Page 1

RoHS

BA/BB Varistor Series

BB Series

Varistor Products

Industrial High Energy Terminal Varistors > BA/BB Series

Description

The BA and BB Series transient surge suppressors are

heavy-duty industrial Metal-Oxide Varistors (MOVs)

designed to provide surge protection for motor

controls and power supplies used in oil-drilling, mining,

transportation equipment and other heavy industrial AC line

applications.

Agency Approvals

Agency Agency File Number

E320116 - for BA Series only.

BA Series

These UL– recognized varistors have similar package

construction but differ in size and ratings. The BA models

are rated from 130 to 880V

to 2800V

M(AC)

.

. The BB models from 1100

M(AC)

Both the BA and BB Series feature improved creep and

strike capability to minimize breakdown along the package

surface, a package design that provides complete electrical

isolation of the disc subassembly, and rigid terminals to

ensure secure wire contacts.

See BA/BB Series Device Ratings and Specifications Table

for part number and brand information.

Features

• High energy absorption

capability W

TM

BA Series 3200J

BB Series 10,000J

• Wide operating voltage

range V

M(AC)RMS

BA Series 130V to 880V

BB Series 1100V to 2800V

• Rigid terminals for

secure wire contact

• Case design provides

complete electrical

isolation of disc

subassembly

• Littelfuse largest

packaged disc

60mm diameter

• No derating up to

85ºC ambient

•

RoHS compliant

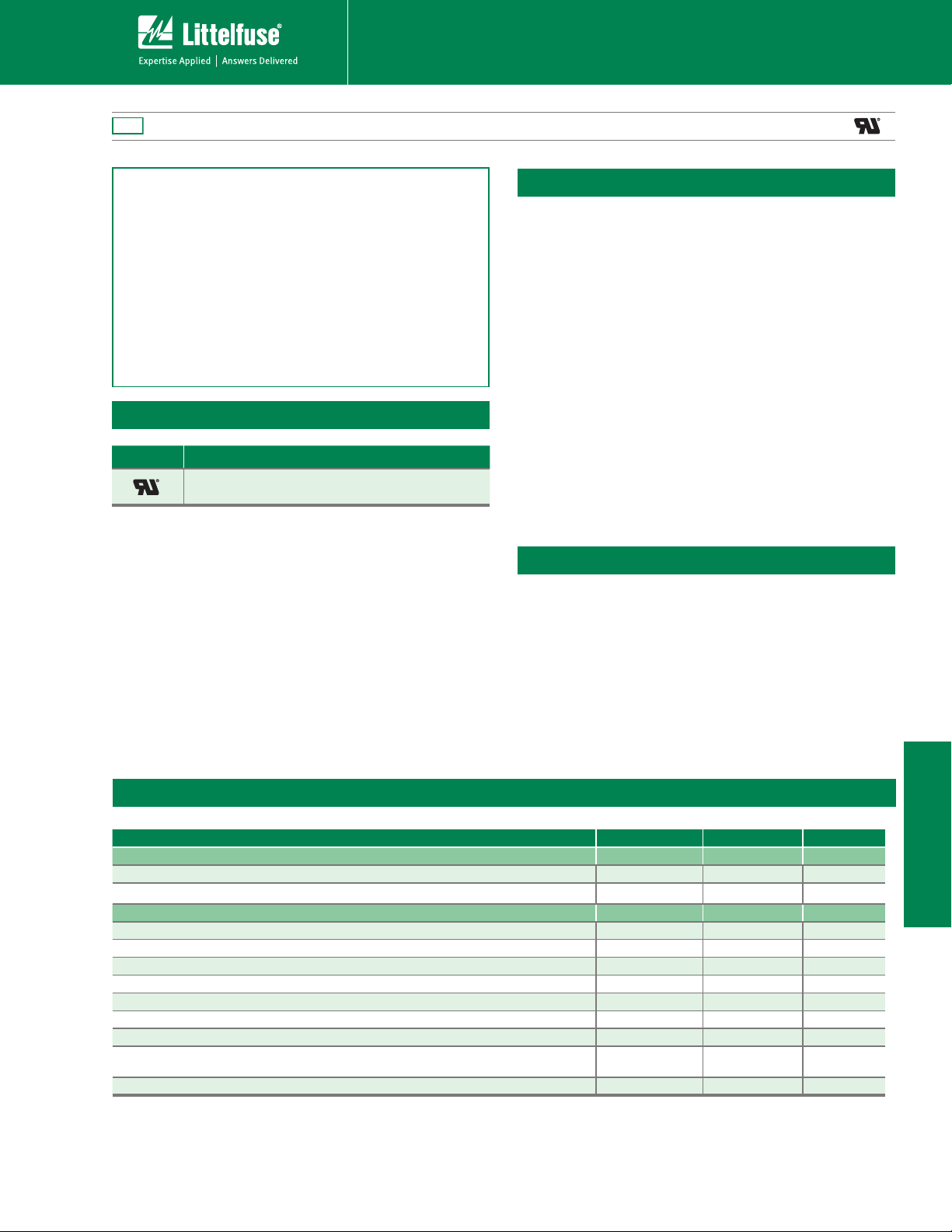

Absolute Maximum Ratings

• For ratings of individual members of a series, see Device Ratings and Specications chart

Continuous BA Series BB Series Units

Steady State Applied Voltage:

AC Voltage Range (V

DC Voltage Range (V

Transients:

Peak Pulse Current (I

For 8/20µs Current Wave (See Figure 2) 50,000 to 70,000 70,000 A

Single Pulse Energy Range

For 2ms Current Squarewave (W

Operating Ambient Temperature Range (T

Storage Temperature Range (T

Temperature Coefficient (a

) -55 to +125 -55 to +125

STG

V

) of Clamping Voltage (VC) at Specified Test Current <0.01 <0.01 %/OC

Hi-Pot Encapsulation (COATING Isolation Voltage Capability)

(Dielectric must withstand indicated DC voltage for one minute per MIL–STD–202, Method 301)

COATING Insulation Resistance 1000 1000 MΩ

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only

rating and operation of the device at these or any other conditions above those indicated in the operational sections of this specification is

not implied.

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/ba or /bb.html for current information.

) 130 to 880 1100 to 2800 V

M(AC)RMS

) 175 to 1150 1400 to 3500 V

M(DC)

)

