Page 1

AF0100

ARC-FLASH RELAY

Instruction Manual

REVISION 0-B-013118

E-mail: techline@littelfuse.com

Tel: +1-800-832-3873

www.littelfuse.com/AF0100

Document Number: PM-1430-EN

Copyright © 2018 Littelfuse

All rights reserved.

Page 2

AF0100 Arc-Flash Relay

This page intentionally left blank.

Page i

REV. 0-B-013118

Page 3

AF0100 Arc-Flash Relay

TABLE OF CONTENTS

1 KEY FEATURES ......................................................1

1.1 Easy Installation ......................................1

1.2 Fail-Safe Operation .................................. 1

1.3 Fast Error and Fault Location ................... 1

1.4 USB Interface ........................................... 1

2 ARC-FLASH PROTECTION SYSTEM DESIGN

3 SENSOR PLACEMENT

........................................... 5

3.1 General Guidelines ..................................5

3.2 Switchgear Protection .............................5

3.3 Transformer Protection ............................5

3.4 Generator Protection ...............................5

4 OPTICAL SENSORS

...............................................6

4.1 PGA-LS10 Photoelectric Point Sensor

with Sensor Check ................................... 7

4.1.1 PGA-LS10 Connection .............................8

4.1.2 PGA-LS10 Installation .............................9

4.2 PGA-LS20 and PGA-LS30

Fiber-Optic Sensors with

Sensor Check ......................................... 10

4.2.1 Fiber Connection ....................................10

4.2.2 Receiver Wiring Connections ................10

4.2.3 Transmitter Wiring Connections ...........10

4.2.4 PGA-LS20 and PGA-LS30 Connection ....

4.2.5 Fiber-Optic Sensor Adjustment .............12

4.2.6 Sensor Adjustment For a Fiber Length

Other Than 60 cm (24 in) ....................... 12

...... 3

11

Page ii

REV. 0-B-013118

7 USER INTERFACE

................................................ 18

7.1 Reset Button .......................................18

7.2 LED Indication and

Relay Operation ..................................18

7.3 USB Conguration Software ...............20

7.3.1 USB Conguration Software –

Screen Examples .................................21

7.4 Firmware Upgrade ..............................24

8 COMMISSIONING

............................................... 25

8.1 Conguration of Installed Sensors .....25

8.2 Testing the Sensors ............................ 25

8.3 Testing the TRIP 1 and TRIP 2 Outputs

and Associated Circuit Breakers ........26

8.4 Full Operation Test..............................26

9 SUPPORT RESOURCES

.......................................27

9.1 Sending Information for Support ................27

10 SPECIFICATIONS

................................................. 28

10.1 AF0100 ...............................................28

10.2 EMC Tests ..........................................29

10.3 Environmental Tests ........................... 29

10.4 Safety ................................................. 30

10.5 Certication ........................................ 30

10.6 Sensors ...............................................31

10.7 Ordering Information ..........................32

10.8 Related Products ................................32

10.9 Warranty ............................................32

5 APPLICATION EXAMPLES

................................... 13

5.1 Basic Scenario: One Sensor –

One Circuit Breaker ...............................13

5.2 Total Clearing Time ...............................14

5.2.1 Arc-Detection Delay ..............................14

5.2.2 Circuit Breaker Operating Time .............14

5.2.3 Total Clearing Time Examples ...............14

6 INSTALLATION AND TERMINALS

6.1 Power Supply.......................................16

6.1.1 Line AC Supply (optional) .................... 16

6.1.2 Station Battery DC Supply (optional) ..16

6.1.3 Auxiliary DC Supply ............................. 16

6.1.4 Supply Surveillance ............................. 16

6.2 Inputs and Outputs .............................. 17

6.2.1 ERROR Signal Relay ............................17

6.3 Sensors ................................................17

6.3.1 Light Immunity Adjustment ................. 17

6.3.2

Extending or Shortening Cable Length ....

..................... 15

17

Page 4

AF0100 Arc-Flash Relay

Page iii

REV. 0-B-013118

APPENDIX A: INSTALLATION LOG SHEET

.............34

APPENDIX B: REDUNDANT TRIP

CIRCUIT DESCRIPTION

APPENDIX C: AF0100 REVISION HISTORY

.............................................35

.............36

LIST OF FIGURES

1 AF0100 Top View (ordering option

AF0100-00 shown) ....................................... 2

2 AF0100 with Sensor and USB View

(ordering option AF0100-00 shown) ............ 2

3 AF0100 Typical Wiring Diagram ..................4

4

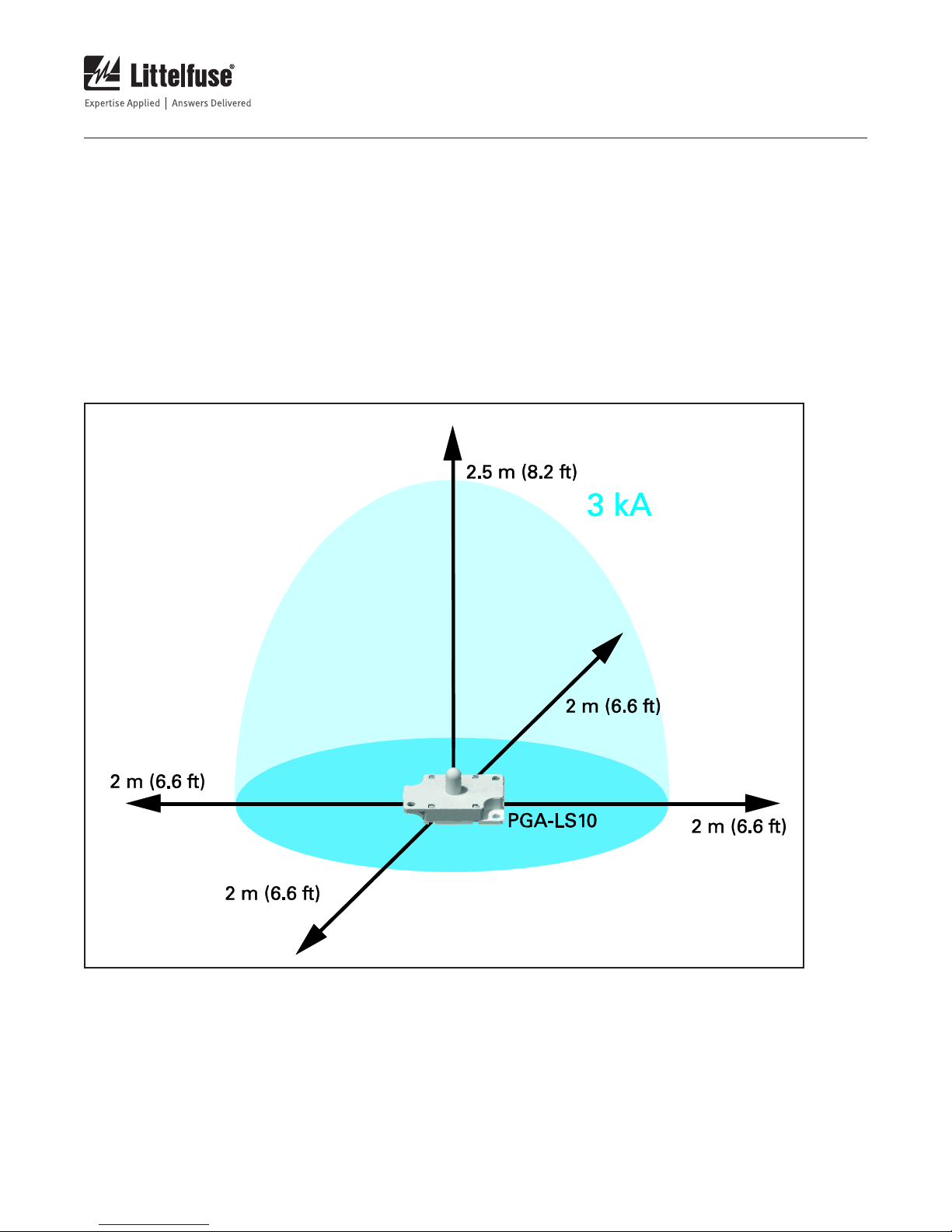

PGA-LS10 Detection Range for a

3 kA Fault .........................................................

5 PGA-LS10 Connection Diagram ...................8

6 PGA-LS10 Mounting Detail .........................9

7 PGA-LS20 and PGA-LS30

Connection Diagram .................................. 11

8 Basic AF0100 Conguration ......................13

9 AF0100 Outline And

Mounting Details ....................................... 15

10 TRIP and ERROR Relays

Maximum Switching Capacity ....................33

7

LIST OF TABLES

1 Circuit Breaker Operating Time .................14

2 AF0100 Firmware Upgrade Sequence ......24

3

Sample Table for Testing a System

............26

Page 5

AF0100 Arc-Flash Relay

Page 1

REV. 0-B-013118

1 KEY FEATURES

The AF0100 Arc-Flash Relay is a high-speed, arc-detection

device for electrical power-distribution systems. The AF0100

has two Form-C Trip relays, and has inputs for up to two

optical sensors for optimal arc detection. The inputs support

both point sensors and fiber-optic line sensors, which cover

a larger area.

Using optical sensors rather than relying strictly on current

measurement allows a much faster detection time than

overcurrent relays or a circuit breaker alone can typically

provide, as the light from the arc is unique to arc faults,

whereas current pulses above the nominal level are part of

normal operation for many systems.

On the occurrence of an arc fault, the AF0100 detects the

fault and activates the trip relays, which trips the circuit

breaker(s) supplying the fault. In a typical system, a trip occurs

within 5ms. The total arcing time is effectively reduced to

the mechanical opening time of the circuit breaker, typically

between 30 and 75 milliseconds. This reduces the energy of

the arc fault significantly, increasing worker safety, reducing

fault damage, and improving uptime.

