Page 1

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

AUML Varistor Series

Size Table

Metric EIA

3216 1206

3225 1210

4532 1812

5650 2220

RoHS

Description

The AUML Series of Multilayer Transient Surge Suppressors

was specifically designed to suppress the destructive

transient voltages found in an automobile. The most common

transient condition results from large inductive energy

discharges. The electronic systems in the automobile, e.g.

antilock brake systems, direct ignition systems, engine

control, airbag control systems, wiper motor controls, etc.,

are susceptible to damage from these voltage transients and

thus require protection. The AUML transient suppressors

have temperature independent suppression characteristics

affording protection from -55ºC to 125ºC.

The AUML suppressor is manufactured from semiconducting

ceramics which offer rugged protection and excellent

transient energy absorption in a small package. The devices

are available in ceramic leadless chip form, eliminating lead

inductance and assuring fast speed of response to transient

surges. These Suppressors require significantly smaller

space and land pads than Silicon TVS diodes, offering greater

circuit board layout flexibility for the designer.

Also see the Littelfuse ML, MLN and MLE Series of

Multilayer Suppressors.

AUML Series

Applications

• Suppression of

inductive switching

or other transient

events such as EFT

and surge voltage at

the circuit board level

• ESD protection for

components sensitive

to IEC 61000-4-2, MILSTD-883C, Method

3015.7, and other

industry specifications

(See Also the MLE

or MLN Series)

• Provides on-board

transient voltage

protection for ICs

and transistors

• Used to help achieve

electromagnetic

compliance of

end products

• Replace larger surface

mount TVS Zeners in

many applications

Features

• AEC - Q200 compliant

• RoHS Compliant

• Load Dump energy

rated per SAE

Specification J1113

• Leadless, surface

mount chip form

• “Zero” Lead

Inductance

• Variety of energy

ratings available

• No temperature

derating up to

• High peak surge

current capability

• Low Profile, compact

industry standard

chip size; (1206, 1210,

1812 and 2220 Sizes)

• Inherent bidirectional

clamping

• No Plastic or epoxy

packaging assures

better than 94V-0

flammability rating

125ºC ambient

Absolute Maximum Ratings

• For ratings of individual members of a series, see Device Ratings and Specifications chart.

Continuous AUML Series Units

Steady State Applied Voltage:

DC Voltage Range (V

Transient:

Load Dump Energy, (WLD) 1.5 to 25 J

Jump Start Capability (5 minutes), (V

Operating Ambient Temperature Range (T

Storage Temperature Range (T

Temperature Coefficient (DV) of Clamping Voltage (V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the device at these or any

other conditions above those indicated in the operational sections of this specification is not implied.

) -55 to +150

STG

) 18 V

M(DC)

) 24.5 V

) -55 to +125

A

JUMP

) at Specified Test Current

C

<0.01 %/OC

O

C

O

C

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/AUML.html for current information.

55

Revised: May 8, 2013

AUML Varistor Series

Page 2

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

Device Ratings and Specifications

ºC

Maximum Ratings (125

Part Number

Maximum

Continuous

DC Voltage

V

M(DC)

Jump Start

Voltage

(5 Min)

V

JUMP

(V) (V) (J) (V) (V) (μA) (V) (A)

V18AUMLA1206 18 24.5 1.5 23 32 50 40 1.5

V18AUMLA1210 18 24.5 3.0 23 32 50 40 1.5

V18AUMLA1812 18 24.5 6.0 23 32 100 40 5.0

V18AUMLA2220 18 24.5 25 23 32 200 40 10.0

For automotive 24V and 42V applications please contact your Littelfuse representative or visit www.littelfuse.com for the latest product update.

NOTES: 1. Average power dissipation of transients not to exceed 0.1W, 0.15W, 0.3W and 1W for model sizes 1206, 1210, 1812 and 2220 respectively.

2. Load Dump energy rating (into the suppressor) of a voltage transient with a resultant time constant of 115ms to 230ms.

3. Thermal shock capability per Mil-Std-750, Method 1051: -55ºC to 125ºC, 5 minutes at 25ºC, 25 Cycles: 15 minutes at each extreme.

