Page 1

Application Note EC635:

Fuse

MOV rated

for 150V rms

continuous

voltage

Load

120V

120V

Designing with Thermally Protected

®

TMOV

Varistors in SPD and AC Line Applications

Introduction

Metal Oxide Varistors (MOVs) are commonly used to

suppress transients in many applications such as: Surge

Protection Devices (SPD), Uninterruptible Power Supplies

(UPS), AC Power Taps, AC Power Meters or other

products. Lightning, inductive load switching, or capacitor

bank switching, are often the sources of these overvoltage transients. Under normal operating conditions,

the AC line voltage applied to an MOV is not expected to

exceed the MOV’s Maximum ACRMS Voltage Rating or

Maximum Continuous Operating Voltage (MCOV).

Occasionally, over-voltage transients may occur that

exceeds these limits. These transients are clamped to a

suitable voltage level by the MOV provided the transient

energy does not exceed the MOV’s maximum rating.

MOVs can also be subjected to continuous abnormal

voltage conditions rather than short duration transients.

If an MOV is subjected to a sustained abnormal overvoltage, limited current condition (as is required in

UL1449), the MOV may go into thermal runaway resulting

in overheating, smoke, and potentially fire. For end

products to comply with UL1449, some level of

protection must be afforded to the MOV to prevent this

failure mode. That protection has traditionally been a

thermal fuse or Thermal Cut-Off (TCO) device.

(a)

Device

110-120V / 220-240V Split 240 110-120V

220-240V / 380-415V 3-wye 4 15 220-240V

254-277V / 440-480V 3-wye 480 254-277V

Rating Phase

110-120V Single 240 All

120V / 208V 3-wye 208 120V

220-240V Single 415 All

240V

254-277V Single 480 All

480V

347V Single 600 All

347V / 600V 3-wye 600 347V

Table 1. Test voltage Selection Table

Notes: (a)“Device” is defined as the end SPD product - example: UPS, SPD Strip etc.

(b) For device ratings not specified in this table, the test voltage shall be the maximum

phase voltage (if available) or twice the conductor pair voltage ratings up to 1000V max.

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

High Leg

Delta

High Leg

Delta

Test

Voltage

240 120V

480 254-277V

Voltage Rating of

(b)

