Page 1

Varistor Testing

Application Note January 1998

Introduction

This note details the common tests of varistor parameters and

describes suitable test methods using simplied test circuits.

All tests are performed at 25

The test circuits and methods given herein are intended as

a general guide. Since the tests frequently entail high

voltages and currents, the user must exercise appropriate

safety precautions.

Engineering Evaluation

It is important to focus on the key characteristics and

ratings to determine if the component can perform as

expected. Typically, for a varistor, its nominal voltage,

clamping voltage, standby current, insulation resistance,

and capacitance are measured. The surge current, or

energy, and waveshape available in the circuit together with

its frequency of occurrence should be measured or

computed. The characteristics of these expected transients

should then be checked against the pulse ratings and the

power dissipation ratings of the selected varistor type.

Where suitable equipment is available, these ratings may

be veried.

Product Qualication

A product qualication plan often will be used to detail the

electrical and environmental tests to which sample

components may be subjected. The suggested electrical

characteristics tests could include (with appropriate

conditions and limits): nominal varistor voltage, V

maximum clamping voltage,

(optional, especially for AC applications); insulation

resistance; and capacitance. A test to ensure surge current

withstand capability may be included in the qualication

plan. This test must be carefully performed and specied (by

using either 8/20µs or 10/1000µs waveshapes) consistent

with the pulse lifetime rating chart of the varistor selected.

Other qualication tests may be used to ensure mechanical

integrity, humidity resistance, solderability, and terminal/lead

strength.

Incoming Inspection

The equipment maker may wish to verify that shipments

received consist of correct parts at the expected quality

level. For incoming inspection of Littelfuse Varistors, it is

recommended that sample testing include nominal varistor

voltage (V

voltages specied on the purchase drawing/specication.

Other electrical sampling tests frequently performed can

include insulation resistance and capacitance. Tests such as

maximum clamping voltage, V

are usually checked only on a periodic audit basis.

) tested against the minimum and maximum

N

o

C, unless otherwise specied.

;

N

VC; DC standby current, ID

, and DC standby current, ID,

C

AN9773

Field Maintenance

Field maintenance testing is done to verify that the varistor is

still providing the intended protection function.

The nominal varistor voltage should be tested against the

minimum limits for the model using the method described in

the Nominal Varistor Voltage V

section. If the varistor is

N

open, short, or more than 10% outside either limit, it should

be replaced. The DC standby current may also be measured.

Measurement of Varistor Characteristics [1]