4. For application specific requirements, please contact Littelfuse.

) Specifications (25ºC)

Load Dump

Energy

(10 Pulses)

W

LD

Nominal Varistor Voltage

at 10mA

DC Test Current

V

Min V

N(DC)

Max I

N(DC)

Maximum

Standby Leakage

(at 13V DC)

Maximum Clamping

Voltage (V

Test Current (8/20μs)

L

V

C

C

) at

I

P

Current, Energy and Power Derating Curve

When transients occur in rapid succession, the average

power dissipation is the energy (watt-seconds) per pulse

times the number of pulses per second. The power so

developed must be within the specifications shown on the

Device Ratings and Characteristics Table for the specific

device. Certain parameter ratings must be derated at high

temperatures as shown below.

100

90

80

70

60

50

40

30

20

PERCENT OF RATED VALUE

10

0

-55 50 60 70 80 90 10 0 110 120 130 140 150

Figure 1

AMBIENT TEMPERATURE (oC)

Maximum Leakage Current/Clamping Voltage Curve for

AUML Series at 25ºC

Peak Pulse Current Test Waveform for Clamping Voltage

100

50

0

PERCENT OF PEAK VALUE

O

1

Figure 2

T

T

1

T

2

TIME

01 = Virtual Origin of Wave

T = Time from 10% to 90% of Peak

T1 = Rise Time = 1.25 x T

T2 = Decay Time

Example - For an 8/20 μs Current Waveform:

8μs = T

= Rise Time

1

20μs = T

= Decay Time

2

Typical V-I Characteristics of the V18AUMLA2220 at -40ºC,

25ºC, 85ºC and 125ºC

100

10

VOLTA GE

1

Figure 3 Figure 4

AUML Varistor Series

MAXIMUM LEAKAGE MAXIMUM CLAMPING VOLTAGE

1210/1206

1812

2220

10mA

CURRENT

100mA

1mA

100μA10μA

1A 10A

1210/1206

1812

2220

100A

Revised: May 8, 2013

100

10

VOLTA GE

1

56

-40oC

25oC

85oC

125oC

1μA 10μA 100μA

Please refer to www.littelfuse.com/series/AUML.html for current information.

10mA 100mA 1A 10A 100A 1000A

1mA

CURRENT

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Page 3

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

Temperature Effects

In the leakage region of the AUML suppressor, the device

characteristics approaches a linear (ohmic) relationship

and shows a temperature dependent affect. In this region

the suppressor is in a high resistance mode (approaching

106Ω) and appears as a near open-circuit. Leakage currents

at maximum rated voltage are in the microamp range.

Load Dump Energy Capability

A Load Dump transient occurs when the alternator load in

the automobile is abruptly reduced. The worst case scenario

of this transient occurs when the battery is disconnected

while operating at full rated load. There are a number of

different Load Dump specifications in existence in the

automotive industry, with the most common one being that

recommended by the Society of Automotive Engineers,

specification #SAE J1113. Because of the diversity of these

Load Dump specifications Littelfuse defines the Load

Dump energy capability of the AUML suppressor range as

that energy dissipated by the device itself, independent

of the test circuit setup. The resultant Load Dump energy

handling capability serves as an excellent figure of merit for

the AUML suppressor. Standard Load Dump specifications

require a device capability of 10 pulses at rated energy,

across a temperature range of -40ºC to +125ºC. This

capability requirement is well within the ratings of all of the

AUML Series (Figure 6 on next page).

Further testing on the AUML Series has concentrated

on extending the number of Load Dump pulses, at rated

energy, which are applied to the devices. The reliability

information thus generated gives an indication of the

inherent capability of these devices. As an example of

device durability the 1210 size has been subjected to over

2000 pulses at its rated energy of 3 joules (J); the 1812 size

has been pulsed over 1000 times at 6J and 2220 size has

been pulsed at its rated energy of 25J over 300 times. In

all cases there has been little or no change in the device

characteristics (Figure 7 on next page).

When clamping transients at higher currents (at and above

the 10mA range), the AUML suppressor approaches

a 1-10 characteristic. In this region the characteristics

of the AUML are virtually temperature independent.

