Littelfuse PGR-6150 Users Manual

POWR-GARD®

Motor Protection

PGR-6150 SERIES

Motor Protection System

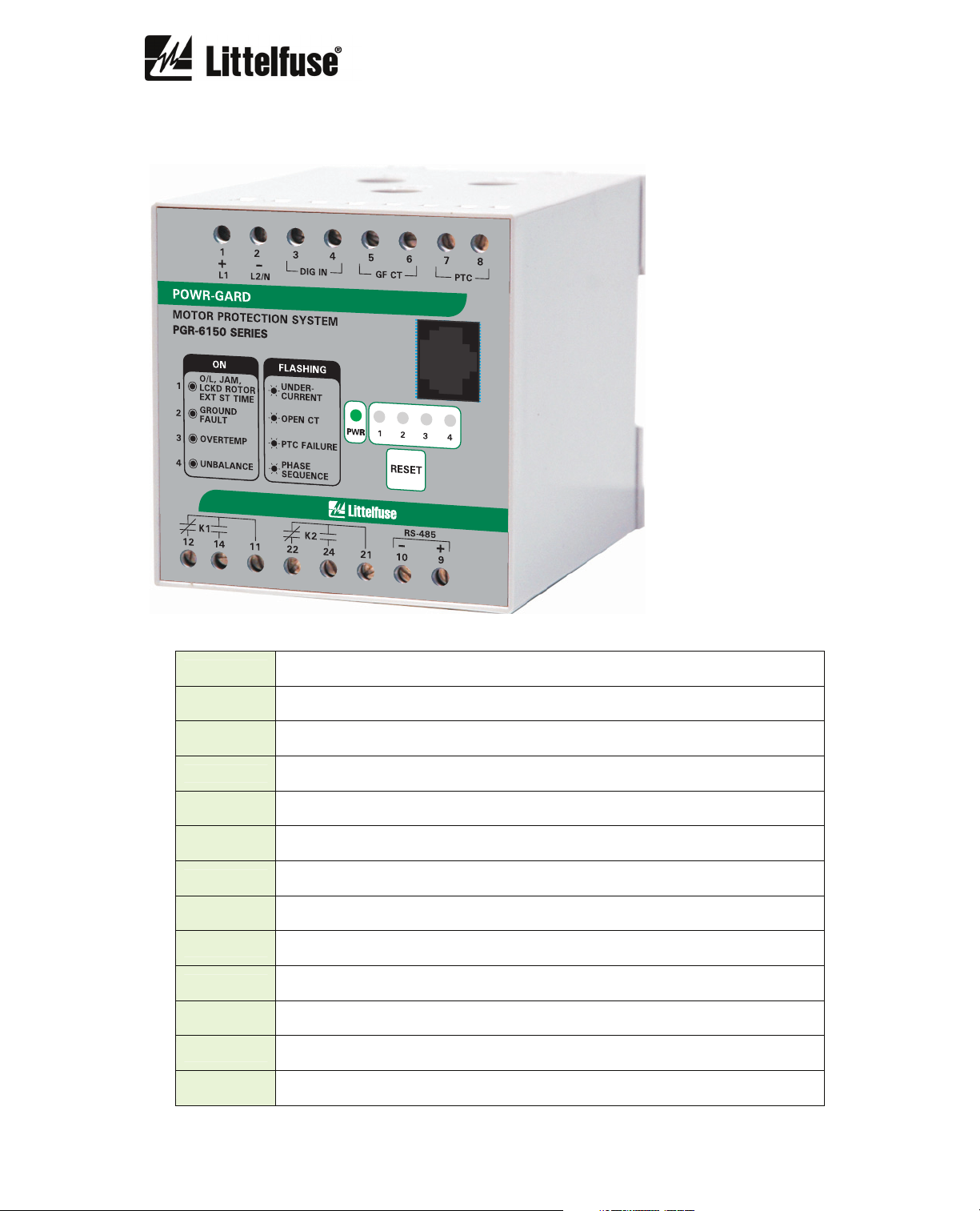

PGR-6150

Motor Protection System

September 29, 2010

REVISION 1

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

1. GENERAL HANDLING ............................................................................................ 5

1.1. Unpacking and Inspection ............................................................................................................. 5

1.2. Handling Electronic Equipment ..................................................................................................... 5

1.3. Installation ..................................................................................................................................... 5

1.4. Storage ......................................................................................................................................... 5

2. DIMENSIONS ...........................................................................................................

2.1. PGR-6150 ..................................................................................................................................... 6

2.2. PGR-6150-OPI .............................................................................................................................. 7

6

3. CONNECTION DIAGRAMS .....................................................................................

3.1. Direct Connection ......................................................................................................................... 8

3.2. Multiple Pass Connection .............................................................................................................. 8

3.3. External CT Connection ................................................................................................................ 9

3.4. PTC and Ground-Fault Connection ............................................................................................... 9

8

4. PGR-6150 BASE-MODULE TERMINALS ............................................................ 10

5. DESCRIPTION .......................................................................................................

5.1. General ....................................................................................................................................... 11

5.2. Features ...................................................................................................................................... 11

5.2.1. Protection ......................................................................................................................... 11

5.2.2. Metering ........................................................................................................................... 11

5.2.3. Data Logging .................................................................................................................... 11

5.2.4. Inputs and Outputs ........................................................................................................... 12

5.2.5. Operator Interface ............................................................................................................ 12

5.3. Ordering Information ................................................................................................................... 12

11

6. PGR-6150 PROTECTIVE FUNCTIONS AND CONTROL .....................................

6.1. Power Supply .............................................................................................................................. 13

6.2. Protective Functions ................................................................................................................... 13

6.2.1. General Settings ................................................................................................................... 13

6.2.2. Overload ............................................................................................................................... 14

6.2.3. Phase Unbalance .................................................................................................................. 15

6.2.4. Phase Loss ........................................................................................................................... 15

6.2.5. Phase Sequence ................................................................................................................... 16

6.2.6. PTC ....................................................................................................................................... 16

6.2.7. Jam ....................................................................................................................................... 17

6.2.8. Locked rotor .......................................................................................................................... 17

6.2.9. Calculated Definite-Time Ground Fault ................................................................................. 18

6.2.10. Calculated Inverse-Time Ground Fault ................................................................................ 18

6.2.11. Measured Definite-Time Ground Fault ................................................................................ 19

6.2.12. Measured Inverse-Time Ground Fault ................................................................................. 19

6.2.13. Undercurrent ....................................................................................................................... 20

6.2.14. Motor-Start-Up Monitoring ................................................................................................... 20

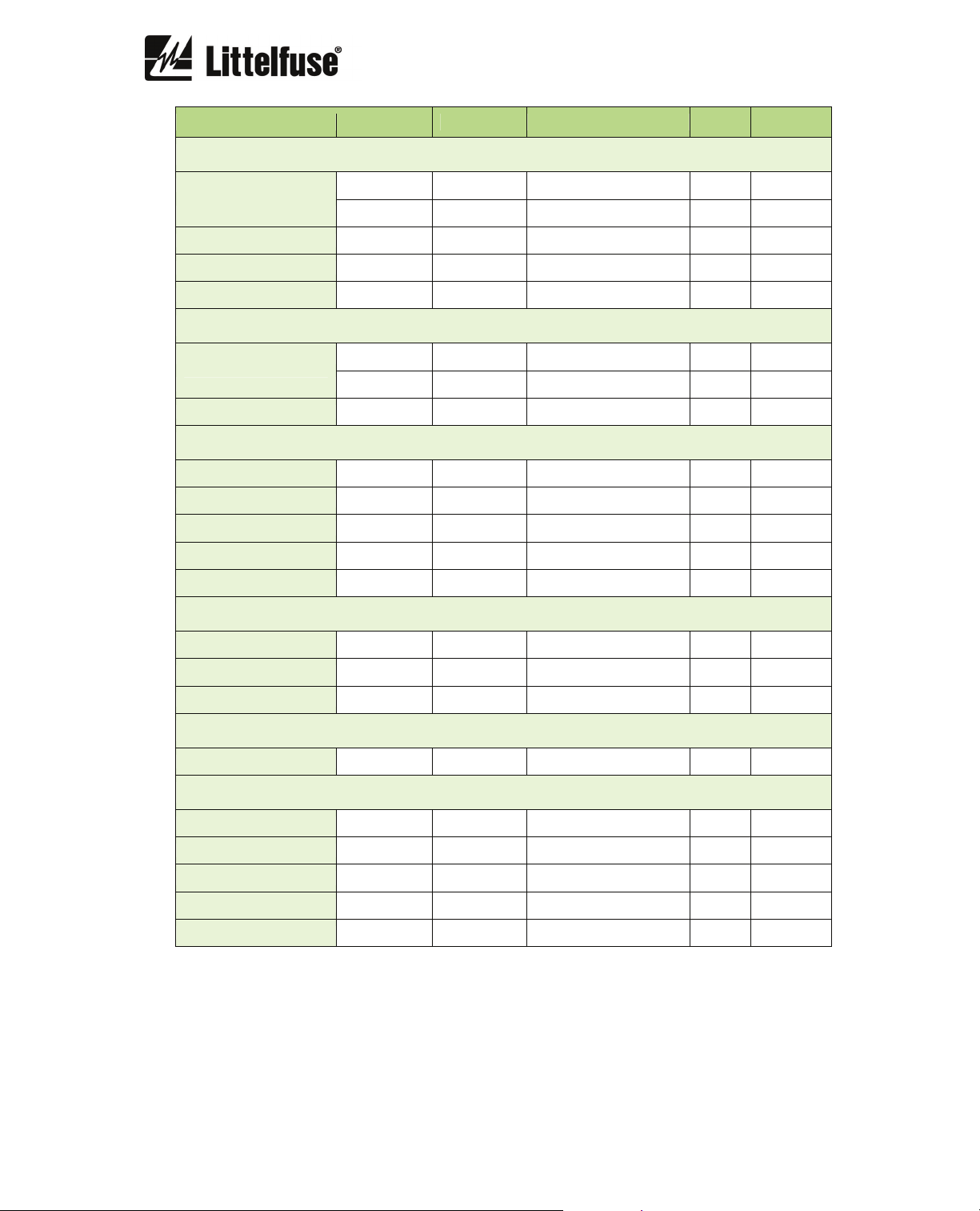

6.2.15. PGR-6150 Settings Summary ............................................................................................. 21