Nominal Varistor Voltage V

This is measured at a DC test current, I

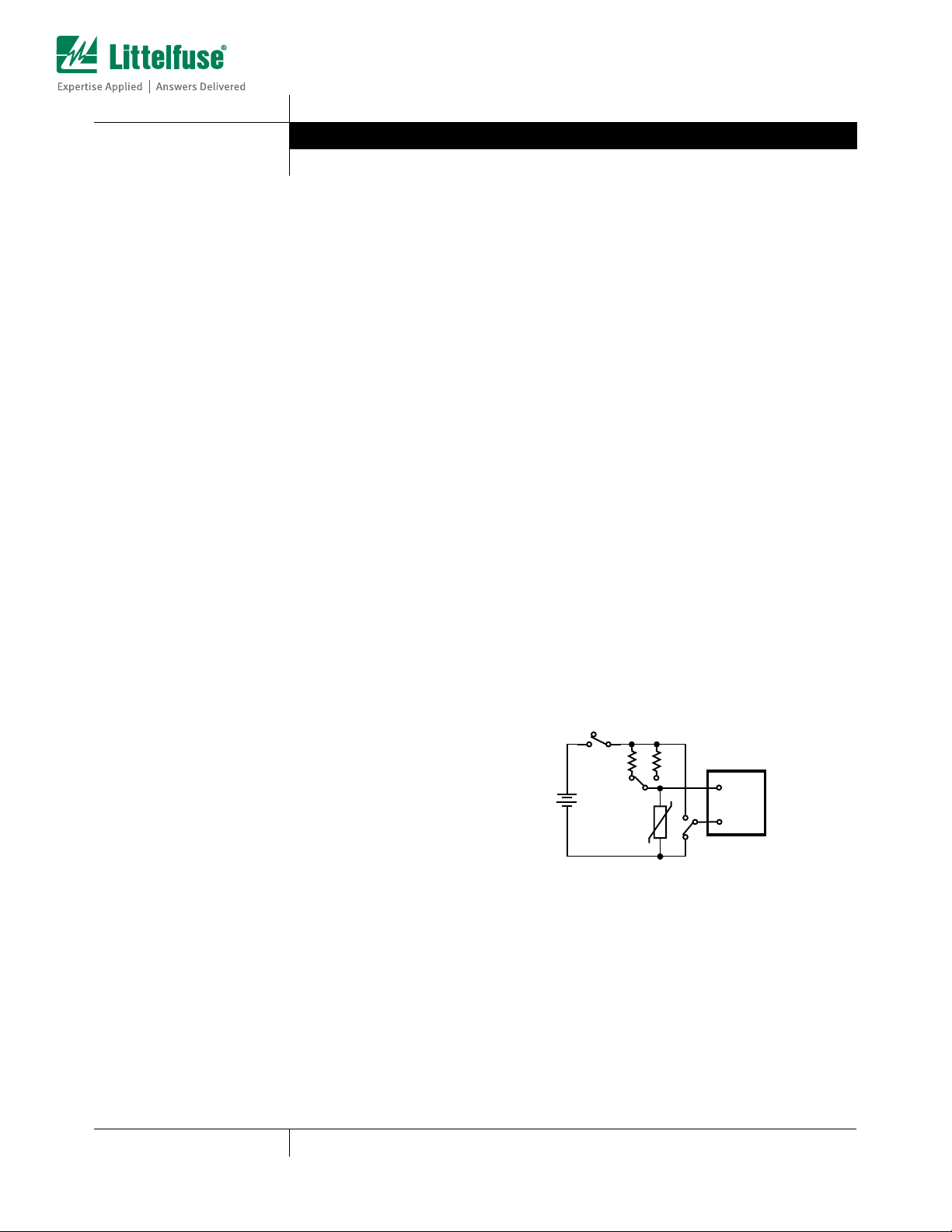

models. A simplied circuit for instrumenting this test, shown

in Figure 1, is suitable for varistors up through a rating of

300V

voltage will be needed. Resistor R1 has a dual purpose. In

conjunction with the variable voltage supply, E1, it forms a

quasi-current source providing up to 6mA when switch S1 is

closed. Also, R1 is used as a current sensor to measure

current owing through the varistor-under-test. To use the

circuit, the operator places switch S2 in position I and S3 into

position V

S1 is closed. E1 is then adjusted to obtain a reading of 100V

±5V on the digital voltmeter. Approximately 1mA of current

will be owing in R1. When switch S2 is placed in position V,

the varistor voltage will be indicated on the voltmeter. The

values of R1 and E1 supply voltage can be scaled

appropriately for other voltage-current test points.

If the varistor voltage test is implemented on automatic test

equipment, a “soak” time of 20ms minimum should be

allowed after application of test current before voltage

measurement. This is necessary to allow varistor voltage to

settle toward a steady-state value. Figure 2 illustrates the

time response of a specimen varistor with a constant 1.0mA

current applied. As can be seen, the varistor voltage initially

may rise to a value up to 6% greater than nal. With a 20ms

or greater soak time, the measured value will differ by less

than 2% from the steady-state value.

. Above the 300V

RMS

. A test device is then inserted into the socket and

N

S1

R1

S3

V

0V-600V

E1

FIGURE 1. SIMPLIFIED CIRCUIT FOR VARISTOR VOLTAGE

AND DC STANDBY CURRENT TESTS

N

N

of 1mA for product

N

rating, a higher supply

RMS

R2

I

D

+

I

DVM

S2

-

V

R1 = 100kΩ, 1%, 1W(V

R2 = 1kΩ, 1%, 1/2W(I

TEST)

N

TEST)