Figure 3 shows the typical effect of temperature on

the V-I characteristics of the AUML suppressor.

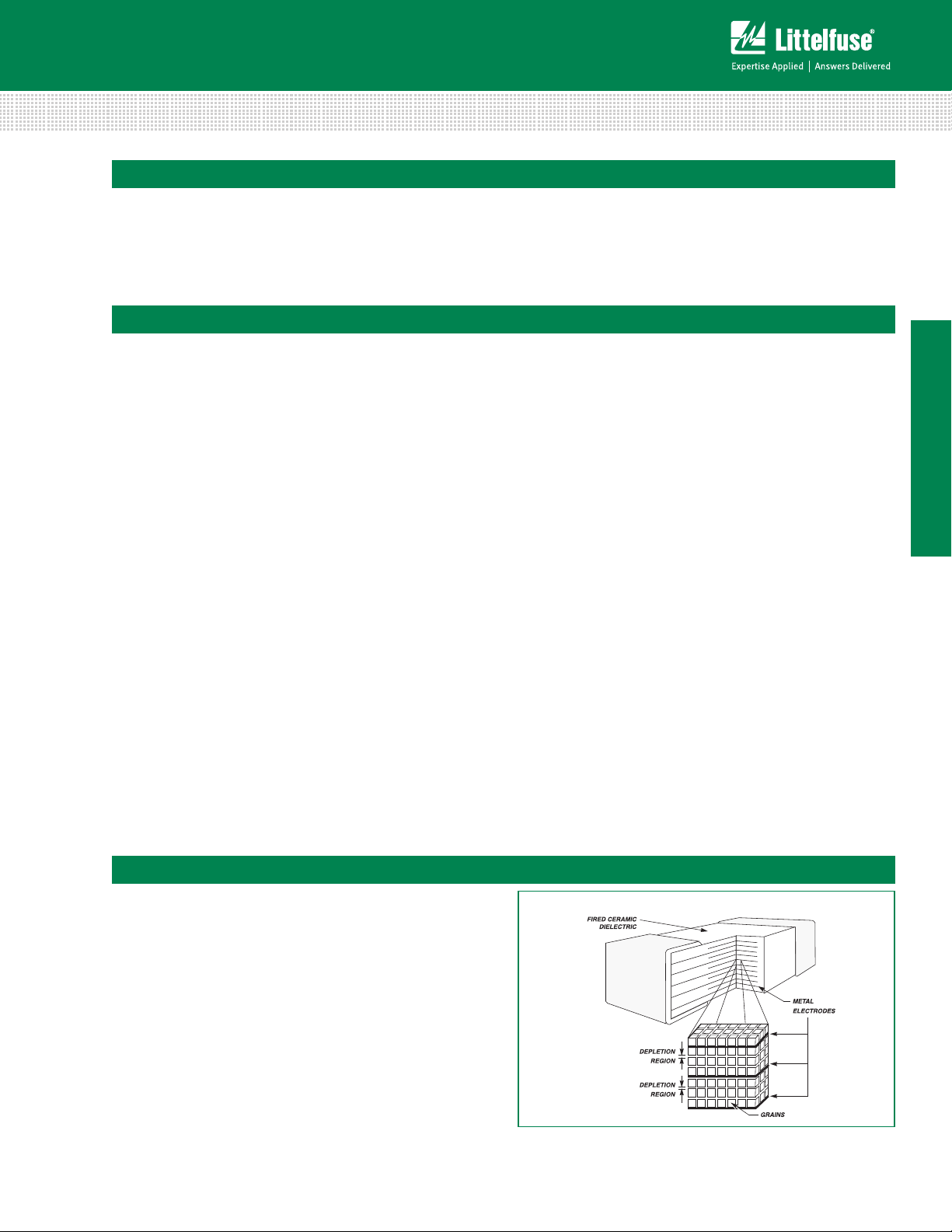

The very high energy absorption capability of the AUML

suppressor is achieved by means of a highly controlled

manufacturing process. This technology ensures that a

large volume of suppressor material, with an interdigitated

layer construction, is available for energy absorption in an

extremely small package. Unlike equivalent rated Silicon

TVS diodes, the entire AUML device volume is available to

dissipate the Load Dump energy.

