Page 1

Protection Relays & Controls

D

D

D

Local

Circuit Breaker

Arc-Flash Monitoring

PGR-8800 SERIES (D1000)

Arc-Flash Relay

Description

The PGR-8800 is a microprocessor-based relay that limits

arc-fault damage by detecting the light from an arc flash and

rapidly tripping. Phase-current-transformer inputs are provided

for current-constrained arc-flash protection and, when so

equipped, a programmable definite-time overcurrent function

can be enabled. An optical sensor on the PGR-8800 and

adjustable trip level reduce the chance of nuisance tripping

by setting a threshold for ambient light. Sensors, inputs, and

connections are monitored to ensure fail-safe operation. A

secondary solid-state trip circuit provides a redundant trip path.

A USB port is used for configuration and access to event logs

and graphs.

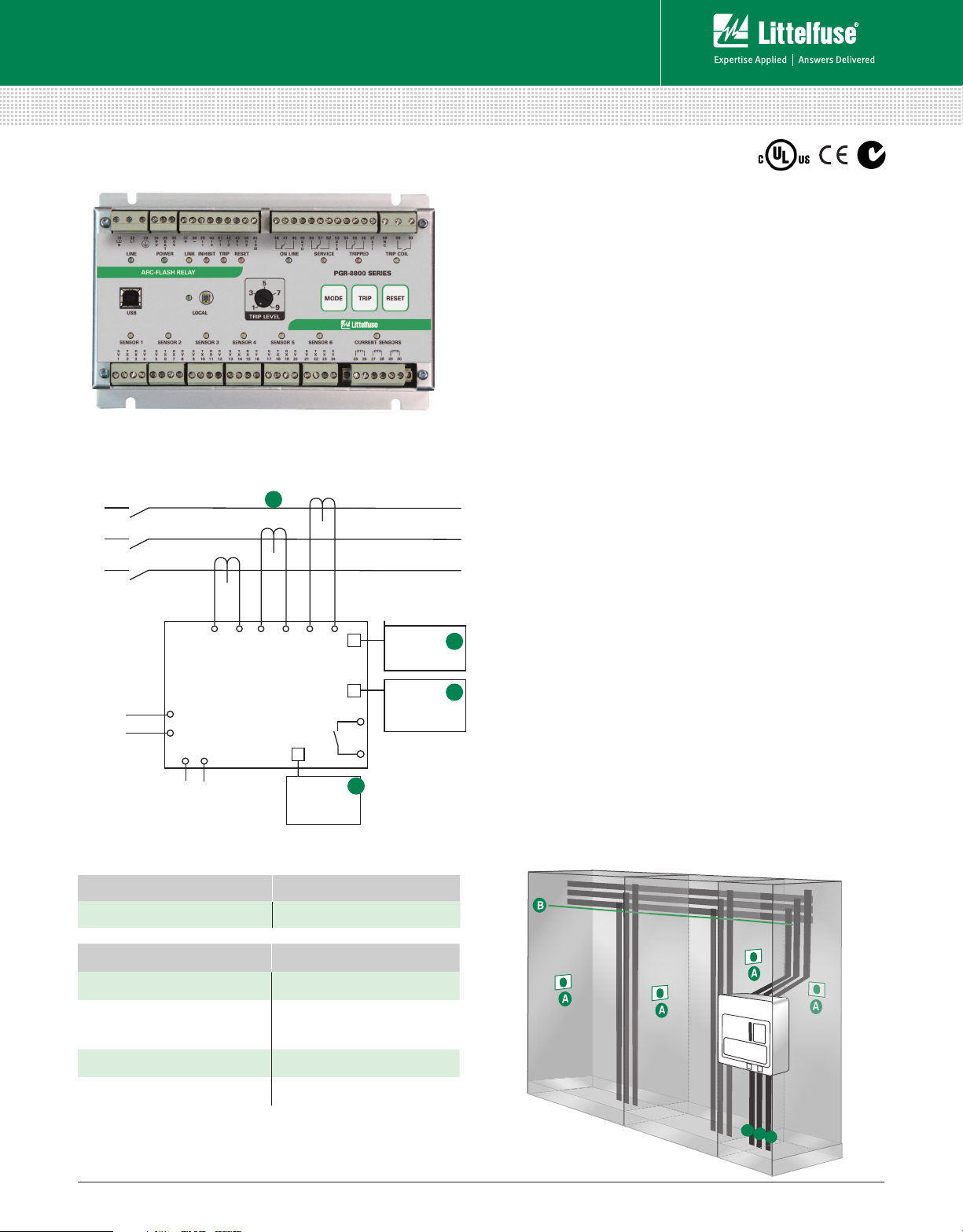

Simplified Circuit Diagram

5-A-SECONDARY PHASE CT’s

A

B

C

PGR-8800

L1

L2

For detailed wiring diagram, see adjacent page.

(Arc-Flash Protection Relay)

24 Vdc Battery

Backup

(Optional)

D

PGA-1100

(Diode Logic Unit)

(Optional)

Trip

C

Ordering Information

ORDERING NUMBER COMMUNICATIONS

(Recommended)

PGA-LS10

(Point Sensor)

PGA-LS20/

PGA-LS25/

PGA-LS30

(Fiber-Optic Sensor)

Optical Sensors

The PGR-8800 accepts both PGA-LS10 and PGA-LS20/PGALS25/PGA-LS30 optical sensors, designed to collect light over

a wide angle and with high sensitivity. For fast fault location,

front-panel and sensor LED’s indicate sensor health and which

sensor detected an arc fault.

Sensor Placement

The PGR-8800 Arc-Flash Relay and sensors are easily

installed in retrofit projects and new switchgear with little or

no re-configuration. Even elaborate systems with multiple

A

power sources take minutes to configure using the relay’s

built-in USB interface software.

Generally, it is recommended to mount 1 or 2 sensors per

B

cubicle to cover all horizontal and vertical bus bars, breaker

compartments, drawers, and anywhere that there is potential

for an arc-fault. Threading a fiber-optic sensor through

the cabinets and in areas where point-sensor coverage is