Conductor Pair

UL1449 Abnormal Overvoltage, Limited Current

Requirements

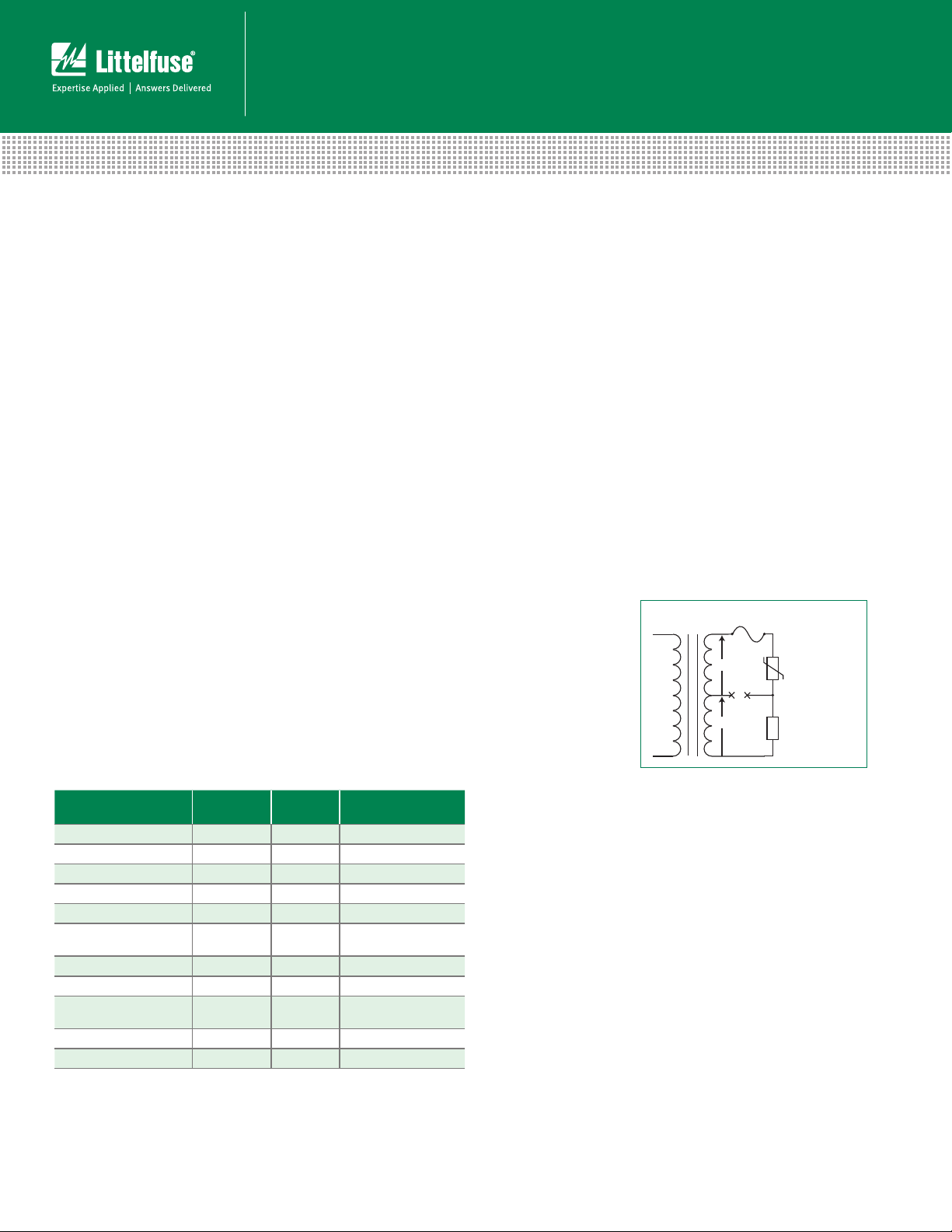

In AC line applications, the loss of a Neutral-Ground

connection may occur in such a way that there exists a

risk that a sustained over-voltage may be applied to an

MOV that is rated for a much lower continuous voltage.

In an unlimited current condition the MOV will first fail to

a low impedance (few Ohms), but due to the high

amount of energy available, it most often ruptures

instantaneously. If, however, there are loads tied to the

AC line that limit current flow, the MOV can overheat and

potentially cause the SPD device to overheat resulting in

smoke, out-gassing and eventually fire.

For example, in a standard U.S. 120V AC Line application,

two 120V AC power lines (180° out of phase) are

commonly fed from a center-tapped 240V transformer.

See Figure 1. Let’s assume a 150V rated MOV is present

in the top 120V

circuit, and some load

exists on the bottom

120V circuit. Both the

MOV and load share

the center tap which

is the Neutral-Ground

Connection. If a break

occurs on the center

tap (X—X), then the

load in the bottom

phase acts as a current limiter and the line fuse may not

clear. In this scenario, the 150V rated MOV is subjected

to 240V at a limited current potentially resulting in

thermal run away for the MOV.

This potential condition is specifically identified and

addressed in the UL1449 SPD Standard. See Table 1.

In many cases, it requires that end-product manufacturers

include a thermal protection element for an MOV.

Table 1. defines the test voltage that should be applied to

various SPD devices depending on the designer’s desired

device rating. Each test voltage is applied across each

conductor pair with a short circuit current of 10A for Type 1

& 2 SPD, and 5A, 2.5A, 0.5A and 0.125A for Type 3 SPD

respectively across each of five SPD devices. Since this

1

Revision: May 31, 2011

Figure 1. Possible Fault Condition for a limited

current abnormal overvoltage event

Page 2

Designing with Thermally Protected

Fuse

Line

TCO

TCO

MOV

MOV

MOV

Neutral

Ground

TCO

120VAC

TMOV® Varistors in SPD and AC Line Applications

test is destructive, five devices are needed to test for each

of the five short circuit currents. The five devices must be

energized for 7 hours, or until current or temperatures

within the SPD device attain equilibrium, or until the SPD

becomes disconnected from the AC Line.

For example shown in Figure 1, in a standard 120V AC Line

application, the requirement is for a 240VACRMS test

voltage to be applied across all conductor pairs. There are

three pairs; Line-Neutral (L-N), Line-Ground (L-G), and

Neutral-Ground (N-G). Again, this test voltage is chosen

because in the U.S., 120V AC power is commonly fed from

a center-tapped 240V transformer. Thermally unprotected

MOVs for this application are typically rated from

130Vacrms to 150Vacrms and will heat up, out-gas and may

catch fire in such circumstances.