The AF0100 can be used on ac or dc electrical systems and

can be powered from either an ac or dc supply, or both. For

all available ordering options, see section 10.7.

1.1 Easy Installation

The relay will automatically learn which sensors and

power supplies are connected, and will indicate an alarm

if a previously connected wire breaks or is unplugged. If a

configuration change is needed, the redetection process

can be triggered by pressing the Reset button for 20 s, see

section 7.1.

1.2 Fail-Safe Operation

The AF0100 continuously monitors its internal circuitry as

well as the connected optical sensors. Any system faults,

including a sensor-cable fault, are indicated by an Error relay

and the Error LED on the front panel.

A redundant trip circuit ensures that the AF0100 will trip

the circuit breaker on an arc flash even if a primary tripcircuit component fails (shunt trip mode only). The design

of the redundant trip circuit also provides a significantly

faster response to an arc on power-up (for example, after

maintenance during a shutdown) than is possible with

microprocessor-only relays, which is an advantage in smaller

self-powered systems.

1.3 Fast Error and Fault Location

The optical sensors used with the AF0100 have built-in LED’s

for indication of health and for easy location of arc faults.

The AF0100 also has one LED per optical sensor on the front

panel to indicate which sensor(s) have caused a trip and for

indicating problems in the installation.

The AF0100 includes two sensor inputs, two trip relays,

one error relay, and a digital input and output interface

which makes it possible to connect additional AF0100 or

AF0500 units. See Fig. 1. The complete configuration and

“programming” of the system can be done by simply wiring

the inputs and outputs marked with green arrows – no

external software is needed.

A system with multiple zones and upstream circuit breakers

can be implemented such that in many applications, the

switchboard wiring diagram can completely describe how

the arc-flash system works.

1.4 USB Interface

A USB interface on the lower panel of the AF0100 provides

easy PC access to configuration settings. No PC driver or

software installation is required.

Page 6

AF0100 Arc-Flash Relay

Page 2

REV. 0-B-013118

FIGURE 1. AF0100 Top View (ordering option AF0100-00 shown).

FIGURE 2. AF0100 with Sensor and USB View (ordering option AF0100-00 shown).

Page 7

AF0100 Arc-Flash Relay

Page 3

REV. 0-B-013118

2 ARC-FLASH PROTECTION SYSTEM DESIGN

In order to find the necessary components and configuration

for protecting a system, a single line diagram and knowledge

of the physical configuration of the system is needed.

1. Start by identifying the number and type of sensors

that are needed to have coverage of the complete

system. In order to have complete coverage, all

bus bar sections, circuit breaker connection points,

and bolted connections must have a sensor nearby.

Typically, a single point sensor per enclosed

switchgear compartment is sufficient, but if a large

internal component is blocking the line-of-sight, an

additional sensor may be necessary. A fiber sensor

can be threaded along a bus bar to protect many

compartments, but only if they are interrupted by

the same circuit breaker. The fiber sensor can also

be used to improve coverage of compartments with

many bulky components.

2. Identify which circuit breakers to open in order to

completely interrupt all current to each sensor. If

more sensors are isolated by the same set of circuit

breakers, these are said to be in the same zone – an

arc-flash event on any of these sensors will open the

same set of circuit breakers.

4. Based on the number of sensors and zones, the

necessary number of outputs and sensors can be

found. Each AF0100 provides one zone (one or two

circuit breaker outputs) and two sensor inputs, which

can be bundled into larger zones by a single wire, and

which can combine fiber and point sensors completely

as needed.

5. Now, place one AF0100 trip output for each circuit

breaker in the system. If there are more than two

sensors per zone, connect additional AF0100 or

AF0500 zones together by connecting the “TRIP” and

“TRIPPED” terminals in all zones. Zones can also be

made larger by using a sensor covering a larger area,

i.e. by changing point sensors to fiber sensors. Place

the sensors in the cabinets, and connect them to the

zone inputs. The sensor cables, which use copper

wire, can be shortened or extended as needed.

3. Identify if the system needs coordinated tripping – if

upstream circuit breakers, which trips the incoming

feeder for several downstream circuit breakers, are

present in the system, a decision must be made to

either merge all the smaller zones and trip all circuit

breakers at once (fast and inexpensive, but may trip

more outgoing feeders than necessary), or to only

trip the upstream circuit breaker if the downstream

circuit breaker fails to interrupt the current (slower

and costlier, but trips only what is necessary).

Page 8

AF0100 Arc-Flash Relay

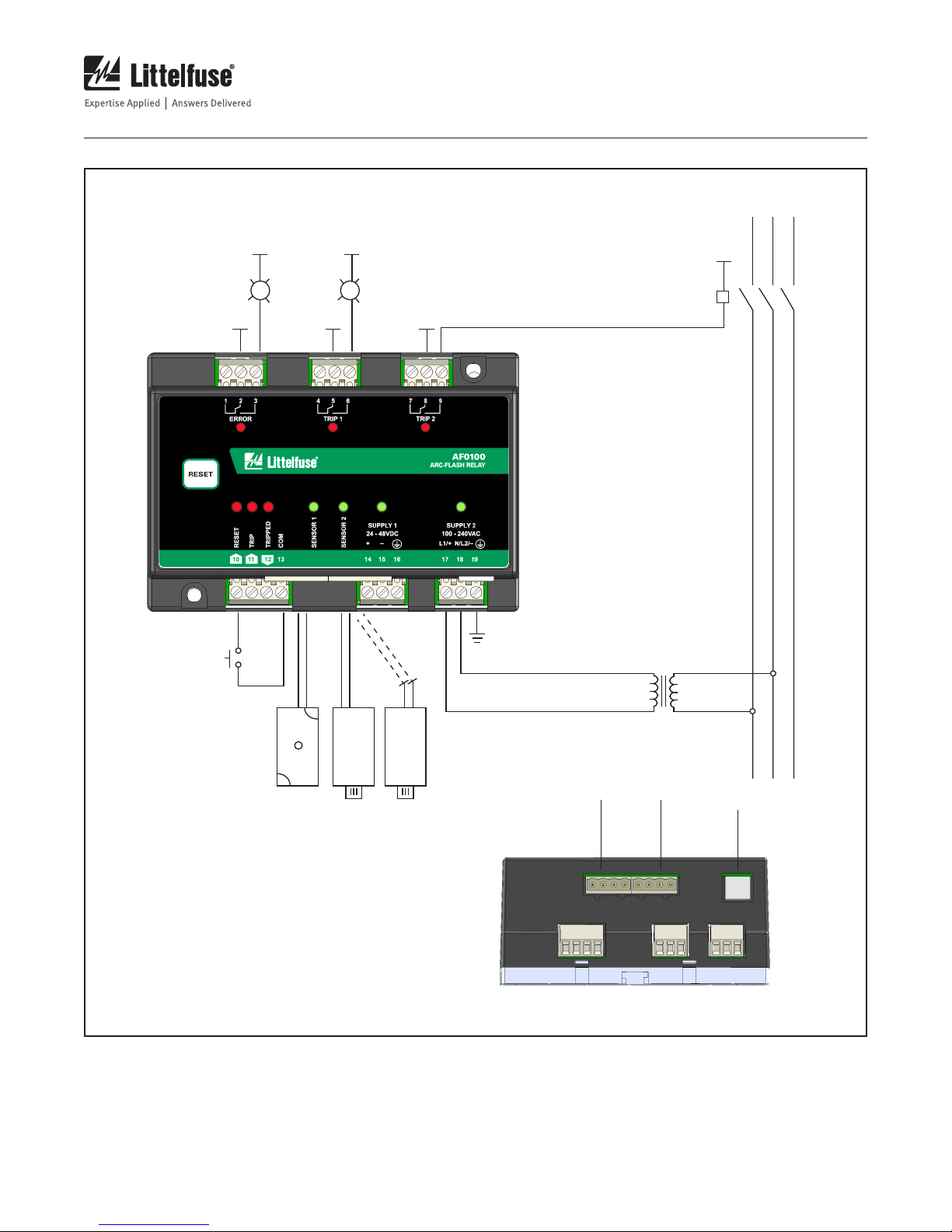

N

L1 L1

N N

Protection

Active

G

Tri p

R

L1

A B C

x x x

Tri p

Coil

Page 4

REV. 0-B-013118

A B C

Reset

L1 L1

Protection

G

Active

N

Tri p

R

N N

L1

Tri p

Coil

N

x x x

PGA-LS10

Point Sensor

NOTES:

1. RELAY OUTPUTS SHOWN DE-ENERGIZED.

2. A TOTAL OF TWO POINT OR FIBER-OPTIC SENSORS

CAN BE CONNECTED.

3. USB ‘B’ CONNECTOR. FOR CONFIGURATION, SEE

SECTION 7.3.

FIGURE 3. AF0100 Typical Wiring Diagram.

PGA-LS20/PGA-LS30

Fiber Optic Sensor

Sensor 1 Sensor 2

L1

USB

Note 3

Page 9

AF0100 Arc-Flash Relay

Page 5

REV. 0-B-013118

3 SENSOR PLACEMENT

3.1 General Guidelines

Optical sensors should have line-of-sight to points being

monitored. Ensure that the point sensors and fiber are not

blocked by fixed or moveable objects. Areas that will be

accessed for maintenance or with moveable parts (such

as draw-out circuit breakers) should be considered a high

priority for installation. Do not place sensors or cables on

bare components that will be energized and avoid sharp

bends in the cable, particularly when using the PGA-LS20

and PGA-LS30 fiber-optic sensors. The electrical cables and

sensors should be considered to be at ground potential when

determining electrical clearances.

Sensors should be mounted in a location that will minimize

the chance of debris or dust build-up and with easy access

for maintenance if needed. A point sensor mounted at the

top of an enclosure and facing down is optimal for reducing

dust build-up. It should be noted that most enclosures are

metallic and the reflectivity combined with the high intensity

of an arc mean that even a moderately dusty sensor will

collect adequate light.

