Littelfuse PGR-6200 Users Manual

POWR-GARD®

Motor Protection

PGR-6200 SERIES

Motor Protection Relay

PGR-6200 MANUAL

MOTOR PROTECTION RELAY

June 1, 2009

Revision 2

Publication: PGR-6200-M

Document: P95-P301-00000

POWR-GARD

MOTOR PROTECTION RELAY PGR-6200

TRIP

ALARM

RUN

UPI

RESET

²Messages Ñ

Copyright © 2009 by Littelfuse, Inc.

MAIN MENU

Metering Ñ

Setup Ñ

All rights reserved.

PGR-6200

SERIES

SERIES

ESC

ENTER

Factory default password is 1111

New Password

See Section 4.5

Motor Identification

Page i

TABLE OF CONTENTS

Page

Table of Contents............................................................i

List of Figures.................................................................ii

List of Tables..................................................................ii

1. INTRODUCTION......................................1-1

1.1 General ............................................................1-1

1.2 PGR-6200 Features........................................1-1

1.2.1 Protection ..............................................1-1

1.2.2 Metering.................................................1-1

1.2.3 Data Logging.........................................1-1

1.2.4 Inputs and Outputs................................1-1

1.2.5 Operator Interface.................................1-1

1.2.6 PGA-0120 Temperature Input Module

(Optional).....................................................1-1

1.2.7 PGA-0140 Differential Current

Module (Optional)........................................1-1

1.2.8 Communications...................................1-1

1.3 Ordering Information .......................................1-1

2. INSTALLATION........................................2-1

2.1 General ............................................................2-1

2.2 PGR-6200 Motor Protection Relay.................2-1

2.3 PGA-0CIM Current Input Module...................2-1

2.4 Sensitive Earth-Fault CT’s ..............................2-1

2.5 PGA-0120 Temperature Input Module...........2-1

2.6 PGA-0140 Differential Current Module ..........2-1

3. SYSTEM WIRING.....................................3-1

3.1 General ............................................................3-1

3.2 Wiring Connections.........................................3-2

3.2.1 PGR-6200 Connections .......................3-2

3.2.1.1 Supply Voltage........................3-2

3.2.1.2 CIM Input.................................3-2

3.2.1.3 Digital Input..............................3-2

3.2.1.4 Analog Output .........................3-2

3.2.1.5 PTC or RTD Input (Local).......3-2

3.2.1.6 I/O Module Interface ...............3-2

3.2.1.7 RS/EIA/TIA-232

Communications..................3-3

3.2.2 PGA-0CIM Connections.......................3-3

3.2.2.1 Standard..................................3-4

3.2.2.2 Residual Earth-Fault............... 3-4

3.2.2.3 Two-CT....................................3-4

3.2.3 PGA-0120 Connections and Address

Selection.............................................3-6

3.2.4 PGA-0140 Connections........................3-6

3.2.4.1 Core Balance...........................3-6

3.2.4.2 PGR-6200 Summation ...........3-6

3.2.4.3 DIF Summation....................... 3-6

3.2.5 Cable Restraint..................................3-6

3.2.6 Dielectric-Strength Testing ...................3-6

4. OPERATION AND SETUP........................4-1

4.1 Display and Indication.....................................4-1

4.1.1 Front-Panel LED Indication ..................4-1

4.1.2 Rear-Panel LED Indication...................4-2

4.1.3 Display Contrast and Test....................4-2

PGR-6200 Motor Protection Relay Rev. 2

Page

4.2 Setup ............................................................... 4-2

4.2.1 Phase-CT Inputs...................................4-2

4.2.2 Earth-Fault-CT Input............................. 4-2

4.2.3 Motor Data ............................................ 4-2

4.2.4 Output Relay Assignment .................... 4-3

4.2.5 Digital Input ........................................... 4-3

4.2.6 Analog Output....................................... 4-4

4.2.7 Miscellaneous Configuration................ 4-4

4.2.8 Communications................................... 4-4

