LITTELFUSE V9MLA0805LWT, V9MLA0805LWA, V9MLA0805LWH, V9MLA0805LT, V9MLA0805LH Datasheet

...

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

140

www.littelfuse.com

The ML Series family of Transient Voltage Surge Suppression devices is

based on the Littelfuse Multilayer fabrication technology. These components are designed to suppress a variety of transient events, including

those specified in IEC 61000-4-2 or other standards used for Electromagnetic

Compliance (EMC). The ML Series is typically applied to protect integrated

circuits and other components at the circuit board level.

The wide operating voltage and energy range make the ML Series suitable for numerous applications on power supply, control and signal lines.

The ML Series is manufactured from semiconducting ceramics, and is

supplied in a leadless, surface mount package.The ML Series is compatible with modern reflow and wave soldering procedures.

It can operate over a wider temperature range than zener diodes, and

has a much smaller footprint than plastic-housed components.

Littelfuse Inc. manufactures other Multilayer Series products. See the

MLE Series data sheet for ESD applications, MHS Series data sheet for

high-speed ESD applications, the MLN for multiline protection and the

AUML Series for automotive applications.

Features

• Leadless 0402, 0603, 0805, 1206 and 1210 Chip Sizes

• Multilayer Ceramic Construction Technology

•-55oC to +125oC Operating Temperature Range

• Operating Voltage Range V

M(DC)

= 5.5V to 120V

• Rated for Surge Current (8 x 20µs)

• Rated for Energy (10 x 1000µs)

• Inherent Bi-directional Clamping

• No Plastic or Epoxy Packaging Assures Better than 94V-0

Flammability Rating

• Standard Low Capacitance Types Available

Applications

• Suppression of Inductive Switching or Other Transient Events Such

as EFT and Surge Voltage at the Circuit Board Level

• ESD Protection for Components Sensitive to IEC 61000-4-2,

MIL-STD-883C Method 3015.7, and Other Industry Specifications

(See Also the MLE or MLN Series)

• Provides On-Board Transient Voltage Protection for ICs and Transistors

• Used to Help Achieve Electromagnetic Compliance of End Products

• Replace Larger Surface Mount TVS Zeners in

Many Applications

Absolute Maximum Ratings For ratings of individual members of a series, see Device Ratings and Specifications table.

Continuous:

Steady State Applied Voltage:

DC Voltage Range (V

M(DC)

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 to 120 V

AC Voltage Range (V

M(AC)RMS

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 to 107 V

Transient:

Non-Repetitive Surge Current, 8/20µs Waveform, (ITM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 500 A

Non-Repetitive Surge Energy, 10/1000µs Waveform, (WTM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 to 2.5 J

Operating Ambient Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55 to + 125

O

C

Storage Temperature Range (T

STG

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55 to + 150

O

C

Temperature Coefficient (αV) of Clamping Voltage (VC) at Specified Test Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <0.01 %/OC

