Page 1

Littelfuse Varistors - Basic Properties,

Terminology and Theory

What Is A Littelfuse Varistor?

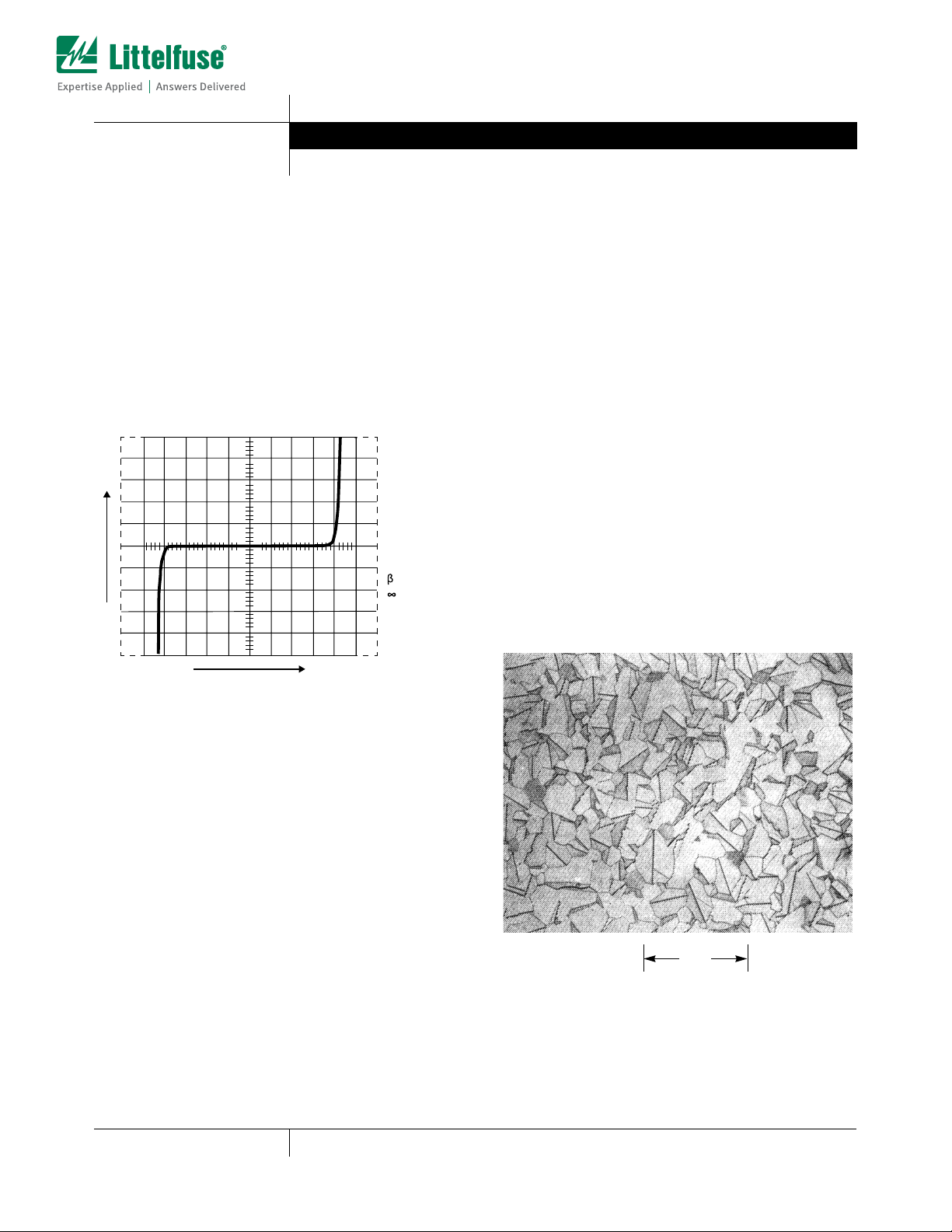

Varistors are voltage dependent, nonlinear devices which

have an electrical behavior similar to back-to-back zener

diodes. The symmetrical, sharp breakdown characteristics

shown in Figure 1 enable the varistor to provide excellent

transient suppression performance. When exposed to high

voltage transients the varistor impedance changes many

orders of magnitude from a near open circuit to a highly

conductive level, thus clamping the transient voltage to a

safe level. The potentially destructive energy of the incoming

transient pulse is absorbed by the varistor, thereby

protecting vulnerable circuit components.

PER VERT

DIV 1mA

PER HORIZ

DIV 50V

I

PER STEP

gm PER DIV

9991 yluJetoN noitacilppA

Littelfuse Varistors are available with AC operating voltages

from 2.5V to 6000V. Higher voltages are limited only by

packaging ability. Peak current handling exceeds 70,000A

and energy capability extends beyond 10,000J for the larger

units. Package styles include the tiny multilayer surface

mount suppressors, tubular devices for use in connectors,

and progress in size up to the rugged industrial device line.

