Page 1

2.24 +/- 0.18

(0.088" +/- 0.007")

2.54

(0.100")

0.15 +/- 0.08

(0.006 +/- 0.003")

TYP

1.09

(0.043")

1.91

(0.075")

0.91

(0.036")

TYP

Equivalent Circuit

3

Wave Solder

1.27

(0.050")

1.27

(0.050")

2.29

(0.090")

0.64

(0.025")

1.02 (0.040")

Reflow Solder

Wave Solder

1.27 (0.050")

0.76 (0.030")

3.30

(0.130")

1.27 (0.050")

0.51 (0.020")

0.76 (0.030") 0.76 (0.030")

1.66 +/- 0.06

(0.066" +/- 0.003”)

0.15 +/- 0.08

(0.006" +/- 0.003”)

0.84 +/- 0.05

(0.033" +/- 0.002”)

0.36 (0.014")

0.43 +/- 0.18

(0.017" +/- 0.007”)

Equivalent Circuit

2

1

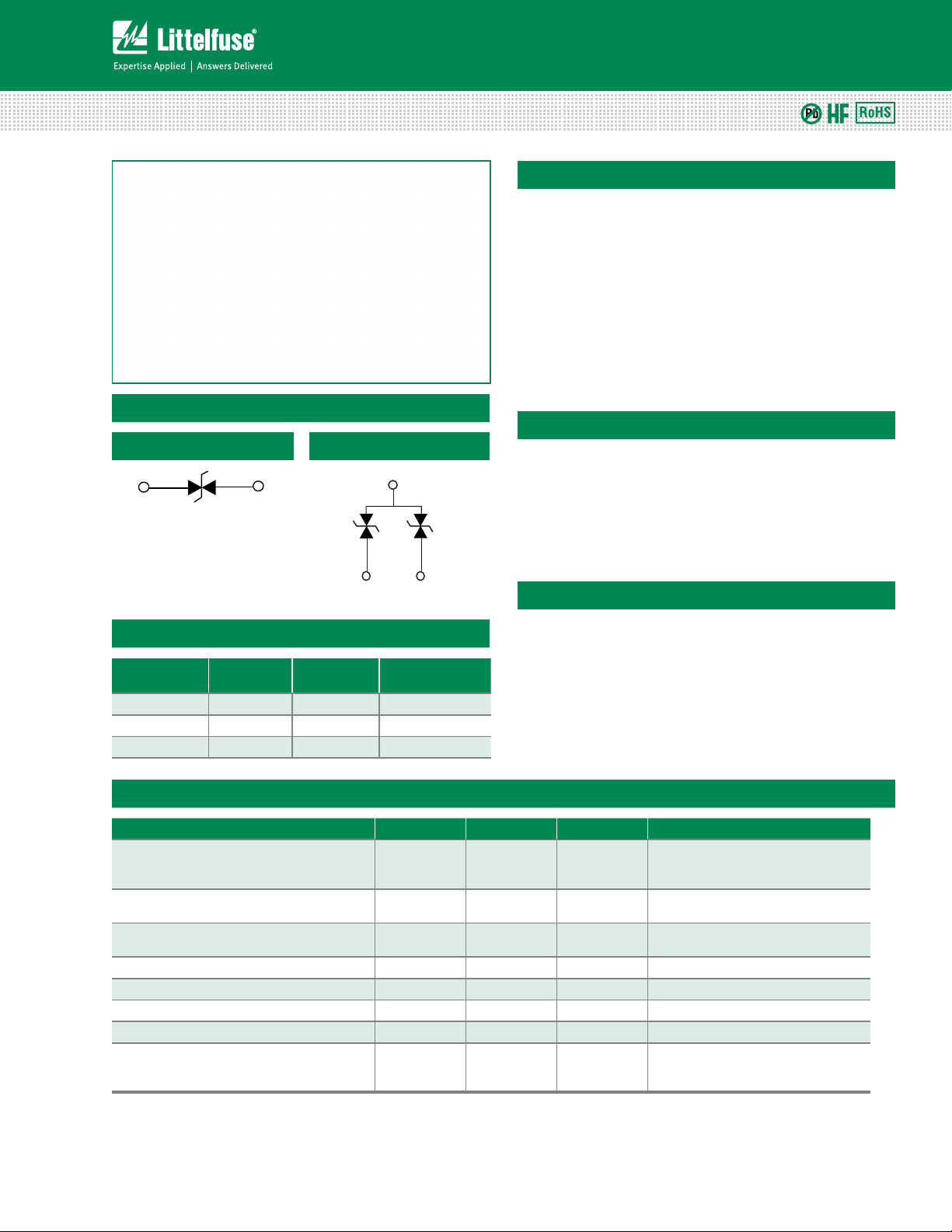

PGB1 Series

Equivalent Circuits

0402 and 0603 Devices

PULSE-GUARD® ESD Suppressors

Surface Mount Polymeric Electrostatic Discharge Suppressors

Description

PULSE-GUARD ESD Suppressors help protect sensitive

electronic equipment against electrostatic discharge (ESD).

They supplement the on-chip protection of integrated

circuitry and are best suited for low-voltage, high-speed

applications where low capacitance is important. Data ports

utilizing such high-speed protocols as USB 2.0, IEEE1394,

HDMI and DVI can benefit from this new technology.

PULSE-GUARD suppressors use polymer composite

materials to suppress fast-rising ESD transients (as specified

in IEC 61000-4-2), while adding virtually no capacitance to

the circuit.

Features

SOT23 Device

• RoHS compliant, lead-free

and available halogen-free

• Ultra-low capacitance

• Low leakage current

