Page 1

TVS Diode Arrays (SPA

VCC

10/100

Ethernet

PHY

TX +

TX -

RX +

RX -

VCC

GND

SRV05-4HTG

TX +

TX -

RX +

RX -

Unused

Unused

Unused

RJ45

Unused

To Twisted-Pair Network

75

75

75

75

1

2

3

6

5

4

10/100 Ethernet Differential Protection

®

Diodes)

Lightning Surge Protection - SRV05 Series

SRV05 Series 6V 10A Diode Array

Pinout

I/O 1

GND

I/O 2

Functional Block Diagram

Additional Information

Datasheet

Life Support Note:

Not Intended for Use in Life Support or Life Saving Applications

The products shown herein are not designed for use in life sustaining or life saving

applications unless otherwise expressly indicated.

6

1

5

2

Resources

4

3

I/O 4

V

CC

I/O 3

Samples

RoHS

Pb

GREEN

Description

The SRV05 integrates low capacitance rail-to-rail diodes with

an additional zener diode to protect each I/O pin against

ESD and high surge events. This robust device can safely

absorb surge current per IEC61000-4-5 (t

=8/20µs) without

P

performance degradation and a minimum ±20kV ESD

per IEC61000-4-2. Their very low loading capacitance also

makes them ideal for protecting high speed signal pins.

Features

• ESD, IEC61000-4-2,

±20kV contact, ±30kV air

• EFT, IEC61000-4-4, 40A

(5/50ns)

• Lightning, IEC61000-4-5,

10A (8/20μs)

• Low capacitance of 2pF

(TYP) per I/O

• Low leakage current of

0.5μA (MAX) at 5V

• Small SOT23-6 (

MO-178) packaging

JEDEC

Applications

• LCD/PDP TVs

• Monitors

• Notebooks

• 10/100/1000 Ethernet

• Firewire

• Set Top Boxes

• Flat Panel Displays

• Portable Medical

Application Examples

USB

Controller

10/100/1000

Ethernet

PHY

USB Dual Port Protection

C

T

C

T

10/100/1000 Ethernet Protection

TX +

TX -

RX +

RX -

VCC

GND

R

T

R

T

C

T

R

T

R

T

C

T

1

2

3

SRV05-4HTG

VCC

6

5

4

V

BUS

SRV05-4HTG

V

BUS

V

BUS

D +

USB

D -

Port

GND

V

BUS

V

BUS

D +

USB

Port

D -

GND

RJ45

Unused

Unused

TX +

TX -

RX +

RX -

To Twisted-Pair Network

Unused

Unused

75

75

75

75

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/25/13

Page 2

TVS Diode Arrays (SPA

®

Diodes)