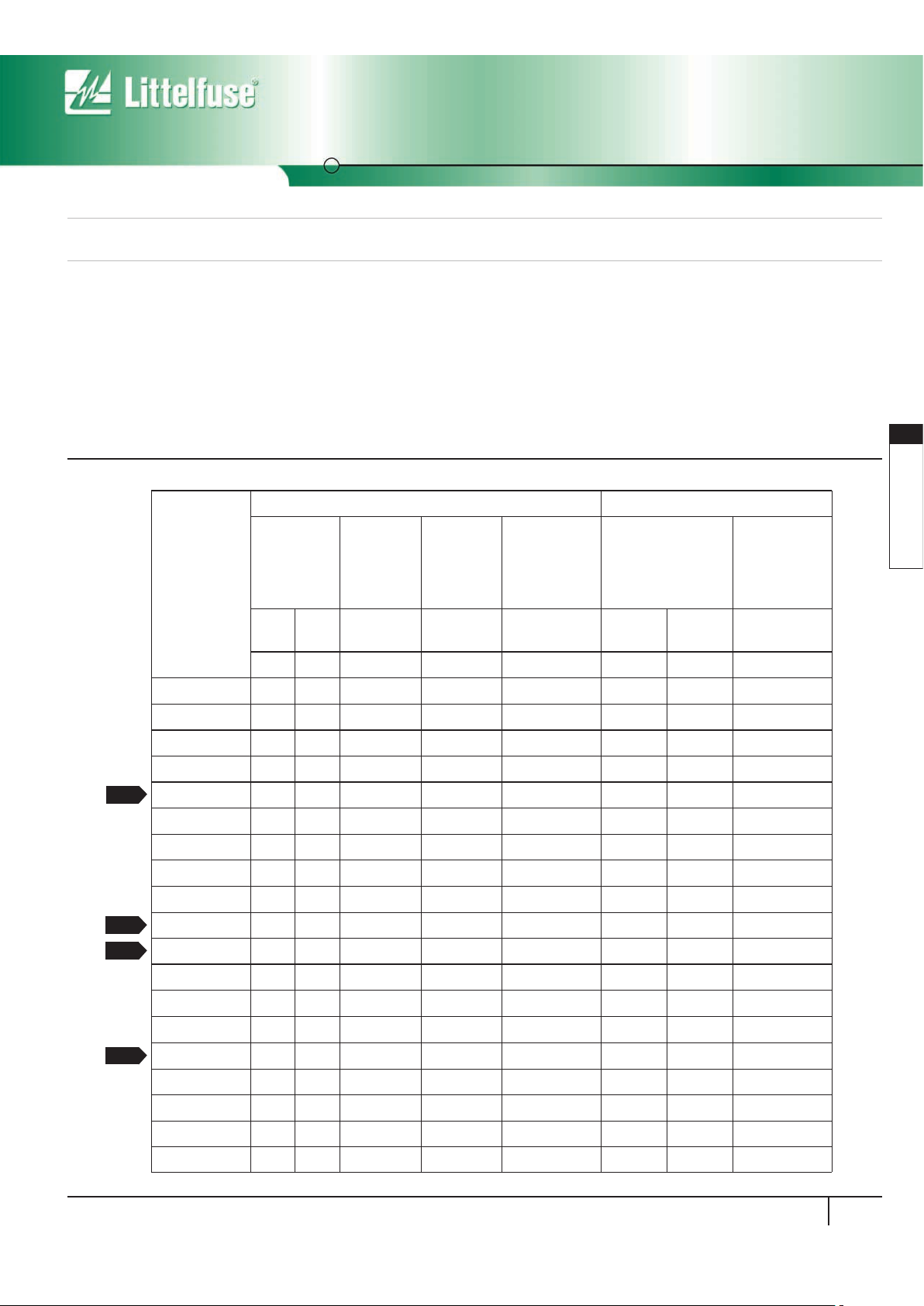

Device Ratings and Specifications

ML SERIES UNITS

PA RT

NUMBER

MAXIMUM RATINGS (125

o

C) SPECIFICATIONS (25oC)

MAXIMUM

CONTINUOUS

WORKING

VO LTAGE

MAXIMUM

NON-

REPETITIVE

SURGE

CURRENT

(8/20µs)

MAXIMUM

NON-

REPETITIVE

SURGE

ENERGY

(10/1000µs)

MAXIMUM

CLAMPING

VO LTAG E AT

10A

(OR AS NOTED)

(8/20µs)

NOMINAL VOLTAGE

AT 1mA DC TEST

CURRENT

TYPICAL

CAPACITANCE

AT f = 1MHz

V

M(DC)VM(AC)

I

TM

W

TM

V

C

V

N(DC)

MIN

V

N(DC)

MAX C

(V) (V) (A) (J) (V) (V) (V) (pF)

