Page 1

Gas Discharge Tube (GDT) Products

CG/CG2 Series

CG/CG2 Series

Agency Approvals

Description

Littelfuse highly reliable CG/CG2 Series GDTs provide

a high degree of surge protection in a small size ideal

for board level circuit protection.

GDTs function as switches which dissipate a

minimum amount of energy and therefore handle

currents that far surpass other types of transient

voltage protection. Their gas-filled, rugged ceramic

metal construction make them well suited to adverse

environments.

The CG/CG2 series comes in a variety of forms

including surface mount, core, straight and shaped

leads, to serve a variety of mounting methods.

AGENCY AGENCY FILE NUMBER

E128662

E320116

2 Electrode GDT Graphical Symbol

The CG Series (75-110V) is ideal for protection of test

and communication equipment and other devices

in which low voltage limits and extremely low arc

voltages are required.

The CG2 Series (145V-1000V) is ideal for protecting

equipment where higher voltage limits and holdover

voltages are necessary.

Features

• Rugged Ceramic-Metal

construction

• Low Capacitance

(<1.5pf)

Applications

• Communication lines

and equipment

• CATV equipment

• Test equipment

• Data lines

• Meets REA PE-80

• Available in surface

mount, and a variety of

lead options options

• Instrumentation circuits

• Medical electronics

• ADSL equipment

• Telecom SLIC

protection

• Power supplies

©2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

Customer should verify actual device performance in their specific applications.