Lightning Surge Protection - SRV05 Series

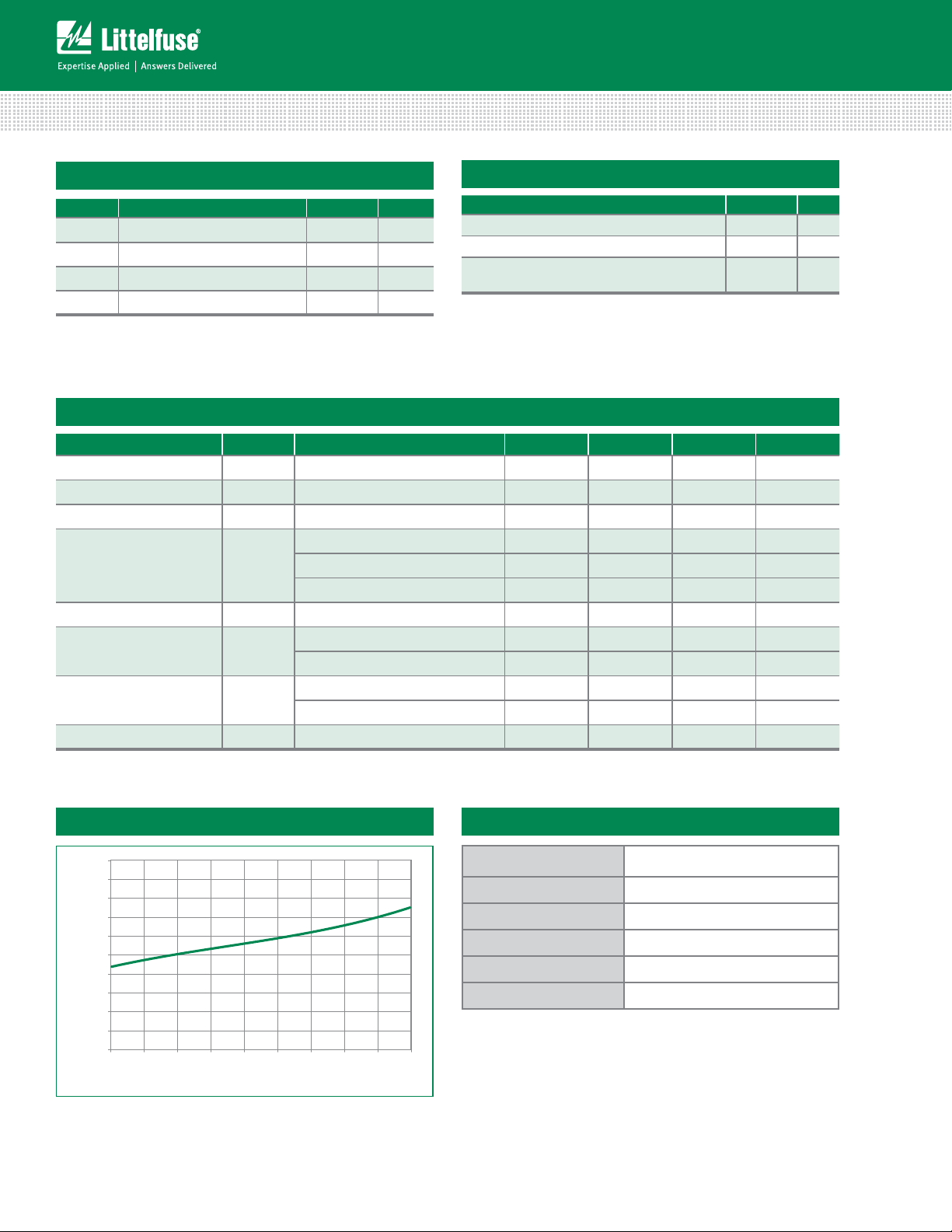

Absolute Maximum Ratings

Symbol Parameter Value Units

OP

V

C

I/O-GND

C

1

=25ºC)

RWM

R

LEAK

V

C

DYN

ESD

I/O-I/O

10 A

IR ≤ 1µA 6.0 V

IR = 1mA 8.0 V

VR=5V 0.1 0.5 µA

IPP=1A, tp=8/20µs, I/O to GND

I

=5A, tp=8/20µs, I/O to GND

PP

I

=8A, tp=8/20µs, I/O to GND

PP

(VC2 - VC1) / (I

IEC61000-4-2 (Contact) ±20 kV

IEC61000-4-2 (Air) ±30 kV

Reverse Bias=0V 2.4 3.0 pF

Reverse Bias=1.65V 2.0 pF

Reverse Bias=0V 1. 2 pF

I

PP

P

PK

T

OP

T

STOR

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specification is not implied.

1

Non-repetitive pulse per waveform on page 3

Peak Current (tp=8/20μs)

Peak Pulse Power (tp=8/20μs) 150 W

Operating Temperature –40 to 125 °C

Storage Temperature –55 to 150 °C

Electrical Characteristics (T

Parameter Symbol Test Conditions Min Typ Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Reverse Leakage Current I

Clamp Voltage

Dynamic Resistance R

ESD Withstand Voltage

Diode Capacitance

Diode Capacitance

Notes: 1 Parameter is guaranteed by design and/or device characterization.

2

Repetitive pulse per waveform on page 3.