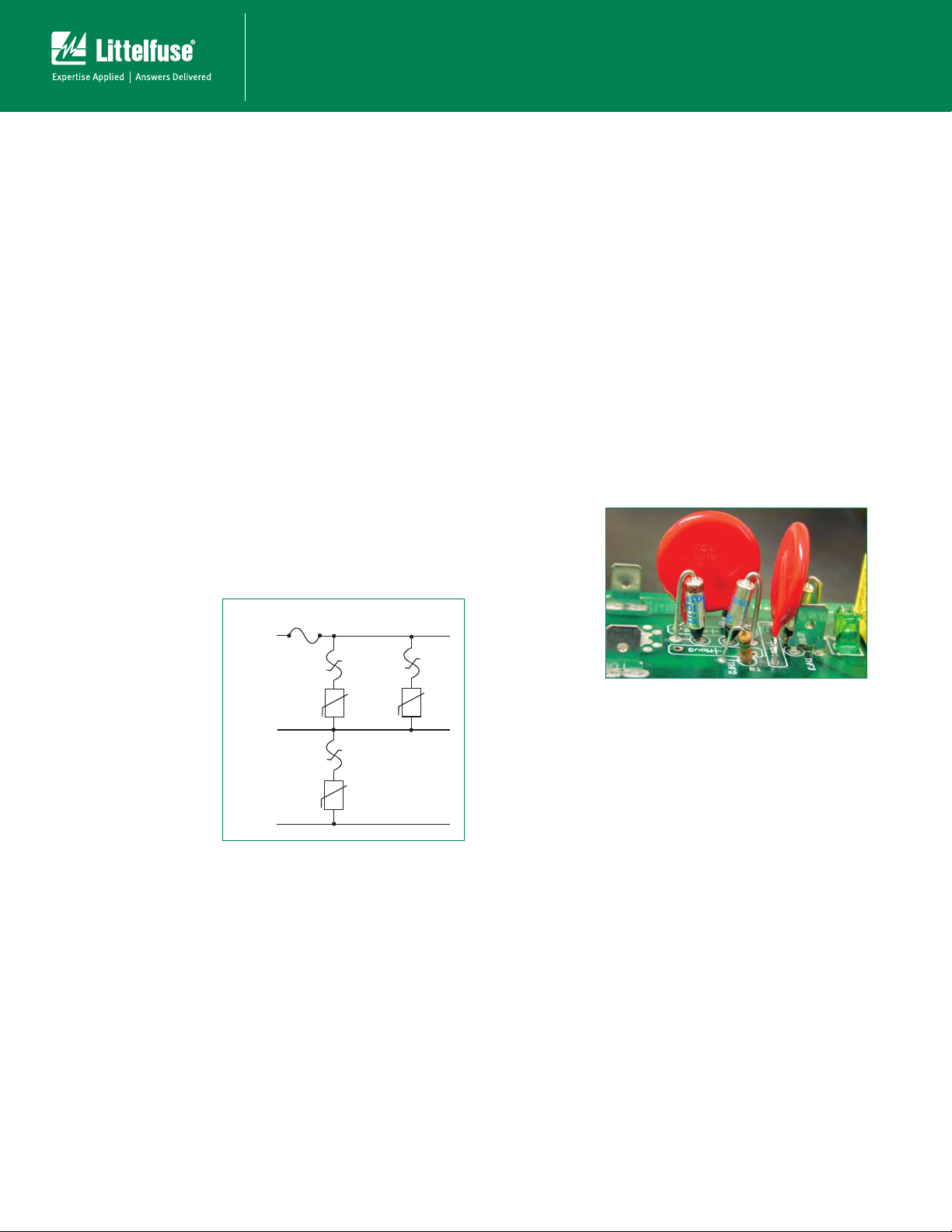

Thermally Protecting MOVs

A simple block diagram of a typical line voltage transient

protection scheme used to meet the sustained abnormal

over-voltage, limited current test requirements of UL1449

is shown in Figure 2. An MOV or several MOVs in parallel

are each placed

across each of the

three conductive

pairs; L-N, L-G, and

N-G. This offers the

utmost protection

for any possible

line transient. A

standard fuse is

placed in series

with the line to

protect the system

from an overcurrent condition that exceeds a predetermined level.

Typically, the current rating of this fuse is higher than the

limited current flowing through the circuit during UL1449

testing. This requires the addition of a TCO that is placed

in series with each MOV or Parallel combination of MOVs

to protect it from a thermal event. Often, the MOVs used

are of the radial leaded 14mm or 20mm disk diameter

variety.

