Page 1

Teccor® brand Thyristors

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

Q6008LH1LED Series

Agency Approval

Agency Agency File Number

®

Main Features

Symbol Value Unit

I

T(RMS)

V

DRM/VRRM

I

GT

Schematic Symbol

L Package: E71639

8 A

600 V

10 mA

RoHS

Description

Q6008LH1LED series is designed to meet low load current

characteristics typical in LED lighting applications.

By keeping holding current at 6mA maximum, this Triac

series is characterized and specified to perform best with

LED loads. The Q6008LH1LED series is best suited for LED

dimming controls to obtain the lowest levels of light output

with a minimum probability of flickering.

Q6008LH1LED series is offered in the industry standard

TO-220AB package with an isolated mounting tab that

makes it best suited for adding an external heat sink.

Features

• As low as 6mA max

holding current

Benefits

• Provides full control

of light out put at the

extreme low end of load

conditions.

• UL recognized TO-220AB

package

• 2500V

min isolation

AC

between mounting tab

and active terminals

• 110

°C rated junction

temperature

• Improves margin of safe

operation with less heat

sinking required

• di/dt performance of

70A/

μs

• Enable survivability

of typically LED load

operating characteristics

• QUADRAC version

includes intergrated DIAC

• Simplicity of circuit design

& layout

MT2 MT1

Q6008LH1LED Series

Applications

Excellent for AC switching and phase control applications

G

such as heating, lighting, and motor speed controls.

Typical applications are AC solid-state switches, lighting

controls with LED lamp loads, small low current motor in

power tools, and low current motors in home/brown goods

appliances.

Internally constructed isolated packages are offered for

ease of heat sinking with highest isolation voltage.

