Page 1

Varistor Products

Radial Leaded Varistors > ATMOV Series

ATMOV Varistor Series

Epoxy Coated

Phenolic Coated

Agency Approvals

Agency Agency File Number

E320116 (only Epoxy coated)

Note: These parts are in compliance with AEC–Q200 (Table 10).

RoHS

Description

The Littelfuse ATMOV Series of low voltage, high surge current, radial leaded varistors provides an ideal circuit protection for load dump, jump start voltage transient conditions

specically for automotive applications.

The maximum peak surge current rating is rated up to 5kA

(8/20 μs pulse) to protect sensitive infotainment systems

from voltage transients. This AEC-Q200 (Table 10) compli

ant series is available in ve disc sizes: 5mm, 7mm, 10mm,

14mm and 20mm; it features a wide VDC voltage range from

16V to 50V.

Features

• Meets the stringent

quality standards of

AEC-Q200

(Table 10)

• Breakthrough in low

voltage varistor design

provides high peak

surge current rating

• Reduced footprint and

volume required for

surge protection

• Optional phenolic coating

for higher operating

temperature up to 125ºC

• Wide operating voltage

range: 14VAC to 42VAC

and 16VDC to 50VDC

• Five disc sizes available:

5, 7, 10, 14, and 20mm

• High resistance to

thermal cycles for

phenolic coating

• High energy absorption

particularly for automotive

load dump and jump start

• Lead–free, Halogen-Free

and RoHS compliant

• High peak surge

current rating up to

5kA (8/20 μs pulse)

-

Series

™

Applications

• Body Electronics Systems

• Powertrain Systems

• Infotainment Systems

• Automotive Control

Module Protection

• Motor or inductive load

transient suppression

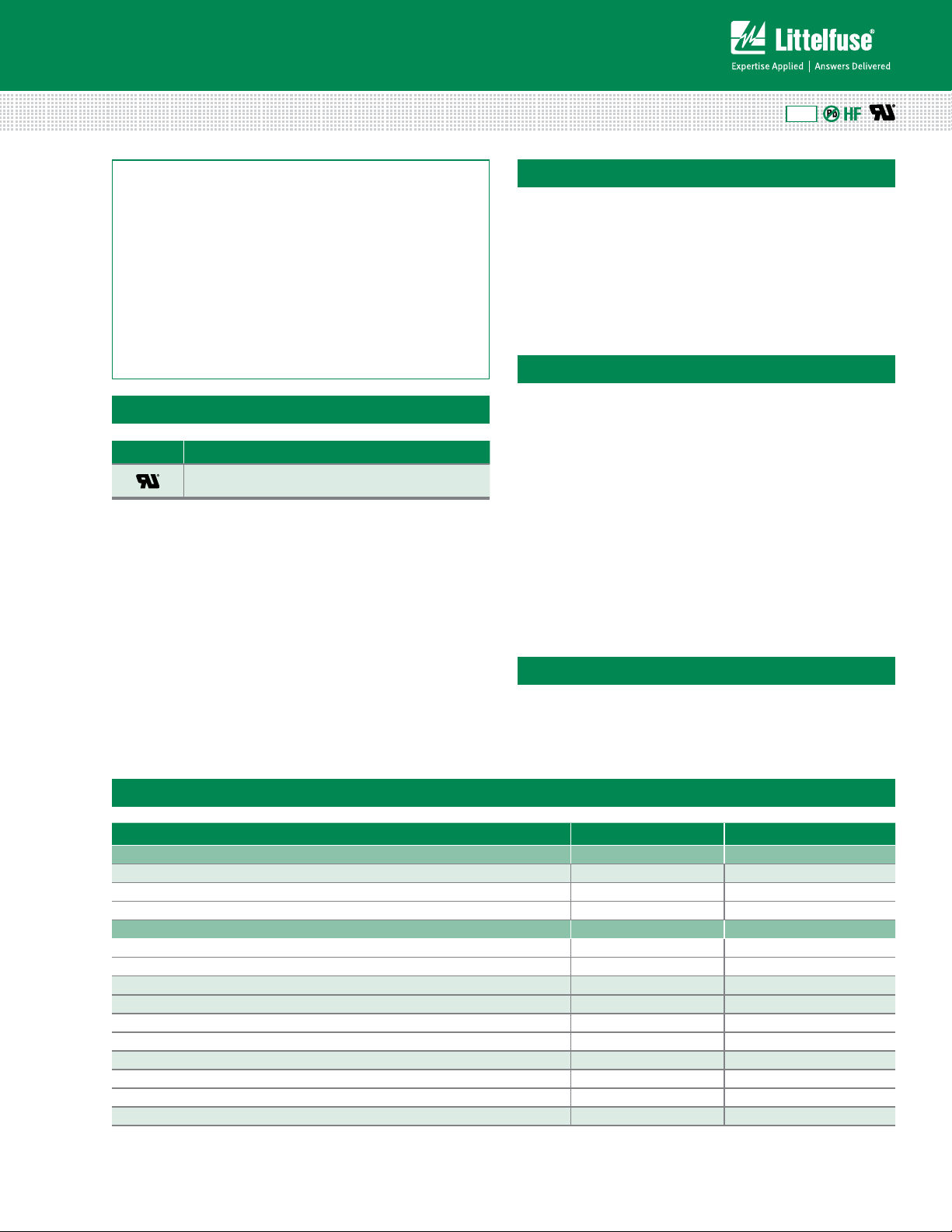

Absolute Maximum Ratings

• For ratings of individual members of a series, see Device Ratings and Specications chart

