V, 60 Hz

USA Cord DIN Cord AUS/NZ Cord No Cord

DP5000-2A DP5000-5A DP5000-7A DP5000-02A

DP5000-2B DP5000-5B DP5000-7B DP5000-02B

230 V, 60Hz 230 V, 50 Hz 230 V, 50Hz 230 V, 50/60Hz

USA Cord UK Cord SWISS Cord No Cord

Connect the pH adjustment pump(s) to the terminal strip for ‘ON/OFF’ control (connect to receptacles directly for 115 V

models) or to cables for ‘PROPORTIONAL’ control. Connect the pH electrode to the BNC connector on the right side of

the control module. Take care not to twist or strain the wires. If equipped, connect the ATC cable (1000 Ω at 32° F

[0° C]) through the cable gland below the BNC connector to the terminal strip. You may optionally connect an alarm,

solenoid, flow switch and low level switch. You may also connect the mA connections (with the option fitted). The ± 5

V supply for electrode pre-amplification is also accessed on the terminal strip. There is a 500 Ω maximum resistance

for 4-20 mA option (refer to Figures 4 and 5).

(Either option is available)

6

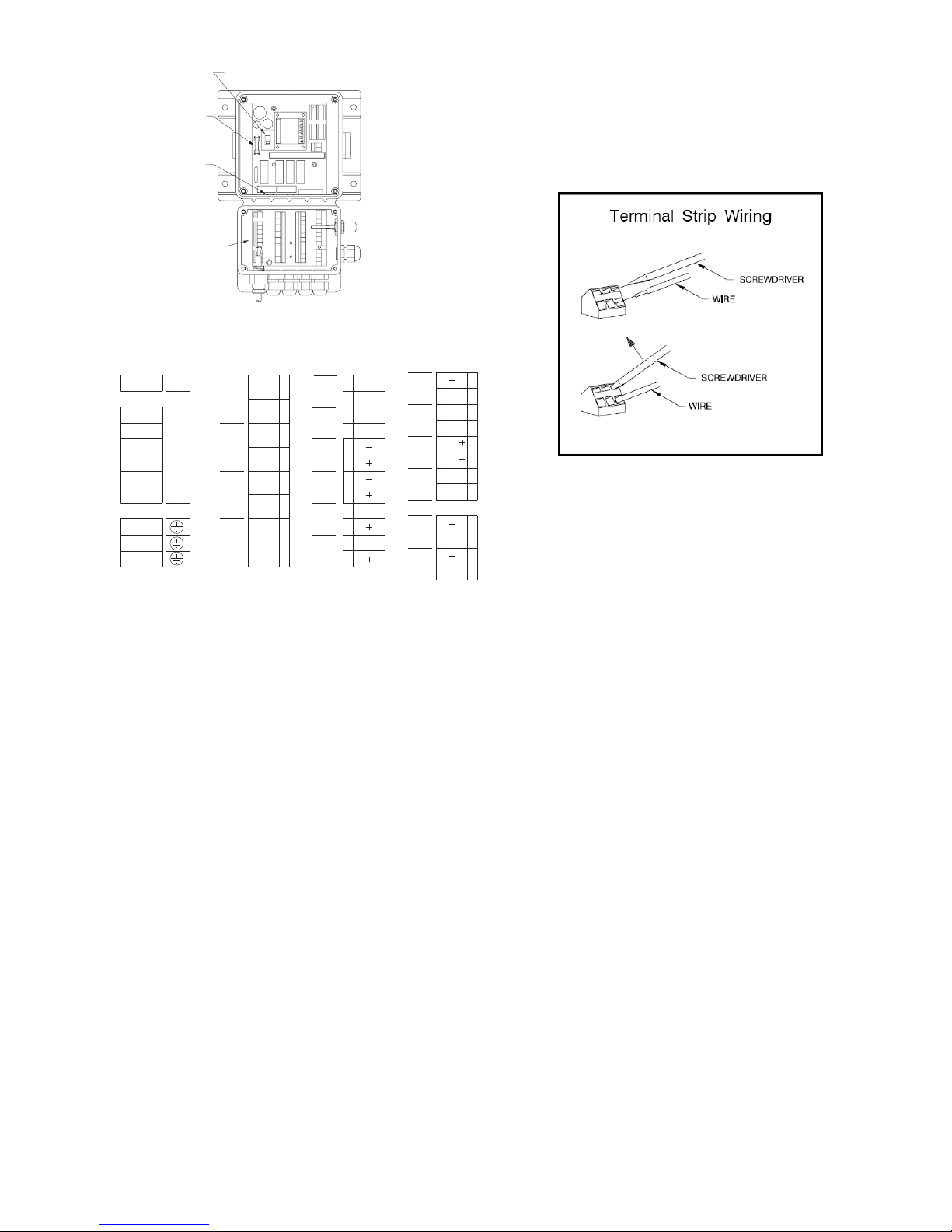

Figure 4: Electrode and Pump Connections

Voltage Selection Switch

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Fuse #2

Fuse #1

See Detail A

TB1 TB3

Live

10

120V/230V

9

8

7

Neutral

6

5

4

3

2

1

Solenoid

Alarm 1

Alarm 2

Pump A

Pump B

NC

NO

NC

NO

NC

NO

NO

NO

115V

TB2

Detail A

8

7

6

5

4

3

2

1

Output

Pump B

Output

Pump A

Output

Fault

Remote

off

TB4

Tem p

Tem p

+ 5V

- 5V

GND

GND

12

11

10

9

8

7

6

5

4

3

2

1

GND

Output

4-20mA

PreAmp

Power

Tem p

Input

Low Level

Flow

12

11

10

9

8

7

6

5

4

3

2

1

Figure 5: Terminal Strip

3.2.1 Terminal Board Signal Description

Terminal blocks are TB1-TB4 from left to right, and Pin 1 is at the bottom of each terminal block.