1

Revised: January 25, 2013 08:34 AM

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Page 2

Teccor® brand Thyristors

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

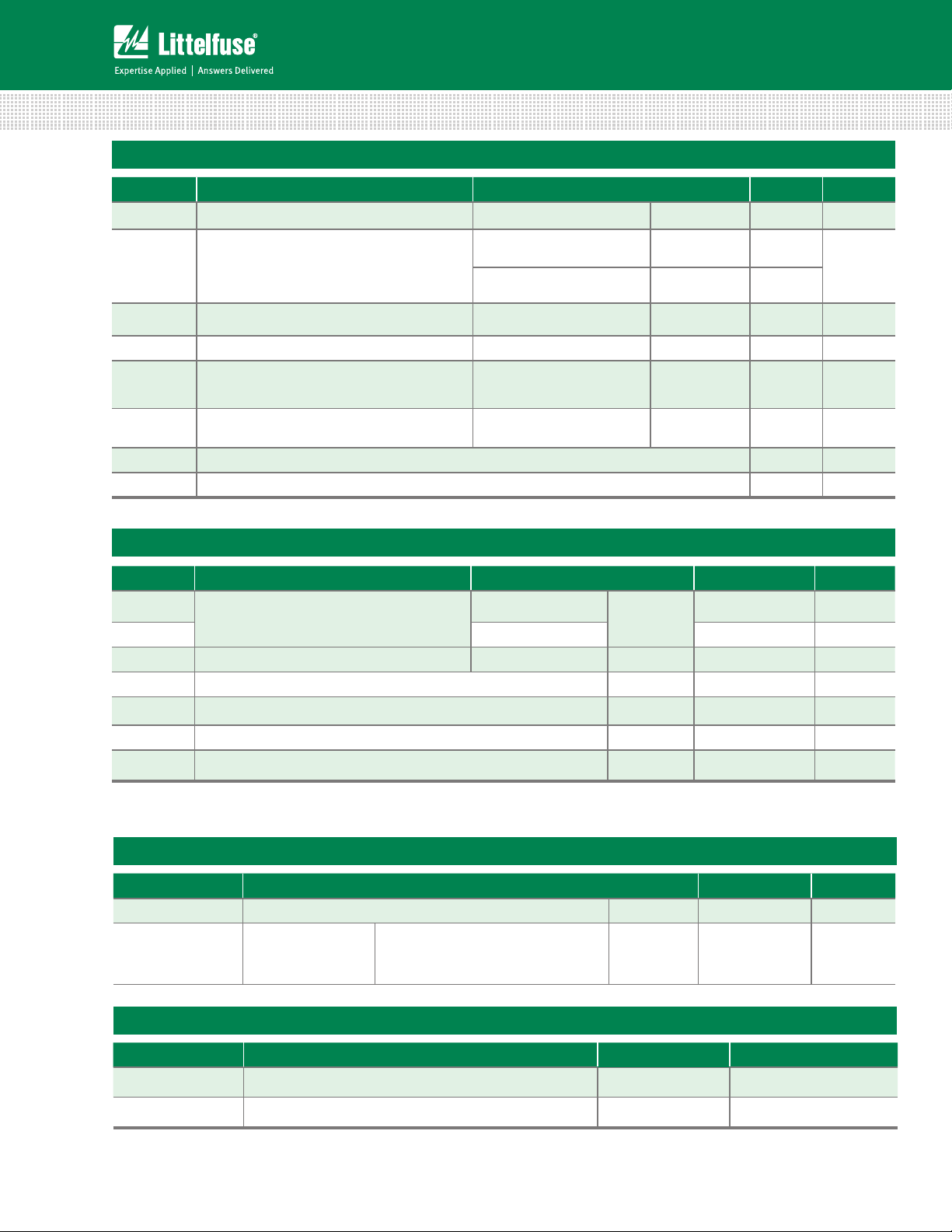

Absolute Maximum Ratings

Symbol Parameter Test Conditions Value Unit

I

T(RMS)

RMS on-state current (full sine wave) TC = 80°C 8 A

I

TSM

Non repetitive surge peak on-state current

(full cycle, TJ initial = 25°C)

f = 50 Hz t = 20 ms 80

f = 60 Hz t = 16.7 ms 85

I2t I2t Value for fusing tp = 8.3 ms 30 A2s

di/dt Critical rate of rise of on-state current f = 120 Hz

I

P

T

T

GTM

G(AV)

stg

J

Peak gate trigger current

Average gate power dissipation

Storage temperature range -40 to 150 °C

Operating junction temperature range -40 to 110 °C

Electrical Characteristics (T

= 25°C, unless otherwise specified)

J

tP ≤ 10 μs;

IGT ≤ I

GTM

T

= 110°C

J

T

= 110°C

J

T

= 110°C

J

= 35mA 0.5 W

I

GT

70 A/μs

1. 6 A

Symbol Test Conditions Quadrant Value Unit

I

GT

V

GT

V

GD

I

H

VD = 12V RL = 60 Ω

VD = V

IT = 15mA MAX. 6 mA

dv/dt VD = V

RL = 3.3 kΩ TJ = 110°C

DRM

Gate Open TJ = 110°C MIN. 50 V/μs

DRM

I – II – III

10 mA

MAX.

I – II – III 1. 3 V

I – II – III MIN. 0.2 V

(dv/dt)c (di/dt)c = 4.3 A/ms TJ = 110°C MIN. 10 V/μs

A

t

gt

IG = 100mA PW = 15µs IT = 11.3 A(pk) TYP. 4.0 μs

Static Characteristics

Symbol Test Conditions Value Unit

V

I

DRM

I

RRM

TM

V

= V

DRM

ITM = 11.3A tp = 380 µs MAX. 1.60 V

RRM

TJ = 110°C MAX. 500 μA

Thermal Resistances

Symbol Parameter Value Unit

R

θ(J-C)

R

θ(J-A)

Q6008LH1LED Series

Junction to case (AC) 2.8 °C/W

Junction to ambient 50 °C/W

2

Revised: January 25, 2013 08:34 AM

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Page 3

Teccor® brand Thyristors

51

81

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

Figure 1: Definition of Quadrants

ALL POLARITIES ARE REFERENCED TO MT1

MT2 POSITIVE

(Positive Half Cycle)

MT2

(-)

I

GT

GATE

MT1

I

GT

GATE

REF

MT2

MT1

REF

I

-

GT

(-)

+

(+)

QII

QI

QIV

QIII

(+)

-

MT2 NEGATIVE

(Negative Half Cycle)