Low Voltage Series Units

Continous:

Steady State Applied Voltage:

AC Voltage Range (V

DC Voltage Range (V

Transient:

Non-Repetitive Surge Current, 8/20µs Waveform (I

Non-Repetitive Energy Capability, 2ms Waveform (W

Operating Ambient Temperature Range (T

Operating Ambient Temperature Range (T

Storage Temperature Range (T

Storage Temperature Range (T

Temperature Coefficient (αV) of Clamping Voltage (V

Hi-Pot Encapsulation (Isolation Voltage Capability) for Epoxy coated 2500 V

Hi-Pot Encapsulation (Isolation Voltage Capability) for Phenolic coated 500 V

Epoxy Coating Insulation Resistance >1,000 MΩ

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of

the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

) for Epoxy coated -40 to +125 °C

STG

) for Phenolic coated -40 to +150 °C

STG

) 14 to 42 V

M(AC)RMS

) 16 to 50 V

M(DC)

) 400 to 5,000 A

TM

) 1.0 to 140 J

) for Epoxy coated -40 to +85 °C

A

) for Phenolic coated -40 to +125 °C

A

) at Specified Test Current < 0.01% °C

C

TM

LV UltraMOV

1

Page 2

Varistor Products

Radial Leaded Varistors > ATMOV Series

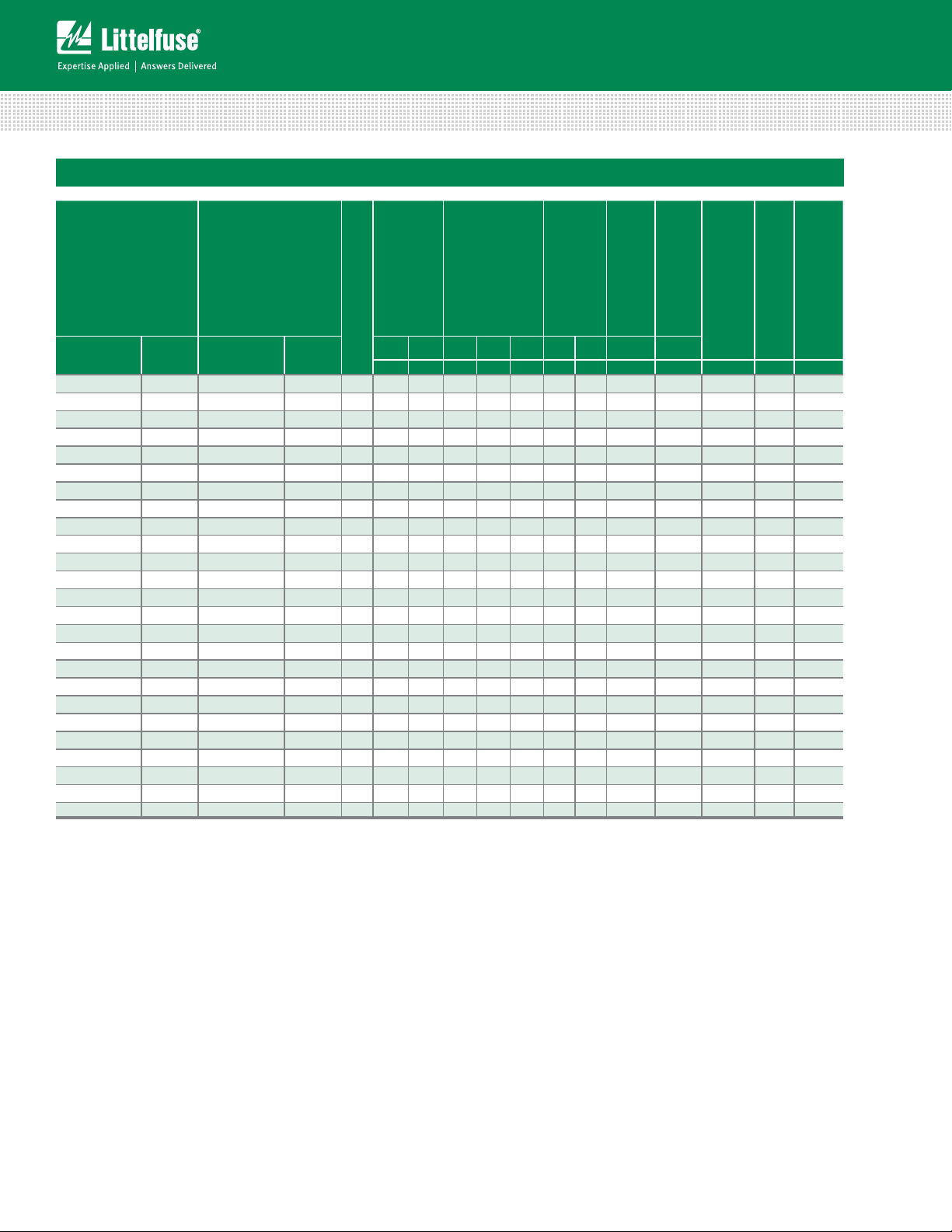

ATMOV Series Device Ratings & Specifications

Epoxy

Coated

Models

Part Number

(Base part)