Hence, the peak temperatures generated by the Load

Dump transient are significantly lower and evenly dissipated

throughout the complete device (Figure 5 below). This

even energy dissipation ensures that there are lower peak

temperatures generated at the P-N grain boundaries of the

AUML suppressor.

There are a number of different size devices available in the

AUML Series, each one with a load dump energy rating,

which is size dependent.

Experience has shown that while the effects of a load dump

tranient is of real concern, its frequency of occurrence is

much less than thoe of low energy inductive spikes. Such

low energy inductive spikes may be generated as a result

of motors switching on and off, from ESD occurrances, fuse

blowing, etc. It is essential that the suppression technology

selected also has the capability to suppress such transients.

Testing on the V18AUMLA2220 has shown that after being

subjected to a repetitive energy pulse of 2J, over 6000

times, no characteristic changes have occurred (Figure 8 on

next page).

AUML Series

Speed of Response

The clamping action of the AUML suppressor depends

on a conduction mechanism similar to that of other

semiconductor devices (i.e. P-N Junctions). The apparent

slow response time often associated with transient

voltage suppressors (Zeners, MOVs) is often due to

parasitic inductance in the package and leads of the

device and less dependent of the basic material (Silicon,

Z

O). Thus, the single most critical element affecting the

N

response time of any suppressor is its lead induc-tance.

The AUML suppressor is a surface mount device, with no

leads or external packaging, and thus, it has virtually zero

inductance. The actual response time of a AUML surge

suppressor is in the 1 to 5 ns range, more than sufficient

for the transients which are likely to be encountered in an

automotive environment.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/AUML.html for current information.

57

Revised: May 8, 2013

Multilayer Internal Construction

Figure 5

AUML Varistor Series

Page 4

Varistor Products

0

Surface Mount Multilayer Varistors (MLVs) > AUML Series

AUML Load Dump Pulsing over a Temperature Range of

-55ºC to +125ºC

V(10mA)

35

30

25

20

15

VOLTA GE

10

5

0

012345678 9101

Figure 6

# OF LOAD DUMPS

2220 = 25J

1812 = 6J

1210 = 3J

112

Repetitive Load Dump Pulsing at Rated Energy

V(10mA)

35

30

25

20

15

VOLTA GE

10

5

0

0 50 100 150 200 250 300 350 1,0 00 2,

Figure 7

# OF LOAD DUMPS

2220 = 25J

1812 = 6J

1210 = 3J

00

Explanation of Terms

Maximum Continuous DC Working Voltage (*V

M*(DC)+

)

+

This is the maximum continuous DC voltage which may

be applied, up to the maximum operating temperature

(125ºC), to the ML suppressor. This voltage is used as the

reference test point for leakage current and is always less

than the breakdown voltage of the device.

Load Dump Energy Rating *W

+

LD

This is the actual energy the part is rated to dissipate

under Load Dump conditions (not to be confused with the

"source energy" of a Load Dump test specification).

Maximum Clamping Voltage *V

+

C

This is the peak voltage appearing across the suppressor

when measured at conditions of specified pulse current

and specified waveform (8/20μs). It is important to note

that the peak current and peak voltage may not necessarily

be coincidental in time.

Leakage Current *I

+

L

In the nonconducting mode, the device is at a very

high impedance (approaching 10

6

Ω at its rated working

voltage) and appears as an almost open circuit in the

system. The leakage current drawn at this level is very

low (<25μA at ambient temperature) and, unlike the

Zener diode, the multilayer TVS has the added advantage

that, when operated up to its maximum temperature,

its leakage current will not increase above 500μA.

Repetitive Energy Testing of V18AUMLA2220

at an Energy Level of 2 Joules

V AT 10mA

100

VOLTA GE

10

1000 2000 3000 4000 5000 6000 7000

Figure 8

AUML Varistor Series

NUMBER OF PULSES

V18AUMLA2220

Nominal Voltage *V

N*DC+

+

This is the voltage at which the AUML enters its

conduction state and begins to suppress transients.