AN9767.1

Physical Properties

Introduction

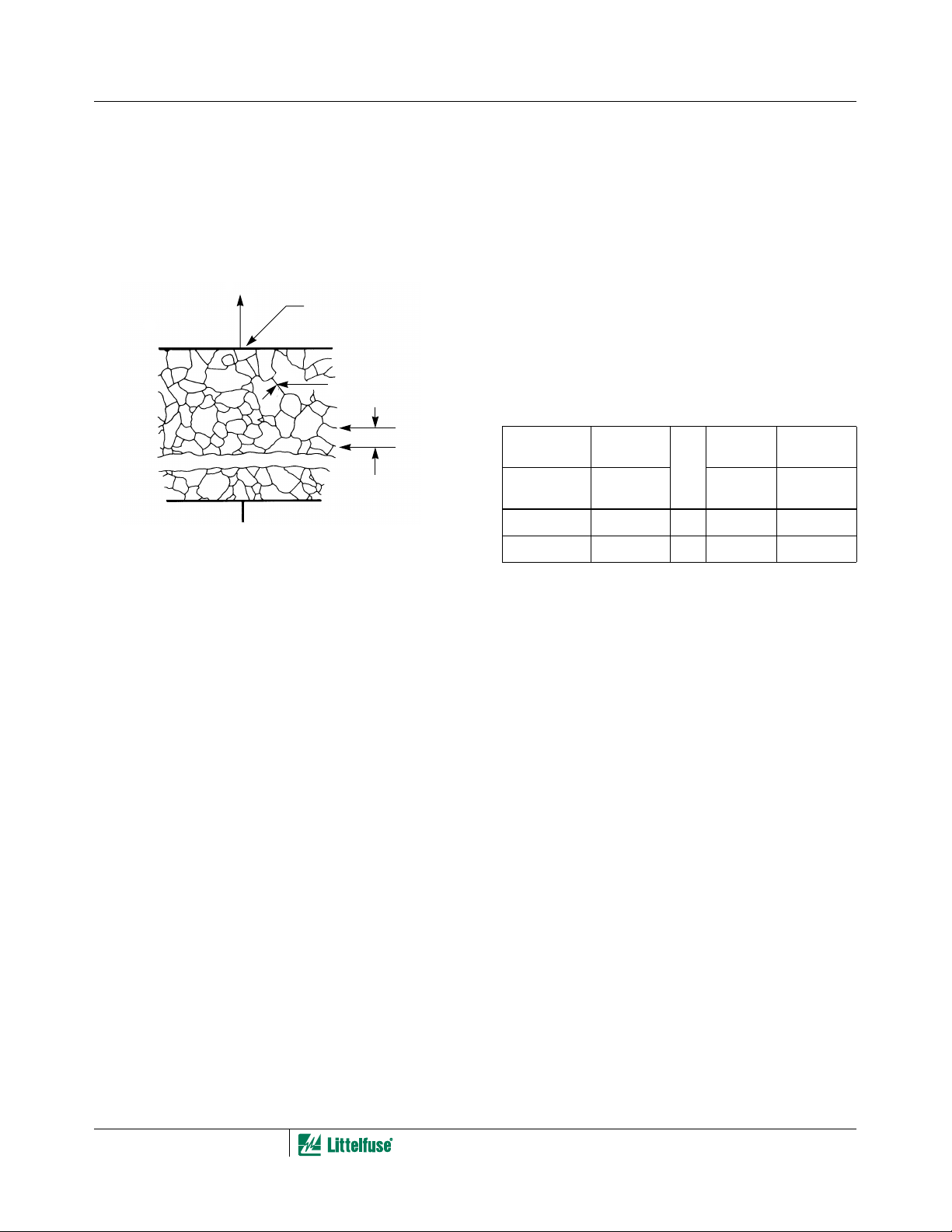

An attractive property of the metal oxide varistor, fabricated

from zinc oxide (ZnO), is that the electrical characteristics

are related to the bulk of the device. Each ZnO grain of the

ceramic acts as if it has a semiconductor junction at the

grain boundary. A cross-section of the material is shown in

Figure 2, which illustrates the ceramic microstructure. The

ZnO grain boundaries can be clearly observed. Since the

nonlinear electrical behavior occurs at the boundary of each

semiconducting ZnO grain, the varistor can be considered a

“multi-junction” device composed of many series and parallel

connections of grain boundaries. Device behavior may be

analyzed with respect to the details of the ceramic

microstructure. Mean grain size and grain size distribution

play a major role in electrical behavior.

V

FIGURE 1. TYPICAL VARISTOR V-I CHARACTERISTIC

The varistor is composed primarily of zinc oxide with small

additions of bismuth, cobalt, manganese and other metal

oxides. The structure of the body consists of a matrix of

conductive zinc oxide grains separated by grain boundaries

providing P-N junction semiconductor characteristics. These

boundaries are responsible for blocking conduction at low

voltages and are the source of the nonlinear electrical

conduction at higher voltages.

Since electrical conduction occurs, in effect, between zinc

oxide grains distributed throughout the bulk of the device, the

Littelfuse Varistor is inherently more rugged than its single PN junction counterparts, such as zener diodes. In the

varistor, energy is absorbed uniformly throughout the body of

the device with the resultant heating spread evenly through

its volume. Electrical properties are controlled mainly by the

physical dimensions of the varistor body which is sintered in

various form factors such as discs, chips and tubes. The

energy rating is determined by volume, voltage rating by

thickness or current ow path length, and current capability

by area measured normal to the direction of current ow.