In dusty environments, sensor cleaning should be part of a

regular maintenance schedule and can be performed using

compressed air or a dry cloth.

3.3 Transformer Protection

The AF0100 can also be used for the protection of transformers.

Two or more point sensors should be used per transformer to

monitor the primary and secondary connection terminals. For

the placement of the sensors, the same considerations apply

as for switchgear protection.

3.4 Generator Protection

The main area of concern for protecting the generator is the

conductors between the generator and the generator breaker.

A fault in this area is not protected by the generator breaker

from overcurrent or arc flash. Often, one or two sensors are

enough to monitor the breaker and bus connection back to

the generator. If other electrical equipment is installed on

the generator, it should also be considered in an arc-flash

risk assessment. When protecting the generator to a breaker

connection, it is important to disconnect all sources of energy

for the arc flash. Open the generator breaker to disconnect

from the utility or other parallel generators, and connect

to the automatic voltage regulator (AVR), emergency stop

or other control circuit to turn off the generator. The two

trip relays on the AF0100 are isolated so that the breaker

and control circuit can both be tripped using independent

voltages if necessary.

3.2 Switchgear Protection

The sensors used for arc-flash detection are optical sensors.

Line-of-sight between the points where an arc could occur

and the sensor is optimal, but the reflectivity of metallic

compartments will help in distributing the light from an arc

fault in the entire cabinet.

Often one point sensor is sufficient to monitor a complete

switchgear compartment. However, if there are large

components such as circuit breakers that cast shadows over

wider areas, more than one point sensor is required.

Page 10

AF0100 Arc-Flash Relay

Page 6

REV. 0-B-013118

4 OPTICAL SENSORS

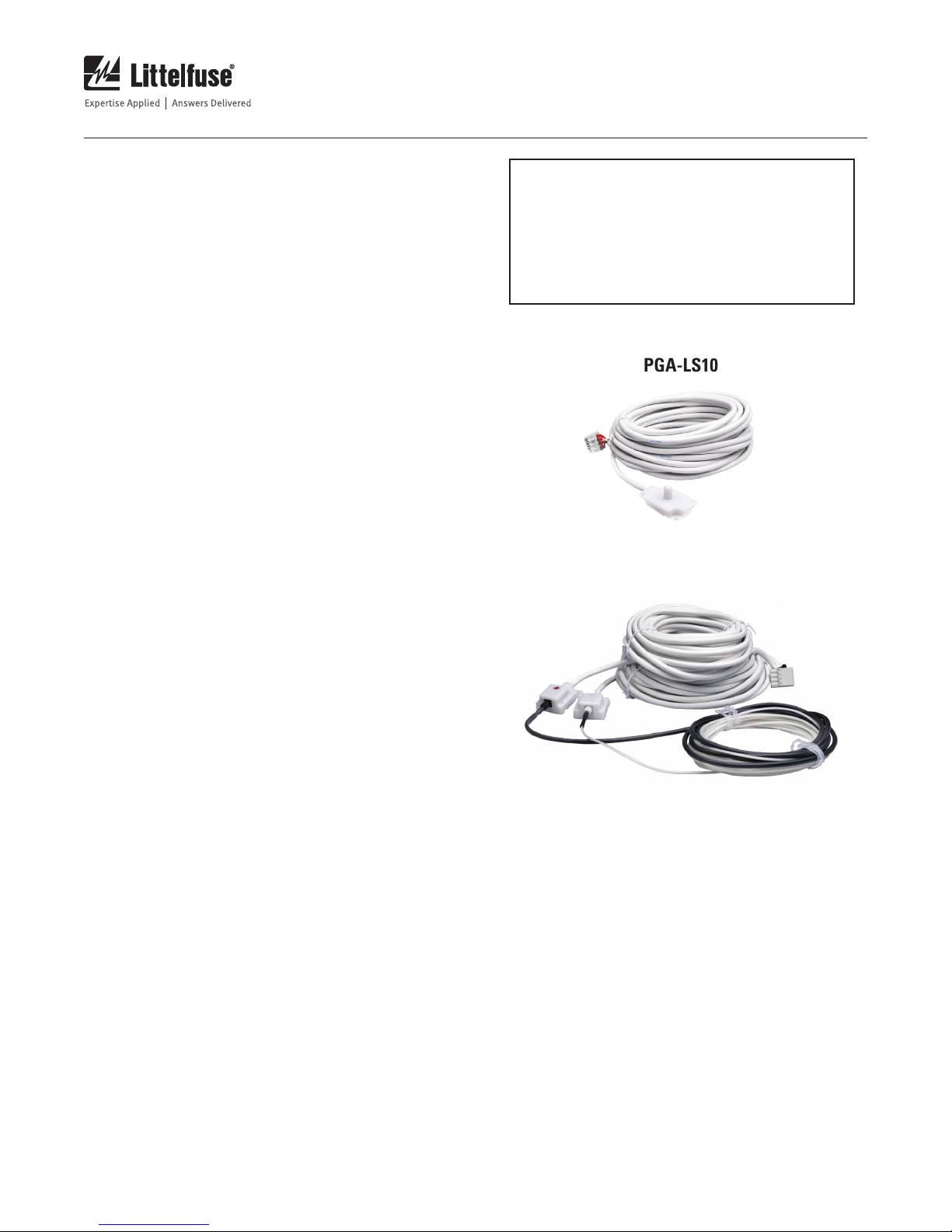

The AF0100 has two inputs for optical arc-fault sensors.

Two sensor types are supported:

• PGA-LS10 Photoelectric Point Sensors with sensor check

• PGA-LS20 and PGA-LS30 Fiber-Optic Sensors with

sensor check

The sensors can be used together, in any combination.

Both sensor types have LED indication of sensor health and

fault location. A sensor-check circuit tests the sensor to verify

that the sensor assembly is functioning correctly. A healthy

sensor will flash its internal red LED every few seconds. A

sensor that has detected an arc will indicate solid red until

the trip is reset.

The sensors connect to the AF0100 with shielded three-wire

20 AWG (0.5 mm2) electrical cable. Each sensor includes 10 m

(33 ft) of cable which can be shortened or extended up to 50 m

(164 ft). These cables should be considered to be at ground

potential when determining electrical clearances in the

cabinet.

NOTE: Inserting and removing a sensor cable can

cause a trip, depending on which terminals make

contact first. To guard against nuisance tripping,

remove the trip coil terminal blocks before

connecting and disconnecting sensors, or perform

the maintenance while the system is de-energized.

PGA-LS10

PGA-LS20 / PGA-LS30

Any connected optical sensor with circuit check will be

automatically detected and cause the AF0100 to report an

error if it is subsequently disconnected.

Page 11

AF0100 Arc-Flash Relay

Page 7

REV. 0-B-013118

4.1 PGA-LS10 Photoelectric Point Sensor with

Sensor Check

This sensor has a detection area of a 2-m (7-ft) half-sphere

for arcs of 3 kA or more.

A built-in LED enables the AF0100 to verify the function of

the light sensor, wiring, and electronics. If the sensor does

not detect the sensor-check LED, a sensor-fail alarm will

occur – the ERROR relay will change state and the sensor

indication LED will begin to flash. See Section 7.

The sensor includes 10 m (33 ft) of shielded three-wire

electrical cable which can easily be shortened or extended to

a maximum of 50 m (164 ft). For more information on sensor

cabling, see Section 6.3.2.

FIGURE 4. PGA-LS10 Detection Range for a 3 kA Fault.