D

10-141

1-800-999-9445 or 1-847-824-1188 | Copyright © Littelfuse, Inc. 1998

Page 2

C

Application Note 9773

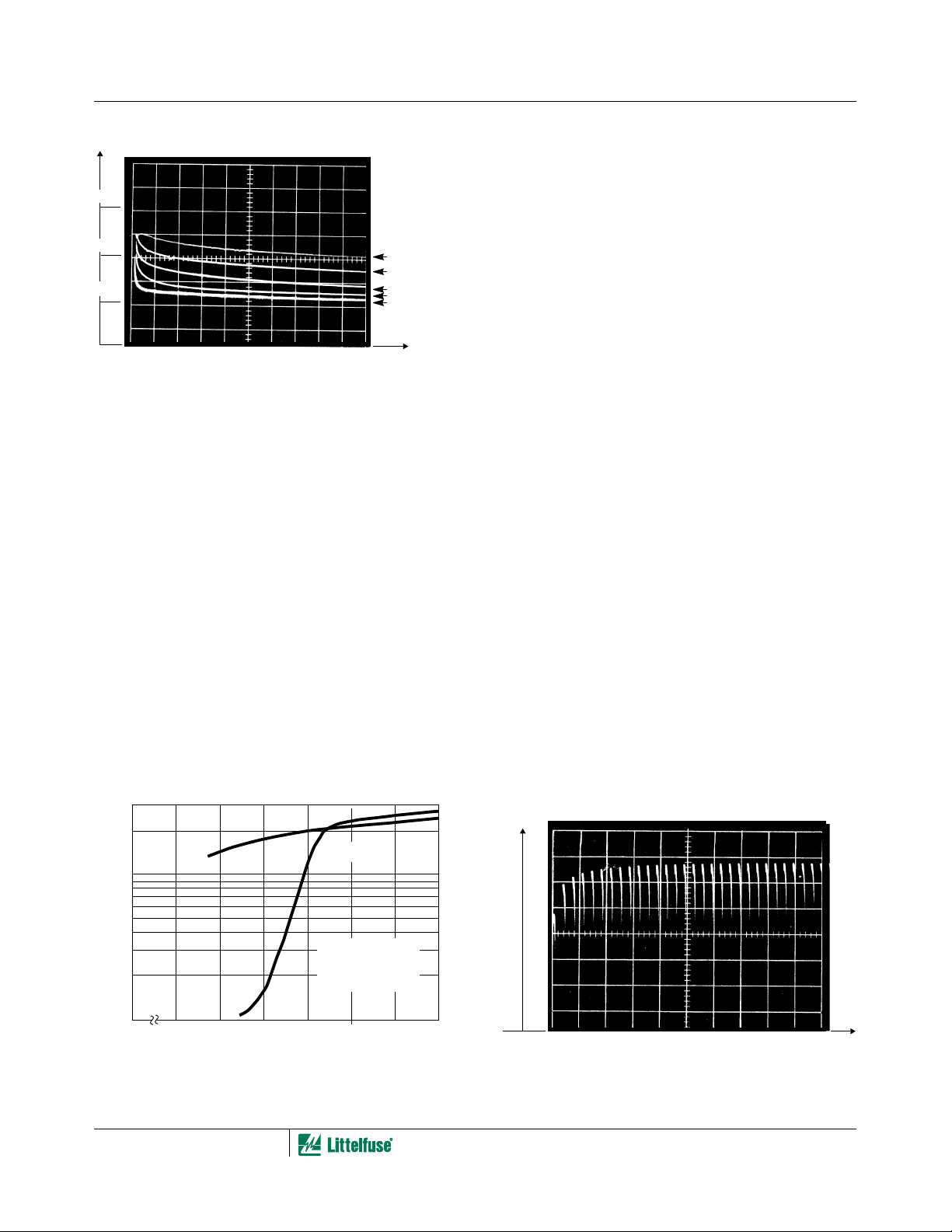

V (T)

5V/DIV

250V

240V

230V

FIGURE 2. VOLTAGE-TIME V(T) CHARACTERISTICS OF A

LITTELFUSE VARISTOR (V130LA10A)

OPERATING AT A CONSTANT DC CURRENT OF

0.1ms/DIV

1ms/DIV

10ms/DIV

100ms/DIV

1000ms/DIV

T

For varistor models that are commonly used on 60Hz power

lines, the V

limits may be specified for a 1.0mA peak AC

N

current applied. If an AC test is preferred by the user, a

schematic approach similar to that shown in Figure 1 is used,

except an AC VARIAC™ is substituted for the DC power supply,

and an oscilloscope is substituted for the voltmeter. This circuit

is equivalent to that of a typical curve tracer instrument.

To avoid unnecessary concern over minor measurement

anomalies, three behavioral phenomena of metal-oxide

varistors should be noted. First, it is normal for the peak

varistor voltage measured with AC current to be about 2% to

5% higher than the DC value, as illustrated by Figure 3. This

“AC-DC difference” is to be expected, since the one-quarter

cycle period of a 60Hz wave is much less than the 20ms

minimum settling time required for DC readout.

Second, it is normal for the varistor voltage to increase

slightly when first subjected to electrical current, as shown in

Figure 4. This might be considered a “break-in” stabilization

of the varistor characteristics. During normal measurement

the voltage shift typically is less than 1%. This voltage shift is

of little consequence for most measurement purposes but

might be noticeable when viewing a DVM as in the test

method of Figure 1. The visual DVM observation should be

made shortly after power is applied, with measurement to

not more than three significant figures.

Third, it is normal for the varistor voltage-current

characteristic to become slightly asymmetrical in polarity

under application of DC electrical stress over time. The

varistor voltage will increase in the same direction as the

polarity of stress, while it will be constant or will decrease in

the opposite polarity. This effect will be most noticeable for a

varistor that has been subjected to unipolar pulse stresses

or accelerated DC life tests. Therefore, to obtain consistent

results during unipolar pulse or operating life tests, it is

essential to provide a polarity identification for the test

specimens. However, for initial readout purposes, this effect

usually is insignificant.

Maximum Clamping Voltage, V

Two typical current impulses that may be used to define the

varistor clamping voltage are the 8/20 µ s and the 10/1000 µ s

pulses. Figure 5 shows typical varistor test waveforms for

these two impulses.

The clamping voltage of a given model varistor at a defined

current is related by a factor of the varistor voltage.

Therefore, a test of the nominal varistor voltage against

specifications may be sufficient to provide reasonable

assurance that the maximum clamping voltage specification

is also satisfied. When it is necessary to perform the V

special surge generators are required. For shorter impulses

than 8/20 µ s, precautions must be observed to avoid an

erroneous “overshoot” in the measurement of the clamping

voltage. The Equipment for Varistor Electrical Testing section

gives general information on surge generators; a brief

description of the “overshoot” effect follows.

test,

C

V(T)

5V/DIV

DC

100

VOLTAGE (V)

10

10

FIGURE 3. AC AND DC CHARACTERISTIC CURVES FIGURE 4. V130LA10A) VARISTOR VOLTAGE FOR THE

-6

-7

10

-5

10

I, CURRENT (A)

10-142

AC 60Hz

130V

RMS

PRODUCT

MEDIUM VOLTAGE

MATERIAL

-4

10

10-310-210

RATED

-1

INITIAL CYCLES OF 60Hz OPERATION AT A

PEAK CURRENT OF 1.0mA

VARIAC™ is a trademark of Glen Rad, Inc.