4.3 Metering........................................................... 4-5

4.4 Messages........................................................4-5

4.4.1 Trip Reset.............................................. 4-5

4.4.2 Data Logging......................................... 4-5

4.4.3 Statistical Data......................................4-6

4.4.4 Emergency Thermal Reset ..................4-6

4.5 Password Entry and Programming................ 4-6

4.6 PGA-0120........................................................4-7

4.7 PGA-0140........................................................4-7

5. PROTECTIVE FUNCTIONS.............. 5-1

5.1 General ....................................................... 5-1

5.2 Overload...................................................... 5-1

5.2.1 Thermal Model .................................. 5-1

5.2.2 Locked-Rotor Times.......................... 5-4

5.2.3 Emergency Thermal Reset............... 5-4

5.3 Overcurrent.................................................5-4

5.4 Auxiliary Overcurrent................................... 5-5

5.5 Reduced Overcurrent.................................. 5-5

5.6 Jam ............................................................. 5-5

5.7 Earth Fault...................................................5-5

5.8 Current Unbalance...................................... 5-6

5.9 Phase Loss ................................................. 5-6

5.10 Phase Reverse............................................ 5-6

5.11 Undercurrent............................................... 5-6

5.12 Differential Current Protection..................... 5-6

5.13 Starts per Hour/Time Between Starts......... 5-7

5.14 PTC Temperature (Local)........................... 5-7

5.15 RTD Temperature (Local)........................... 5-7

5.16 RTD Temperature (PGA-0120 Module)...... 5-8

5.17 Hot-Motor Compensation............................ 5-8

6. THEORY OF OPERATION................ 6-1

6.1 Signal-Processing Algorithms..................... 6-1

6.2 Temperature Input Module (PGA-0120) ..... 6-1

6.3 Differential Current Module (PGA-0140)..... 6-1

7. COMMUNICATIONS............................ 7-1

7.1 Personal-Computer Interface......................7-1

7.1.1 Firmware Upgrade............................. 7-1

7.1.2 PGW-COMM..................................... 7-1

7.2 Network Interface........................................ 7-1

7.2.1 TIA-485 Option.................................. 7-1

7.2.2 DeviceNet Option.............................. 7-1

7.2.3 Ethernet Option................................. 7-1

Page ii

Page

8. TECHNICAL SPECIFICATIONS......8-1

8.1 PGR-6200....................................................8-1

8.2 Current Input Module (PGR-0CIM)..............8-3

8.3 Temperature Input Module (PGA-0120)......8-3

8.4 Differential Current Module (PGA-0140).....8-4

Appendix A PGR-6200 Menu Map.......................A-1

Appendix B PGR-6200 Setup Record..................B-1

Appendix C Not Used..........................................C-1

Appendix D PGR-6200 TIA-232 Modbus

Protocol ................................................................D-1

Appendix E Communications Database Table.....E-1

Appendix F Register Formats...............................F-1

Appendix G Ground-Fault Performance Test......G-1

LIST OF FIGURES

Page

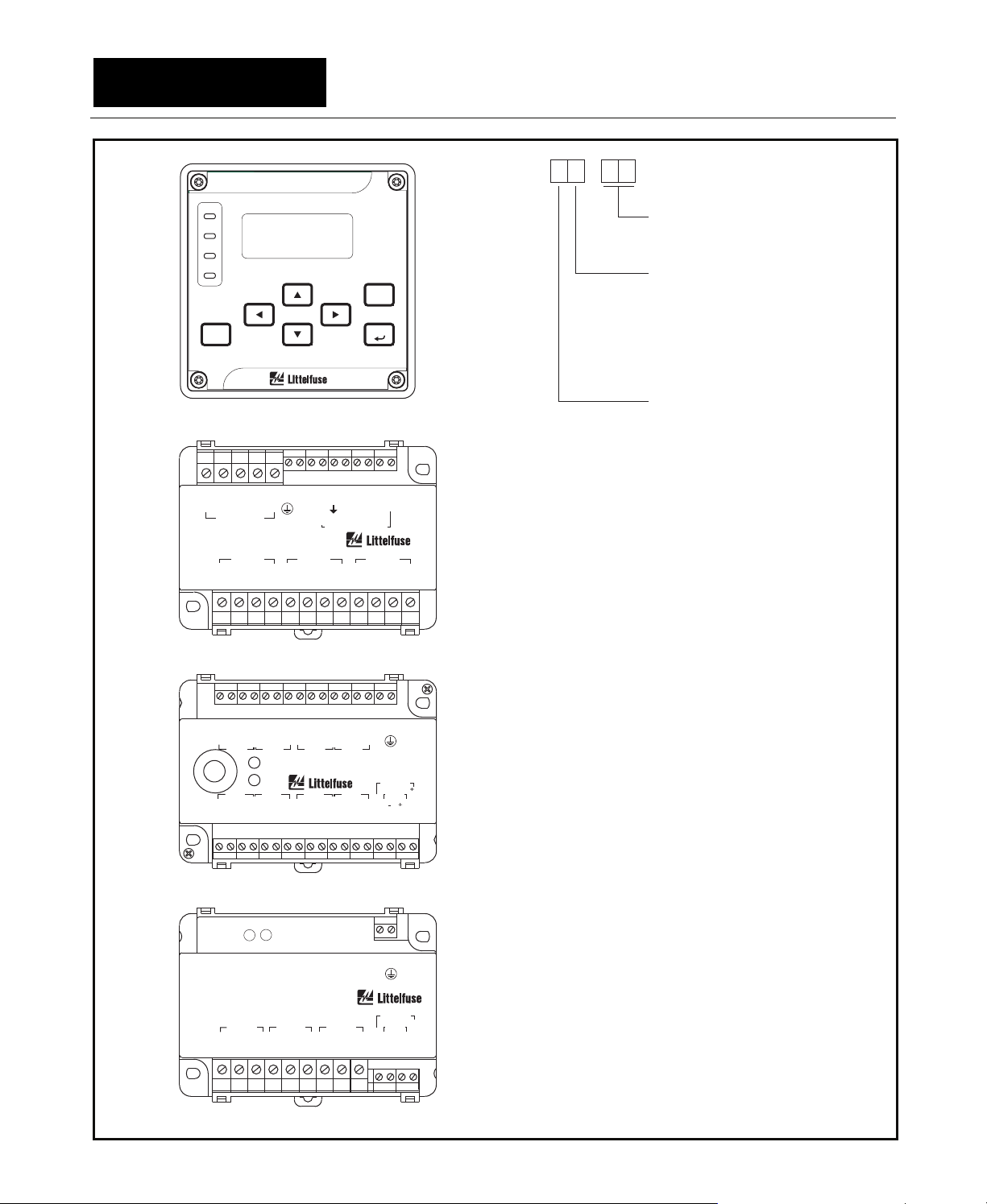

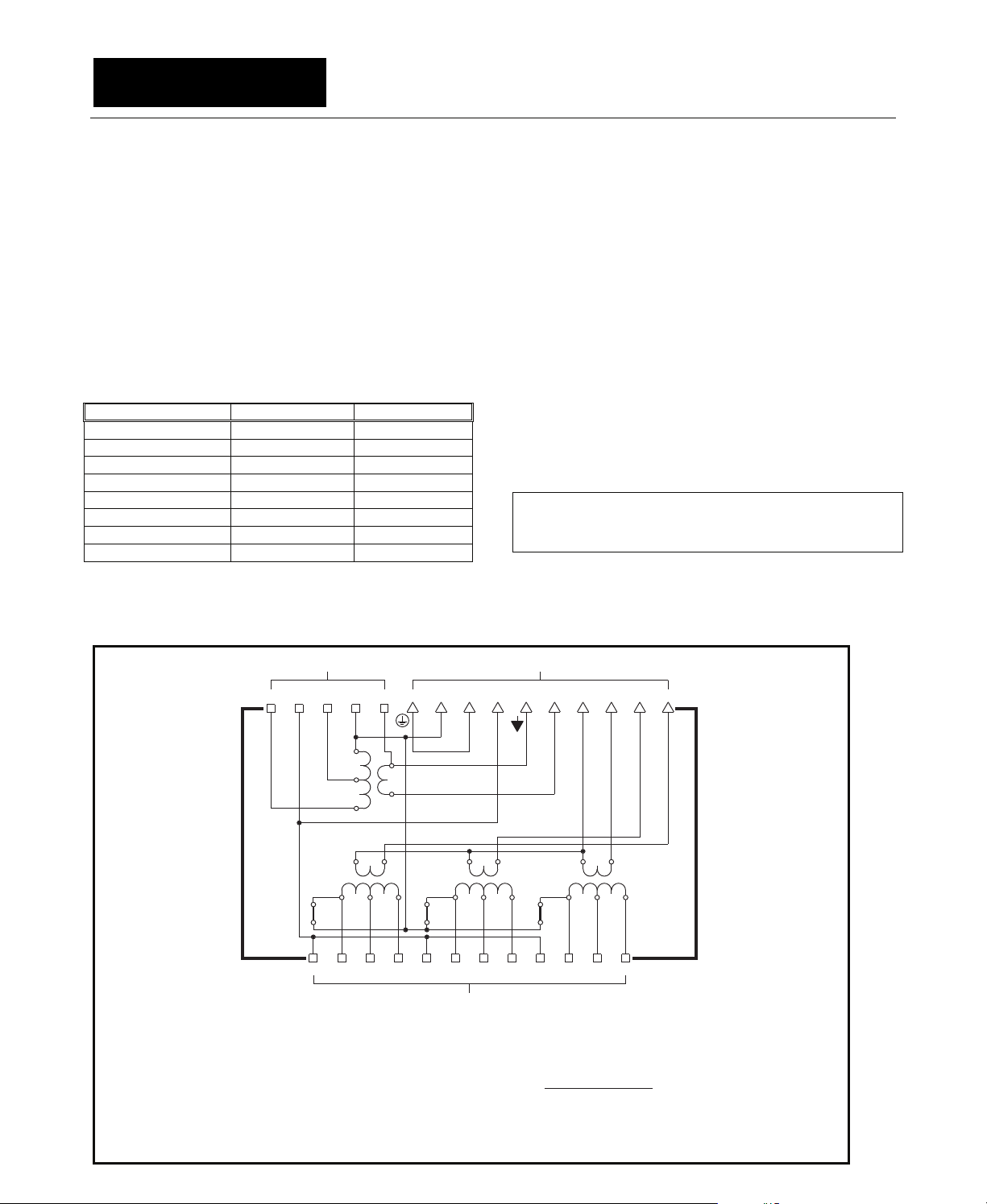

1.1 Motor Protection Relay Block Diagram..........1-2

1.2 PGR-6200 Ordering Information ....................1-3

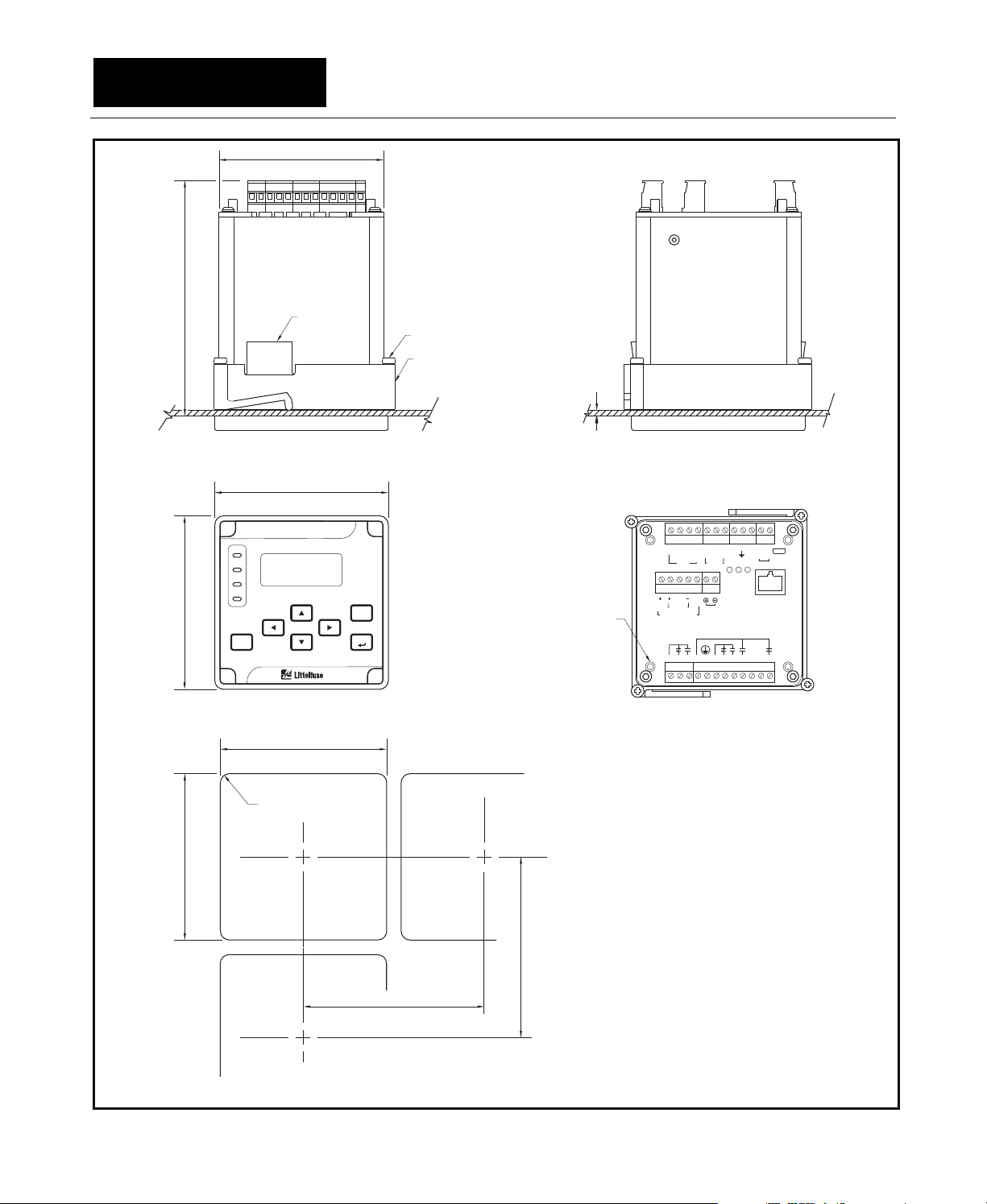

2.1 PGR-6200 Outline and Pane l-Mounting

Details...............................................................2-2

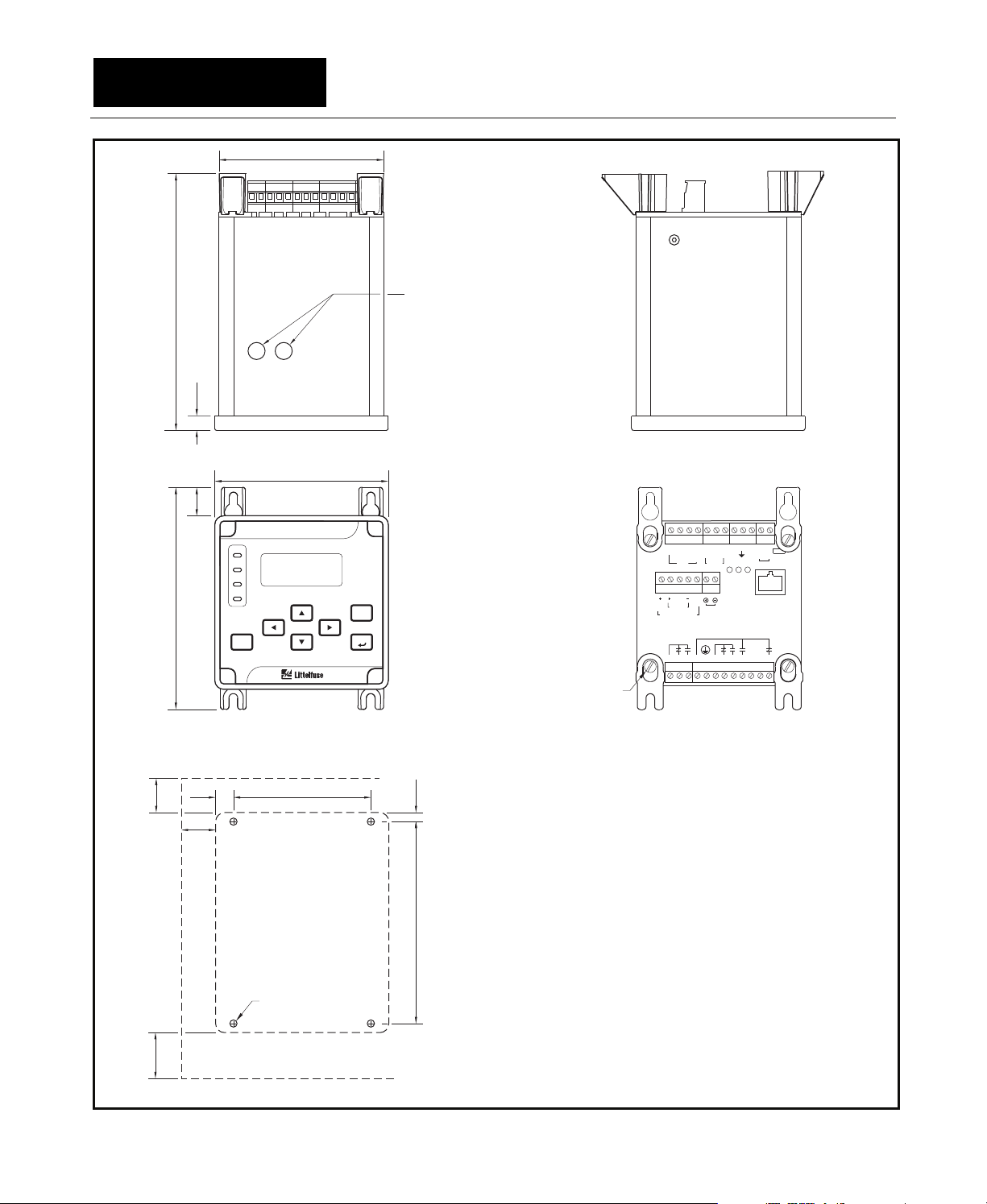

2.2 PGR-6200 Outline and Surface-Mounting

Details...............................................................2-3

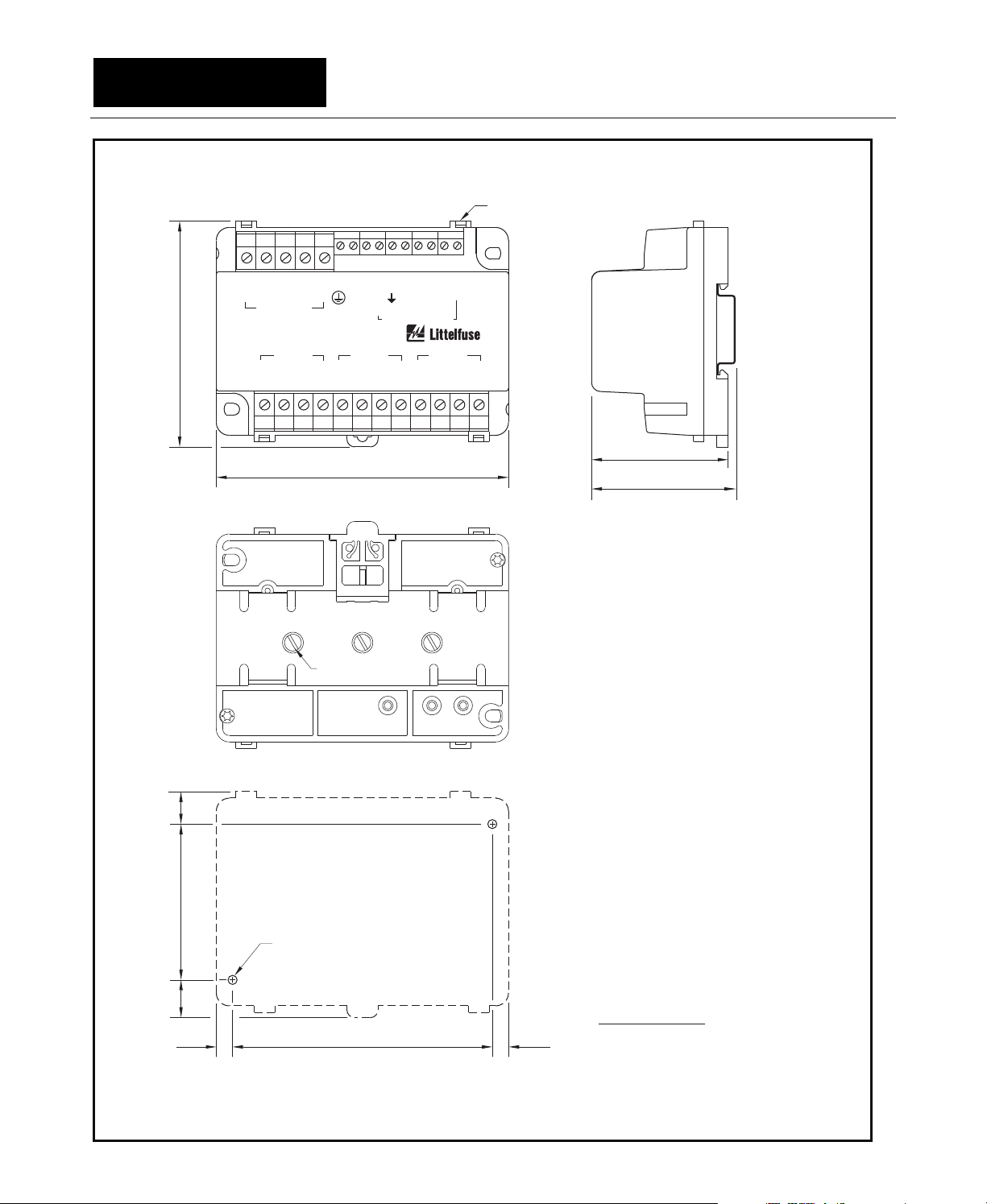

2.3 PGA-0CIM Outline and Mounting Details......2-4

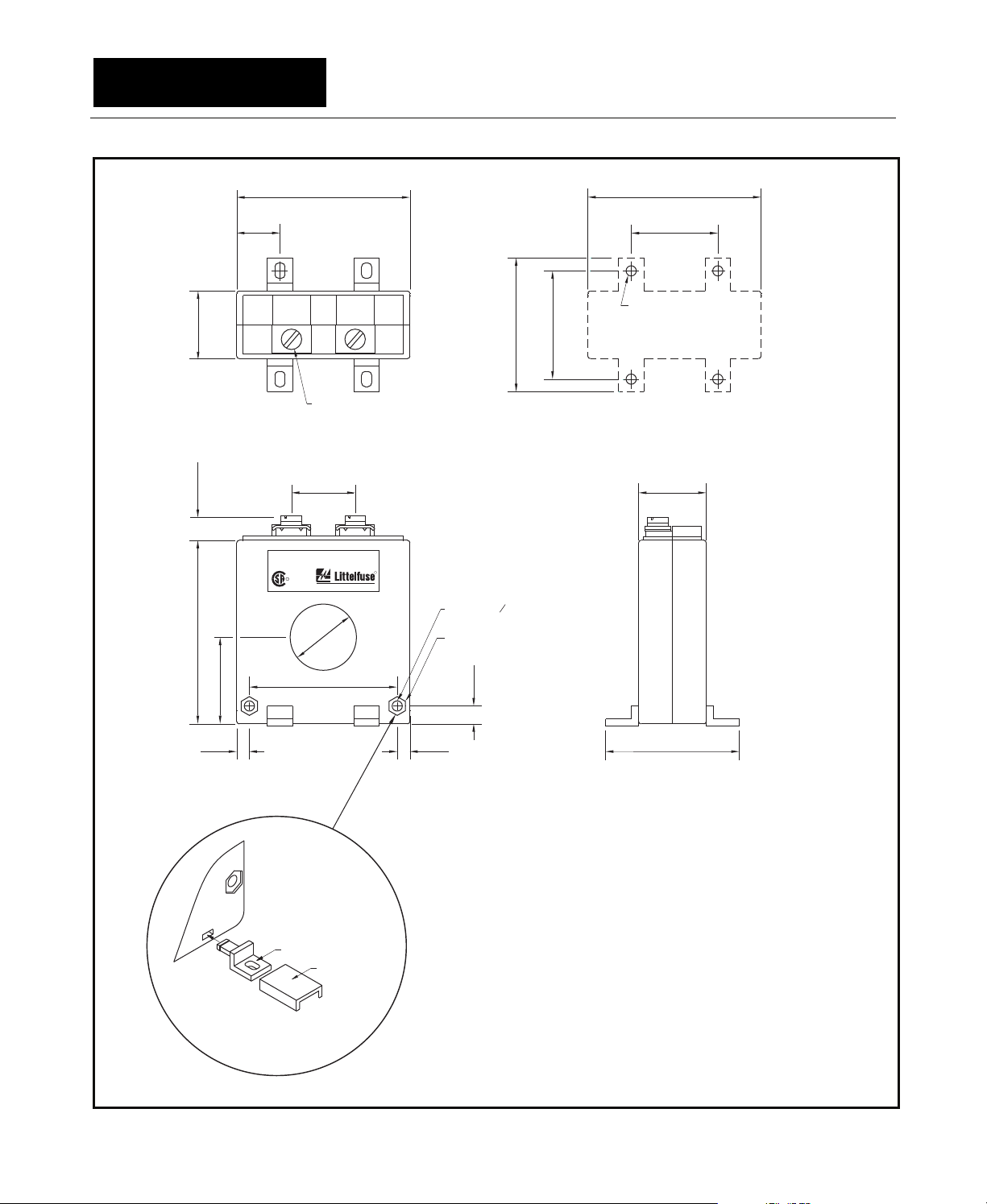

2.4 PGC-3082 Outline and Mounting Details.......2-5

2.5 PGC-3140 Outline and Mounting Details.......2-6

2.6 PGC-3026 Outline and Mounting Details.......2-7

2.7 PGA-0120 Outline and Mounting Details.......2-8