TB1 Terminal Strip

TB1 Pin 1-Pin 3 ............. Earth connection (one for input power connection)

TB1 Pin 4-Pin 9 ............. Neutral power connection (one for input power connection)

TB1 Pin 10 .................... AC Mains live input

TB2 Terminal Strip

TB2 Pin 1 ...................... Form A contact closed when Pump B (base) is ON

TB2 Pin 2 ...................... Form A contact closed when Pump A (acid) is ON

TB2 Pin 3-4 ................... Form C contact activated, (if programmed) when pH is within programmed limits

(solenoid pump)

TB2 Pin 5-6 ................... Form C contact activated when Alarm Setpoint 2 exceeded (powered output contacts)

TB2 Pin 7-8 ................... Form C contact activated when Alarm Setpoint 1 exceeded (powered output contacts)

TB3 Terminal Strip

TB3 Pin 1-2 ................... Opto isolated input - low or short stops pumps (OFF on display)(Remote OFF)

TB3 Pin 3-4 ................... Opto isolated output - low when alarm condition exists

TB3 Pin 5-6 ................... Opto isolated output - pulse train to drive Pump A

TB3 Pin 7-8 ................... Opto isolated output - pulse train to drive Pump B

TB3 Pin 9-10 ................. Spare, not programmed

TB3 Pin 11-12 ............... Spare, not programmed

TB4 Terminal Strip

TB4 Pin 1-2 ................... Opto isolated input - flow switch input (add jumper if no flow switch is used)

TB4 Pin 3-4 ................... Opto isolated input - level switch input (add jumper if no level switch is used)

TB4 Pin 5-6 ................... Spare, not programmed

TB4 Pin 7-8 ................... Temperature input (from platinum RTD probe) (polarity sensitive)

TB4 Pin 9-10 ................. Power voltage source for preamp

TB4 Pin 11-12 ............... 4-20 mA output proportional to pH (programmable limits) (optional) (polarity sensitive)

7

3.2.2 Field Wiring Instructions

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Typical US field installation would include a 6 ft (2 m) AC cord wired and two (2) 1 ft (30 cm) AC receptacles (‘ON/OFF’

mode) or two (2) 10 ft (3 m) pump drive cables (‘PROPORTIONAL’ mode) installed. A BNC receptacle would be installed

for the pH probe.

Connect the two (2) pumps appropriately. Install the probe, run the cable back to the controller and attach to BNC receptacle.

If the probe is farther than 25 ft (7.6 m) from the controller, a pre-amp may be desirable to reduce noise effects. If this is

the case, run +5 V/-5 V as required by your preamp. Current draw must not be greater than 10 mA.

If a flow switch and/or low-level tank switch is available, run wires to the controller - entering through one of the spare

cable ports. Remove the appropriate jumper(s) and attach the external wires. Polarity does not matter. Wire size #20-22

is adequate.

Alarm relays 1 and 2 are provided to signal an out of tolerance condition externally. These are Form C contacts, providing

a common, a normally open and a normally closed connection.These terminals provide power output.

A solenoid drive relay is provided that can be connected to drain a tank when the pH is within programmed limits. This

form C contact provides a common, a normally open and a normally closed connection. A delay can be programmed after

initially entering this programmed zone, to allow conditions to settle within the tank. The duration of solenoid ON time

is separately programmable. Wire size #16-18 is adequate. These terminals provide output power (main voltage).

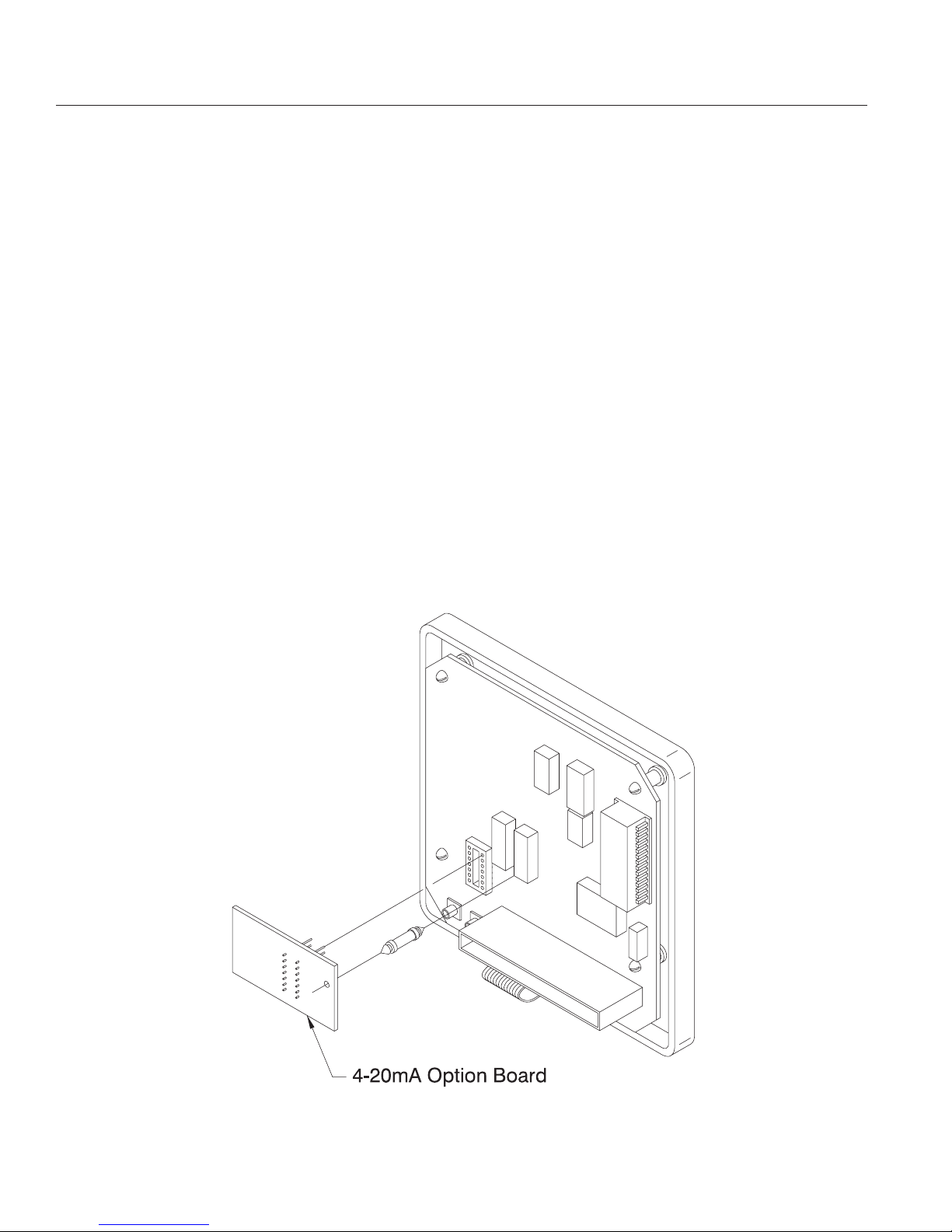

The optional 4-20 mA PCB provides a fully programmable 4-20 mA output based on the pH readings. The optional PCB

plugs into the back of the computer pc board, as shown in Figure 6.

