LITTELFUSE PGB008CA10PR Datasheet

1

PULSEGUARD®SUPPRESSOR

SURFACE MOUNT ESD SUPPRESSORS

8-Line CA10

PRODUCT OVERVIEW

PulseGuard ESD Suppressors help protect sensitive electronic equipment against electrostatic discharge (ESD).

They supplement the on-chip protection of integrated circuitry and are best suited for low-voltage, high-speed

applications where low capacitance is important.

Applications such as computer I/O ports (eg. video displays), network hardware, cell phone data ports, point-ofsale terminals, and industrial controls will benefit

from this new technology. PulseGuard suppressors use

polymer composite materials to suppress fast-rising ESD

transients (as specified in IEC 61000-4-2 and MIL-STD-

883E).

FEATURES

• Ultra-low capacitance

• Low leakage current

• Fast response time

• Bi-directional

• Withstands multiple ESD strikes

• Packaged in chip array (capacitor/resistor) format

• Compatible with pick-and-place processes

• Available on 2,000 piece reels (EIA-RS481)

TYPICAL APPLICATIONS

• Computer I/O ports (e.g. video displays)

• Computer peripherals

• Network hardware/ports (e.g. Gigabit Ethernet)

• Point-of-Sale terminals

• Cell phone data ports

• Audio/video components

• Test Equipment

• Medical Equipment

ELECTRICAL CHARACTERISTICS

Notes:

1. 8 kV direct discharge method, per IEC 61000-4-2.

2. Measured at 1 MHz.

3. Measured at 6 VDC. Testing at fast ESD pulse rates (1-20Hz) may

cause a change in leakage current performance (6µA, max).

PHYSICAL SPECIFICATIONS

Materials:

Body: Glass Epoxy

Terminations: Tin-Lead

Soldering Parameters:

Wave solder -- 260

o

C, 10 seconds maximum

Reflow solder -- 260oC, 30 seconds maximum

Operating Temperature Range:

-65

o

C to +125oC

ORDERING INFORMATION

Catalog Number Pieces per Reel

PGB008CA10PR 2,000

DESIGN CONSIDERATION

Because of the fast rise-time of the ESD transient, placement of PulseGuard suppressors is a key design consideration. To achieve optimal ESD suppression, the devices

should be placed on the circuit board as close to the

source of the ESD transient as possible. Install

PulseGuard suppressors directly behind the connector so

that they are the first board-level circuit component

encountered by the ESD transient. They are connected

from signal/data line to ground.

Trigger Voltage

1

Clamping Voltage

1

Rated Voltage

Capacitance

2

Response Time

1

Leakage Current

3

ESD Pulse Withstand

1

1,000V, typical

150V, typical

24VDC, max

0.055pF

<1ns

<1nA

1,000 pulses, minimum

Obsoleted Part. Please consider PGB0010603,

PGB002ST23 or PGB0040805 for new designs.