2.8 PGA-0140 Outline and Mounting Details.......2-9

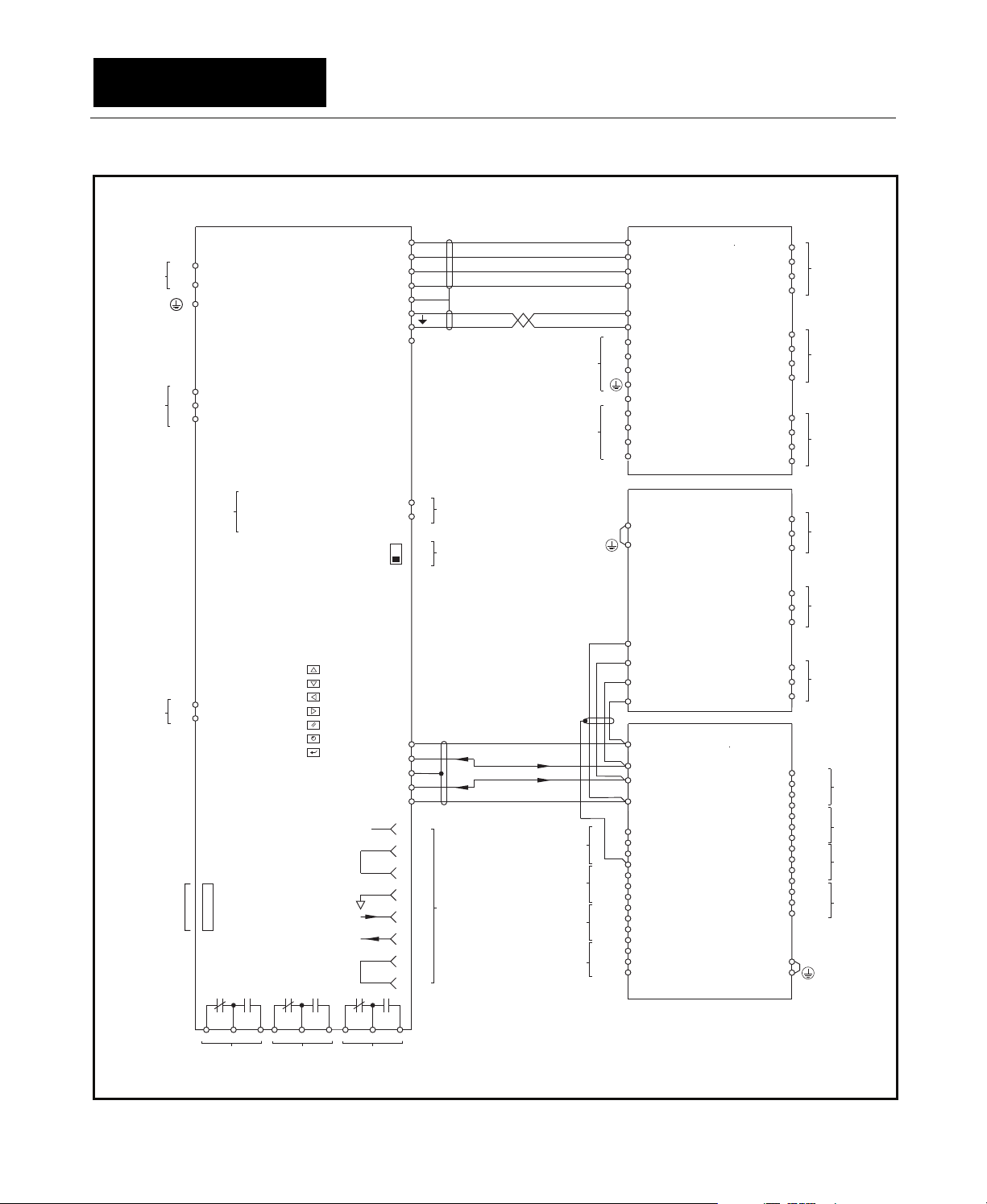

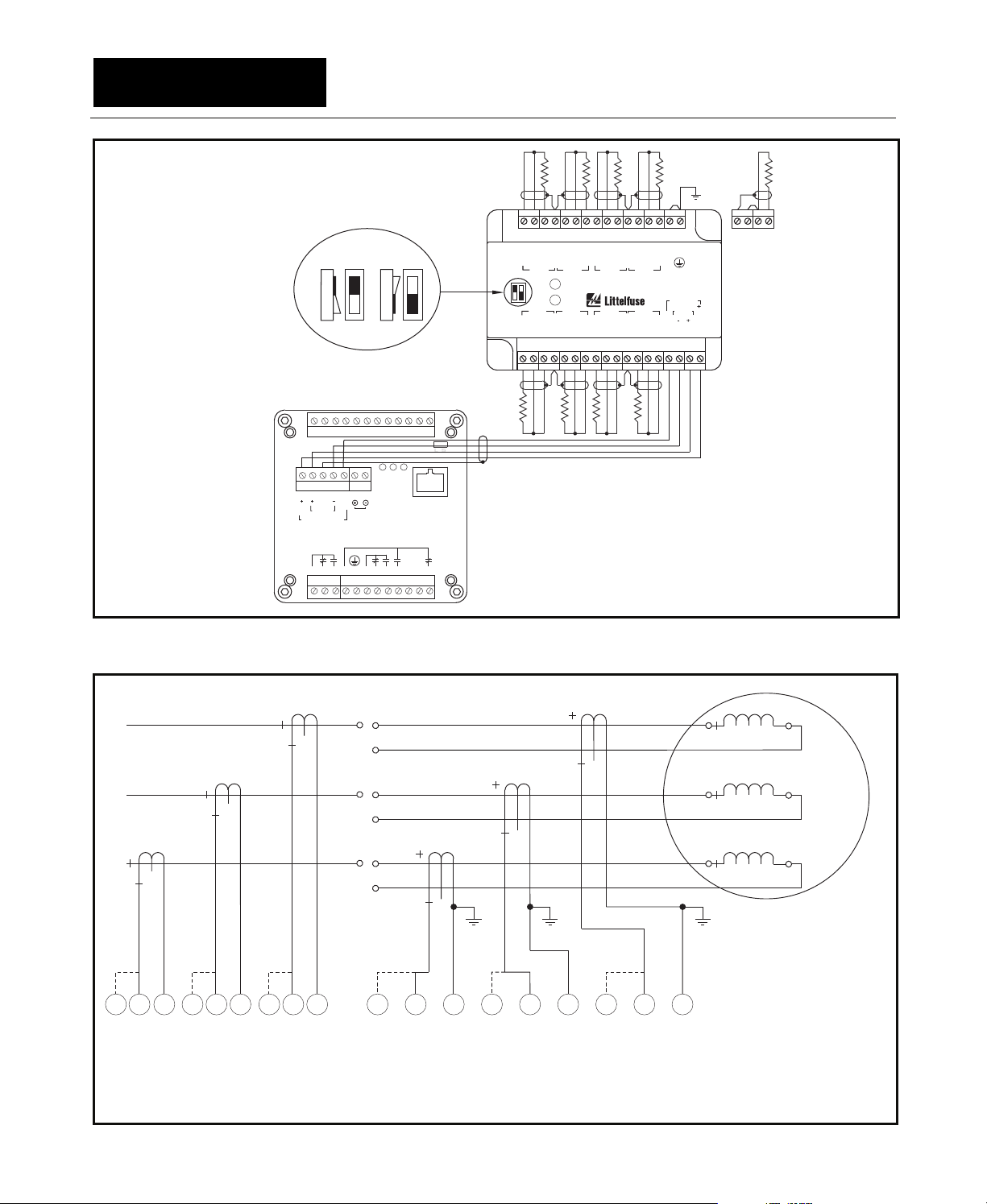

3.1 Typical PGR-6200 Connection Diagram........3-1

3.2 Analog-Output Connections............................3-2

3.3 Local Temperature-Sensor Connections.......3-2

3.4 I/O Module Connection Diagram....................3-2

3.5 PGA-0CIM Schematic.....................................3-3

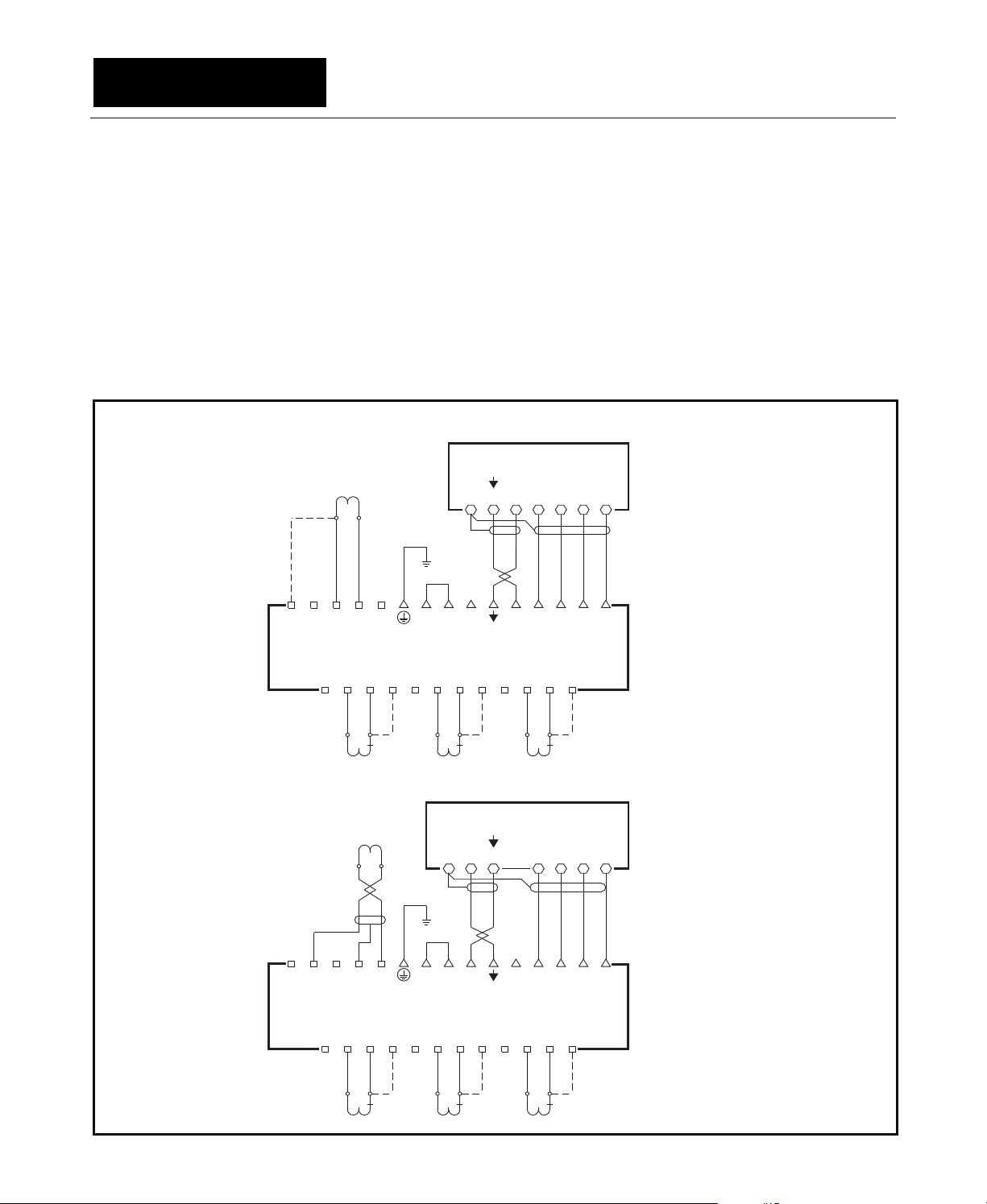

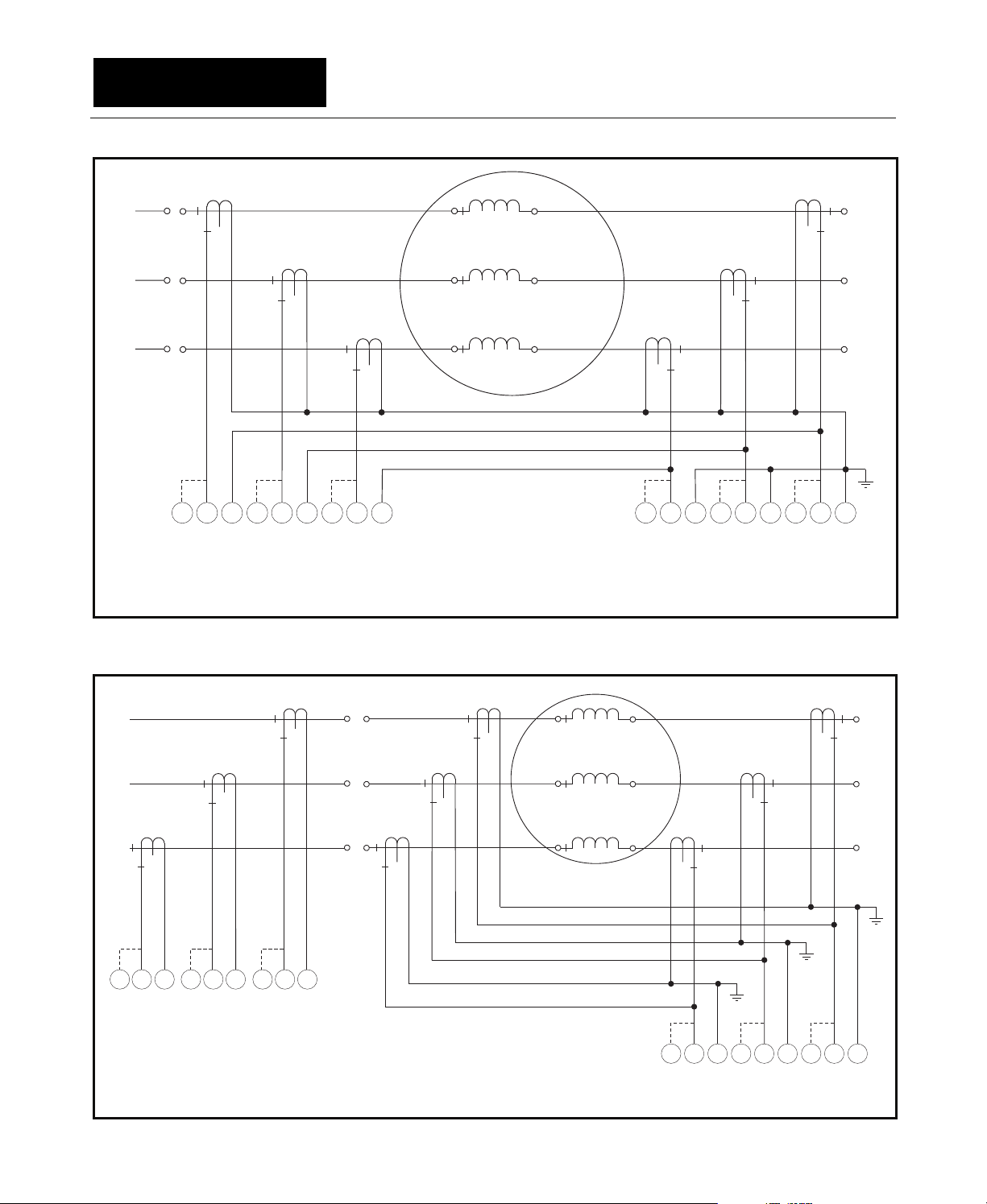

3.6 PGA-0CIM Standard Connections .................3-4

3.7 Other PGA-0CIM Connections.......................3-5

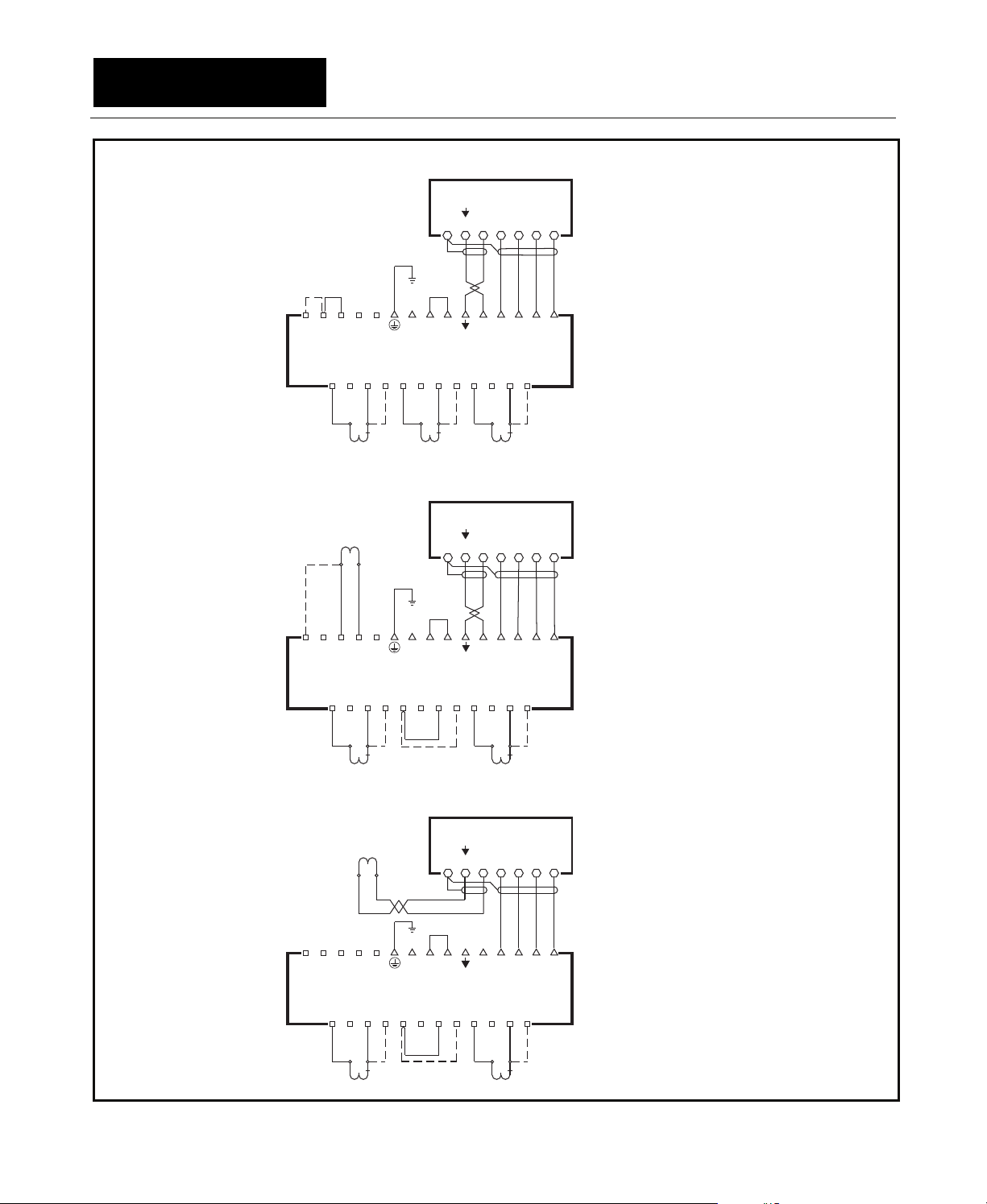

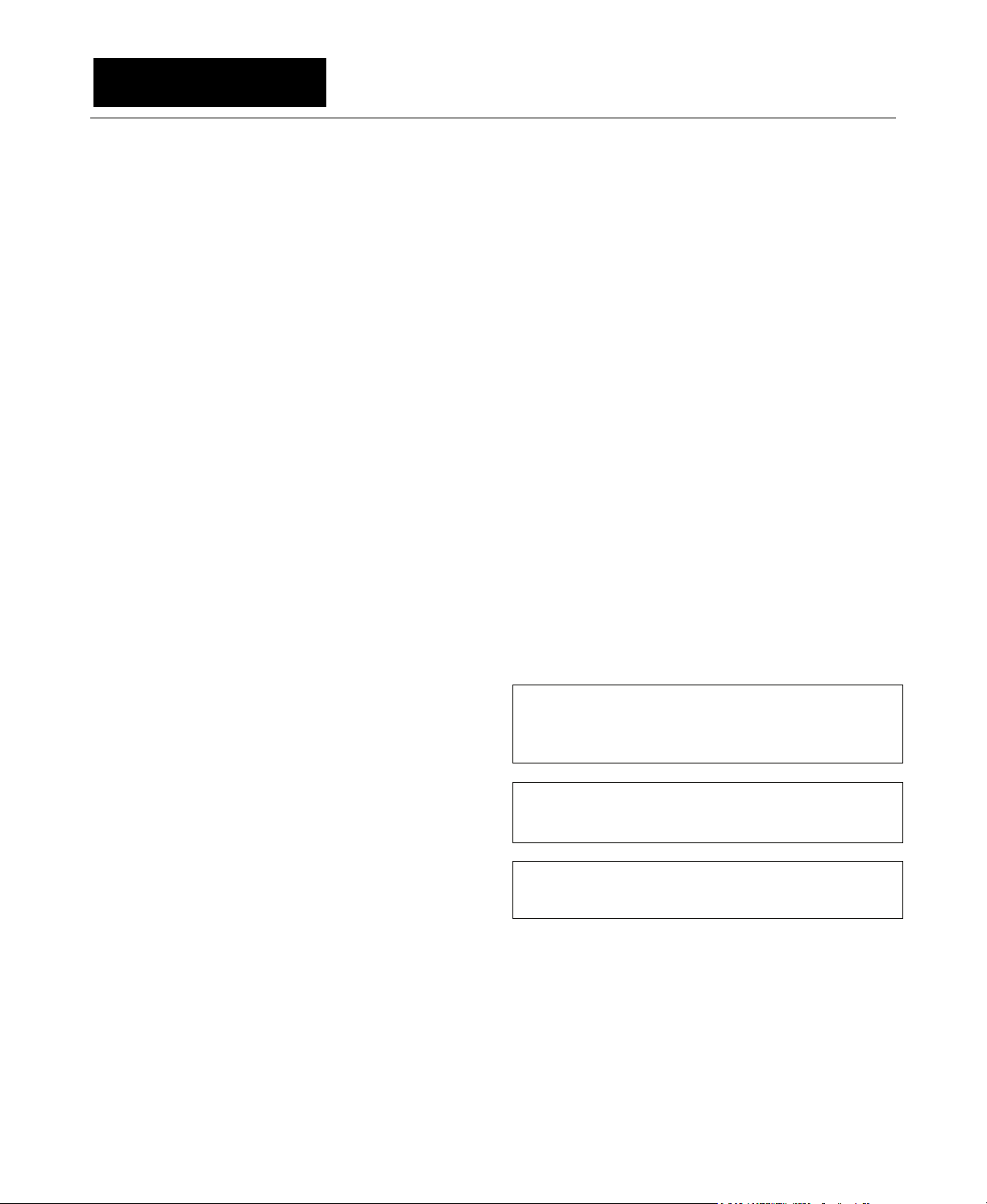

3.8 PGA-0120 Connection Diagram.....................3-7

3.9 Core-Balance Connection...............................3-7

3.10 PGR-6200-Summation Connection................3-8

3.11 PGA-0140-Summation Connections..............3-8

4.1 Menu Example.................................................4-1

4.2 Menu Symbols.................................................4-1

5.1 Class-20 Overload Curve................................5-3

5.2 Asymmetrical-Current Multipliers....................5-5

5.3 Used I

2

t Bias Curve.........................................5-8

PGR-6200 Motor Protection Relay Rev. 2

LIST OF TABLES

Page

3.1 PGA-0420 Adapter Pinout.............................. 3-3

3.2 PGA-0120 Address Selection......................... 3-6

4.1 UPI LED Functions.......................................... 4-1

4.2 Output-Relay Functions.................................. 4-3

4.3 Digital-Input Functions .................................... 4-3

4.4 Analog-Output Parameters............................. 4-4

4.5 Metering Display.............................................. 4-5

5.1 Fault Duration Required for Trip or Alarm...... 5-4

DISCLAIMER

Specifications are subject to change without

notice. Littelfuse, Inc. is not liable for contingent or

consequential damages, or for expenses sustained

as a result of incorrect application, incorrect

adjustment, or a malfunction.

This product has a variety of applications. Those

responsible for its application must take the

necessary steps to assure that each installation

meets all performance and safety requirements

including any applicable laws, regulations, codes,

and standards.

Information provided by Littelfuse is for purposes of

example only. Littelfuse does not assume

responsibility for liability for use based upon the

examples shown.

Page 1-1

PGR-6200 Motor Protection Relay Rev. 2

1. INTRODUCTION

Thermal capacity used during starts

Start time

1.1 General

The POWR-GARD® PGR-6200 is a motorprotection relay that provides integrated protection,

metering, and data-logging functions for fixed- and

variable-frequency applications. The PGR-6200 can

be programmed using the front-panel operator

interface, the TIA-232 port, or an optional

communications network.

The PGR-6200 uses a PGA-0CIM current-input

module for current-transformer connections as

shown in Fig. 1.1. Each PGR-6200 includes a

PGA-0CIM.

1.2 PGR-6200 Features

1.2.1 Protection

• Overload (49, 51)

• Overcurrent (50, 51)

• Earth fault (50G/N, 51G/N)

• Unbalance (46)

• Phase loss (46)

• Phase reverse (46)

• Jam

• Undercurrent (37)

• Starts per hour (66)

• Differential (87)

• PTC overtemperature (49)

• RTD temperature (38, 49)

1.2.2 Metering

• Line currents

• Current unbalance

• Positive-sequence current (I

• Negative-sequence current (I

• Zero-sequence current (3I

)

1

)

2

, calculated)

0

• Earth-leakage current (CT input)

• Differential currents

• Used thermal capacity

• Thermal trend

• RTD temperatures

• Frequency

1.2.3 Data Logging

• One-hundred records

Date and time of event

Event type

Cause of trip

Line currents

Current unbalance

Earth-leakage current

Differential currents

RTD temperatures

• Trip counters

• Running hours

1.2.4 Inputs and Outputs

• Phase-current inputs

• Earth-leakage-current input

• Programmable digital input (24 Vdc)

• 24-Vdc source for digital input

• 4–20-mA analog output, programmable

• Temperature-sensor input, Pt100 RTD or PTC