Figure 6: Circuit Board

8

3.3 pH Adjustment Pump(s)

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

There are two (2) versions of the DP5000, one is the ‘ON/OFF’ Output and the second is ‘PROPORTIONAL’ Output.

The On/Off Output DP5000 pH Controller will operate any pH adjustment pump(s) which operate on the same line voltage

as the controller itself. Combined continuous controlled load must not exceed 4A @ 115 V or 2A @ 230 V. To ensure

efficient control, the pumps should be capable of delivering at least 150% of the maximum pumping requirement. Install

and calibrate the pumps according to the manufacturer's recommendations.

The Proportional Output DP5000 pH Controller will operate any LMI A9, A7, B9, B7, C9, C7, E7 or L7 pump, or any

other pump which operates by providing direct proportional response to a modulated pulse input signal. The pumps must

be set to the ‘external’ control mode. To ensure efficient control, the pumps should be capable of delivering at least 150%

of the maximum pumping requirement. Install and calibrate the pumps according to the manufacturer’s recommendations.

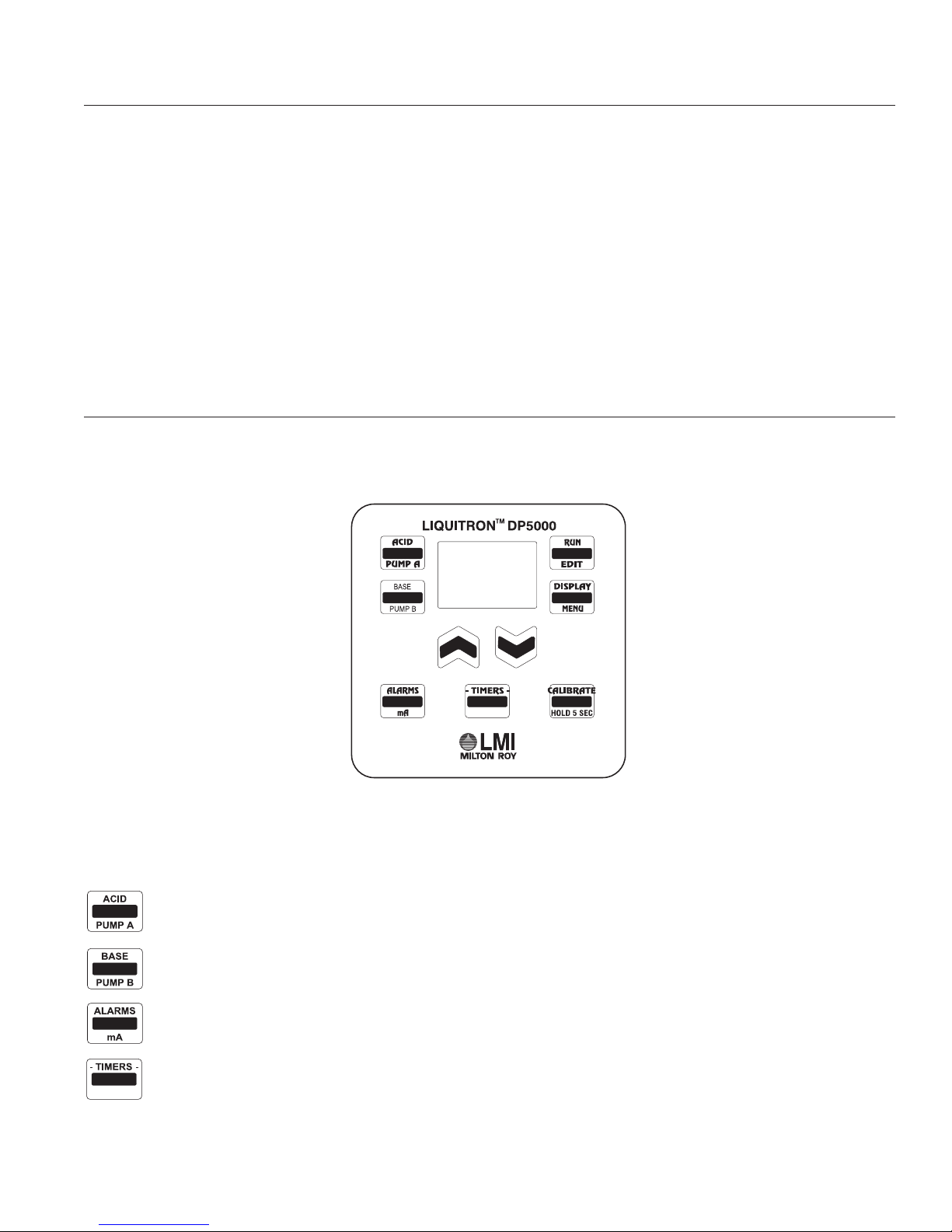

3.4 Keypad and Display

The DP5000 pH Controller menu allows the user to input all the variables necessary to customize the controller for the

application. The keypad is used for all programming (see Figure 7).

Figure 7: Keypad

Keys:

This key is used to set up the control profile for the acid dosing pump. (Holding the key for five (5) seconds

will allow priming of Pump A) (Factory setting 90 SPM).

This key is used to set up the control profile for the base (alkali) dosing pump. (Holding key for five (5)

seconds will allow priming of Pump B) (Factory setting 65 SPM).

This key is used to program the high and low alarm points and hysteresis (ON/OFF mode). It also allows

programming of the mA output when installed.

This key is used to program ‘run times’ for Pumps A and B, ‘delay times’ 1 and 2 for actuating and controlling

a solenoid valve (when programmed ‘ON’ in the advanced features menu). This key also allows setting of

the ‘manual temperature’ and the controller response rate ∆ pH. If pump run time is over 11:01 hours, the

run time is disabled. The pump will not be stopped and will run continuously.