uncertain results in complete coverage and an added level

of redundancy. Even if policy is to only work on de-energized

systems, all maintenance areas should be monitored to

prevent potential damage and additional cost. At least one

sensor should have visibility of an arc fault if a person blocks

the other sensor(s).

PGR-8800-00 (UL, CE, C-tick) Multi-unit linking, Modbus® RTU

ACCESSORIES REQUIREMENT

PGA-LS10 (A1000) Required*

PGA-LS20 (A2000)/

PGA-LS25 (A2000.0020)

PGA-LS30 (A2000.0030)

PGA-1100 (D1100) Optional

Required*

Current Transformer Recommended

*At least one sensor is required. Ho wever, the exact number of sensors for prope r cover age

depen ds on the applica tion.

© 2013 Littelfuse Protection Relays & Controls

Littelfuse.com/ArcFlash

Based on Manual Rev 3-A-112913

Rev: 4-F-012214

Page 2

Protection Relays & Controls

Arc-Flash Monitoring

PGR-8800 SERIES (D1000)

Arc-Flash Relay

Features & Benefits

FEATURES BENEFITS

Arc-Flash trip time <1 ms Limits arc-flash damage and risk of injury

Multiple sensors (up to 24) Single module can monitor 6 sensors. Up to 4 PGR-8800 units can be linked into one system

Fail-safe system Continuous monitoring of optical sensors and inputs ensures protection

Redundant trip circuit Solid-state backup arc-detection circuit adds a second layer of safety

Adjustable light sensitivity Allows for operation in bright environments and maximum sensitivit y in dark environments

LED indication (on unit and each sensor) 18 LEDs provide at-a glance status for module and I/O state

Current detection Phase-CT inputs provide overcurrent protection and prevent nuisance trips

Optical detection Point and fiber-optic sensors provide wide detection area with sensor health trip indication

Digital inputs (6) Two each: remote trip, inhibit, and reset inputs

Service mode Allows for system test without tripping

Trip coil contact Solid-state 24-300 Vdc/24-300 Vac IGBT

Indication contacts Form C and status outputs

USB interface Data logging and configuration software uses a USB interface with no drivers or sof tware installation