TM

) 450 to 3200 3800 to 10000 J

) -55 to +85 -55 to +85

A

TM

5000 5000 V

Revision: September 25, 2011

O

C

O

C

BA/BB Varistor Series

HI–ENERGY MOV’S BA/BB Series

Page 2

Varistor Products

Industrial High Energy Terminal Varistors > BA/BB Series

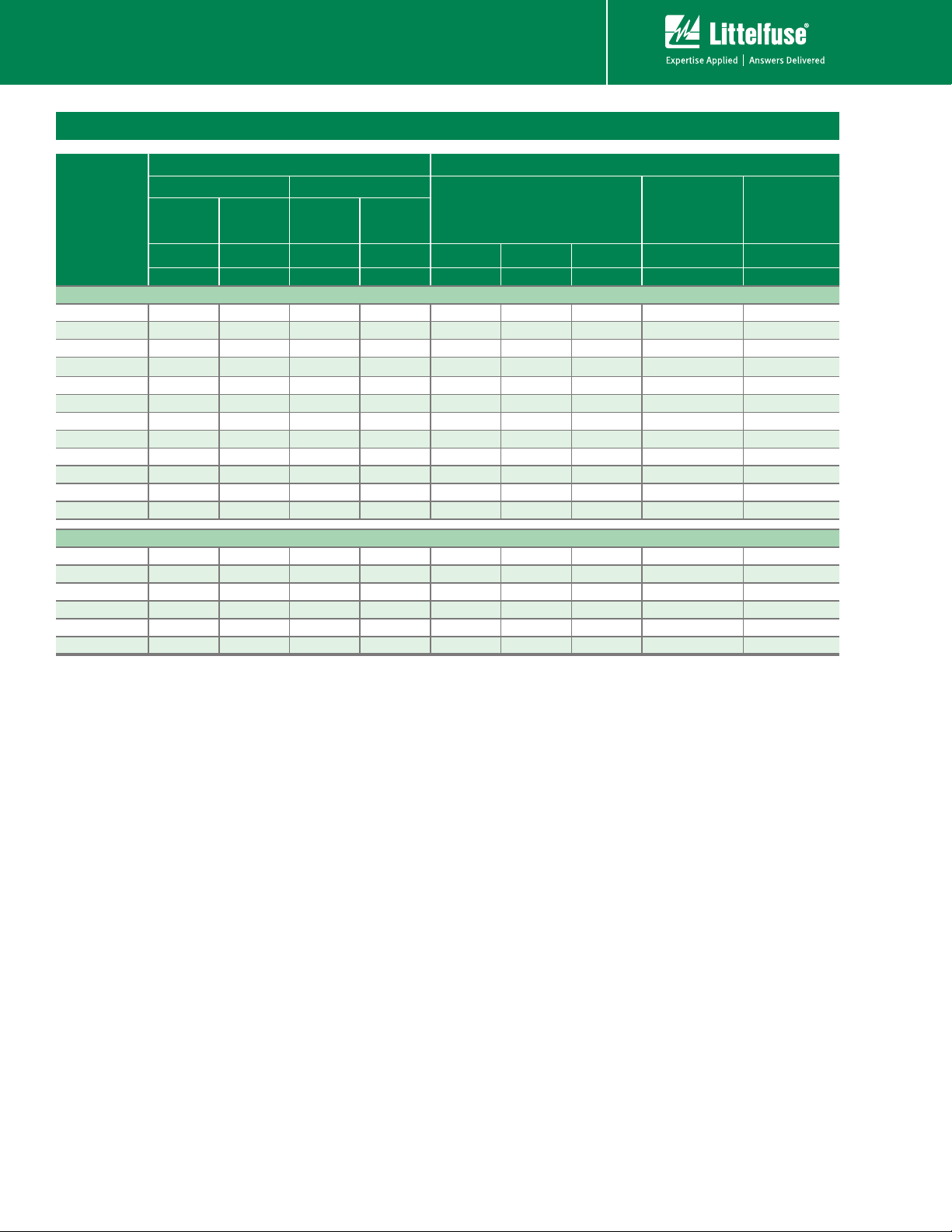

BA/BB Series Ratings & Specifications

Maximum Rating (85°C) Specifications (25°C)

Part

Number

Continuous Transient

V

RMS

V

M(AC)

V

V

M(DC)

DC

Energy

(2ms)

WTM ITM Min V

Peak

Current

8 x 20µs

Varistor Voltage at 1mA

DC Test Current

N(DC)

Max VC C

Maximum

Clamping Volt

at 200A

V

C

Current (8/20µs)

(V) (V) (J) (A) (V) (V) (V) (V) (pF)

BA Series

V131BA60 130 175 450 50000 184 200 228 340 20000

V151BA60 150 200 530 50000 212 240 268 400 16000

V251BA60 250 330 880 50000 354 390 429 620 10000

V271BA60 275 369 950 50000 389 430 473 680 9000

V321BA60 320 420 110 0 50000 462 510 561 760 7500

V421BA60 420 560 150 0 70000 6 10 680 74 8 1060 6000

V481BA60 480 640 160 0 70000 670 750 825 116 0 5500

V511BA60 5 10 675

1800 70000 735 820 910 1300 5000

V571BA60 575 730 2100 70000 805 910 1000 1420 4500

V661BA60 660 850 2300 70000 940 1050 11 60 1640 4000

V751BA60 750 970 2600 70000 1080 120 0 1320 1880 3500

V881BA60 880 115 0 3200 70000 1290 15 00 1650 2340 2700

Typical

Capaci-

tance f =

1MHz

BB Series

V112BB60 110 0 1400 3800 70000 1620 180 0 2060 2940 2200

V142BB60 1400 1750 5000 70000 2020 2200 2550 3600 1800

V172BB60 17 00 2150 6000 70000 2500 2700 3030 4300 15 00

V202BB60 2000 2500 7500 70000 2970 3300 3630 5200 1200

V242BB60 2400 3000 8600 70000 3510 3900 4290 6200 1000

V282BB60 2800 3500 10000 70000 4230 4700 5170 74 0 0 800

NOTE: Average power dissipation of transients not to exceed 2.5W. See Figures 3 and 4 for more information on power dissipation.