9

This key when pressed will display details of the last successful electrode calibration. (Holding this key for

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

five (5) seconds will allow entry into a new calibration procedure [single or two point]).

Pressing this key will cause the display to alternate showing various settings. (Holding the key for five (5)

seconds will allow entry to the ‘advanced features’ menu).

This key is used for starting and stopping (run or edit) the pumps and changing set points in the controller.

It changes the mode of the controller from ‘RUN’ to ‘OFF.’

These keys are used to change values on the display.

Simultaneously pressing these two (2) keys will lock the keypad to prevent casual tampering.

Pressing them a second time will unlock the keypad. (Wait five (5) seconds between locking and

unlocking).

4.0 OPERATION

4.1 Default Settings

In the default mode, as shipped from the factory without any extended features programmed in the ‘menu’, the controller

is set to operate two (2) dosing pumps towards a single desired pH region as defined by the set points. It will do this in one

of two ways, ‘ON/OFF’ or ‘PROPORTIONAL,’ shown graphically below:

Figure 8: ON/OFF Control Figure 9: Proportional

When the unit is plugged in, the computer powers up and the display illuminates. The display flashes the pH reading and

‘OFF’. This indicates the pumps will not operate and the unit is in the ‘OFF’ mode. When the

controller starts and switches into the ‘RUN’ mode.

Example: (Proportional Controller)

This display shows a pH value of 12.0. Pump A is

flashing indicating that the acid pump is in

operation. The pump will stop pumping after 46:35

minutes if set point is not reached.

For two (2) seconds in every eight (8) seconds the

display shows pump speed in pulses/minute. The

pulses/minute displayed relates to the pump that is in

operation.

10

OUTOFRANGE

key is pressed the

When the pH value exceeds the programmed pH

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

alarm point (12.5), the ‘ALARM’ flashes and the

alarm relay is activated.

Throughout this manual, the term ‘pulse’ is used to describe the mechanical stroke of the pump, as strokes per minute

(SPM).

4.1.1 Proportional Mode

The unit is shipped preset at the factory for the ‘PROPORTIONAL’ or ‘ON/OFF’ mode. To change the unit to the opposite

mode see ‘Advanced Menu List,’ Option 2, on page 20.

Controller must be in ‘OFF’ mode to program changes.

Figure 10: Pump A Control Profile

Pressing

switches the mode back and forth from RUN’

to ‘OFF’. The pH set points and pump speed (pulses/min) can

be changed only in the ‘OFF’ mode.

(1) ...... Press

(2) ...... Press to the increase/decrease the pH value of Set

Point 1 for turning on ‘Pump A’.

(3) ...... Press

(4) ...... Press

again.

to increase/decrease pump speed (pulse/min) for

set point 1.

(5) ...... Press again.

11

(6) ...... Press to increase/decrease the pH for Set Point 2.

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

(7) ...... Press again.

(8) ...... Press

to increase/decrease pump speed (pulse/min)

for Set Point 2.

‘Pump B’ (Base Pump) is programmed in a similar way.

Set points 1 and 2 must be separated by 0.5 pH minimum. If ‘Point 3’ is selected in the Advanced Features Menu,

the user will be prompted to enter a pH value for Set Point 3 and a Pump Speed at Set Point 3. Set points 1 and 3,

2 and 3 must be separated by 0.1 pH minimum.

4.1.2 On / Off Mode

Pump A Control Profile

Controller must be in ‘OFF’ mode to program changes.

• Hysteresis values can be set as low as 0.1 pH

• Lowest setpoint value for pump B is 1pH

• Highest setpoint value for pump B is 12 pH

• Lowest setpoint value for pump A is 2 pH

• Highest setpoint value for pump A is 13 pH

For ‘ON/OFF’ controllers with relay outputs (instead of pulse outputs) each pump is programmed as follows:

(1) ...... Press ....to display Set Point.

(2) ...... Press

(3) ...... Press

(4) ...... Press

relay. In this example, ‘Pump A’ will turn on at a pH of

to increase/decrease pH Set Point.

to save programmed Set Point.

to program ∆ pH (Hysteresis) period for

8.0 (set point + ∆ pH). ‘Pump A’ will turn off when pH

drops to 7.5.

‘Pump B’ (Base Pump) is programmed in a similar way.

12

In this example, ‘Pump B’ will turn on at a pH of 3.5 (set point - ∆ pH) and will turn off when pH reaches 4.0.

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

It is highly recommended that the hysteresis (pump off function) be used to prevent relay chatter.

The function of the hysteresis is to prevent pump relay chattering. It operates by allowing the pump to be turned on when

the control point plus (or minus) the hysteresis value has been met, but does not allow the pump to turn off until the control

point has been met. The chosen value will be used for both upper and lower set points.

The hysteresis, or dead band, designates how many pH units beyond set point the pump runs before turning off. Any value

from 0 to 14.00 is acceptable. If use of this function is undesirable, set it to 0.

Example: If the lower set point is pH 4.0 and the hysteresis has been set at 0.50, a falling pH will cause the pump to activate

at pH 3.50 and it will run until reaching set point (4.0).

4.2 Alarms

Controller must be in ‘OFF’ mode to program change Set Points.

(1) ...... Press to display Alarm data.

(2) ...... Press

(Pump B)

(3) ...... Press

Alarm Point 2.

(4) ...... Press

(Pump A).

to program Alarm Point 1 (low pH).

to save Alarm Point 1 value and to move to

to program Alarm Point 2 (high pH).

(5) ...... Press to save Alarm Point 2 value and to move to

Alarm Hysteresis.

(6) ...... Press

to program Alarm Hysteresis.

This is the point where the alarm turns off.

13

If the 4-20 mA option board is installed, the following screens

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

will appear. If these do not appear and the 4-20 mA PCB is

installed, go to Section 4.6, Advanced Menu, and program

option “7” to “1” and option “6” to “1”.

(7) ...... Press

(8) ...... Press

(9) ...... Press

to display current mA output value.

again to program the 4-20 mA output.

to select the pH value for Point 1 mA

output. Default is 4 mA = 0 pH, 20 mA =14 pH.

(10) .... Press again. Press

Point 1.

to select the mA value at

(11) .... Press

value for Point 2 mA output.