Branding

Phenolic

Coated

Models

Part Number

(Base part)

Branding

Max

Energy

Size

Disc

Dia.

(mm)

Max

Continuous

Voltage

V

RMSVDC

Varistor Voltage

at 1mA

Min Nom Max

Maximum

Clamping

Voltage

VCI

PKITM

Peak

Current

(8 x

20µs 1

pulse)

WTM

Rating

pulse)

(2ms,

1

Energy

Dump,

pulses)*

(V) (V) (V) (V) (V) (V) (A) (A) (J) (J) (V) (pF)

(Load

10

Jump

Start

DC

V

jump

(5

min)

Typical

Capaci-

tance

f =

1MHz

V05E14AUTO 5E14A V05P14AUTO 5P14A 5 14 16 19.8 22 24.2 43 1 400 1 6 25 110 0

V07E14AUTO 7E14A V07P14AUTO 7P14A 7 14 16 19.8 22 24.2 43 2.5 800 2.2 12 25 2450

V10E14AUTO 10E14A V10P14AUTO 10P14A 10 14 16 19.8 22 24.2 43 5 1500 5 25 25 4650

V14E14AUTO 14E14A V14P14AUTO 14P14A 14 14 16 19.8 22 24.2 43 10 3000 10 50 25 10200

V20E14AUTO 20E14A V20P14AUTO 20P14A 20 14 16 19.8 22 24.2 43 20 5000 28 10 0 25 22200

V05E17AUTO 5E17A V05P17AUTO 5P17A 5 17 20 24.3 27 29.7 53 1 400 1. 4 6 30 950

V07E17AUTO 7E17A V07P17AUTO 7P17A 7 17 20 24.3 27 29.7 53 2.5 800 2.8 12 30 2 10 0

V10E17AUTO 10E17A V10P17AUTO 10P17A 10 17 20 24.3 27 29.7 53 5 150 0 6.5 25 30 3900

V14E17AUTO 14E17A V14P17AUTO 14P17A 14 17 20 24.3 27 29.7 53 10 3000 13 50 30 8700

V20E17AUTO 20E17A V20P17AUTO 20P17A 20 17 20 24.3 27 29.7 53 20 5000 35 10 0 30 18750

V05E25AUTO 5E25A V05P25AUTO 5P25A 5 25 28 35.1 39 42.9 77 1 400 2.5 6 40 750

V07E25AUTO 7E25A V07P25AUTO 7P25A 7 25 28 35.1 39 42.9 77 2.5 800 5.5 12 40 1500

V10E25AUTO 10E25A V10P25AUTO 10P25A 10 25 28 35.1 39 42.9 77 5 150 0 13 25 40 2900

V14E25AUTO 14E25A V14P25AUTO 14P25A 14 25 28 35.1 39 42.9 77 10 3000 25 50 40 6200

V20E25AUTO 20E25A V20P25AUTO 20P25A 20 25 28 35.1 39 42.9 77 20 5000 77 10 0 40 13500

V05E30AUTO 5E30A V05P30AUTO 5P30A 5 30 34 42.3 47 51.7 93 1 400 3.1 6 45 650

V07E30AUTO 7E30A V07P30AUTO 7P30A 7 30 34 42.3 47 51.7 93 2.5 800 7 12 45 1350

V10E30AUTO 10E30A V10P30AUTO 10P30A 10 30 34 42.3 47 51.7 93 5 1500 15.5 25 45 2550

V14E30AUTO 14E30A V14P30AUTO 14P30A 14 30 34 42.3

47 51.7 93 10 3000 32 50 45 5550

V20E30AUTO 20E30A V20P30AUTO 20P30A 20 30 34 42.3 47 51.7 93 20 5000 90 10 0 45 12000

V05E42AUTO 5E42A V05P42AUTO 5P42A 5 42 50 61.2 68 74.8 135 1 400 5 6 55 500

V07E42AUTO 7E42A V07P42AUTO 7P42A 7 42 50 61.2 68 74.8 135 2.5 800 11 12 55 1000

V10E42AUTO 10E42A V10P42AUTO 10P42A 10 42 50 61.2 68 74.8 135 5 1500 25 25 55 1850

V14E42AUTO 14E42A V14P42AUTO 14P42A 14 42 50 61.2 68 74.8 135 10 3000 50 50 55 4000

V20E42AUTO 20E42A V20P42AUTO 20P42A 20 42 50 61.2 68 74.8 135 20 5000 140 10 0 55 8500

Note: 1. Average power dissipation of transients not to exceed 0.2W, 0.25W, 0.4W, 0.6W or 1W for model sizes 5mm, 7mm, 10mm, 14mm and 20mm, respectively.