V3.5MLA0603 3.5 2.5 30 0.1 10 at 2A 3.7 7.0 1100

V3.5MLA0805 3.5 2.5 120 0.3 10 at 5A 3.7 7.0 2200

V3.5MLA0805L 3.5 2.5 40 0.1 10 at 2A 3.7 7.0 1200

V3.5MLA1206 3.5 2.5 100 0.3 14 3.7 7.0 6000

V5.5MLA0402 5.5 4.0 20 0.050 15.5 at 1A 7.1 9.3 220

V9MLA0402 9 6.5 20 0.050 22 at 1A 11 14 120

V9MLA0402L 9 6.5 4 0.020 25 at 1A 11 14 33

V14MLA0402 14 10 20 0.050 30 at 1A 15.9 20.3 70

V5.5MLA0603 5.5 4.0 30 0.1 15.5 at 2A 7.1 9.3 660

V5.5MLA0805 5.5 4.0 120 0.3 15.5 at 5A 7.1 9.3 1600

V5.5MLA0805L 5.5 4.0 40 0.1 15.5 at 2A 7.1 9.3 860

V5.5MLA1206 5.5 4.0 150 0.4 15.5 7.1 9.3 4500

V9MLA0603 9.0 6.5 30 0.1 23 at 2A 11.0 16.0 420

V9MLA0805L 9.0 6.5 40 0.1 20 at 2A 11 14 450

V12MLA0805L 12 9.0 40 0.1 25 at 2A 14 18.5 350

V14MLA0603 14 10 30 0.1 30 at 2A 15.9 20.3 150

V14MLA0805 14 10 120 0.3 30 at 5A 15.9 20.3 480

V14MLA0805L 14 10 40 0.1 30 at 2A 15.9 20.3 270

V14MLA1206 14 10 150 0.4 30 15.9 20.3 1600

NEW

NEW

NEW

NEW

ML Varistor Series

Surface Mount Varistors

Multilayer Transient Voltage Surge Suppressors

141

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

142

www.littelfuse.com

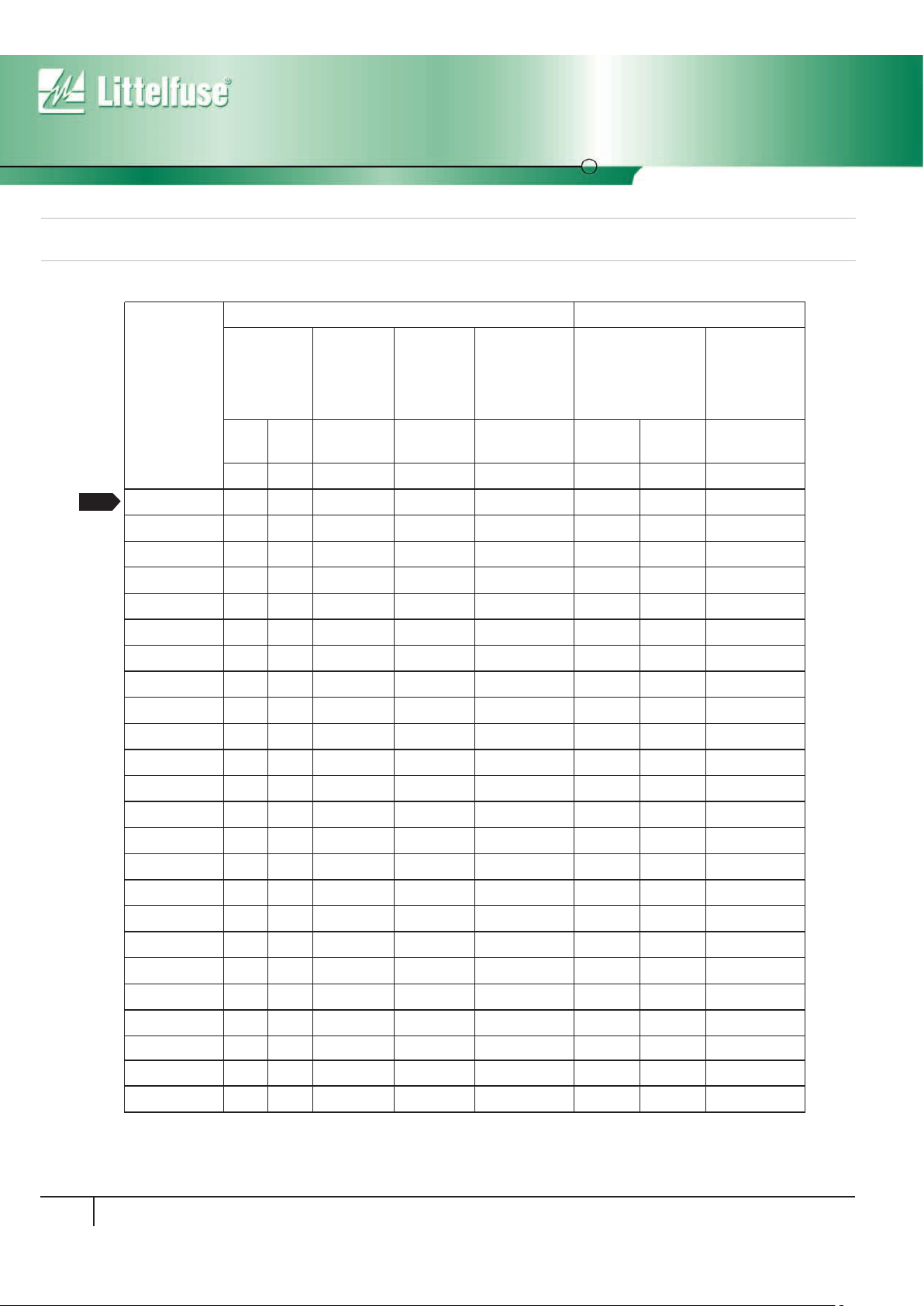

Device Ratings and Specifications

(Continued)

