Page 1

Electronic Control “HPH-HPR-HPS”

User Manual

HP

EN

MC00005_04-EN - 01/2016

Firmware 3.1

True life inside

air and water

handling

for a confortable life

Page 2

HP User Manual

firmware 3.1 Rev.04 IT 2/ 51

Page 3

HP User Manual

firmware 3.1 Rev.04 IT 3/ 51

Summary

1 Control Features ................................................................................................................................................. 4

2 Wiring the remote terminal ................................................................................................................................ 5

3 User terminal ...................................................................................................................................................... 6

4 MENU DESCRIPTION ......................................................................................................................................... 10

PGD Menu ............................................................................................................................................................. 10

4.1. A. On/Off Unit ...................................................................................................................................... 11

4.2. B. Setpoint ........................................................................................................................................... 11

4.3. C. Clock/Scheduler ............................................................................................................................... 12

4.4. D. Input/Output ................................................................................................................................... 13

4.5. E. Data logger ...................................................................................................................................... 18

4.6. G. Service ............................................................................................................................................. 19

4.7. G.a. Change Language ................................................................................................................................ 19

4.8. G.b. Information ........................................................................................................................................ 19

4.9. G.c. Summer/Winter .................................................................................................................................. 20

4.10. G.d. Working hours ................................................................................................................................ 20

4.11. G.e. BMS config. ..................................................................................................................................... 21

4.12. G.f. Service setting ................................................................................................................................. 21

4.12.1. G.f.a. Working hours set......................................................................................................................... 21

4.12.2. G.f.b. Probe adjustment ......................................................................................................................... 22

4.12.3. G.f.c. Thermoregulation ......................................................................................................................... 24

4.12.4. G.f.d. User DEV/Change PW1 ................................................................................................................. 28

4.13. G.g.Manual management ....................................................................................................................... 28

4.14. H. Manufacturer .............................................................................................................................. 29

4.15. H.a. Configuration .................................................................................................................................. 29

4.16. H.b.I/O Configuration ............................................................................................................................. 31

4.17. H.c. Factory settings ............................................................................................................................... 33

4.18. H.d. Initialization .................................................................................................................................... 37

4.19. H.e. Input/Output Test ........................................................................................................................... 37

5 BMS USER VARIABLES ....................................................................................................................................... 38

6 ALARMS ............................................................................................................................................................ 47

NOTE ........................................................................................................................................................................ 51

Page 4

HP User Manual

firmware 3.1 Rev.04 IT 4/ 51

1 Control Features

Automatic selection

EC fans management

Management of the cooling circuit with inverter compressor

Management of the cooling circuit with inverter compressor

Reading pressure and temperature of the cooling circuit

Management of cooling unit defrost

Management of summer dehumidification

Manual ON-OFF

Cool/change over valve management

Defrost recovery management

Water coil anti-freeze management

ON-OFF electric heater management

Filter pressure switch management

Management of ventilation with CO2 probe

Management of ventilation with one or two pressure sensors

Free-cooling modulating management

Free-heating modulating management

Management of mixing chamber

Management of motorized dampers

Alarms management

Post ventilation

Weekly programming

Remote ON-OFF

Mode change (hot/cold) from digital input

Display on board machine

Remote display

Fixed point adjustment at flow

Adjustment of temperature and ambient humidity

BMS Modbus RS485 protocol

Page 5

HP User Manual

firmware 3.1 Rev.04 IT 5/ 51

2 Wiring the remote terminal

The remote terminal can be installed at max 50m using a 6 poles phone type cable.

Connect the terminal into the A connector of TCONN6J000

TCONN6J000 board

Wiring diagram for a distance up to 50 meters

pLAN setting with remote controller

When the display is ON press together the indicated buttons

Set “Display address setting” to 31 and press

When the display is ON press together the indicated buttons

Press twice

Set as shown the following screen

Then select “Ok?”, set “Yes” and press .

Now the matster board is configured

Display address

Setting..........: 21

I/O Board address: 01

Terminal config

Press ENTER

to continue

P:01 Adr Priv/Shared

Trm1 32 Sh

Trm2 21 Sh

Trm3 None -- Ok?No

max 50 m

Local terminal

Remote terminal

TCONN6J000

J14 and J15 on 2-3

alimentatore

power supply

20…30Vdc – 150mA

_

+

1 2 5

6

address 21

address 32

MASTER

SLAVE

address 1

address 2

Only size 144-205

Page 6

HP User Manual

firmware 3.1 Rev.04 IT 6/ 51

3 User terminal

Display PGD

The PGD1 is semi-graphic type with 8 rows per 22 columns with a 132x64 pixel resolution.

There are 6 buttons used to set the system:

PDG1

BUTTON

ALARM

See the active alarm list.

BUTTON PRG

Enter in main menu root.

BUTTON ESC

Back.

BUTTON UP

Scroll up or value increase.

On main screen, direct access to set-point menu.

BUTTON

DOWN

Scroll down or value decrease.

BUTTON

ENTER

Enter in the selected submenu or confirm setting.

+

BUTTON ESC

+

BUTTON UP

On main screen turn ON-OFF the unit.

+

BUTTON ESC

+

BUTTON

DOWN

Switch visualisation parameters circuit 1 or 2.

Display contrast setting

Press simultaneously + + and with the arrows set the contrast

Page 7

HP User Manual

firmware 3.1 Rev.04 IT 7/ 51

Home page

In the following image you can see the first page, showing mosto f the necessary information sto see the unit working mode.

On this windows you can see the working mode :

STATE UNIT

Unit off by

Alarm

Unit off by

Supervision

Unit off by

Scheduler

Unit off by

Digital input

Unit off by

keyboard

State mode unit

Manual Cold

Manual Hot

Auto Cold

Auto Hot

Defrost State

Heat recovery Defrost

Heat pump defrost

Clock

State Unit

Date

Page 8

HP User Manual

firmware 3.1 Rev.04 IT 8/ 51

Pressing down button you’ll access the the following page.

Electric Pre Heater State

Electric Post Heater State

Compressor State

Page 9

HP User Manual

firmware 3.1 Rev.04 IT 9/ 51

Pressing up button you’ll access the the following page.

This page is active when regulation probe is the supply air sensor

his page is active when regulation probe is the return air sensor

.

