Page 1

USBR Series

POLYFUSE® Resettable PTCs

Radial Leaded > USBR Series

Description

t5IF64#34FSJFTSBEJBMMFBEFEEFWJDFJTEFTJHOFEUP

provide overcurrent protection for USB applications

where space is not a concern.

Features

Agency Approvals

AGENCY AGENCY FILE NUMBER

E183209

R50119318

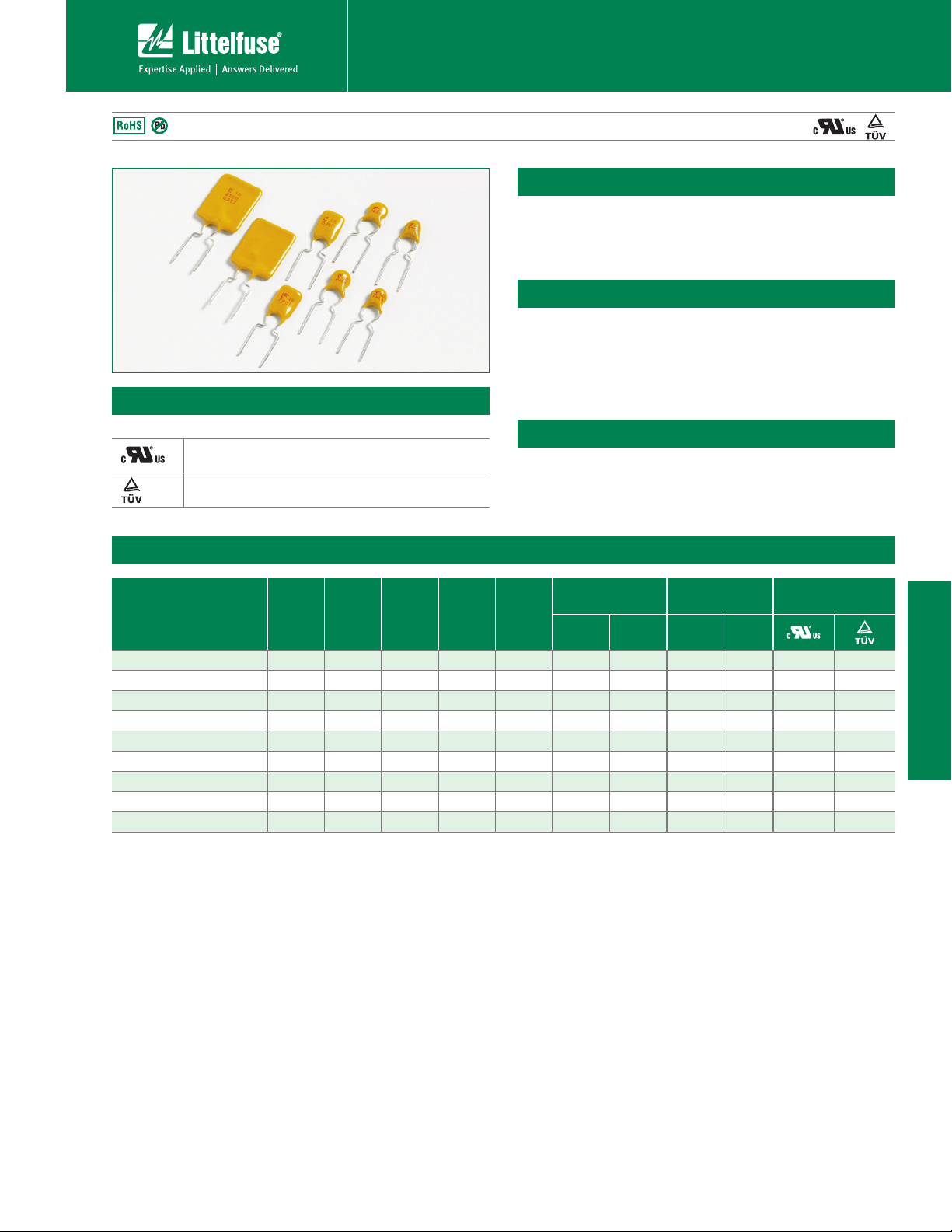

Electrical Characteristics

I

Part Number

hold

(A)