TCOs are available in a variety of different opening

temperatures. The position and orientation of the TCO is

important if it is to be effective in thermally protecting an

MOV. When subjected to a sustained over-voltage, MOVs

will short at a random point on the disk and will rapidly

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

Figure 2. Typical offline protection scheme

begin to self-heat if a limited current is maintained. TCOs

are activated by a combination of conducted, converted

and radiated heat from the MOV, although the majority of

the heat is transferred via conduction. The position of the

TCO in relation to the heat source at this shorting point

has a considerable effect on the speed of operation of

the TCO. The most effective heat coupling has been

observed to be via conduction through the varistor

terminal lead to the insulated terminal of a metal jacket

TCO. Thermal convection and radiation processes are

effective when the heat source is immediately beside or

below the TCO. Although conduction is the most

effective means of heat transfer, the MOV and TCO are

not in full contact in most cases. The position of the

terminal leads of the TCO makes it difficult for the TCO to

be located closely enough to the MOV for effective heat

transfer. The result is less than efficient conduction from

case to case.

An example of

a typical

arrangement of

MOVs and

TCOs is shown

in Figure 3.

Note the TCO

does not touch

the case of the

M O V.

Figure 3. Typical Arrangement of TCOs with MOVs

** one of the MOVs has been removed for clarity

The response time of this arrangement can be

disproportionately increased if the TCO is not placed in

close enough proximity to the MOV and/or the punchthrough point on the MOV occurs remotely from the

TCO’s insulated terminal. In such cases, considerable

charring of the MOV can occur and fire is a real

possibility. Shrink-wrap or other bonding materials can aid

coupling, but in adverse circumstances they are a source

of combustible material and may actually make things

worse.

While this scheme is generally effective in removing the

MOV from the circuit during abnormal over-voltage testing

such that the MOV does not reach critical temperatures,

the downside to this method is that TCOs can be difficult

to handle during the assembly process. Because of the

low opening temperatures, TCOs must be soldered

carefully. When hand soldering, the iron cannot remain in

contact with the lead of the TCO for prolonged periods.

Another option is to use clips or pliers as a heat-sink.

2

Revision: May 31, 2011

Page 3

Designing with Thermally Protected

Fuse

Line

TMOV™

Varistor

TMOV

TMOV

Neutral

Ground

120VAC

Integrated

Thermal

Element

MOV Disk

0 10 20 30 40 50 60 70 80 90 100 110

0

50

100

150

200

250

300

350

400

450

Time (seconds)

Case Temperature (C)

MOV/TCO

TMOV Varistor

MOV

TMOV® Varistors in SPD and AC Line Applications

TCOs with useful opening temperatures for the MOVs

typically cannot be wave soldered, as the device will clear

in the solder bath. In general, the use of TCOs in these

types of applications becomes largely a hand assembly

process.

A new technology has been developed that will aid the

designer in meeting UL1449 requirements including the

sustained abnormal over-voltage limited current testing,

while eliminating most of the problems associated with

other methods. This technology is a fully integrated,

thermally self-protected MOV - TMOV Varistor Series. This

new device uses a patent pending thermal element

internal to the MOV so that it is in direct contact with the

metal oxide disk, allowing for optimum heat transfer.

Because of the proximity of the thermal element to the

MOV body, a higher opening temperature element can be

used. This allows the thermally self-protected MOV to be

wave soldered simplifying the assembly process. The

construction method also allows the new device to

perform to standard MOV ratings with regards to peak

current, peak

energy, voltage

clamp levels, etc.

while providing the

safety of a

thermally protected

device. Figure 4.

illustrates the

integrated function.

Figure 4. TMOV varistor offline protection scheme

UltraMOV varistors) in combination with TCOs of various

opening temperatures, Tf, were tested and compared

with several thermally self protected MOVs (Littelfuse

20mm, 130Vacrms, TMOV® varistor – TMOV20R130).

Both methods were subjected

to a sustained abnormal overvoltage of 240V at 5A. As can be

seen in Table 2a and as

expected, the TCOs with higher

Tf take longer to clear. The 73ºC

TCO proved difficult to hand

solder without clearing the

device despite the use of an

appropriate heat-sink. Table 2b

shows the clearing times for the

internally protected MOV.

Clearly, the times are shorter

than for any of the MOV/TCO

combinations tested.