(12) .... Press

value at Point 2.

again. Press to select the pH

again. Press to select the mA

14

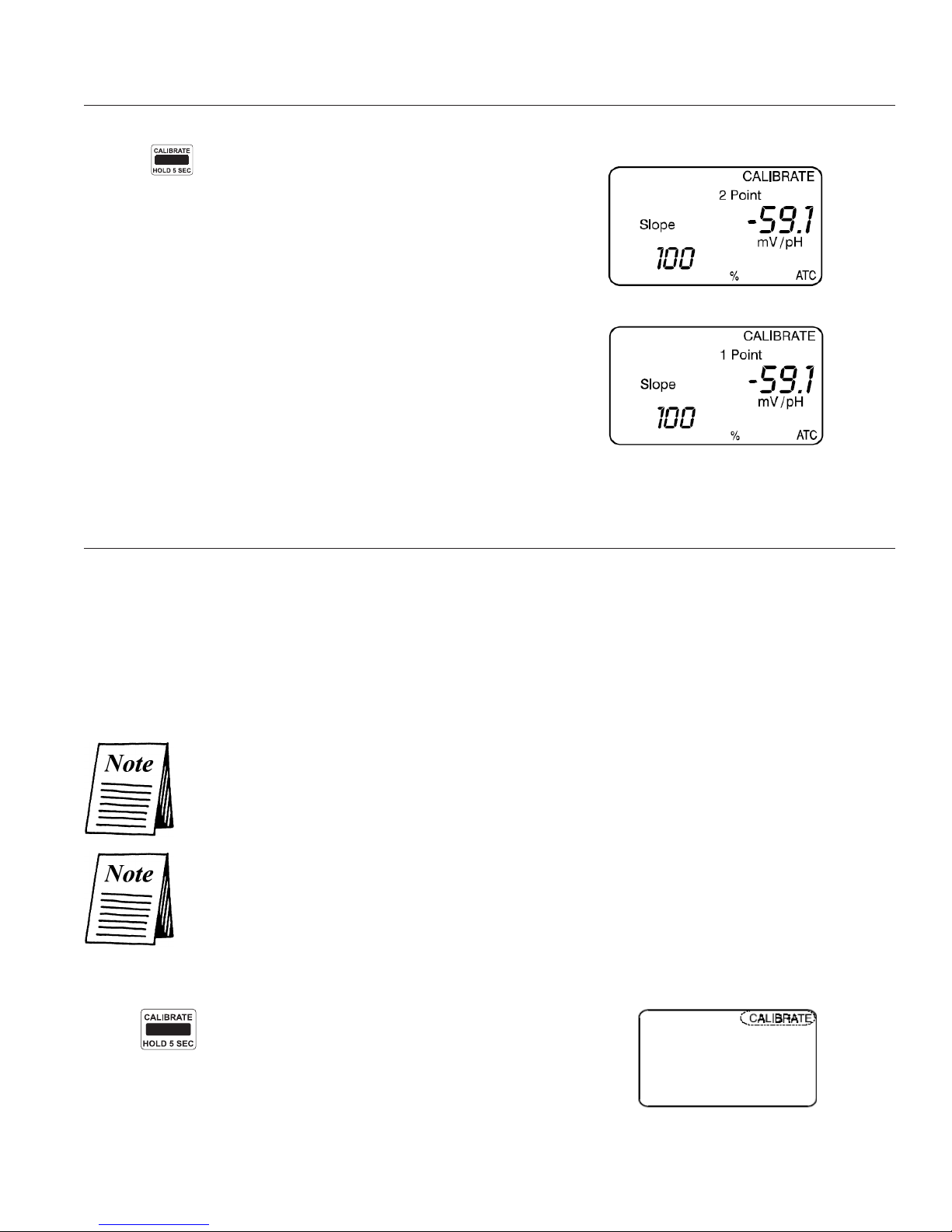

4.3 Calibration (Viewing Last Calibration Data)

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Press the key once.

CALIBRATE will be visible and the ‘mV/pH’ and ‘%’ (slope) of

the previous calibration will be displayed. The display will alternate

between ‘mV/pH’ and ‘°

C.’

‘2 Point’ indicates that the previous calibration was a two-point

calibration.

‘1 Point’ indicates that the previous calibration was a one-point

calibration.

4.4 New Calibration

For two-point calibration, the default settings are Buffer 1 = 7.00 pH and Buffer 2 = 10.00 pH but these values may be

changed.

Because it is not always possible to transfer the temperature probe from the process to the pH buffer, automatic

temperature probe detection can be switched off in pH calibration mode.

The calibration parameters (temperature, ATC [automatic temperature compensation] or manual, buffer pH and one or two

point calibration) of the previous calibration are the initial values for the current calibration.

If the LMI temperature cable and probe are connected, then the computer automatically selects and uses this ATC

(automatic temperature compensation) during calibration. If no temperature probe is connected, then ‘MANUAL’

will be selected during calibration. You must manually measure the temperature of the process being controlled and

enter that value here.

The unit must be placed in the ‘OFF’ mode. The unit cannot be calibrated in the ‘Run’ mode.