Page 10

HP User Manual

firmware 3.1 Rev.04 IT 10/ 51

To access these parameters, you must enter the

password PW2

4 MENU DESCRIPTION

PGD Menu

A. On/Off Unit

B. Setpoint

C. Clock/Scheduler

D. Input/Output

E. Data logger

G. Service

a. Change Language

b. Information

c. Summer / Winter

d. Working hours

e. BMS config.

f. Service settings

a. Working hour set

b. Probe adjustment

c. Thermoregulation

d. User DEV/Change PW1

g. Manual management

H. Manufacturer

a. Configuration

Compressor/Inverter

a. Configuration

b. Regolation

c. Custom

Driver EVD EVO o EVO

OnBoard

a. Configuration

b. Regolation

c. Custom

b. I/O Configuration

c. Factory settings

d. Initialization

e. Input/Output Test

To access these

parameters, you must

enter the password

PW1= 0010

Page 11

HP User Manual

firmware 3.1 Rev.04 IT 11/ 51

4.1. A. On/Off Unit

On the main menu (A.) you can set the unit state.

Or pressing the buttons Esc+UP from every first level menu.

+

TASTO ESC

+

TASTO SU

Premere contemporaneamente i tasti Esc+UP per accendere/spegnere l’unità.

4.2. B. Setpoint

The following figures shows the set-point screens .

Page active with regulation on return air sensor, automatic mode

Page active with regulation on return air sensor, manual mode

Page active with dehumidification active

Page active with air quality sensor active active

Page 12

HP User Manual

firmware 3.1 Rev.04 IT 12/ 51

4.3. C. Clock/Scheduler

Working mode:

The controller has an internal clock with a battery that preserve the clock operation.

Time and date setting and scheduler setting can be done on C.Clock/Scheduler menu. The related screen are:

Time and date setting;

Summer time enabling and setting;

Scheduler enabling;

Profile 1;

Profile 2;

Profile 3;

Profile enabling.

See the following screens:

Time and date setting

Summer time enabling and setting

Scheduler must be enable on the following screen:

Scheduler enabling

You can set on this screen 3 different set-points called profiles

Each profile includes the automatic and manual unit set-points and enabling of night fan speed reducing.

Once profiles have been defined you can set every half hour the required profile.

Page 13

HP User Manual

firmware 3.1 Rev.04 IT 13/ 51

On the screen you can:

select the day of the week

move on the timer ange and set the profile

copy the day schedule on an other day

None rectangle:

Status = OFF

Low rectangle:

Profile 1

Medium rectangle:

Profile 2

High rectagle:

Profile 3

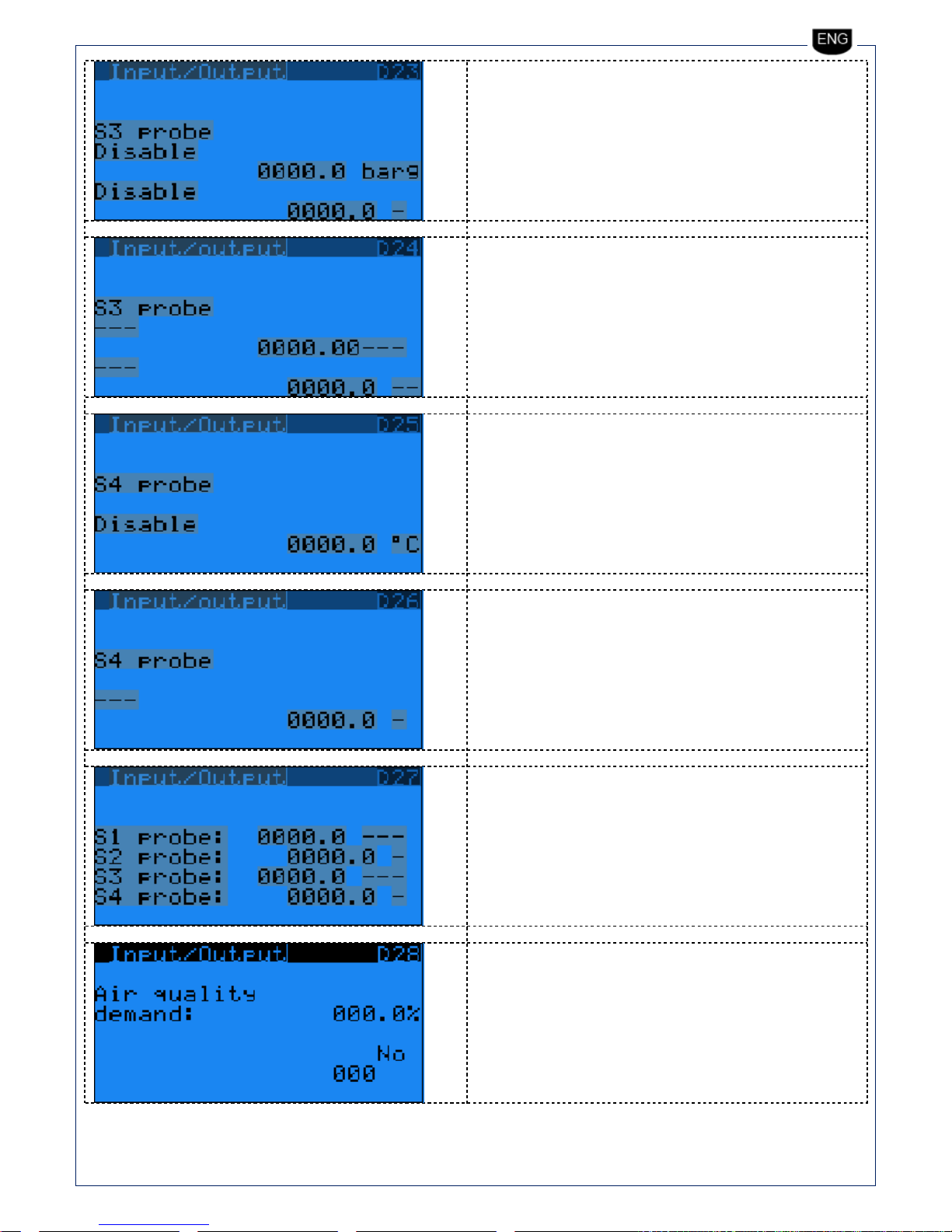

4.4. D. Input/Output

On this menu you can see the analog and digital input and output status. In case of not used I/O you’ll see “---“.