T, 50ms/DIV

Page 3

Application Note 9773

10A/DIV

100V/DIV

0

FIGURE 5A. 8/20 µ s, WAVE I

OUTPUT LEAD

FROM

TRANSIENT

GENERATOR

AREA ≈

0.5cm

10µs/DIV

= 50A, V

P

= 315V

P

FIGURE 5B. 10/1000 µ s, WAVE I

FIGURE 5. TYPICAL CLAMPING VOLTAGE TEST WAVEFORMS (LITTELFUSE

FIGURE 6. VARISTOR TYPE V130LA10A)

VOLTAGE PROBE

2

COPPER TUBE

SURROUNDING

VOLTAGE PROBE

CURRENT

PATH

AREA

22cm

≈

2

1ms/DIV

= 50A, V

P

= 315V

C

10A/DIV

100V/DIV

0

CURRENT

PAT H

VARISTOR

FIGURE 7A. MINIMAL LOOP AREA

GROUND

VARISTOR

FIGURE 7B. EXCESSIVE LOOP AREA TYPICAL

“OVERSHOOT” OF LEAD-MOUNTED VARISTOR

WITH STEEP CURRENT IMPULSES

FIGURE 7C. CURRENT RISE OF 8 µ s FIGURE 7D. CURRENT RISE OF 0.5 µ s

FIGURE 7. EFFECT OF LEAD LENGTH ON “OVERSHOOT”

10-143

Page 4

Application Note 9773

D

The Littelfuse Varistor specification sheets show the VI

characteristic of the devices on the basis of maximum voltage

appearing across the device during a current pulse of 8/20 µ s. If

current impulses of equal magnitude but faster rise are applied

to the varistor, higher voltages will appear across the device.

These higher voltages, described as “overshoot,” are partially

the result of an intrinsic increase in the varistor voltage, but

mostly of the inductive effect of the unavoidable lead length.

Therefore, as some applications may require current impulses

of shorter rise time than the conventional 8 µ s, careful attention

is required to recognize the contribution of the voltage

associated with lead inductance [1].

The varistor voltage, because of its nonlinearity, increases only

slightly as the current amplitude of the impulse increases. The

voltage from the lead inductance is strictly linear and therefore

becomes large as high current amplitudes with steep fronts are

applied. For that reason, it is impractical to specify clamping

voltages achieved by lead-mounted devices with current

impulses having rise times shorter than 0.5 µ s, unless circuit

geometry is very accurately controlled and described.