V18MLA0603 18 14 30 0.1 40 at 2A 22 28.0 125

V18MLA0402 18 14 20 0.050 40 at 1A 22 28.0 40

V18MLA0805 18 14 120 0.3 40 at 5A 22 28.0 450

V18MLA0805L 18 14 40 0.1 40 at 2A 22 28.0 250

V18MLA1206 18 14 150 0.4 40 22 28.0 1100

V18MLA1210 18 14 500 2.5 40 22 28.0 1250

V26MLA0603 26 20 30 0.1 58 at 2A 31 38 90

V26MLA0805 26 20 100 0.3 58 at 5A 29.5 38.5 190

V26MLA0805L 26 20 40 0.1 58 at 2A 29.5 38.5 115

V26MLA1206 26 20 150 0.6 56 29.5 38.5 900

V26MLA1210 26 20 300 1.2 54 29.5 38.5 1000

V30MLA0603 30 25 30 0.1 65 at 2A 37 46 75

V30MLA0805L 30 25 30 0.1 65 at 2A 37 46 80

V30MLA1210 30 25 280 1.2 62 35 43 1575

V30MLA1210L 30 25 220 0.9 62 35 43 1530

V33MLA1206 33 26 180 0.8 72 38 49 550

V42MLA1206 42 30 180 0.8 86 46 60 550

V48MLA1210 48 40 250 1.2 100 54.5 66.5 450

V48MLA1210L 48 40 220 0.9 100 54.5 66.5 430

V56MLA1206 56 40 180 1.0 110 61 77 150

V60MLA1210 60 50 250 1.5 120 67 83 375

V68MLA1206 68 50 180 1.0 130 76 90 150

V85MLA1210 85 67 250 2.5 160 95 115 225

V120MLA1210 120 107 125 2.0 230 135 165 65

NOTES:

1.

2.

3.

PA RT

NUMBER

MAXIMUM RATINGS (125

o

C) SPECIFICATIONS (25oC)

MAXIMUM

CONTINUOUS

WORKING

VO LTAGE

MAXIMUM

NON-

REPETITIVE

SURGE

CURRENT

(8/20µs)

MAXIMUM

NON-

REPETITIVE

SURGE

ENERGY

(10/1000µs)

MAXIMUM

CLAMPING

VO LTAG E AT

10A

(OR AS NOTED)

(8/20µs)

NOMINAL VOLTAGE

AT 1mA DC TEST

CURRENT

TYPICAL

CAPACITANCE

AT f = 1MHz

V

M(DC)VM(AC)

I

TM

W

TM

V

C

V

N(DC)

MIN

V

N(DC)

MAX C

(V) (V) (A) (J) (V) (V) (V) (pF)

L suffix is a low capacitance and energy version; Contact your Littelfuse Sales Representative for custom capacitance requirements.

Typical leakage at 25 C<25µA, maximum leakage 50µA at V ; for 0402 size, typical leakage <5µA, maximum leakage 10µA at V

o

M(DC)

M(DC).

Average power dissipation of transients for 0402, 0603, 0805, 1206 and 1210 sizes not to exceed 0.03W, 0.05W, 0.1W, 0.1W and 0.15W respectively.