ID00 = Number of

digital input and

description

B00 = Number of

analog input and

description

Page 14

HP User Manual

firmware 3.1 Rev.04 IT 14/ 51

Compressor data screen

Heat pump data screen

Heat pump data screen

NO00 = Number of

digital output and

description

Page 15

HP User Manual

firmware 3.1 Rev.04 IT 15/ 51

Compressor data screen

EEV data screen

Compressor data screen

Compressor data screen

Compressor data screen

Compressor data screen

Page 16

HP User Manual

firmware 3.1 Rev.04 IT 16/ 51

Compressor data screen

Compressor data screen

Page 17

HP User Manual

firmware 3.1 Rev.04 IT 17/ 51

Page 18

HP User Manual

firmware 3.1 Rev.04 IT 18/ 51

4.5. E. Data logger

On this menu you can see the alarm history; to reset them you need to enter on service menu (password is needed).

Pressing the alarm button you can mute the buzzer, and see the active alarms and reset them (of course the alarm log will not be reset) and

then directly enter in the alarm history menu.

alarm date

alarm clock

alarm sequence number

Page 19

HP User Manual

firmware 3.1 Rev.04 IT 19/ 51

4.6. G. Service

This menu is divided inn sub-menu, the first four (a,b,c,d) are not password protected and allos you to set the following:

4.7. G.a. Change Language

Language set-up:

To exit press button

4.8. G.b. Information

you can find information about software code and version, and

installed electronic board .

Page 20

HP User Manual

firmware 3.1 Rev.04 IT 20/ 51

4.9. G.c. Summer/Winter

Automatic or manual season changeover.

4.10. G.d. Working hours

You can see the working hours of the main components installed on the

unit.

Page 21

HP User Manual

firmware 3.1 Rev.04 IT 21/ 51

Note: to access to the following sub-menu you need to enter the service password (PW1 ).

4.11. G.e. BMS config.

BMS setting: all the parameters necessary to set a BMS

communication.

4.12. G.f. Service setting

4.12.1. G.f.a. Working hours set

Working hour setting: it allows to set the maximum working hour of

unit main components that need a periodic maintenance.

On the same screen you can reset the worked hours of each

component.

Page 22

HP User Manual

firmware 3.1 Rev.04 IT 22/ 51

4.12.2. G.f.b. Probe adjustment

Sensors calibration: you can set an offset to add or remove on each

sensor reading. Once confirmed the sensor value is automatically

updated (reported on side).

Page 23

HP User Manual

firmware 3.1 Rev.04 IT 23/ 51

Page 24

HP User Manual

firmware 3.1 Rev.04 IT 24/ 51

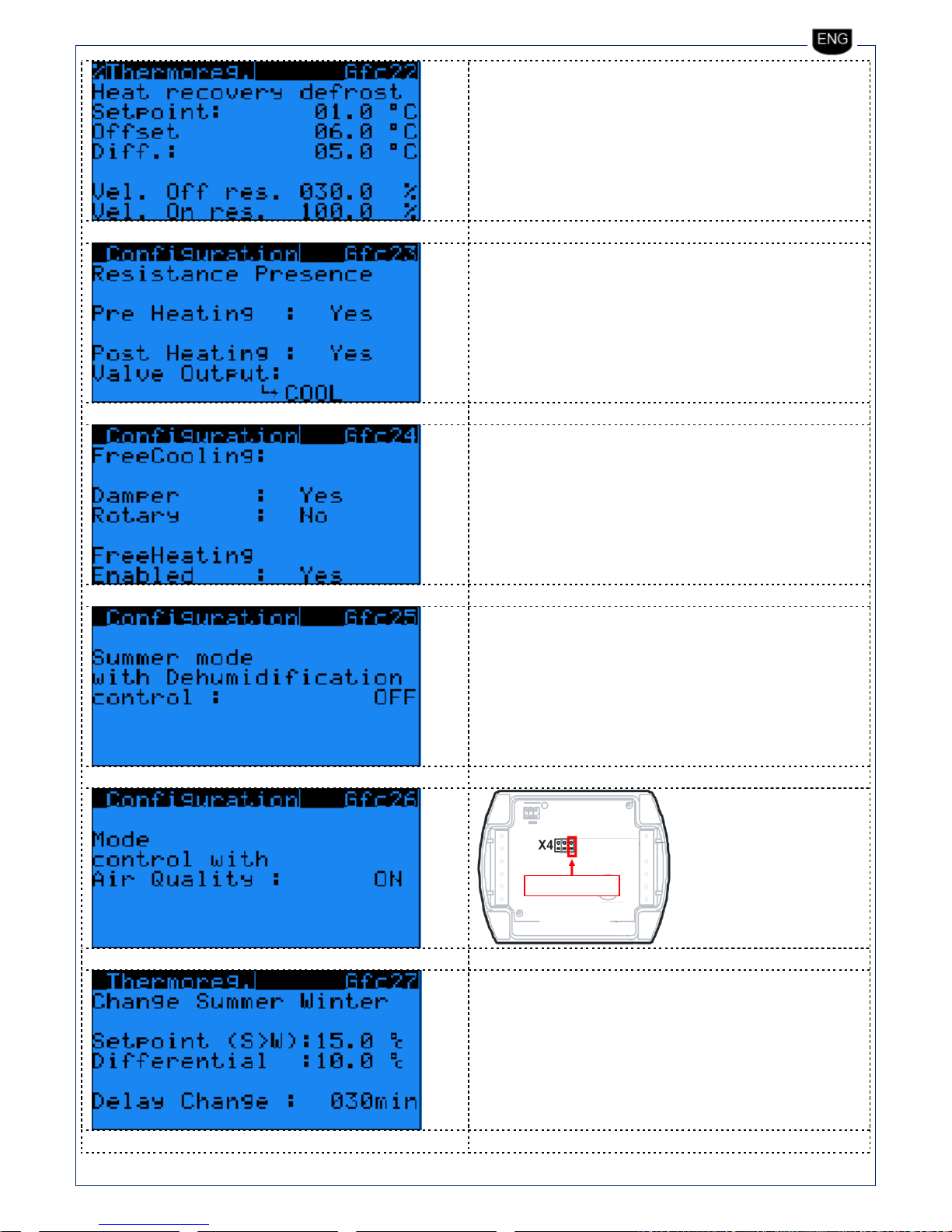

4.12.3. G.f.c. Thermoregulation

Setting of thermoregulation.