06R075B 0.75 1.30 6 40 0.3 8.00 0.4 0.100 0.230 XX

06R120B 1.20 2.00 6 40 0.6 8.00 0.5 0.065 0.140 XX

06R155B 1.55 2.70 6 40 0.6 7.75 2.2 0.040 0.100 XX

16R090B 0.90 1.80 16 40 0.6 8.00 1.2 0.070 0.180 XX

16R110B 1.10 2.20 16 40 0.7 8.00 2.3 0.050 0.140 XX

16R135B 1.35 2.70 16 40 0.8 8.00 4.5 0.040 0.120 XX

16R160B 1.60 3.20 16 40 0.9 8.00 9.0 0.030 0.110 XX

16R185B 1.85 3.70 16 40 1.0 8.00 10.0 0.030 0.090 XX

16R250B 2.50 5.00 16 40 1.2 8.00 40.0 0.020 0.060 XX

I

= Hold current: maximum current device will pass without tripping in 20°C still air.

hold

= Trip current: minimum current at which the device will trip in 20°C still air.

I

trip

= Maximum voltage device can withstand without damage at rated current (I max)

V

max

= Maximum fault current device can withstand without damage at rated voltage (V

I

max

= Power dissipated from device when in the tripped state at 20°C still air.

P

d

I

(A)

V

trip

max

(Vdc)

I

(A)

max

t3P)4DPNQMJBOUBOE

lead–free

t'BTUUJNFoUPoUSJQ

t"TIPSUDJSDVJUSBUJOH

t0QFSBUJOHWPMUBHFTPG

6-16V

t.FFUTBMM64#QSPUFDUJPO

requirements

Applications

t$PNQVUFSTQFSJQIFSBMT

t"OZ64#BQQMJDBUJPO

P

max.

(W)

)

max

Maximum Time

d

R

= Minimum resistance of device in initial (un-soldered) state.

min

= Typical resistance of device in initial (un-soldered) state.

R

typ

= Maximum resistance of device at 20°C measured one hour after tripping or reflow

R

1max

Caution: Operation beyond the specified rating may result in damage and possible arcing

and flame.

To Trip

Current

(A)

soldering of 260°C for 20 sec.

Time

(Sec.)

Resistance

R

min

(Ω)

R

1max

(Ω)

Agency

Approvals

USBR Series

© 2010 Littelfuse, Inc

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/USBR.html for current information.