Page 12

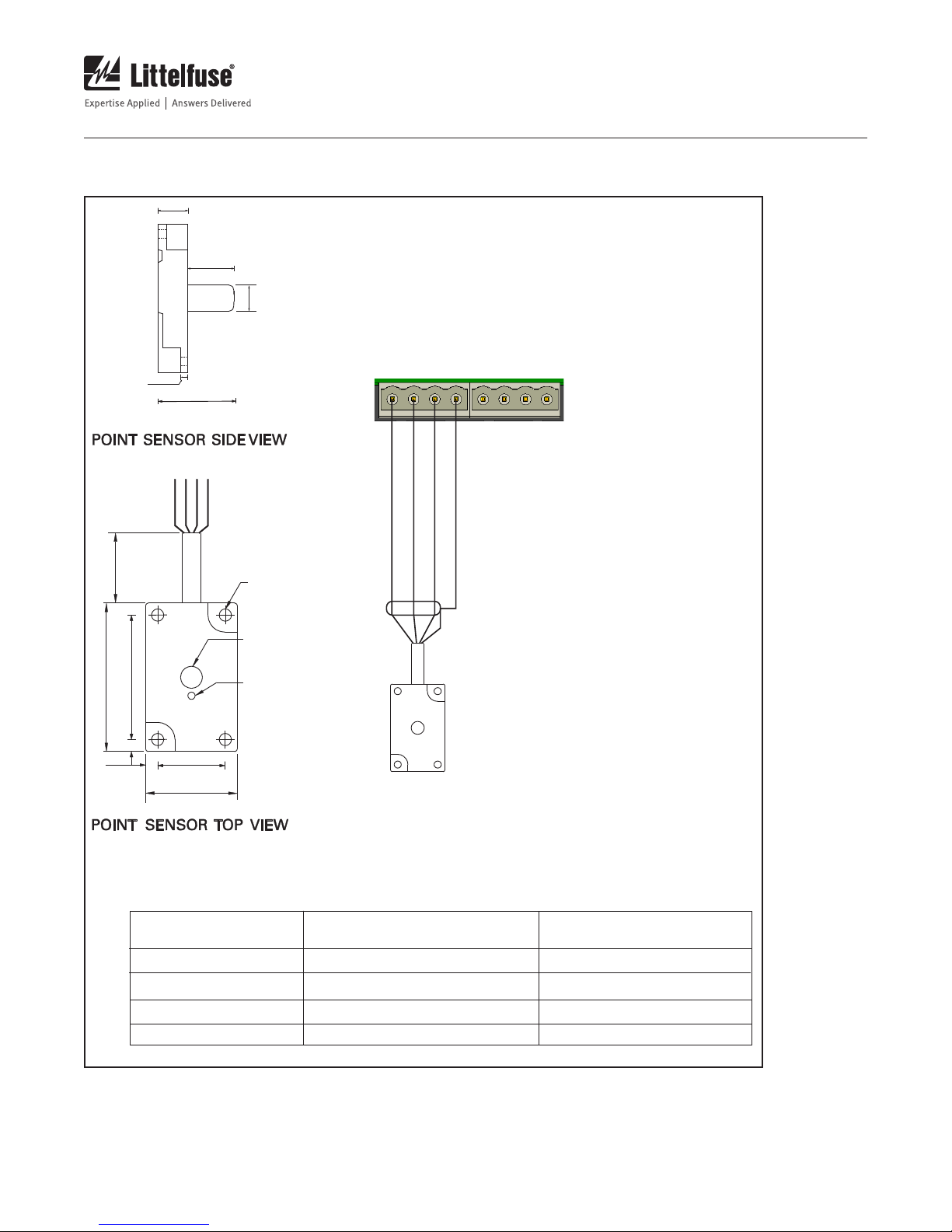

4.1.1 PGA-LS10 Connection

9.6

(0.38)

14.2

(0.56)

8.3

(0.33)

2.4

(0.09)

23.8

(0.94)

AF0100 Arc-Flash Relay

SENSOR 1 SENSOR 2

5V TX RX 0V

5V TX RX 0V

Page 8

REV. 0-B-013118

52.0

(0.16)

10 m

4.0

(32.8 ft)

44.0

(2.05)

RED

WHITE

SHIELD / BLACK

YELLOW

(1.73)

24.0

(0.94)

32.0

(1.26)

Ø4.25(0.167)

MOUNTING HOLES

Ø8.3(0.33)

SENSOR LENS

RED LED FOR

CIRCUIT CHECK AND

VISUAL DIAGNOSTICS

RED

WHITE

SHIELD / BLACK

YELLOW

NOTE 2

NOTES

1. DIMENSIONS IN MILLIMETERS (INCHES) UNLESS OTHERWISE STATED.

2. UP TO 2 PGA-LS10 PHOTOELECTRIC POINT SENSORS WITH BUILT-IN

CIRCUIT CHECK CAN BE CONNECTED.

3. THE PGA-LS10 SENSOR SHIPS ASSEMBLED WITH A PLUG-IN CONNECTOR.

IT MAY BE NECESSARY TO DISCONNECT THE PLUG-IN CONNECTOR

DURING INSTALLATION.

TERMINAL FUNCTION COLOR

5V

TX

RX

0V

SUPPLY

CIRCUIT CHECK TRANSMIT

RECEIVE

SHIELD

RED

WHITE

YELLOW

BLACK/COPPER

FIGURE 5. PGA-LS10 Connection Diagram.

Page 13

AF0100 Arc-Flash Relay

REV. 0-B-013118

4.1.2 PGA-LS10 Installation

The PGA-LS10 point sensor includes an adhesive-backed drill template for easy surface or panel-mount installation.

Page 9

FIGURE 6. PGA-LS10 Mounting Detail.

Page 14

AF0100 Arc-Flash Relay

Page 10

REV. 0-B-013118

4.2 PGA-LS20 and PGA-LS30 Fiber-Optic Sensors

with Sensor Check

The PGA-LS20 and PGA-LS30 sensors have a 360° detection

zone along the fiber’s length. A built-in LED enables the

AF0100 to verify the function of the light sensor, wiring, and

electronics. If the sensor does not detect the sensor-check

LED, a sensor-fail alarm will occur. The ERROR output will

change state, and both the LED on the front panel and the

indicator LED in the sensor itself will begin to flash red. See

Section 7.

The PGA-LS20 and PGA-LS30 sensors have three components:

1. A fiber-optic cable, with one end covered with a black

sleeve.

• PGA-LS20 has 8 m (26 ft) of active fiber and 2 m (7

ft) of covered fiber.

• PGA-LS30 has 18 m (59 ft) of active fiber and 2 m

(7 ft) of covered fiber.

2. A transmitter with a white enclosure and a white

thumb nut.

3. A receiver with a white enclosure, a black thumb nut,

and an adjustment screw behind an access hole.

Both the receiver and the transmitter connect to one AF0100

input using shielded three-wire electrical cable. All three

components are monitored to ensure correct operation.

4.2.1 Fiber Connection

Connect the black-sleeve-covered end to the receiver using

the black thumb nut, and the white uncovered end to the

transmitter using the white thumb nut. Ensure the fiber is

inserted completely into the transmitter and receiver and the

nuts are tightened. Pull gently on the cable to verify a secure

connection. The maximum pull strength of the fiber is 30 N

(6.7 lbf).

The fiber should not be sharply bent or pinched. The minimum

bending radius is 5 cm (2 in). Ensure that any drilled holes

are free of any sharp edges or burrs. Use grommets for

further protection.

NOTE: Removing the fiber from the transmitter

can cause a trip if the fiber end is pointed towards

a light source, since the fiber conducts light. This

can also happen if the receiver is pointing directly

towards a light source without a fiber connected.

To guard against nuisance tripping, remove the

trip coil terminal blocks before connecting and

disconnecting sensors and fibers, or perform the

maintenance while the system is de-energized.

4.2.2 Receiver Wiring Connections

Connect the red wire to 5V.

Connect the yellow wire to RX.

Connect the white wire and the shield to 0V.

The fiber is the light-collecting element of the PGA-LS20

and PGA-LS30. It must be installed so it has line-of-sight

to all current-carrying parts. In some cases this may be

accomplished by following the bus bars along the back wall

of the cabinets.

Drill holes using the included drill template and fasten the

transmitter and receiver to the cabinet walls using rivets or

screws. Connect the attached cables to the AF0100. The

wires of the transmitter and receiver must be connected as

shown in Fig. 7.

4.2.3 Transmitter Wiring Connections

Connect the red wire to 5V.

Connect the white wire to TX.

Connect the shield to 0V.

The yellow wire is not used.

Page 15

AF0100 Arc-Flash Relay

Page 11

REV. 0-B-013118

4.2.4 PGA-LS20 and PGA-LS30 Connection

The sensor is shipped with the wires mounted in a terminal

block. See Fig 7.

The transmitter and receiver include 10 m (33 ft) of shielded

three-wire electrical cable which can be shortened or

extended up to 50 m (164 ft). Transmitter and receiver cables

can be different lengths and must be independently shielded.

SENSOR 1 SENSOR 2

5V TX RX 0V

RED

SHIELD / BLACK

WHITE

RED

5V TX RX 0V

SHIELD / BLACK

YELLOW

WHITE

Failure to independently shield transmitter and receiver

cables can lead to an incorrect circuit check – a faulty sensor

could be falsely detected as continuous. However, if there is

no sensor fault, arc-flash detection will function normally in

this condition. For more information on sensor cabling, see

Section 6.3.2.

2.0

(0.08)

46.0

(1.81)

18.8

(0.74)

(PGA-LS20: 8 m, 26.2 ft)

(PGA-LS30: 18 m, 59 ft)

FIBER

BLACK SLEEVE

(PGA-LS20: 2 m, 6.5 ft)

(PGA-LS30: 2 m, 6.5 ft)

NOTES

1. DIMENSIONS IN MILLIMETERS (INCHES) UNLESS OTHERWISE

STATED.

2. UP TO 2 PGA-LS20 / PGA-LS30 FIBER-OPTIC SENSORS

WITH BUILT-IN CIRCUIT CHECK CAN BE CONNECTED.

3. THE PGA-LS20 AND PGA-LS30 SENSORS SHIP

ASSEMBLED WITH A PLUG-IN CONNECTOR. IT MAY BE NECESSARY

TO DISCONNECT THE PLUG-IN CONNECTOR DURING INSTALLATION.

TERMINAL FUNCTION COLOR

5V

SUPPLY (TRANSMITTER AND

RECEIVER)

TX

RX

0V

SENSOR CHECK (TRANSMITTER)

SIGNAL (RECEIVER)

SENSOR CHECK (RECEIVER) AND

BOTH SHIELDS

46.0

(1.81)

4.0

(0.16)

42.0

4.0

(0.16)

(1.65)

32.0

(1.26)

24.0

(0.94)

Ø4.25(0.167)

MOUNTING HOLES

RECEIVER

SENSITIVITY

ADJUSTMENT

SCREW

DECREASE

SENSITIVITY

THUMB NUT

RED

WHITE

YELLOW

BLACK/COPPER

FIGURE 7. PGA-LS20 and PGA-LS30 Connection Diagram.

Page 16

AF0100 Arc-Flash Relay

Page 12

REV. 0-B-013118

4.2.5 Fiber-Optic Sensor Adjustment

The sensor is calibrated at the factory for 60 cm (24 in) of fiber

in each monitored compartment. When using a fiber-optic

sensor in compartments with less than 60 cm (24 in) of fiber,

the sensitivity may have to be adjusted. The sensor is unable

to differentiate between 10,000 lux on 60 cm (24 in) of fiber

and 30,000 lux on 20 cm (8 in) of fiber – the same amount

of light is transmitted through the fiber to the receiver. To

achieve the desired sensitivity, the receiver (with the black

thumb nut) must be adjusted.

4.2.6 Sensor Adjustment For a Fiber Length Other

Than 60 cm (24 in)

To adjust the fiber length, a powerful light source of at least

100 lumen (e.g. 500 W halogen lamp) and a spare point

sensor is required. Use the following procedure to calibrate

the sensor:

1. Remove the trip coil connector to avoid tripping the

circuit breaker while testing.