Screen active with free-cooling active

Page 25

HP User Manual

firmware 3.1 Rev.04 IT 25/ 51

Screen active with free-cooling active

Screen active with free-heating active

Screen active with free-heating active

Page 26

HP User Manual

firmware 3.1 Rev.04 IT 26/ 51

R1

R2

R3

QPM2100

QPM2100

remove jumper

QPM2100

remove jumper R3

R3 jumper open= 0-5V

R3 jumper close= 0-10V

Page 27

HP User Manual

firmware 3.1 Rev.04 IT 27/ 51

Set (%)costant flow pressur sensor:

Taglia

014

020

026 k

60

95

121

Taglia

050

092

144

205 k

121

197

308

394

Page 28

HP User Manual

firmware 3.1 Rev.04 IT 28/ 51

4.12.4. G.f.d. User DEV/Change PW1

User DEV/Change PW1: you can reset the alarm history and change the

password PW1.

4.13. G.g.Manual management

Page 29

HP User Manual

firmware 3.1 Rev.04 IT 29/ 51

4.14. H. Manufacturer

To access to this menu you need the manufacturer password (PW2 ):

4.15. H.a. Configuration

Configuration: you can select the main features of the unit and the operation of each component.

On the following screens you can see the features of the installed components and the hardware seting.

You can also see the EEV driver setting (a.Configuration, b.Regolation, c.Custom ) and of the compressor / driver (a.Configuration,

b.Regolation, c.Custom).

These parameters are related to the serial port of the compressor

driver.

Page 30

HP User Manual

firmware 3.1 Rev.04 IT 30/ 51

These parameters are related to the serial port of the compressor

driver.

Page 31

HP User Manual

firmware 3.1 Rev.04 IT 31/ 51

4.16. H.b.I/O Configuration

I/O Configuration

On this menu you can activate and set each I/O.

Page 32

HP User Manual

firmware 3.1 Rev.04 IT 32/ 51

Page 33

HP User Manual

firmware 3.1 Rev.04 IT 33/ 51

4.17. H.c. Factory settings

Factory setting: the following screens allows the set all the manufacturer reserved parameter.

Page 34

HP User Manual

firmware 3.1 Rev.04 IT 34/ 51

Page 35

HP User Manual

firmware 3.1 Rev.04 IT 35/ 51

Page 36

HP User Manual

firmware 3.1 Rev.04 IT 36/ 51

Page 37

HP User Manual

firmware 3.1 Rev.04 IT 37/ 51

4.18. H.d. Initialization

Default installation: complete reset of the default value.

On this screen you can change the manufacture value.

4.19. H.e. Input/Output Test

Page 38

HP User Manual

firmware 3.1 Rev.04 IT 38/ 51

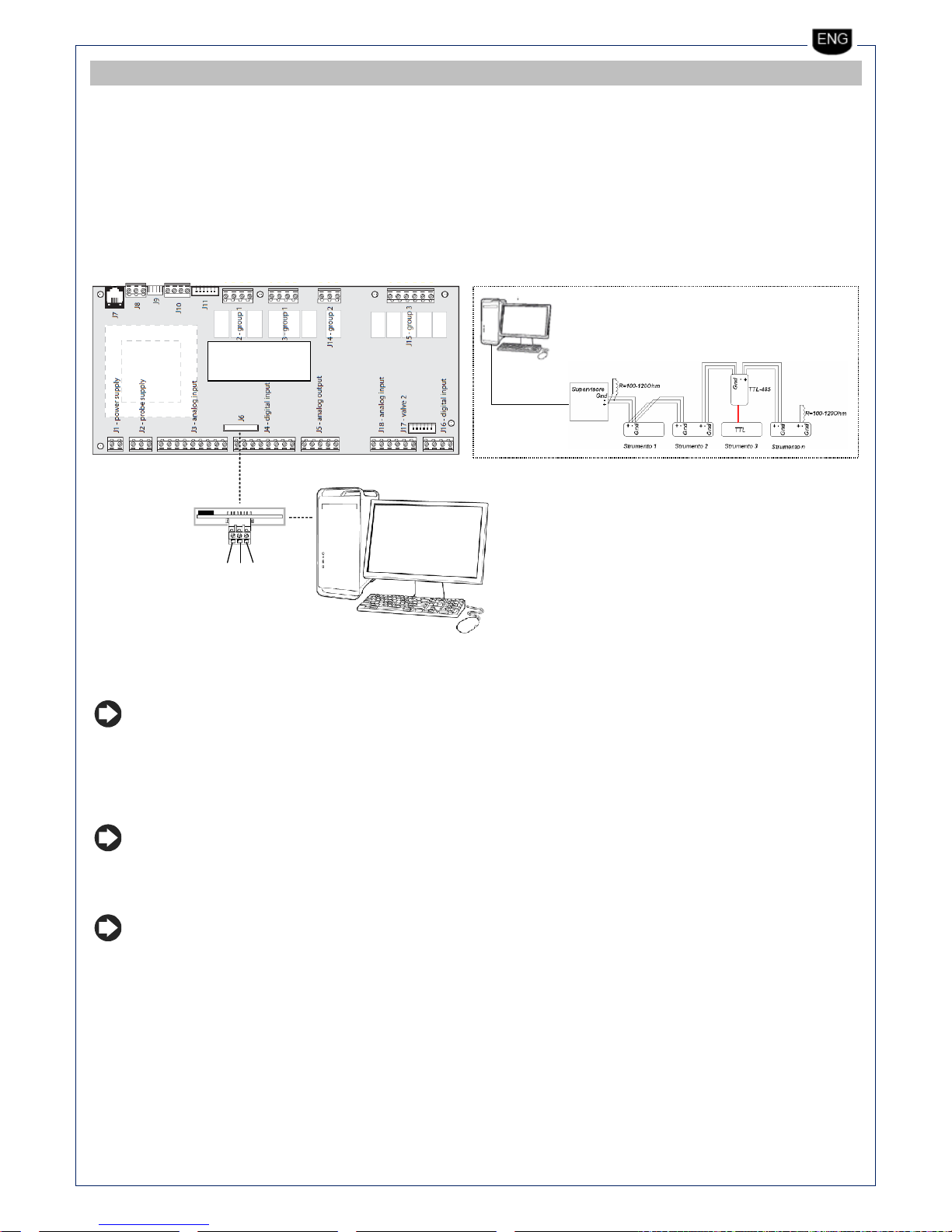

5 BMS USER VARIABLES

The unit can be connected the several supervision system, in particular the following BMS protocols can be used:

Carel and Modbus.