100µ

FIGURE 2. OPTICAL PHOTOMICROGRAPH OF A POLISHED

AND ETCHED SECTION OF A VARISTOR

10-89

1-800-999-9445 or 1-847-824-1188 | Copyright © Littelfuse, Inc. 1999

Page 2

Application Note 9767

Varistor Microstructure

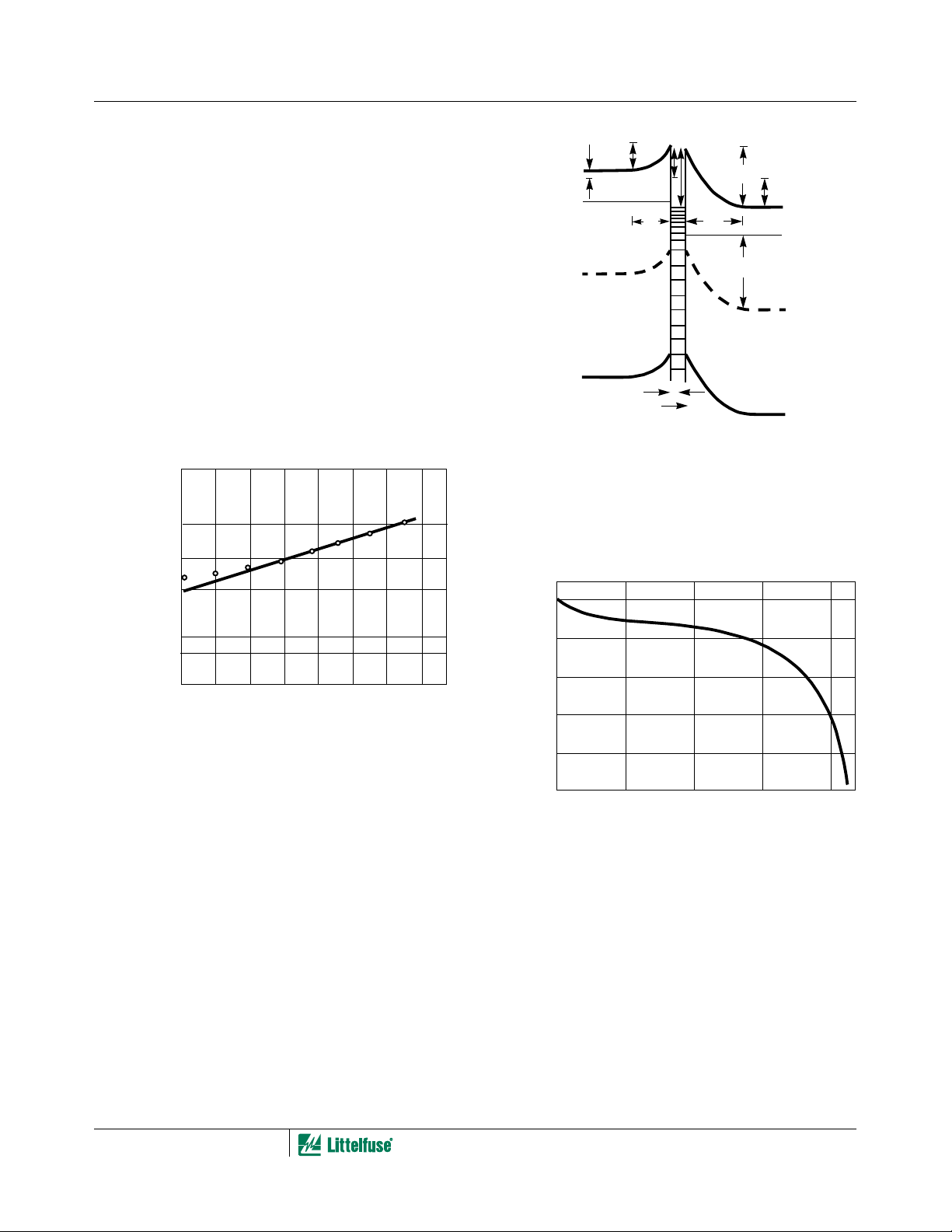

Varistors are fabricated by forming and sintering zinc

oxide-based powders into ceramic parts. These parts are

then electroded with either thick film silver or arc/flame

sprayed metal. The bulk of the varistor between contacts is

comprised of ZnO grains of an average size “d” as shown in

the schematic model of Figure 3. Resistivity of the ZnO is

<0.3 Ω -cm.

CURRENT

FIGURE 3. SCHEMATIC DEPICTION OF THE

MICROSTRUCTURE OF A METAL-OXIDE

VARISTOR. GRAINS OF CONDUCTING ZnO

(AVERAGE SIZE d) ARE SEPARATED BY

INTERGRANULAR BOUNDARIES

Designing a varistor for a given nominal varistor voltage, V

is basically a matter of selecting the device thickness such

that the appropriate number of grains, n, are in series

between electrodes. In practice, the varistor material is

characterized by a voltage gradient measured across its

thickness by a specific volts/mm value. By controlling

composition and manufacturing conditions the gradient

remains fixed. Because there are practical limits to the range

of thicknesses achievable, more than one voltage gradient

value is desired. By altering the composition of the metal

oxide additives it is possible to change the grain size “d” and

achieve the desired result.

A fundamental property of the ZnO varistor is that the

voltage drop across a single interface “junction” between

grains is nearly constant. Observations over a range of

compositional variations and processing conditions show a

fixed voltage drop of about 2V-3V per grain boundary

junction. Also, the voltage drop does not vary for grains of

different sizes.

It follows, then, that the varistor voltage will be determined by

the thickness of the material and the size of the ZnO grains.

The relationship can be stated very simply as follows:

ELECTRODES

INTERGRANULAR

BOUNDARY

d

N

Varistor Voltage, V

Where, n = average number of grain boundaries

and, varistor thickness, D = (n + 1)d

where, d = average grain size

The varistor voltage, V

(DC) = (3V)n

N

between electrodes

VNd×

-----------------

≈

3

, is defined as the voltage across a

N

varistor at the point on its V-I characteristic where the transition

is complete from the low-level linear region to the highly

nonlinear region. For standard measurement purposes, it is

arbitrarily defined as the voltage at a current of 1mA.

Some typical values of dimensions for Littelfuse Varistors are

given in Table 1.

TABLE 1.

VARISTOR

VOLTAGE

VOLTS MICRONS

150V

RMS

25V

RMS

NOTE: Low voltage formulation.

AVERAGE

GRAIN SIZE

20 75 150 1.5

80 (Note) 12 39 1.0

GRADIENT

V/mm AT

n

1mA mm

DEVICE

THICKNESS

Theory of Operation

,

Because of the polycrystalline nature of metal-oxide

semiconductor varistors, the physical operation of the device

is more complex than that of conventional semiconductors.

Intensive measurement has determined many of the device’s

electrical characteristics, and much effort continues to better

define the varistor's operation. In this application note we will

discuss some theories of operation, but from the user’s

viewpoint this is not nearly as important as understanding

the basic electrical properties as they relate to device

construction.

The key to explaining metal-oxide varistor operation lies in

understanding the electronic phenomena occurring near the

grain boundaries, or junctions between the zinc oxide grains.

While some of the early theory supposed that electronic

tunneling occurred through an insulating second phase layer

at the grain boundaries, varistor operation is probably better

described by a series-parallel arrangement of

semiconducting diodes. In this model, the grain boundaries

contain defect states which trap free electrons from the

n-type semiconducting zinc oxide grains, thus forming a

space charge depletion layer in the ZnO grains in the region

adjacent to the grain boundaries [6].

Evidence for depletion layers in the varistor is shown in

Figure 4 where the inverse of the capacitance per

boundary squared is plotted against the applied voltage per

boundary [7]. This is the same type of behavior observed

10-90

Page 3

Application Note 9767

for semiconductor abrupt P-N junction diodes. The

relationship is:

2V

1

-------

2

C

Where V

V+()

b

--------------------------=

qε sN

is the barrier voltage, V the applied voltage, q the

b

electron charge, ε s the semiconductor permittivity and N is

the carrier concentration. From this relationship the ZnO

carrier concentration, N, was determined to be about

2 x 10

17

per cm

3

[7]. In addition, the width of the depletion

layer was calculated to be about 1000 Angstrom units.

Single junction studies also support the diode model [9].

It is these depletion layers that block the free flow of carriers

and are responsible for the low voltage insulating behavior in

the leakage region as depicted in Figure 5. The leakage current

is due to the free flow of carriers across the field lowered

barrier, and is thermally activated, at least above about 25

(1014)

/cm

4

4

3

2

0 0.4 0.8 1.2

V

PER BOUNDARY

A

VARISTOR RESEMBLES A SEMICONDUCTOR

ABRUPT-JUNCTION REVERSED BIASED DIODE

Nd ~ 2 x 10

17

3

/cm

1

-------------

2n2

c

FIGURE 4. CAPACITANCE-VOLTAGE BEHAVIOR OF

o

C.

Figure 5 shows an energy band diagram for a ZnO-grain

boundary-ZnO junction [10].

biased, V

, and the right side is reverse biased to V

L

depletion layer widths are X

barrier heights are φ

is φ

. As the voltage bias is increased, φ

O

φ

is increased, leading to a lowering of the barrier and an

R

L

The left-hand grain is forward

and X

L

and φ

. The zero biased barrier height

R

, and the respective

R

is decreased and

L

. The

R

increase in conduction.