• I/O module interface

• Three output relays, programmable

• TIA-232 communications

• Network communications

1.2.5 Operator Interface

• 4 x 20 backlit LCD display

• Display-control and programming keys

• LED status indication

1.2.6 PGA-0120 Temperature Input Module (Optional)

• Eight-RTD inputs per module

• Individually selectable RTD types

• Solid-state multiplexing

• Up to three modules per system

• Remote operation up to 1.2 km (4,000’)

• Powered by PGR-6200

1.2.7 PGA-0140 Differential Current Module (Optional)

• 3-CT core balance connection

• 6-CT summation connection

• Remote operation up to 1.2 km (4,000’)

• Powered by PGR-6200

1.2.8 Communications

The standard communications interface is a

TIA-232 port using the Modbus

addition to the standard interface, network

communications options include TIA-485 with both

Modbus

DeviceNet

®

RTU and A-B® DF1 protocols,

TM

, and an IEEE 802.3 port with Modbus®

TCP Ethernet protocol.

®

RTU protocol. In

1.3 Ordering Information

See Fig. 1.2 for PGR-6200, PGA-0CIM,

PGA-0120 and PGA-0140 model numbers.

Used thermal capacity

Page 1-2

PGR-6200 Motor Protection Relay Rev. 2

A

SUPPLY

PTC/RTD

INPUT

24VDC

DIGITAL

INPUT

OPTIONAL

NETWORK COM

PGR-6200

2

L1

L2

3

8

TA

17

18

TB

19

TC

MOTOR

PROTECTION

RELAY

LED INDICATORS:

TRIP

13

B

14

C

15

COM

16

29

EF

22

21

20

NC

CONFIGURATION

SELECTION

EARTH FAULT CT

ALARM

RUN

UPI (USER PROG INDICATOR)

NS (NETWORK STATUS)

ON

MS (MODULE STATUS)

REAR

PANEL

ER (ERROR)

L

S

23 AB

24 AA

4-20mA

ANALOG

OUTPUT

ANALOG OUTPUT

SELF/LOOP

POWER SELECTOR

DISPLAY:

4 x 20ALPHANUMERIC LCD,

LED BACKLIGHTING

KEYPAD:

UP

DOWN

LEFT

25

-

+

RIGHT

26

RESET

ESC

ENTER

0V

27

-

28

29

+

30

+24V

31

I/O COMMUNICATIONS

1

DCE

DCD

DTR

SG

RD

TD

CTS

RTS

2

3

4

TIA-232

5

6

7

8

RTD 4

RTD 3

RTD 2

RTD 1

EF1

SPG

+24V

+24V

SHIELD

SHIELD

13

PGA-0CIM

14

CURRENT

15

16

17

18

19

Y

20

21

X

22

E

23

S

24

25

5

26

27

1

MODULE

PGA-0140

15

DIFFERENTIAL

14

13

-

11

+

12

0V

10

0V

15

+

16

-

17

18

14

C

13

D

12

R

11

10

C

9

D

8

R

7

C

6

D

5

R

4

C

3

2

D

R

1

MODULE

LED INDICATORS:

PGA-0120

TEMPERATURE

MODULE

LED INDICATORS:

ADDRESS SWITCHES

INPUT

PWR

COMM

INPUT

PWR

COMM

12 1

11 5

10 S

9R

81

75

6S

5R

4

3

2RS

1

9

8

7

6

5

4

3

2

1

21

22

23

24

25

26

27

28

29

30

31

32

33

34

20

19

PHASE CT

PHASE CT

1

5

PHASE CT

R

1

DIFFERENTIAL

5

CT

C

1

DIFFERENTIAL

5

CT

C

1

DIFFERENTIAL

5

CT

C

R

D

C

SHIELD

R

D

C

R

D

C

SHIELD

R

D

C

SPG

RTD 5

RTD 6

RTD 7

RTD 8

12 9 7

11 1 6

10 4 5

OUTPUT

RELAY 2

OUTPUT

RELAY 3

OUTPUT RELAY CONTACTS SHOWN

OUTPUT

RELAY 1

FIGURE 1.1 Motor Protection Relay Block Diagram.

DE-ENERGIZED.WITH PGR-6200

Page 1-3

PGR-6200 Motor Protection Relay Rev. 2

POWR-GARD

MOTOR PROTECTION RELAY PGR-6200

TRIP

ALARM

RUN

UPI

RESET

27 26 25 24 23 22 21 20 19 18 17 16 15 14 13

1R5SE XYE

EARTH FAULT

POWR-GARD

CURRENT INPUT MODULE

RS51RS51RS51

123456789101112

MAIN MENU

Metering Ñ

²Messages Ñ

Setup Ñ

PHASE A PHASE B PHASE C

PGA-0CIM

PGR-6200

SERIES

SERIES

C

E

O

F

F

M

2

1

PGR-6200/PGR-7200

ESC

ENTER

CBA

PGR-6200-

PGA-0CIM

-

Options:

00 CIM Input

Network Communications:

0 None, TIA-232 only

1 TIA-485 c/w A-B DF1 &

Modbus RTU Protocols

®

2 DeviceNet

®

TM

4 IEEE 802.3 (Ethernet)

Power Supply:

0 Universal ac/dc

(65 to 265 Vac and

80 to 275 Vdc)

NOTE:

The PGR-6200 consists of the

Motor Protection Relay and the PGA-0CIM

Current Input Module. To order the relay only,

add (-MPU) to the part number listed above.

31

34 33 32 30 29 28 27 26 25 24 23 22 21 20 19

CDR CDRCDR CDRS

S

H

INP 8 INP 7 INP 6 INP 5

INP 1 INP 2 INP 3 INP 4

RDC RDCRDC RDC

1234567891011121314

PWR

POWR-GARD®

DIFFERENTIAL INPUT MODULE PGA-0140PGA-0140

PHASE A PHASE B PHASE C

C51C51C51

123456789

POWR-GARD

PWR

TEMPERATURE INPUT MODULE PGA-0120PGA-0120

COMM

S

H

COMM

S

H

P

G

PGR-6200

PGR-6300

S

H

COMM

0

V

15 16 17 18

15 14

S

P

G

PGR-6200

PGR-6300

COMM

0

-

+

V

10 11 12 13

FIGURE 1.2 PGR-6200 Ordering Information.