The connection is made by a BMS serial port.

The connetion protocol is managed by the following optional board:

Modbus RS485: cod. PCOS004850 (see Fig. 8.a)

On the following figure you can see the connection diagram between BMS and uPC.

120ohm

MASTER

GND

RX/TX +

RX/TX -

Fig. 8.a

Note:

Suggested cable for data line with 100-120ohm impedance type BELDEN 3105A EIA Industrial RS-485 PLTC/CM

The following table shows the variables shared with supervisor.

Nota: On the first column shows the Carel address, the second one the ModBus address (packet), in case of

“register” communication mode, the address of the ModBus column must be increased of 1, both for digital variable

(coil) and for analog variable (register).

Nota: (*) “nome” indica il nome della variabile utilizzato internamente per il programma di commissionino

Page 39

HP User Manual

firmware 3.1 Rev.04 IT 39/ 51

CAREL

MODBUS

COIL (1)-Digital/MODBUS

TAG NAME

TAG DESCRIPTION

1

2

DIGITAL INPUT 1

din1_msk

Status of digital input (0=Closed;

1=Open) 2 3

DIGITAL INPUT 2

din2_msk

Status of digital input (0=Closed;

1=Open) 3 4

DIGITAL INPUT 3

din3_msk

Status of digital input (0=Closed;

1=Open) 4 5

DIGITAL INPUT 4

din4_msk

Status of digital input (0=Closed;

1=Open) 5 6

DIGITAL INPUT 5

din5_msk

Status of digital input (0=Closed;

1=Open)

6

7

DIGITAL INPUT 6

din6_msk

Status of digital input (0=Closed;

1=Open)

7

8

DIGITAL INPUT 7

din7_msk

Status of digital input (0=Closed;

1=Open)

8

9

DIGITAL INPUT 8

Din8_msk

Status of digital input (0=Closed;

1=Open)

9

10

DIGITAL INPUT 9

Din9_msk

Status of digital input (0=Closed;

1=Open)

10

11

DIGITAL INPUT 10

Din10_msk

Status of digital input (0=Closed;

1=Open)

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

DIGITAL OUTPUT 1

Dout1_Value

(0-Open;1-Close)

21

22

DIGITAL OUTPUT 2

Dout2_Value

(0-Open;1-Close)

22

23

DIGITAL OUTPUT 3

Dout3_Value

(0-Open;1-Close)

23

24

DIGITAL OUTPUT 4

Dout4_Value

(0-Open;1-Close)

24

25

DIGITAL OUTPUT 5

Dout5_Value

(0-Open;1-Close)

25

26

DIGITAL OUTPUT 6

Dout6_Value

(0-Open;1-Close)

26

27

DIGITAL OUTPUT 7

Dout7_Value

(0-Open;1-Close)

27

28

DIGITAL OUTPUT 8

Dout8_Value

(0-Open;1-Close)

28

29

DIGITAL OUTPUT 9

Dout9_Value

(0-Open;1-Close)

29

30

DIGITAL OUTPUT 10

Dout10_Value

(0-Open;1-Close)

30

31

DIGITAL OUTPUT 11

Dout11_Value

(0-Open;1-Close)

31

32

DIGITAL OUTPUT 12

Dout12_Value

(0-Open;1-Close)

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

Summer-winter working mode

Summer -Winter

Status (0: Summer; 1: Winter)

41

42

BMS On/Off

Off-On

Status (0: Off; 1: On)

100

101

101

102

A001 Clock board error

Page 40

HP User Manual

firmware 3.1 Rev.04 IT 40/ 51

102

103

A002 Extend memory error

103

104

A003 Compressor start-up failed

104

105

A004 Envelope zone alarm:

105

106

A005 High compressor discharging temperature

106

107

A006 Low pressure difference

107

108

A007 Inverter type not compatible

108

109

A008 Power+ Device Offline

109

110

A009 Power+ see “Inverter erros list”

110

111

A010 S1 sensor failure

Low pressure

111

112

A011 S2 sensor failure

Compressor Suction Temp.

112

113

A012 S3 sensor failure

High pressure

113

114

A013 S4 sensor failure

Compressor discharge Temp.

114

115

A014 (LowSH) Low overhetaing

115

116

A015 (LowSH) Low overheting

116

117

A016 (LOP) Low evaporation temperature

117

118

A017 (LOP) Low evaporation temperature

118

119

A018 (MOP) High evaporation temperature

119

120

A019 (MOP) High evaporation temperature

120

121

A020 High condensing temperature

121

122

A021 Low condensing temperature

122

123

A022 Low suction temperature

123

124

A023 Autotune Valve A-

124

125

A024 Autotune Valve B-

125

126

NOT USED

NOT USED

126

127

NOT USED

NOT USED

127

128

A027 High Pressure Alarm Compressor 1

128

129

A028 Low Pressure Allarm Compressor 1

129

130

A029 Disabled Compressor Start DP

130

131

A030 Air Flow Switch (ID)

131

132

A031 Fan Alarm (ID)

132

133

A032 Filter Pressure Switch Supply/Return (ID)

133

134

A033 High Pressure Alarm Compressor 1 (ID)

134

135

A034 Mix room alarm

135

136

A035 B1 sensor failure

Exhaust temp.

136

137

A036 B2 sensor failure

Fresh air temp.

137

138

A037 B12 sensor failure

Air quality sensor

138

139

A038 NOT USED

NOT USED

139

140

A039 NOT USED

NOT USED 140

141

A040 Door Micro switch Alarm

141

142

A041 High Pressure Prevention Function

142

143

A042 B8 sensor failure

Saturation Temp.

143

144

A043 B9 sensor failure

Return Temp.

144

145

A044 B10 sensor failure

Return humidity

145

146

A045 Circuit 2 Offline

146

147

A046 Circuit 1 Offline

147

148

A047 Circuit 1 Alarm

148

149

A048 Circuit 2 Alarm

149

150

A049 B3 sensor failure

Supply temp.