63

Revised: July 12, 2010

USBR Series

Page 2

POLYFUSE® Resettable PTCs

Radial Leaded > USBR Series

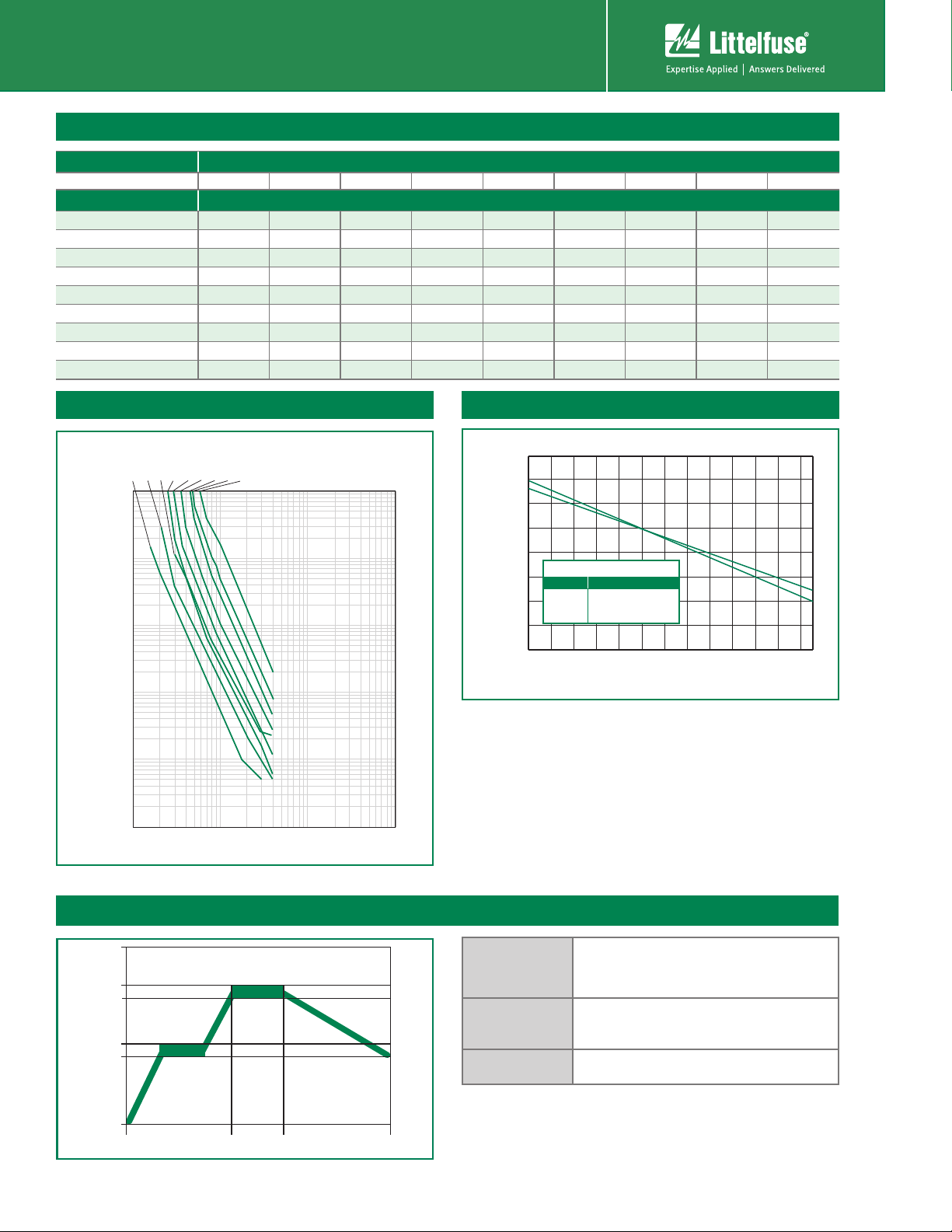

Temperature Rerating

Ambient Operation Temperature

-40°C -20°C 0°C 23°C 40°C 50°C 60°C 70°C 85°C

Part Number Hold Current (A)

06R075B 1.05 0.95 0.85 0.75 0.65 0.60 0.55 0.50 0.43

06R120B 1.69 1.52 1.36 1.20 1.04 0.96 0.88 0.80 0.68

06R155B 2.17 1.96 1.75 1.55 1.34 1.24 1.13 1.03 0.88

16R090B 1.31 1.17 1.04 0.90 0.75 0.69 0.61 0.55 0.47

16R110B 1.60 1.43 1.27 1.10 1.00 0.92 0.75 0.67 0.57

16R135B 1.96 1.76 1.55 1.35 1.12 1.04 0.92 0.82 0.70

16R160B 2.32 2.08 1.84 1.60 1.33 1.23 1.09 0.98 0.83

16R185B 2.68 2.41 2.13 1.85 1.54 1.42 1.26 1.13 0.96

16R250B 3.63 3.25 2.88 2.50 2.08 1.93 1.70 1.53 1.30

Average Time Current Curves

0.75A

1.20A

1.55A

0.90A

1.10A

1.35A

1.60A

100

10

1

0.1

Time in Seconds

0.01

0.001

1 10 100 1000

1.85A

Current in Amperes

2.50A

USBR

Temperature Rerating Curve

170%

B

150%

A

130%

110 %

90%

70%

50%

Percentage of Rated Current

30%

10%

The average time current curves and Temperature Rerating curve performance is affected

by a number or variables, and these curves provided as guidance only. Customer must

verify the performance in their application.