CG/CG2 Series

Revised: January 10, 2013

Page 2

Gas Discharge Tube (GDT) Products

CG/CG2 Series

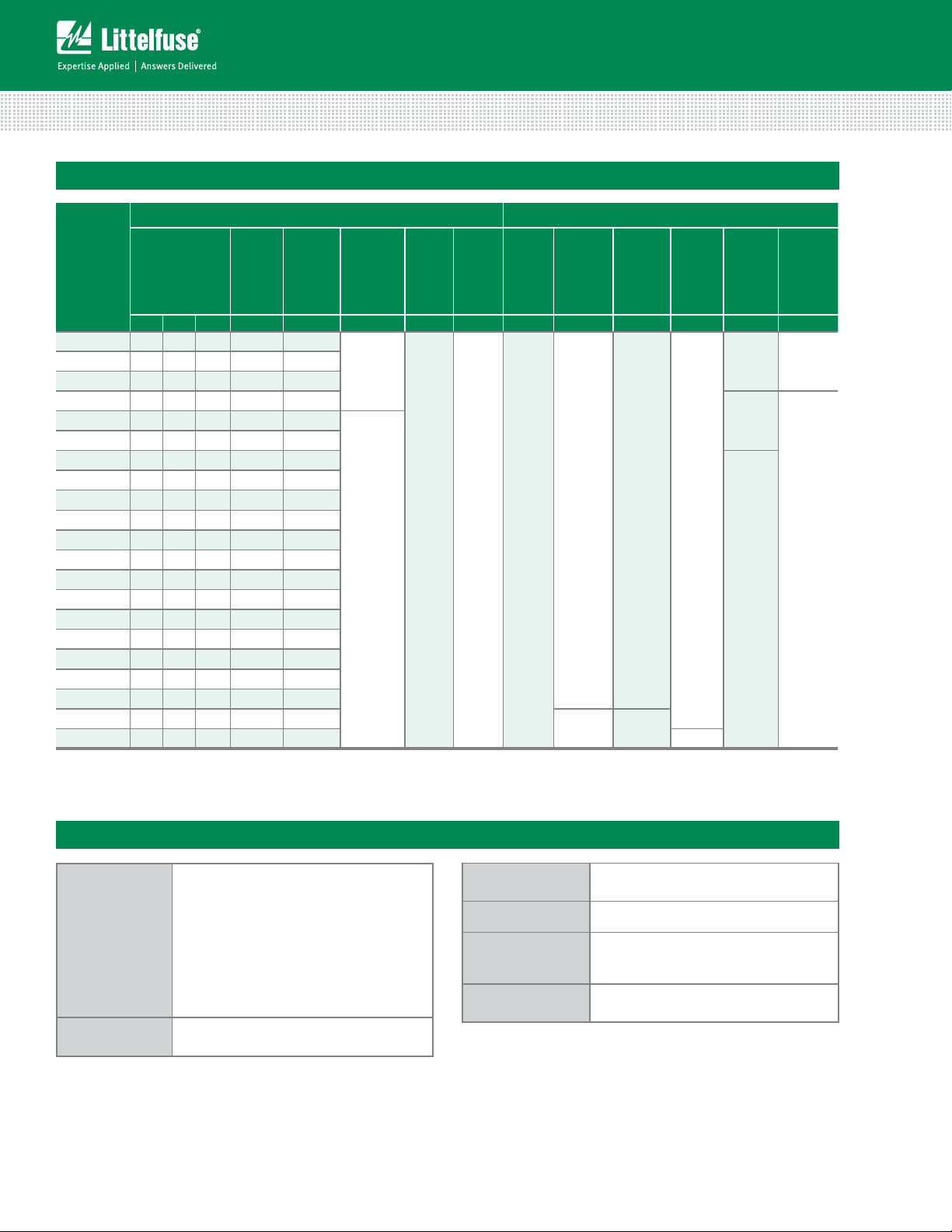

Electrical Characteristics

Device Specifications (at 25°C) Life Ratings

DC Breakdown

in Volts

(@100V/s)

Part

Number

CG75

CG90

CG90 SN

CG110

CG2145

CG2145 SN

CG2230

CG2230 SN

CG2250

CG2250 SN

CG2300

CG2300 SN

CG2350

CG2350 SN

CG2420

CG2470

CG2470 SN

CG2600

CG2600 SN

MIN TYP MAX MAX MIN MAX TYP TYP

60 75 90 400 650

72 90 108 400 600

72 90 108 400 600

88 110 132 450 600

116 145 174 500 600

120 145 174 500 600

195 230 265 600 700

184 230 276 600 700

213 250 288 625 725

200 250 300 625 725

255 300 345 700 800

240 300 360 700 800

297 350 403 750 900

280 350 420 750 900

357 420 483 800 1000

400 470 540 850 1200

376 470 564 850 1200

510 600 690 1000 1400

480 600 720 1000 1400

CG28001680 800 920 1200 1500

CG210001850 1000 1150 1500 1600 65 A

NOTES:

1. Tested to UL1449 Third Edition

2. Reference REA PE-80, 0.2A. Tested to ITU-T Rec K.12 and REA PE 80 < 150 mSec.

Impulse

Break-

down

in Volts

(@100V/µs)

Impulse

Break-

down In

Volts

(@1 Kv/µsec)

Insulation

Resistance

10

10

Ω

(at 50V)

10

Ω

10

(at 100V)

Capaci-

tance

Voltage

(@1MHz)

(on state

Voltage)

@1Amp

1.5 pf 15 V

Arc

Min

Surge

Life

(@500A

10/1000µs)

400

shots

Nominal

Impulse

Discharge

Current

(8/20µs)

10 shots

(@20kA)

10 shots

(@10kA)

Nominal

AC

Discharge

Current

(10x1sec

@50-60Hz)

20 A

3

10 A

Dischage

Current

(9 cycle

@50Hz)

100 A

AC

DC

Holdover

Voltage

Impulse

2

Discharge

(1 Application

@ 10/350µs)

52 V 4kA

80 V

135 V

Max

Current

2.5kA

Product Characteristics

LS, Axial:

Device: Tin Plated 2–5 Microns

Lead Wires: Tin Plated 17.5 ± 12.5 Microns

Construction: Ceramic Insulator

Materials

Product Marking

CG/CG2 Series

Core:

Device: Tin Plated 17.5 ± 12.5 Microns.

Construction: Ceramic Insulator

MS:

Device: Dull Tin Plated 7–9 Microns

Construction: Ceramic Insulator

LF Logo, Voltage and date code; Black in

positive print

Glow to arc

transition current

Glow Voltage

Storage and

Operational

Temperature

Maximum Follow

On Current

Revised: January 10, 2013

< 0.5Amps

60-160 Volts

-40 to +90

1

Customer should verify actual device performance in their specific applications.