Page 41

HP User Manual

firmware 3.1 Rev.04 IT 41/ 51

150

151

A050 Electric Heating Thermal protection

199

200

200

201

201

202

Comp_On_1

Compressor power on

202

203

Comp_Request_Env

Request to switch on/off compressor

from envelope

203

204

204

205

205

206

206

207

207

208

208

209

209

210

210

211

211

212

212

213

En_Inverter

EnablePower + Inverter

213

214

214

215

215

216

216

217

217

218

218

219

219

220

CAREL

MODBUS

INPUT (2)- Analog/MODBUS

TAG NAME

TAG DESCRIPTION

1

2

ANALOG INPUT VALUE 1

Ain1_Std_UM

Exhaust temp. 2 3

ANALOG INPUT VALUE 2

Ain2_Std_UM

Fresh air temp. 3 4

ANALOG INPUT VALUE 3

Ain3_Std_UM

Supply air temp. 4 5

ANALOG INPUT VALUE 4

Ain4_Std_UM

Compressor 1 suction temp.

5

6

ANALOG INPUT VALUE 5

Ain5_Std_UM

Compressor 1 discharge temp.

6

7

ANALOG INPUT VALUE 6

Ain6_Std_UM

C1 high pressure transducer

7

8

ANALOG INPUT VALUE 7

Ain7_Std_UM

C1 low pressure transducer

8

9

ANALOG INPUT VALUE 8

Ain8_Std_UM

Saturation temp.

9

10

ANALOG INPUT VALUE 9

Ain9_Std_UM

Return air temp.

10

11

ANALOG INPUT VALUE 10

Ain10_Std_UM

Return air humidity

11

12

ANALOG INPUT VALUE 11

Ain11_Std_UM

12

13

ANALOG INPUT VALUE 12

Ain12_Std_UM

Air quality sensor

13

14

ANALOG OUTPUT Y1

Supply fan

14

15

ANALOG OUTPUT Y2

Return fan

15

16

ANALOG OUTPUT Y3

Water valve

16

17

ANALOG OUTPUT Y4

By-pass modulating damper

17

18

18

19

19

20

20

21

RoomSet_Heat

Room PI regulheatig setpoint

21

22

RoomSet_Cool

Room PI regul cooling setpoint

22

23

RoomSetP_Operative

23

24

Calculated Set point

DelivAirSetP_Temp

Delivery air setpoint (calculated)

Page 42

HP User Manual

firmware 3.1 Rev.04 IT 42/ 51

24

25

25

26

ANALOG INPUT VALUE 4 SLAVE

Compressor 2 suction temp.

26

27

ANALOG INPUT VALUE 5 SLAVE

Compressor 2 discharge temp.

27

28

ANALOG INPUT VALUE 6 SLAVE

C2 high pressure transducer

28

29

ANALOG INPUT VALUE 7 SLAVE

C2 low pressure transducer

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

Return air Set-point (automatic mode)

RoomSetP

Room setpoint

41

42

Return air Set-point (summer)

RoomSetP_Summer

42

43

Return air set-point (winter)

RoomSetP_Winter

43

44

Neutral zone

RoomDeadBand

200

201

201

202

Rotor_Speed_Hz

202

203

Rotor_Speed_rps_1

Compressor rotor speed rps [1/10rps]

203

204

Maximum_output_freq

uency_Rps

Maximum power+ output frequency set

(Rps)

204

205

Minimum_output_freq

uency_Rps

Minimum drive output frequency (rps)

205

206

Motor_Current

Motor current [1/10 A]

206

207

Inverter_Req_0_1000

Speed request to inverter (filtered by

envelop) 0-1000 [1/10%]

207

208

A100_DISCHARGE_SH_

SET_1

SetPoint of Discharge SH (EE Valve

subregulation) [1/10°C]

208

209

A101_DISCHARGE_TEM

P_SET_1

SetPoint of Discharge Temp (EE Valve

subregulation) [1/10°C]

209

210

MOP_Inhibition_Thr_1

to EVD Pin of MOP inhibition threshold

210

211

A107_MOP_THRESHOL

D_FAST_CHANGE_1

211

212

A106_S4_NTC_THERM

AL_TIME_K_1

212

213

Evap_Reg_Setpt_T_1

Evaporating temp. limit Setpoint (Fan

regul. in Pdc) [1/10°C]

213

214

Evap_Reg_Setpt_P_1

Evaporating press.limit Setpoint (Fan

regul. in Pdc) (1/10bar]

214

215

Cond_Reg_Setpt_P_1

Condensing press. limit Setpoint (Fan

regul. in chiller) [1/10bar]

215

216

Cond_Reg_Setpt_T_1

Condensing temp. limit Setpoint (Fan

regul. in chiller) [1/10°C]

216

217

217

218

218

219

219

220

220

221

300

301

301

302

Suction_Temp_A1

Suction temperature - EE valve [1/10°C]

Page 43

HP User Manual

firmware 3.1 Rev.04 IT 43/ 51

302

303

Evaporation_Temp_A1

Evaporation temperature - EE valve

[1/10°C]

303

304

Evaporation_Press_A1

Evaporation pressure valve A

304

305

Superheat_A1

Superheat - EE valve [1/10°C]

305

306

Condensing_Press1

Condensing pressure

306

307

Condensing_Temp1

Condensing temperature - EE Valve

[1/10°C]

307

308

A104_DISCHARGE_SH1

308

309

Tdischarge_Gas_EVO

Discharge gas temperature with EVD

[1/10°C]

309

310

310

311

311

312

A10_SH_SH

Superheat valve A

312

313

A5_SH_SUCT_TEMP

Suction temperature valve A

313

314

314

315

A17_EEV_POSITION_PE

RCENT_SHOW

315

316

316

317

A7_SH_EVAP_PRES

Evaporation pressure valve A

317

318

A6_SH_EVAP_TEMP

Evaporation temperature valve A

318

319

319

320

320

321

321

322

322

323

323

324

324

325

325

326

326

327

327

328

328

329

CAREL

MODBUS

INTEGER (3)-

INTEGER/MODBUS

TAG NAME

TAG DESCRIPTION

1

5003

Unit_Status

{;Unit'ON;OFFbyALR;OFFbyNET;OFFbyBMS;OFFbyFSC;OF

FbyDIN;OFFbyKEY;;OFF_CST1;OFF_CST2;OFF_CST3;OFF_

CST4;}

2

5004

3

5005

4

5006

5

5007

6

5008

7

5009

8

5010

9

5011

10

5012

SetSpeedExhaustFan

Set Speed of exhaust fan (FAN1)

11

5013

SetSpeedSupplyFan

Set speed of supply fan (FAN2)

12

5014

AOut3 ( Valvola Acqua )

Analogic Output Y3 value

13

5015

14

5016

15

5017

16

5018

17

5019

Page 44

HP User Manual

firmware 3.1 Rev.04 IT 44/ 51

18

5020

19

5021

20

5022

100

5102

101

5103

102

5104

103

5105

104

5106

Envelope_Zone_1

Envelopeworking zone:

0=Null;1=OK;2=Max.comp.R.;3=Max.disch.P.;4=HCurr.;5

=Max.suct.P.;6=Min.comp.R.;7=LowDP;8=Min.disch.P.;9=

Min.suct.P.