In the automotive environment this voltage is

defined at the 10mA point and has a minimum

(V

58

Revised: May 8, 2013

) and maximum (V

N(DC) MIN

) voltage specified.

N(DC) MAX

Please refer to www.littelfuse.com/series/AUML.html for current information.

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Page 5

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

Lead (Pb) Soldering Recommendations

The principal techniques used for the soldering of

components in surface mount technology are IR Re-flow

and Wave soldering. Typical profiles are shown on the right.

The termination option available for each solder technique is:

Reflow Wave

1. Nickel Barrier (preferred) 1. Nickel Barrier (preferred)

2. Silver/Platinum

The recommended solder for the AUML suppressor is

a 62/36/2 (Sn/Pb/Ag), 60/40 (Sn/Pb) or 63/37 (Sn/Pb).

Littelfuse also recommends an RMA solder flux.

Wave soldering is the most strenuous of the processes.

To avoid the possibility of generating stresses due to

thermal shock, a preheat stage in the soldering process

is recommended, and the peak temperature of the solder

process should be rigidly controlled.

When using a reflow process, care should be taken to

ensure that the AUML chip is not subjected to a thermal

gradient steeper than 4 degrees per second; the ideal

gradient being 2 degrees per second. During the soldering

process, preheating to within 100 degrees of the solder's

peak temperature is essential to minimize thermal shock.

Once the soldering process has been completed, it

is still necessary to ensure that any further thermal

shocks are avoided. One possible cause of thermal

shock is hot printed circuit boards being removed from

the solder process and subjected to cleaning solvents

at room temperature. The boards must be allowed to

cool gradually to less than 50ºC before cleaning.

Reflow Solder Profile

Figure 9

Wave Solder Profile

300

250

C)

200

o

150

100

TEMPERATURE (

50

0

Figure 10

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

230

AUML Series

MAXIMUM WAVE 260oC

SECOND PREHEAT

FIRST PREHEAT

TIME (MINUTES)

Lead–free (Pb-free) Soldering Recommendations

Littelfuse offers the Nickel Barrier Termination finish for the

optimum Lead–free solder performance.

The preferred solder is 96.5/3.0/0.5 (SnAgCu) with an RMA

flux, but there is a wide selection of pastes and fluxes

available with which the Nickel Barrier parts should be

compatible.

The reflow profile must be constrained by the maximums

in the Lead–free Reflow Profile. For Lead–free Wave

soldering, the Wave Solder Profile still applies.

Note: the Lead–free paste, flux and profile were used for

evaluation purposes by Littelfuse, based upon industry

standards and practices. There are multiple choices of all

three available, it is advised that the customer explores the

optimum combination for their process as processes vary

considerably from site to site.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/AUML.html for current information.

Lead–free Re-flow Solder Profile

59

Revised: May 8, 2013

Figure 11

MAXIMUM TEMPERATURE 260˚C

20 - 40 SECONDS WITHIN 5˚C

RAMP RATE

<3˚C/s

PREHEAT ZONE

60 - 150 SEC

> 217˚C

5.0 6.0 7.0

AUML Varistor Series

Page 6

Product Dimensions (mm)

PAD LAYOUT DIMENSIONS CHIP LAYOUT DIMENSIONS

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

E

L

SYMBOL

Note: Avoid metal runs in this area, parts are not recommended

for use in applications using Silver (Ag) epoxy paste.