• Fast response time

• Bi-directional

• Withstands multiple

ESD strikes

• Compatible with

pick-and-place processes

• Available in 1000, 3000,

5000 and 10000 piece

reels (EIA-RS481)

Product Characteristics

Part Number

PGB1010603 1 0603 Ye s

PGB102ST23 2 SOT23 Ye s

Electrical Characteristics

Specification PGB1010402 PGB1010603 PGB102ST23 Notes

ESD Capability:

IEC 61000-4-2 Contact Discharge (typical)

IEC 61000-4-2 Air Discharge (maximum)

Peak Voltage (typical) 1000V 500V 500V

Clamping Voltage (typical) 250V 150V 150V

PGB1010402 1 0402 No

Rated Voltage (maximum) 12VDC 24VDC 24VDC

Capacitance (typical) 0.04 pF 0.06 pF 0.12 pF Measured at 250 MHz

Response Time <1nS <1nS <1nS

Leakage Current (typical) <1nA (12 VDC) <1nA (6 VDC) <1nA (6 VDC)

ESD Pulse Withstand

Notes: 1. PGB1 0402 product not offered as Halogen Free. See PGB2 series 0402 product instead (http://www.littelfuse.com/series/PGB2010402.html).

2. Testing performed on Littelfuse test setup as described in Typical Test Setup Section on page 4 of this document.

Lines

Protected

Component

Package

1

Halogen-Free

pulses min

2

Available as

1

8kV

15kV

100

Applications

• HDTV Hardware

• Laptop/Desktop

Computer

• Network Hardware

• Computer Peripherals

8kV

15kV

1000

pulses min

8kV

15kV

1000

pulses min

• Digital Camera

• External Storage

• Set-Top Box

• Antenna

Measured per IEC 61000-4-2

8kV Contact Discharge

Measured per IEC 61000-4-2

8kV Contact Discharge2, at 25 nsec.