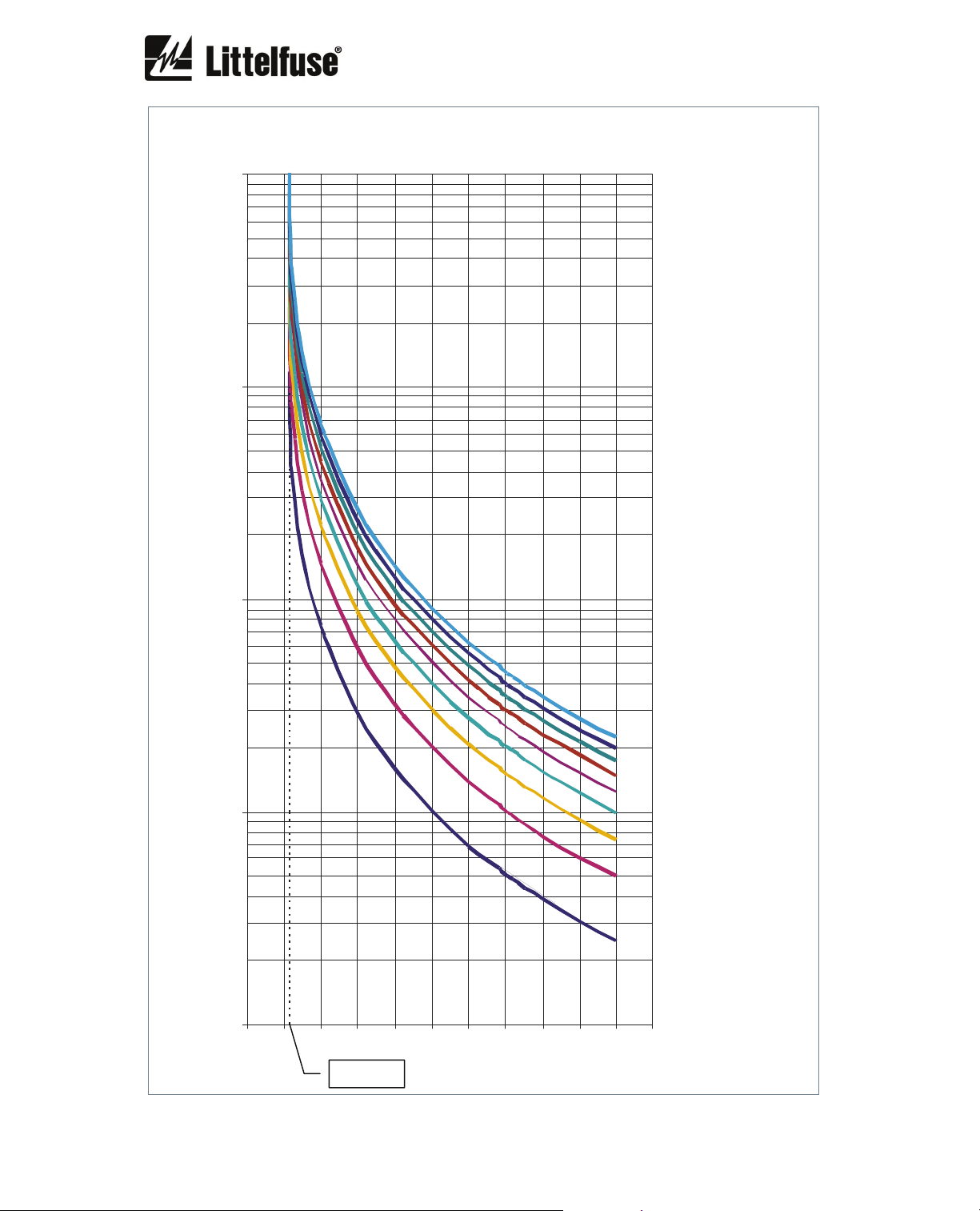

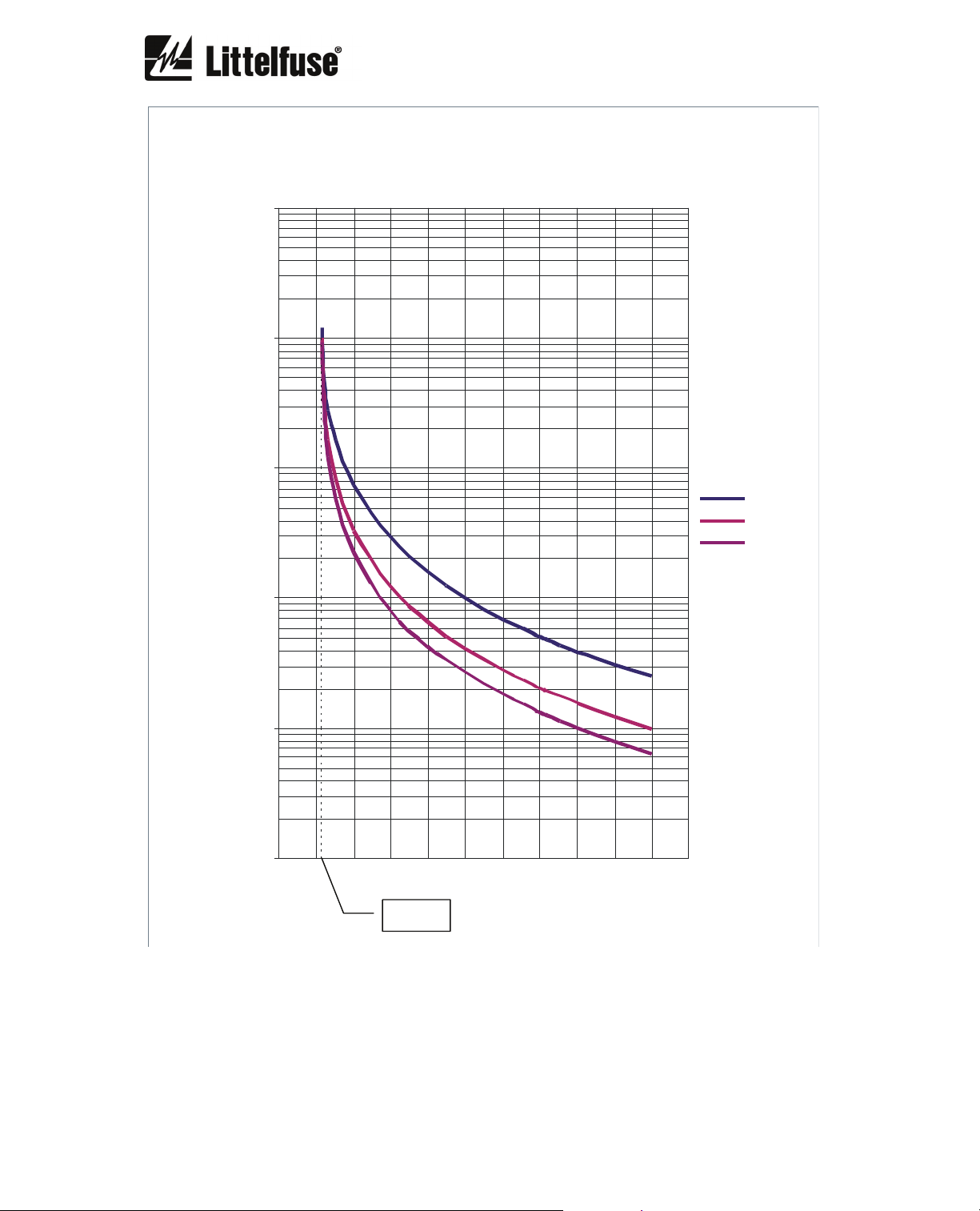

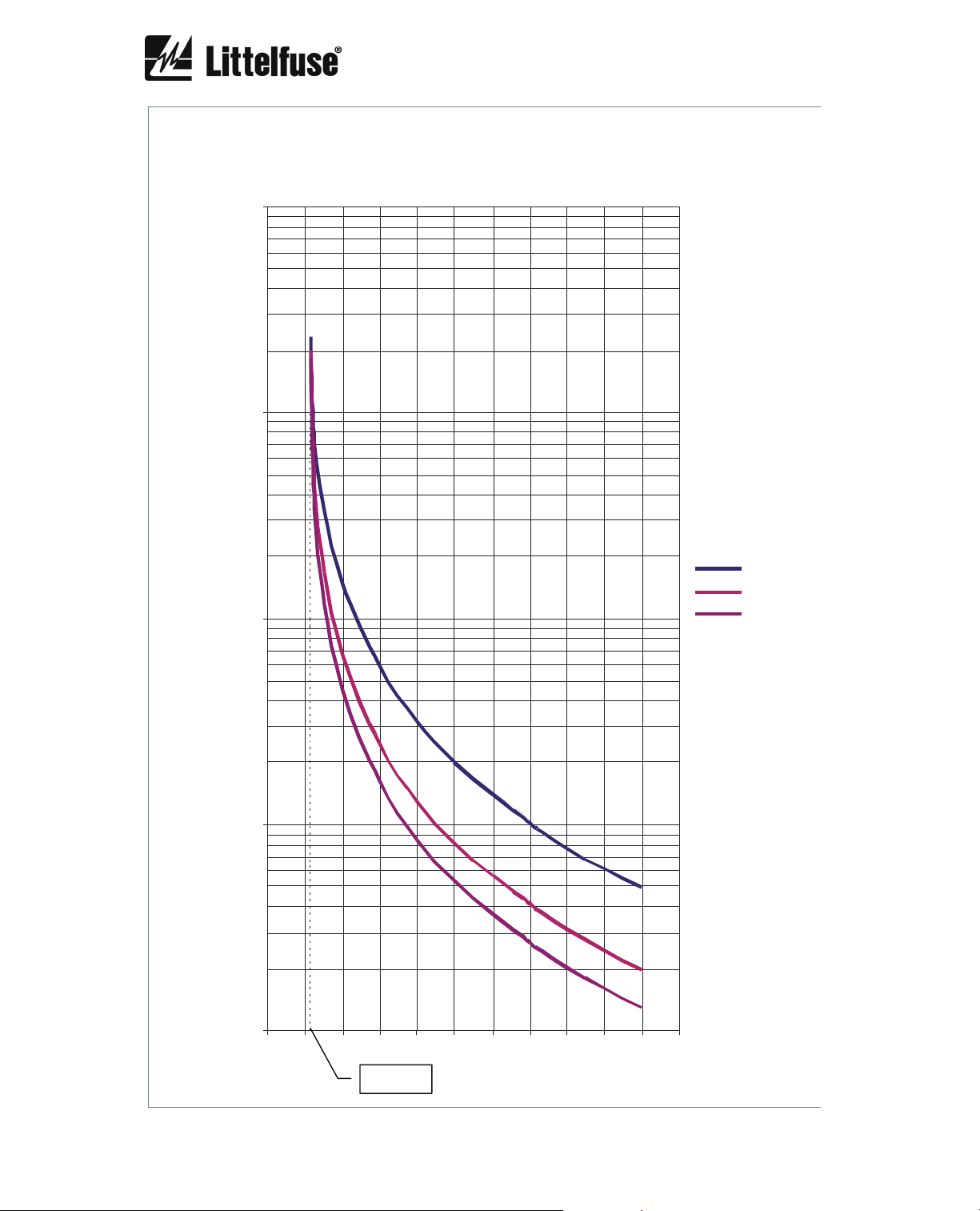

6.2.16. Overload Curves ................................................................................................................. 24

6.2.17. IEC255-4/BS-142 Curves .................................................................................................... 35

6.3. Monitoring and Control ................................................................................................................ 39

6.3.1. Metering ................................................................................................................................ 39

6.3.2. States .................................................................................................................................... 40

6.3.3. Ground-Fault Current-Transformer Monitoring ...................................................................... 43

6.3.4. Time Delayed PGR-6150 Start .............................................................................................. 43

6.3.5. Reset .................................................................................................................................... 44

6.3.6. Thermal Image Reset ............................................................................................................ 44

6.3.7. Reset/Test Button ................................................................................................................. 44

6.3.8. Reports/Event Records ......................................................................................................... 44

6.3.9. Statistics................................................................................................................................ 45

6.3.10. Commands .......................................................................................................................... 46

13

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6.3.11. Digital Input ......................................................................................................................... 46

6.3.12. Outputs ............................................................................................................................... 46

6.3.13. PGR-6150 Base Module LED’s ........................................................................................... 47

6.3.14. Adjustable PGR-6150-OPI LED’s ........................................................................................ 47

6.3.15. Self-Diagnostics .................................................................................................................. 49

6.3.16. Date-Time Synchronization ................................................................................................. 49

6.3.17. RS-485 Communications .................................................................................................... 49

6.3.18. Modbus RTU Protocol ......................................................................................................... 49

6.3.19. User Password .................................................................................................................... 50

6.3.20. PGR-6150 Base Module Test Program ............................................................................... 50

6.3.21. PGR-6150-OPI Test program .............................................................................................. 51

6.3.22. PGR-6150 LCD Contrast .................................................................................................... 51

7. TECHNICAL SPECIFICATIONS AND STANDARDS

7.1. Technical Specifications ............................................................................................................... 52

7.2. Standards .................................................................................................................................... 56

.................................................. 52

8. ACCESSORIES

8.1. Ground-Fault Current Transformer .............................................................................................. 57

8.2. Cable Section.............................................................................................................................. 57

8.3. PGR-6150 Connection Cable ...................................................................................................... 57

....................................................................................................................... 57

9. PGR-6150-OPI OPERATOR INTERFACE

9.1. PGR-6150-OPI Front Panel ........................................................................................................ 58

9.2. LED Indicators ............................................................................................................................ 58

9.3. LCD and Keypad ......................................................................................................................... 58

9.4. Menus ......................................................................................................................................... 58

9.4.1. Standby Mode ...................................................................................................................... 58

9.4.2. Date-Time Menu ................................................................................................................... 59

9.4.3. Version .................................................................................................................................. 59

9.4.4. Communications Menu ......................................................................................................... 60

9.4.5. Test Menu ............................................................................................................................. 60

9.4.6. Functions Menu .................................................................................................................... 61

9.4.7. Metering Menu ...................................................................................................................... 61

9.4.8. States Menu .......................................................................................................................... 62

9.4.9. Settings Menu ....................................................................................................................... 63

9.4.10. Configuration Menu ............................................................................................................. 65

9.4.11. Reports Menu ..................................................................................................................... 65

9.4.12. Command Menu.................................................................................................................. 67

9.4.13. Password Menu .................................................................................................................. 67

............................................... ....................... 58

10. COMMISSIONING ................................................................................................

10.1. Checklist for commissioning ...................................................................................................... 68

10.2. Inspection ................................................................................................................................. 68

10.2.1. Visual inspection ................................................................................................................. 68

10.2.2. Current Transformers .......................................................................................................... 68

10.3. Commissioning ......................................................................................................................... 68

68

11. MODBUS RTU PROTOCOL

11.1. Modbus Package Format .......................................................................................................... 70

11.2. Function Codes ......................................................................................................................... 70

11.3. Error Responses and Exceptions .............................................................................................. 71

11.4. Types of Data ............................................................................................................................ 71

11.5. Data Reading ............................................................................................................................ 72

11.6. Set-Point Writing ....................................................................................................................... 72

11.7. Command ................................................................................................................................. 73

11.8. PGR-6150 Memory Map ........................................................................................................... 74

.............................................................................................. 69

12. APPENDIX

..................................................... ............................ ........................... ................... 89

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

1. GENERAL HANDLING

1.1. Unpacking and Inspection

The PGR-6150 must only be handled by qualified personnel and special care must be taken to

protect its parts from damage during unpacking and installation.

Inspect the PGR-6150 at delivery to ensure no damage occurred during transport. Inform

Littelfuse Inc. immediately if the product is deemed to be defective.

1.2. Handling Electronic Equipment

Relays contain electronic components that are sensitive to electrostatic discharge.

To ensure that electronic parts are not damaged due to electrostatic discharge, do not remove

the plastic housing.

1.3. Installation

Please read documentation carefully before installing and commissioning the motor protection

system.

Check polarity and voltage before energizing the relay.

The equipment must be used within the stipulated electrical and environmental limits.

Current transformer circuits: Do not open a live CT secondary circuit. The high voltage

NOTE:

produced as a result could damage the insulation and present a personnel hazard.