NEW

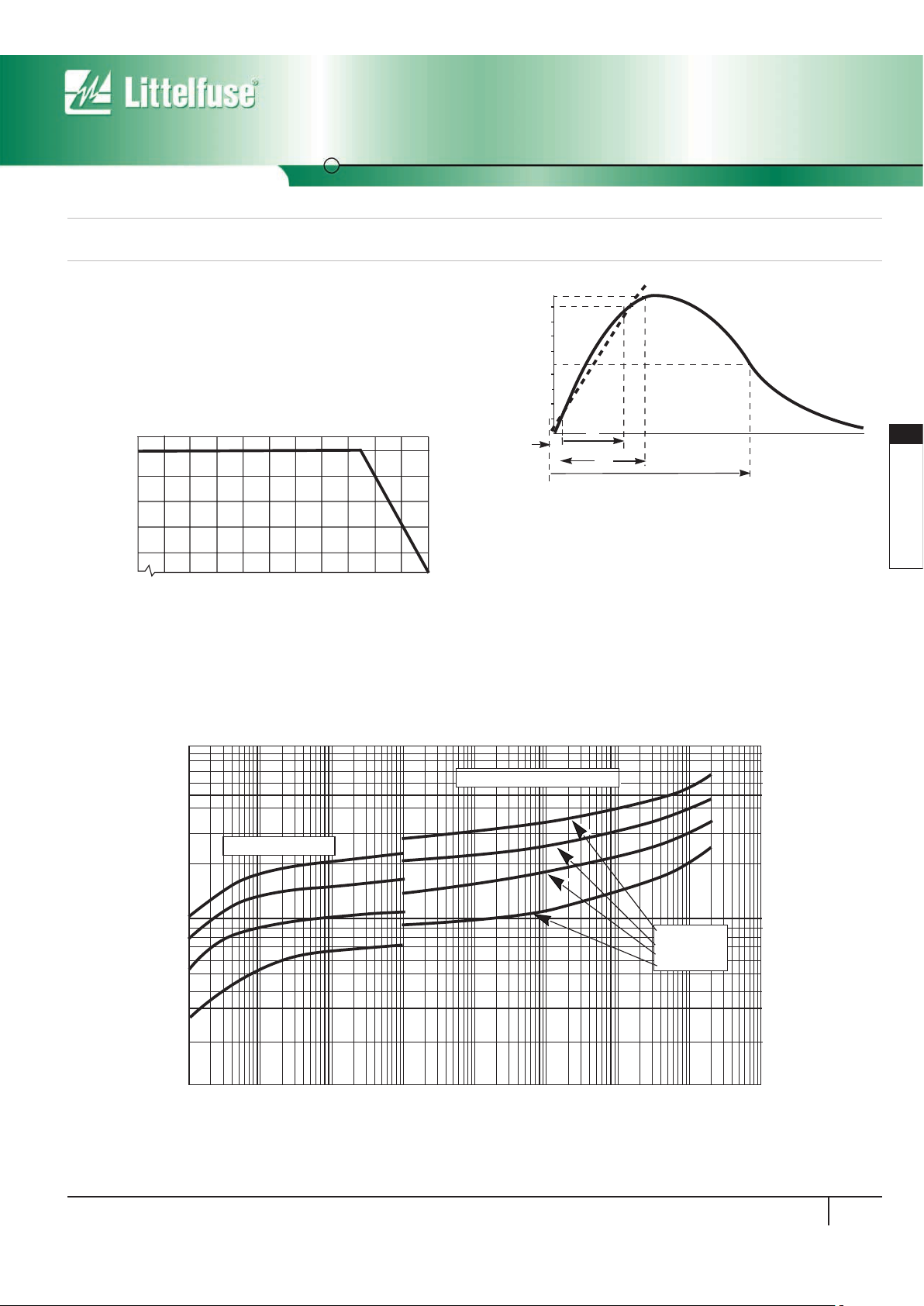

Temperature De-rating

When transients occur in rapid succession, the average power dissipation is the energy (watt-seconds) per pulse times the number of pulses

per second. The power so developed must be within the specifications

shown on the Device Ratings and Specifications table for the specific

device. For applications exceeding 125oC ambient temperature, the peak

surge current and energy ratings must be derated as shown in Figure 1.

100

80

60

40

20

0

-55 50 60 70 80 90 100 110 120 130 140 150

PERCENT OF RATED VALUE

AMBIENT TEMPERATURE (oC)

FIGURE 1. PEAK CURRENT AND ENERGY

DERATING CURVE

t

1

t

2

100

50

0

O

1

TIME

PERCENT OF PEAK VALUE

O1 = VIRTUAL ORIGIN OF WAVE

t

1

= VIRTUAL FRONT TIME = 1.25 x t

(IMPULSE DURATION)

t = TIME FROM 10% TO 90% OF PEAK

t

2

= VIRTUAL TIME TO HALF VALUE

EXAMPLE:

FOR AN 8/20µs CURRENT WAVEFORM

8µs = t

1

= VIRTUAL FRONT TIME

20µs = t

2

= VIRTUAL TIME TO

HALF VALUE

FIGURE 2. PEAK PULSE CURRENT TEST WAVEFORM

FOR CLAMPING VOLTAGE

t

FIGURE 3. LIMIT V-I CHARACTERISTIC FOR V5.5MLA0402 TO V18MLA0402

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

MAXIMUM LEAKAGE

10µA 100 µA 1mA 10mA 100mA 1A 10A 100A

MAXIMUM CLAMPING VOLTAGE

V18MLA0402

V14MLA0402

V09MLA0402

V5.5MLA0402

ML Varistor Series

Surface Mount Varistors

Multilayer Transient Voltage Surge Suppressors

143

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

144

www.littelfuse.com

Maximum Transient V-I Characteristic Curves

FIGURE 5. LIMIT V-I CHARACTERISTIC FOR V3.5MLA0603 TO V30MLA0603

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

V3.5MLA0603

MAXIMUM LEAKAGE

MAXIMUM CLAMPING VOLTAGE

V5.5MLA0603

V9MLA0603

10µA 100µA 1mA 10mA 100mA 1A 10A 100A

V14MLA0603

V18MLA0603

V26MLA0603

V30MLA0603

FIGURE 6. LIMIT V-I CHARACTERISTIC FOR V3.5MLA0805L TO V30MLA0805L

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

V3.5MLA0805L

MAXIMUM LEAKAGE

MAXIMUM CLAMPING VOLTAGE

V5.5MLA

0805L

V9MLA0805L

10µA 100µA 1mA 10mA 100mA 1A 10A 100A

V14MLA0805L

V18MLA0805L

V26MLA0805L

V30MLA0805L

FIGURE 4. LIMIT V-I CHARACTERISTIC FOR V9MLA0402L

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

10µA 100µ A 1mA 10mA 100mA 1A 10A

MAXIMUM LEAKAGE

MAXIMUM CLAMPING VOLTAGE

V9MLA0402L

Maximum Transient V-I Characteristic Curves (Continued)

FIGURE 7. LIMIT V-I CHARACTERISTIC FOR V3.5MLA0805 TO V26MLA0805

1mA

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

10µA 100µA 10mA 100mA 1A 10A 100A 1000A

V3.5MLA0805

MAXIMUM CLAMPING VOLTAGE

MAXIMUM LEAKAGE

V14MLA0805

V5.5MLA0805

V18MLA0805

V26MLA0805

FIGURE 9. LIMIT V-I CHARACTERISTIC FOR V18MLA1210 TO V120MLA1210

1mA

100

10

1µA

CURRENT (A)

Varistor Voltage (V)

10µA 100µA 10mA 100mA 1A 10A 100A 1000A

MAXIMUM CLAMPING VOLTAGE

MAXIMUM LEAKAGE

1000

1

V60MLA1210

V85MLA1210

V120MLA1210

V48MLA1210, V48MLA1210L

V30MLA1210, V30MLA1210L

V26MLA1210

V18MLA1210

FIGURE 8. LIMIT V-I CHARACTERISTIC FOR V3.5MLA1206 TO V68MLA1206

1mA1µA

CURRENT (A)

Varistor Voltage (V)

10mA 1000A100mA 1A 10A 100A

MAXIMUM CLAMP

VOLTAG E

10µA 100µA

MAXIMUM

LEAKAGE

V56MLA1206

V42MLA1206

V26MLA1206

V33MLA1206

V18MLA1206

V68MLA1206

V3.5MLA1206

V5.5MLA1206

V14MLA1206

100

10

1

1000

ML Varistor Series

Surface Mount Varistors

Multilayer Transient Voltage Surge Suppressors

145

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

146

www.littelfuse.com

Device Characteristics

At low current levels, the V-I curve of the multilayer transient voltage

suppressor approaches a linear (ohmic) relationship and shows a

temperature dependent effect (Figure 10). At or below the maximum

working voltage, the suppressor is in a high resistance mode (approaching 106Ω at its maximum rated working voltage). Leakage currents at

maximum rated voltage are below 50µA, typically 25µA; for 0402 size

below 10µA, typically 5µA.

Speed of Response

The Multilayer Suppressor is a leadless device. Its response time is not

limited by the parasitic lead inductances found in other surface mount

packages. The response time of the Zinc Oxide dielectric material is less

than 1 nanosecond and the ML can clamp very fast dV/dT events such

as ESD. Additionally, in “real world” applications, the associated circuit

wiring is often the greatest factor effecting speed of response. Therefore,

transient suppressor placement within a circuit can be considered

important in certain instances.

100%

1E

-9

1E

-8

SUPPRESSOR CURRENT (ADC)

10%

1E

-7

1E

-6

1E

-5

1E

-4

1E

-3

1E

-2

25 50 75 100

125oC

SUPPRESSOR VOLTAGE IN PERCENT OF

V

NOM

VALUE AT 25

o

C (%)

FIGURE 10. TYPICAL TEMPERATURE DEPENDANCE OF THE CHARACTERISTIC

CURVE IN THE LEAKAGE REGION

o

oo

o

GRAINS

DEPLETION

FIRED CERAMIC

DIELECTRIC

REGION

METAL

ELECTRODES

DEPLETION

REGION

METAL END

TERMINATION

FIGURE 11. MULTILAYER INTERNAL CONSTRUCTION

Energy Absorption/Peak Current Capability

Energy dissipated within the ML is calculated by multiplying the clamping

voltage, transient current and transient duration. An important advantage

of the multilayer is its interdigitated electrode construction within the mass

of dielectric material. This results in excellent current distribution and the

peak temperature per energy absorbed is very low.The matrix of semiconducting grains combine to absorb and distribute transient energy (heat)

(Figure 11). This dramatically reduces peak temperature; thermal stresses

and enhances device reliability.