TCO

Tf (°C)

73

94

121

Table 2a. MOV/TCO observed clearing

times for 5A limited current test

Tf (°C)

TMOV

Clearing Time (s)

Mean

30

34

36

Clearing Time (s)

Mean

13

Range

11-52

20-46

16-56

Range

2-25

varistor

Table 2b. TMOV varistor observed clearing

times for 5A limited current test

Figure 5. shows the effects of applying a UL1449

abnormal over-voltage test (240VRMS, 5A) on three

devices or combination of devices - 1) MOV alone

(20mm, 130Vacrms – V20E130) 2) MOV/TCO combination

(20mm, 130Vacrms MOV – V20E130 and TCO with Tf =

94°C), and 3) TMOV varistor (20mm, 130Vacrms –

TMOV20R130).

Comparing Methods of Thermally Protecting MOVs

The internally thermally protected TMOV varistor

overcomes most of the disadvantages of the MOV/TCO

combination method. Placing the thermal element inside

the epoxy coating and close to the center of the disk

provides several benefits. 1) It optimizes heat transfer

between the MOV disk and the thermal element by

placing the thermal element as close to the point of

failure as possible. This greatly improves clearing

(opening) times. 2) Allows for the thermal element to

have a higher opening temperature than most TCOs used

while being protected from external heat sources. This

allows the device to be wave soldered. See Section 6.

In order to compare the clearing times of both methods,

several standard MOVs (Littelfuse 20mm, 130Vacrms,

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

Figure 5. Typical surface temperature vs. time for several protection schemes

Epoxy surface temperature vs. time was captured for each

method. As can be seen, the case temperature of a

standard MOV rated for 130VRMS will continue to rise (to

the point of combustion) if no thermal protection is used.

The MOV/TCO combo performs better reaching

3

Revision: May 31, 2011

Page 4

Designing with Thermally Protected

Wavesolder trials on TMOV varistor vs. TCO

142 deg TCO

14/20mm TMOV varistor

0

500

1000

1500 2000

TMOV® Varistors in SPD and AC Line Applications

temperatures of 220°C before the TCO clears. The

internally protected MOV has a faster response time,

clearing at temperatures of around 150°C in less than 20

seconds. Note that the temperature continues to rise once

the thermal fuses have cleared. Heat generated within the

zinc oxide disk is at a higher

temperature than the outer

epoxy coating. Heat

continues to flow outward to

the epoxy for some time

before finally cooling down.

Figures 6a – 6c illustrate the

effects of the temperature

rise on each MOV. As can be

Figure 6a. Standard MOV

seen, the new technology

eliminates much of the

charring when compared

with a standard MOV or

MOV/TCO combination.

Since the same size zinc

oxide disks are being used

for both MOV and TMOV,

the TMOV has the same

Figure 6b. MOV/TCO combination

surge perfomance as a

same size MOV, and

complies with IEC 60950-1,

Annex Q. The TMOV device

is a fail-safe product, so no

additional interruptor device

is needed in series to

protect, as required in

clause 1.5.9.2, IEC60950-1.

Figure 6c. TMOV varistor

Wave Soldering the TMOV Varistor

Figure 7 shows a suitable wave solder profile that can be

used for the TMOV varistor. The profile temperatures are

very typical to those

found in general

wave solder

methods. In contrast,

the solder profile

shown for the TCO

shows temperatures

much lower than

those found in a

typical solder bath. In

fact, the profile

shown for the TCO

actually depicts a

profile at which the

Figure 7. Wave solder profile of TMOV varistor vs. TCO (Tf=142°C)

TCO fails (opens)

generally indicating that a TCO (even one with a high Tf

(142°C) cannot be wave soldered.

Generally, there will be a cost benefit associated with

eliminating the TCO which must be hand soldered

carefully to avoid opening the element.

Integrity of an Open Thermal Element

Once the thermal element of a TMOV varistor opens, it is

important that the element stay open and that a

reconnection not occur. The thermal element cleared

(opened) because the varistor disk heated due to thermal

run-away, and the thermal runaway began with a failed

(shorted) varistor.

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

In order to ascertain the integrity of an open thermal

element within a TMOV varistor, devices were first

subjected to an abnormal over-voltage limited current

event causing the thermal element to clear. These devices

were then subjected to two tests. First, the devices were

subjected to 6kV, 3kA 8x20µsec pulses. The TMOV

varistors were then subjected to bias voltage and

monitored for leakage currents indicating a full or partial

reconnection. None were noted. Next, 1000Vrms was

applied for several hours, again with no connection as

verified by the leakage test.