1.4. Storage

Relays should be stored in a dry and dust-free environment.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

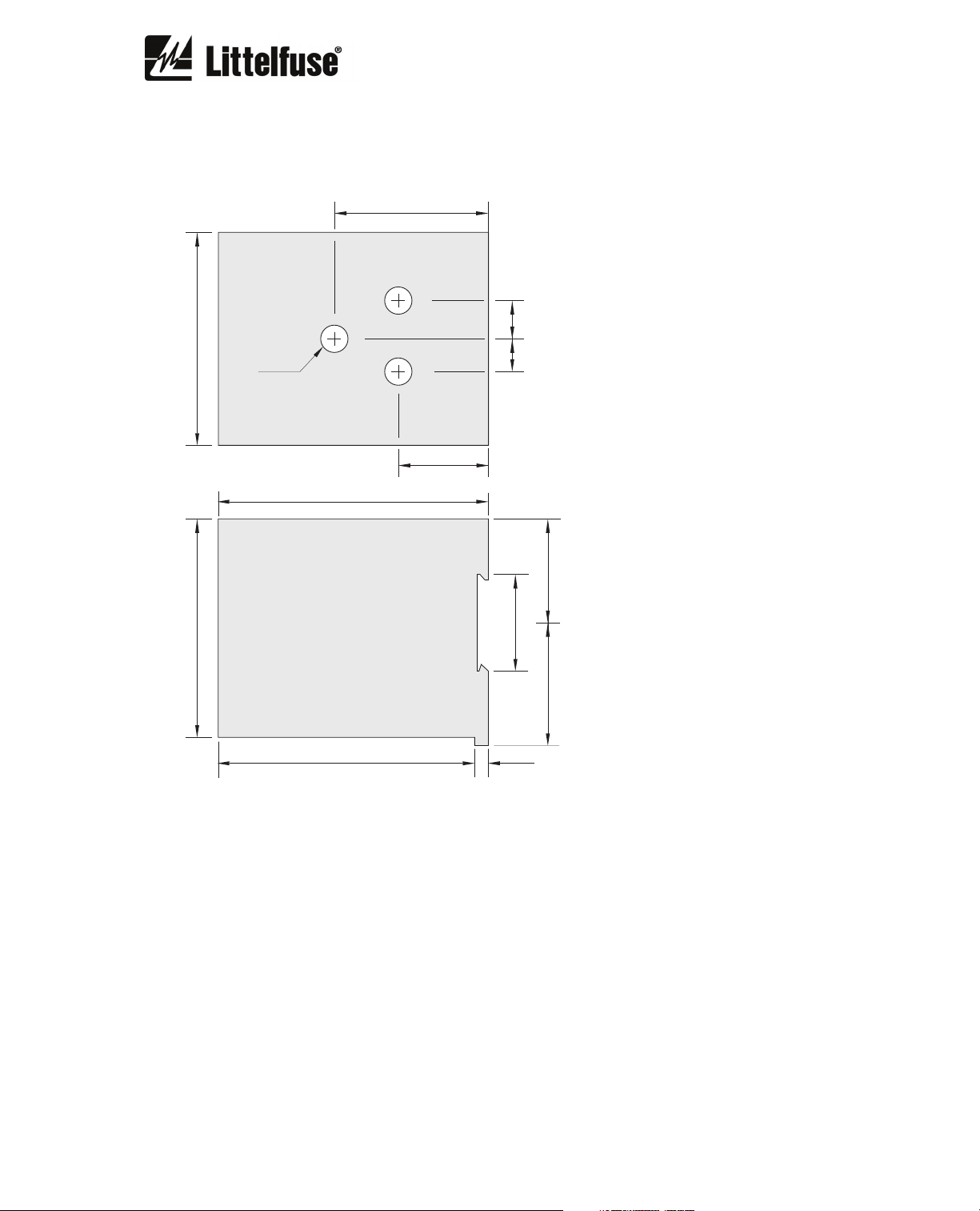

2. DIMENSIONS

2.1. PGR-6150

56.5

(2.22)

14.0

12.0

(0.55)

(0.47)

78.0

(3.07)

ø10

(ø0.39)

TOP VIEW

99.0

(3.90)

33.0

(1.30)

80.0

(3.15)

94.0

(3.70)

SIDE VIEW

35.4

5.0

(0.20)

38.0

(1.39)

45.0

(1.50)

(1.77)

NOTES:

DIMENSIONS IN MILLIMETRES (INCHES).

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

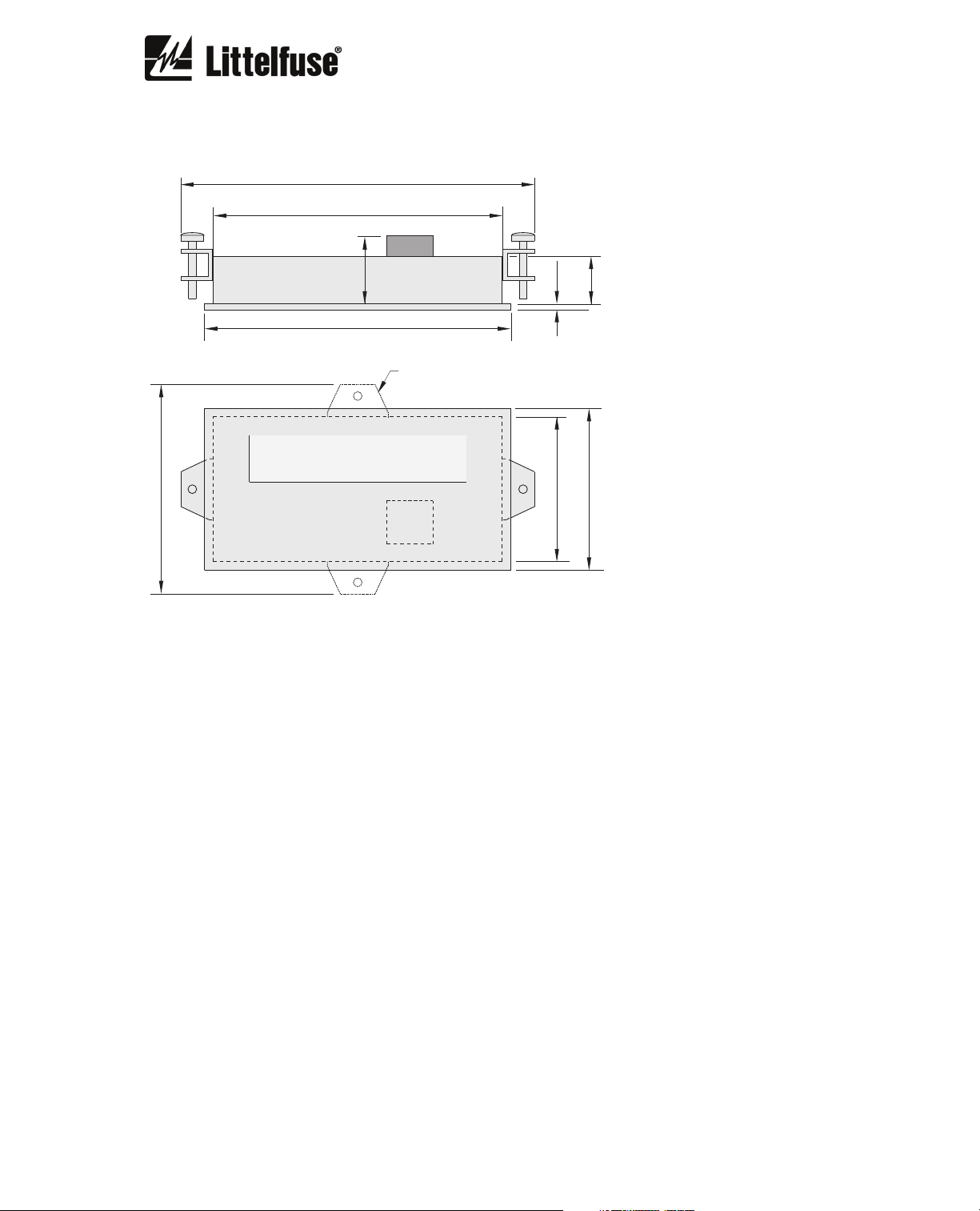

2.2. PGR-6150-OPI

122.5

(4.82)

100.0

(3.94)

72.5

(2.85)

23.5

(0.93)

106.0

(4.17)

TOP VIEW

FRONT VIEW

ALTERNATE CLAMP

LOCATIONS

2.0

50.0

16.5

(0.08)

56.0

(1.97)

(0.65)

(2.20)

NOTES:

DIMENSIONS IN MILLIMETRES (INCHES).

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

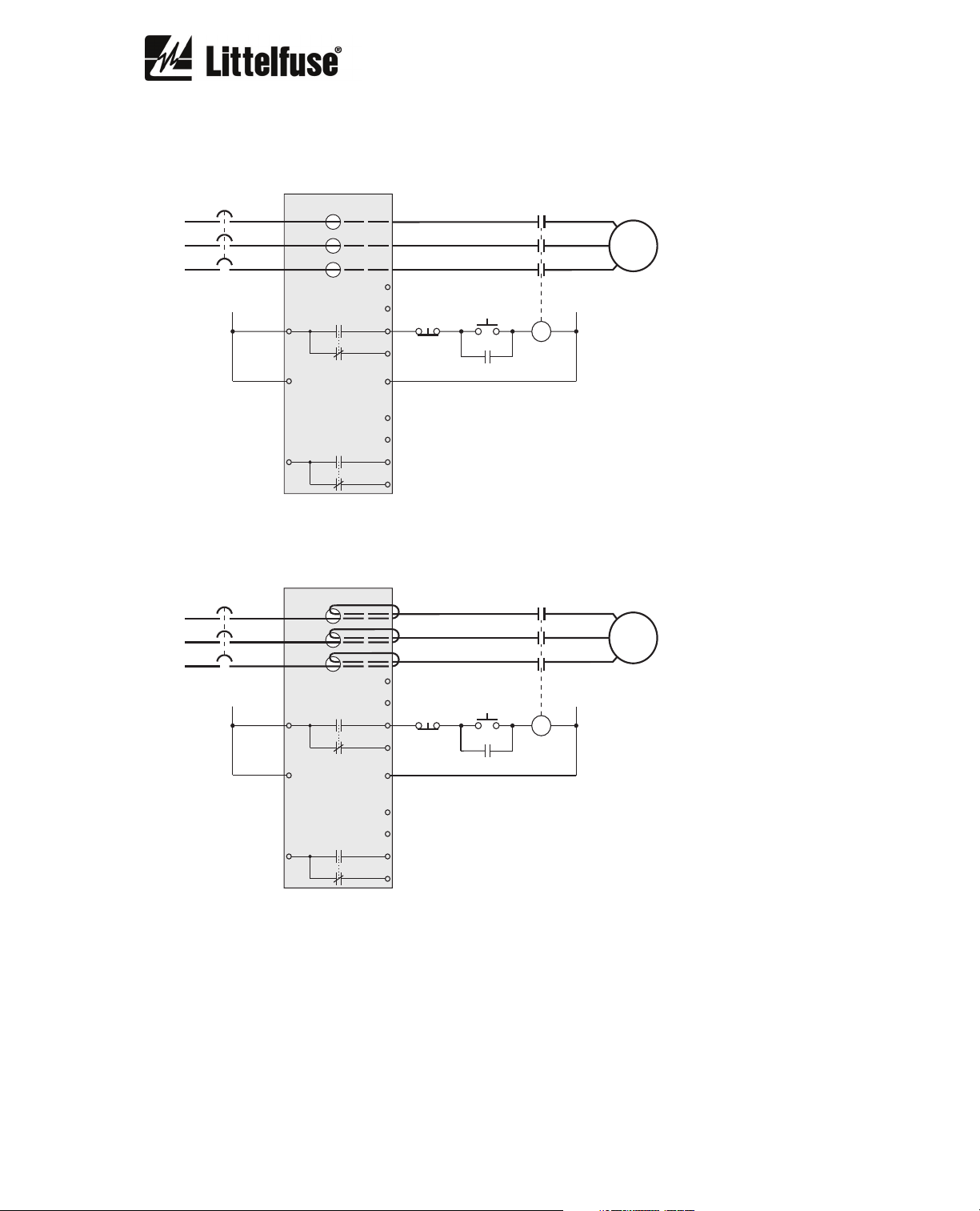

3. CONNECTION DIAGRAMS

3.1. Direct Connection

C

MOTOR

AUX VOLTAGE

SUPPLY

L

TRIP

K1

11

+

L1

PGR-6150

ALARM

K2

21 24

GF CT

PTC

5

6

14

12

-

L2

N

7

8

22

3.2. Multiple Pass Connection

AUX VOLTAGE

SUPPLY

L

TRIP

K1

11

GF CT

5

6

14

12

STOP

STOP

START

C

START

C

N

C

C

MOTOR

N

C

PTC

-

L2

N

7

8

22

+

L1

PGR-6150

ALARM

K2

21 24

For motors with nominal current below the minimum relay set-point value, multiple turns can be

used. Set the value I

and CT Turns Ratio as explained in Section 6.2.1.