2. Use a point sensor to find the distance to the lamp

at which the sensor just trips. Note the distance

between the lamp and the point sensor (typically

15-40 cm (5.9-15.7 in), depending on the lamp).

3. Adjust the receiver (black thumb nut) sensitivity

level to the minimum by turning the small metal

screw clockwise until it begins to click. This may be

too low to detect the sensor-check signal and may

cause the related LED on the relay to flash red to

signal the error. This has no implication for the rest

of the procedure, since the trip signal is transmitted

anyway.

4. Place the lamp facing the fiber in the compartment

closest to the transmitter end (white thumb nut) of

the fiber. This allows for loss along the full length

of the fiber. The distance between the lamp and the

fiber should be the same as the distance observed

in step 2.

5. Slowly turn the metal screw on the receiver counterclockwise until the AF0100 sensor-indicator LED for

that sensor changes to red, indicating a trip.

6. Press reset on the relay, and check that the sensor

indicator LED turns green, indicating that the

sensor-check signal is detected, and that the fiber

is thus protected by circuit check.

If the system compartment is very small, it may not be

possible to adjust the fiber to provide sufficient sensitivity.

Contact Littelfuse for support.

Page 17

AF0100 Arc-Flash Relay

5 APPLICATION EXAMPLES

5.1 Basic scenario: One Sensor – One Circuit Breaker

No configuration necessary.

Page 13

REV. 0-B-013118

AF010 0

Trip 1

Sensor

1 or 2

+24

Circuit

Breaker

Sensor

Incoming

FIGURE 8. Basic AF0100 Configuration.

Page 18

AF0100 Arc-Flash Relay

Page 14

REV. 0-B-013118

5.2 Total Clearing Time

The AF0100 is capable of tripping a circuit breaker in less

than 5 ms (typical) from when light hits the sensor. This is not

the same as the clearing time for the fault. The arc fault will

continue until the current to the fault has stopped flowing,

which happens when the circuit breaker connected to the

unit has reacted.

5.2.1 Arc-Detection Delay

The AF0100’s default arc-flash detection intentional delay

time is 1 ms, but can be configured between 0 and 10 ms via

the USB configuration software.

The total operating time will be the intentional delay plus the

relay operating time based on wiring and configuration. The

AF0100 operating times with no intentional delay are shown

below.

OPERATING MODE

Shunt

(Non-fail-safe)

Undervoltage

(Fail-safe)

CONTACT

CONFIGURATION

N.O.

(Normally Open)

N.C.

(Normally Closed)

N.O.

(Normally Open)

N.C.

(Normally Closed)

TRIP TIME

< 5 ms

< 3 ms

< 3 ms

< 8 ms

The total clearing time is:

Total Clearing Time = Arc-Detection Delay + Local Circuit

Breaker Operating Time

With the AF0100, the dominating time by far is the circuit

breaker operating time.

5.2.3 Total Clearing Time Examples

Example: Total Clearing Time with a 3-cycle circuit

breaker

A 3-cycle circuit breaker at 50 Hz tripping due to light on an

AF0100 sensor will have a total clearing time of:

5 + 60 = 65 ms

It is possible to reduce the total clearing time by installing

special devices, which shunt the current away from the arc

fault. These can be found with clearing times down to 1-2

ms, reducing the total clearing time down to less than 7 ms.

5.2.2 Circuit Breaker Operating Time

Circuit breakers have a predetermined operating time,

dependent on the type of circuit breaker. Older circuit breakers

have clearing times up to eight cycles, while modern circuit

breakers are able to open in one to five cycles. Refer to the

specifications of the installed circuit breaker.

TABLE 1. CIRCUIT BREAKER OPERATING TIME.

CIRCUIT BREAKER OPERATING TIME 50 HZ 60 HZ

8 cycles 160 ms 133 ms

5 cycles 100 ms 83 ms

3 cycles 60 ms 50 ms

2 cycles 40 ms 33 ms

1½ cycles 30 ms 25 ms

1 cycle 20 ms 17 ms

Page 19

AF0100 Arc-Flash Relay

TOP

2 MOUNTING HOLES

TOP

REVISION

NO.BYDATE

JR

0

INITIAL RELEASE

127.6

5.03

95.2

3.75

76.6

3.02

16.2

0.64

16.2

0.64

6.3

0.25

6.3

0.25

89.2

3.51

FRONT

TOP

PURCHASER

PROJECT IDENT.

PURCHASE ORDER NO.

EQUIPMENT NO.

REFERENCE DWG. NO.

REVISION

NO.BYDATE

JR

0

INITIAL RELEASE

Confidential and Proprietary

The information and know-how shown in this drawing are the property of Littelfuse Startco

and may not be copied or reproduced without the written permission of Littelfuse Startco nor

may they be used in any manner directly

or indirectly detrimental to the interest of Littelfuse Startco.

127.6

5.03

2 MOUNTING HOLES

5.2

0.20

95.2

3.75

76.6

3.02

16.2

0.64

16.2

0.64

6.3

0.25

6.3

0.25

89.2

3.51

FRONT

BOTTOM

35.3

1.39

59.8

2.36

SIDE

TOP

NOTES:

DIMENSIONS IN MILLIMETERS [INCHES].

1.

MOUNT USING DIN RAIL OR TWO #6 SCREWS

2.

PURCHASER

PROJECT IDENT.

PURCHASE ORDER NO.

EQUIPMENT NO.

REFERENCE DWG. NO.

DES D.

DWN.

PROJECT NO.

REVISION

INITIAL RELEASE

The information and know-how shown in this drawing are the property of Littelfuse Startco

and may not be copied or reproduced without the written permission of Littelfuse Startco nor

or indirectly detrimental to the interest of Littelfuse Startco.

127.6

5.03

2 MOUNTING HOLES

5.2

0.20

95.2

3.75

76.6

3.02

16.2

0.64

16.2

0.64

6.3

0.25

89.2

3.51

FRONT

TOP

Page 15

REV. 0-B-013118

6 INSTALLATION AND TERMINALS

The AF0100 can be surface mounted using two #6 screws

(19mm or longer), or it can be DIN-rail mounted.

NOTES:

DIMENSIONS IN MILLIMETERS [INCHES].

1.

MOUNT USING DIN RAIL OR TWO #6 SCREWS

2.

59.8

2.36

35.3

1.39

Ensure there is enough clearance around the module to allow

the plug-in terminals to be removed and inserted.

Do not install modules which have been damaged in transport.

TOP

127.6

5.03

16.2

0.64

95.2

3.75

16.2

0.64

6.3

76.6

0.25

3.02

89.2

3.51

SIDE

89.2

3.51

6.3

76.6

6.3

0.25

3.02

0.25

16.2

0.64

127.6

5.03

95.2

3.75

MOUNTING DETAIL

FIGURE 9. AF0100 Outline and Mounting Details.

16.2

0.64

5.2

0.20

FRONT

BOTTOM

6.3

0.25

Page 20

AF0100 Arc-Flash Relay

Page 16

REV. 0-B-013118

6.1 Power Supply

The AF0100 Arc-Flash Relay can be supplied by either a high

voltage ac or dc supply, an auxiliary low voltage supply, or

both.

6.1.1 Line AC Supply (optional)

Connect an ac supply to terminals 17 and 18. The supply

voltage must be 100 to 240 Vac.

6.1.2 Station Battery DC Supply (optional)

6.1.3 Auxiliary DC Supply

Connect a dc supply to terminals 14 and 15, ensuring correct

polarity. The supply voltage must be 24 to 48 Vdc.

6.1.4 Supply Surveillance

The AF0100 will automatically learn which supplies to

expect, and will indicate an error if one of the supplies is

missing or out of nominal range. This is useful to make sure

that a failure in a redundant supply is detected.

Connect a dc supply to terminals 17 and 18. The supply

voltage must be 100 to 240 Vdc.

The error will auto-reset when the supply is re-established or

can be cleared by holding the RESET button for 20 seconds.

This will redetect any connected sensors and power supplies.

See Section 7.1 for more information on the RESET button.

Page 21

AF0100 Arc-Flash Relay

Page 17

REV. 0-B-013118

6.2 Inputs and Outputs

An LED provides visual indication of each input and output

status. The output contacts are shown on the front panel in

the de-energized state.

6.2.1 ERROR Signal Relay

The ERROR output signals the health of the arc-flash relay

and its connected sensors and supplies.

The ERROR output consists of an insulated electromechanical

change-over contact (Form C / SPDT) on terminals 1, 2, and

3. In the fail-safe mode, the ERROR relay will be energized

when there are no alarms. The ERROR relay mode can

be configured with the USB configuration software.

See Section 7.3

If an error is currently active and an additional error occurs,

the ERROR output will briefly change state. This is to

communicate to connected equipment the error state has

changed, but there are outstanding errors.

If possible, an LED on the front panel will indicate where

the error is by flashing. Otherwise, the USB configuration

software will show an overview of the current errors.

The ERROR relays of several units can be combined into

one fail-safe signal by daisy-chaining terminals 2 and 3 (all

ERROR relays must be configured for fail-safe mode). In that

way, if just one of the linked units experiences an error, the

connection between the ends will be broken. Likewise, if the

wire breaks, an alarm will be raised.

6.3 Sensors

Two optical sensors can be used with the AF0100. Sensor

locations are identified as SENSOR 1 or SENSOR 2 on the top

of the AF0100. See Section 4.

6.3.1 Light Immunity Adjustment

By default, the sensors will signal an arc-fault event if the

light intensity is above approximately 10 klux. The light

intensity from an arc fault is very high, typically in the area

of 1 Mlux, and the choice of 10 klux is mostly a compromise

between being sufficiently above normal light levels (about 1

klux in a very well lit office environment) and the need to be

able to test the system with a manageable light source such

as a flashlight.