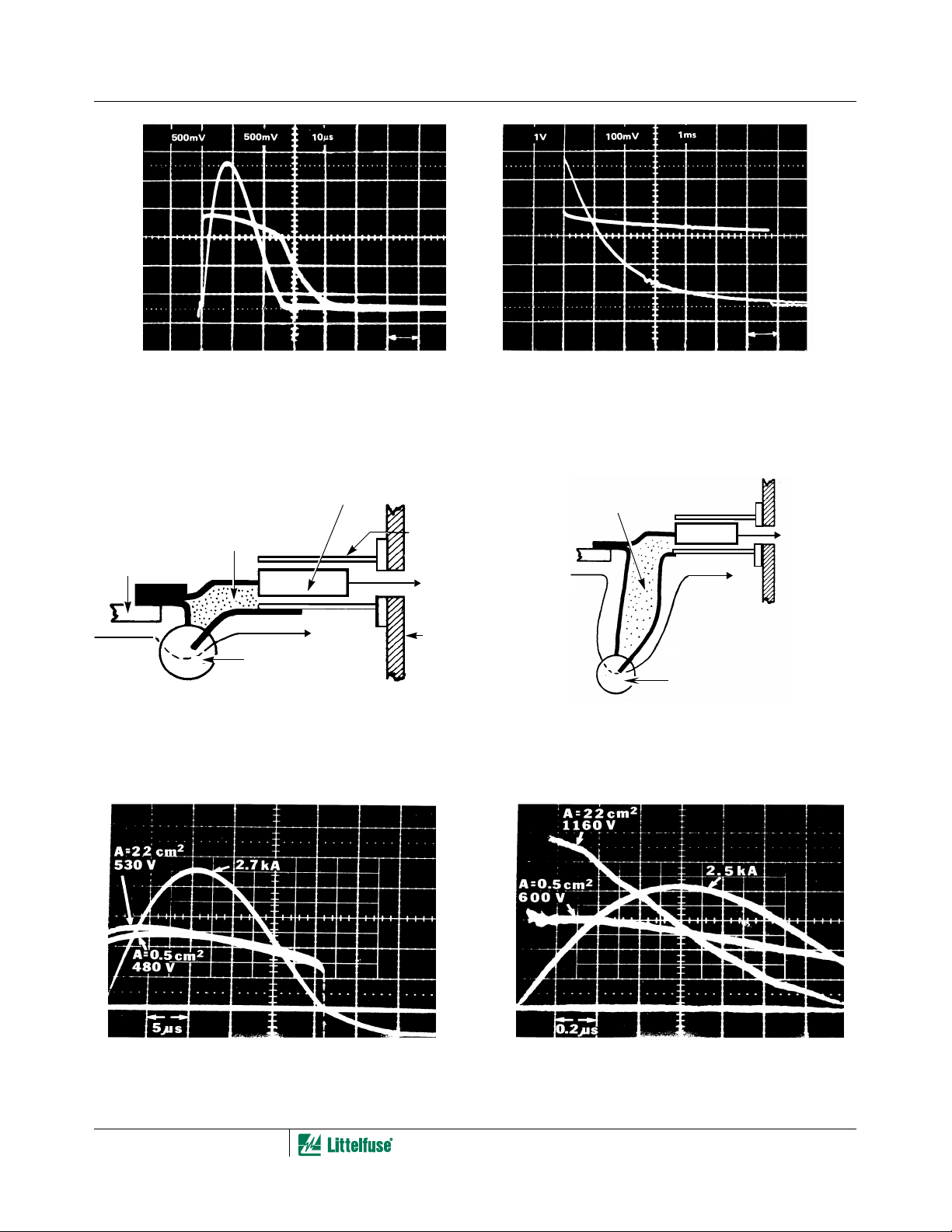

To illustrate the effect of lead length on the “overshoot,” two

measurement arrangements were used. As shown in Figures

6A and 6B, respectively, 0.5cm2 and 22cm2 of area were

enclosed by the leads of the varistor and of the voltage probe.

The corresponding voltage measurements are shown in the

oscillograms of Figures 6C and 6D. With a slow current front

of 8 µ s, there is little difference in the voltages occurring with

a small or large loop area, even with a peak current of 2.7kA.

With the steep front of 0.5 µ s, the peak voltage recorded with

the large loop is nearly twice the voltage of the small loop.

(Note on Figure 6D that at the current peak, L di/dt = 0, and

the two voltage readings are equal; before the peak, L di/dt

is positive, and after, it is negative.)

Hence, when making measurements as well as when

designing a circuit for a protection scheme, it is essential to

be alert to the effects of lead length (or more accurately of

loop area) for connecting the varistors. This is especially

important when the currents are in excess of a few amperes

with rise times of less than 1 µ s.

With reasonable care in maintaining short leads, as shown in

Figure 6A, it is possible to describe the “overshoot” effect as an

increase in clamping voltage relative to the value observed with

a 8/20 µ s impulse. Figure 7 shows a family of curves indicating

the effect between 8 µ s and 0.5 µ s rise times, at current peaks

ranging from 20A to 2000A. Any increase in the lead length, or

area enclosed by the leads, would produce an increase in the

voltage appearing across the varistor terminals - that is, the

voltage applied to the protected load.

DC Standby Current, I

This current is measured with a voltage equal to the rated

continuous DC voltage, V

The circuit of Figure 1 is applicable where current sensing

resistor R2 has a value of 1000 Ω . The test method is to set

the voltage supply, E1, to the specified value with switch S1

closed and S2 in the V position. Then S2 is placed in position

I and S3 in position, I

. S1 is then opened, the test device is

D

inserted in the test socket, and S1 is closed. The DVM

reading must be converted into current. For example, if a

maximum standby current of 200 µ A is specified, the

maximum acceptable DVM reading would be 0.200V.

The measurement of DC standby current can be sensitive to

the device behavioral phenomena of “break-in” stabilization

and polarization of the VI characteristics, as described in the

Nominal Varistor Voltage V

has prior unipolar electrical history, polarity indicators should

be observed and test values interpreted accordingly.

, applied across the varistor.

M(DC)

section. If the device under test

N

DEVICE: V130LA20A

LEAD AREA <1cm

1000

800

600

400

200

CLAMPING VOLTAGE (V)

10

FIGURE 8. TYPICAL “OVERSHOOT” OF LEAD-MOUNTED

VARISTOR WITH STEEP CURRENT IMPULSES

2

WAVESHAPE

0.5/1.5µs

1/3µs

8/20µs

604020

80100 200 400 600 800 1000 2000

PEAK CURRENT (A)

10-144

100

80

60

50

C (%)

o

40

30

20

VALUE AT 25

N

V

VARISTOR VOLTAGE IN PERCENT OF

10

-9

10

FIGURE 9. TYPICAL TEMPERATURE DEPENDENCE OF DC

C

o

o

50

25

-8

10

STANDBY CURRENT VARISTOR TYPE

V130LA10A

C

C

o

5

7

-7

10

VARISTOR CURRENT (ADC)

C

C

o

o

5

2

100

1

SPECIMEN: V130LA10A

-5

-6

10

10

-3

-4

10

10

-2

10

Page 5

Application Note 9773

1400

1200

1000

CAPACITANCE (pF)

800

600

10

FIGURE 10. CAPACITANCE VARIATION WITH FREQUENCY FIGURE 11. DISSIPATION FACTOR VARIATION WITH

2

3

10

10

10410

FREQUENCY (Hz)

X

X

XX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

5

10610710

X

X

X

X

X

X

X

X

X

X

X

X

X

8

The value of DC standby current also can be sensitive to

ambient temperature. This is unlike varistor characteristics

measured at currents of 1mA or greater, which are relatively

insensitive to ambient temperatures. With V

85% of V

, Figure 8 shows the typical DC standby current of

N

a model V130LA10A varistor in the order of 10 µ A or 20 µ A at

room temperature. I

increases to about 80 µ A at 85

D

M(DC)

around

o

C, the

0.12

x

x

0.10

0.08

0.06

0.04

DISSIPATION FACTOR, D

0.02

0

10210

10

FREQUENCY

3

4

10

FREQUENCY (Hz)

x

x

x

x

x

x

x

10

x

5

6

10

may be obtained by measurement methods similar to those

already given for nominal varistor voltage and maximum

clamping voltage. These miscellaneous characteristics may

be useful in some cases to enable comparison of Littelfuse

Varistors with other types of nonlinear devices, such as those

based on silicon carbide, selenium rectifier or zener diode

technologies.

maximum operating temperature without derating.