B

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

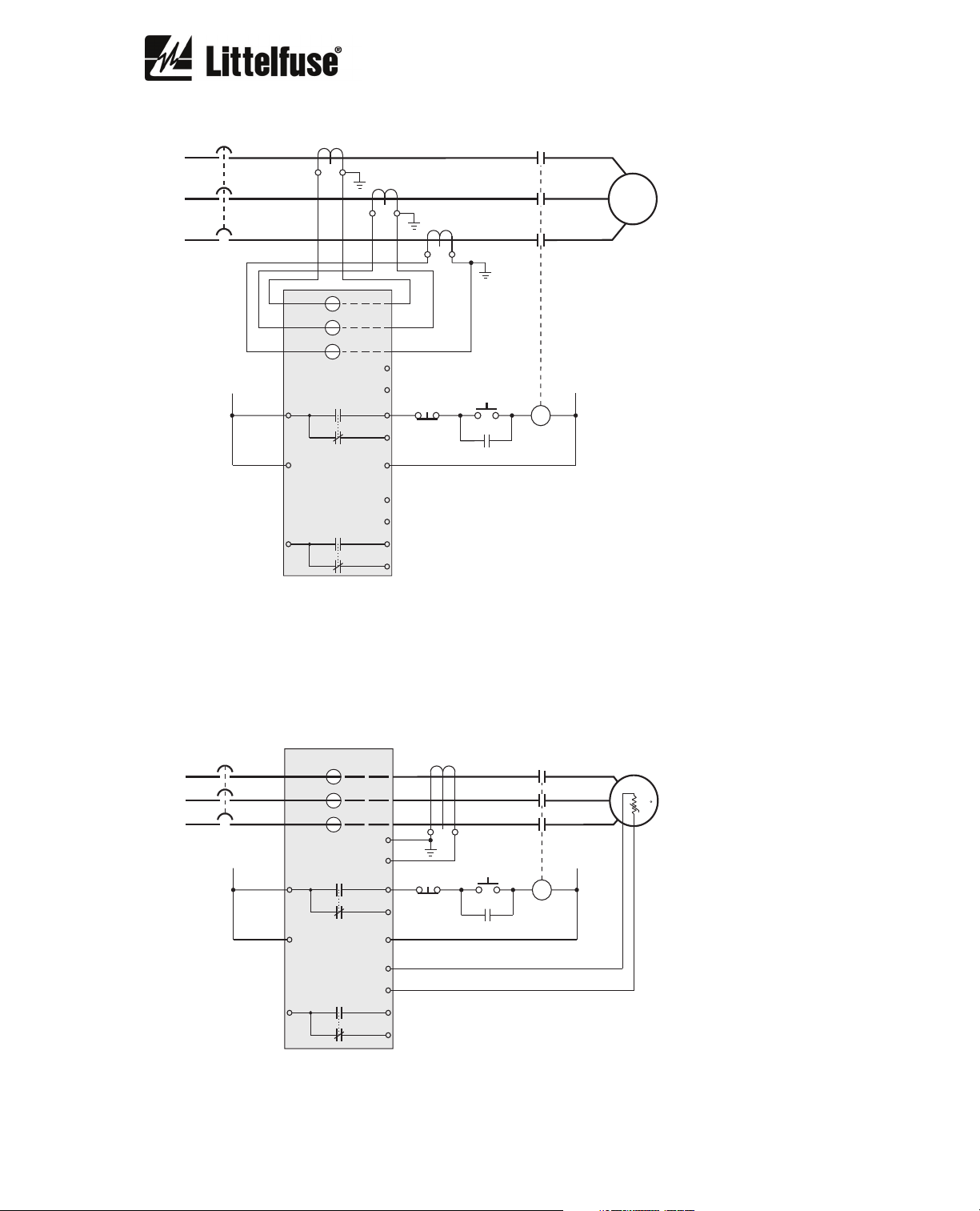

3.3. External CT Connection

CT1

CT2

CT3

5

AUX VOLTAGE

SUPPLY

L

11 14

+

L1

PGR-6150

21 24

TRIP

K1

ALARM

K2

GF CT

PTC

6

STOP

12

-

L2

N

7

8

22

START

C

For motors with nominal current over the maximum relay current set-point value, combine the

relay with current transformers. Set the value IB and CT Turns Ratio as explained in Section

6.2.1.

C

N

C

3.4. PTC and Ground-Fault Connection

GF CT

5

TRIP

K1

ALARM

K2

GF CT

PTC

6

STOP

12

-

L2

N

7

8

22

START

AUX VOLTAGE

SUPPLY

L

11 14

+

L1

PGR-6150

21 24

C

+t

N

C

C

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

4. PGR-6150 BASE-MODULE TERMINALS

DIG IN

GF CT

PTC PTC temperature sensor connection

+

-

14

12

11

24

22

21

+ L1

24 Vac/dc digital input

Ground-fault current transformer connection

RS-485 connection +

RS-485 connection -

Output K1 contact normally open

Output K1 contact normally closed

Output K1 common

Output K2 contact normally open

Output K2 contact normally closed

Output K2 common

Supply voltage (+ for direct current)

- L2/N

Supply voltage (- for direct current)

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

5. DESCRIPTION

5.1. General

The PGR-6150 is a modular system that provides integrated protection, metering and data

logging functions. The PGR-6150 base module can operate as a stand-alone unit or with the

operator interface PGR-6150-OPI, the voltage module PGA-0160, and the input/output module

PGA-0180. The base module can be programmed using the PGR-6150-OPI or using SCADA

communications through the RS-485 port.

5.2. Features

5.2.1. Protection

• Overload

• Phase unbalance

• Phase loss

• Phase sequence

• PTC overtemperature

• Jam

• Locked rotor

• Calculated definite-time ground fault

• Calculated inverse-time ground fault

• Measured definite-time ground fault

• Measured inverse-time ground fault

• Undercurrent

• Excessive-start-up time

5.2.2. Metering

• Line currents

• Zero-sequence current

• Ground-fault current

• Thermal image

• Frequency

• Positive-sequence current

• Negative-sequence current

• Average-phase current

5.2.3. Data Logging

• Four fault records

o Date of event

o Line currents

o Frequency

o Overload

o Current unbalance

o PTC overtemperature

o PTC fault

o Jam

o Locked rotor

o Ground-fault current

• Trip counters

o Number of overloads

o Number of overtemperature

o Number of jams

o Number of locked rotors

o Number of ground faults

o Number of startups

• Startup maximum current

• Last startup maximum current

• Last startup average current

• Operating hours

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

5.2.4. Inputs and Outputs

• One digital input

• One trip output relay

• One alarm output relay

• PTC input

• Ground-fault current transformer input

• Relay closing time delay

• RJ-45 24 Vdc output to PGR-6150-OPI and optional voltage and input/output modules

• RS-485 communications

• 1 Power On LED

• 4 LED status indicators

5.2.5. Operator Interface

• 2 x 20 LCD display

• Display control and programming keys

• 6 programmable LED status indicators

The four status LEDs on the PGR-6150 give indication of faults on the system being monitored.

The system checks both equipment malfunction and external input connections. LED functions

are labelled on the front face of the PGR-6150.

An adjustable power-up timer from 0 to 3600 s allows motors to be started in a staggered

sequence.

The trip and alarm output relay contacts operate in failsafe mode.

The algorithm used to measure the currents calculates the RMS (Root Mean Square) value.

16 samples per cycle are used. The sampling frequency is determined by the system frequency

setting. It can be set to 50, 60 Hz, or variable. The accuracy of the measurement is 2% over the

whole range. The variable frequency sampling is only valid for models with alternating supply as

the alternating supply signal is taken as reference to calculate the line frequency (45 Hz to 65 Hz).

The PGR-6150 information can be accessed from the PGR-6150-OPI or from an RS-485

communications port on terminals 9 and 10, which allows for the PGR-6150 to be included as

part of a SCADA system. The Modbus RTU protocol is used.

Each LED on the PGR-6150-OPI is programmable and can be set as latching or none latching

and/or as flashing or not flashing.

The PGR-6150-OPI is also equipped with a start button and a stop button. To use the start

function “I”, a PGA-0180 Input/Output module is required.

The RESET button can be used to reset the output relays and latched LED’s and to test the

LED’s both on the main module and the operator interface.

5.3. Ordering Information

PGR-6150-24 24/48 Vdc Base Module

PGR-6150-120 120/240 Vac/dc Base Module

PGR-6150-OPI Operator Interface

ACCESSORIES

PGC-6035 Ground-fault current transformer, 35 mm

PGC-6060 Ground-fault current transformer, 60 mm

PGC-6080 Ground-fault current transformer, 80 mm

PGC-6110 Ground-fault current transformer, 110 mm

PGC-6210 Ground-fault current transformer, 210 mm

PGA-0160 Voltage Module

PGA-0180 Input/Output Module

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6. PGR-6150 PROTECTIVE FUNCTIONS AND CONTROL

6.1. Power Supply

• The PGR-6150 comes with a 110/240 Vac/dc, 5 W power supply.

The PGR-6150 generates 24 Vdc available through the RJ-45 port to supply auxiliary modules.

6.2. Protective Functions

6.2.1. General Settings

The equipment's general settings are as follows:

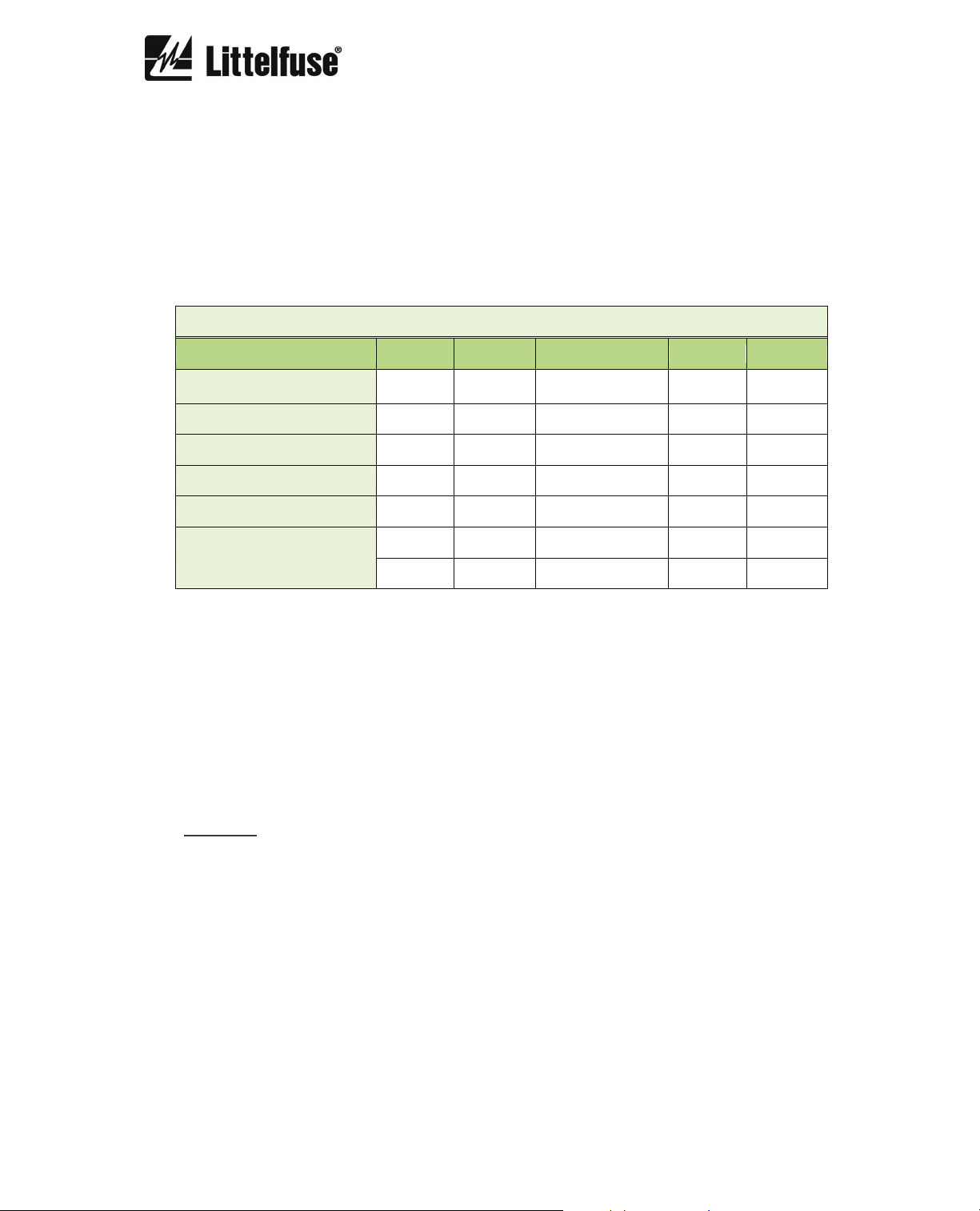

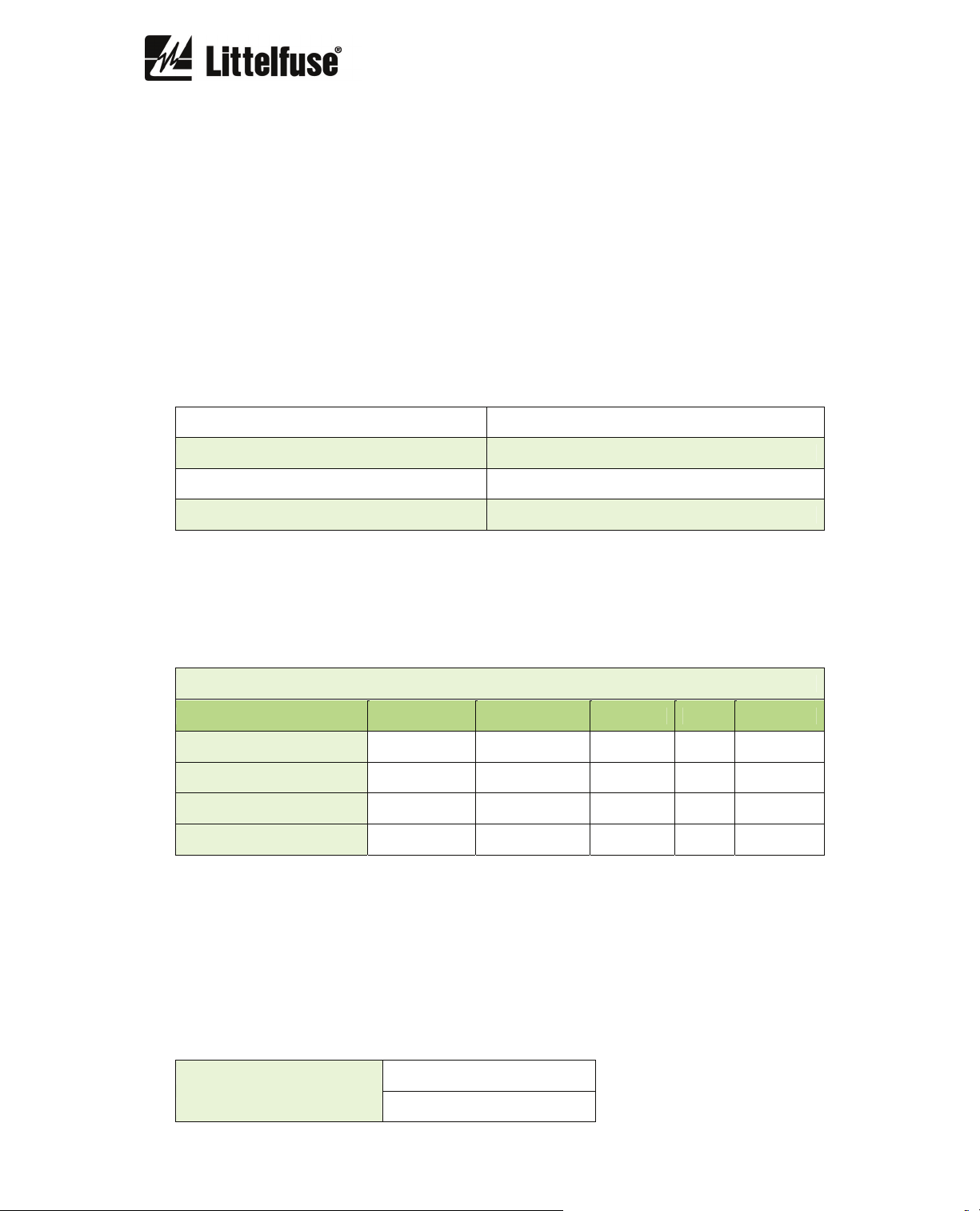

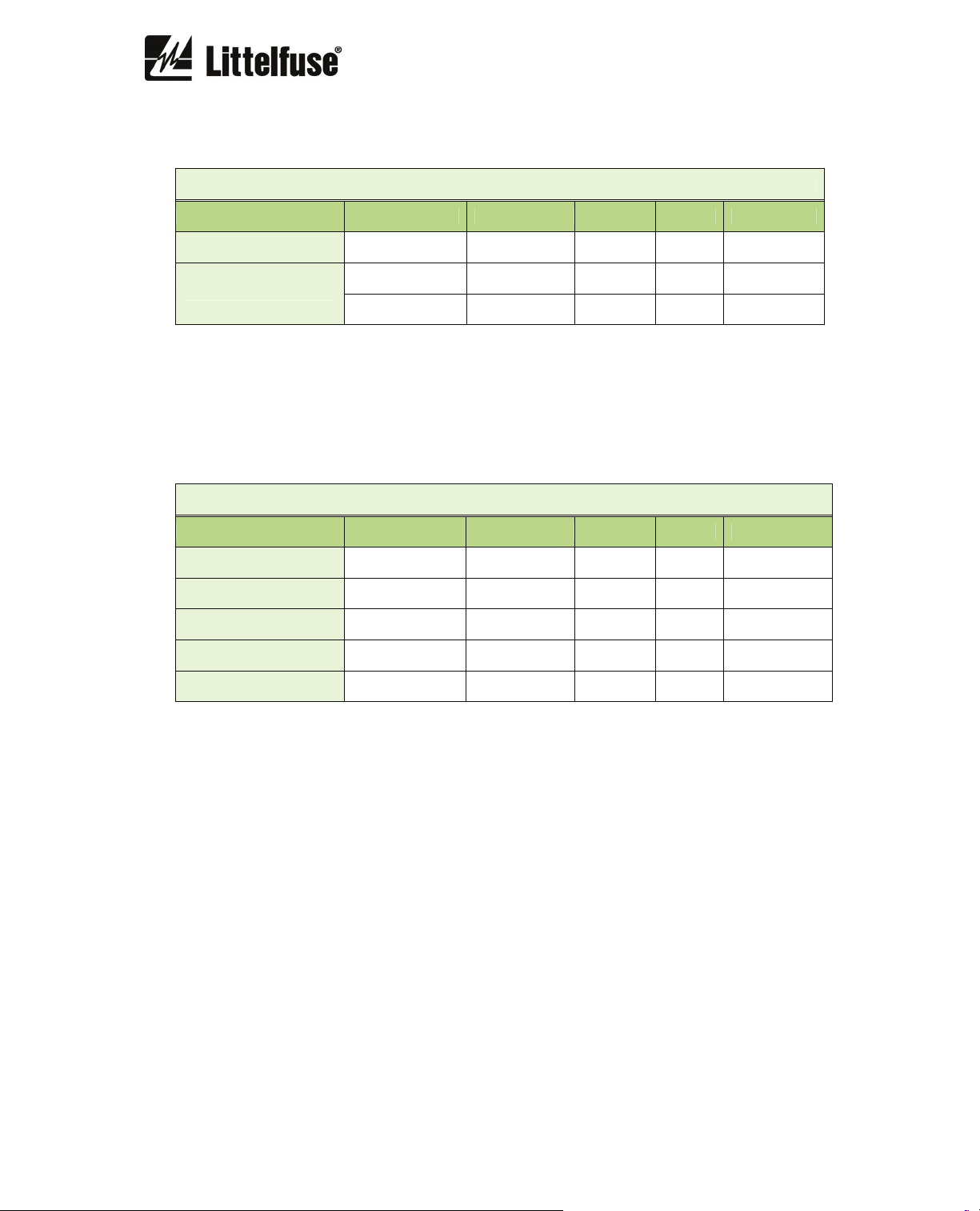

General Settings

Description Mínimum Maximum Step Unit Default

Nominal current IB

CT turns ratio 1 2000 1 - 1

Frequency - - 50Hz/60Hz/var Hz 50

Motor start limit 1 8 0.01 X IB 1.5

Motor starting time 1 200 1 s 60

Phase sequence - - ABC/ACB - ABC

PGR-6150 Initial time 0 3600 1 s 0

To protect the motor, the “Nominal current (I

nameplate.

If the “nominal current” is below the minimum relay current set-point value, pass cables through the

relay “n” time. “I

nameplate.

If the “nominal current” is greater than the maximum relay current set-point range, use external current

transformers. “I

divided by the CT Turns Ratio.

The “motor start limit” and "motor starting time" settings are used to adjust motor start up limits. A trip

will result when this limit is exceeded.

“ set value will be “IN x n”, where IN is the nominal current shown on the motor

B

“ set-point value will be the nominal current shown on the motor nameplate

B

4 25 0.01 A 4

)”, must be set to the value stated on the motor

B

,NOTE: For “Motor starting time” choose a value between 1 and 200. It is possible to

deactivate this function by setting the value to 0. A value 0f 0 is not recommended as it may

result in motor damage.

The frequency can be adjusted to 50 Hz, 60 Hz and variable frequency (with the equipment

maintaining measurement accuracy and time within a range of 45 Hz to 65 Hz). The variable

frequency setting applies to models with alternating supply voltage.

The “phase sequence” setting is set to match the phase rotation of the installation.

The “PGR-6150 initial time" is used to delay motor starting in applications where a staggered

start is required.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6.2.2. Overload

The overload function meets international standard IEC 947-4-1 and IEC 255-8.

A mathematically based thermal model is used to simulate the motor's thermal condition. The

model combines two thermal images: A heating image and a cooling image. The heating image

represents the thermal condition of the windings of the stator and rotor, and the cooling image

represents the thermal condition of the motor housing.

This heating and cooling thermal model ensures that the motor is operated in a safe zone.

Time to trip depends on the trip class selected, the circulating current and the previous motor

thermal condition.

The thermal image is calculated based on the following equation:

θ = 100 x (I/I

)2 x (1 – e

t

-t/ζ

) + θ’0 x e

Where:

• I, maximum current of the three phases

trip threshold current

• I

t,

• ζ, thermal constant.

• θ’

, initial thermal condition

0

The trip time comes from the equation:

t = ζ x ln { [(I/I

)2 – (θ’0 / 100) ] / [(I/It)2 - 1] }

t

The trip time accuracy is 5%.

The algorithm uses the maximum current of the three phase currents. If the maximum current is

greater than 15% of the adjusted current I

maximum current is less than 15% of the adjusted current I

applied.

The overload function trips when the thermal image reaches a value of 100%.

A thermal image adjustable level is established to generate an alarm. Should a trip occur, the

overload function is reset when the thermal image drops below the set alarm level.

The thermal constant has the following values:

-t/ζ

, the heating thermal constant is applied. If the

B

, the cooling thermal constant is

B

• ζ heating = 37 x trip class

• ζ cooling = 90 x trip class

If there is external ventilation,

• ζ cooling = (90 x trip class) / 4

•

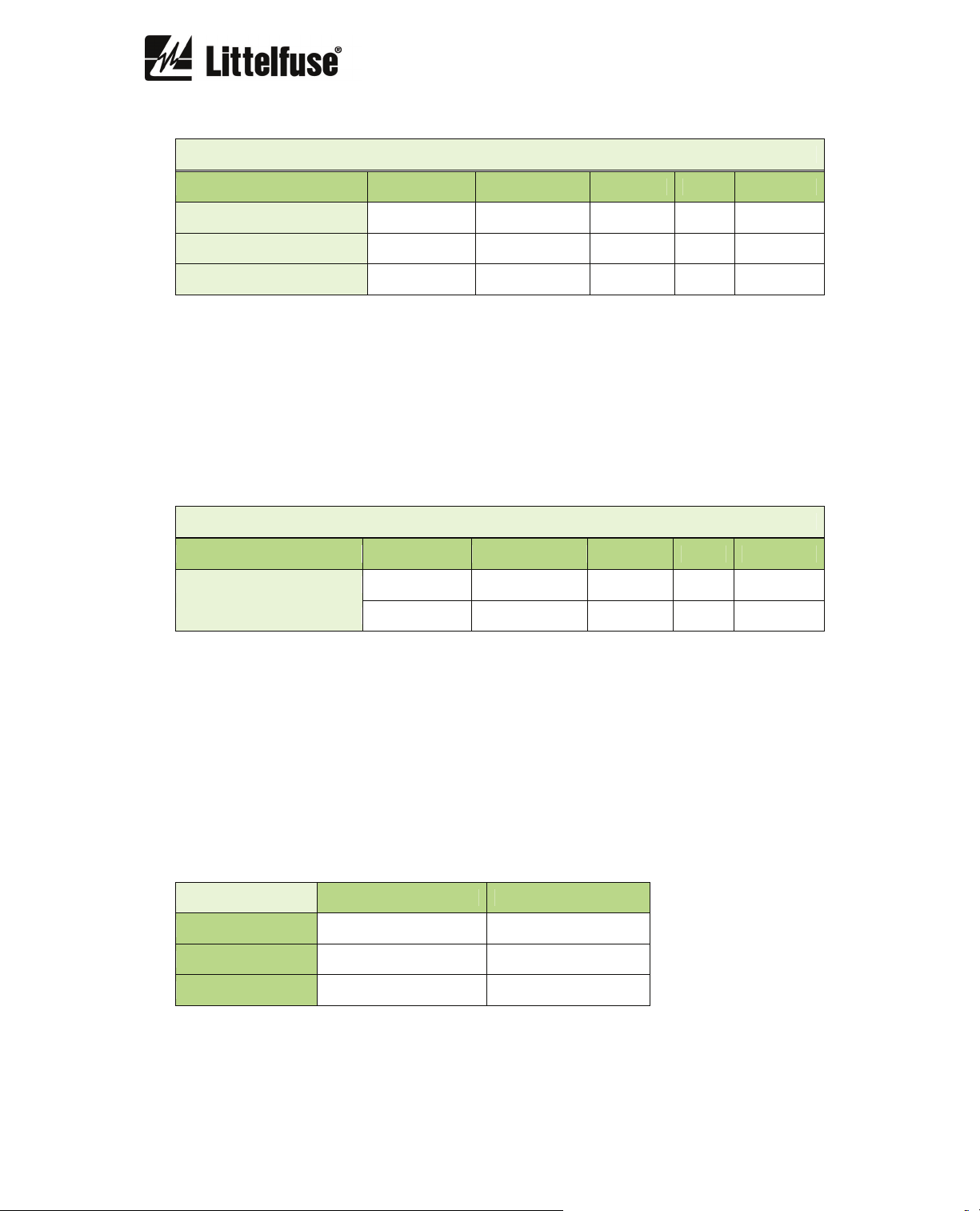

Overload

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - yes

Service factor 1 2 0.01 IB 1.15

Trip class - - 5,10,15,20,25,30,35,40,45 - 5

External ventilation - - Yes/No - No

Alarm 20 95 1 % 80

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

The PGR-6150 allows for overload function settings between 1 and 2 times IB. Note however

that standard IEC-947-4-1 recommends the tap setting to be between 1.05 and 1.20 times I

.

B

6.2.3. Phase Unbalance

The unbalance function is applied on a three phase system made up of three phase currents

(IA, IB, IC). The average current of the three values is taken as reference. The function is

operative when the average current is greater than 10% of the motor set current I

inoperative if the average current is less than 8%.