PGA-0120

2

4

V

PGA-0140

®

+

2

4

V

Supplied Interconnect Cable:

P75-P300-20030 . . PGA-0CIM to PGR-6200 Interconnect Cable,

3124A ..........I/OModule to PGR-6200 Interconnect Cable,

6 m (19’) Included with PGA-0CIM

4 m (13’) Included with PGA-0120 and PGA-0140

Page 1-4

PGR-6200 Motor Protection Relay Rev. 2

Current Transformers:

PGC-3026 ..................Sensitive Earth-Fault CT,

5-A-primary rating,

26-mm (1”) window

PGC-3082 ..................Sensitive Earth-Fault CT,

5-A-primary rating,

82-mm (3.2”) window

PGC-31FC .................Flux Conditioner for

PGC-3082,

70-mm (2.7”) window

PGC-3140…..………..Sensitive Earth-Fault CT

with Flux Conditioner,

5-primary rating,

139-mm (5.5”) window

Other Earth-Fault CT’sContact factory

Phase CT’s.................Contact factory

Accessories:

PGK-0SMK….............Surface-mounting

hardware kit

PGA-016A..................Watertight faceplate cover

PGA-0420 ..................DB9 to RJ-45 Adaptor with

1.5 m (5’) cable

PGA-0440 ..................USB to TIA-232 serial

converter

Software:

PGW-COMM..............PC Interface

PGW-FLSH................Firmware Upgrade

(1)

(1)

(1)

Available at www.littelfuse.com/protectionrelays

Page 2-1

2. INSTALLATION

2.1 General

A basic system consists of a PGR-6200, a

PGR-0CIM, and three 1-A- or 5-A-secondary linecurrent transformers. Earth-fault protection can be

provided from a core-balance CT or from phase

CT’s. A core-balance CT (1-A, 5-A, or PGC-3000

series) is recommended. In addition to a single

PTC/RTD input provided on the PGR-6200, up to

three PGA-0120 modules (eight RTD inputs per

module) and one PGA-0140 differential module can

be connected to a PGR-6200.

The PGR-6200 switch-mode power supply is rated

65 to 265 Vac and 80 to 275 Vdc.

All modules can be mounted in any orientation.

PGR-6200 Motor Protection Relay Rev. 2

2.5 PGA-0120 Temperature Input Module

Outline and mounting details for the PGA-0120

are shown in Fig. 2.7. The PGA-0120 will fit inside

most motor RTD-termination junction boxes and it is

certified for use in Class I, Zone 2 hazardous

locations. The PGA-0120 can be surface or DIN-rail

mounted.

2.6 PGA-0140 Differential Current Module

Outline and mounting details for the PGA-0140

are shown in Fig 2.8. The PGA-0140 can be surface

or DIN-rail mounted.

2.2 PGR-6200 Motor Protection Relay

Outline and details for PGR-6200 panel-mounting

are shown in Fig. 2.1. The PGR-6200 mounts in a

92 mm (3.62”) ¼ DIN square cutout and is secured

by a panel-mount clamp. Insert the PGR-6200

through the panel cutout and slip the panel-mount

clamp over the PGR-6200 body. Slide the clamp

forward until the latch tabs snap into the mating

holes. Lock the unit in place by tightening the four

clamp screws against the panel.

Caution:

Do not over tighten the clamp screws as this may

deform the clamp and release the latch tabs.

Outline and details for PGR-6200 surfacemounting are shown in Fig. 2.2. Ensure that the L/S

switch is set before installing surface-mounting

brackets. See Section 3.2.1.4 for switch positions.

A detailed installation instruction sheet is included

with the PGK-0SMK, Surface-Mounting Hardware

Kit.

2.3 PGA-0CIM Current Input Module

The PGA-0CIM can be surface or DIN-rail

mounted. Outline and mounting details are shown

in Fig. 2.3. To minimize CT-lead burden, a

PGA-0CIM can be located close to the CT’s. The

PGA-0CIM terminates phase- and earth-fault-CT

secondaries⎯shorting blocks are not required for

PGA-0CIM outputs.

2.4 Sensitive Earth-Fault CT’s

Outline and mounting details for the PGC-3026,

PGC-3082, and PGC-3140 are shown in Figs. 2.4,

2.5, and 2.6.

Page 2-2

PGR-6200 Motor Protection Relay Rev. 2

91.1

(3.59)

(5.20)

132.0

LATCH TAB

CLAMP SCREWS

PANEL-MOUNT CLAMP

1.6 (0.06) TO 4.8 (0.19)

PANEL THICKNESS

96.0

92.0

(3.78)

(3.62)

TOP

96.0

(3.78)

POWR-GARD

MOTOR PROTECTION RELAY PGR-6200

TRIP

ALARM

RUN

UPI

RESET

MAIN MENU

Metering Ñ

²Messages Ñ

Setup Ñ

FRONT

92.0

(3.62)

R=4.8 (0.19)

MAXIMUM

PGR-6200

SERIES

SERIES

ESC

ENTER

6-32 CABLING RESTRAINT

FASTENING POINT

4 PLACES

NOTES:

1.2.DIMENSIONS IN MILLIMETRES (INCHES).

REAR VIEW SHOWN WITHOUT NETWORK

COMMUNICATIONS.

SIDE

20 2321

18 19

13 15 1714 16

TATBT

AB C

C

C

O

M

CIM

TEMP AN OUT

ERMSN

31 29 2730 28

26 25

SH0

2

V

4

COMM

DIG IN

V

I/O MODULE

RELAY 2

RELAY 1

12 11 10 9 8 7 6 5 4 3 2 1

REAR

22

EFABA

S

TIA-232 ONLY

RELAY 3

L

2

L

/

N

1

24

A

LS

100.0

100.0

(3.94)

MINIMUM

PANEL CUTOUT DETAIL

FIGURE 2.1 PGR-6200 Outline and Panel-Mounting Details.

(3.94)

MINIMUM

Page 2-3

PGR-6200 Motor Protection Relay Rev. 2

91.1

(3.59)

HOLE PLUGS

(TOP AND BOTTOM

142.9

(5.63)

8.0

(0.32)

SURFACES)

19.0

122.5

(0.75)

16.6

(4.82)

(0.39)

19.0

(0.75)

(0.65)

POWR-GARD

MOTOR PROTECTION RELAY PGR-6200

TRIP

ALARM

²Messages Ñ

RUN

UPI

RESET

(NOTE 5)

M4 OR 8-32 TAP

TOP

96.0

(3.78)

MAIN MENU

Metering Ñ

Setup Ñ

FRONT

76.29.9

(3.00)

PGR-6200

SERIES

SERIES

ESC

ENTER

5.0

112.0

(0.20)

(4.41)

SIDE

20 2321

24

22

18 19

13 15 1714 16

TATBT

AB C

C

O

M

CIM

31 29 2730 28

SH0

2

V

4

COMM

V

I/O MODULE

RELAY 2

12 11 10 9 8 7 6 5 4 3 2 1

EFABA

C

TEMP AN OUT

ERMSN

S

26 25

DIG IN

RELAY 1

TIA-232 ONLY

RELAY 3

L

2

/

N

A

LS

L

1

NOTE 3

REAR

NOTES:

1.

DIMENSIONS IN MILLIMETRES (INCHES).

2.

REAR VIEW SHOWN WITHOUT NETWORK

COMMUNICATIONS.

3.

MOUNT SURFACE MOUNTING BRACKETS

WITH 6-32 x 0.375 PAN-HEAD SCREWS AND

LOCKWASHERS. (INCLUDED WITH

SURFACE-MOUNTING KIT).

4.

PGR-6200 MOUNTING SCREWS: M4 OR

8-32 PAN HEAD.

5.

MINIMUM CLEARANCE TO ADJACENT

OBJECTS.

25.4

(1.00)

(NOTE 5)

MOUNTING DETAIL

FIGURE 2.2 PGR-6200 Outline and Surface-Mounting Details.

Page 2-4

PGR-6200 Motor Protection Relay Rev. 2

CABLE-TIE EYELET

4 PLACES

87.0

(3.43)

27 26 25 24 23 22 21 20 19 18 17 16 15 14 13

1R5SE XYE

EARTH FAULT

POWR-GARD

CURRENT INPUT MODULE

PHASE A PHASE B PHASE C

RS51RS51RS5 1

1

3456789 101112

2

PGA-0CIMPGA-0CIM

112.5

(4.43)

F

1

CBA

C

E

O

F

M

2

PGR-6200/PGR-7200

TOP

SHORTING SCREWS

A,B,&C(NOTES4&5)

52.5

(2.07)

56.0

(2.20)

SIDE

(NOTE 3)

BOTTOM

12.5

(0.50)

60.0

(2.36)

M4 OR 8-32 TAP

14.5

(0.57)

100.06.8 6.8

(3.94)(0.27) (0.27)

MOUNTING DETAIL

FIGURE 2.3 PGA-0CIM Outline and Mounting Details.

NOTES:

DIMENSIONS IN MILLIMETRES (INCHES).

1.

MOUNTING SCREWS: M4 OR 8-32.

2.

OVERALL HEIGHT WHEN MOUNTED

3.

ON DIN EN50022 35-mm x 7.5-mm

TOP-HATRAIL.

SHORTING SCREWS ARE ACCESSIBLE

4.

FROM BOTTOM OF PGA-0CIM.

5.

SHORTING SCREWS: 6-32 x 0.375

NICKEL-PLATED-BRASSBINDING HEAD.

DO NOT SUBSTITUTE.

Page 2-5

PGR-6200 Motor Protection Relay Rev. 2

26.5

110.0 MAX

72.0

(1.04)

(0.43)

(2.83)

17.0

(0.67)

68.0

(2.68)

P

2

SS

2

1

P

1

M5 SCREWS

52.5

(2.07)

42.6

(1.68)

68.0

(2.68)

34.0

(1.34)

M4 OR 8-32 TAP

TOP MOUNTING DETAIL

26.525.0

(1.04)(0.98)

PGC-3026

EARTH FAULTCURRENT

LR 53428

TRANSFORMER

TM

POWR-GARD Products

26.0

(1.02)

R

4.0 (0.16) 0

RECESSED FOR

7-mm HEX NUT

3.0 (0.12) DEEP

600 VClass,

Insulation ClassA

R

USC

34.0

(1.34)

58.0

(2.28)

7.0

FRONT SIDE

MOUNTING FOOT

INSTALLATION

TOOL

DETAIL ‘A’

FIGURE 2.4 PGC-3026 Outline and Mounting Details.

(0.87)

52.55.05.0

(2.07)(0.20)(0.20)

NOTES:

1.

DIMENSIONS IN MILLIMETRES (INCHES).

2.

PRESS MOUNTING FEET IN PLACE USING

INSTALLATION TOOL PROVIDED (DETAIL ‘A’)

3.

MOUNTING SCREWS: M4 OR 8-32.

Page 2-6

PGR-6200 Motor Protection Relay Rev. 2

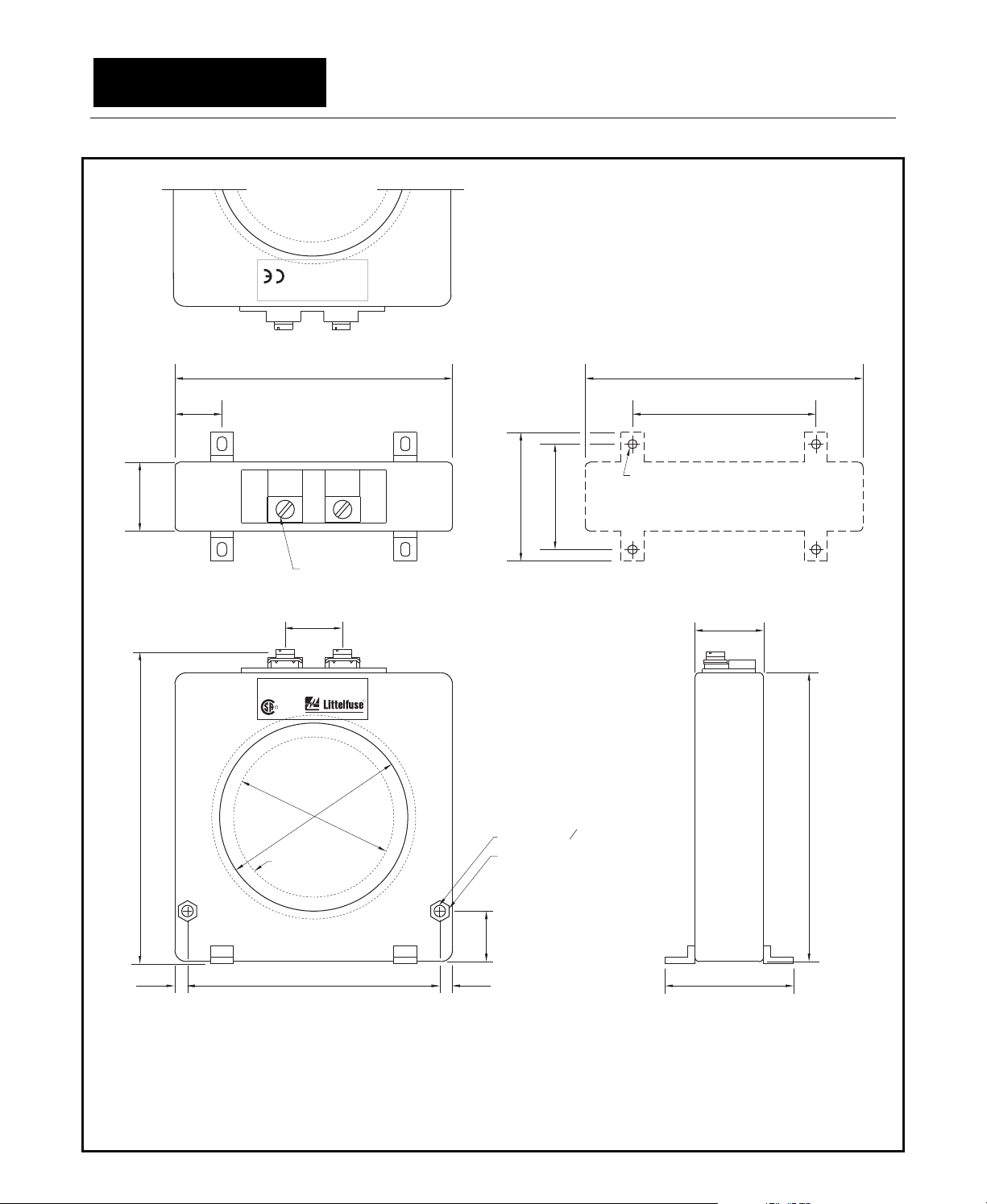

1

P

2

S

1

S

30.0

(1.18)

(5.43)

138.0 MAX

20.5

(0.81)

121.0

(4.76)

121.0

(4.76)

80.0

(3.15)

NOTE 2

56.0

46.0

(2.21)

(1.81)

M5 SCREWS

TOP MOUNTING DETAIL

25.0

(0.98)

PGC-3082

EARTH FAULTCURRENT

600 VClass,

Insulation ClassA

R

LR 53428

USC

PGC-31FC

FLUX

CONDITIONER

(OPTIONAL)

TRANSFORMER

TM

POWR-GARD Products

82.0

(3.23)

69.8

(2.75)

R

5.0 (0.20) 0

RECESSED FOR

8-mm HEX NUT

1.0 (0.04) DEEP

30.0

(1.18)

(4.96)

126.0

110.05.5 5.5

(4.33)(0.22) (0.22)

FRONT SIDE

NOTES:

1.

DIMENSIONS IN MILLIMETRES (INCHES).

2.

MOUNTING SCREWS: M4 OR 8-32.

3.

PRESS MOUNTING FEET IN PLACE USING

INSTALLATION TOOL PROVIDED.

FIGURE 2.5 PGC-3082 Outline and Mounting Details.