I

GT

GATE

I

GT

GATE

MT2

REF

MT2

REF

MT1

MT1

+ I

GT

Note: Alternistors will not operate in QIV

Figure 3: Normalized DC Holding Current

vs. Junction Temperature

3.5

3.0

2.5

H

I

2.0

= 25°C)

J

(T

H

I

1.5

Figure 2: Normalized DC Gate Trigger Current for

All Quadrants vs. Junction Temperature

3.5

3.0

2.5

GT

I

= 25°C)

J

2.0

(T

GT

I

1.5

1.0

Ratio of

0.5

0.0

-65 -40 -15 10 35 60 85 110

Junction Temperature (TJ)- ºC

Figure 4: Normalized DC Gate Trigger Voltage for

All Quadrants vs. Junction Temperature

2.0

1.5

GT

= 25°C)

J

V

(T

GT

1.0

V

1.0

Ratio of

0.5

0.0

-65 -40 -151035608

Junction Temperature (TJ)- ºC

Figure 5: Power Dissipation (Typical)

vs. RMS On-State Current

18

16

14

) - Watts

12

D(AV)

10

8

6

Average On-State

4

Power Dissipation (P

2

0

0246

RMS On-State Current (I

T(RMS)

) - Amps

0.5

Ratio of

0.0

10

-65 -40 -1510356085110

Junction Temperature (TJ)- ºC

Figure 6: Maximum Allowable Case Temperature

vs. On-State Current (Standard / Alternistor Triac)

130

120

110

) - °C

C

100

90

80

Maximum Allowable

Case Temperature (T

70

0

60

012345678

RMS On-State Current (I

T(RMS)

) - Amps

Q6008LH1LED Series

3

Revised: January 25, 2013 08:34 AM

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Page 4

Teccor® brand Thyristors

41

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

Figure 7: On-State Current vs. On-State Voltage

(Typical)

20

) - Amps

T

On-State Current (i

Postitive or Negative Instantaneous

TC = 25°C

16

12

8

4

0

0.6 0.8 1.01.2 1.

Postitive or Negative Instantaneous

On-State Voltage (vT) - Vo lts

.6

Figure 9: Surge Peak On-State Current vs. Number of Cycles

100

Figure 8: Maximum Allowable Ambient Temperature vs.

On-State Current

120

CURRENT WAVEFORM: Sinusoidal

LOAD: Resistive or Inductive CONDUCTION

100

) - °C

A

80

60

Maximum Allowable

40

Ambient Temperature (T

20

0.0 0.2 0.4 0.6 0.8 1. 01.2 1. 41.6 1.8

RMS On-State Current (I

SUPPLY FREQUENCY: 60 Hz Sinusoidal

LOAD: Resistive

RMS On-State Current: [I

Value at Specified Case Temperature

ANGLE: 360

FREE AIR RATING - NO HEATSINK

) - Amps

T(RMS)

]: Maximum Rated

T(RMS)

) - Amps

TSM

10

Peak Surge (Non-Repetitive)

On-State Current (I

1

110100 1000

Surge Current Duration- Full Cycles

Notes:

1. Gate control may be lost during and immediately

following surge current interval.

2. Overload may not be repeated until junction

temperature has returned to steady-state

rated value.

Q6008LH1LED Series

4

Revised: January 25, 2013 08:34 AM

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Page 5

Soldering Parameters

eat

Ramp-do

Teccor® brand Thyristors

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

Reflow Condition Pb – Free assembly

T

P

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (min to max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus Temp)

(TL) to peak

T

to TL - Ramp-up Rate 5°C/second max

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (tp)

) 150°C

s(min)

) 200°C

s(max)

5°C/second max

+0/-5

°C

20 – 40 seconds

T

L

T

S(max)

Temperature

T

S(min)

25

Ramp-upRamp-up

PreheatPreh

t

S

time to peak temperature

Ramp-down Rate 5°C/second max

Time 25°C to peak Temperature (TP) 8 minutes Max.