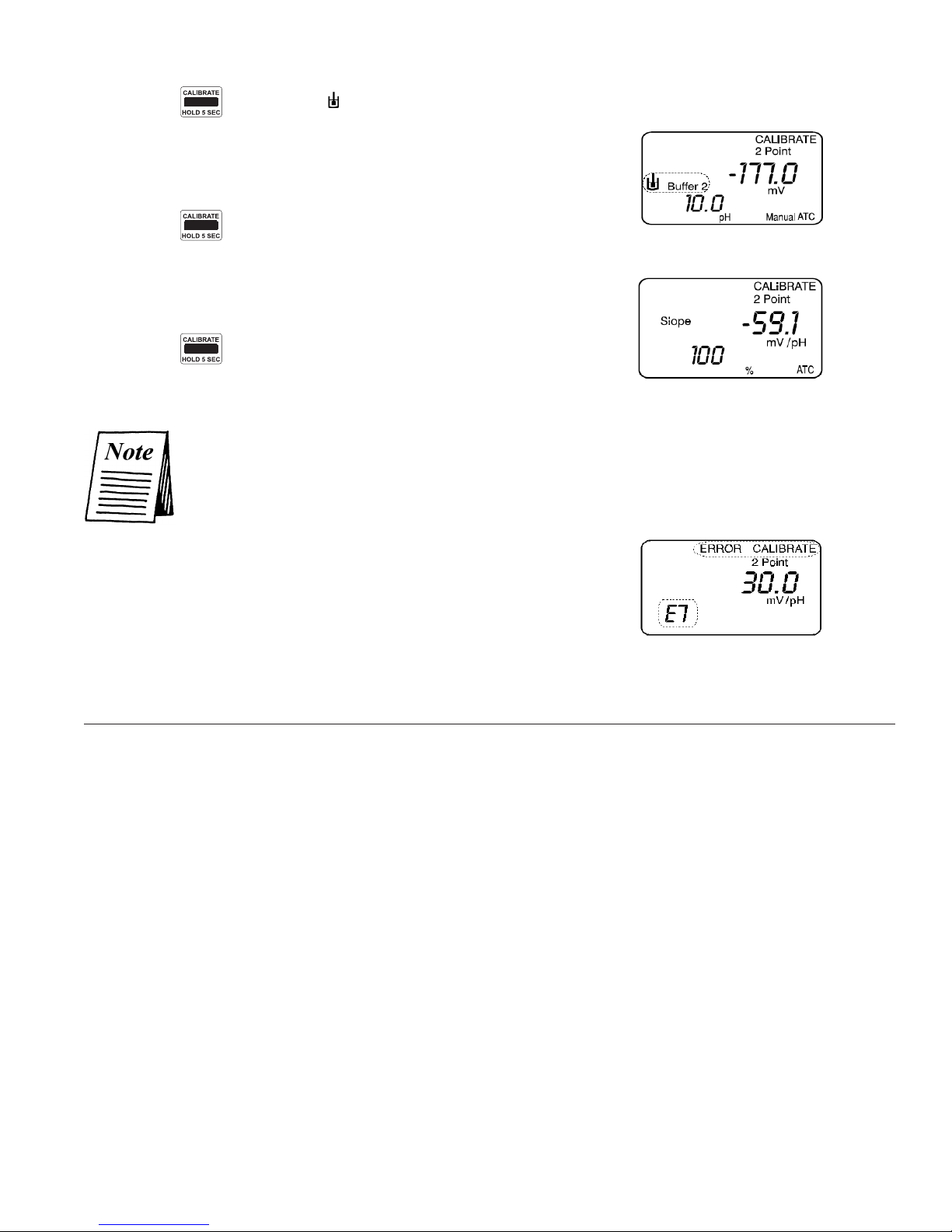

Calibration (e.g., 2 Point)

(1) ......

+ 5 seconds

Hold the ‘CALIBRATE’ key down for five (5) seconds.

‘CALIBRATE’ will start flashing.

15

(2) ...... Press again.

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

‘2 Point’ will start flashing. Use the

keys to

toggle between ‘1 Point’ and ‘2 Point.’

(3) ...... Press

flashing. Use the

again. ‘ATC’ (or ‘MANUAL’) will start

keys to toggle between ‘ATC’

and ‘MANUAL’ temperature.

(4) ...... Press

again. Use keys to program actual

temperature of buffer.

It is not possible to program temperature if ‘ATC’ is selected.

Automatic temperature probe detection can be over-ridden in pH calibration mode. If the ATC probe is not connected,

the controller will not detect it and only the ‘MANUAL’ temperature option above will be displayed.

(5) ...... Press again. The ‘Buffer 1’ value will start

flashing. Use

keys to program ‘Buffer 1’ pH

(or leave at 7.0).

(6) ...... Press again. The symbol will prompt you to

put the probe in ‘Buffer 1’. Wait for the mV value to

settle.

(7) ...... Press

again. This will accept the first calibration

value and will display the ‘Buffer 2’ pH. Use

keys to program ‘Buffer 2’ (or leave) as desired.

16

(8) ...... Press again and the symbol will prompt you to

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

put the probe in ‘Buffer 2’. Wait for the mV value to

settle.

(9) ...... Press

again. This will accept the second

calibration value and will display the ‘mV/pH’ (and ‘%’

Slope) result of the calibration.

(10) .... Press

again to accept this calibration and exit

calibration mode. Press any other key to abort calibration.

For a single-point calibration, only one (1) buffer is used. The theoretical value for pH 7.00 is used to complete the

Calibration Curve.

If the calibration is unsuccessful (slope < 70% or offset > ± 30 mV)

and ‘ERROR CALIBRATE’ and ‘E7’ are displayed; the calibration

should be repeated or else the controller reverts to using the ‘last

successful’ calibration performed.

A slope of less than 70% indicates a dirty/faulty probe or contaminated buffer.

4.5 Pump Timers and Solenoid Valve Control Timers

It is not possible to change timer values while in ‘RUN’ mode. Unit must be in the ‘OFF’ mode to change values and

settings.

Pump Run Time:

This timer is set to the maximum time the pump can be on. If the timer is set to over 11:01 hours, the pump will run

continuously.

This timer is started when a pump is on and the pH value is outside the set points. The controller will stop the pumps when

the time reaches ‘0’ and activate ‘ALARMS.’ The run time is reset each time the pH enters the desired set point region.

Solenoid Delay Pump Valve Time:

The Solenoid Valve Relay output may be activated when the pH is within the set points for the time specified by ‘Delay

1.’ This may be used for system integration and for emptying a batch tank etc.

The ‘Delay 1’ Timer defines the period to allow pH and system parameters to settle.

The ‘Delay 2’ Timer (ON time) defines how long the valve will stay open. When these Delay Timers are active, pump

dosing cannot take place but the DP5000 will monitor the pH. The ‘Delay 2’ timer starts when the outputs are activated.

If the pH drifts outside of the set point and range, the solenoid relay will be deactivated.

If a ‘Delay 2’ time goes below one hour, then the display will change to ‘minutes : seconds’ from ‘hours : minutes.’

17

Setting Timers:

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

The unit must be in the ‘OFF’ (edit) mode to change the timer settings.

For proportional mode pump run time must be set above 11 HR 01 Min to ensure continuous operation.

(1) ...... Press the key to view the run time for ‘Pump A’.

(2) ...... Use

to adjust to desired maximum run time.