4

Revision: May 31, 2011

Page 5

Designing with Thermally Protected

Fuse

Line

TMOV™

Varistor

TMOV20R130M

Neutral

120VAC

D1

LED

Normally

On

R1

47k,0.5W

TMOV® Varistors in SPD and AC Line Applications

Indication of an Open Thermal Element: iTMOV Varistor

The benefits of the TMOV varistor have been thoroughly

discussed, but one question remains:

How do I know when the thermal element has cleared?

By design, MOVs exhibit a very high impedance when

subjected to voltages below its MCOV (Maximum

Continuous Operating Voltage). So, once installed into an

end product, how do you know if the TMOV varistor is

still operational? Enter the iTMOV varistor.

The iTMOV varistor adds an additional third indicator lead

that provides access to the connection between the

thermal element and the MOV electrode. Having access

to this point of the circuit makes indication of the thermal

element a simple procedure. Figures 8 shows a simple

application circuit with indication.

In Figure 8, an iTMOV

varistor is used to protect

the L-N connection of a

typical U.S. 120Vac line. An

AC rated LED is placed

across the iTMOV

varistor’s indicator lead and

the Neutral line. A series

resistor, R1, is added to

limit current through the

LED. A 47kΩ, 0.5W

resistor is shown, but the designer should review the

LED’s ratings to choose the correct value.

A series diode, D1, may be needed if the reverse voltage

rating of the LED is insufficient to handle negative

voltages from the AC line. Additionally, a Littelfuse 3AG,

10A (313010) fuse is shown to protect against excessive

over-current into the load, but the designer should choose

a value specific to his/her design.

Figure 8. Indicator circuit using the iTMOV

varistor (LED normally on)

Conclusion

The UL1449 standard was created to protect the end

product and users from a loss of neutral situation where

an abnormal over-voltage/limited current condition could

be applied to Metal Oxide Varistors. This event would

cause an MOV to have a sustained voltage applied in

excess of its maximum working voltage, which in turn

would cause the MOV to enter a thermal runaway

condition.

Several methods exist to prevent the MOV from reaching

combustible temperatures - the most common of which is

to use TCOs. While TCOs perform adequately in limiting

MOVs from reaching very high temperatures, there are

limitations. Out-gassing and some charring are evident

when the test is applied. Additionally, the assembly

process is difficult to automate, as wave soldering is

typically not an option.

Overall, the new integrated TMOV varistor thermal fuse

technology reduces part count, saves space and is

UL1449 recognized. It performs better than other

methods of protection when subjected to a limited

current over-voltage condition, by clearing more quickly at

a lower temperature to reduce the potential for outgassing or charring. It has all the performance capability

of a standard MOV, including peak pulse current

capability, energy rating and clamping voltage. The new

device can also be wave soldered which saves on

assembly costs and simplifies the assembly process by

eliminating most of the hand assembly required with

other methods.

Under normal conditions, the LED is forward biased from

the line voltage through the thermal element to Neutral.

If the thermal element opens current will be interrupted

and the LED will go off. The LED will also go off if the

Line Fuse opens indicating a loss of power.

When paralleling TMOV varistors, the iTMOV varistor can

be used for several or all parallel devices. That is, one

may wish to indicate when a certain percentage or TMOV

varistors fail. Generally, once some of the MOVs in

parallel begin to fail, all begin to fail.

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

5

Revision: May 31, 2011

Page 6

Designing with Thermally Protected

TMOV® Varistors in SPD and AC Line Applications

Note:

All data was taken with a limited sample size. Results

may vary due to normal variations in electrical and

mechanical parameters. Designers are encouraged to

evaluate their end design with a large enough sample

size to ensure consistent results. In some instances

TMOV varistors may exhibit substantial heating and

venting prior to opening. Module design should be such

as to contain this possibility. Application testing is

strongly recommended.

References:

1. Surge Protective Devices - UL1449, April 19, 2010

2. Littelfuse Datasheet, Thermally Protected Metal Oxide

Varistor (TMOV Varistor), March 2001

3. Littelfuse Datasheet, High Surge Current Radial Lead

Metal Oxide Varistor (UltraMOV Varistor Series), March

2001

4. Paul Traynham and Pat Bellew, Using Thermally

Protected MOVs in TVSS or Power Supply Applications,

Power Systems World, Intertec Exhibition Proceedings,

September 2001

5. Information Technology Equipment - Safety, IEC60950-1,

Amendment 1, December 2009

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

6

Revision: May 31, 2011

Loading...

Loading...