*2. Energy rating (auto load dump) for impulse duration of 40ms minimum to one half of peak current, 60sec interval (ISO7637-2 5a).

3. The shift of Vnom ( Varistor Volatge ) may be to +/-15% for Load dump or Jump Start test.

2

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 02/18/14

Page 3

Varistor Products

100

90

80

70

60

50

40

30

20

10

0

-55 50 60 70 80 90 100110 120130 14 0150

AMBIENT TEMPERATURE (

o

C)

PERCENT OF RATED VALUE

100

90

80

70

60

50

40

30

20

10

0

-55 50 60 70 80 90 100110 120130 140150

AMBIENT TEMPERATURE (

o

C)

PERCENT OF RATED VALUE

Radial Leaded Varistors > ATMOV Series

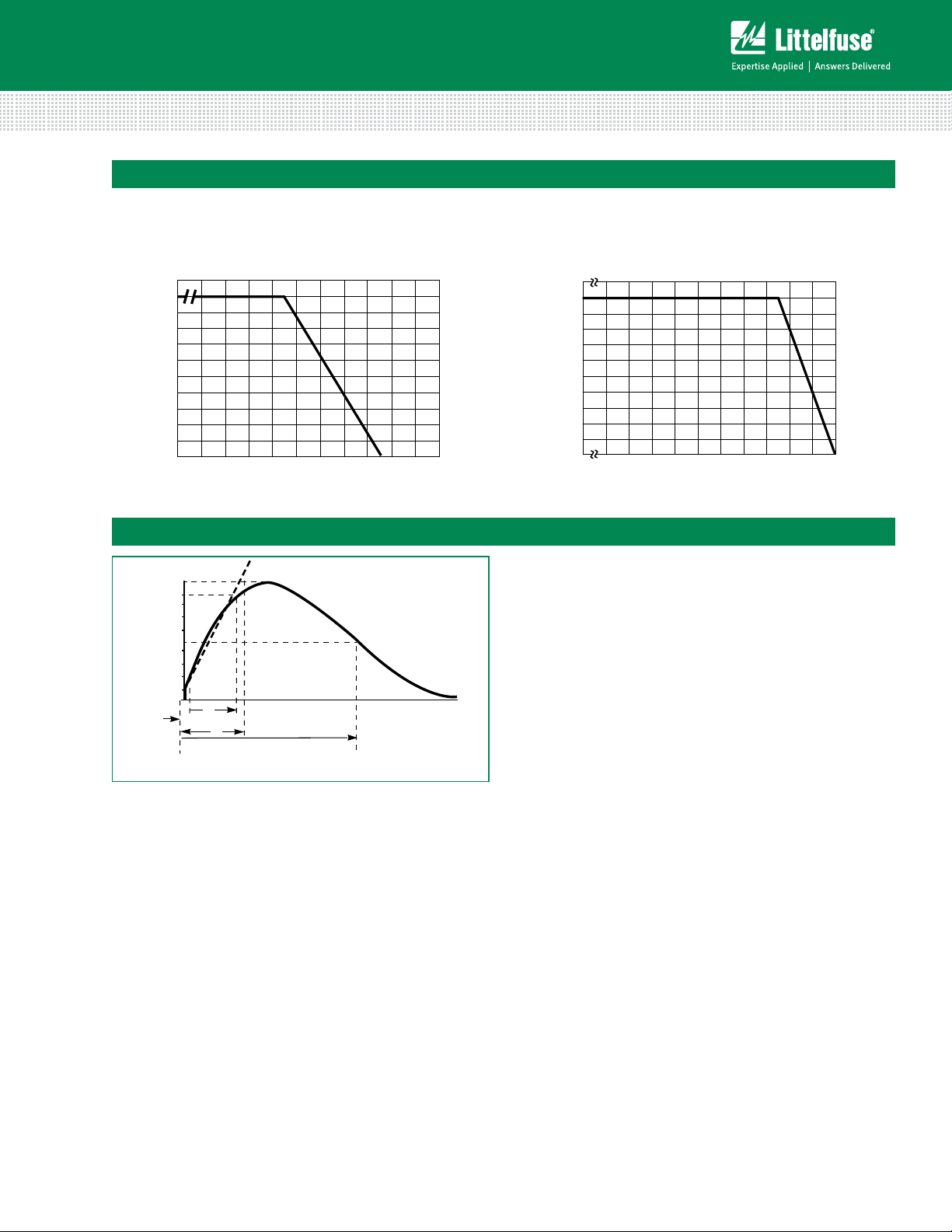

Current Energy and Power Dissipation Ratings

Figure 1A - Power Derating for Epoxy Coated

For applications exceeding 85ºC ambient temperature,

the peak surge current and energy ratings must be

reduced as shown below.