As a measure of the device capability in energy and peak current

handling, the V26MLA1206A part was tested with multiple pulses at its

peak current rating (150A, 8/20µs). At the end of the test, 10,000 pulses

later, the device voltage characteristics are still well within specification

(Figure 13).

100

10

20

V26MLA1206

40 60 80 100 120 140

TEMPERATURE (

o

C)

CLAMPING VO LTAGE (V)

V5.5MLA1206

0-20-40-60

FIGURE 12. CLAMPING VOLTAGE OVER TEMPERATURE

(V

C

AT 10A)

100

10

0

V26MLA1206

2000 4000 6000 8000 10000 12000

NUMBER OF PULSES

VO LTAGE

FIGURE 13. REPETITIVE PULSE CAPABILITY

PEAK CURRENT = 150A

8/20µs DURATION, 30s BETWEEN PULSES

Soldering Recommendations

The principal techniques used for the soldering of components in surface

mount technology are Infrared (IR) re-flow, vapour phase re-flow and wave

soldering. Typical profiles are shown in Figures 14, 15 and 16. When wave

soldering, the ML suppressor is attached to the circuit board by means of an

adhesive. The assembly is then placed on a conveyor and run through the

soldering process to contact the wave. With IR and vapour phase reflow; the

device is placed in a solder paste on the substrate. As the solder paste is

heated, it re-flows and solders the unit to the board.

The recommended solder for the ML suppressor is a 62/36/2 (Sn/Pb/Ag),

60/40 (Sn/Pb) or 63/37 (Sn/Pb). Littelfuse also recommends an RMA

solder flux.

Wave soldering is the most strenuous of the processes. To avoid the

possibility of generating stresses due to thermal shock, a preheat stage

in the soldering process is recommended, and the peak temperature of

the solder process should be rigidly controlled. For 0402 size devices, IR

re-flow is recommended.

When using a reflow process, care should be taken to ensure that the ML

chip is not subjected to a thermal gradient steeper than 4 degrees per

second; the ideal gradient being 2 degrees per second. During the

soldering process, preheating to within 100 degrees of the solder’s peak

temperature is essential to minimize thermal shock. Examples of the

soldering conditions for the ML suppressor are given in the tables below.

Once the soldering process has been completed, it is still necessary

to ensure that any further thermal shocks are avoided. One possible

cause of thermal shock is hot printed circuit boards being removed

from the solder process and subjected to cleaning solvents at room

temperature. The boards must be allowed to cool gradually to less than

50oC before cleaning.

Termination Options

Littelfuse offers three types of electrode termination finish for the

Multilayer product series:

1. Silver/Platinum (standard, not available for 0402)

2. Silver/Palladium (optional)

(The ordering information section describes how to designate them.)

FIGURE 14. REFLOW SOLDER PROFILE

FIGURE 15. WAVE SOLDER PROFILE

FIGURE 16. VAPOR PHASE SOLDER PROFILE

TEMPERATURE (

o

C)

TIME (MINUTES)

300

250

200

150

100

50

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

MAXIMUM WAVE 260oC

SECOND PREHEAT

FIRST PREHEAT

TEMPERATURE (

o

C)

TIME (MINUTES)

250

200

150

100

50

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

RAMP RATE

PREHEAT ZONE

>50

o

C/s

MAXIMUM

TEMPERATURE 222

o

C

40-80

SECONDS

ABOVE 183

o

C

TEMPERATURE (

o

C)

TIME (MINUTES)

250

200

150

100

50

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

MAXIMUM

PREHEAT DWELL

PREHEAT ZONE

TEMPERATURE 222

o

C

RAMP RATE

<2

o

C/s

40-80

SECONDS

ABOVE 183

o

C

ML Varistor Series

Surface Mount Varistors

Multilayer Transient Voltage Surge Suppressors

147

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

3. Nickel Barrier (optional for 0402-1210 package size)

(The ordering information section describes how to designate them.)

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

148

www.littelfuse.com

Recommended Pad Outline

C

B

A

NOTE: Avoid metal runs in this area.