1206 Size 1210 Size 1812 Size 2220 Size

IN MM IN MM IN MM IN MM

D

W

A 0.203 5.150 0.219 5.510 0.272 6.910 0.315 8.000

B 0.103 2.620 0.147 3.730 0.172 4.360 0.240 6.190

C 0.065 1.650 0.073 1.850 0.073 1.850 0.073 1.850

D (max.) 0.071 1.80 0.070 1.80 0.07 1.80 0.118 3.00

E 0.020 -/+ 0.010 0.50 -/+0.25 0.020 -/+ 0.010 0.50 -/+ 0.25 0.020 -/+ 0.010

L 0.125 -/+ 0.012 3.20 -/+ 0.03 0.125 -/+ 0.012 3.20 -/+ 0.30 0.180 -/+ 0.014

W 0.060 -/+ 0.011 1.60 -/+ 0.28 0.100 -/+ 0.012 2.54 -/+ 0.30 0.125 -/+ 0.012

0.50 -/+

0.25

4.50 -/+

0.35

3.20 -/+

0.30

0.030 -/+ 0.010 0.75 -/+ 0.25

0.225 -/+ 0.016 5.70 -/+ 0.40

0.197 -/+ 0.016 5.00 -/+ 0.40

Part Numbering System

V

18 AUML

DEVICE FAMILY

TVSS Device

MAXIMUM DC

WORKING VOLTAGE

AUTOMOTIVE

MULTILAYER DESIGNATOR

LOAD DUMP ENERGY RATING

INDICATOR

A 2220 X X

PACKING OPTIONS

A: Bulk Pack, 2500 pieces

H: 7in (178mm) Diameter Reel*

T: 13in (330mm) Diameter Reel*

* See quanttities in Packaging table below

END TERMINATION OPTION

No Letter: Ag/P

N: Nickel Barrier

DEVICE SIZE

i.e., 220 mil x 200 mil

2220 size only

t

Packaging*

Quantity

Device Size

1206 10,000 2,500 2,500

1210 8,000 2,000 2,000

1812 4,000 1,000 1,000

2220 4,000 1,000 1,000

*(Packaging) It is recommended that parts be kept in the sealed bag provided and that parts be used as soon as possible when removed from bags.

AUML Varistor Series

13” Inch Reel

('T' Option)

7” Inch Reel

('H' Option)

Bulk Pack

('A' Option)

Revised: May 8, 2013

60

Please refer to www.littelfuse.com/series/AUML.html for current information.

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Page 7

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > AUML Series

Tape and Reel Specifications

Symbol Description Dimensions in Millimeters

A

B

K

W Width of Tape 8 -/+ 0.2 12 -/+ 0.2

P

P

P

D

D

T

T

NOTE: Dimensions in millimeters.

• Conforms to EIA-481-1, Revision A

• Can be supplied to IEC publication 286-3

Tape 8mm Wide Tape 12mm Wide Tape

Chip Size 1206 1210 1812 2220

Width of Cavity Dependent on Chip Size to Minimize Rotation.

0

Length of Cavity Dependent on Chip Size to Minimize Rotation.

0

Depth of Cavity Dependent on Chip Size to Minimize Rotation.

0

F Distance Between Drive Hole Centers and Cavity Centers 3.5 -/+ 0.5 5.4 -/+ 0.5

E Distance Between Drive Hole Centers and Tape Edge 1.75 -/+ 0.1 1.75 -/+ 0.1

Distance Between Cavity Center 4 -/+ 0.1 8-/+ 0.1

1

Axial Distance Between Drive Hole Centers and Cavity Centers 2 -/+ 0.1 2 -/+ 0.1

2

Axial Distance Between Drive Hole Centers 8 -/+ 0.1 8 -/+ 0.1

0

Drive Hole Diameter 1.55 -/+ 0.05 1.55 -/+ 0.05

0

Diameter of Cavity Piercing 1.05 -/+ 0.05 1.55 -/+ 0.05

1

Embossed Tape Thickness 0.3 Max 0.4 Max

1

Top Tape Thickness 0.1 Max 0.1 Max

2

AUML Series

Standard Packaging

Tape and reel is the standard packaging method of the

AUML Series. The standard 300 millimeter (13–inch) reel

utilized contains 4000 pieces for the 2200 and 1812 chips,

8000 pieces for the 1210 chip and 10,000 pieces for the

1206 size.

To order: add 'T' to the standard part number,

e.g.V18AUMLA222OT.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/AUML.html for current information.

Special Packaging

Option1: 178 millimeter (7–inch) reels containing 1000

Option 2 For small sample quantities (less than 100

e.g. V18AUMLA2220A.

61

Revised: May 8, 2013

(2220, 1812), 2000 (1210), 2500 (1206), pieces

are available. To order add 'H' to the standard

part number, e.g. V18AUMLA2220H.

pieces) the units are shipped bulk pack. To

order add 'A' to the standard part number,

AUML Varistor Series

Loading...

Loading...