The barrier height φ

of a low voltage varistor was measured

L

as a function of applied voltage [11], and is presented in

Figure 6. The rapid decrease in the barrier at high voltage

represents the onset of nonlinear conduction [12].

φ

φ

B

0

V

E

C

E

E

E

V

FIGURE 5. ENERGY BAND DIAGRAM OF A

LφL

f

X

L

I

δ

ZnO-GRAINBOUNDARY-ZnO JUNCTION

φR

V

X

R

φ

F

0

R

Transport mechanisms in the nonlinear region are very

complicated and are still the subject of active research. Most

theories draw their inspiration from semiconductor transport

theory and the reader is referred to the literature for more

information [3, 5, 13, 14, 15]

o

φ

1.0

⁄

L

φ

0.8

0.6

0.59=

o

0.4

φ

0.2

0

NORMALIZED THERMAL BARRIER

0

FIGURE 6. THERMAL BARRIER vs APPLIED VOLTAGE

.

4

8

VOLTAGE (V)

12

16

Turning now to the high current upturn region in Figure 10,

we see that the V-I behavior approaches an ohmic

characteristic. The limiting resistance value depends upon

the electrical conductivity of the body of the semiconducting

ZnO grains, which have carrier concentrations in the range

17

of 10

to 10

18

per cm

3

. This would put the ZnO resistivity

below 0.3 Ω cm.

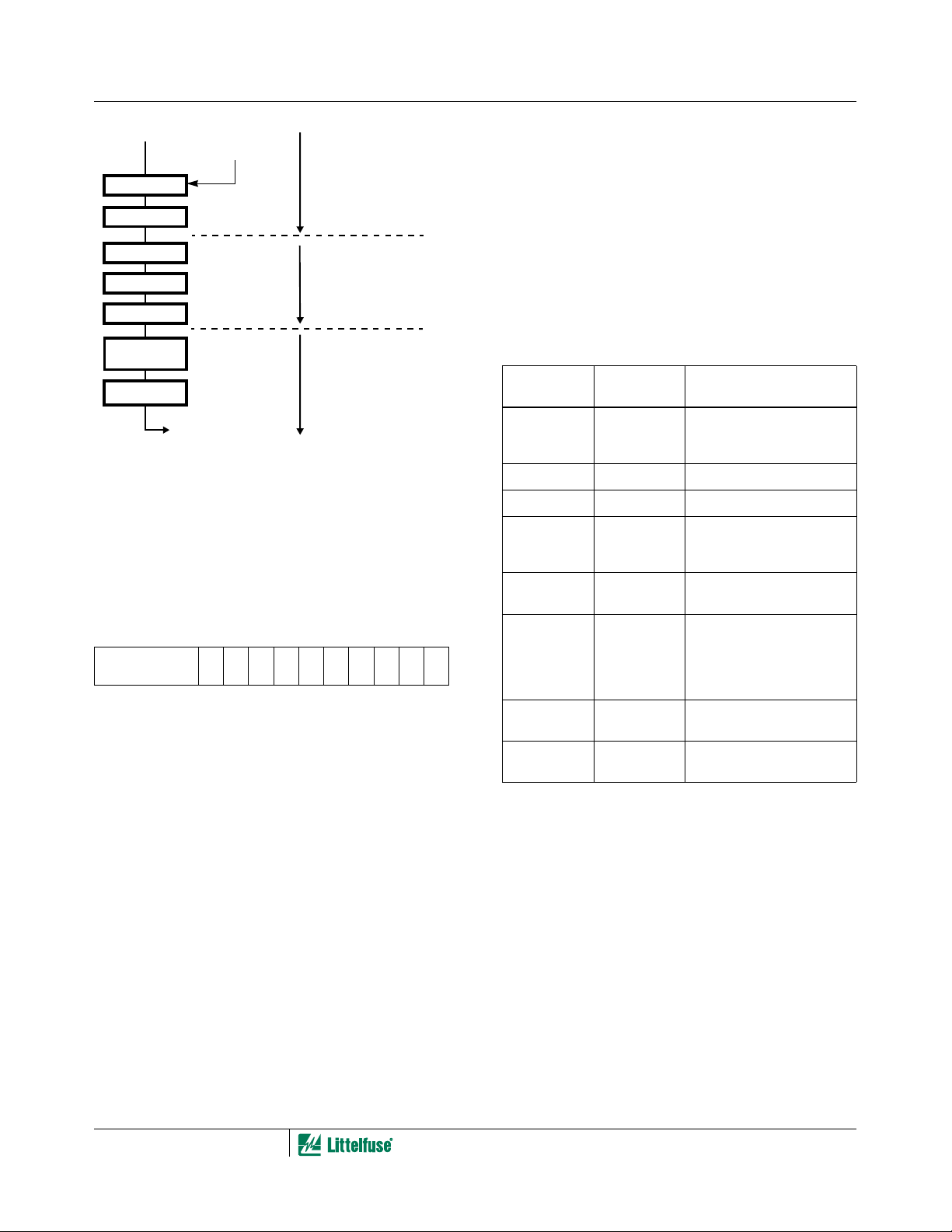

Varistor Construction

The process of fabricating a Littelfuse Varistor is illustrated in

the flow chart of Figure 7. The starting material may differ in

the composition of the additive oxides, in order to cover the

voltage range of product.

10-91

Page 4

Application Note 9767

ZnO

MIXING

POWDER

PRESS

SINTER

ELECTRODE

MECHANICAL

ASSEMBLY

ENCAPSULATE

FIGURE 7. SCHEMATIC FLOW DIAGRAM OF LITTELFUSE

ADDITIVE OXIDES

(MAINLY BL

FINAL PRODUCT TO

ELECTRICAL TEST

VARISTOR FABRICATION

203

)

POWDER PREPARATION

FORM CERAMIC BODY

PACKAGE AS/IF REQUIRED

Device characteristics are determined at the pressing

operation. The powder is pressed into a form of

predetermined thickness in order to obtain a desired value of

nominal voltage. To obtain the desired ratings of peak

current and energy capability, the electrode area and mass

of the device are varied. The range of diameters obtainable

in disc product offerings is listed here:

Nominal Disc

Diameter - mm

3 5 7 10 14 20 32 34 40 62

Of course, other shapes, such as rectangles, are also

possible by simply changing the press dies. Other ceramic

fabrication techniques can be used to make different shapes.

For example, rods or tubes are made by extruding and

cutting to length. After forming, the green (i.e., unfired) parts

are placed in a kiln and sintered at peak temperatures in

excess of 1200

o

825

C, assisting in the initial densification of the

o

C. The bismuth oxide is molten above

polycrystalline ceramic. At higher temperatures, grain growth

occurs, forming a structure with controlled grain size.