A dynamic operating band is established based on the average current. An excursion of a phase

current outside of this band for the selected time delay results in an unbalance trip. The band

upper and lower limits are defined by the % unbalance setting. A 5% hysteresis value is applied

for the reset level.

The unbalance reset and activate limits are determined as follows, based on the % unbalance

setting (value d1%):

Upper limit activation I

* (100 + d1)%

average

and becomes

B

Upper limit reset I

Lower limit activation I

Lower limit reset I

* (100 + d1– 5)%

average

* (100 - d1)%

average

* (100 - d1+ 5)%

average

Once the function has been activated, and the phase current drops below the upper reset limit or

rises above the lower reset limit, the function is instantly reset.

Two different time delays apply: one applies when the motor is starting, and the other when the

motor is in operation. As a result, a possible phase loss can be detected in the motor start up

and a fast trip can be executed.

Unbalance

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - yes

% Unbalance (d1) 5 30 1 %

30

Starting trip time 0.02 20 0.001 s 0.6

Running trip time 0.02 20 0.001 s 5

6.2.4. Phase Loss

The phase loss function is applied on a three phase system made up of three phase currents

(IA, IB, IC). The average current of the three values is taken as reference. The function is

operative if the average current is greater than 10% of the nominal current I

inoperative if the average current is less than 8%.

Based on the average current, a lower limit is established resulting from the % unbalance setting (d2)

and 5% reset hysteresis.

and becomes

B

Lower limit activation Iaverage* (100 – d2)%

Lower limit reset Iaverage* (100 – d2+ 5)%

The criteria is applied to the three phases. If a phase current is less than the lower limit for the

selected time delay, an unbalance trip occurs.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

There is only one operating time, regardless of whether the motor is starting up or in operation.

Phase loss

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - yes

% Unbalance (d2) 10 100 1 %

30

Time 0.02 20 0.001 s 5

6.2.5. Phase Sequence

The sequence function is activated when the phase sequence detected is not in accordance with

the phase sequence setting (ABC/ACB).

The phase sequence detection algorithm is based on the determination of the positive and

negative sequence of the fundamental currents component.

The function is operative if the positive sequence current or the negative sequence current is

greater than 10% of the current I

setting and stops operating if the positive sequence current

B

and the negative sequence current is less than 8%.

Phase sequence

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Time 0.02 2 0.001 s 0.02

6.2.6. PTC

PTC sensor protection should be applied in the following cases:

• Motors with a high number of starts/stops

• Motor operating at speeds lower than the range it is designed for

• When there is a restricted air supply

• In intermittent operations and/or constant braking

• High air temperatures

PTC sensor short circuit or open circuit and overtemperature are detected. Overtemperature

activates the trip contact, while a PTC sensor open circuit and short circuit activate the alarm

contact. The PTC sensor protection limits are preset and cannot be changed by the user.

Activation resistance Reset resistance

Overtemperature > 3,600 Ω < 1,800 Ω

Short circuit < 20 Ω > 30 Ω

Open circuit > 4,000 Ω < 3,900 Ω

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

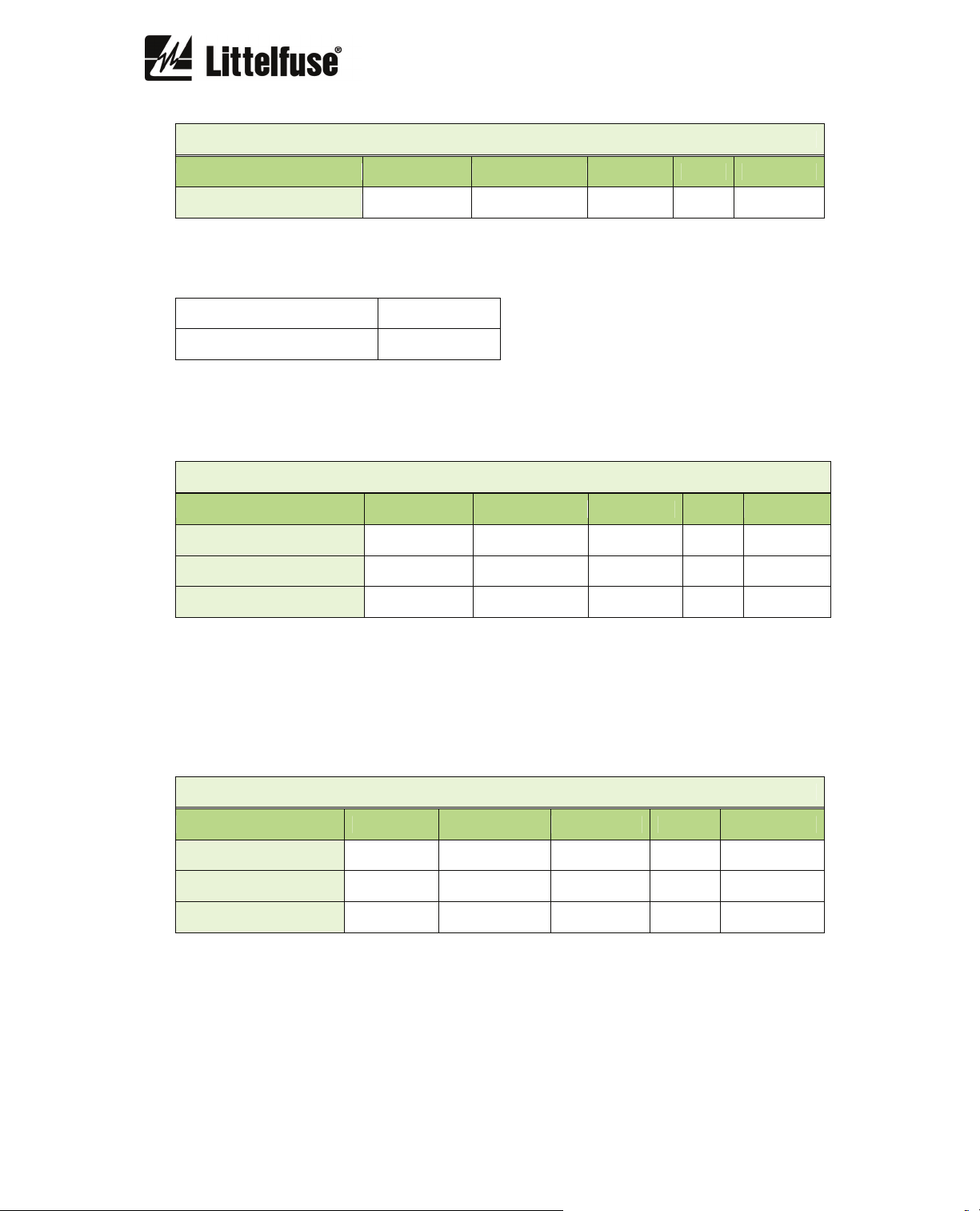

PTC

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

The trip time is 500 ms.

The PTC sensor current is 1 mA and a maximum of 2.3 V is used.

Maximum cold resistance 1,500 Ω

Minimum cold resistance 50 Ω

6.2.7. Jam

This function detects a motor jam and is disabled during motor start up.

JAM

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Pickup 1 3.5 0.01 I

B

2.5

Operating time 0.02 50 0.001 s 10

This function is enabled after the motor start-up sequence has been completed. See

Section 6.2.14

6.2.8. Locked Rotor

This function detects a locked rotor and is disabled during motor start up.

Locked rotor

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Pickup 3.5 6 0.01 I

B

Time 1 30 0.001 s 5

This function is enabled after the motor start-up sequence has been completed. See

Section 6.2.14

3.5

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6.2.9. Calculated Definite-Time Ground Fault

This function detects motor ground-fault current based on phase currents.

I0>> GF CALC DEF

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Pickup 0.1 1 0.01 I

Time 0.02 5 0.001 s 1

This function is enabled after the motor start-up sequence has been completed. See

Section 6.2.14

B

0.1

6.2.10. Calculated Inverse-Time Ground Fault

This protection function can be set by using five parameters:

I0> GF CALC INVERSE

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Curve - - (1*) - Inverse

Dial 0.05 1.25 0.01 - 1.25

Pickup 0.1 1 0.01 IB 1.00

Time 0.02 5 0.001 s 0.2

(1*) Inverse, Very inverse, Extremely inverse, Definite time

If the option "Definite time" is selected for the curve setting, the unit behaves like an

instantaneous overcurrent unit. In this case, the time parameter is active.

If a curve “Inverse”, “Very inverse” or “Extremely inverse” is selected for the curve setting, the trip

time depends on the curve, dial and pickup settings.

If the unit operates as definite time, the function is activated at 100% of the set pickup value, and

it deactivates at 95%.

If the unit operates with a curve, the function is activated at 110% of the set pickup value, and it

deactivates at 100%.

The reset is instantaneous in both cases.

The activation time is accurate to ±5% or ±30 ms, whichever is greater.

The curves used are IEC255-4/BS-142, which are described in Section 6.2.17.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6.2.11. Measured Definite-Time Ground Fault

This option requires a ground-fault current transformer.

IG>> GF MEASURED DEF

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Pickup 100 15,000 1 mA 100

Time 0.02 5 0.001 s 0,2

This function is enabled after the motor start-up sequence has been completed. See

Section 6.2.14

6.2.12. Measured Inverse-Time Ground Fault

This option requires a ground-fault current transformer.

IG> GF MEASURED INV

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Curve - - (1*) - Inverse

Dial 0.05 1.25 0.01 - 1.25

Pickup 100 450 1 mA 100

Time 0.02 5 0.001 s 0.2

(1*) Inverse, Very inverse, Extremely inverse, Definite time

If the option "Definite time" is selected for the curve setting, the unit behaves like an

instantaneous overcurrent unit. In this case, the time parameter is active.

If a curve “Inverse”, “Very inverse” or “Extremely inverse” is selected for the curve setting, the

time depends on the curve, dial and pickup settings.

If the unit operates as definite time, the function is activated at 100% of the set pickup value, and

it deactivates at 95%.

If the unit operates with a curve, the function is activated at 110% of the set pickup value, and it

deactivates at 100%. The reset is instantaneous in both cases.

The activation time is accurate to ±5% or ±30ms, whichever is greater.

The curves used are IEC255-4/BS-142, which are described in Section 6.2.17.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

6.2.13. Undercurrent

The undercurrent function is not enabled during motor start-up.

I < Undercurrent

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Pickup 0.3 1 0.01 I

B

0.5

Time 0.02 200 0.001 s 1

Activation is at 100% of the pickup value and reset at 105%. The reset is instantaneous.

The accuracy of the operation time is equal to the set time plus a maximum of 30 ms.

6.2.14. Motor-Start-Up Monitoring

The settings for motor start up are in the General Settings:

Motor start up monitoring

Description Minimum Maximum Step Unit Default

Function enabled - - yes/no - no

Motor start limit 1 8 0.01 IB 1.5

Motor starting time 1 200 0.001 s 60

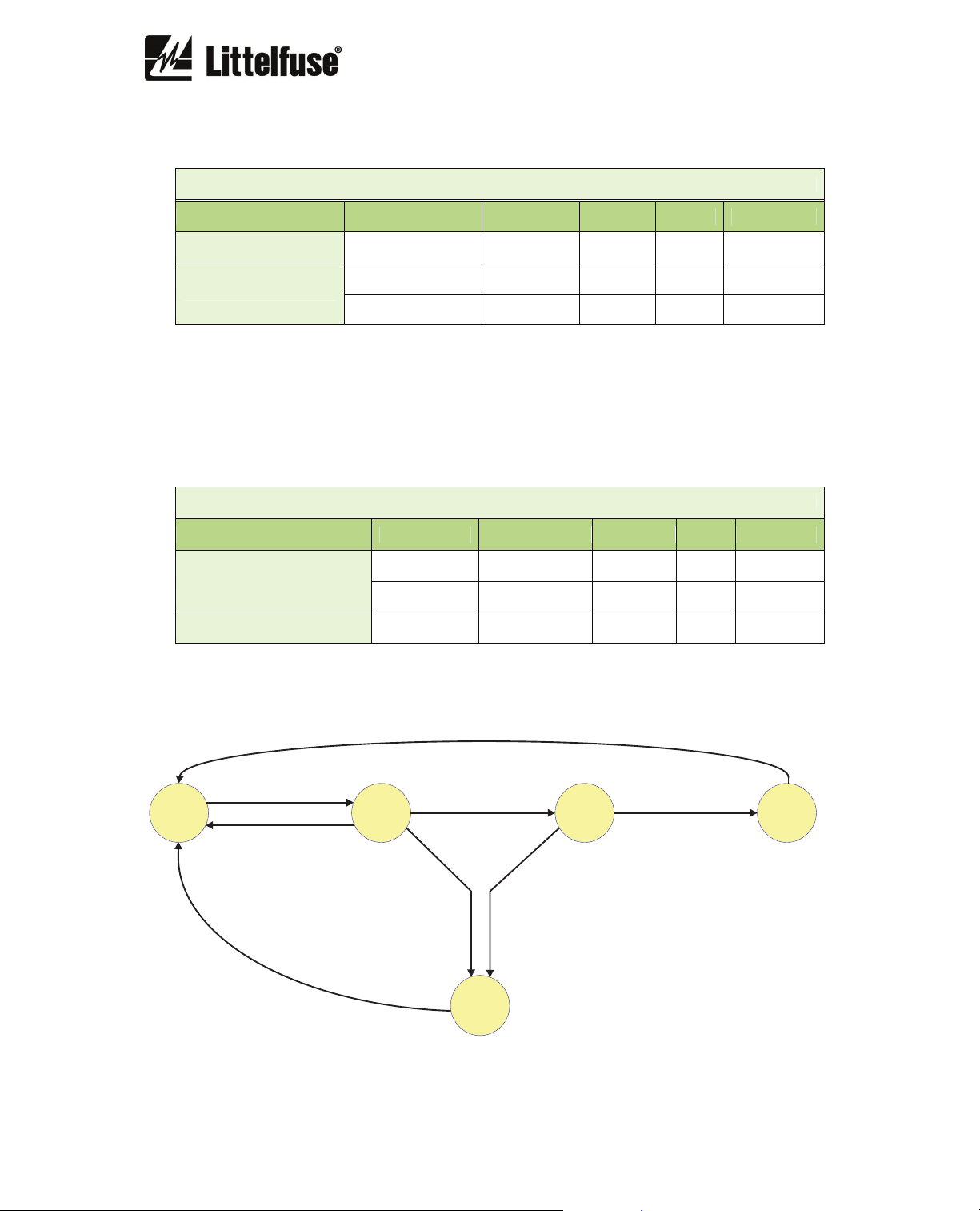

MOTOR START FLOWCHART

Iaverage < 8%

I

B

Iaverage > 10%

Iaverage < 8%

MOTOR

ON STANDBY

I

B

I

B

MOTOR STARTING

FIRST STEP

Iaverage < 8%

I

average >

I

B

MOTOR

START LIMIT

MOTOR STARTING

TIME EXCEEDED

START TIME

EXCEEDED

I

average <

MOTOR STARTING

SECOND STEP

95%

MOTOR

START LIMIT

The motor is considered to be on standby when the average current is less than 8% of the

nominal current I

average current is greater than 10% of the nominal current I

B. The PGR-6150 switches to the “Motor starting first step” stage when the

B. It switches to “Motor starting

second step" when the average current is greater than the “Motor start limit”, “Motor running”

mode is reached when the average current is less than 95% of the “Motor start limit”.