22.0

(0.87)

56.0

(2.21)

Page 2-7

PGR-6200 Motor Protection Relay Rev. 2

POWR-GARD Products

USC

TM

LR53428

TRANSFORMER

215.0

(8.46)

R

InsulationClass A

600V Class,

PGC-3140 EARTH FAULT CURRENT

215.0

(8.46)

26.5

(1.04)

162.0

(6.38)

R

64.0

(2.52)

236 MAX

31.0

(9.29)

(1.22)

P

2

SS

2

1

P

1

52.3

(2.06)

M5 OR 10-32 TAP

M5 SCREWS

TOP MOUNTING DETAIL

25.0

(0.98)

1

S

1

P

139.7

(5.50)

FLUX CONDITIONER

(INCLUDED)

BONDING

SCREW

5.0 (0.20) DIA

31.0

(1.22)

215.0

(8.46)

198.0 8.58.5

(7.80) (0.33)(0.33)

NOTES:

1. DIMENSIONS IN MILLIMETRES (INCHES).

2.

MOUNTING SCREWS: M5 OR 10-32.

FIGURE 2.6 PGC-3140 Outline and Mounting Details.

60.0

(2.36)

SIDEFRONT

Page 2-8

PGR-6200 Motor Protection Relay Rev. 2

CABLE-TIE EYELET

4 LOCATIONS

31

34 33 32 30 29 28 27 26 25 24 23 22 21 20 19

CDR CDRCDR CDRS

87.0

(3.43)

S

H

INP 8 INP 7 INP 6 INP 5

INP 1 INP 2 INP 3 INP 4

RDC RDCRDC RDC

1234567891011121314

ADDRESS SWITCH

ACCESS COVER

POWR-GARD

PWR

TEMPERATURE INPUT MODULE PGA-0120PGA-0120

COMM

S

H

112.5

(4.43)

H

S

H

TOP

S

P

G

PGR-6200

PGR-6300

COMM

0

V

15 16 17 18

2

4

V

52.5

(2.07)

(NOTE 3)

56.0

(2.20)

SIDE

12.5

(0.50)

60.0

(2.36)

M4 OR 8-32 TAP

14.5

(0.57)

100.06.3 6.3

(3.94)(0.25) (0.25)

MOUNTING DETAIL

FIGURE 2.7 PGA-0120 Outline and Mounting Details.

NOTES:

DIMENSIONS IN MILLIMETRES (INCHES).

1.

MOUNTING SCREWS: M4 OR 8-32.

2.

OVERALL HEIGHT WHEN MOUNTED

3.

ON DIN EN50022 35-mm x 7.5-mm

TOP-HAT RAIL.

Page 2-9

PGR-6200 Motor Protection Relay Rev. 2

CABLE-TIE EYELET

4 PLACES

87.0

(3.43)

PWR

POWR-GARD®

DIFFERENTIAL INPUT MODULE PGA-0140PGA-0140

PHASE A PHASE B PHASE C

C51C51C51

123456789

COMM

112.5

(4.43)

TOP

15 14

S

P

G

PGR-6200

PGR-6300

COMM

0

-

+

V

10 11 12 13

®

+

2

4

V

52.5

(2.07)

(NOTE 3)

56.0

(2.20)

SIDE

BOTTOM

12.5

(0.50)

60.0

(2.36)

M4 OR 8-32 TAP

14.5

(0.57)

100.06.8 6.8

(3.94)(0.27) (0.27)

MOUNTING DETAIL

FIGURE 2.8 PGA-0140 Outline and Mounting Details.

NOTES:

DIMENSIONS IN MILLIMETRES (INCHES).

1.

MOUNTING SCREWS: M4 OR 8-32.

2.

OVERALL HEIGHT WHEN MOUNTED

3.

ON DIN EN50022 35-mm x 7.5-mm

TOP-HATRAIL.

Page 2-10

PGR-6200 Motor Protection Relay Rev. 2

This page intentionally left blank.

Page 3-1

PGR-6200 Motor Protection Relay Rev. 2

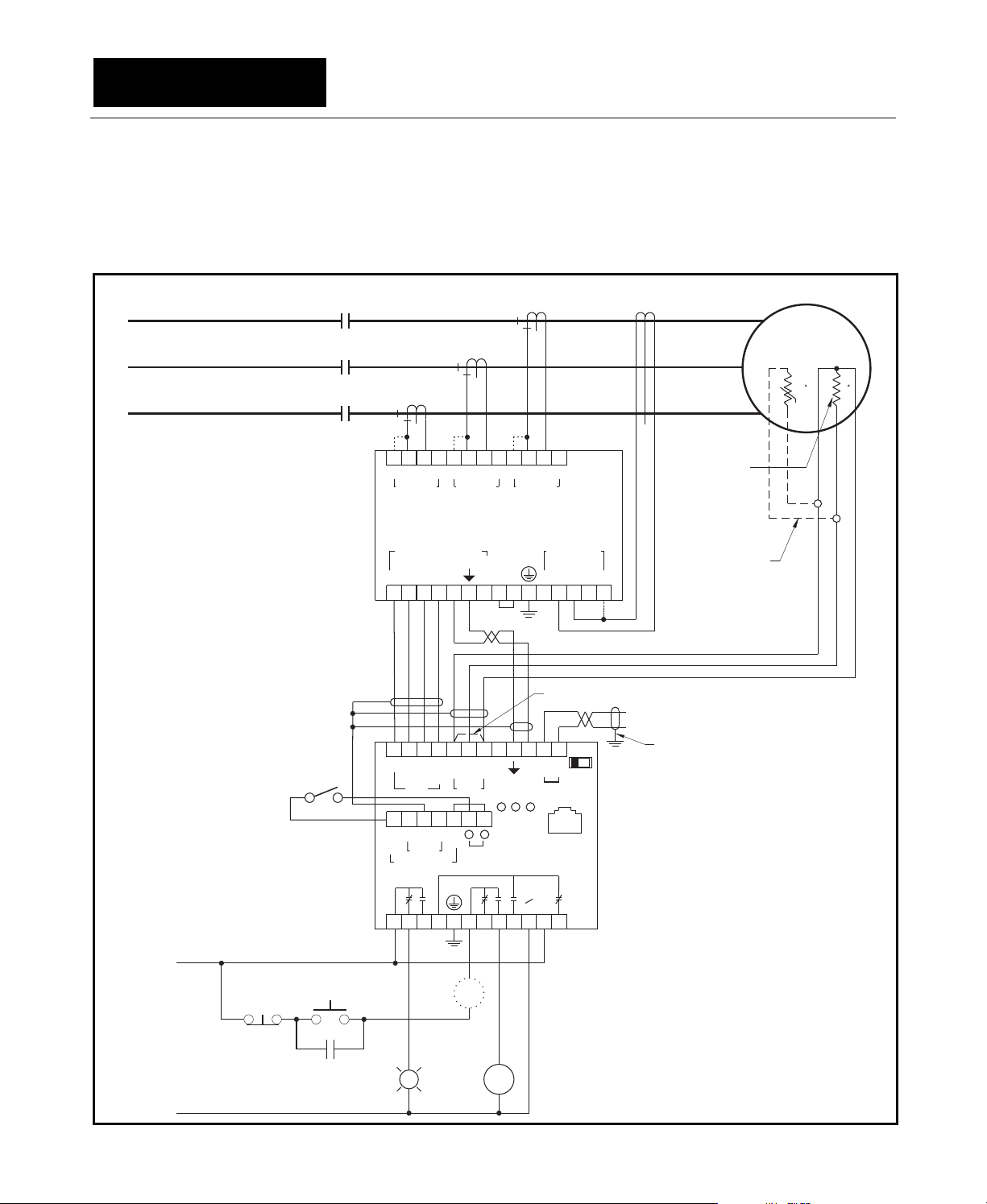

3. SYSTEM WIRING

3.1 General

A typical connection diagram for a PGR-6200 and

PGA-0CIM is shown in Fig. 3.1. See Sections 3.2.3

and 3.2.4 for PGA-0120 and PGA-0140

connections.

CONTACTOR

A

K1

B

PHASE CT'S

(NOTE 9)

EARTH-FAULT CT

MOTOR

(NOTE 6)

C

11 10 9

12

111555

PHASE C PHASE B PHASE A

8

7654321

RRR

SSS

PGA-0CIM

(NOTE 8)

PGR-6200/PGR-7200

C

E

O

F

M

WHITE

RED

GREEN

BCC

O

M

CIM

SH-++

COMM

2

17

BLUE

TEMP

0

V

18 19

BROWN

TBTAT

+

DIG IN

(NOTE 7)

S1

ABC

13 14 15 16

BLACK

(NOTE 3)

133114301529162817271826192520 21 22 23 24

A

24

V

I/O MODULE

RELAY 2 RELAY 1

12 11 10 9 8 7 6 5 4 3 2 1

L1

STOP

START

(NOTE 5)

K1

K1

L2/N

FIGURE 3.1 Typical PGR-6200 Connection Diagram.

E

F

1

YX

20 21 22 23 24 25

EFA

C

AN OUT

TIA-232 ONLY

ERMSN

S

-

PGR-6200

RELAY 3

L

2

N

K1AALARM

EARTH FAULT

ES5R261

(NOTE 10)

(NOTE 6)

A

B

A

LS

18

L

1

+t t

Pt100 RTD

SENSOR

ALTERNATE

CONNECTION FOR

PTC-THERMISTOR

27

SENSOR(S)

OUTPUT

(NOTE 4)

NOTES:

PGR-6200 REAR VIEW SHOWN.

1.

RELAYS SHOWN DE-ENERGIZED.

2.

GROUND CABLE SHIELDS AT PGR-6200 END ONLY.

3.

GROUND OUTPUT-CABLE SHIELD AT RECEIVER

4.

END ONLY.

5.

ALTERNATE CONTACTOR-COIL LOCATION.

6.

ALTERNATE CONNECTION FOR PTC-THERMISTOR

SENSOR(S).

PROGRAMMABLE DIGITAL INPUT .

7.

8.

DOTTED LINES SHOW 1-A-CT CONNECTIONS.

9.

A-B-C PHASE ROTATION REQUIRED.

10.

EARTH-FAULT INPUT IS NOT POLARITY SENSITIVE.

11.

OPTIONAL NETWORK COMMUNICATIONS

NOT SHOWN.

Page 3-2

PGR-6200 Motor Protection Relay Rev. 2

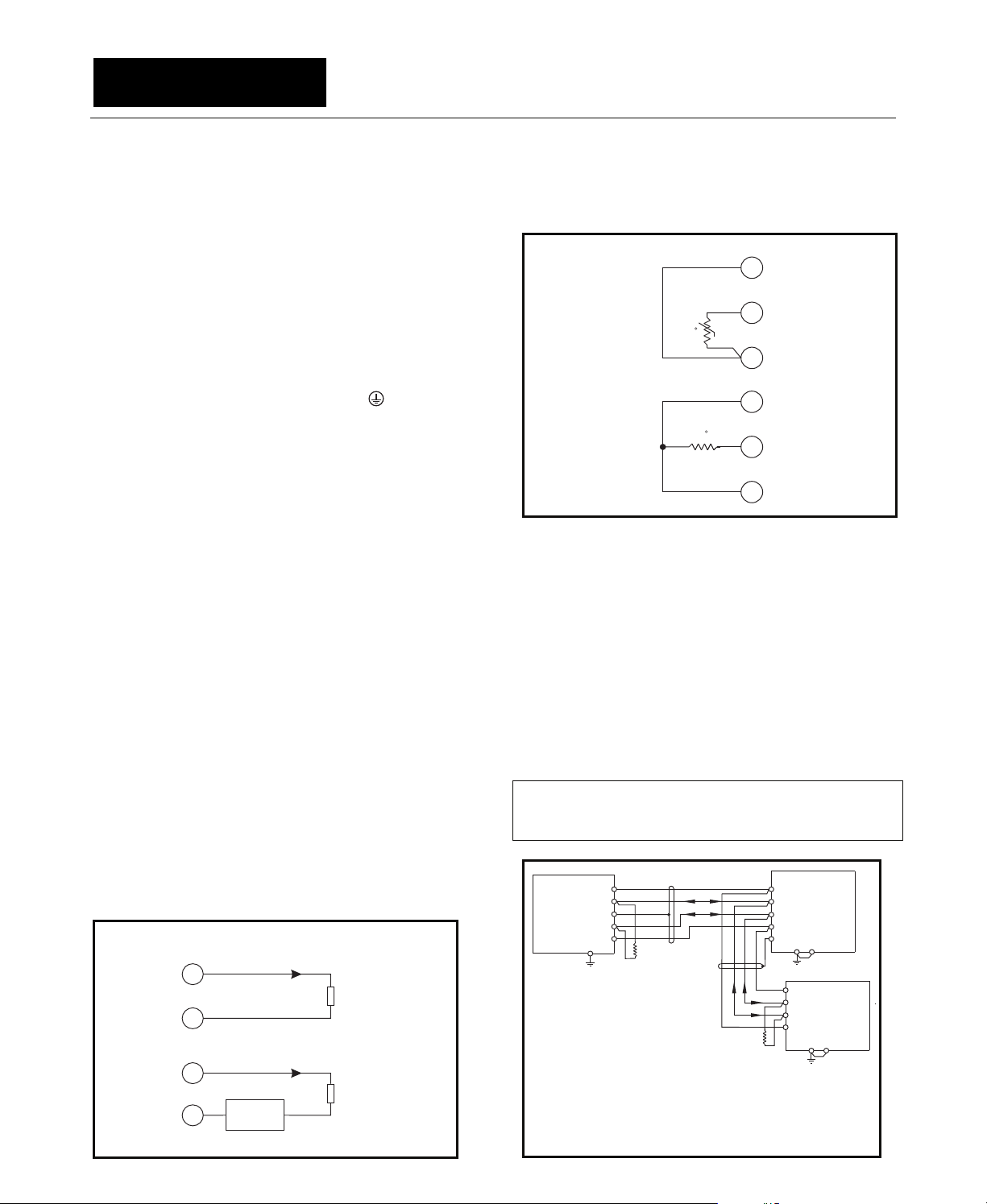

3.2 Wiring Connections

3.2.1 PGR-6200 Connections

The PGR-6200 wire-clamping terminal blocks

accept 24 to 12 AWG (0.2 to 2.5 mm

These terminal blocks unplug to allow the

PGR-6200 to be easily removed.

2

) conductors.

3.2.1.1 Supply Voltage

3.2.1.5 PTC or RTD Input (Local)

The temperature-sensor input on the PGR-6200

can be configured for either PTC or Pt100 RTD

operation as shown in Fig. 3.3.

a) PTC

19 TC

Derive supply voltage from the line side of the

motor controller or from an independent source.

Connect supply voltage to terminals 2 and 3 (L1

and L2/N) as shown in Fig. 3.1. In 120-Vac

systems, L2/N is designated as the neutral

conductor. For direct-current power supplies, use

L1 for the positive terminal and L2/N as the

negative terminal. Ground terminal 8 (

).

+t

b) Pt100 RTD

18 TB

17 TA

19 TC

3.2.1.2 CIM Input

Connect the PGR-6200 to the PGA-0CIM as

t

18 TB

shown in Figs. 3.6 and 3.7 using the cable

provided.

3.2.1.3 Digital Input

A 24-Vdc digital input is provided on terminals 25

and 26. This input is polarity sensitive. For a

logical 1, terminal 26 must be positive with respect

to terminal 25. See Section 4.2.5.

The current-limited 24-Vdc source (terminals

27 & 31) can be used to power the digital input.

3.2.1.4 Analog Output

The analog output is switch selectable as self

powered or loop powered.

For the self-powered connection, set the L/S

switch to the S position. The self-powered

connection is shown in Fig. 3.2 (a). The analog

output is referenced to the I/O module supply,

terminal 27.

For the loop-powered connection, set the L/S

switch to the L position. The loop-powered

connection is shown in Fig. 3.2 (b). In looppowered operation, the analog-output is isolated

from all other PGR-6200 terminals.

a) SELF POWERED (S POSITION)

24AA

RECEIVER

23AB

b) LOOP POWERED (L POSITION)

24AA

+-

23AB

LOOP

SUPPLY

FIGURE 3.2 Analog-Output Connections.