Radials are also available with phenolic coatings applied

using a wet process. The PA series package consists of

plastic molded around a 20mm disc subassembly. The RA,

DA, and DB series devices are all similar in that they all are

composed of discs or chips, with tabs or leads, encased in a

molded plastic shell filled with epoxy. Different package

styles allow variation in energy ratings, as well as in

mechanical mounting. Figures 8 and 9 illustrate several

package forms.

Figure 9 shows construction details of some packages.

Dimensions of the ceramic, by package type, are given in

Table 2.

TABLE 2. BY-TYPE CERAMIC DIMENSIONS

PACKAGE

TYPE SERIES CERAMIC DIMENSIONS

Leadless

Surface Mount

Connector Pin CP Series 22, 20, 16 ID Gauge Tube

Axial Leaded MA Series 3mm Diameter Disc

Radial

Leaded

Boxed, Low

Profile

Industrial

Packages

Industrial Discs CA, NA Series 32mm, 40mm, 60mm

Arrester AS Series 32mm, 42mm, 60mm

Littelfuse multilayer suppressor technology devices.

†

CH, AUML

ML

†

MLN

ZA, LA, “C” III,

UltraMOV™

Series

RA Series 5mm x 8mm, 10mm x 16mm,

PA Series

HA Series

HB Series

DA, DB Series

BA, BB Series

, MLE

Series

†

,

5mm x 8mm Chip, 0603, 0805,

†

1206, 1210, 1812, 2220

†

5mm, 7mm, 10mm, 14mm,

20mm Diameter Discs

14 x 22 Chips

20mm Diameter Disc

32mm, 40mm Diameter Disc

34mm Square Disc

40mm Diameter Disc

60mm Diameter Disc

Diameter Discs, 34mm Square

Diameter Discs

Electroding is accomplished, for radial and chip devices, by

means of thick film silver fired onto the ceramic surface. Wire

leads or strap terminals are then soldered in place. A

conductive epoxy is used for connecting leads to the axial

3mm discs. For the larger industrial devices (40mm and

60mm diameter discs) the contact material is arc sprayed

aluminum, with an overspray of copper if necessary to give a

solderable surface.

Many encapsulation techniques are used in the assembly of

the various Littelfuse Varistor packages. Most radials and

some industrial devices (HA Series) are epoxy coated in a

fluidized bed, whereas epoxy is “spun” onto the axial device.

10-92

Page 5

Application Note 9767

DA

BA

RA

AS

PA

CA

BB

DB

HA

MA

CP/CS CH AUML

FIGURE 8. PACKAGE FORMS

10-93

UltraMOV/LA/ ZA

ML

Page 6

Application Note 9767

PA SERIES

FIGURE 9A. CROSS-SECTION OF MA

PACKAGE

DB SERIES

FIGURE 9B. CROSS-SECTION OF

RADIAL LEAD PACKAGE

DA SERIES

FIGURE 9C. PICTORIAL VIEW OF

POWER MOV PACKAGE

BA/BB SERIES

FIGURE 9D. PICTORIAL VIEW OF HIGH ENERGY PACKAGES, DA, DB, AND BA/BB SERIES

Electrical Characterization

Varistor VI Characteristics

Varistor electrical characteristics are conveniently displayed

using log-log format in order to show the wide range of the

V-I curve. The log format also is clearer than a linear

representation which tends to exaggerate the nonlinearity

in proportion to the current scale chosen. A typical V-I

10-94

characteristic curve is shown in Figure 10. This plot shows a

wider range of current than is normally provided on varistor

data sheets in order to illustrate three distinct regions of

electrical operation.

Page 7

Application Note 9767

Ω

1000

500

200

100

50

VOLTAGE (V)

20

10

-8

10

LEAKAGE

REGION

Ω

9

0

1

=

R

10

-6

NORMAL VARISTOR

SLOPE =

-4

10

CURRENT (A)

OPERATION

1

---

α

(TYPICAL V130LA20A)

-2

10

0

10

I = kV

UPTURN

REGION

Ω

α

= 1 - 10

R

2

10

10

FIGURE 10. TYPICAL VARISTOR V-I CURVE PLOTTED ON

LOG-LOG SCALE

Equivalent Circuit Model

An electrical model for the varistor can be represented by

the simplified equivalent circuit of Figure 11.

(LEAD

L

INDUCTANCE)

(TYPICAL V130LA20A)

capacitance abruptly decreases. Capacitance remains nearly

constant with frequency change up to 100kHz. Similarly, the

change with temperature is small, the 25

capacitance being well within ± 10% from -40

o

C value of

o

C to 125

o

C.

The temperature effect of the V-I characteristic curve in the

leakage region is shown in Figure 13. A distinct temperature

dependence is noted.

100

80

60

50

C (%)

o

4

40

30

VALUE AT 25

20

NOM

V

VARISTOR VOLTAGE IN PERCENT OF

10

10

-8

-9

10

25 50 100

75

-7

10

VARISTOR CURRENT (A

SPECIMEN V130LA10A

125oC

-6

10

-5

10

10-410-310

)

DC

FIGURE 13. TEMPERATURE DEPENDENCE OF THE

CHARACTERISTIC CURVE IN THE LEAKAGE

REGION

-2

C

(0.002µF)

V

R

x

(0 TO ∞)

RON

(1Ω)

R

OFF

(1000MΩ)

FIGURE 11. VARISTOR EQUIVALENT CIRCUIT MODEL

Leakage Region of Operation

At low current levels, the V-I Curve approaches a linear

(ohmic) relationship and shows a significant temperature

dependence. The varistor is in a high resistance mode

(approaching 10

nonlinear resistance component, R

because R

insignificant compared to R

FIGURE 12. EQUIVALENT CIRCUIT AT LOW CURRENTS

For a given varistor device, capacitance remains

approximately constant over a wide range of voltage and

frequency in the leakage region. The value of capacitance

drops only slightly as voltage is applied to the varistor. As the

voltage approaches the nominal varistor voltage, the

9

) and appears as an open circuit. The

, can be ignored

OFF

X

.

L

R

OFF

in parallel will predominate. Also, R

OFF

C

ON

will be

The relation between the leakage current, I, and

temperature, T, is:

-V

/kT

B

I = IO ε

where:

I

= constant

O

k = Boltzmann’s Constant

V

= 0.9eV

B

The temperature variation, in effect, corresponds to a

change in R

resistance value even at elevated temperatures. For

example, it is still in the range of 10M Ω to 100M Ω at 125

Although R

. However, R

OFF

is a high resistance it varies with frequency.