MOTOR

RUNNING

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

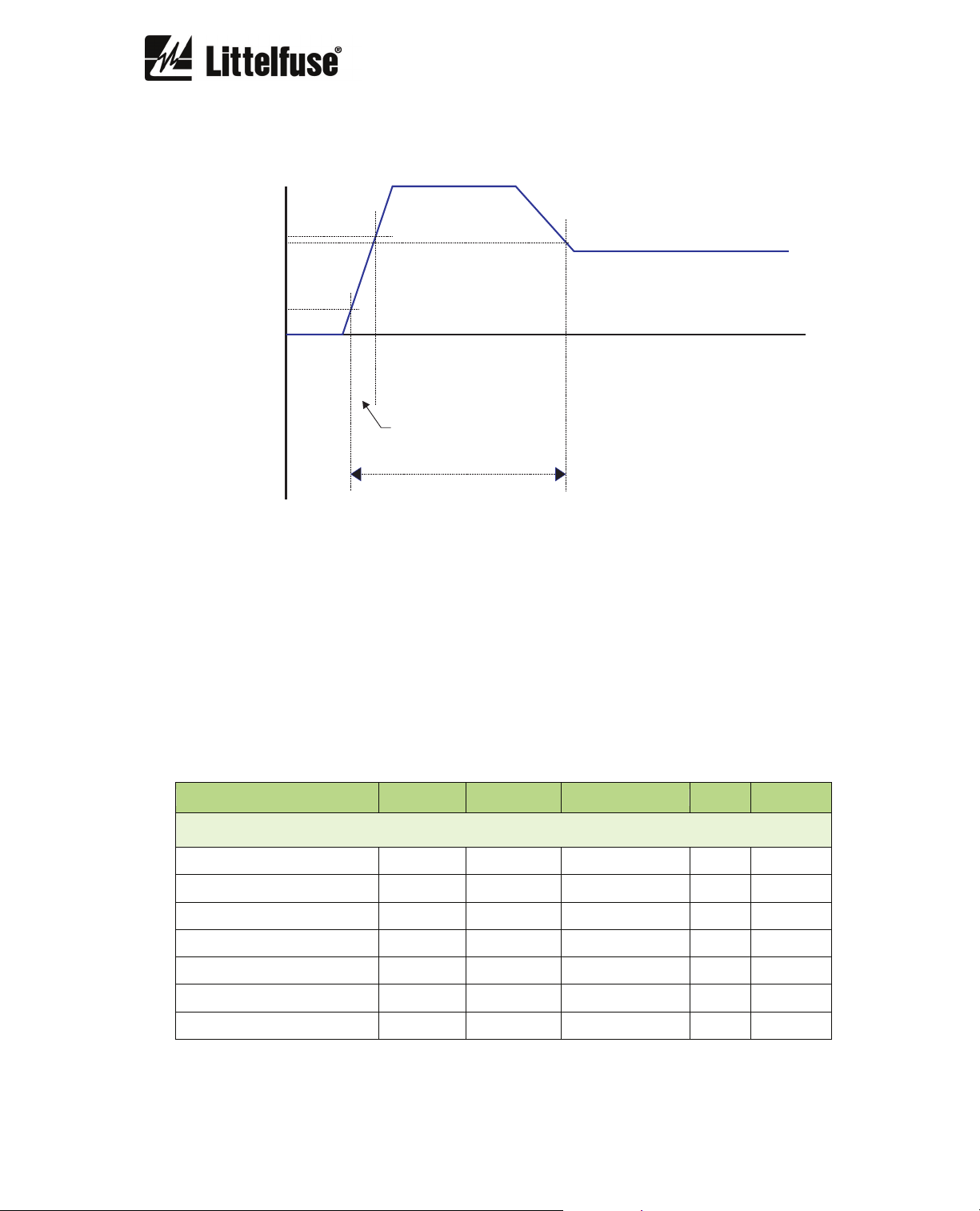

In “Motor first step” and “Motor second step” the start-up time is monitored. If the measured

start-up time is greater than the “Motor starting time” selected, the start up will be aborted due to

a “Start time exceeded” condition.

I

MOTOR START LIMIT

95% MOTOR START LIMIT

10%

I

B

STAND BY

SECOND STEP MOTOR RUNNING

FIRST STEP

MOTOR STARTING TIME

I

average

There are two status bits in the miscellaneous group, related to motor monitoring: “Motor

running” and “Start time exceeded”.

The following statistics are related to motor start up:

• Number of starts

• Maximum start current:

• Last start maximum current:

• Last start average current:

• Measured start time (second step time)

• Number of operating hours (motor in operation)