Line/Part Number:

AB

16R090B

06R075B

16R110B

06R120B

16R135B

06R155B

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 85

16R160B

16R185B

16R250B

Temperature (°C)

A

B

Soldering Parameters

260

220

Preheating

0

60 min.

Temperature (°C)

USBR Series

190

160

Soldering Cooling

5 max.

Time(s)

Pre-Heating

Zone

Soldering Zone

Cooling Zone Cooling by natural convection in air.

64

Revised: July 12, 2010

Refer to the condition recommended by the

flux manufacturer. Max. ramping rate should

not exceed 4°C/Sec.

Max. solder temperature should not exceed

260°C

© 2010 Littelfuse, Inc.

Please refer to www.littelfuse.com/series/USBR.html for current information.

Specifications are subject to change without notice.

Page 3

POLYFUSE® Resettable PTCs

Radial Leaded > USBR Series

Physical Specifications

Lead Material

Soldering

Characteristics

Insulating Material

Device Labeling

.90-2.50A: Tin-plated Copper clad steel

.75A: Tin-plated Copper

Solderability per MIL–STD–202,

Method 208E

Cured, flame retardant epoxy polymer

meets UL 94V-0 requirements.

Marked with ‘LF’, voltage, current rating,

and date code.

Dimensions (mm)

Environmental Specifications

Operating/Storage

Temperature

Maximum Device Surface

Temperature in Tripped State

Passive Aging

Humidity Aging

Thermal Shock

Solvent Resistance MIL–STD–202, Method 215F

Moisture Sensivitivy Level Level 1, J–STD–020C

A

E

A

B

E

B

-40°C to +85°C

125°C

+85°C, 1000 hours

-/+5% typical resistance change

+85°C, 85% R.H., 1000 hours

-/+5% typical resistance change

+85°C to -40°C 10 times

-/+5% typical resistance change

D

C

Figure 1

D

C

Figure 2

A B C D E Physical Characteristics

Part

Number

Figure

Inches mm Inches mm Inches mm Inches mm Inches mm Lead (dia)

Max. Max. Max. Max. Typ. Typ. Min. Min. Max. Max. Inches mm

Material

06R075B 1 0.27 6.9 0.45 11.4 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/Cu

06R120B 1 0.27 6.9 0.46 11.7 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

06R155B 1 0.27 6.9 0.46 11.7 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R090B 2 0.29 7.4 0.48 12.2 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R110B 2 0.29 7.4 0.56 14.2 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R135B 2 0.35 8.9 0.53 13.5 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R160B 2 0.35 8.9 0.60 15.2 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R185B 2 0.40 10.2 0.62 15.7 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

16R250B 2 0.45 11.4 0.72 18.3 0.20 5.1 0.30 7.6 0.12 3 0.020 0.51 Sn/CuFe

Part Marking System

Littelfuse

Trademark

Double Sided Marking

0.75A to 1.55A

Top Side

06

075B

Voltage Rating

Current Rating

Littelfuse

Trademark

Bottom Side

06

XXXX

Voltage Rating

Date Code

(Contact Littelfuse

for additional

information)

Littelfuse

Trademark

Single Sided Marking

1.35A to 2.50A

16

135B

XXXX

Voltage Rating

Current Rating

Date Code

(Contact Littelfuse

for additional

information)

Littelfuse

Trademark

Double Sided Marking

0.90A to 1.10A

Top Side

16

110U

Voltage Rating

Current Rating

Littelfuse

Trademark

Bottom Side

16

XXXX

Voltage Rating

Date Code

(Contact Littelfuse

for additional

information)

USBR Series

© 2010 Littelfuse, Inc

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/USBR.html for current information.