BA/BB Varistor Series

Revision: September 25, 2011

©2011 Littelfuse, Inc.

Please refer to www.littelfuse.com/series/ba or /bb.html for current information.

Specifications are subject to change without notice.

Page 3

Varistor Products

TYPICAL TEMPERATURE COEFFICIENT

OF POWER DISSIPATION = 2.2%/

o

C

MAX AT TA = 85oC

MAX AT TA = 25oC

TYP AT TA = 25oC

1. 0

0.8

0.6

0.4

0.2

0.1

0.08

0.06

0.04

80 90 10 0110

PERCENTAGE OF MAXIMUM RATED V

RMS

(%)

POWER DISSIPATION (W) PER kV

OF RATED V

RMS

1,000 HOURS, TA = 85oC

0.5

0.4

0.3

0.2

0.1

0

010100 1,000

POWER DISSIPATION (W) PER kV

OF RATED V

RMS

TIME AT RATED V

RMS

(HOURS)

100

90

80

70

60

50

40

30

20

10

0

-55 50 60 70 80 90 100110 120130 140150

AMBIENT TEMPERATURE (

o

C)

PERCENT OF RATED VALUE

100

90

50

10

O

1

T

T

1

T

2

TIME

PERCENT OF PEAK VALUE

O1 = Virtual Origin of Wave

T = Time From 10% to 90% of Peak

T1 = Virtual Front Time = 1.25 • t

T2 = Virtual Time to Half Value (Impulse Duration)

Example: For an 8/20 s Current Waveform:

8s = T

1

= Virtual Front Time

20 s = T2 = Virtual Time to Half Value

Industrial High Energy Terminal Varistors > BA/BB Series

Power Dissipation Ratings

Peak Pulse Current Test Waveform

Figure 1 Figure 2

Should transients occur in rapid succession, the average power

dissipation required is simply the energy (watt-seconds) per pulse

times the number of pulses per second. The power so developed

must be within the specifications shown on the Device Ratings

and Characteristics Table for the specic device. Furthermore,

the operating values need to be derated at high temperatures as

shown in the above diagram. Because varistors can only dissipate

a relatively small amount of average power they are, therefore, not

suitable for repetitive applications that involve substantial amounts

of average power dissipation.

01 = Virtual Origin of Wave

T = Time from 10% to 90% of Peak

T1 = Rise Time = 1.25 x T

T2 = Decay Time

Example - For an 8/20 µs Current Waveform:

8µs = T1 = Rise Time

20µs = T2 = Decay Time

Stand by Power Dissipation vs Applied V

Temperatures

Figure 3 Figure 4

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/ba or /bb.html for current information.

at Varied

Rms

Typical Stability of Standby Power Dissipation at Rated

V

RMS

Revision: September 25, 2011

vs Time

HI–ENERGY MOV’S BA/BB Series

BA/BB Varistor Series

Page 4

Varistor Products

30,000

20,000

10,000

9,000

8,000

7, 000

6,000

5,000

4,000

3,000

2,000

10

-210-1100

10110210310410

5

PEAK AMPERES (A)

MAX PEAK VOLTS (V)

V282BB60

V242BB60

V202BB60

V172BB60

V142BB60

V112BB60

MAX CLAMPING VOLTAG E

DISC SIZE 60mm

1100 TO 2800V

M(AC)

RATING

T

A

= -55oC TO 85oC

MAX CLAMPING VOLTAG E

DISC SIZE 60mm

130 TO 880V

M(AC)

RATING

T

A

= -55oC TO 85oC

6,000

5,000

4,000

3,000

2,000

1,000

900

800

700

600

500

400

300

200

10

-210-1

10010110210310410

5

PEAK AMPERES (A)

V881BA60

V751BA60

V661BA60

V571BA60

V151BA60

V131BA60

MAXIMUM PEAK VOLTS (V)

V511BA60

V481BA60

V421BA60

V321BA60

V271BA60

V251BA60

50,000

20,000

10,000

5,000

2,000

1,000

500

200

100

50

20

10

SURGE CURRENT (A)