Peak Pulse Current Test Waveform for Clamping Voltage

100

50

Figure 1B - Power Derating for Phenolic Coated

For applications exceeding 125ºC ambient temperature,

the peak surge current and energy ratings must be

reduced as shown below.

Series

™

PERCENT OF PEAK VALUE

0

O

1

t

t

1

Figure 2: Peak Pulse Current Test Waveform for Clamping Voltage

01 = Virtual Origin of Wave

t = Time from 10% to 90% of Peak

t1 = Virtual Front Time = 1.25 x t

t2 = Virtual Time to Half-Value (Impulse Duration)

Example - For an 8/20 µs Current Waveform:

8µs = t1 = Virtual Front Time

20µs = t2 = Virtual Time to Half-Value

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

LV UltraMOV

TIME

t

2

3

Page 4

Varistor Products

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

PEAK AMPERES (A)

V07x42AUTO

V07x30AUTO

V07x25AUTO

V07x17AUTO

V07x14AUTO

MODEL SIZE 7mm

600

500

400

300

200

100

90

80

70

60

50

40

30

20

MAXIMUM PEAK VOLTS (V)

PEAK AMPERES (A)

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 5mm

10

V05x42AUTO

V05x30AUTO

V05x25AUTO

V05x17AUTO

V05x14AUTO

10

-3

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

PEAK AMPERES (A)

V07x42AUTO

V07x30AUTO

V07x25AUTO

V07x17AUTO

V07x14AUTO

MODEL SIZE 7mm

V07x14AUTO - V07x42AUTO

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

PEAK AMPERES (A)

V07x42AUTO

V07x30AUTO

V07x25AUTO

V07x17AUTO

V07x14AUTO

MODEL SIZE 7mm

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

PEAK AMPERES (A)

V10x42AUTO

V10x30AUTO

V10x25AUTO

V10x17AUTO

V10x14AUTO

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 10mm

600

500

400

300

200

100

90

80

70

60

50

40

30

20

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

PEAK AMPERES (A)

MAXIMUM PEAK VOLTS (V)

V14x42AUTO

V14x30AUTO

V14x25AUTO

V14x17AUTO

V14x14AUTO

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 14mm

CLAMPING VOLTAGE FOR V05x14AUTO - V05x42AUTO

600

500

400

300

200

100

90

80

70

60

50

40

30

20

MAXIMUM PEAK VOLTS (V)

PEAK AMPERES (A)

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 5mm

10

V05x42AUTO

V05x30AUTO

V05x25AUTO

V05x17AUTO

V05x14AUTO

10

-3

CLAMPING VOLTAGE FOR

V07x14AUTO - V07x42AUTO

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

PEAK AMPERES (A)

V07x42AUTO

V07x30AUTO

V07x25AUTO

V07x17AUTO

V07x14AUTO

MODEL SIZE 7mm

600

500

400

300

200

100

90

80

70

60

50

40

30

20

10

-3

10

-2

10

-1

10

0

10

1

10210

3

PEAK AMPERES (A)

MAXIMUM PEAK VOLTS (V)

V14x42AUTO

V14x30AUTO

V14x25AUTO

V14x17AUTO

V14x14AUTO

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 14mm

CLAMPING VOLTAGE FOR

V07x14AUTO - V07x42AUTO

V10x14AUTO - V10x42AUTO

V14x14AUTO - V14x42AUTO

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

PEAK AMPERES (A)

V07x42AUTO

V07x30AUTO

V07x25AUTO

V07x17AUTO

V07x14AUTO

MODEL SIZE 7mm

500

400

300

200

100

90

80

70

60

50

40

30

20

10

MAXIMUM PEAK VOLTS (V)

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

PEAK AMPERES (A)

V10x42AUTO

V10x30AUTO

V10x25AUTO

V10x17AUTO

V10x14AUTO

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 10mm

600

500

400

300

200

100

90

80

70

60

50

40

30

20

10

-3

10

-2

10

-1

10

0

10

1

10

2

10

3

PEAK AMPERES (A)

MAXIMUM PEAK VOLTS (V)

V14x42AUTO

V14x30AUTO

V14x25AUTO

V14x17AUTO

V14x14AUTO

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 14mm

CLAMPING VOLTAGE FOR V05x14AUTO - V05x42AUTO

600

500

400

300

200

100

90

80

70

60

50

40

30

20

MAXIMUM PEAK VOLTS (V)

PEAK AMPERES (A)

10

-2

10

-1

10

0

10

1

10

2

10

3

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 5mm

10

V05x42AUTO

V05x30AUTO

V05x25AUTO

V05x17AUTO

V05x14AUTO

10

-3

MAXIMUM PEAK VOLTS (V)

PEAK AMPERES (A)