65

Revised: July 12, 2010

USBR Series

Page 4

Part Ordering Number System

16 R 090 B P R

SERIES

I

HOLD

R: RADIAL

VOLTAGE RATING (VDC)

Ordering Information

QUANTITY CODE: P=2000 U=500

TYPE: B=USB

CURRENT CODE (SEE TABLE BELOW)

POLYFUSE® Resettable PTCs

Radial Leaded > USBR Series

PACKAGING STYLE

BLANK: Bulk

R: Tape & Ammo

Part Number Ordering Number

06R075B

06R120B

06R155B

16R090B

16R110B

16R135B

16R160B

16R185B

16R250B

06R075BU

06R075BPR Tape and Ammo 2000 PR

06R120BU

06R120BPR Tape and Ammo 2000 PR

06R155BU

06R155BPR Tape and Ammo 2000 PR

16R090BU

16R090BPR Tape and Ammo 2000 PR

16R110BU

16R110BPR Tape and Ammo 2000 PR

16R135BU

16R135BPR Tape and Ammo 2000 PR

16R160BU

16R160BPR Tape and Ammo 2000 PR

16R185BU

16R185BPR Tape and Ammo 2000 PR

16R250BU

16R250BPR Tape and Ammo 2000 PR

I

hold

I

Code Packaging Option Quantity

(A)

hold

0.75 075

1.20 120

1.55 155

0.90 090

1. 10 11 0

1.35 135

1.60 160

1.85 185

2.50 250

Quantity & Packaging

Codes

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

Bulk 500 U

USBR Series

66

Revised: July 12, 2010

© 2010 Littelfuse, Inc.

Please refer to www.littelfuse.com/series/USBR.html for current information.

Specifications are subject to change without notice.

Page 5

POLYFUSE® Resettable PTCs

Radial Leaded > USBR Series

Tape and Ammo Specifications

Devices taped using EIA468-B/IE286-2 standards. See table below and Figure 1 for details.

Dimension EIA Mark IEC Mark

Carrier tape width WW18 -0.5 / +1.0

Hold down tape width W

Top distance between tape edges W

Sprocket hole position W

Sprocket hole diameter* D

Abscissa to plane(straight lead) HH18.5 -/+ 3.0

Abscissa to plane(kinked lead) H

Abscissa to top H

Overall width w/o lead protrusion C

Overall width w/ lead protrusion C

Lead protrusion L

Protrusion of cut out L L 11 max.

Protrusion beyond hold-down tape l

Sprocket hole pitch P

Pitch tolerance

Device pitch 12.7

Tape thickness tt0.9 max.

Tape thickness with splice t

Splice sprocket hole alignment 0 -/+ 0.3

Body lateral deviation Δh Δh 0 -/+ 1.0

Body tape plane deviation Δp Δp 0 -/+ 1.3

Ordinate to adjacent component lead* P

Lead spacing* FF5.08 -/+ 0.8

*Differs from EIA specification.

4

6

5

0

0

1

1

2

1

2

0

1

1

W

0

W

2

W

1

D

0

H

0

H

1

l

1

l

2

P

0

P

1

Dim. (mm) Tol. (mm)

11 min.

3 max.

9 -0.5 / +0.75

4 -/+ 0.32

16 -/+ 0.5

32.2 max.

42.5 max.

43.2 max.

1.0 max.

Not specified

12.7 -/+ 0.35

20

consecutive

2.0 max.

3.81 -/+ 1.0

Dimensions

-/+ 1

USBR Series

Tape and Ammo Diagram

Δh

H

Δh

1

A

1

L

I

2

P

L

1

© 2010 Littelfuse, Inc

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/USBR.html for current information.

0

Figure 1

Δh

Reference plane

C

H

1

F

H

A

B

0

W

W

D

0

5

4

W

Direction of unreeling

1

C

H

2

Cross section A - B

t

67

Revised: July 12, 2010

Δp

USBR Series

Loading...

Loading...