230 Volts r.m.s, 200 Amps.

(800V and 1000V devices tested to UL1449 3rd edition)

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

©2013 Littelfuse, Inc.

Page 3

Gas Discharge Tube (GDT) Products

6.05 ± 0.2

[0.268 ± 0.0080]

5.58 [0.232]

8.71 [0.343]

2.29 [0.090]

5.89 [0.232]

DIA. MAX.

CG/CG2 Series

Device Dimensions

Leaded 'L' Type Straight Axial Devices

PROFILE VIEW

6.07 ± 0.15

[0.239 ± 0.006]

62 ± 2

0.81 DIA. TYP.

TOP VIEW

[0.032]

Core Devices

TOP VIEW PROFILE VIEW SEMI–PROFILE VIEW

8.10 Max.

[0.032 Max.]

.

8.10 Max

0.47 ± 0.1

[0.019 ± 0.0039]

6.07 ± 0.15

[0.239 ± 0.0059]

5.89 [0.232]

8.10

[0.319]

Leaded 'LS' Type Shaped Lead Devices

6.07 ± 0.3

[0.239 ± 0.012]

8.40 ± 0.3

[0.331 ± 0.012]

8.60

[0.339]

0.004

2 Surfaces

9.85 ± 0.30

[0.388 ± 0.012]

11.15 ± 0.30

[0.439 ± 0.012]

SOLDER PAD LAYOUT

9.85

[0.388]

11.65

[0.459]

0.40 ± 0.03

[0.0157 ± 0.0012]

1.80

[0.071]

'MS' Type Devices

R5.29 [R0.208]

TOP VIEW

8.30 ± 0.1

[0.327 ± 0.0039]

4 ± 0.2

[0.157 ± 0.0079]

PROFILE VIEW SEMI–PROFILE VIEW

5.58 [0.220]

6.05 ± 0.2

[0.238 ± 0.0079]

TOP VIEWPROFILE VIEW

8.10 Max.

[0.319 DIA Max.]

8.4 ± 0.3

[0.331 ± 0.012]

0.80

[0.032]

©2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

Customer should verify actual device performance in their specific applications.

Revised: January 10, 2013

[0.366 ± 0.0079]

9.30 ± 0.2

ø8.30±0.1

0.47 ± 0.1

[0.019 ± 0.0039]

SOLDER PAD LAYOUT

2.29 [0.090]

8.71 [0.343]

5.89 [0.232]

CG/CG2 Series

Page 4

Gas Discharge Tube (GDT) Products

240

Temperature (°C) - Measured on bottom side of board

CG/CG2 Series

Soldering Parameters - Reflow Soldering (Surface Mount Devices)

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (Min to Max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus Temp

(T

) to peak

L

to TL - Ramp-up Rate 5°C/second max

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (T

Do not exceed 260°C

) 150°C

s(min)

) 200°C

s(max)

3°C/second max

+0/-5

°C

10 – 30 seconds

) 8 minutes Max.

P

T

Temperature

S(max)

T

S(min)

T

P

T

L

25

time to peak temperature

Preheat

t

S

(t 25ºC to peak)

Ramp-up

t

P

Critical Zone

T

to T

L

P

t

L

Ramp-down

Time

Soldering Parameters - Wave Soldering (Thru-Hole Devices)

300

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0

0

102030405060708090

Time (Seconds)

Preheat Time

100

110

120

130

140

150

160

170

180

190

200

210

220

230

Dwell Time

Cooling Time

Soldering Parameters - Hand Soldering

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Recommended Process Parameters:

Wave Parameter Lead-Free Recommendation

Preheat:

(Depends on Flux Activation Temperature)

Temperature Minimum:

Temperature Maximum:

Preheat Time: 60-180 seconds

Solder Pot Temperature:

Solder Dwell Time: 2-5 seconds

(Typical Industry Recommendation)

100

° C

150

° C

280

° C Maximum

CG/CG2 Series

Revised: January 10, 2013

Specifications are subject to change without notice.

Customer should verify actual device performance in their specific applications.

Please refer to www.littelfuse.com for current information.

©2013 Littelfuse, Inc.