OFF

remains at a high

OFF

o

C.

The relationship is approximately linear with inverse

frequency.

1

OFF

---

~

f

and C is

OFF

R

However, the parallel combination of R

predominantly capacitive at any frequency of interest. This is

because the capacitive reactance also varies approximately

linearly with 1/f.

At higher currents, at and above the milliamp range,

temperature variation becomes minimal. The plot of the

temperature coefficient (DV/DT) is given in Figure 14. It

should be noted that the temperature coefficient is negative

and decreases as current rises. In the clamping voltage range

of the varistor (I > 1A), the temperature dependency

approaches zero.

10-95

Page 8

Application Note 9767

NORMAL

OPERATION

0

10

10

10

2

1

10

0.1

C)

o

SAMPLE TYPE

V130LA10A

0

-0.1

-0.2

-0.3

-0.4

-0.5

TEMPERATURE COEFFICIENT (%/

10

V22ZA3

-4

-5

10

LEAKAGE REGION

-2

-3

10

10

CURRENT (A)

-1

10

NOTE: Typical Temperature Coefficient of Voltage vs Current, 14mm

Size, 55oC to 125oC.

FIGURE 14. RELATION OF TEMPERATURE COEFFICIENT

DV/DT TO VARISTOR CURRENT

Normal Varistor Region of Operation

The varistor characteristic follows the equation I = kVα,

where k is a constant and the exponent α defines the degree

of nonlinearity. Alpha is a figure of merit and can be

determined from the slope of the V-I curve or calculated from

the formula:

I

⁄()log

-------------------------------=

-------------------------------

.

ON

V

1

V

2I1

⁄()log

2V1

⁄()log

2V1

for I

⁄ 1==

2I1

ON

and R

will

. RX becomes many

OFF

but remains larger than

OFF

X

α

In this region the varistor is conducting and R

predominate over C, R

orders of magnitude less than R

R

Plots of typical resistance values vs current, I, are given in

Figure 16.

500

100

50

10

5

1

0.5

STATIC RESISTANCE

3

0.1

0.05

Ω PER RATED RMS INPUT VOLT)

(

0.01

0.01 0.1 1 10010

PEAK CURRENT (A)

FIGURE 16A. RX STATIC VARISTOR RESISTANCE FIGURE

5

1

0.5

0.01

0.05

0

.01

DYNAMIC RESISTANCE

0.005

Ω PER RATED RMS INPUT VOLT)

(

0.001

0.01 0.1 1.0 10 100

PEAK CURRENT (A)

FIGURE 16B. ZX DYNAMIC VARISTOR RESISTANCE

L

R

X

FIGURE 15. EQUIVALENT CIRCUIT AT VARISTOR CONDUCTION

During conduction the varistor voltage remains relatively

constant for a change in current of several orders of

magnitude. In effect, the device resistance, R

, is changing

X

in response to current. This can be observed by examining

the static or dynamic resistance as a function of current. The

static resistance is defined by:

V

R

----=

X

I

and the dynamic resistance by:

dv

Z

------ V αI⁄ R

X

di

α⁄== =

X

10-96

Upturn Region of Operation

At high currents, approaching the maximum rating, the varistor

approximates a short-circuit. The curve departs from the

nonlinear relation and approaches the value of the material bulk

resistance, about 1Ω-10Ω. The upturn takes place as R

approaches the value of R

. Resistor RON represents the

ON

bulk resistance of the zinc oxide grains. This resistance is linear

(which appears as a steeper slope on the log plot) and occurs

at currents 50A to 50,000A, depending on the varistor size.

L

R

ON

FIGURE 17. EQUIVALENT CIRCUIT AT VARISTOR UPTURN

X

Page 9

Application Note 9767

Speed of Response and Rate Effects

The varistor action depends on a conduction mechanism

similar to that of other semiconductor devices. For this

reason, conduction occurs very rapidly, with no apparent

time lag - even into the nanosecond range. Figure 18 shows

a composite photograph of two voltage traces with and

without a varistor inserted in a very low inductance impulse

generator. The second trace (which is not synchronized with

the first, but merely superimposed on the oscilloscope

screen) shows that the voltage clamping effect of the varistor

occurs in less than one nanosecond.

TRACE 1

LOAD

VOLTAGE

WITHOUT

VARISTOR

100V/DIV.

TRACE 2

LOAD

VOLTAGE

CLAMPED BY

VARISTOR

500ps/DIV.

FIGURE 18. RESPONSE OF A ZnO VARISTOR TO A FAST

RISE TIME (500ps) PULSE

In the conventional lead-mounted devices, the inductance of

the leads would completely mask the fast action of the

varistor; therefore, the test circuit for Figure 18 required

insertion of a small piece of varistor material in a coaxial line

to demonstrate the intrinsic varistor response.

Tests made on lead mounted devices, even with careful

attention to minimizing lead length, show that the voltages

induced in the loop formed by the leads contribute a

substantial part of the voltage appearing across the

terminals of a varistor at high current and fast current rise.

Fortunately, the currents which can be delivered by a

transient source are invariably slower in rise time than the

observed voltage transients. The applications most

frequently encountered for varistors involve current rise

times longer than 0.5µs.

Voltage rate-of-rise is not the best term to use when

discussing the response of a varistor to a fast impulse (unlike

spark gaps where a finite time is involved in switching from

nonconducting to conducting state). The response time of

the varistor to the transient current that a circuit can deliver is

the appropriate characteristic to consider.

The V-I characteristic of Figure 19A shows how the response

of the varistor is affected by the current waveform. From

such data, an “overshoot” effect can be defined as being the

relative increase in the maximum voltage appearing across

the varistor during a fast current rise, using the conventional

8/20µs current wave as the reference. Figure 19B shows

typical clamping voltage variation with rise time for various

current levels.

140

1000

CLAMPING VOLTAGE (V)

DEVICE: V130LA20A

(LEAD AREA <1cm

800

600

400

200

10

20 10040 60 200 400 600 1000 2000

2

) (NOTE)

PEAK CURRENT (A)

WAVESHAPE

0.5/1.5µs

1/3µs

8/20µs

FIGURE 19A. V-I CHARACTERISTICS FOR VARIOUS CURRENT

RISE TIMES

1000A/cm

130

120

110

100

% OF CLAMPING VOLTAGE AT 8µs

90

0.2 0.4 0.6 0.8 1 2 4 6 8 10

FIGURE 19B. OVERSHOOT DEFINED WITH REFERENCE TO

THE BASIC 8/20µs CURRENT PULSE

2

(2.5kA)

2

100A/cm

(250A)

2

10A/cm

(25A)

PULSE RISE TIME (µs)

NOTE: Refer to the Maximum Clamping Voltage section of DB450, Transient Voltage Suppression Devices.