The immunity level can be changed up to 25 klux via the

USB configuration software. For information on using the

USB configuration software, see Section 7.3.

This may be required for applications with powerful work

lights or regulation requirements for the trip level.

The light sensors are not usable outdoors or in direct

sunlight, as the intensity of direct sunlight will saturate the

sensors.

6.3.2 Extending or Shortening Cable Length

Both point and fiber sensors are delivered with 10 m (33 ft) of

three-wire shielded cable. If the installation requires it, these

cables can be shortened or extended up to 50 m (164 ft). See

Sections 4.1 and 4.2.4. Use Belden 85240 or equivalent cable

(wire colors may vary).

Do not combine several sensor cables within the same

shield. Do not combine the cables to transmitter and

receiver for the fiber sensors within the same shield.

Page 22

AF0100 Arc-Flash Relay

Page 18

REV. 0-B-013118

7 USER INTERFACE

7.1 Reset Button

The RESET button on the front panel of the AF0100 has two

functions: A momentary press will reset any trip events or

errors, and holding the button will initiate additional reset

functions as described below.

Pressing the reset button will reset trip indications and

error indications for any existing error. The error indication

will remain if the error is still present and cannot be reset,

e.g. if a sensor is missing or a supply voltage is outside the

specification.

Holding the reset button for 10 seconds will reset the

internal drive to factory defaults. This does not affect the

configuration.

Holding the reset button for 20 seconds will redetect any

connected sensors and power supplies which will clear

the alarms. Do not do this until the reason for the alarm is

known, and has been rectified.

If password protection is enabled in the USB configuration,

resetting the list of connections is not allowed. In this case,

use the USB configuration software to reset the alarm.

7.2 LED Indication and Relay Operation

Input LED’s follow the input state. Since the TRIPPED digital

output is pulsed, its LED will indicate if the output has been

activated since the last reset. Blinking LED’s on the front

panel indicate errors e.g. an expected sensor is missing, etc.

To reset the expected state, use the RESET button.

SUPPLY 1 and 2 (Terminals 14 to 16 and 17 to 19,

respectively)

On, green Supply voltage is connected.

Flashing green Supply voltage on this terminal has

previously been detected, but is now

missing, or the connected supply is

outside the specifications.

Off Supply voltage is not connected.

ERROR Relay (Terminals 1 to 3)

On, red An error has been detected, and the

ERROR relay has been de-energized

(fail-safe mode) or energized (nonfail-safe mode). If another LED

is flashing, use this to localize the

error and correct the problem. The USB

configuration software can also be used to

show the cause for any standing alarm,

see section 7.3.

Off No errors detected.

The LED will not always follow the internal contacts. The

ERROR relay will be in the state shown on the front panel

when power is not connected.

In the fail-safe mode, the ERROR relay will energize if no

errors are detected, and will de-energize on errors, or if

power is removed.

In the non-fail-safe mode, the ERROR relay will de-energize

if no errors are detected or if power is removed, and will

energize on errors.

The ERROR relay will also pulse for one second if an additional

error is detected while errors are already present.

Page 23

AF0100 Arc-Flash Relay

Page 19

REV. 0-B-013118

TRIP 1 and TRIP 2 (Terminals 4 to 6 and 7 to 9,

respectively)

On, red A TRIP output is or has been active due

to an arc-flash event. Press RESET to

clear the trip.

Off No unacknowledged trips.

The LED will not always follow the status of the internal

contacts. The trip relays are shown on the front panel in their

de-energized state.

In the fail-safe mode, trip relays will energize when not in a

tripped state, and will de-energize when in a tripped sate, or

if power is removed.

In the non-fail-safe mode, the trip relays will de-energize

when not in a tripped sate, or if power is removed, and will

energize when in a tripped state.

RESET Input (Terminal 10)

On, red RESET input or another reset source

(RESET button) is active.

Off RESET input is inactive.

If the RESET input is permanently activated, errors and trips

will be reset as soon as they are cleared or completed.

TRIP Input (Terminal 11)

Sensors

On, green The sensor input is active and has a

functional sensor connected.

On, red The sensor caused a trip event. The LED

in the sensor will also be solid red. Press

the RESET button to clear the trip.

Flashing red The circuit check of the sensor failed;

check the wiring and that fiber sensors

are fully seated in the thumb screws. If

possible, the LED in the sensor will also

be flashing red. If a sensor has been

removed temporarily or on purpose,

press and hold the RESET button for a

20 seconds to redetect any connected

sensors.

Off The input has not detected a connected

sensor. The input will by default still be

active.

PGA-LS10, PGA-LS20 and PGA-LS30

Flashing Red The sensor is operating normally.

On, red (brief

flashing red

every 2 s) The sensor caused a trip event.

On, red TRIP input is active.

Off TRIP input is inactive.

TRIPPED Output (Terminal 12)

On, red The TRIPPED output is or has been

active. Press RESET to clear the trip.

Off The TRIPPED output is inactive.

Off The sensor is unplugged or faulty, or

the AF0100 is without power (check the

wiring and that fiber sensors are fully

seated in the thumb screws).

Page 24

AF0100 Arc-Flash Relay

Page 20

REV. 0-B-013118

7.3 USB Conguration Software

To access the configuration software, plug in a USB connector

and connect to a Windows1 computer.

After a few seconds, the following will appear:

Open the Configuration drive, and double click on the file

named ’config.hta’

The configuration software will now open.

Tabs show each logical section of the relay.

Hovering above each setting will display the valid limits for

the setting.

Press the Save button and remove the USB connector to

apply the new configuration.

NOTE:

1

All Microsoft Windows versions from and including

Windows XP are supported. Some corporate networks may

disallow HTA applications, in which case you should contact

your system administrator to allow local HTA files to run.

Page 25

AF0100 Arc-Flash Relay

Page 21

REV. 0-B-013118

It is not possible to view live data from the unit via USB.

The values shown for e.g. sensor state are the values at

the moment the USB connector was plugged in. Setting the

7.3.1 USB Conguration Software – Screen Examples

password in the USB configuration software will prevent

the list of connected devices from being reset via the reset

button on the front panel.

Page 26

AF0100 Arc-Flash Relay

Page 22

REV. 0-B-013118

Page 27

AF0100 Arc-Flash Relay

The USB configuration software also shows the cause of any standing alarms in clear text.

Page 23

REV. 0-B-013118

Page 28

AF0100 Arc-Flash Relay

Page 24

REV. 0-B-013118

7.4 Firmware Upgrade

NOTE: The AF0100 will restart during the firmware

upgrade process. The TRIP and ERROR relays may

change state. Ensure the equipment is in a safe

state prior to starting the upgrade process. Do not

interrupt the firmware upgrade process.

NOTE: The redundant trip circuit is active during

the firmware upgrade process, but will operate

in a shunt-trip mode only. Once the firmware

upgrade process has completed,normal operation

will continue as previously configured via the

configuration software. See Appendix B for more

information.

Product information, including hardware and firmware details,

can be reviewed in the About tab as shown in Section 7.3.1.

Follow the procedure below to perform a firmware upgrade:

1. Contact Littelfuse at relays@littelfuse.com to obtain the

newest firmware file.

4. Disconnect the USB cable. The firmware upgrade will

begin. Progress will be shown on the front panel as

outlined below. The firmware upgrade can take up to five

minutes.

TABLE 2. AF0100 FIRMWARE UPGRADE SEQUENCE.

Sensor 1 Sensor 2 Description

Sensor 2 flashing

Sensor 1 flashing

Sensor 1 ON,

Sensor 2 flashing

Sensor 1 flashing,

Sensor 2 ON

Unit reset AF0100 will reset

Sensor 1 and 2 flashing green for

3 seconds – Upgrade passed

or

Sensor 1 and 2 flashing red for

3 seconds – Upgrade failed

2. Connect the AF0100 to a computer using a USB cable.

See Section 7.3.

3. Copy the AF0100.bin and AF0100.md5 files to the AF0100

Configuration drive.

Unit reset AF0100 will reset

Firmware upgrade process complete.

Legend:

OFF FLASHING ON

5. The AF0100 will restart twice when the firmware

upgrade has been completed.

6. Close the Configuration Software screen (HTA file).

7. Reconnect the AF0100 to the computer as in Step 2.

8. Confirm that the firmware revision shown in the About

tab is correct.

Page 29

AF0100 Arc-Flash Relay

Page 25

REV. 0-B-013118

8 COMMISSIONING

With no manual configuration, a freshly unpacked and wired

AF0100 will work using the factory default settings. It will

trip the TRIP 1 and TRIP 2 outputs if light applied to any

sensors connected to SENSOR 1 or SENSOR 2 exceeds the

default setting of 10 klux, even if a circuit check is reporting

a cable to be broken.

The digital I/O (TRIP and RESET inputs, TRIPPED output) will

also be enabled.

Littelfuse recommends always doing a full system test on all

sensors and outputs to ensure that any errors in the cabling

or configuration will be detected and can be corrected before

the system is put into normal operation.

CAUTION: Make sure that the area is safe before this

test. Ensure that loads and power are disconnected at

the transformers, etc.

8.1 Conguration of Installed Sensors

The AF0100 will auto-detect sensors as they are connected.

To reset any errors (shown as blinking red LED in a position

where no sensor is attached), e.g. after moving a sensor to

another position on the unit, press and hold the RESET button

for 20 seconds. This will redetect any connected sensors and

power supplies.

8.2 Testing the Sensors

To test the tripping of point sensors, the intensity of light

at the sensors needs to rise above 10 klux (or the defined

light immunity setting, if changed). The LED flash on most

phones are not sufficient, nor are most LED flashlights. Most

incandescent flashlights (e.g. Mini Maglite with Xenon bulb

or larger) can be used, if the beam can be focused to a very

small circle and the flashlight is brought right next to the

sensor. A normal AC light bulb can also be used.