Capacitance

Since the bulk region of a Littelfuse Varistor acts as a

dielectric, the device has a capacitance that depends

directly on its area and varies inversely with its thickness.

Therefore, the capacitance of a Littelfuse Varistor is a

function of its voltage and energy ratings. The voltage

rating is determined by device thickness, and the energy

rating is directly proportional to volume.

Littelfuse Varistor capacitance can be measured through use

of a conventional capacitance bridge and is found to vary

with frequency, as shown in Figure 9. Typically, capacitance

measurements are made at 1MHz. Dissipation factor also is

frequency-dependent, as shown in Figure 10.

When measured with a DC bias, the capacitance and

dissipation factor show little change until the bias approaches

or exceeds the V

value. Furthermore, the capacitance change

N

caused by an applied voltage (either DC or AC) may persist

when the voltage is removed, with the capacitance gradually

returning to the prebias value. Because of this phenomenon, it

is important that the electrical history of a Littelfuse Varistor be

known when measuring capacitance.

Miscellaneous Characteristics

A number of characteristic measurements can be derived

from the basic measurements already described, including

the nonlinear exponent (alpha), static resistance, dynamic

impedance, and voltage clamping ratio. The data, however,

Varistor Rating Assurance Tests

Continuous Rated RMS and DC Voltage [V

and V

These are established on the basis of operating life tests

conducted at the maximum rated voltage for the product

model. These tests usually are conducted at the maximum

rated ambient operating temperature, or higher, so as to

accelerate device aging. Unless otherwise specified,

end-of-lifetime is defined as a degradation failure equivalent

to a V

point the device is still continuing to function. However, the

varistor will no longer meet the original specifications.

A typical operating life test circuit is shown in Figure 11. If

the varistor is intended principally for a DC voltage

application, then the AC power source should be changed to

DC. It is desirable to fuse the varistors individually so testing

is not interrupted on other devices if a fuse should blow. The

voltage sources should be regulated to an accuracy of ± 2%

and the test chamber temperature should be regulated to

within ± 3

fan to assure a uniform temperature throughout its interior.

The varistors should receive an initial readout of

characteristics at room ambient temperature i.e., 25 ± 3

They should then be removed from the chamber for

subsequent readout at 168,500, and 1000 hours. A minimum

of 20 minutes should be allowed before readout to ensure

that the devices have cooled off to the room ambient

temperature.

]

M(DC)

shift in excess of ± 10% of the initial value. At this

N

o

C. The chamber should contain an air circulation

x

x

x

x

x

x

x

x

7

10

M(AC)

8

10

o

C.

10-145

Page 6

Application Note 9773

FUSE

1/4A

130V

AC

±2%

V130LA10A

TEST CHAMBER

FIGURE 12. SIMPLIFIED OPERATING LIFE TEST CIRCUIT

Transient Peak Current, Energy, Pulse Rating, and

Power Dissipation Ratings

Special surge generator equipment is required for testing.

Since high energy must be stored at high voltages to

perform these tests, especially on larger sizes of Littelfuse

Varistors, the equipment must be operated using adequate

safety precautions.

The peak current rating, I

on an 8/20µs test impulse waveshape. The specifications

include a maximum single value in the ratings table. A pulse

rating graph defines the peak current rating for longer

impulse duration as well, such as for a 10/1000µs wave. A

family of curves defines the rated number of impulses with a

given impulse duration and peak current.

Energy rating, W

, is defined for a 10/1000µs current impulse

TM

test wave. This waveshape has been chosen as being the best

standard wave for tests where impulse energy, rather than peak

current, is of application concern. A direct determination of

energy dissipated requires that the user integrate over time the

product of instantaneous voltage and current.

Peak voltage and current are readily measured with

available equipment. Therefore, the energy rating can be

tested indirectly by applying the rated peak impulse current

of a 10/1000µs waveshape to the test specimen. Then, the

energy dissipated in the varistor can be estimated from the

known pulse waveshape. For a 10/1000µs waveshape the

approximate energy is given by the expression E = 1.4V

For example, a model V130LA10A varistor has a single pulse

rating for a 10/1000µs impulse waveshape of about 75A peak,

and a maximum clamping voltage at 75A of about 360V. Thus,

the computation of estimated energy dissipation is 38J.

The transient power dissipation rating, P

maximum average power of test impulses occurring at a

specified periodic rate. It is computed as the estimated energy

dissipation divided by the test pulse period. Therefore, varistors

can be tested against this rating by applying two or more

impulses at rated current with a specified period between

pulses. For example, a model V130LA10A varistor has a pulse

rating of two 10/1000µs test impulses with a peak current of

about 65A. The estimated energy dissipation per pulse

computed as per the preceding example is about 30J. If a

period of 50s is allowed after the first test pulse, the estimated

of Littelfuse Varistors is based

TM

, is defined as the

TA M

Iτ.