NOTE

DIMENSION

PAD SIZE

1210

SIZE DEVICE

1206

SIZE DEVICE

0805

SIZE DEVICE

0603

SIZE DEVICE

IN MM IN MM IN MM IN MM

A 0.160 4.06 0.160 4.06 0.120 3.05 0.100 2.54

B 0.100 2.54 0.065 1.65 0.050 1.27 0.030 0.76

C 0.040 1.02 0.040 1.02 0.040 1.02 0.035 0.89

TABLE 1: PAD LAYOUT DIMENSIONS

0402

SIZE DEVICE

IN MM

0.067 1.70

0.020 0.51

0.024 0.61

Ordering Information

VXXML TYPES

E

L

W

D

Mechanical Dimensions

V 18 1206

PACKING OPTIONS

T: 13in (330mm) Diameter Reel

H: 7in (178mm) Diameter Reel (Note)

A: Bulk Pack

DEVICE SIZE:

i.e 120 mil x 60 mil

DEVICE FAMILY

Littelfuse TVSS Device

X

MAXIMUM DC

WORKING VOLTAGE

MLA X X

CAPACITANCE OPTION

No Letter:Standard

L: Low Capacitance Version

END TERMINATION OPTION

No Letter: Ag/Pt (Standard)

W: Ag/Pd

MULTILAYER SERIES

DESIGNATOR

(3MM X 1.5MM)

N: Nickel Barrier (0402 -1210). For 0402 package size,

Nickel Barrier termination is subject to availibility.

Please contact a Littelfuse sales representative.

DIMENSION

CHIP SIZE

1210 1206 0805 0603

IN MM IN MM IN MM IN MM

D Max. 0.113 2.87 0.071 1.80 0.043 1.10 0.035 0.90

E 0.02 ±0.01 0.50 ±0.25 0.02 ±0.01 0.50 ±0.25 0.01 to 0.029 0.50 to 0.25 0.015 ±0.008 0.4 ±0.2

L 0.125 ±0.012 3.20 ±0.30 0.125 ±0.012 3.20 ±0.30 0.079 ±0.008 2.01 ±0.20 0.063 ±0.006 1.6 ±0.15

W 0.10 ±0.012 2.54 ±0.30 0.06 ±0.011 1.60 ±0.28 0.049 ±0.008 1.25 ±0.20 0.032 ±0.06 0.8 ±0.15

0402

IN MM

0.024 0.61

0.010 ±0.006 0.25 ±0.15

0.039 ±0.004 1.0 ±0.1

0.020 ±0.004 0.5 ±0.1

Standard Shipping Quantities

DEVICE SIZE “13” INCH REEL (“T” OPTION) “7” INCH REEL (“H” OPTION) BULK PACK (“A” OPTION)

1210 8,000 2,500 2500

1206 10,000 2,500 2500

0805 10,000 2,500 2500

0603 10,000 2,500 2500

0402 N/A 10,000 N/A

ML Varistor Series

Surface Mount Varistors

Multilayer Transient Voltage Surge Suppressors

149

www.littelfuse.com

3

SURFACE MOUNT

VARISTORS

Multilayer Transient Voltage Surge Suppressors

ML Varistor Series

Surface Mount Varistors

150

www.littelfuse.com

Tape and Reel Specifications

• Conforms to EIA - 481-1, Revision A

• Can be supplied to IEC Publication 286 - 3

SYMBOL DESCRIPTION

DIMENSIONS IN MILLIMETERS

A

0

Width of Cavity Dependent on Chip Size to Minimize Rotation.

B

0

Length of Cavity Dependent on Chip Size to Minimize Rotation.

K

0

Depth of Cavity Dependent on Chip Size to Minimize Rotation.

W Width of Tape 8 ±0.2

F Distance Between Drive Hole Centers and Cavity Centers 3.5 ±0.05

E Distance Between Drive Hole Centers and Tape Edge 1.75 ±0.1

P

1

Distance Between Cavity Centers 4 ±0.1

P

2

Axial Drive Distance Between Drive Hole Centers & Cavity Centers 2 ±0.1

P

0

Axial Drive Distance Between Drive Hole Centers 4 ±0.1

D

0

Drive Hole Diameter 1.55 ±0.05

D

1

Diameter of Cavity Piercing 1.05 ±0.05

T

1

0.1 Max

Top Tape Thickness

0402 Size 0603, 0805, 1206 & 1210 Sizes

2±0.05

N/A

K

0

t

1

D

0

P

0

D

1

P

1

A

0

P

2

B

0

F

E

W

PLASTIC CARRIER TAPE

EMBOSSMENT

TOP TAPE

8mm

NOMINAL

PRODUCT

IDENTIFYING

LABEL

178mm

OR 330mm

DIA. REEL

EMBOSSED PAPER (0402 SIZE ONLY)

Loading...

Loading...