FIGURE 19. RESPONSE OF LEAD-MOUNTED VARISTORS TO CURRENT WAVEFORM

10-97

DEVICE: V130LA20A

(LEAD AREA <1cm

2

) (NOTE)

100%

AT

8µs

Page 10

Application Note 9767

Varistor Terminology

The following tabulation defines the terminology used in

varistor specifications. Existing standards have been

followed wherever possible.

Definitions (IEEE Standard C62.33, 1982)

A characteristic is an inherent and measurable property of a

device. Such a property may be electrical, mechanical, or

thermal, and can be expressed as a value for stated

conditions.

A rating is a value which establishes either a limiting

capability or a limiting condition (either maximum or

minimum) for operation of a device. It is determined for

specified values of environment and operation. The ratings

indicate a level of stress which may be applied to the device

without causing degradation or failure. Varistor symbols are

defined on the linear V-I graph illustrated in Figure 20.

I

P

I

X

Test Waveform

At high current and energy levels, varistor characteristics are

measured, of necessity, with an impulse waveform. Shown in

Figure 21 is the ANSI Standard C62.1 waveshape, an

exponentially decaying waveform representative of lightning

surges and the discharge of stored energy in reactive

circuits.

The 8/20µs current wave (8µs rise and 20µs to 50% decay of

peak value) is used as a standard, based on industry

practices, for the characteristics and ratings described. One

exception is the energy rating (W

waveform of 10/1000µs is used. This condition is more

representative of the high energy surges usually

experienced from inductive discharge of motors and

transformers. Varistors are rated for a maximum pulse

energy surge that results in a varistor voltage (V

less than ±10% from initial value.

100

90

50

), where a longer

TM

) shift of

N

CURRENT (A)

I

N(DC)

I

PM

I

1000

V

N(DC)

VOLTAGE (V)

D

10

-6

10

V

M(DC)

VOLTAGE (V)

I

N(DC)

CURRENT (A)

V

PM

VARISTOR

SYMBOL

V

N(DC)VXVC

o

10

FIGURE 20. I-V GRAPH ILLUSTRATING SYMBOLS AND

DEFINITIONS

10

VIRTUAL START OF WAVE

CURRENT IN PERCENT OF PEAK VALUE

IMPULSE DURATION

VIRTUAL FRONT DURATION

= 1.25 x RISETIME FROM 10% TO 90%

PEAK CURRENT(A)

FIGURE 21. DEFINITION OF PULSE CURRENT WAVEFORM

10-98

Page 11

Application Note 9767

TABLE 3. VARISTOR CHARACTERISTICS (IEEE STANDARD C62.33-1982 SUBSECTION 2.3 AND 2.4)

TERMS AND DESCRIPTIONS SYMBOL

Clamping Voltage. Peak voltage across the varistor measured under conditions of a specified peak VC pulse current and specified

waveform. NOTE: Peak voltage and peak currents are not necessarily coincidental in time.

Rated Peak Single Pulse Transient Currents (Varistor). Maximum peak current which may be applied for a single 8/20µs im-

pulse, with rated line voltage also applied, without causing device failure.

Lifetime Rated Pulse Currents (Varistor). Derated values of ITM for impulse durations exceeding that of an 8/20µs waveshape,

and for multiple pulses which may be applied over device rated lifetime.

Rated RMS Voltage (Varistor). Maximum continuous sinusoidal RMS voltage which may be applied. V

Rated DC Voltage (Varistor). Maximum continuous DC voltage which may be applied. V

DC Standby Current (Varistor). Varistor current measured at rated voltage, V

For certain applications, some of the following terms may be useful.

Nominal Varistor Voltage. Voltage across the varistor measured at a specified pulsed DC current, I

I

of specific duration. I

N(DC)

is specified by the varistor manufacturer.

N(DC)

Peak Nominal Varistor Voltage. Voltage across the varistor measured at a specified peak AC current, I

I

is specified by the varistor manufacturer.

N(AC)

Rated Recurrent Peak Voltage (Varistor). Maximum recurrent peak voltage which may be applied for a specified duty cycle and

waveform.

Rated Single Pulse Transient Energy (Varistor). Energy which may be dissipated for a single impulse of maximum rated current

at a specified waveshape, with rated RMS voltage or rated DC voltage also applied, without causing device failure.

Rated Transient Average Power Dissipation (Varistor). Maximum average power which may be dissipated due to a group of

pulses occurring within a specified isolated time period, without causing device failure.

Varistor Voltage. Voltage across the varistor measured at a given current, IX. V

Voltage Clamping Ratio (Varistor). A figure of merit measure of the varistor clamping effectiveness as defined by the symbols

VC/V

M(AC)

, VC/V

M(DC)

.

Nonlinear Exponent. A measure of varistor nonlinearity between two given operating currents, I1 and I2, as described by I = kV

where k is a device constant, I

α

12

I2I1⁄log

--------------------------=

V

⁄log

2V1

≤ I ≤ I2, and

1

.I

M(DC)

, of specific duration.

N(DC)

, of specific duration.

N(AC)

V

V

W

P

T(AV)M

------------

V

α

V

C

I

TM

-

M(AC

M(DC)

D

N(DC)

N(AC)

V

PM

TM

X

V

C

PM

α

)

Dynamic Impedance (Varistor). A measure of small signal impedance at a given operating point as defined by: Z

dV

X

-----------=

Z

X

dI

X

Resistance (Varistor). Static resistance of the varistor at a given operating point as defined by: R

V

X

R

-------=

X

I

X

Capacitance (Varistor). Capacitance between the two terminals of the varistor measured at C specified frequency and bias. C

AC Standby Power (Varistor). Varistor AC power dissipation measured at rated RMS voltage V

Voltage Overshoot (Varistor). The excess voltage above the clamping voltage of the device for a given current that occurs when

.P

M(AC)

V

current waves of less than 8µs virtual front duration are applied. This value may be expressed as a % of the clamping voltage (VC)

for an 8/20 current wave.

Response Time (Varistor). The time between the point at which the wave exceeds the clamping voltage level (VC) and the peak

of the voltage overshoot. For the purpose of this definition, clamping voltage as defined with an 8/20µs current waveform of the

same peak current amplitude as the waveform used for this response time.

Overshoot Duration (Varistor). The time between the point voltage level (VC) and the point at which the voltage overshoot has

decayed to 50% of its peak. For the purpose of this definition, clamping voltage is defined with an 8/20µs current waveform of the

same peak current amplitude as the waveform used for this overshoot duration.