10-210-110010110210310

4

10

-3

10-510

-4

10

-6

CLAMPING VOLTAGE FOR

CLAMPING VOLTAGE FOR CLAMPING VOLTAGE FOR

10

20

30

40

50

60

70

80

90

600

700

800

900

100

200

300

400

500

1000

MAXIMUM CLAMPING VOLTAGE

MODEL SIZE 20mm

V20x14AUTO

V20x17AUTO

V20x25AUTO

V20x30AUTO

V20x42AUTO

Radial Leaded Varistors > ATMOV Series

Maximum Clamping Voltage for 5mm Parts

V05x14AUTO - V05x42AUTO

Maximum Clamping Voltage for 10mm Parts

V10x14AUTO - V10x42AUTO

Maximum Clamping Voltage for 7mm Parts

V07x14AUTO - V07x42AUTO

Maximum Clamping Voltage for 14mm Parts

V14x14AUTO - V14x42AUTO

Maximum Clamping Voltage for 20mm Parts

V20x14AUTO - V20x42AUTO

4

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 02/18/14

Page 5

Varistor Products

10 100 1000 10000

5MM V05E14...E42AUTO

Surge Current (A)

Impulse Duration (µs)

7MM V07E14....E42AUTO

1

10

100

1000

10000

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

7MM V07E14....E42AUTO

10 100 1000 10000 10 100 1000 10000

Surge Current (A)

Impulse Duration (µs)

5MM V05E14...E42AUTO

Surge Current (A)

Impulse Duration (µs)

7MM V07E14....E42AUTO

1

10

100

1000

10000

10MM V10E14...E42AUTO

Surge Current (A)

Impulse Duration (µs)

14MM V14E14...E42AUTO

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

0.1

1

10

100

1000

1

10

100

1000

10000

10 100 1000 10000

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

Surge Current (A)

Impulse Duration (µs)

7MM V07E14....E42AUTO

14MM V14E14...E42AUTO

1

10

100

1000

10000

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

10 100 1000 10000 10 100 1000 10000

Surge Current (A)

Impulse Duration (µs)

5MM V05E14...E42AUTO

Surge Current (A)

Impulse Duration (µs)

7MM V07E14....E42AUTO

1

10

100

1000

10000

1

10

100

1000

10000

Surge Current (A)

Impulse Duration (µs)

10MM V10E14...E42AUTO

Surge Current (A)

Impulse Duration (µs)

14MM V14E14...E42AUTO

20MM V20E14...E42AUTO

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

0.1

1

10

100

1000

1

10

100

1000

10000

10 100 1000 10000

10 100 1000 10000

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

1x

2x

15x

10

2

x

10

3

x

10

4

x

10

5

x

10

6

x

Radial Leaded Varistors > ATMOV Series

Repetitive Surge Capability for 5mm Parts

V05x14AUTO – V05x42AUTO

Repetitive Surge Capability for 7mm Parts

V07x14AUTO – V07x42AUTO

1000

1x

2x

15x

100

2

10

x

3

10

x

4

x

10

5

x

10

6

10

x

10

Repetitive Surge Capability for 10mm Parts

V10x14AUTO – V10x42AUTO

1

Surge Current (A)

0.1

10 100 1000 10000

Impulse Duration (µs)

Surge Current (A)

Repetitive Surge Capability for 14mm Parts

V14x14AUTO – V14x42AUTO

10000

1000

Surge Current (A)

1x

2x

15x

2

10

x

3

10

x

4

100

10

x

5

10

x

6

x

10

10

1

10 100 1000 10000

Impulse Duration (µs)

Repetitive Surge Capability for 20mm Parts

V020x14AUTO – V20x42AUTO

10000

1000

Surge Current (A)

100

1x

2x

15x

2

10

x

3

x

10

4

10

x

5

x

10

6

10

x

10

1

10 100 1000 10000

Impulse Duration (µs)

NOTE: If pulse ratings are exceeded, a shift of V

more then +/-10% could result. This type of shift, which normally results in a

decrease of V

specications, but does not prevent the device from continuing to function,

and to provide ample protection.

Surge Current (A)

10000

1000

100

1x

2x

15x

2

x

10

3

10

x

4

10

x

5

10

x

6

10

x

10

1

10 100 1000 10000

Impulse Duration (µs)

10000

1x

2x

15x

1000

100

2

10

x

3

x

10

4

10

x

5

10

x

6

10

x

10

1

10 100 1000 10000

Impulse Duration (µs)

(at specied current) of

N(DC)

, may result in the device not meeting the original published

N(DC)

Series

™

LV UltraMOV

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

5

Page 6

Wave Solder Profile

300

S)

TEMPERATURE (ºC)

300

TEMPERATURE (ºC)

Varistor Products

Radial Leaded Varistors > ATMOV Series

Non Lead–free Profile

250

200

150

100

50

0

00.5 11.5 22.5 33.5 4

Maximum Wave 240C

TIME(MINUTE

Physical Specifications

Lead Material Copper Clad Steel Wire

Soldering

Characteristics

Insulating Material

Solderability per MIL–STD–202,

Method 208E

Cured, ame retardant epoxy polymer

meets UL94V–0 requirements

Lead–free Profile

250

200

150

100

50

0

00.5 11.5 22.5 33.5 4

Maximum Wave 260C

TIME(MINUTES)