C

average power dissipation can be computed as about 0.6W,

which is the specification rating. It should be noted that

Littelfuse Varistors are not rated for continuous operation with

high-level transients applied. The transient power dissipation

rating is based on a finite number of pulses, and the pulse

rating of the varistor must be observed. See Figure 12.

1V

100mV

10/1000µs WAVEFORM

FIGURE 13. SURGE TEST WAVEFORMS

1ms

10A/DIV

100V/DIV

0

1ms/DIV

Table 1 outlines a suggested program of testing to verify

varistor transient and pulse ratings with a minimum of

expensive, time-consuming testing. New specimens should

be used for each test level and failure judged according to

the specification criteria.

TABLE 1. TESTING OF TRANSIENT CURRENT, ENERGY,

PARAMETER

Maximum Peak

Current

Pulse/Energy

Rating, Power

Dissipation

Pulse Rating 10 8/20 25

Pulse Rating 100 8/20 12

PULSE RATING, AND POWER DISSIPATION

RATINGS

NO. PULSES AT

RATED

TEST

CURRENT

(ALTERNATING

POLARITY)

1 (Same Polarity

as Readout)

2 10/1000 or

TEST

WAVESHAPE

2ms Square

Wave

MINIMUM

PULSE

(µs)

8/20 NA

PERIOD

(s)

50

Continuous Power Dissipation

Since Littelfuse Varistors are used primarily for transient

suppression purposes, their power dissipation rating has

been defined and tested under transient impulse conditions.

If the devices are to be applied as threshold sensors or

coarse voltage regulators in low power circuits, then a

dissipation test under continuous power is more appropriate.

This continuous power test will aid the user in determining if

the device is suitable for his specific application.

10-146

Page 7

Application Note 9773

A circuit for continuous power dissipation testing is shown

in Figure 13. The DC power supply voltage should be set to

a value of approximately twice the nominal varistor voltage

of the product model under test. In that case, nearly

constant power dissipation is maintained in the varistor.

Since the circuit transfers nearly equal power to the series

resistor and varistor-under-test, the series resistor value is

simply chosen to achieve the test design value of power

dissipation. In Figure 13 a nearly constant power

dissipation of about 0.6W is obtained.

68kΩ

1W

400V

DC

±2%

FIGURE 14. CONSTANT POWER LIFE TEST CIRCUIT

5%

V130LA10A

TEST CHAMBER

Mechanical and Environmental Testing of

Varistors

Introduction

Many tests have been devised to check the reliability of

electronic components when subjected to mechanical and

environmental stresses. Although individual equipment

makers may specify their own tests on component purchase

documents, these tests are often based on an equivalent

MIL-STD specification. Therefore, it is convenient to

summarize these tests in MIL-STD terms. Since the ratings

of Littelfuse Varistors may vary with product series and

model, the test conditions and limits should be as specified

on the applicable detail specification.

Littelfuse Varistors are available in a high reliability series.

This series incorporated most standard mechanical and

environmental tests, including 100% pre-screening and

100% process conditioning.

UL Recognition Tests

The standards of Underwriters Laboratories, Inc. (UL) under

which applicable Littelfuse Varistors have been tested and

recognized are:

• UL-1449 Transient Voltage Surge Suppressors, File E75961

• UL-1414 Across the Line Components, File E56529

• UL-497B Protectors for Data Communications, File E135010

The tests were designed by UL and included discharge

(withstand of charged capacitor dump), expulsion (of

complete materials), life, extended life, and flammability

(UL94V0) tests, etc.

Equipment for Varistor Electrical Testing

Impulse Generators

A convenient method of generating current or voltage surges

consists of slowly storing energy in a capacitor network and

abruptly discharging it into the test varistor. Possible energy

storage elements that can be used for this purpose include

lines (lumped or distributed) and simple capacitors,

depending on the waveshape desired for the test. Figure 14

shows a simplified schematic for the basic elements of an

impulse generator.

R1

R2

VARISTOR

UNDER

TEST

R3

OSCILLOSCOPE

V

COM

I

S2S1

L

E1

FIGURE 15. SIMPLIFIED CIRCUIT OF SURGE IMPULSE

C

GENERATOR

The circuit is representative of the type used to generate

exponentially decaying waves. The voltage supply, E1, is

used to charge the energy storage capacitor, C, to the

specified open-circuit voltage when switch S1 is closed.

When switch S2 (an ignition or a triggered gap) is closed, the

capacitor, C, discharges through the waveshaping elements

of the circuit into the suppressor device under test. With

capacitances in the order of 1µF to 10µF and charging

voltages of 10kV to 20kV, the typical 8/20µs or 10/1000µs

impulses can be obtained by suitable adjustment to the

waveshaping components L, R1, and R2, according to

conventional surge generator design [2, 3, 4, 5].

Measurement Instrumentation

Transient measurements include two aspects of varistor

application: (1) detection of transients to determine the need

for protection, and (2) laboratory measurements to evaluate

varistor performance. Transient detection can be limited to

recording the occurrence of transient overvoltages in a

particular system or involve comprehensive measurements

of all the parameters which can be identified. Simple

detection can be performed with peak-indicating or peakrecording instruments, either commercial or custom-made.