For fiber sensors, the light intensity needs to be above 10 klux

on a much larger area, which is not possible with a flashlight

or standard light bulbs. To test fiber sensors, a 300-500 W

halogen lamp or a powerful photo flash with a guide number

of at least 15 m (50 ft) is needed. See Section 10.7.

1. Unplug the TRIP outputs to avoid tripping the circuit

breakers. If the AF0100 output is connected to other

devices, disconnect these connectors as well.

2. Confirm that there is a solid green LED for each

connected optical sensor. This confirms that sensors

are connected and healthy.

3. Confirm that a short red flashing light occurs

periodically in each sensor. This indicates that the

sensor circuit is being checked.

4. Point the light source at a sensor and check that

the LED on the sensor and the front panel of the

AF0100 turns red continuously. The TRIPPED LED

will also turn on. If this does not happen, the light

source may not be powerful enough, especially for

fiber sensors.

5. Repeat for the remaining sensors.

6. Check that the indicator LED’s on the front panel of

the unit have turned red for all connected sensors.

7. Press the RESET button to clear the trip indication.

Replace any connectors removed to re-establish protection.

Page 30

AF0100 Arc-Flash Relay

Page 26

REV. 0-B-013118

8.3 Testing the TRIP 1 and TRIP 2 Outputs and

Associated Circuit Breakers

To ensure the system is ready to test, the system should

only have supply power. The TRIP 1 and TRIP 2 outputs will

be tripped during this procedure. Also be aware that other

devices connected to the trip outputs will also trip, unless

the connection is removed for the test.

1. Reset the AF0100. Ensure there are no trips or

errors present.

2. Connect the TRIP input to COM using a piece of

wire, terminals 11 to 13.

3. Observe that the connected trip coil operates.

4. Press the RESET button to reset the trip indication.

Reset the tripping device if necessary.

5. Replace any connectors removed to re-establish

protection.

6. Repeat for each TRIP 1 and TRIP 2 output.

8.4 Full Operation Test

2. Make a table with a row for each sensor, and mark

which circuit breakers should trip in order to remove

power completely from the area. See Table 2.

3. Confirm that there is a solid green LED for each

connected optical sensor. This confirms that sensors

are connected and healthy.

4. Confirm that a short red flashing light occurs

periodically in each sensor. This indicates that the

sensor circuit is being checked.

5. Move a light source towards the sensor. Confirm

that the TRIP1 and TRIP 2 outputs trip and that the

LED’s of the TRIP outputs and sensor change to red.

Confirm that all circuit breakers which supply the

area which the sensor can see have tripped. Note

the result in the table.

6. Press RESET on all affected units, and reset the

tripping device if necessary.

7. Repeat steps 3 to 6 for the remaining sensors.

To ensure the system is ready to test, the system should only

have supply power. The TRIP outputs will change state during

this procedure.

1. Use the system diagram to find out which circuit

breakers should trip for each sensor. Generally, the

system should be set up so that light on a sensor

removes power from any conductor that the sensor

can see.

TABLE 3. SAMPLE TABLE FOR TESTING A SYSTEM.

SENSOR: SHOULD TRIP THESE CIRCUIT BREAKERS: OBSERVED TRIPS:

Unit 1, sensor 1

Placed on Busbar

Unit 1, sensor 2

Placed in Circuit Breaker 2 Cabinet

Unit 2, sensor 1

Placed in Circuit Breaker 3 Cabinet

Etc.

Incoming Circuit Breaker 1

Incoming Circuit Breaker 1

Circuit Breaker 2

Page 31

AF0100 Arc-Flash Relay

Page 27

REV. 0-B-013118

9 SUPPORT RESOURCES

The most up-to-date manuals, data sheets, instruction

videos, etc. can be found on the AF0100 site at

www.littelfuse.com/AF0100.

The AF0100 is supported through the Littelfuse network of

technical sales and distributors. For installation help and

support, please contact your sales representative. Include

detailed information about the installation and application.

See Section 2.

9.1 Sending Information For Support

A picture or video of the installation makes it much easier to

provide assistance. Also, the configuration and log files can

be very helpful, as is the serial number of the unit.

Attaching the files to the support email can be done as

follows:

Plug in a USB connector and connect to a computer.

After a few seconds, one new drive appears.

From the CFG drive, select and attach the CONFIG.CFG,

AF0100.LOG, and AF0100.TXT files.

Provide a single line diagram of the installation if possible.

Page 32

AF0100 Arc-Flash Relay

Page 28

REV. 0-B-013118

10 SPECIFICATIONS

10.1 AF0100

Supply:

Supply 1:................. .................... 4 W, 24 to 48 Vdc

(+10%, -25%)

Supply 2:... ................ ................. 10 VA, 100 to 240 Vac

AF0100-00 only

Optical Settings:

External Sensors: .......................2 Light sensors

Sensor Types: .............................PGA-LS10, PGA-LS20, and

PGA-LS30, all with sensor

Immunity

Adjustment: ...............................Trip above 10 to 25 klux

Intentional Trip

Delay Settings: .......................... 0 to 10 ms

TRIP 1 and TRIP 2 Outputs:

Configuration: ............................ Change-over (Form C)

UL Rating ................................... 6 A resistive 240 Vac,

Supplemental Ratings:

Make/Carry 0.2 s: ...............30 A

Rating Code: .......................B300, R300

Minimum Switching Load ...100 mA, 5 Vdc

Maximum Switching

Capacity...............................Fig. 17

Break:

dc: ..................................28 W Resistive

ac: .................................1500 VA (PF=1.0)

360 VA (PF=0.4)

Subject to maximums of

Operating Mode: ....... ................ . Shunt trip (non-fail-safe)

(+10%, -20%) 50/60 Hz,

5 W, 100 to 250 Vdc

(+10%, -20%)

check

0 ms intentional delay

results in a maximum 0.8

ms total delay (plus relay

operate time)

isolated contact

6 A resistive 30 Vdc

6 A and 250 V (ac or dc)

or undervoltage trip

(fail-safe), independently

configurable

Isolation:.....................................1,600 Vac

Trip Time (with 0 ms intentional delay):

Mode:

Shunt Trip (non-fail-safe):

Normally open contact:

.......<

Normally closed contact:

....

5 ms

.< 3 ms

Undervoltage Trip (fail-safe):

Normally open contact:

......

Normally closed contact:

.< 3 ms

.....<

8 ms

Error Output:

Configuration:

............................. Change-over (Form C)

isolated contact

UL Rating: .................................. 6 A resistive 240 Vac,

6 A resistive 30 Vdc

Supplemental Ratings:

Make/Carry 0.2 s................30 A

Rating Code: .......................B300, R300

Minimum Switching Load ..100 mA, 5 Vdc

Maximum Switching

Capacity...............................Fig. 17

Break:

dc:.................................28 W Resistive

ac:................................ 1500 VA (PF=1.0)

360 VA (PF=0.4)

Subject to maximums of 6

A and 250 V (ac or dc)

Operating Mode: ........ ................Fail-Safe or Non-Fail-Safe

Isolation: ....................................1,600 Vac

Redundant Circuit Trip Time.............. 10 ms max,

Shunt Trip Operation Only

See Appendix B.

Terminals............................... ............Wire Clamping, 22-12

AWG (0.14 to 2.5 mm2)

copper conductors

Torque:................................ .... ...........7 lbf∙in (0.79 N∙m)

Local Interface: ................................. USB 2.0 Full speed Mass

storage device

Dimensions:

Height: ................................90 mm (3.5 in)

Width: ................................128 mm (5.0 in)

Depth: .................................60 mm (2.4 in)

Shipping Weight: ..............................0.9 kg (2 lb)

Page 33

AF0100 Arc-Flash Relay

Page 29

REV. 0-B-013118

Mounting: .......................................... 35 mm DIN rail or

surface mount

Environment:

Operating Temperature:

............... -40 to 70°C

(-40 to 158°F)

Storage Temperature: ................ -40 to 70°C

(-40 to 158°F)

Humidity: .................. ................93% Non-condensing

Enclosure Rating ........................IP20

Altitude:

Below 2,000 m (6,500 ft): ........... Normal Operation

Above 2,000 m (6,500 ft): ........... 24 Vdc supply only

Above 4,000 m (13,000 ft): ......... Contact Littelfuse

for further

information.

10.2 EMC Tests

Verification tested in accordance with EN 60255-26:2013.