Environmental Specifications

Humidity Aging

Thermal Shock

Solvent Resistance MIL–STD–202, Method 215F

+85°C, 85% RH,1000 hours

+/-10% typical voltage change

+85°C to -40°C 10 times

+/-10% typical voltage change

Device Labeling Marked with LF, voltage and date code

Moisture Sensitivity Level 1, J–STD–020C

6

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 02/18/14

Page 7

Varistor Products

Radial Leaded Varistors > ATMOV Series

Product Dimensions (mm)

øD

A

e

V

RMS

Model

øb

e1 e1

L

E

Dimen-

sion

Voltage

A All -

A1 All -

ØD All -

e All

11 - 30

e

1

35 - 40

11 - 30 -

E

35 - 40 -

Øb All

L All

L

TRIM

All 2.41 (0.095)

øD

A1

SEATING

PLANE

L

E

øb

e

5mm Size 7mm Size 10mm Size 14mm Size 20mm Size

Min.

mm (in)

4

(0.157)6 (0.236)4 (0.157)6 (0.236)

1

(0.039)3 (0.118)1 (0.039)3 (0.118)1 (0.039)3 (0.118)

1. 5

(0.059)

0.585

(0.023)

25.4

(1.00)

Max.

mm (in)

10

(0.394)

13

(0.512)

7

(0.276)

3.5

(0.138)

5.0

(0.197)

5.6

(0.220)

0.685

(0.027)

-

4.69

(0.185)

Min.

mm (in)

-

-

-

1.5

(0.059)

-

-

0.585

(0.023)

25.4

(1.00)

2.41

(0.095)

Max.

mm (in)

12

(0.472)

15

(0.591)

9

(0.354)

3.5

(0.138)

5.0

(0.197)

5.6

(0.220)

0.685

(0.027)

-

4.69

(0.185)

Min.

mm (in)

-

-

-

6.5

(0.256)

1.5

(0.059)

-

-

0.76

(0.030)

25.4

(1.00)

2.41

(0.095)

Max.

mm (in)

16

(0.630)

19.5

(0.768)

12.5

(0.492)

8.5

(0.335)

3.5

(0.138)

5.0

(0.197)

5.6

(0.220)

0.86

(0.034)

-

4.69

(0.185)

Min.

mm (in)

-

-

-

6.5

(0.256)

Max.

mm (in)

20

(0.787)

22.5

(0.886)

17

(0.669)

8.5

(0.335)

Min.

mm (in)

-

-

-

6.5

(0.256)

1

(0.039)3 (0.118)1 (0.039)3 (0.118)

1.5

(0.059)

-

-

0.76

(0.030)

25.4

(1.00)

2.41

(0.095)

3.5

(0.138)

5.0

(0.197)

5.6

(0.220)

0.86

(0.034)

-

4.69

(0.185)

1.5

(0.059)

-

-

0.76

(0.030)

25.4

(1.00)

2.41

(0.095)

Max.

mm (in)

26.5

(1.043)

29

(1.142)

23

(0.906)

8.5

(0.335)

3.5

(0.138)

5.0

(0.197)

5.6

(0.220)

0.86

(0.034)

-

4.69

(0.185)

Series

™

LV UltraMOV

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

7

Page 8

Tape and Reel Specifications

P1

P0

W0

E

DP

DH

DH

W1

W

F

t

W2

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

Crimped Leads "ZT"

Crimped Leads "ZT"

P1

P0

E

DP

DH

DH

W1

W

F

t

W2W0

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

P1

P0

W0

E

DP

DH

DH

W1

W

F

t

W2

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

DH

E

DH

DP

W1

W

F

t

W2

P

DP

Db

H

DD0

H1

P1

P2

W0

Crimped Leads "ZT"

P1

P0

W0

E

DP

DH

DH

W1

W

F

t

W2

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

Crimped Leads "ZT"

Crimped Leads "ZT"

Straight Leads "ZS"

Straight Leads "ZS"

P1

P0

E

DP

DH

DH

W1

W

F

t

W2W0

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

P1

P0

W0

E

DP

DH

DH

W1

W

F

t

W2

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

P0

DH

E

DH

DP

W1

W

F

t

W2

P

DP

Db

H

DD0

H1

P1

P2

W0

P1

P0

P2

DH

E

DH

DP

W1

W

F

t

W2W0

P

DP

Db

H

DD0

H1

H

P0

U

DH

E

DH

DP

W1

W

F

t

W2

P

DP

Db

Ho

DD0

H1

P2

W0

P1

Crimped Leads "ZT"

Straight Leads "ZS"

P1

P0

W0

E

DP

DH

DH

W1

W

F

t

W2

P

DP

C

Db

H0

DD0

H1

SEATING

PLANE

P2

P0

DH

E

DH

DP

W1

W

F

t

W2

P

DP

Db

H

DD0

H1

P1

P2

W0

5 and 7mm Devices 10, 14 and 20mm Devices

STRAIGHT LEADS "L1" STRAIGHT LEADS "L1"