Page 5

Gas Discharge Tube (GDT) Products

22.8

[0.898]

52.4

[2.063]

6.4

[0.252]

<1.2 Max. Lead Bend

5.0 Pitch

[0.197]

CG/CG2 Series

Packaging Dimensions

For 'L' Type Axial Lead Items

<0.8 Max

52.4

[2.063]

22.8

[0.898]

6.4

[0.252]

Core and 'MS' Type Items

8.5 ± 0.1

[0.335 ± 0.004]

0.4 ± 0.05

[0.016 ± 0.002]

8.6 ± 0.1

[0.339 ± 0.004]

[0.630 +0.012 / -0.004]

[0.069 ± 0.004]

7.5 ± 0.1

[0.295 ± 0.004]

16 +0.3 / -0.1

1.75 ± 0.1

5.0 Pitch

[0.197]

10x4 ± 0.1 = 40 ± 0.2

[10 x 0.157 ± 0.004 = 1.575 ± 0.008]

1.5 DIA. MAX.

[0.059]

1.5 DIA. MAX.

[0.059]

<1.2 Max. Lead Bend

4 ± 0.1

[0.157 ± 0.004]

12 ± 0.1

[0.472 ± 0.004]

17.7

[0.697]

254.0 - 356.0

[10.0 - 14.0]

]

275.0

[10.83]

100.0

[3.94]

76.0

[2.99]

Direction of Feed

25.0

[0.98]

Direction of Feed

For 'LS' Type Shaped Lead Items

11.75 ± 0.1

[0.463 ± 0.004]

[0.075]

[0.315 ± 0.004]

1.9

0.5 ± 0.05

[0.020 ± 0.002]

8 ± 0.1

9 ± 0.1

[0.354 ± 0.004]

[0.945 +0.019 / -0.004]

0.5 ± 0.01

[0.020 ± 0.004]

©2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com for current information.

Customer should verify actual device performance in their specific applications.

[0.069 ± 0.004]

11.5 ± 0.1

[0.453 ± 0.004]

24 +0.3 / -0.1

1.75 ± 0.1

1.5 DIA. MAX.

1.5 DIA. MAX.

[0.059]

10x4 ± 0.1 = 40 ± 0.2

[10x.157 ± 0.004 = 1.575 ± 0.008]

4 ± 0.1

[0.157 ± 0.004]

[0.059]

16 ± 0.1

[0.630 ± 0.004]

Revised: January 10, 2013

25.7

[1.01]

275.0

[10.82]

76.0

[2.99]

100.0

[3.93]

25.0

[0.98]

Direction of Feed

CG/CG2 Series

Page 6

Gas Discharge Tube (GDT) Products

CG2 XXX XX * XX

Breakdown Voltage

75

90

110

145

230

250

300

350

470

600

800

1000

Series

CG -- for 75, 90, or 110V

CG2 -- for 145V to 1000V

Lead Option Code

Option Code*

(Blank) = No Leads / Core

L = Straight Leads

LS = Shaped Leads

MS = Surface Mount

Packaging Option Code

(Blank) = No Leads / Core, Bulk Bag - 400 pcs

L(Blank) = Straight Lead, Tray - 50 pcs

LTR = Straight Lead, Tape & Reel per EIA RS-296-E - 500 per reel

LTE = Straight Lead, Tape & Reel per IEC 60286-1 - 500 per reel

LS(Blank) = Shaped Lead (see LS dimensions), Tape & Reel - 500 per reel

SN = may have different DC Breakover

Voltage Limit. Please refer to Electrical

Characteristics table for additional

information.

CG/CG2 Series

Part Numbering System and Ordering Information

Examples:

CG75 -- A non-leaded 75V device

CG2230L -- A leaded 230V device

CG2800LTR -- A leaded 800V device, tape-and-reel (per EIA standard RS-296-D)

Notes:

CG/CG2 devices with other breakdown voltages in the 75-1000 V range are available upon request.

CG/CG2 Series

Revised: January 10, 2013

Specifications are subject to change without notice.

Customer should verify actual device performance in their specific applications.

Please refer to www.littelfuse.com for current information.

©2013 Littelfuse, Inc.

Loading...

Loading...