Radiated and Conducted

Emissions:.......................................... CISPR 11:2009,

CISPR 22:2008,

EN 55022:2010

Class A

Current Harmonics and

Voltage Fluctuations .......................... IEC 61000-3-2

and IEC 61000-3-3

Class A

Electrostatic Discharge ..................... IEC 61000-4-2 ± 6 kV

contact discharge

(direct and indirect) ± 8

kV air discharge

Radiated RF Immunity .......... ............. IEC 61000-4-3

10 V/m, 80-1,000 MHz,

80% AM (1 kHz)

10 V/m, 1.0 to 2.7 GHz,

80% AM (1 kHz)

Fast Transient ....................... ............. IEC 61000-4-4 Zone B

± 2 kV (power supply

port), ± 1 kV (all other-

ports)

Surge Immunity ................................ IEC 61000-4-5

Zone B

± 1 kV differential mode

± 2 kV common mode

Conducted RF Immunity ....... ............ IEC 61000-4-6

10 V, 0.15-80 MHz,

80% AM (1 kHz)

Magnetic Field Immunity.................. IEC 61000-4-8

50 Hz and 60 Hz

30 A/m and 300 A/m

Power Frequency3 ............................ IEC 61000-4-16

Zone A: differential mode

100 Vrms

Zone A: common mode

300 Vrms

1 MHz Burst ..................................... IEC 61000-4-18

± 1 kV differential mode

(line-to-line)

± 2.5 kV common mode

Voltage Interruption ......................... IEC 61000-4-11,

IEC 61000-4-29

0% for 10, 20, 30,

50 ms (dc)

0% for 0.5, 1, 2.5,

5 cycles (60 Hz)

IEC 61000-4-17

Level 4, 15% of rated

dc value

Surge Withstand: .............................. ANSI/IEEE C37.90.1-2002

(Oscillatory and Fast

Transient)

10.3 Environmental Tests

Cold:.................................................. IEC 60068-2-1:2007

Test Temperature:........................-40°C

Duration:......................................16 hours

Dry Heat:...........................................IEC 60068-2-2:2007

Test Temperature:........................70°C

Duration:......................................16 hours

Humidity:......................................50% RH

Damp Heat Cyclic.............................IEC 60068-2-30:2005

Lower Temperature:

Humidity Range:..........................95 – 100 % RH

Upper Temperature:

Humidity Range:..........................90 – 96 % RH

Number of Cycles:.......................2

Vibration:

EN60225-21-1............................. Vibration, Shock, and

EN60225-21-2.............................Shock and Bump

......................25°C

......................55°C

Seismic

Page 34

AF0100 Arc-Flash Relay

Page 30

REV. 0-B-013118

10.4 Safety

Safety: ............................ IEC 61010-1: 2010 + AMD1:2016

3rd Edition

Safety Requirements for Electrical

Equipment for Measurement, Control,

and Laboratory Use – Part I

UL508 Industrial Control Equipment

10.5 Certication

Certification:

UL508 Industrial Control Equipment

Australia, Regulatory Compliance Mark (RCM)

CE, European Union

EMC directive 2014/30/EU: Certified to

IEC/EN 60255-26:2013

Low voltage directive 2014/35/EU: Certified to

IEC/EN 61010-1:2010 + AMD1:2016

1

FCC Part 15, Subpart B, Class A –

Unintentional Radiators

Page 35

AF0100 Arc-Flash Relay

10.6 Sensors

PGA-LS10 PGA-LS20 and PGA-LS30

Type: Point sensor Fiber-optic sensor

Page 31

REV. 0-B-013118

Detection Zone:

Output:

Electrical Cable:

180 x 360° (half sphere)

0-35 mA

Shielded 3-wire 20 AWG (0.5 mm2) electrical cable

360° along fiber

0-35 mA

Shielded 3-wire 20 AWG (0.5 mm2)

electrical cable

PGA-LS20:

8 m (26 ft) active;10 m (33 ft) total

(2 m (7 ft) shielded),

Factory Cable Length: 10 m (33 ft) electrical cable

2 x 10 m electrical cable

PGA-LS30:

18 m (59 ft) active; 20 m (66 ft) total

(2 m (7 ft) shielded),

2 x 10 m (33 ft) electrical cable

Max. Elec. Cable Length: 50 m (164 ft) 50 m (164 ft)

Sensor Check: Built-in LED for visual feedback Built-in LED for visual feedback

Transmitter and Receiver:

32 x 56 x 19 mm

(1.3 x 2.2 x 0.7 in)

Dimensions:

32 x 52 x 24 mm

(1.3 x 2.0 x 0.9 in)

Enclosure: IP 30 IP 30

Page 36

AF0100 Arc-Flash Relay

Page 32

REV. 0-B-013118

10.7 Ordering Information

AF0100-

Accessories:

PGA-LS10 Point Sensor

PGA-LS20 Fiber-Optic Sensor, 8 m (26 ft)

active length

PGA-LS30 Fiber-Optic Sensor, 18 m (59 ft)

active length

PGA-FLSH-00 Photo Flash for commissioning testing

PGA-FLSH-01 Photo Flash, CE and RoHS

0 -

Conformal Coating

Blank - No Conformal Coating

CC - Full Conformal Coating

Supply:

0: Dual Supply (100-240 Vac/100-250 Vdc,

24-48 Vdc)

1: Single Supply (24-48 Vdc)

10.8 Related Products

AF0500 Stand-alone Arc-Flash Relay with 4 sensor inputs,

2 trip coil outputs, 2 zones

PGR-8800 Stand-alone Arc-Flash Relay with 6 sensor inputs,

1 trip coil output, current inputs

10.9 Warranty

The AF0100 Arc-Flash Relay is warranted to be free from

defects in material and workmanship for a period of five

years from the date of purchase.

Littelfuse will (at Littelfuse’s option) repair, replace, or refund

the original purchase price of a AF0100 that is determined

by Littelfuse to be defective if it is returned to the factory,

freight prepaid, within the warranty period. This warranty

does not apply to repairs required as a result of misuse,

negligence, an accident, improper installation, tampering,

or insufficient care. Littelfuse does not warrant products

repaired or modified by non-Littelfuse personnel.

NOTES:

1. The AF0100 Arc-Flash Relay is currently listed as a

protective relay (UL category NRGU) and complies with the

UL508 Industrial Control Equipment standard. UL did not

evaluate the functionality of the arc-fault protection afforded

by this product. A file review will occur when the requirements

for investigation of arc detection and mitigation systems are

developed and additional tests will be performed if required.

2. The AF0100 uses the open source component FreeMODBUS

internally. For license, version, and source-code information

please contact opensource@littelfuse.com.

3. Remote-reset wiring is limited to 10 m (32 ft).

Page 37

10.0

Remote-Indication Relay

Maximum Switching Capacity

CURRENT, A

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

Page 33

AF0100 Arc-Flash Relay

REV. 0-B-013118

AC Resistive

Load

DC Resistive

Load

.9

.8

.7

.6

.5

.4

.3

.2

.

1

304050

10

20

FIGURE 10. TRIP and ERROR Relays Maximum Switching Capacity.

708090

60

100

VOLTAGE, V

200

250

300

400

500

600

700

800

900

1000

Page 38

AF0100 Arc-Flash Relay

APPENDIX A INSTALLATION LOG SHEET

GENERAL INSTALLATION SETTINGS MIN DEFAULT MAX UNIT COMMENTS

Date Installed

Operator

Comment 1

Comment 2

GENERAL

System Name

Description Of This Unit AF0100 Arc-Flash Relay

LIGHT SENSORS

Common Settings

Light Immunity Lower Limit 10 10 25 klux _________ klux

Page 34

REV. 0-B-013118

Arc Detection Time Before Tripping

Light Sensor 1

Sensor Status

Sensor Description Sensor 1

Change Configuration No Change

Light Sensor 2

Sensor Status

Sensor Description Sensor 2

Change Configuration No Change

COMMON CONTROL BLOCK

Trip Input

Enabled Enabled

Trip Output

Circuit Breaker Type

ADVANCED

Possibility To Reset Configuration And

Drive – No Setup Parameters

ALARMS

Shows Currently Standing Alarms

0

(Effective 0.8)

1 10 ms _________ ms

Shunt Coil (Trips When

Powered)

q Sensor Present

q No Sensor Detected

q Sensor Missing

q Sensor Tripped

q No Change

q No Sensor Expected

q Sensor Expected

q Sensor Present

q No Sensor Detected

q Sensor Missing

q Sensor Tripped

q No Change

q No Sensor Expected

q Sensor Expected

q Enabled q Disabled

Shunt Coil (Trips When Powered)

q Undervoltage Coil (Closed While

Powered)

Page 39

AF0100 Arc-Flash Relay

APPENDIX B REDUNDANT TRIP CIRCUIT

DESCRIPTION

The AF0100 includes a redundant trip circuit which is active

any time the CPU is not actively monitoring. Two conditions

in which the CPU is not actively monitoring are during

initialization (approximately 500ms following application of

power) and in the extremely rare event that an internal CPU

failure is detected.

When the CPU is active, it assumes control over the trip

circuitry. When the CPU is inactive or initializing the AF0100

behaves as follows:

• Light Sensor Programmed Delay – the redundant trip

circuit is hard wired and includes no delay, the

programmed sensor delay is ignored

• Trip Relay Mode – the fail-safe/non-fail-safe

setting is ignored, and trip relays operate in shunt

or non-fail-safe mode, so a trip condition causes the

trip relays to be energized

Page 35

REV. 0-B-013118

• Sensor Detection – sensor detection and failure

reporting is inactive, but light intensity is monitored

• TRIP Input – the TRIP 1 and TRIP 2 relays are

energized while the TRIP Input is active

• TRIPPED Output – the TRIPPED output is active

while light is detected or while the TRIP Input

is active

• RESET Input – the reset input is ignored

• RESET Button – the reset button is ignored

• ERROR Relay – the error relay is de-energized

• LEDs – all LEDs are off

NOTE: When under software control, the outputs

operate in their configured operating mode (shunt

trip or undervoltage trip). When controlled via redundant hardware, they are held statically as long

as the sensor reports light over the threshold, and

will operate only in the shunt trip mode.

Page 40

AF0100 Arc-Flash Relay

APPENDIX C

AF0100 REVISION HISTORY

Page 36

REV. 0-B-013118

MANUAL RELEASE

DATE

January 31, 2018 0-B-013118

December 5, 2017 0-B-120517

March 1, 2017 0-A-030117 1.00.01

MANUAL REVISION

HARDWARE REVISION

(REVISION NUMBER ON

PRODUCT LABEL)

0

MANUAL REVISION HISTORY

Revision 0-B-013118

Section 10.9

Updated warranty information.

Revision 0-B-120517

Section 10

Updated certification information.

Revision 0-A-030117

Initial release.

HARDWARE REVISION HISTORY

Hardware Revision 0

Initial release.

FIRMWARE REVISION HISTORY

Firmware Revision 1.00.02

The RESET function was corrected to properly

reset an external TRIP.

Firmware Revision 1.00.01

Initial release.

FIRMWARE REVISION

1.00.02

1.00.02

Loading...

Loading...