Some shifting in characteristics may

occur when tested over multiple

pulses at a very rapid rate

2

1

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/26/13

Page 2

PULSE-GUARD® ESD Suppressors

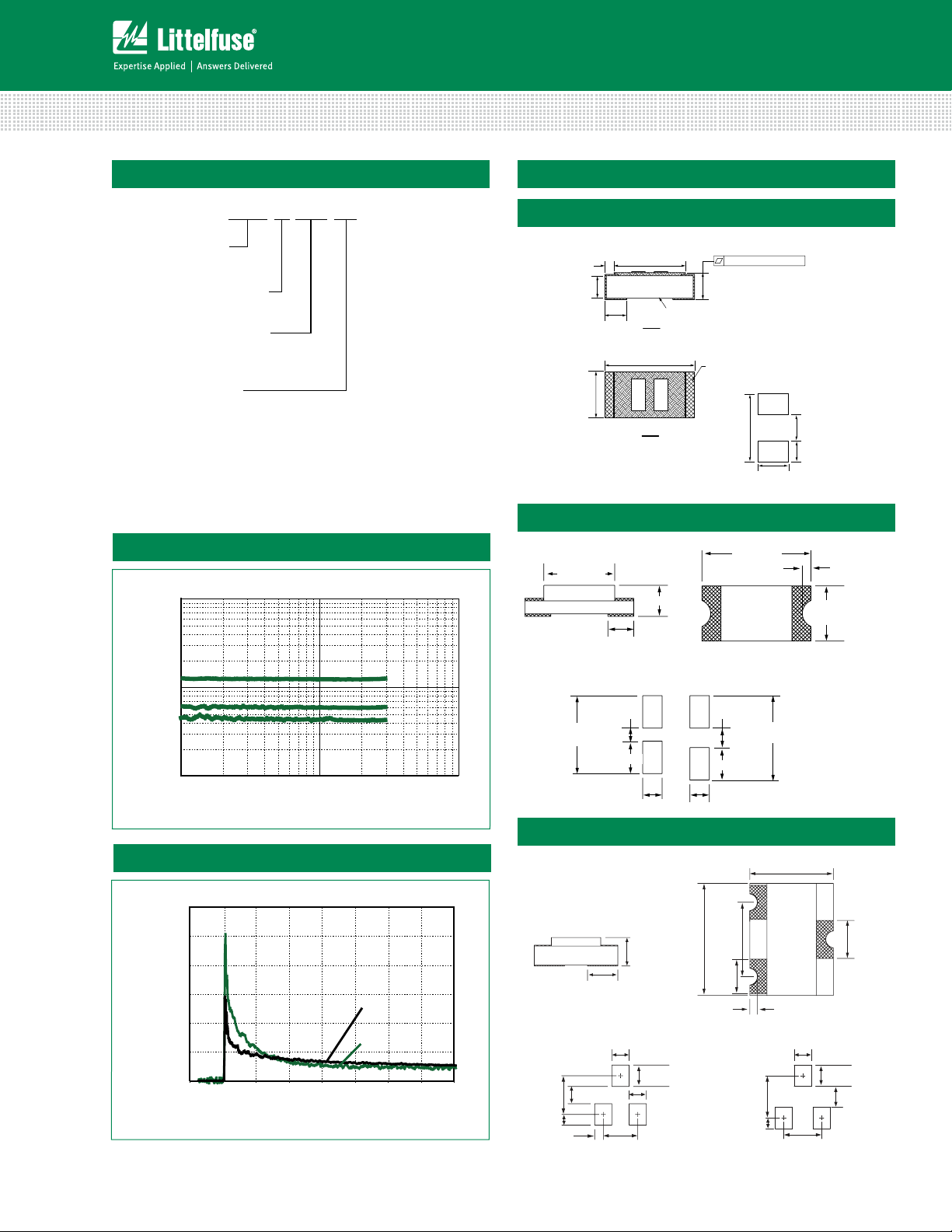

** Note: 1,000 fF = 1 pF

Frequency (GHz)

Capacitance (fF)

60

50

1.0

70

40

2.01.50.5

0

200

400

600

800

1000

1200

-250 25 50 75 100 125 150 175

PGB1010603

PGB102ST23

PGB1010402

Time (ns)

Voltage (V)

0.01

0.10

1.00

100 1,000 10,000

Frequency (MHz)

PGB1040805

PGB1010402

PGB1010603

PGB102ST23

0

200

400

600

800

1000

1200

-250 25 50 75 100125 150 175

PGB1010603

PGB102ST23

PGB1040805

PGB1010402

Time (ns)

Voltage (V)

0

200

400

600

800

1000

1200

-250 25 50 75 100125 150 175

PGB1010603

PGB102ST23

PGB1040805

PGB1010402

Time (ns)