The ‘hr : min’ will change to ‘min : sec’ automatically as the run time is reduced below one (1) hour.

(3) ...... Press the key to advance to run time for ‘Pump B’.

(4) ...... Use

to adjust to desired maximum run time.

The ‘hr : min’ will change to ‘min : sec’ automatically as the run time is reduced below one (1) hour.

Delay Timers are factory set in the deactivated mode. The ‘Delay 1 and Delay 2’ Timers are activated/deactivated

in the ‘Advanced Features Menu.’ These screens will not display when the delay option is deactivated.

Solenoid Valve Control:

(5) ...... Press the

activated). ‘Delay 1’ is the wait time after pH enters the

desired region, before the Solenoid is activated.

(6) ...... Press the

activated). ‘Delay 2’ is the Solenoid ‘ON’ time.

If the pH should go out of the desired range during ‘Delay1’ or ‘Delay 2’, the Solenoid cycle will terminate.

It will start again from zero when pH re-enters the desired region. If pH remains in the desired region, the controller

will enter ‘OFF’ mode at the end of the Solenoid ‘ON’ time. The controller turns ‘ON’, again in one minute and the

cycle repeats.

18

key to advance to ‘Delay 1’ time (if

key to advance to ‘Delay 2’ time (if

(7) ...... Press key to advance to ‘Response Rate’. This is

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

programmed in ∆ pH units.

The smoothing of the input signal is determined by delta

(pH) time. The ‘Response Rate’ is the time that the

computer display takes before it updates the pH readings.

The following values can be programmed (min : sec):

00 : 01 00 : 10 00 : 20 00 : 30. . . . . . 04 : 00 (In increments of 10 seconds)

When 00 : 01 is programmed the controller responds to a change in input in one (1) second.

If 00 : 10 is selected the controller responds to a change in input in ten (10) seconds. (i.e., the value displayed is the average

of the 10 previous 1 second readings.)

Examples: The sampling time (delta) is 00 : 10 and the current reading is 2.00 pH.

When the pH input is increased instantaneously to 12.00 pH, the display will respond as follows:

Seconds 0 1 234567891011

pH 2345678910111212

If the sampling was 00 : 01 seconds, the response would be:

Seconds 0 1 234567891011

pH 21212121212121212121212

Press the key to advance to set temperature.

This setting is relevant when no temperature probe

(1000 Ω platinum RTD) is connected.

Display Key:

While in the Run Mode the

key can be pressed once to display current parameters. Each screen will come up for

three (3) seconds and then returns to pH display or System Run automatically (screens shown below are: mV, °C, and mA).

+ 3 Seconds

+ 3 Seconds

19

Similarly, the Pump Control Points can be displayed while in the ‘RUN’ Mode by pressing the ‘Pump A’ or ‘Pump B’ keys

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

once.

Press

and the following screens display:

+3 Seconds

4.6 Advanced Menu:

Holding the key for five (5) seconds accesses the ‘Advanced Features’ Menu, and allows these settings to be

changed.

Press the ‘DISPLAY/MENU’ key for five (5) seconds while the controller is in the ‘EDIT’or ‘OFF’ mode.

The first item displayed is the software revision. Pressing ‘Display/Menu’ again cycles to the first option. The first number

is the option. The second is the setting. Use the

Option Setting

1 1 Control returns to Run 60 seconds after last keypress

0 Run/Edit key is On/Off

to change the setting.

21On/Off Control

0 Proportional Control (and On/Off)

2 Proportional Control

3 1 Point 3 Programming Enabled

0 Point 3 Programming Disabled (Two point only)

4 1 Solenoid programmed to switch on after programmed time‘DELAY 1’ and to switch Off

after programmed time ‘DELAY 2’

0 Solenoid Disabled

5 1 (NA)

0

6 1 mA Enabled - Option Board must be fitted

0 mA Disabled

7 1 Allows editing of #5 & #6

0 Lockout #5 and #6

The Option Board (37830) is required for Option 6.

20

5.0 Maintenance

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

5.1 pH Electrode and Cable

The most frequently replaced part is the pH electrode (not supplied with controller), which will deteriorate with age.

Refillable electrodes should be checked for level frequently, and replenished with filling solution as necessary. An electrode

may also fail because of:

• aging (slow response to changing pH)

• coatings over the glass bulb (slow response to changing pH)

• abrasion of the glass bulb (shift in calibration)

• chemical attack

• breakage

If you experience instability or lack of response, check the electrode, replace if necessary and recalibrate. Follow

manufacturer's recommendation for cleaning the electrode.

Take care not to damage input cables, or allow the connections to get wet.

6.0 Troubleshooting

Troubleshooting and repair of the malfunctioning unit should only be attempted by qualified personnel using caution to

ensure safety and limit unnecessary damage.

Should an error or alarm condition occur, the controller will alert the operator by flashing an ‘ERROR MESSAGE’. These

messages are depicted on the following page with a brief explanation.

21

6.1 Error Messages

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Turn system off to clear error message.

E 1

E 2

E 3

E1 = LOW LEVEL SWITCH

E2 = FLOW SWITCH

E3 = ALARM 1: LOW pH (PUMP B)

E 4

E 5

E 6

E 7

E4 = ALARM 2: HIGH pH (PUMP A)

E5 = Pump B ‘LOCKOUT

E6 = Pump A ‘LOCKOUT

E7 = CALIBRATION ERROR

Probe is out of Manufacturer’s Limits

E9 = FAULTY/DISCONNECTED PROBE

E 9

22

7.0 DP5000 Specifications

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Power

Requirements

115 VAC ±15%, 60 Hz

230 VAC ±15%, 50 Hz

Voltage input selectable via a selector switch located on the I/O PCB.

Inputs

Outputs

Output Type:

Keypad

Material:

Actuation Force:

Travel:

Termination Connector:

Temperature Input

Probe:

Circuit Accuracy:

Temperature Display:

Temperature Resolution:

pH Probe Input

Accuracy:

Resolution:

Input pH Range:

Input Impedance Differential:

Input Impedance Common:

ESD Protection:

Flow Switch, Remote ON/OFF, Spares. All low voltage inputs active low, i.e., the

active state is when the switch is closed. The switch must be capable of switching 2

mA at ± 15 VDC.

Pulse Pump A and B, Alarm.