P2

P

DP

Varistor Products

Radial Leaded Varistors > ATMOV Series

E

DP

DH

DH

P2

P

DP

E

DP

DH

DH

H1

DD0

H1

DD0

1

DD0

H1

W1

H

P1

Db

P0

F

t

W2W0

W

H

DD0

P1

P0

Db

F

CRIMPED LEADS "L2" CRIMPED LEADS "L2"

P2

SEATING

PLANE

H0

P1

P0

P

DP

C

Db

F

E

DP

DH

DH

W1

W2W0

W

t

H1

H0

DD0

SEATING

PLANE

P2

P1

P0

P

DP

C

Db

F

UNDER CRIMPED / IN-LINE LEADS "L3" UNDER CRIMPED / IN-LINE LEADS "L3"

P2

Ho

P1

P

DP

P0

Db

F

E

DP

DH

DH

U

W1

W2W0

W

t

H1

Ho

DD0

P2

P1

P0

P

DP

Db

F

W0

W1

W2

W

t

E

DP

DH

DP

DH

DH

W1

W2

W0

W

t

E

DH

U

W0

W1

W2

W

t

Refer to next page for dimension measurement specifics.

8

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

Page 9

Varistor Products

Radial Leaded Varistors > ATMOV Series

Tape and Reel Specifications (continued)

NOTES:

• Radial devices on tape are supplied with crimped leads, straight leads, or under-crimped leads

• Leads are offset by product dimension e1

• Conforms to ANSI and EIA specications

• Can be supplied to IEC Publication 286-2

SYMBOL DESCRIPTION

P Pitch of Component 12.7 +/- 1.0 12.7 +/- 1.0 25.4 +/- 1.0 25.4 +/- 1.0 25.4 +/- 1.0

Feed Hole Pitch 12.7 +/- 0.2 12.7 +/- 0.2 12.7 +/- 0.2 12.7 +/- 0.2 12.7 +/- 0.2

P

0

Feed Hole Center to Pitch 3.85 +/- 0.7 3.85 +/- 0.7 8.85 +/- 0.7 8.85 +/- 0.7 8.85 +/- 0.7

P

1

Hole Center to Component Center 6.35 +/- 1.0 6.35 +/- 1.0 12.7 +/- 0.7 12.7 +/- 0.7 12.7 +/- 0.7

P

2

F Lead to Lead Distance 5.0 +/- 1.0 5.0 +/-1.0 7.5 +/- 1.0 7.5 +/- 1.0 7.5 +/- 1.0

h Component Alignment 2.0 Max 2.0 Max 2.0 Max 2.0 Max 2.0 Max

W Tape Width 18.0 +1.0 / -0.5 18.0 +1.0 / -0.5 18.0 +1.0 / -0.5 18.0 +1.0 / -0.5 18.0 +1.0 / -0.5

Hold Down Tape Width 12.0 +/- 0.3 12.0 +/- 0.3 12.0 +/- 0.3 12.0 +/- 0.3 12.0 +/- 0.3

W

0

Hole Position 9.0 +0.75 / -0.50 9.0 +0.75 / -0.50 9.0 +0.75 / -0.50 9.0 +0.75 / -0.50 9.0 +0.75 / -0.50

W

1

Hold Down Tape Position 0.5 Max 0.5 Max 0.5 Max 0.5 Max 0.5 Max

W

2

Height from Tape Center to

H

Component Base

Seating Plane Height 16.0 +/- 0.5 16.0 +/- 0.5 16.0 +/- 0.5 16.0 +/- 0.5 16.0 +/- 0.5

H

0

Component Height 29.0 Max 32.0 Max 36.0 Max 40.0 Max 46.5 Max

H

1

Feed Hole Diameter 4.0 +/- 0.2 4.0 +/- 0.2 4.0 +/- 0.2 4.0 +/- 0.2 4.0 +/- 0.2

D

0

t Total Tape Thickness 0.7 +/- 0.2 0.7 +/- 0.2 0.7 +/- 0.2 0.7 +/- 0.2 0.7 +/- 0.2

U Undercrimp Width 8.0 Max 8.0 Max 8.0 Max 8.0 Max 8.0 Max

p Component Alignment 3° Max 3º

5mm 7mm 10mm 14mm 20mm

18.0 +2.0 / -0.0 18.0 +2.0 / -0.0 18.0 +2.0 / -0.0 18.0 +2.0 / -0.0 18.0 +2.0 / -0.0

Max 3° Max 3° Max 3° Max

MODEL SIZE

Series

™

LV UltraMOV

Part Numbering System

V05E

Littelfuse Varistor

Disc Size

05, 07, 10, 14 or 20 mm

Coating

E: Epoxy

P: Phenolic

VM(AC)RMS

14V to 42V

ATMOV Series

Lead-Free, RoHS and

Halogen free Compliant

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 02/18/14

14 XXXXX

AUTO L1 B

Other

Non-Standard Options

Packaging

Blank or B: Bulk Pack

T: Ta pe and Reel

A: Ammo Pack

Lead Formation

Blank or L1: Straight

L2: Crimped

L3: In-Line

L4: Trim/Crimp (Bulk pack only)

9

Loading...

Loading...