Voltage (V)

Reference Dimensions:

Note: For wave solder, increase the spacing

in both the horizontal and vertical dimensions by

0.254 (.010") where denoted by an asterisk (*)

Reference Dimensions:

Note:

The device has two rectangular ink marking

to improve its identification by Automated

Optical Inspection systems

0.99 +/- 0.05

(0.039" +/- 0.002")

0.25

(0.010")

0.24 +/- 0.09

(0.009" +/- 0.004")

0.71 (0.028”)

0.86 (0.034”)

0.31 +/- 0.08

(0.012" +/- 0.003")

0.51 +/- 0.05

(0.020" +/- 0.002")

Termination

SIDE

0.1 +/- 0.09

(0.004" +/- 0.004")

Body

TOP

0 - 0.025 (0” - 0.0010”)

0.56

(0.022")

Recommended for

reflow soldering only

0.38

(0.015")

.58

(0.023")

1.55

(0.061")

Reflow Solder

PGB1 01 0603 MR

Surface Mount Polymeric Electrostatic Discharge Suppressors

Part Numbering System

LEAD-FREE

PULSE-GUARD®

ESD SUPPRESSORS

LINES PROTECTED:

01 = 1 line

02 = 2 lines

DEVICE SIZE CODE:

0402 = 0402 (1005)*

0603 = 0603 (1608)

ST23 = SOT23

QUANTITY &

PACKAGING CODE:

MR = 1000 pieces, tape & reel

WR = 3000 pieces, tape & reel

NR = 5000 pieces, tape & reel

KR = 10,000 pieces, tape & reel

*Note: PGB1 0402 product not available as Halogen Free item.

See PGB2 0402 product instead, part number PGB2010402KRHF

(http://www.littelfuse.com/series/PGB2010402.html).

Typical Device Capacitance

1.00

0.10

Capacitance (pF)

0.01

Typical ESD Response

Voltage (V)

2

1200

1000

100 1,000 10,000

800

600

400

200

0

-250 25 50 75 100 125 150 175

Frequency (MHz)

PGB1010603

PGB102ST23

PGB1010402

Time (ns)

Dimensions

0402 Device

Dimensions: mm (inch)

0603 Device

Dimensions: mm (inch)

1.04

(0.041") REF

0.43 +/- 0.18

PGB102ST23

PGB1010603

PGB1010402

(0.017" +/- 0.007”)

Reflow Solder

0.51 (0.020")

3.05

(0.120")

0.76 (0.030") 0.76 (0.030")

1.27 (0.050")

SOT23 Device

Dimensions: mm (inch)

0.81

(0.032")

TYP

Reflow Solder

1.02 (0.040")

2.29

1.02 (0.040")

(0.090")

0.64

(0.025")

0.51

(0.020")

(0.080")

0.36 (0.014")

3.00 +/- 0.20

(0.118" +/- 0.008")

0.69 +/- 0.10

(0.027" +/- 0.004)

1.27

(0.050")

1.02 (0.040")

2.03

1.66 +/- 0.06

(0.066" +/- 0.003”)

0.84 +/- 0.05

(0.033" +/- 0.002”)

Wave Solder

0.76 (0.030")

1.27 (0.050")

(0.075")

0.91

(0.036")

TYP

0.15 +/- 0.08

(0.006 +/- 0.003")

TYP

1.91

3.30

(0.130")

2.24 +/- 0.18

(0.088" +/- 0.007")

Wave Solder

1.02 (0.040")

2.54

(0.100")

0.64

(0.025")

Specifications are subject to change without notice.

2.29

(0.090")

© 2013 Littelfuse, Inc.