Test Waves and Standards

The varistor test procedures described in this section have

been established to ensure conformity with applicable

standards [6], as well as to reflect the electromagnetic

environment of actual circuits [7] which need transient

protection.

10-147

Page 8

Application Note 9773

Test Waves

A number of test waves have been proposed, in order to

demonstrate capability of survival or unimpeded

performance in the environment. A proposal also has been

made to promote a transient control level concept [7]

whereby a few selected test waves could be chosen by

common agreement between users and manufacturers. The

intent being that standard test waves would establish certain

performance criteria for electronic circuits.

Source Impedance

The effective impedance of the circuit which introduces the

transient is an extremely important parameter in designing a

protective scheme. Impedance determines the energy and

current-handling requirements of the protective device.

When a transient suppressor is applied, especially a

suppressor of the energy-absorbing type, such as a varistor,

the transient energy is then shared by the suppressor and

the rest of the circuit, which can be described as the

“source”.

As in the case of waveshapes, various proposals have been

made for standardizing source impedances. The following list

summarizes the various proposals intended for AC power lines:

1. The Surge Withstand Capability (SWC) standard

specified a 150Ω source.

2. The Ground Fault (UL-GFCI) standard is 50Ω source [8].

3. The Transient Control Level (TCL) proposals of Martzloff

et. al. [7] include a 50Ω resistor in parallel with a 50µH

inductor.

4. The installation category concept of ANSI/IEEE Standard

C62.41-1980 implies a range of impedances from 1Ω to

50Ω as the location goes from outside to inside.

5. The FCC regulation for line-connected telecommunication

equipment implies a 2.5Ω source impedance [9]. However,

the requirement of the FCC is aimed at ensuring a

permanent “burning” of a dielectric puncture and does not

necessarily imply that the actual source impedance in the

real circuits is 2.5Ω.

6. Reported measurements [10] indicate the preponderance

of the inductance in branch circuits. Typical values are µH

per meter of conductors.

7. There is no agreement among the above proposals on a

specific source impedance. Examining the numbers

closer, one can observe that there is a variance between

2.5Ω to about 50Ω. Going back to ANSI/IEEE Standard

C62.41-1980 by using the Open Circuit voltage (OCV)

and SCI (short circuit current) for the different location

categories, one can calculate a source impedance.

Any practical power circuit will always have some finite

impedance due to the resistance and inductance of the

power line and distribution transformer. Table 2 shows

representations of the surge source impedance implied in

the environment description of ANSI/IEEE C62.41-1980.

TABLE 2. SOURCE IMPEDANCE AT DIFFERENT LOCATION

CATEGORIES IN LOW VOLTAGE AC SYSTEMS (UP

TO 1000V)

Category A Ring Wave 6kV/200A = 30Ω

Category B Ring Wave 6kV/500A = 12Ω

Category B Impulse 6kV/3kA = 2Ω

Category C Impulse 10kV/10kA = 1Ω

The impedance of industrial or commercial systems

generally supplied by underground entrances, or a separate

substation of relatively large kVA rating, tends to be low, and

the injection of any lightning transients occurs at a remote

point. This results in lower transient peaks than those that

can be expected in residential circuits, but the energy

involved may be, in fact, greater. Therefore, transient

suppressors intended for industrial use should have greater

energy-handling capability than the suppressors

recommended for line-cord-powered appliances.

References

For Littelfuse documents available on the web, see

http://www.littelfuse.com/

[1] Fisher, F.A., “Overshoot - A Lead Effect in Varistor

Characteristics,” Report 78CRD, General Electric,

Schenectady, N.Y., 1978.

[2] Heller, B. and A. Veverka, “Surge Phenomena in

Electrical Machine”, ILIFFE Books Ltd., London, 1968.

[3] Greenwood, Allen, “Electrical Transients in Power

Systems”, Wiley Interscience, New York, 1971.

[4] Craggs, J.D. and J.M. Meek, “High Voltage Laboratory

Techniques”, Buttersworth Scientific Publications,

London, 1954.

[5] Martzloff, F.D., “Transient Control Level Test

Generators”, Report 77CRD241, General Electric,

Schenectady, N.Y., 1977.

[6] “Test Specifications for Varistor Surge-Protective

Devices”, ANSI/IEEE Std. C62.33, 1982.

[7] Martzloff, F.D., and F.A. Fisher, “Transient Control Level

Philosophy and Implementation - The Reasoning

Behind the Philosophy,” 77CH1224-5EMC,

“Proceedings of the 2nd Symposium on EMC”,

Montreux, June 1977.

[8] “Standard for Safety: Ground Fault Circuit Interrupters,”

UL943, Underwriters Laboratories, May 12,1976.

[9] “Longitudinal Voltage Surge Test #3,” Code of Federal

Regulations, Section 68.302(e), Title 47,

Telecommunications.

[10] F.D. Martzloff, “The Propagation and Attenuation of

Surge Voltages and Surge Currents in Low-Voltage AC

Circuits,” IEEE Transactions on Power Apparatus and

Systems, PAS-102, pp. 1163-1170, May 1983.

10-148

Loading...

Loading...