Built-in sensor Can be used in single-sensor systems, as a seventh sensor, and for calibration

Universal power supply/Battery backup

Data logging On-board event recorder helps with system diagnostics

Modbus Remotely view measured values, event records & reset trips

Upstream Tripping Ability to trip upstream device if the local breaker fails to clear the fault

100-240 Vac, 14-4 8 Vdc, or 110-250 Vdc supply accepted. Ability to charge and run off an external, user-supplied

24 Vdc battery.

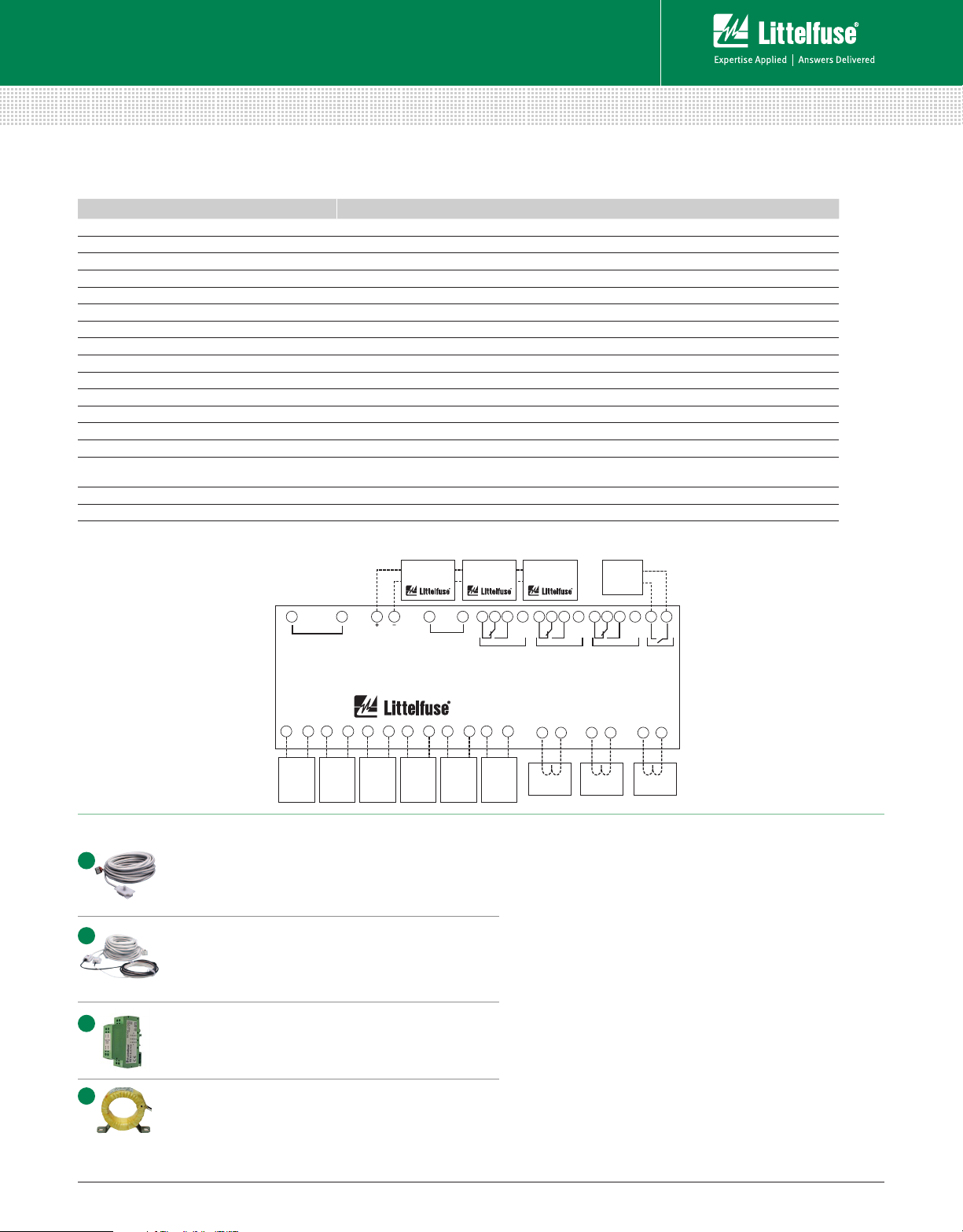

Wiring Diagram

Accessories

A

B

C

D

PGA-LS10 (A1000) Point Sensor

Line-of-sight light sensor detects an arc as small as 3 kA

within a 2-m half-sphere. Sensor health and trip indication.