IMPULSE DURATION (μs)

1,000 10,000

10

10

2

10

3

10

4

10

5

INDEFINITE

10

6

20

100

2

DISC SIZE 60mm

V131BA60 - V321BA60

1

100,000

50,000

20,000

10,000

5,000

2,000

1,000

500

200

100

50

20

10

20 100 1,000 10,000

IMPULSE DURATION (μs)

10

10

2

10

3

10

4

10

5

10

6

2

1

DISC SIZE 60mm

V421BA60 - V282BB60

INDEFINITE

SURGE CURRENT (A)

Industrial High Energy Terminal Varistors > BA/BB Series

Maximum Clamping Voltage BA Series

V131BA60 - V881BA60

Maximum Clamping Voltage BB Series

V112BB60 - V282BB60

Figure 5 Figure 6

Repetitive Surge Capability BA Series

V131BA60 - V321BA60

Repetitive Surge Capability BB Series

V421BA60 - V282BB60

Figure 7 Figure 8

NOTE: If pulse ratings are exceeded, a shift of VN(DC) (at specified current) of more than +/-10% could result.This type of shift, which normally results in a decrease of VN(DC), may result in

the device not meeting the original published specifications, but it does not prevent the device from continuing to function, and to provide ample protection.

Physical Specifications

Lead Material BA / BB – Copper with Tin Plating

Insulating Material

Device Labeling

BA/BB Varistor Series

Cured, flame retardant epoxy polymer

meets UL94V–0 requirements.

Marked with LF, Part Number and Date

code

Environmental Specifications

Operating/Storage

Temperature

Humidity Aging

Thermal Shock

Solvent Resistance MIL–STD–202, Method 215F

Moisture Sensitivity Level 1, J–STD–020C

Revision: September 25, 2011

Please refer to www.littelfuse.com/series/ba or /bb.html for current information.

-55°C to +85°C/

-55°C to +125°C

+85°C, 85% RH, 1000 hours

+/- 5% typical resistance

change

+85°C to -40°C 10 times

+/- 5% typical resistance

change

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Page 5

Dimensions

BB Series

40.0 (1.575)

M6 INTERNATIONAL THREAD

PAN HEAD SLOTTED SCREW

44.5

(1.752)

10.5

(0.41)

10.5

(0.41)

86.0 (3.38)

100 (3.94)

BA Series

40.0 (1.575)

M6 INTERNATIONAL THREAD

PAN HEAD SLOTTED SCREW

23.5

(0.925)

86.0 (3.38)

100 (3.94)

7. 0

(0.28)

7. 0

(0.28)

Varistor Products

Industrial High Energy Terminal Varistors > BA/BB Series

40±2

6 (0.24)

(1.575 ± 0.08)

86±2

(3.38±0.08)

100 (3.94)

M6 INTERNATIONAL

THREAD

79±3

(3.11±0.12)

Notes:

Typical weight: BA Series:250g and BB Series: 600g

Dimensions are in mm; inches in parentheses for reference only.

95 (3.74)

MAX

7. 0

(0.28)

(0.28)

BA Series

40.0 (1.575)

86.0 (3.38)

100 (3.94)

BB Series

40.0 (1.575)

7. 0

86.0 (3.38)

100 (3.94)

M6 INTERNATIONAL THREAD

PAN HEAD SLOTTED SCREW

23.5

(0.925)

M6 INTERNATIONAL THREAD

PAN HEAD SLOTTED SCREW

10.5

(0.41)

44.5

(1.752)

10.5

(0.41)

Part Numbering System

V XX XBA60

VARISTOR

V

V

V

M(AC)

M(AC)

M(AC)

First Tw o Significant Digits*

V

M(AC)

Decade Multiplier*

(1 or 2)

*Refer to Rating & Specifications table

Examples:

130 V

2800 V

M(AC) = 131

M(AC) = 282

DISC SIZE (60mm)

SERIES DESIGNATOR

BA or BB

HI–ENERGY MOV’S BA/BB Series

©2011 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/ba or /bb.html for current information.

Revision: September 25, 2011

BA/BB Varistor Series

Loading...

Loading...