1

1

1

1

Thermal Information

Parameter Rating Units

Storage Temperature Range –55 to 150 °C

Maximum Junction Temperature 150 °C

Maximum Lead Temperature

(Soldering 20-40s)

2

2

2

- I

) 0.7 Ω

PP2

PP1

8.8 10.0 V

11. 5 13.0 V

13.2 15.0 V

260 °C

Clamping Voltage vs. I

20.0

18.0

16.0

)

14.0

C

12.0

10.0

8.0

6.0

Clamp Voltage (V

4.0

2.0

0.0

1 2 3 4 5 6 7 8 9 10

PP

Peak Pulse Current-IPP (A)

Product Characteristics

Lead Plating Matte Tin

Lead Material Copper Alloy

Lead Coplanarity 0.0004 inches (0.102mm)

Substitute Material Silicon

Body Material Molded Epoxy

Flammability UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold ash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte nish VDI 11-13.

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 11/25/13

Page 3

TVS Diode Arrays (SPA

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DC Bias (V)

Capacitance (pF)

VCC=Float

V

CC

=5V

V

CC

=3.3V

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Percent of I

PP

t

R

R

o

C

e

T

T

L*4

L * 4

Product Series

L = SRV05

Number of Channels

Assembly Site

(Varies)

L = S

(Varies)

®

Diodes)

Lightning Surge Protection - SRV05 Series

Pulse WaveformCapacitance vs. Reverse Bias

Soldering Parameters

Reflow Condition Pb – Free assembly

Pre Heat

- Temperature Min (T

- Temperature Max (T

) 150°C

s(min)

) 200°C

s(max)

- Time (min to max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

) to peak

L

to TL - Ramp-up Rate 3°C/second max

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

3°C/second max

+0/-5

°C

20 – 40 seconds

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (T

) 8 minutes Max.

P

Do not exceed 260°C

Part Numbering System

SRV05

–

4

H T

G

T

P

T

L

T

S(max)

Temperature

T

S(min)

25

time to peak temperature

Part Marking System

t

S

PreheatPrehea

Ramp-up

amp-up

t

P

t

L

Critical Zone

ritical Zon

L to TP

to

T

Ramp-down

amp-d

Time

Series

Number of

Channels

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/25/13

G= Green

T= Tape & Reel

Package

H: SOT23-6

Ordering Information

Part Number Package Marking Min. Order Qty.

SRV05-4HTG SOT23-6 L*4 3000

Page 4

Package Dimensions — SOT23-6

Recommended Solder Pad Layout

P

R

TVS Diode Arrays (SPA

®

Diodes)

Lightning Surge Protection - SRV05 Series

Package SOT23-6

Pins 6

JEDEC MO-178

A 0.900 1.450 0.035 0.057 -

A1 0.000 0.150 0.000 0.006 -

A2 0.900 1.300 0.035 0.051 -

b 0.350 0.500 0.0138 0.0196 -

C 0.080 0.220 0.0031 0.009 -

D 2.800 3.000 0.11 0.118 3

E 2.600 3.000 0.102 0.118 -

E1 1.500 1.750 0.06 0.069 3

e 0.95 Ref 0.0374 ref -

e1 1.9 Ref 0.0748 Ref -

L 0.100 0.600 0.004 0.023 4,5

N 6 6 6

a 0º 10 º 0º 10 º -

M 2.590 0.102 -

O 0.690 .027 TYP -

P 0.990 .039 TYP -

M

R 0.950 0.038 -

Notes:

1. Dimensioning and tolerances per ANSI 14.5M-1982.

2. Package conforms to EIAJ SC-74 (1992).

3. Dimensions D and E1 are exclusive of mold ash, protrusions, or gate burrs.

4. Footlenth L measured at reference to seating plane.

5. “L” is the length of at foot surface for soldering to substrate.

6. “N” is the number of terminal positions.

7. Controling dimension: MILLIMETER. Converted inch dimensions are not necessarily exact.

Millimeters Inches

Min Max Min Max

Notes

Embossed Carrier Tape & Reel Specification — SOT23-6

8mm TAPE AND REEL

ACCESS HOLE

180mm

14.4mm

13mm

60mm

8.4mm

DIA. HOLE

8mm

1.5mm

SOT-23 (8mm POCKET PITCH)

USER DIRECTION OF FEED

4.0mm

4.0mm

2.0mm

PIN 1

1.75mm

C

L

GENERAL INFORMATION

1. 3000 PIECES PER REEL.

2. ORDER IN MULTIPLES OF FULL REELS ONLY.

3. MEETS EIA-481 REVISION "A" SPECIFICATIONS.

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 11/25/13

Loading...

Loading...