105

5107

106

5108

107

5109

108

5110

Inv_PowerPlus_Device_Number

Progressive device nr. in the system

109

5111

Current_error_code_1

Inverter error code: 0: No fault;1: Overcurrent;2: Motor

overload;3: Overvoltage;4: Undervoltage;5: Drive

overT.;6: Drive underT;7: Overcurrent HW;8: Motor

overtemp.;9: Reserved;10: Cpu error;11: Param.

default;12: DC bus ripple;13: Data comms fault;14: Drive

thermistor;15: Autotune fault;16: Drive disabled;17:

Motor phase;18: Fan fault;19: Speed fault

110

5112

111

5113

112

5114

113

5115

114

5116

115

5117

116

5118

117

5119

118

5120

119

5121

120

5122

121

5123

122

5124

123

5125

124

5126

125

5127

Alarm_Code_EBM1

126

5128

Alarm_Code_EBM2

127

5129

128

5130

129

5131

130

5132

131

5133

132

5134

133

5135

134

5136

135

5137

136

5138

137

5139

138

5140

Page 45

HP User Manual

firmware 3.1 Rev.04 IT 45/ 51

139

5141

140

5142

200

5202

201

5203

Rotor_Speed_0_1000

Compressorrotorspeed 0-1000

202

5204

Rotor_Speed_rpm

Compressorrotorspeed [rpm]

203

5205

Drive_Status

Show the inverter status: 0 = Stopped 1= run 2 = alarm

204

5206

Motor_Voltage

Motor Voltage [V- Integer]

205

5207

Drive_Temp

Inverter Temperature [°C]

206

5208

DC_Bus_Voltage

DC Bus Voltage [V]

207

5209

Current_error_code_1

Inverter error code: 0: No fault;1: Overcurrent;2: Motor

overload;3: Overvoltage;4: Undervoltage;5: Drive

overT.;6: Drive underT;7: Overcurrent HW;8: Motor

overtemp.;9: Reserved;10: Cpu error;11: Param.

default;12: DC bus ripple;13: Data comms fault;14: Drive

thermistor;15: Autotune fault;16: Drive disabled;17:

Motor phase;18: Fan fault;19: Speed fault

208

5210

Refrigerant_1

Gas type - Valve A

209

5211

Circuit_Cooling_Capacity_Env_A

Actual circuit cooling capacity for EVD valve from

envelope

210

5212

I89_REGULATION_SUB_TYPE_1

regulationsubtipe

211

5213

Env_Countdown_1

Countdown of out of envelop alarm [s]

212

5214

Envelope_Zone_1

Envelopeworking zone: 0=Null; 1=OK; 2=Max.comp.R.;

3=Max.disch.P.; 4=HCurr.; 5=Max.suct.P.;

6=Min.comp.R.; 7=LowDP; 8=Min.disch.P.; 9=Min.suct.P.

213

5215

Disch_Temp_Zone_1

Discharge temperature zone: 0 = null; 1= OK; 2 =

Controlled; 3 = Limited

214

5216

215

5217

216

5218

217

5219

218

5220

219

5221

220

5222

221

5223

Motor_Type

0=Custom; 1=Siam ANB33F-400V; 2=Siam ANB42F400V;3=Siam ANB52F-400V;4=Samsung UG5T520F-400V

222

5224

223

5225

224

5226

225

5227

226

5228

227

5229

228

5230

229

5231

230

5232

300

5302

301

5303

LP_cents_EVO_high_precision

Low pressure: cents of Bar

302

5304

HP_cents_EVO_high_precision

High pressure cents of Bar

303

5305

I4_EEV_POSITION_STEPS

Position valve A

304

5306

I8_REG_STATUS

EVD Evolution OnBoard regulation status valve A

305

5307

306

5308

307

5309

Page 46

HP User Manual

firmware 3.1 Rev.04 IT 46/ 51

308

5310

309

5311

310

5312

Page 47

HP User Manual

firmware 3.1 Rev.04 IT 47/ 51

6 ALARMS

When Alarm button is blinking an alarm is active. Pressing the button you directly acces to the active alarm list.

Note: Two alarm need to be manually reset (inverter and doors micro switch), to reset them keep pressed the Alarm button, once done

the system automatically switches to the home page.

N° ALARM end DESCRIPTION

CHECK TO BE DONE

A001 Clock board error

Replace the button battery (CR2430 3V type)

A002 Extend memory error

Replace main PCB

A003 Compressor start-up failed (Check motor connection)(tent.: /

max.: )

Check compressor motor wiring (follow the electric wiring diagram

supplied with the unit)

A004 Envelope alarm Zone:1,2,3,4,5,6,7,8,9 see “Envelope Alarm

list”

Contact service dept

A005 High compressor discharging temperature

Contact service dept

A006 Low pressure difference (poor lubrication.)

Contact service dept

A007 Inverter type not compatible (only type Power+)

Contact service dept

A008 Power+ n° Device Offline

Check compressor driver power supply and wiring

A009 Power+ n° see “Inverter error list”

Contact service dept

A010 S1 sensor failure (Low pressure)

Check wiring and sensor type (SPKT0043R0 0-17,3bar)

A011 S2 sensor failure (Compressor Suction Temp.)

Check wiring and sensor type (NTC030WF00)

A012 S3 sensor failure (High pressure)

Check wiring and sensor type (SPKT00B6R0 0-44,8bar)

A013 S4 sensor failure (Compressor discharge Temp.)