10-99

X

X

D

OS

-

-

Page 12

Application Note 9767

How to Connect a Littelfuse Varistor

Transient suppressors can be exposed to high currents for

short durations in the nanoseconds to millisecond time

frame.

Littelfuse Varistors are connected in parallel to the load, and

any voltage drop in the leads to the varistor will reduce its

effectiveness. Best results are obtained by using short leads

that are close together to reduce induced voltages and a low

ohmic resistance to reduce I • R drops.

Electrical Connections

Single Phase

LINE

1

NEUTRAL

3 2

GND

FIGURE 22.

This is the most complete protection one can select, but in

many cases only Varistor 1 or Varistor 1 and 2 are selected.

LINE

SINGLE PHASE

2 WIRE 110V

SINGLE PHASE

2 WIRE 240V

SINGLE PHASE

3 WIRE 120V/240V

LINE

GND OR

NEUTRAL

LINE

FIGURE 23.

GND

LINE

GND

110V

240V

120V

240V

120V

3 Phase

SUPPRESSOR

CONNECTION

1

3

8

0

V

220V

4

23

110V

220V

23

SUPPRESSOR

CONNECTION

220V

FIGURE 24A. 3 PHASE 220V/380V,

UNGROUNDED

LOWER

VOLTAGE

1

220V 220V

4

110V

FIGURE 24D. 3 PHASE 220V

1 - 4

2 - 4

3 - 4

1 - 3

1 - 2

2 - 4

3 - 4

SUPPRESSOR

CONNECTION

1 - 2

2 - 3

(3

8

0

V

)

1

220V 220V

220V

3 - 1

23

FIGURE 24B. 3 PHASE 220V OR 380V,

UNGROUNDED

SUPPRESSOR

CONNECTION

21

2

0

8

2

110V

8

0

V

110V

V

3

110V

208V

1 - 2

1 - 3

3 - 2

1 - GND

2 - GND

3 - GND

If only 3 suppressor use 1-GND, 2-GND,

3-GND

FIGURE 24E. 3 PHASE 120V/208V, 4-WIRE

SUPPRESSOR

CONNECTION

1 - 2

2 - 3

1

220V 220V

220V

1 - 3

23

FIGURE 24C. 3 PHASE 220V, ONE PHASE

GND

SUPPRESSOR

CONNECTION

21

4

1

5

240V

1

4

V

240V

V

5

240V

3

1 - 2

1 - 3

3 - 2

1 - GND

4

1

5

V

2 - GND

3 - GND

If only 3 suppressor use 1-GND, 2-GND,

3-GND

FIGURE 24F. 3 PHASE 240V/415V

For higher voltages use same connections, but select varistors for the appropriate voltage rating.

10-100

Page 13

Application Note 9767

DC Applications

DC applications require connection between plus and minus

or plus and ground and minus and ground.

For example, if a transient towards ground exists on all

3 phases (common mode transients) only transient

suppressors connected phase to ground would absorb

energy. Transient suppressors connected phase to phase

would not be effective.

COMMON

MODE

TRANSIENT

FIGURE 25A. INCORRECT

FIGURE 25. COMMON MODE TRANSIENT AND CORRECT

SOLUTION

On the other hand if a differential mode of transient (phase to

phase) exists then transient suppressors connected phase

to phase would be the correct solution.

DIFFERENTIAL

MODE

TRANSIENT

FIGURE 26A. INCORRECT

FIGURE 26. DIFFERENTIAL MODE TRANSIENT AND CORRECT

SOLUTION

This is just a selection of some of the more important

variations in connecting transient suppressors.

The logical approach is to connect the transient suppressor

between the points of the potential difference created by the

transient. The suppressor will then equalize or reduce these

potentials to lower and harmless levels.

FIGURE 25B. CORRECT

FIGURE 26B. CORRECT

References

For Littelfuse documents available on the web, see

http://www.littelfuse.com/

[1] Harnden, J.D., F.D. Martzloff, W.G. Morris and F.B.

Golden, “The GEMOV® Varistor - The Super Alpha

Varistor” Electronics, Vol. 45, No. 21,1972, p. 91.

[2] Morris, W.G., “Electrical Properties of ZnO-Bi

Ceramics,” Journal of the Am. Ceram. Soc., Vol. 56,

1973.

[3] Matsuoka, M., “Non-Ohmic Properties of Zinc Oxide

Ceramics,” Japanese Jnl. Appl. Phys., Vol. 10,1971, p.

736.

[4] Mahan, G., L. Levinson and H. Philipp, “Single Grain

Junction Studies at ZnO Varistors Theory &

Experiment,” Report #78CRF160, General Electric,

Schenectady, N.Y., 1978. Forthcoming in Applied

Physics Letters.

[5] Mahan, G., L. Levinson and H. Philipp, “Theory of

Conduction in ZnO Varistors,” Journal of Applied

Physics (in press).

[6] Levine, J.D., “Theory of Varistor Electronic Properties,”

Critical Review of Solid State Science, 5,1975, pp.

597-608.

[7] May, J.E., “Carrier Concentration and Depletion Layer

Model of Zinc Oxide Varistors,” Bulletin of the American

Ceramic Society, Vol. 57, No. 3, 1978, p. 335.

[8] Sze, S.M., “Physics of Semiconductor Devices,” John

Wiley & Sons, New York, N.Y., 1969.

[9] Einzinger, R., “Microcontact Measurement of ZnO

Varistors,” Ber. Dt. Keram, Vol. 52, 1975, pp. 244-245.

[10] Lou, L.F., “Current- Voltage Characteristics of ZnO-

Bi

Heterojunction,” Journal of Applied Physics,

2O3

Vol. 50, 1979, p. 555.

[11] Lou, L.F. “Semiconducting Properties of ZnO-Grain

Boundary-ZnO Junctions in Ceramic Varistors,” Appl.

Phys. Letters, Vol. 36, 1980, pp. 570-572.

[12] Lou, L.F., and J.E. May, Unpublished Research,

General Electric, Syracuse, N.Y., 1981.

[13] Morris, W., “Physical Properties of the Electrical

Barriers in Varistors,” J. Vac. Sci. Technol., 13,1976,

pp. 926-931.

[14] Bernasconi, J., S. Strassler, B. Knecht, H. Klein and A.

Menth, Solid State Communication, Vol. 21,1977,

pp. 867-869.

[15] Pike, G. and C. Seager, “The DC Voltage Dependence

of Semiconductor Grain-Boundary Resistance,” Journal

of Appl. Phys., Vol. 50, 1979, pp. 3414-3422

2O3

10-101

Loading...

Loading...