Do not exceed 280°C

Physical Specifications Environmental Specifications

Terminal Finish 100% Matte Tin-plated

Body Material

UL recognized epoxy meeting ammability

classification 94V-0

Terminal Material Copper Alloy

Design Considerations

Careful selection of the correct device for the application’s

operating parameters and environment will go a long way

toward extending the operating life of the Thyristor. Good

design practice should limit the maximum continuous

current through the main terminals to 75% of the device

rating. Other ways to ensure long life for a power discrete

semiconductor are proper heat sinking and selection of

voltage ratings for worst case conditions. Overheating,

overvoltage (including dv/dt), and surge currents are

the main killers of semiconductors. Correct mounting,

soldering, and forming of the leads also help protect

against component damage.

Test

AC Blocking (V

DRM

)

Temperature Cycling

Temperature/

Humidity

High Temp Storage

Low-Temp Storage 1008 hours; -40°C

Thermal Shock

Autoclave

Resistance to

Solder Heat

Solderability ANSI/J-STD-002, category 3, Test A

Lead Bend MIL-STD-750, M-2036 Cond E

Specifications and Conditions

MIL-STD-750, M-1040, Cond A Applied

Peak AC voltage @ 110°C for 1008 hours

MIL-STD-750, M-1051,

100 cycles; -40°C to +150°C; 15-min

dwell-time

EIA / JEDEC, JESD22-A101

1008 hours; 320V - DC: 85°C; 85%

rel humidity

MIL-STD-750, M-1031,

1008 hours; 150°C

MIL-STD-750, M-1056

10 cycles; 0°C to 100°C; 5-min dwell-

time at each temperature; 10 sec (max)

transfer time between temperature

EIA / JEDEC, JESD22-A102

168 hours (121°C at 2 ATMs) and

100% R/H

MIL-STD-750 Method 2031

t

P

t

L

Ramp-down

Time

Q6008LH1LED Series

5

Revised: January 25, 2013 08:34 AM

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Page 6

Teccor® brand Thyristors

TO-220 AB - (L Package)

8 Amp Alternistor (High Commutation) Triac for LED dimmer application

Dimensions — TO-220AB (L-Package) — Isolated Mounting Tab

7. 01

.276

2

13.36

.526

T

MEASURING POINT AREA (REF.) 0.17 IN

C

E

C

D

G

A

B

F

R

L

H

K

J

MT1

MT2

GATE

O

P

N

M

8.13

.320

Note: Maximum torque to

be applied to mounting tab

is 8 in-lbs. (0.904 Nm).

Dimension

Inches Millimeters

Min Max Min Max

A 0.380 0.420 9.65 10.67

B 0.105 0.115 2.67 2.92

C 0.230 0.250 5.84 6.35

D 0.590 0.620 14.99 15.75

E 0.142 0.147 3.61 3.73

F 0.110 0.130 2.79 3.30

G 0.540 0.575 13.72 14.61

H 0.025 0.035 0.64 0.89

J 0.195 0.205 4.95 5.21

K 0.095 0.105 2.41 2.67

L 0.060 0.075 1.52 1.91

M 0.085 0.095 2.16 2.41

N 0.018 0.024 0.46 0.61

O 0.178 0.188 4.52 4.78

P 0.045 0.060 1. 14 1.52

R 0.038 0.048 0.97 1.22

Product Selector

Part Number

Q6008LH1LED 10 mA Alternistor Triac TO-220L

Packing Options

Part Number Marking Weight Packing Mode Base Quantity

Q6008LH1LED Q6008LH1 2.2 g Bulk 500

Q6008LH1LEDTP Q6008LH1 2.2 g Tube Pack 500 (50 per tube)

Part Numbering System Part Marking System

DEVICE TYPE

Q

:

Alternistor Triac

VOLTAGE RATING

60 :

600V

CURRENT

08: 8A

Gate Sensitivity Quadrants

Q 60 08 L H1 LED

I – II – III

LED LIGHTING APPLICATION

SENSITIVITY & TYPE

H1: 10mA (QI, II & III)

PACKAGE TYPE

L : TO-220 Isolated

Type Package

Q6008LH1

YMXXX

®

Q6008LH1LED Series

6

Revised: January 25, 2013 08:34 AM

Date Code Marking

Y:Year Code

M: Month Code

XXX: Lot Trace Code

Please refer to http://www.littelfuse.com for current information.

Specifications are subject to change without notice.

©2013 Littelfuse, Inc

Loading...

Loading...