TERMINATION

RECEIVER

TERMINATION

FIGURE 3.3 Local Temperature-Sensor Connections.

3.2.1.6 I/O Module Interface

The I/O module interface supplies power and

communications to optional I/O modules such as

the PGA-0120 and PGA-0140.

I/O module communication is based on the twowire multi-drop TIA-485 standard but uses a

proprietary protocol. Overall line length must not

exceed 1.2 km (4,000’). For line lengths exceeding

10 m (33’), 150-Ω terminations are required at the

cable ends. I/O modules are supplied with 4 m

(13’) of interconnection cable. See Fig. 3.4.

Note: I/O communication is shared with the display.

Incorrect wiring can cause the display and keypad to

freeze.

RED

31

GREEN

+

PGR-6200

MOTOR

PROTECTION

NOTES:

1.

2.

FIGURE 3.4 I/O Module Connection Diagram.

30

29

WHITE

-

28

BLACK

27

RELAY

3

INTERCONNECT CABLE BELDEN 3124A

OR EQUIVALENT.

R =150 OHMS, 1/4 WATT. REQUIRED FOR LINE

t

LENGTHS EXCEEDING 10 M (33’).

R

t

17 TA

+

-

R

t

18

PGA-0120

17

16

TEMPERATURE

INPUT

15

MODULE

11

20

19

10

-

11

PGA-0140

+

12

DIFFERENTIAL

13

MODULE

14 15

Page 3-3

PGR-6200 Motor Protection Relay Rev. 2

3.2.1.7 RS/EIA/TIA-232 Communications

An RJ-45 TIA-232 connector is provided on the

rear panel of the PGR-6200. This port uses

Modbus

PGW-COMM PC-interface software. For Modbus

RTU protocol, see Appendix D. The slave ID and

communication baud rate are set in the Setup ⏐

Hardware ⏐ Local Comms menu.

Table 3.1 shows the pinout for the optional

PGA-0420 adapter for operation with PGW-COMM.

See Fig 3.1 for RJ-45 pinout.

For a USB connection, use an PGA-0440 adapter.

®

RTU protocol to communicate with

TABLE 3.1 PGA-0420 Adapter Pinout

SYMBOLIC NAME RJ-45 DB9

RI/DSR 1 9

CD 2 1

DTR 3 4

SG 4 5

RD 5 2

TD 6 3

CTS 7 8

RTS 8 7

®

3.2.2 PGA-0CIM Connections

The PGA-0CIM CT-input terminal blocks accept 22

to 10 AWG (0.3 to 4.0 mm

remaining PGA-0CIM clamping blocks accept 24 to

12 AWG (0.2 to 2.5 mm

2

) conductors.

The PGA-0CIM contains four signal-conditioning

interface transformers which are interconnected as

shown in Fig. 3.5. These transformers isolate the

PGR-6200 from the phase and earth-fault CT's. The

PGA-0CIM eliminates the need for CT shorting

contacts when the PGR-6200 is disconnected.

Phase-CT and earth-fault-CT secondaries can be

simultaneously grounded through terminal 22 and a

jumper to terminal 20. For applications where the CT

secondaries must be grounded at another location,

the CT secondaries can be isolated by removing

shorting screws A, B, and C through holes in the

bottom of the PGA-0CIM. See Figs. 2.3 and 3.5.

Note: A-B-C phase sequence and polarity must be

observed when connecting phase CT’s. See Section

4.2.1.

Connect the PGA-0CIM to the PGR-6200 as

2

) conductors. The

shown in Figs. 3.6 and 3.7 using the cable

provided.

TB3

TB2

27126R25524S23E22 21 20

AB

R1S2531

NOTES:

1.

REMOVE SHORTING SCREWS A, B, AND C TO ISOLATE PHASE-CT

AND EARTH-FAULT-CT SECONDARIES FOR IN-LINE APPLICATIONS.

2.

SHORTING SCREWS A, B, AND C: 6-32 x 0.375

NICKEL-PLATED-BRASS BINDING HEAD.

3.

SHORTING SCREWS A, B, AND C MUST NOT BE REMOVED FOR

RESIDUAL OR TWO-CT CONNECTIONS.

4.

EACH TERMINAL ON TB1 AND TB3 WILL ACCEPT ONE

NO. 10 AWG CONDUCTOR

FIGURE 3.5 PGA-0CIM Schematic.

XY19E

RS6571

5

4

TB1

18 17 16 15

F

1

E

F

2

C

R9S105111

8

DO NOT SUBSTITUTE

14 13

C

C

O

M

BA

12

Page 3-4

PGR-6200 Motor Protection Relay Rev. 2

3.2.2.1 Standard

Standard connections with earth-fault CTs are

shown in Fig. 3.6. Dotted lines indicate 1-A-CT

connections. Use shielded cable for PGC-3000series current-transformer connections. Ensure

only current-carrying phase conductors pass

through the earth-fault-CT window and that ground

conductors do not.

3.2.2.2 Residual Earth-Fault

The wired residual earth-fault connection is

shown in Fig. 3.7 (a). Dotted lines indicate 1-A-CT

connections. Use three identical CT's for this

connection.

The PGR-6200 also calculates residual current.

See Section 4.2.2.

3.2.2.3 Two-CT

The two-CT connection is shown in Figs. 3.7 (b)

and 3.7 (c). Dotted lines indicate 1-A-CT

connections. Since this connection derives the

current in the unmonitored phase, it should be used

only in retrofit applications where it is not possible

to install a third CT.

a) STANDARD CONNECTION

1-A OR 5-A

EARTH-FAULT

CT

5A

1A

272726262525242423232222212120

11RR55SSE

XXY

PGA-0CIM

R

S

112233445

A

CT

5

5A

1

1A

R

PGR-6200

19

S

5

5A

CT B

S

H

181817

E

F

1

1

1A

21212229

BROWN

R

C

O

E

M

F

CCBBA

16161515141413

GREEN

RED

BLUE

16

15

E

C

C

F

O

2

M

S

5

5A

CT C

14

1

1A

WHITE

13

B

BLACK

A

S TERMINALS ARE GROUNDED

THROUGH TERMINAL 22

b) STANDARD CONNECTION WITH PGC-3000-SERIES CURRENT TRANSFORMER

PGC-3XXX

PGR-6200

S

E

H

F

2229

BLUE

BROWN

C

O

M

GREEN

RED

WHITE

A

13

BLACK

E

PGA-0CIM

R

S

CT A

R

5

1

566778899101011111212

5A

1A

FIGURE 3.6 PGA-0CIM Standard Connections.

20

S

CT B

19

17

16

15

14

13

Y

E

E

C

C

B

5

5A

F

F

1

1

1A

O

2

M

R

S

5

5A

CT C

1

1A

A

S AND E TERMINALSARE GROUNDED.

S THROUGH TERMINAL22,

E THROUGH TERMINAL18

Page 3-5

PGR-6200 Motor Protection Relay Rev. 2

a) RESIDUAL CONNECTION

27

1A 5A

26

1

25

5

R

PGA-0CIM

R

2

1

PGR-6200

S

H

18

19

20

21

22

23

24

E

S

1

5

S

5

4

3

5A

1A

E

Y

X

F

1

5

S

R

8

7

6

5A

1

1A

21

BROWN

17

R

9

2229

10

E

F

BLUE

E

F

2

16

S

C

O

M

16

GREEN

15

C

O

M

11

5

5A

A

B

C

13

14

15

RED

WHITE

BLACK

13

14

A

B

C

1

12

1A

SHORTING SCREWS

A, B, & C MUST

NOT BE REMOVED.

R TERMINALS ARE

GROUNDED THROUGH

TERMINAL 22.

CT A

CT B CT C

b) TWO-CT CONNECTION

1-A OR 5-A

EARTH-FAULT

1A

25

26

27

R

1

R

1

CT

5A

23

24

E

S

5

PGA-0CIM

5

S

4

3

2

5A

CT A

PGR-6200

S

H

18

19

20

21

22

1

5

1A

E

Y

X

F

1

5

S

R

8

7

6

5A

1

1A

21

BROWN

17

R

9

E

F

2229

BLUE

E

F

2

10

16

S

CT C

C

O

M

16

GREEN

15

C

O

M

5

11

5A

15

RED

C

12

A

B

C

13

14

WHITE

BLACK

13

14

A

B

1

1A

SHORTING SCREWS

A, B, & C MUST

NOT BE REMOVED.

R TERMINALS ARE GROUNDED

THROUGH TERMINAL 22.

EARTH-FAULT CT MUST

NOT BE GROUNDED.

c) TWO-CT CONNECTION WITH PGC-3000-SERIES CURRENT TRANSFORMER

PGR-6200

R

BROWN

BLUE

20

X

S

6

S

H

18

19

E

Y

F

1

5

8

7

5A

PGC-3XXX

21

22

23

24

25

26

27

R

1

E

S

5

PGA-0CIM

1

5

S

R

2

1

5

4

3

5A

1A

C

E

O

F

M

16

2229

21

GREEN

16

17

C

E

O

F

M

2

1

S

R

11

10

9

1A

A

B

C

13

14

15

RED

WHITE

BLACK

13

14

15

A

B

C

1

5

12

5A

1A

SHORTING SCREWS

A, B, & C MUST

NOT BE REMOVED.

R TERMINALS ARE GROUNDED

THROUGH TERMINAL 22.

CT A

FIGURE 3.7 Other PGA-0CIM Connections.

CT C

Page 3-6

PGR-6200 Motor Protection Relay Rev. 2

3.2.3 PGA-0120 Connections and Address Selection

Connect the PGA-0120 Temperature Input

Module to the PGR-6200 using the four-conductor

shielded cable (Belden 3124A or equivalent)

supplied with the PGA-0120 as shown in Fig. 3.8.

The PGR-6200 24-Vdc supply can power up to

three PGA-0120 modules.

Connect RTD’s to the PGA-0120 as shown in

Fig 3.8. When the RTD module is installed in a

motor junction box, RTD-lead shielding is not

required. PGA-0120 terminal blocks accept 24 to

12 AWG (0.2 to 2.5 mm

2

) conductors.

Connect surge-protection (SPG) terminal 20 to

terminal 19 (

) and ground terminal 19.

The PGA-0120 has two switches to select its

network address. See Fig. 3.8. Up to three

PGA-0120 modules can be connected to the I/O

MODULE bus, and each RTD-module address

must be unique. If one module is used, address 1

must be used. If two RTD Modules are used,

addresses 1 and 2 must be used. If three RTD

Modules are used, addresses 1, 2, and 3 must be

used.

Table 3.2 shows the address selection format.

TABLE 3.2 PGA-0120 Address Selection

ADDRESS SWITCH 1 SWITCH 2

0 (Off line) Open Open

1 (First RTD module) Closed Open

2 (Second RTD module) Open Closed

3 (Third RTD module) Closed Closed

3.2.4 PGA-0140 Connections

Connect the PGA-0140 Differential Input Module

to the PGR-6200 using four-conductor shielded

cable (Belden 3124A or equivalent) as shown in

Fig. 3.4.

Connect the surge-protection (SPG) terminal 15

to terminal 14 (

The PGA-0140 CT-input terminal blocks accept

22 to 10 AWG (0.3 to 4.0 mm

remaining PGA-0140 clamping blocks accept 24 to

12 AWG (0.2 to 2.5 mm

), and ground terminal 14.

2

) conductors. The

2

) conductors.

3.2.4.2 PGR-6200 Summation

The PGR-6200-summation connection uses three

phase CT’s and three differential CT’s as shown in

Fig. 3.10. Both CT-ratio and CT-saturation

characteristics must be matched to avoid differential

currents under motor starting and running

conditions. The PGA-0140 module should be

located near the PGA-0CIM to minimize CT-wire

length. It is preferred to use three dedicated phase

CT’s and three core-balance differential CT’s as

described in Section 3.2.4.1.

For the delta connection, the FLA Rating is set

equal to the motor’s full-load current multiplied by

√3.

3.2.4.3 DIF Summation

The DIF-summation connection uses six

differential CT’s as shown in Fig. 3.11. Both CTratio and CT-saturation characteristics must be

matched to avoid differential currents under motor

starting and running conditions. It is preferred to

use three core-balance CT’s as described in

Section 3.2.4.1. This six-CT connection allows the

CT’s and PGA-0140 to be placed near the motor to

minimize power-cable and CT-lead length.

3.2.5 Cable Restraint

All conductors should be restrained within

100 mm (4") of the terminal blocks. Four cablingrestraint points are provided on the PGR-6200 rear

panel. Secure cables to the PGA-0CIM, PGA-0120

and PGA-0140 using the cable-tie eyelets and the

cable ties provided. See Figs. 2.1, 2.3, 2.7 and 2.8.

3.2.6 Dielectric-Strength Testing

Dielectric-strength testing can be performed only

on CT inputs, supply-voltage input, and output

relays. Unplug all other I/O and remove the

PGA-0CIM

dielectric-strength testing.

connection (terminal 22) during

3.2.4.1 Core Balance

The core-balance connection uses three

differential CT’s as shown in Fig. 3.9. To minimize

power-cable and CT secondary lead lengths, both

the differential CT’s and the PGA-0140 can be

located near the motor. The primary rating of the

differential CT does not have to match the phaseCT primary rating and is usually selected with a

lower ratio resulting in more sensitive differential

protection. The core-balance method avoids CTmatching issues and is the preferred connection.

Page 3-7

PGR-6200 Motor Protection Relay Rev. 2

ADDRESS

SELECTION

SWITCHES

12

OPEN

OPEN

CLOSED OPEN

18 19 20 2321

RELAY 1

ERMSN

22

S

TIA-232 ONLY

RELAY 3

L

2

/

N

13 15 1714 16

31 29 2730 28

2

4

V

26 25

SH0

V

COMM

DIG IN

I/O MODULE

RELAY 2

12 11 10 9 8 7 6 5 4 3 2 1

FIGURE 3.8 PGA-0120 Connection Diagram.

S

P

G

PGR-6200

PGR-6300

COMM

0

V

15 16 17 18

WHITE

BLACK

GREEN

ALTERNATE

2-WIRE RTD

CONNECTION

S

H

2

4

V

RED

C

RD

3-WIRE RTD

CONNECTION

t° t° t°t° t°

31

34 33 32 30 29 28 27 26 25 24 23 22 21 20 19

CDR CDRCDR CDRS

S

H

INP 8 INP 7 INP 6 INP 5

12

OPEN

PWR

COMM

INP 1 INP 2 INP 3 INP 4

S

RDC RDCRDC RDC

H

1234567891011121314

H

POWR-GARD

TEMPERATURE INPUT MODULE PGA-0120PGA-0120

S

H

t° t° t°t°

24

LS

INTERCONNECT CABLE

BELDEN 3124A OR EQUIVALENT

L

1

ØA

ØB

ØC

S 15S 15S5

1

10876 43211

12

PGA-0CIM

FIGURE 3.9 Core-Balance Connection.

1

4

MOTOR

2

5

3

6

C15C15C51

765432189

PGA-0140

CONNECTIONS:

WYE: ØA & 1, ØB & 2, ØC & 3,4&5&6

DELTA: ØA&1&6, ØB&2&4,ØC&3&5

Page 3-8

PGR-6200 Motor Protection Relay Rev. 2

1

ØA

2

ØB

3

ØC

S51

234

CONNECTIONS:

WYE: ØA & 1, ØB & 2, ØC & 3,4&5&6

DELTA: ØA&1&6,ØB&2&4,ØC&3&5

S51

678

S51

101112

FIGURE 3.10 PGR-6200-Summation Connection.

MOTOR

C51

789

NOTES:

1. REMOVE MPU-CIM SHORTING SCREWS

A, B, & C.