Check wiring and sensor type (NTC030HTF00)

A014 (LowSH) Low overheating valve A-

Contact service dept

A015 (LowSH) Low overheating valve B-

NOT USED

A016 (LOP) Low evaporation temperature valve A-

Contact service dept

A017 (LOP) Low evaporation temperature valve B-

NOT USED

A018 (MOP) High evaporation temperature valve A-

Contact service dept

A019(MOP) High evaporation temperature valve B-

NOT USED

A020 High condensing temperature (HiTCond)

Contact service dept

A021 Low suction temperature valve A-

Contact service dept

A022 Low suction temperature valve B-

NOT USED

A023 Autotune Valve A-

Contact service dept

A024 Autotune Valve B-

NOT USED

A025 NOT USED

NOT USED

A026 NOT USED

NOT USED

A027 High Pressure Alarm Compressor 1

1) Summer mode: exhaust airflow too low

a. exhaust fan speed too low

b. dirty filters or clogged ductwork

c. air conditions over limit

2) Winter mode: supply airflow rate too low

a. supply fan speed too low

b. dirty filters or clogged ductwork

3) Freon filling too high

A028 Low Pressure Alarm Compressor 1

1) Summer mode: supply airflow too low

a. supply fan speed too low

b. dirty filters or clogged ductwork

Page 48

HP User Manual

firmware 3.1 Rev.04 IT 48/ 51

c. outside air conditions over limit

2) Winter mode: exhaust airflow too low

a. exhaust fan speed too low

b. dirty filters or clogged ductwork

c. air conditions over limit

3) Freon filling insufficient

A029 Disabled Compressor Start DP

Contact service dept

A030 Air Flow Switch (DI)

Check digital input DI4

A031 Fan Alarm (DI)

Check fan fuses or replace fans

A032 Filter Pressure Switch Supply/Return (DI)

Clean or replace air filter

A033 High Pressure Alarm Compressor 1 (DI)

Check digital input DI6

A034 Mix box alarm

Additional PCB SMD4500 failure (managing mixing box and modulating

electric pre-heater)

A035 B1 sensor failure (Exhaust temp.)

Check sensor wiring or replace it (NTC10k 25°C)

A036 B2 sensor failure (Fresh air temp.)

Check sensor wiring or replace it (NTC10k 25°C)

A037 B12 sensor failure (Air quality sensor)

Check sensor wiring or replace it (2000ppm 0-5V)

A038 NOT USED

NOT USED

A039 NOT USED

NOT USED

A040 Door Micro switch Alarm

Check digital input DI5

A041 High Pressure Prevention Function

Reduced operation mode warning.

1) Summer mode: bassa exhaust airflow too low

a. exhaust airflow too low

b. dirty filters or clogged ductwork

c. air conditions over limit

2) Winter mode: supply airflow too low

a. supply fan speed too low

b. dirty filters or clogged ductwork

c. air conditions over limit

4) Freon filling too high

A042 B8 sensor failure (Saturation Temp.)

Check sensor wiring or replace it (NTC10k 25°C)

A043 B9 sensor failure (Return Temp.)

Check sensor wiring or replace it (NTC10k 25°C)

A044 B10 sensor failure (Return humidity)

Check sensor wiring or replace it (0-100% 4-20mA)

A045 Circuit 2 Offline

Check compressor driver & main PCB Modbus connection

A046 Circuit 1 Offline

Check compressor driver & main PCB Modbus connection

A047 Circuit 1 Alarm

Alarm conditions on circuit 1 while visualizing circuit 2.

.

Select circuit 1 by keys +

A048 Circuit 2 Alarm

Alarm conditions on circuit 2 while visualizing circuit 1.

Select circuit 2 by keys +

A049 B3 sensor failure (Supply temp.)

Check sensor wiring or replace it (NTC10k 25°C)

A050 Electric Heating Thermal protection

Insufficient airflow rate

Page 49

HP User Manual

firmware 3.1 Rev.04 IT 49/ 51

“ENVELOPE ERROR”

1: Inside envelope

2: High compression ratio

3: High condensing pressure

4: High current

5: High evaporation pressure

6: Low compression ratio

7: Low pressure difference

8: Low condensing pressure

9: Low evaporating pressure

“ENVELOPE ERROR”

1: Over current

2: Motor over current

3: High voltage

4: Low voltage

5: High temperature

6: Low temperature

7: HW overcurrent

8: Motor High temperature

9: Drive fault

10: Cpu error

11: Default parameters

12: DC bus ondulation

13: timeout com.ser.

14: Thermistor error

15: Autotuning error

16: Drive disabled

17: Motor missing phase

18: Fan fault

19: Motor stalemate

20: PFC module fault

21: Alarm code 21

22: PFC low voltage

23: STO reading error

24: STO reading error

25: Alarm code 25

26: Alarm code 26

27: Alarm code 27

28: Alarm code 28

29: Alarm code 29

30: Alarm code 30

…. 99: Unexpected inverter stop

Page 50

HP User Manual

firmware 3.1 Rev.04 IT 50/ 51

HPR-H-S

14

20

26

50

92

144

205

k x Fan

N° Fan 1 1 1 1 1 2 2

RH25C

60

60

RH31C 95 95

GR35C

121

121 121

GR40C 308 154

GR45C

197 394

197

Air flow m³/h (V) MAX HPR-H

1200

2100

2900

5700

9500

13500

19000

HPR-H

Air flow m³/h (V) MAX HPS

1200

2100

2600

4800

7700

11400

13200

HPS

Air flow m³/h (V) Min HPR-H

360

630

870

1710

2850

4050

5700

HPR-H

Air flow m³/h (V) Min HPS

360

630

780

1440

2310

3420

3960

HPS

Set DP (Pa) MAX HPR-H

400

489

574

2219

2325

1921

2325

DP (Pa)= (V/k)²

Set DP (Pa) MAX HPS

400

489

462

1574

1528

1370

1122

Set DP (Pa) Min HPR-H

36

44

52

200

209

173

209

DP (Pa)= (V/k)²

Set DP (Pa) Min HPS

36

44

42

142

137

123

101

FSS Pressure sensor range (Pa)

1000

1000

1000

5000

5000

5000

5000

Signal % 0-10V MAX HPR-H

40

49

57

44

47

38

47

%= (Set/FSS)*100

Signal % 0-10V MAX HPS

40

49

46

31

31

27

22

Signal % 0-10V Min HPR-H

10.0

10.0

10.0

10.0

10.0

10.0

10.0

All

Signal % 0-10V Min HPS

10.0

10.0

10.0

10.0

10.0

10.0

10.0

Set= 10% (1.0V)

Signal % 0 10 =

()

× 100

Page 51

HP User Manual

firmware 3.1 Rev.04 IT 51/ 51

NOTE

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

Loading...

Loading...