2

PULSEGUARD®SUPPRESSOR

SURFACE MOUNT ESD SUPPRESSORS

8-Line CA10

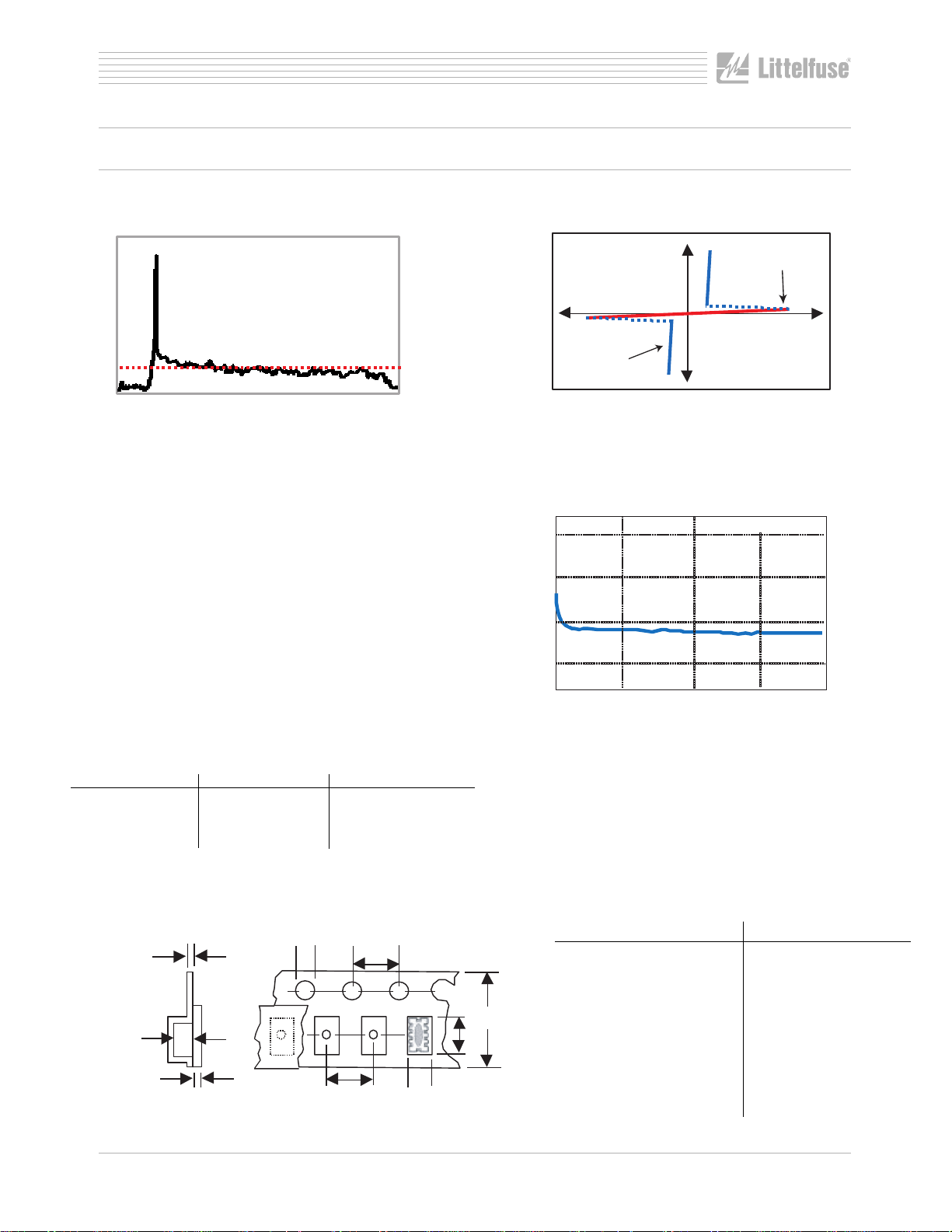

DEFINITIONS

Trigger Voltage: The measured peak voltage across the ESD

suppressor before it transitions from high to low resistance.

It is manifested as a “spike” before the clamping voltage is

achieved. This voltage is typically well below the damage

threshold of on-chip IC protection.

Clamping Voltage: The voltage level to which the ESD

impulse voltage is reduced. This is the voltage that the suppressor holds at, until the ESD transient energy is dissipated.

ESD Impulse Voltage: Also known as the ESD Threat Voltage.

This is the voltage that is “zapped” into the circuit. Voltages

generated by people can exceed 15 kV. The IEC 61000-4-2

defines four levels of impulse voltage for testing

purposes:

SEVERITY LEVEL

1

2

3

4

AIR DISCHARGE

2 kV

4 kV

8 kV

15 kV

DIRECT DISCHARGE

2 kV

4 kV

6 kV

8 kV

Carrier Tape Specifications

Parts are delivered on 7” (178mm) reel, plastic carrier tape

Description

Ct- Cover tape thickness

Dd- Drive hole diameter

Ds- Drive hole spacing

Pd- Pocket depth

Ph- Pocket height

Ps- Pocket spacing

Pw- Pocket width

Tt- Carrier tape thickness

Tw- Carrier tape width

Measurement (mm)

0.06

1.50

4.00

1.02

5.38

4.00

2.44

0.30

12.00

Generalized PulseGuard Response to ESD

(Positive and Negative Polarity ESD Pulses)

Generalized I-V Curve

(Positive and Negative Polarity ESD Pulses)

Capacitance vs. Frequency

Trigger Voltage

Voltage (V)

Clamping Voltage

Time (ns)

Current (A)

Clamping

Voltage

Voltage (V)

Trigger

Voltage

70

60

50

Capacitance (fF)

40

** Note: 1,000 fF = 1 pF

T

t

P

d

C

t

D

D

d

++

s

++++

+

P

P

s

w

1.0

Frequency (GHz)

T

w

P

h

2.01.50.5

Loading...

Loading...