•

t

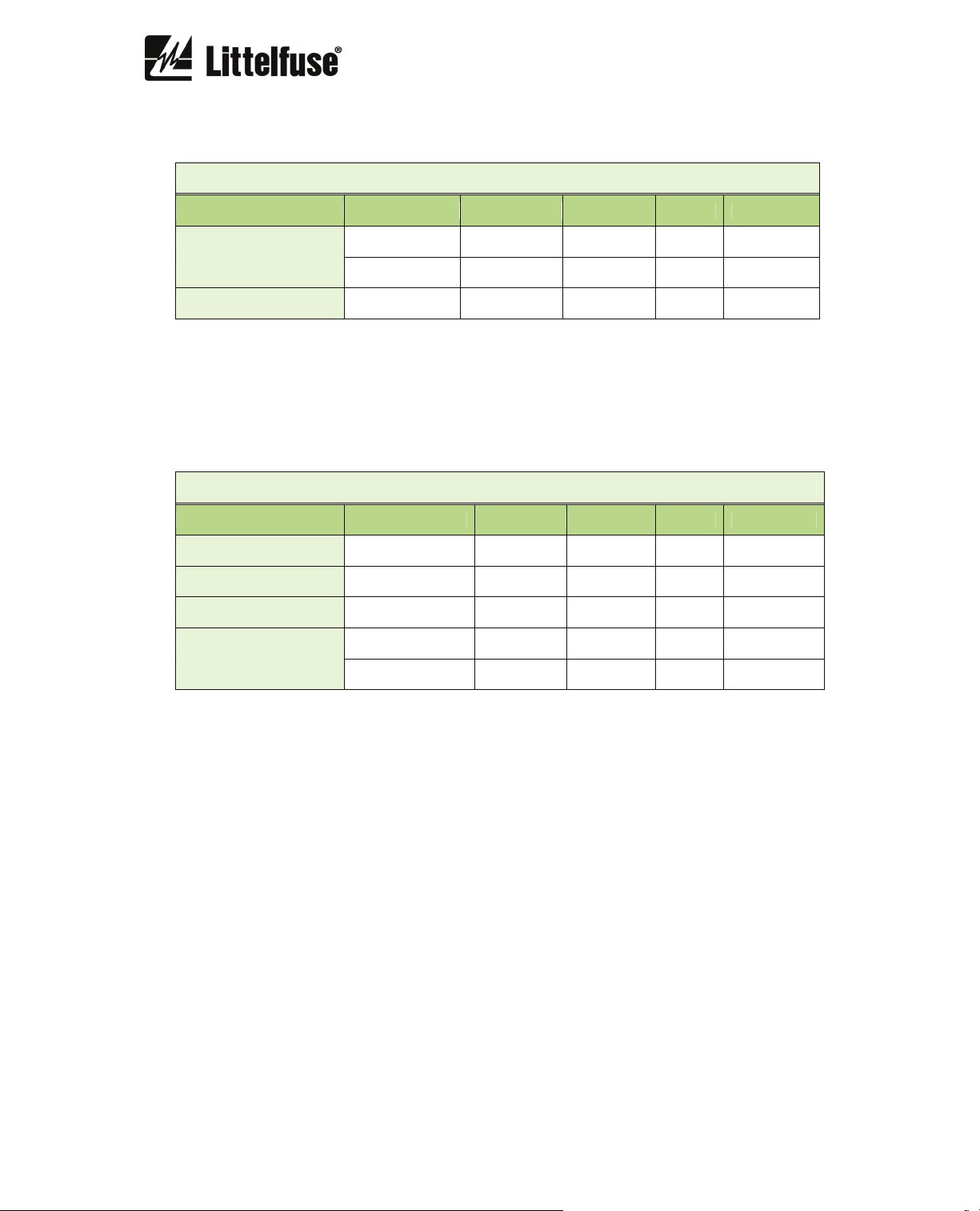

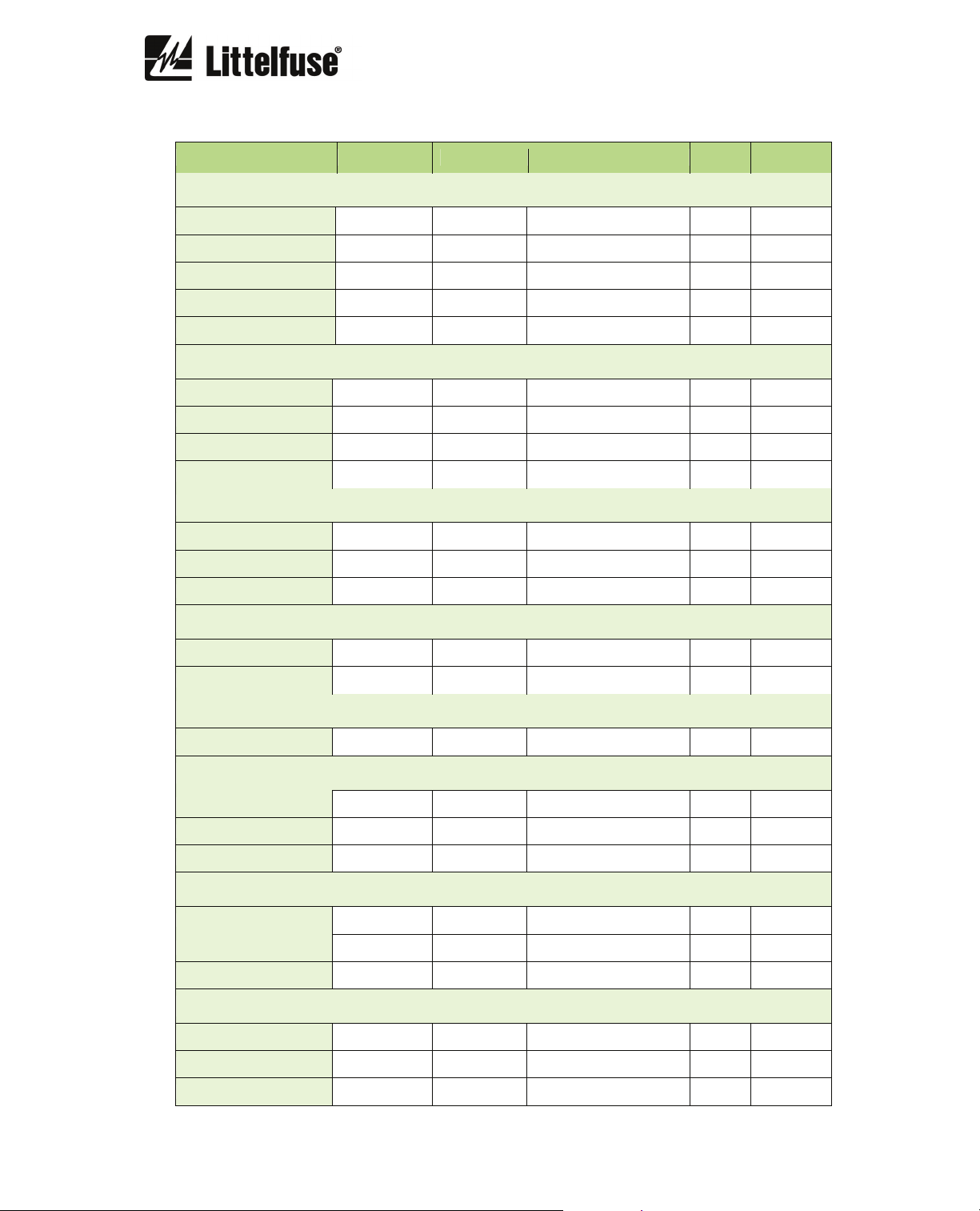

6.2.15. PGR-6150 SETTINGS Summary

Description Minimum Maximum Step Unit Default

GENERAL

Nominal current IB 4 25 0.01 A 4

CT turns ratio 1 2,000 1 - 1

Frequency - - 50Hz/60Hz/var (1*) - 50 Hz

Motor start limit 1 8 0.01 IB 1.5

Motor starting time 1 200 1 s 60

Phases sequence - - ABC/ACB - ABC

PGR-6150 initial time 0 3,600 1 s 0

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

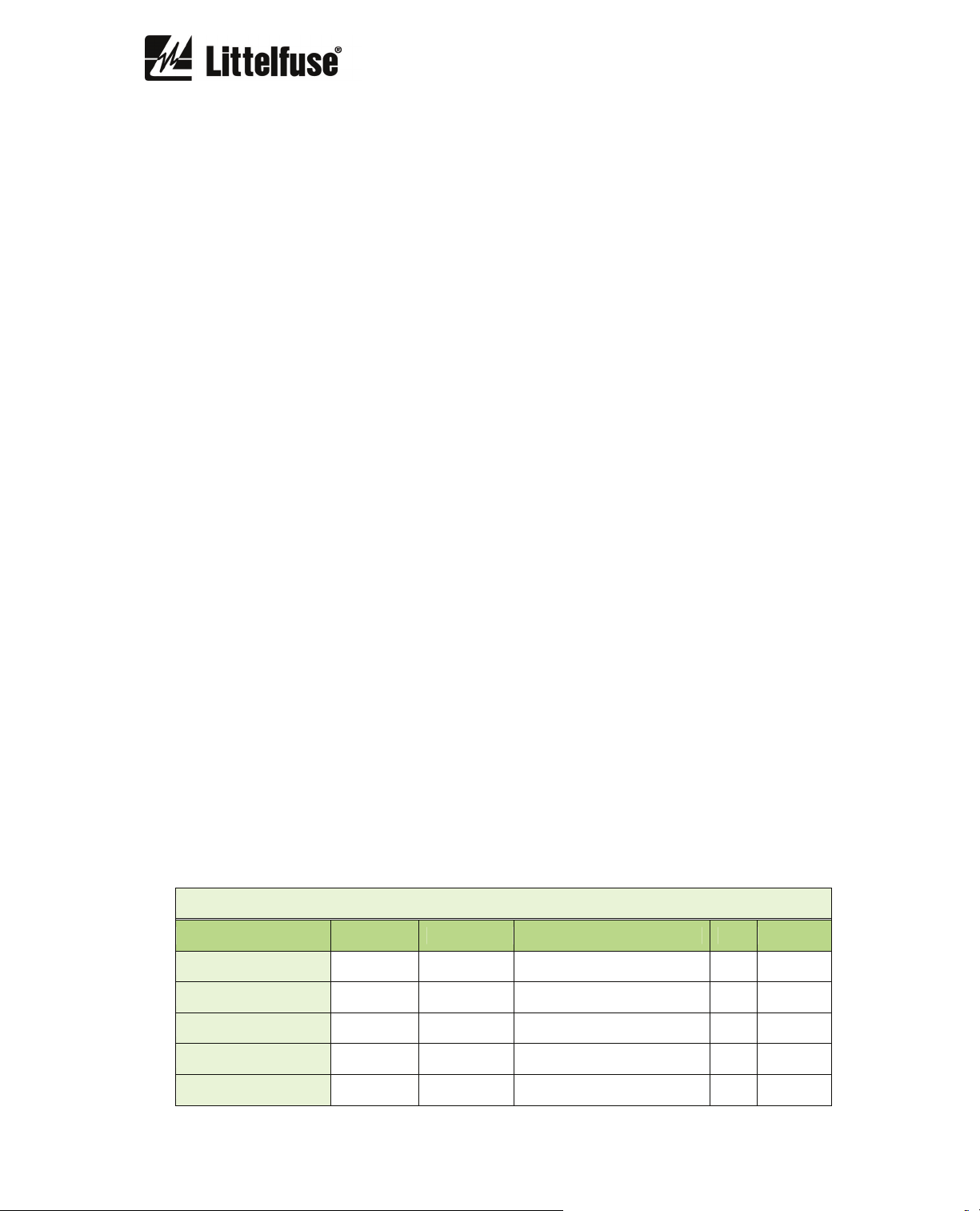

Description Minimum Maximum Step Unit Default

OVERLOAD

Function enabled - - yes/no - yes

Service factor 1 2 0.01 I

Trip class - - 5,10,15,20,25,30,35,40,45 - 5

External ventilation - - Yes/No - No

Alarm 20 95 1 % 80

B

1.15

UNBALANCE

Function enabled - - yes/no - yes

% Unbalance 5 30 1 % 30

Starting trip time 0.02 20 0.001 s 0.6

Running trip time 0.02 20 0.001 s 5

PHASE LOSS

Function enabled - - yes/no - yes

% Unbalance 10 100 1 % 30

Time 0.02 20 0.001 s 5

SEQUENCE

Function enabled - - yes/no - no

Time 0.02 2 0.001 s 0.02

PTC

Function enabled - - yes/no - no

JAM

Function enabled - - yes/no - no

Pickup 1 3.5 0.01 I

Operating time 0.02 50 0.001 s 10

B

2.5

LOCKED ROTOR

Function enabled - - yes/no - no

Pickup 3.5 6 0.01 I

Operating time 1 30 0.001 s 5

B

3.5

I0>> GF CALC DEF

Function enabled - - yes/no - no

Pickup 0.1 1 0.01 I

Operating time 0.02 5 0.001 s 1

B

0.1

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

Description Minimum Maximum Step Unit Default

I0> GF CALC INVERSE

Function enabled - - yes/no - no

Curve - - (2*) - Inverse

Dial 0.05 1.25 0.01 - 1.25

Pickup 0.1 1 0.01 IB 1.00

Operating time 0.02 5 0.001 s 0.2

IG>> GF MEASURED DEF

Function enabled - - yes/no - no

Pickup 100 15,000 1 mA 100

Operating time 0.02 5 0.001 s 0.2

IG> GF MEASURED INV

Function enabled - - yes/no - no

Curve - - (2*) - Inverse

Dial 0.05 1.25 0.01 - 1.25

Pickup 100 450 1 mA 100

Operating time 0.02 5 0.001 s 0.2

I< UNDERCURRENT

Function enabled - - yes/no - no

Pickup 0.3 1 0.01 IB 0.5

Operating time 0.02 200 0.001 s 1

COMMUNICATION

Modbus address (3*) 1 255 1 - 1

RESET

Enable OPI - - yes/no - no

Enable command - - yes/no - no

Enable input - - yes/no - no

Reset type - - (4*) - Manual

Reset time 0.02 200 0.001 s 0.1

(1*) The frequency can be set to values of 50Hz, 60Hz, and variable frequency in a range of 45 Hz to 65 Hz. The variable

frequency only applies to models with alternating supply voltage.

(2*) Inverse, very inverse, extremely inverse and definite time curves.

(3*) The Modbus address can only be modified from the PGR-6150-OPI. The other settings can be modified from the

PGR-6150-OPI and communications.

(4*) The reset types are: Automatic, Automatic time delay, and Manual.

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

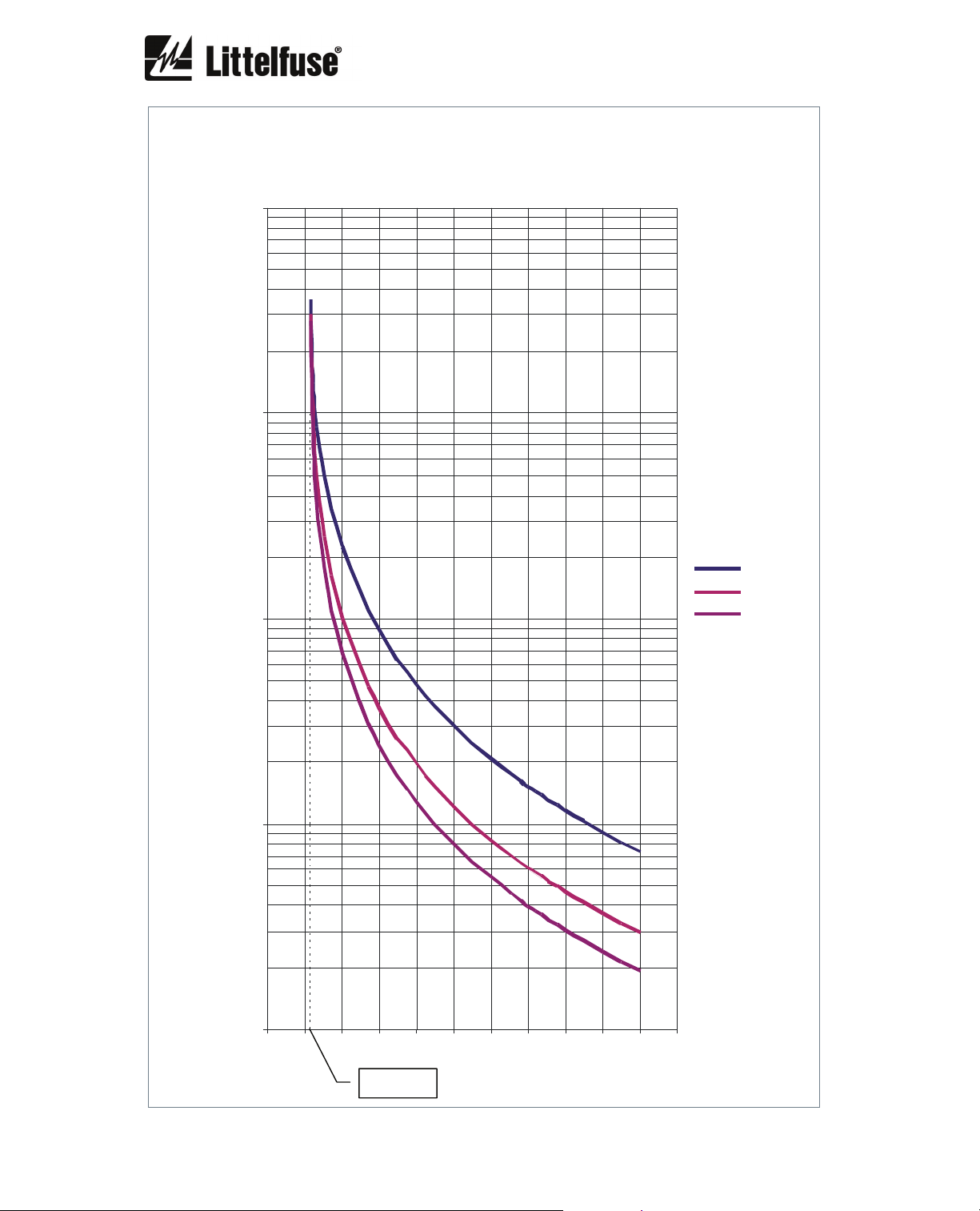

6.2.16. Overload curves

The first graph shows the class 5, 10, 15, 20, 25, 30, 35, 40 and 45 trip curves starting from an

initial thermal condition of 0% (cold).

The following graphs show individually the class 5, 10, 15, 20, 25, 30, 35, 40 and 45 trip curves

with initial thermal conditions of 0% (cold), 60% (hot 60%), 75% (hot 75%).

The 60% hot thermal curves represent the trip time starting from an initial thermal condition of

60% which is reached when I = 0.9 I

The 75% hot thermal curves represents the trip time starting from an initial thermal condition of

75% which is reached when I = I

The x axis represents the current in multiples of I

curves have been represented for an overload pickup current of 1.15 I

and service factor = 1.15.

B

and service factor = 1.15.

B

and the y axis represents time in seconds. The

B

. (service factor = 1.15.)

B

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

OVERLOAD (cold)

10,000

1,000

100

TIME (s)

CLASS 45

CLASS 40

CLASS 35

CLASS 30

CLASS 25

10

1

01234567891011

x

I

1.15 I

B

CLASS 20

CLASS 15

CLASS 10

CLASS 5

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

OVERLOAD CLASS 5

10,000.0

1,000.0

100.0

COLD

HOT 60%

HOT 75%

TIME (s)

10.0

1.0

Hot 60% I = 0.9IB

Hot 75% I = I

B

0.1

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 1 0.0 11.0

I

x

1.15 I

B

B

PGR-6150 Motor Protection System Rev. 1

I

_________________________________________________________________________________

OVERLOAD CLASS 10

10,000 .0

1,000.0

TIME (s)

100.0

10.0

1.0

0.0 1.0 2.0 3.0 4 .0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

COLD

HOT 60%

HOT 75%

Hot 60% I = 0.9 I

Hot 75% I = I

B

B

I

1.15

B

x

B

PGR-6150 Motor Protection System Rev. 1

_________________________________________________________________________________

OVERLOAD CLASS 15

10,000.0

1,000.0

TIME (s)

100.0

10.0

1.0

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

COLD

HOT 60%

HOT 75%

Hot 60% I = 0.9 I

Hot 75% I = I

B

B

I

x

1.15 I

B

B

Loading...

Loading...