0.15 +/- 0.08

(0.006" +/- 0.003”)

1.09

(0.043")

1.27

(0.050")

1.27

(0.050")

Revised: 12/26/13

Page 3

PULSE-GUARD® ESD Suppressors

o

Surface Mount Polymeric Electrostatic Discharge Suppressors

Physical Specifications

Materials

Solderability MIL-STD-202, Method 208

Soldering

Parameters

Body: Glass Epoxy

Terminations: Copper/Nickel/Tin

Wave solder - 260°C, 10 seconds maximum

Reow solder - 260°C, 30 seconds maximum

Design Consideration

Because of the fast rise-time of the ESD transient, proper

placement of PULSE-GUARD suppressors are a key design

consideration to achieving optimal ESD suppression. The

devices should be placed on the circuit board as close to the

source of the ESD transient as possible. Install PULSE-GUARD

suppressors (connected from signal/data line to ground)

directly behind the connector so that they are the first boardlevel circuit component encountered by the ESD transient.

Soldering Parameters

Environmental Specifications

Operating Temperature -65°C to +125°C

0402 series:

Moisture Resistance

Thermal Shock

Vibration

Chemical Resistance MIL-STD-202, Method 215

Solder Leach Resistance and

Terminal Adhesion

40°C, 95% RH, 1000 hours

0603, ST23:

85°C, 85% RH, 1000 hours

MIL-STD-202, Method 107,

-65°C to 125°C, 30 min. cycle,

10 cycles

MIL-STD-202, Method 201, (10

to 55 to 10 Hz, 1 min. cycle, 2

hrs each in X-Y-Z)

IPC/EIA J-STD-002

Reflow Condition Pb – Free assembly

Pre Heat

- Temperature Min (T

- Temperature Max (T

) 150°C

s(min)

) 200°C

s(max)

- Time (min to max) (ts) 60 – 180 seconds

Average ramp up rate (Liquidus Temp

(TL) to peak

T

to TL - Ramp-up Rate 3°C/second max

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

3°C/second max

Peak Temperature (TP) 260°C

Time within 5°C of actual peak

Temperature (tp)

10 – 30 seconds

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (TP) 8 minutes max

t

T

P

amp-up

Ramp-up

T

L

T

S(max)

Preheat

T

S(min)

Temperature

25

time to peak temperature

t

reheat

S

P

t

L

Ramp-down

amp-d

Time

Based on IPC/JEDEC J-STD-020

3

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/26/13

Page 4

Packaging

PULSE-GUARD® ESD Suppressors

Surface Mount Polymeric Electrostatic Discharge Suppressors

Part Number

PGB1010402

Quantity &

Packaging Code

Quantity Packaging Option

KR 10000 Tape & Reel (7” reel) EIA RS-481-1 (IEC 286, part 3)

Packaging Specification

PGB1010603 MR 1000 Tape & Reel (7” reel) EIA RS-481-1 (IEC 286, part 3)

PGB102ST23 WR 3000 Tape & Reel (7” reel) EIA RS-481-1 (IEC 286, part 3)

PGB1010603

NR 5000 Tape & Reel (7” reel) EIA RS-481-1 (IEC 286, part 3)

Tape and Reel Specifications

T

t

P

d

C

t

D

d

D

s

T

w

P

h

P

P

s

w

Description

C

- Cover tape thickness 0.05 0.05 0.06

t

D

- Drive hole diameter 1.50 1.50 1.50

d

D

- Drive hole spacing 4.00 4.00 4.00

s

P

- Pocket depth 0.41 0.58 1.02

d

P

- Pocket height 1. 1 2 1.85 3.23

h

P

- Pocket spacing 2.00 4.00 4.00

s

P

- Pocket width 0.62 1.02 2.46

w

T

- Carrier tape thickness 0.61 0.65 1.77

t

T

- Carrier tape width 8.00 8.00 8.00

w

0402 Series

(mm)

0603 Series

(mm)

SOT23 Series

(mm)

Typical Test Setup

FARADAY CAGE

COMPUTER

AGILENT INFINIIUM

1.5 GHz 8 GS/s

QUADTECH 1865

RESISTANCE METER

RESISTANCE

TEST FIXTURE

ESD TEST FIXTURE

TEST BOARD W/ DUT

ESD PULSE GENERATOR

30dB PASTERNAK ATTENUATOR

PE7025-30

TEKTRONIX LOW CAP PROBE

6158 (20x TIP)

4

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/26/13

Loading...

Loading...