All low voltage outputs capable of switching 2 mA at + 24 VDC. The pulse output

frequency range will be 0-100 per minute. The pulse output active low. The pulse

width 100 ms in the active (low) state.

Opto-Isolated NPN transistor open collector configuration.

Nine key membrane keypad with tactile response.

(The switches are multiplexed 3 x 3.)

Polyester with a hard coat finish

2.6 N to 3.3 N

0.65 mm 6-way gold plated Berg clincher type 65801-035

The temperature input interfaces to a platinum 1000 ohm RTD probe.

PT1000 (Platinum, 1000 Ω base resistance)

± 0.9° F (± 0.5° C)

32° F to 212° F (0° C to100° C)

± 1.8° F (± 1° C)

± 0.02 pH (500M Ω probe ambient cycle 32° F to 113° F [0° C to 45° C])

0.01 pH

0-14 pH

1013 Ω

1016 Ω

700 V

Relays

Alarm Relays (2):

Solenoid Valve Relay (1):

Current/Voltage Rating:

Contact Type:

Pump ON/OFF Relay (2)

(ON/OFF CONTROL)

Fuse:

LCD Display

Operating Voltage:

Operating Temperature

Viewing Area:

Backlight:

Memory Backup

Data Retention No Power:

Fuse protected

Electromechanical

115/230 VAC, 10 A/6 A

10A, 115 VAC or 6A, 230 VAC

Normally open and normally closed contacts

(FORM C) Change over relay

115 V/230 VAC, 10 A/6 A (NO)

ON/OFF Relays are Fuse Protected

(FORM C). Normally open relay

4 A, 250 VAC time delay (Anti-surge)

5 V

32° F to +122° F (0° C to +50° C)

1.2 x 1.8 inches (30 x 46 mm)

An 8 emitter (dual LED type), double row, reflective backed, backlight module will be

used. The light output color and reflective backing color will be high performance green.

EEPROM

10 year minimum

23

Pre-amplifier

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Output Voltages

Voltage:

Output Voltage Tolerance:

Current Output:

Optional Output

4-20 mA Load:

Accuracy:

Control Outputs

(Pump A / Pump B)

(Proportional Control)

Fault:

Control Inputs

Remote ON / OFF:

Flow Switch:

Low Level Input:

Aux (spare):

± 5 V

± 5% maximum

± 10 mA maximum

500 Ω maximum resistance

± 0.2 mA - The 4-20 mA isolated

Opto-Isolated Open Collector (2 mA)

Opto-Isolated Open Collector (2 mA)

Opto-Isolated (2 mA)

Opto-Isolated (2 mA)

Opto-Isolated (2 mA)

Opto-Isolated (2 mA)

Environmental

Operating Temperature:

Enclosure:

Mechanical

Control Board:

Terminal/Power Board:

Option Board:

Printed Circuit Boards conformally coated

32° F to 122° F (0° C to 50° C)

IEC IP65, NEMA 4X

Two printed circuit boards (3 if option installed)

(Microcontroller & Display) - Low Voltage

Transformer, fuses, terminal blocks, relays

(4-20 mA output ) - Low Voltage

24

8.0 Program Log

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

For record keeping, a program log is provided below.

Proportional ON/OFF Proportional ON/OFF

Pt 1 Pt 2 Pt 1 Pt 2

Pump A Set Point 7.5 10.5 7.5

Pump A Pulses/Min 20 90 / / /

Pump B Set Point 6.5 2.5 6.5

Pump B Pulses/Min 30 65 / / /

Hysteresis 1 / / / / / / 0.5

Hysteresis 2 / / / / / / 0.5

Alarm 1 2.0 pH

Alarm 2 12.5 pH

Hysteresis 0.5 pH

Alarms

mA Response

Current Low 4.0 mA

Signal Low 0.0 pH

Current High 20.0 mA

Signal High 14.0 pH

Timers

Pump A On-Time 20:00 Min

Pump B On-Time 30:00 Min

Sampling Time 00:10 Min

Delay to Solenoid ON 5:00 Min

Solenoid On-Time 20:00 Min

Temperature 24o C

Calibration

Number of Points 2

Buffer Temperature Manual

Buffer Temperature 24

Buffer 1 7.0

Buffer 2 10.0

25

9.0 Parts List

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

Key No. Part No. Description

1 34691 Housing, Machined

2 32186 Screw, 4-40 x .37

3 32187 Nut, 4-40 Flush

4 32209 Latch, Machined

5 34270 I/O Board Assembly

6 34716 Standoff, Self Adhesive

7 31632 Screw, #6 x .38

8 34329 BNC Cable Assembly

9 34330 Ribbon Cable Assembly

10 25957-1 Cord Clamp (PG-9) Clamp for female outlet power cord)

11 36810 Dowel

12 31571 Clamp, Cord (PG-9) Clamp for 4pin cable

13 34074 Gasket, Foam

14 34088 Cover, Utility Box

15 30588 Label LMI Logo

16 37524 Front Panel Assembly

17 31617 Cover, Liquitron™

18 32094 Label, Housing cover LMI

19 32211 Cap, .125 x .38

20 32352 O-Ring, Sponge

21 32395 Screw, Self-Tapping

22 34911 Cover, Fuse

23 35711 Cord, Power, 115V, NEMA 15-R - DP5000-XA (On/Off)

33636 4-Pin Cable - DP5000-XB (Proportional)

24 34930 Terminal Cover Label

25 34315 PCB Support

26 30749 Power Cord 115V - DP5000-1A/B

30751 Power Cord 220V US - DP5000-2A/B

30752 Power Cord DIN - DP5000-3A/B

34783 Cord Assembly UK - DP5000-5A/B

30754 Power Cord AUST - DP5000-6A/B

34784 Cord Assembly SWISS - DP5000-7A/B

27 37830 4-20mA Circuit Board Assembly

28 35712 Fuse, 4A Time Delay

26

10.0 Exploded View

(866) 433-6682 • (281) 359-8538 • sales@novatech-usa.com • www.novatech-usa.com

27

© 2006 LMI Milton Roy - All Rights Reserved

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

28

Printed in USA

Specifications subject to change without notice.

201 Ivyland Road

Ivyland, PA 18974 USA

TEL: (215) 293-0401

FAX: (215) 293-0445

www.lmipumps.com

Loading...

Loading...