Dimensions: See PGR-8800 Manual

PGA-LS20 (A2000)/PGA-LS25 (A2000.0020)/PGALS30(A2000.0030) Fiber-Optic Sensor

360° light sensor for tricky installations with many shadows

or to run along bus bars. Sensor health and trip indication.

Dimensions: See PGR-8800 Manual

PGA-1100 (D1100) Diode Logic Unit

This module allows multiple PGR-8800 relays to trip the

same breaker, for example an upstream or a tie-breaker.

Dimensions: H 80mm (3.15”) W 20mm(.79”) D 70mm(2.76”)

Current Transformers

Eliminate nuisance arc-flash trips and use for

overcurrent protection.

31 36 39 37 45 46 47 48 49 50 51 52 53 54 55 56 57 59 60 38

.....................

CONTROL POWER

and BATTERY

ARC-FLASH RELAY

PGR-8800 SERIES

1

4

5 8

........

PGA-LS10

PGA-LS20

PGA-LS25

or

PGA-LS30

OPTICAL

SENSOR

9 12

........

PGA-LS10

PGA-LS20

PGA-LS25

PGA-LS30

OPTICAL

SENSOR

........

PGA-LS10

PGA-LS20

PGA-LS25

or

PGA-LS30

OPTICAL

SENSOR

+

LINK

or

ARC-FLASH RELAY

PGR-8800

(optional)

–

13 16

........

PGA-LS10

PGA-LS20

PGA-LS25

or

PGA-LS30

OPTICAL

SENSOR

.............

DIGITAL INPUTS

17 20

........

PGA-LS10

PGA-LS20

PGA-LS25

or

PGA-LS30

OPTICAL

SENSOR

ARC-FLASH RELAY

PGR-8800

(optional)

ONLINE

21 24

........

PGA-LS10

PGA-LS20

PGA-LS25

or

PGA-LS30

OPTICAL

SENSOR

ARC-FLASH RELAY

PGR-8800

(optional)

STATUS STATUS STATUS

25 26 27 28 29 30

PHASE CT

(recommended)

DIODE LOGIC

UNIT

PGA-1100

PHASE CT

(recommended)

(optional)

TRIP COILTRIPPEDSERVICE

PHASE CT

(recommended)

Specifications

IEEE Device Numbers Overcurrent (50), Arc Flash (AFD)

Input Voltage 100-240 Vac, 14-48 Vdc, and 110-250 Vdc

Dimensions H 130 mm (5.2”); W 200 mm (7.9”);

D 54 mm (2.2”)

Optical Trip Settings 9-25 klux, 800 μs-20 s

Current Trip Setting (A) Programmable

Indication Contact Mode Fail-safe

Trip Coil Voltage

Trip Coil Contact Mode Selectable fail-safe or non-fail-safe

Redundant Trip Circuit Standard feature

Input Monitoring Standard feature

USB Interface Standard feature

Trip, Reset,

Service Buttons Standard feature

Expandable System Link up to 4 PGR-8800 units

Warranty 5 years

Mounting DIN (with D0050 adapter clips), Surface

(1)

24-300 Vdc, 24-300 Vac

NOTE (1) - Contact Littelfuse for trip coil voltages higher than 300 Vdc/Vac.

Littelfuse reserves the righ t to make produ ct changes, withou t notice. Mat erial in this document is as accura te as known at the time of p ublication. V isit Littelfuse. com for the most up-to-da te information.

© 2013 Littelfuse Protection Relays & Controls

Littelfuse.com/ArcFlash

Based on Manual Rev 3-A-112913

Rev: 4-F-012214

Loading...

Loading...