C51

456

PGA-0140PGA-0CIM

4

5

6

C51

123

1

ØA

2

ØB

3

ØC

S 15S 15S5

10876 43211112

PGA-0CIM

CONNECTIONS:

WYE: ØA& 1, ØB & 2, ØC & 3,4&5&6

DELTA: ØA&1&6,ØB&2&4,ØC&3&5

FIGURE 3.11 DIF-Summation Connectiion.

4

MOTOR

5

6

C51

789

PGA-0140

C51

456

C51

123

Page 4-1

PGR-6200 Motor Protection Relay Rev. 2

4. OPERATION AND SETUP

4.1.1 Front-Panel LED Indication

Menu: Setup | System Config | UPI LED

4.1 Display and Indication

All PGR-6200 information displays and settings

can be accessed using the PGR-6200 menu

system, the TIA-232 interface, or a networkcommunications interface.

In the following sections, menu items and setup

parameters are listed in italics and are shown in the

format displayed on the alphanumeric LCD. The

LCD cannot display subscripts and superscripts.

Menu selection is in the following format:

Menu 1 | Sub Menu 1 | Sub Menu 2 | Sub Menu

3 |……

Example: For the menu item shown in Fig. 4.1,

the notation is Setup | System Ratings | CT Primary

Metering 4

Messages 4

5Setup4 Protection4

•

•

•

•

•

•

FIGURE 4.1 Menu Example.

Fig. 4.2 shows the symbols that assist in

navigating the menu system and how these

symbols relate to the arrow keys on the PGR-6200.

See the PGR-6200 menu map in Appendix A.

vSystem Ratings4

Digital Input4

6CT Primary→

EF Source→

EF-CT-Primary→

The red TRIP and yellow ALARM LED’s indicate

a trip or alarm condition. The green RUN LED is

OFF when current is not detected, flashes when the

motor is starting, and is ON when the motor is

running. The yellow UPI LED is a userprogrammable indicator and its function is defined

by one of the menu selections shown in Table 4.1.

TABLE 4.1 UPI LED Functions

SELECTION DEFINITION

None LED remains off.

Trip1 Trip1 condition exists.

Trip2 Trip2 condition exists.

Trip3 Trip3 condition exists.

Alarm1 Alarm1 condition exists.

Alarm2 Alarm2 condition exists.

Alarm3 Alarm3 condition exists.

Relay1 Relay1 is energized.

Relay2 Relay2 is energized.

Relay3 Relay3 is energized.

Digital Input Digita l Input is valid.

Current Detected Current is above minimum

threshold.

Current > 125% Current is above 125% FLA.

Run Mode PGR-6200 is in Run mode.

ETR PGR-6200 is in Emergency

Thermal Reset state

Start Inhibit In I2t or starts-per-hour inhibit

state.

Network Run1 Run1 is issued by a network

command.

Net Activity Activity is detected on the

communications interface.

Reduced OC Reduced Overcurrent protection

is active.

These symbols indicate the

menu level. Up to five submenulevel symbols may be displayed.

Use left-arrow key or ESC to

move back one menu level.

Cursor indicates selected

menu item and shape

indicates available scrolling

directions.

Indicates top of list. Scroll

using down-arrow key.

Scroll using up- or downarrow keys.

Indicates bottom of list.

Scroll using up-arrow key.

FIGURE 4.2 Menu Symbols.

Indicates that there are related data

displays to the left or right of this

display. Use left- or right-arrow

keys to view adjacent data displays.

¬¬¬¬¬ TITLE ¬Ñ

½ MENU ITEM 1 Ñ

² MENU ITEM 2 ¼

« MENU ITEM 3 *

Use right-arrow key to

select submenu.

Use right-arrow key to

display data.

Indicates active item in

list-type set-point

displays.

Page 4-2

PGR-6200 Motor Protection Relay Rev. 2

4.1.2 Rear-Panel LED Indication

The three LED’s on the rear panel are labeled

ER, MS, and NS. The red ER (Error) LED is OFF

during normal operation and is ON when there is a

processor error or during firmware-update

operation. Output relays are de-energized when

this LED is ON. The MS (Module Status) and NS

(Network Status) LED’s are used for networkcommunications and firmware-update annunciation.

The specific colour and function of these LED’s is

defined by the network-communications option

installed in the PGR-6200. For detailed information,

see the applicable communications manual.

4.1.3 Display Contrast and Test

Contrast control and test operator-interface

features are available when the display is in Local

mode. To prevent a Display Comm Trip, select

Disabled in the Setup ⏐ Hardware ⏐ OPI Display ⏐

Trip Action menu. To enter Local mode, press the

up-arrow, right-arrow, and ENTER keys

simultaneously.

In Local mode, all face-plate LED’s are ON and

the display indicates three menu items; Contrast,

Address, and Enter Test Mode. Use the up- and

down-arrow keys to select the menu item.

Contrast: Use the right- and left-arrow keys to

increase or decrease contrast.

Address: The display address indicates 1 and

cannot be changed.

Enter Test Mode: Press the right-arrow key to

enter test mode. In test mode, the LED test,

Display test, and Display-Heater test are

automatically performed. The Interactive-Key test

is then entered and the following symbols are

displayed when a key is pressed.

Left Key: ¬

Right Key Ñ

Up Key «

Down Key ½

ESC: ^

ENTER: ª

RESET: Press RESET to exit this menu.

Press the ESC key to exit Local mode and return to

the PGR-6200 menu. Re-enable OPI Diplay Trip

Action.

4.2 Setup

Certain PGR-6200 settings cannot be changed

when the motor is running. See Appendix B.

4.2.1 Phase-CT Inputs

Menu: Setup | System Ratings | CT Pri mary

The CT-primary setting range is 1 to 5,000 A. To

maintain specified accuracy, phase CT’s should be

selected with a primary rating between 100 and

300% of motor full-load current.

For A-B-C sequence, the +Seq I

larger than the –Seq I

display value and positive

2

current unbalance is indicated. Negative current

unbalance will be indicated if the phase sequence is

B-A-C. If negative unbalance is indicated, correct the

phase-CT connections. Severe current unbalance

may be indicated when phase-CT polarity is

incorrect.

4.2.2 Earth-Fault-CT Input

Menu: Setup | System Ratings | EF Source

Menu: Setup | System Ratings | EF-CT Primary

The EF Source menu selects the earth-fault

source as Calculated (3I

The Calculated (3I

) or Measured (Ict).

0

) selection uses the 3I0 value

0

obtained from the sequence-component calculation

and is based on the phase currents only. Set the

EF-CT Primary to the phase-CT-primary rating

when Calculated (3I

The Measured (I

) is selected.

0

) selection uses current

ct

measured by an earth-fault CT or the residual

connection. Set EF-CT Primary to the earth-faultCT-primary rating when an earth-fault CT is used.

For the sensitive PGC-3082 and PGC-3140 earthfault CT’s, set EF-CT Primary to 5 A. Set EF-CT

Primary to the phase-CT-primary rating for the

residual-CT connection.

The setting range for the EF-CT-Primary rating is

1 to 5,000 A.

Note: Calculated 3I

does not detect CT saturation.

0

Enable overcurrent protection when earth-fault

current can exceed 15 times the phase-CT primary

rating.

Note: 3I

and Ict values will be shown in the

0

Metering ⏐ Earth Leakage display regardless of the

EF Source selection or CT connections.

Note: For the residual connection and Calculated

(3I0) selection, the earth-fault-trip setting should be

greater than 5%.

4.2.3 Motor Data

Menu: Setup | System Ratings

Menu: Setup | Protection ⏐ Overload

In the System Ratings menu, motor data must be

entered for the FLA Rating (full-load current),

Frequency, and Service Factor.

Set Frequency at 50 Hz , 60 Hz, or Variable. Use

Variable for adjustable-speed drive applications.

LR Current (locked-rotor current), LR Time Cold

(cold locked-rotor time), and LR Time Hot (hot

locked-rotor time) must be entered in the Setup |

Protection ⏐ Overload menu to provide customized

overload protection. See Sectio n 5.2.

display value is

1

Page 4-3

PGR-6200 Motor Protection Relay Rev. 2

4.2.4 Output Relay Assignment

Menu: Setup | Relay Outputs | Relay x

Menu: Setup | Relay Outputs | RY Pulse Time

Each of the three output relays can be assigned

to one of the functions listed in Table 4.2. More

than one relay can be assigned the same function.

Trip and alarm assignments operate in the selected

fail-safe or non-fail-safe mode.

The default assignment for Relay 1 is Trip1, for

Relay 2 is Alarm1, and for Relay 3 is None. The

default mode setting for all three relays is Fail-Safe.

4.2.5 Digital Input

Menu: Setup | Digital Input | Input Function

Menu: Setup | Digital Input | Start Bypass

Menu: Setup | Digital Input | Bypass Del ay

Menu: Setup | Digital Input | Trip Delay

The digital input can be assigned to one of the

functions listed in Table 4.3.

When the digital input is assigned the Trip1

function, Start Bypass, Bypass Delay, and Trip

Delay set points become active. When Start

Bypass is enabled, the digital input is bypassed

during a start for the duration specified by Bypass

Delay. Start detection is based on motor current.

After the Bypass Delay, the digital input is enabled

and a trip occurs if the digital-input voltage is

removed for the time specified by the Trip Delay. If

Start Bypass is disabled, Bypass Delay is not used

enabled. The bypass feature can be used in pumpcontrol applications to allow time for a pressure

switch to close.

When the digital input is assigned to Reset, trips

can be reset using an external reset switch. The

Reset input is a “one-shot” reset and requires a

transition from open to closed. Maintaining a reset

switch closure does not inhibit trips.

When assigned to Program Enable, password

protection is disabled and program access is a

function of the digital-input state as defined in Table

4.3.

TABLE 4.3 Digital-Input Functions

FUNCTION STATE

Trip1 1 = No Trip1

0 = Trip1 (Delay selectable, reset

required)

Reset 1 = Reset Trips

Program

Enable

Reduced OC 1 = Reduced Overcurrent set point not

None No assignment (Default)

(1)

1 = 24 Vdc applied, 0 = 24 Vdc not applied

(2)

Password is disabled.

1 = Program changes allowed

(2)

0 = Program changes not allowed

operational (ROC = Off)

0 = Reduced Overcurrent set point

operational (ROC = On)

(1)

and the digital input Trip1 function is always

TABLE 4.2 Output-Relay Functions

FUNCTION ASSIGNMENT OR ACTION

Trip1 Relay operates when a trip occurs in a protective function assigned Trip1, Trip1&2, Trip1&3, or

Trip1,2&3 trip action. Fail-safe or non-fail-safe mode selection is active.

Trip2 Relay operates when a trip occurs in a protective function assigned Trip2, Trip1&2, Trip2&3, or

Trip1,2&3 trip action. Fail-safe or non-fail-safe mode selection is active.

Trip3 Relay operates when a trip occurs in a protective function assigned Trip3, Trip1&3, Trip2&3, or

Trip1,2&3 trip action. Fail-safe or non-fail-safe mode selection is active.

Alarm1 Relay operates when an alarm occurs in a protective function assigned Alarm1, Alarm1&2,

Alarm2 Relay operates when an alarm occurs in a protective function assigned Alarm2, Alarm1&2,

Alarm3 Relay operates when an alarm occurs in a protective function assigned Alarm3, Alarm1&3,

Current Relay is energized when current is detected.

Run Mode Relay is energized when in run mode. (Current <125% FLA for Run-Mode Delay).

Start Inhibit Relay is energized when in an I2t or starts-per-hour inhibit condition.

Trip 1 Pulse

Run1 Relay is energized by a network “Run1 Set” command and de-energized by a “Run1 Clear”

Watchdog Relay is energized when the PGR-6200 is operating properly.

Reduced OC Relay is energized when in reduced overcurrent mode (ROC = On)

(1)

None No Assignment

Assign this function to only one relay. Non-fail-safe operation only.

Alarm1&3, or Alarm1,2&3 alarm action. Fail-safe or non-fail-safe mode selection is active.

Alarm2&3, or Alarm1,2&3 alarm action. Fail-safe or non-fail-safe mode selection is active.

Alarm2&3, or Alarm1,2&3 alarm action. Fail-safe or non-fail-safe mode selection is active.

(1)

Trip 1 energizes relay for the time duration specified by the RY Pulse Time set point.

command.

Page 4-4

PGR-6200 Motor Protection Relay Rev. 2

The Reduced OC selection operates in

conjunction with the reduced-overcurrent set point

which must be enabled. See Section 5.5.

When Reduced OC is selected and no digital-

input voltage is applied, the reduced-overcurrent set

point is operational. When digital-input voltage is

applied, the reduced-overcurrent set point is not

operational

4.2.6 Analog Output

Menu: Setup | Analog Output

The 20-mA analog output can be programmed for

one of the parameters shown in Table 4.4.

The analog output is factory calibrated for zero

equals 4.0 mA and full scale equals 20.0 mA.

If adjustment is required, use the Analog Output

menus.

Zero Calibration:

• Select Zero in the Output Parameter menu.

• Measure the output current and adjust the Zero

Calibrate setting for the desired output. The

calibration number for 4 mA will be in the range

of 100 to 110.

Full-Scale Calibration:

• Select Full Scale in the Output Parameter

menu.

• Measure the output current and adjust the FS

Calibrate setting for the desired output. The

calibration number for 20 mA will be in the

range of 540 to 550.

Calibration numbers are not changed when

factory defaults are loaded, or during a firmware

update.

4.2.7 Miscellaneous Configuration

Menu: Setup | System Config

System Name Appears on many of the display

screens and can be set by the

user (18-character alphanumeric

field).

Password Used to change the 4-character

alphanumeric password.

Clock Setting Used to set the date and 24-

hour clock.

Password Timeout Used to set the password time-

out delay. Delay is measured

from last key press.

Run Mode Delay Run mode is entered when

current is between 5 and 125%

FLA for the specified time.

UPI LED Used to assign an internal

parameter to the UPI LED.

Maintenance Used to clear event records,

trip counters, and run hours.

Used to load defaults.

Used to view firmware version,

unit serial number, and MAC

address.

Used for firmware updates.

4.2.8 Communications

Menu: Setup | Hardware

The TIA-232 interface uses the Modbus

protocol. Set the ID and baud rate to match the

requirements of the communications device.

Default settings are the same as PGW-COMM PCinterface software defaults.

If equipped with an optional networkcommunications interface, refer to the appropriate

communications-interface manual.

®

RTU

Note: RS-232, EIA-232 and TIA-232 signal

specifications are compatible with the PGR-6200.

TABLE 4.4 Analog-Output Parameters

PARAMETER DESCRIPTION FULL SCALE

Phase Current Maximum of the three phase currents. Phase-CT-primary rating

EF (Ict Measured) Measured earth-leakage current from EF-CT. Earth-fault-CT-primary rating

EF (3I0 Calculated) Calculated earth-leakage current from phase CT’s. Phase-CT-primary rating

Used I2t Used thermal capacity. 100% I2t

Local RTD Local RTD temperature.

Mod Stator RTD Temp. module maximum stator temperature.

Mod Bearing RTD Temp. module maximum bearing temperature.

Mod Load RTD Temp. module maximum load temperature.

Mod Ambient RTD Temp. module maximum ambient temperature.

Unbalance Current unbalance (I2/I1). 1 per unit or 100%

Zero Zero calibration. Not applicable

Full Scale Full-scale calibration. Not applicable

Differential Maximum phase-differential current Differential-CT-primary rating

(1)

The output defaults to the calibrated zero output for an open or shorted RTD sensor.

(2)

Requires optional PGA-0120 Temperature Input Module.

(1)

(1,2)

(1,2)

(1,2)

(1,2)

200°C

200°C

200°C

200°C

200°C

Loading...

Loading...