Page 1

Axial Lead & Cartridge Fuses

3AB 1000VAC / DC High Voltage Fuse

508 Series Lead-Free 3AB Fuse

Description

A 1000Vac/Vdc rated ceramic fuse with remarkable

interrupting rating in a compact 6.3×32mm package,

which is well suited for circuit protection in high energy

applications.

Features

Agency Approvals

Agency Agency File Number Ampere Range

Recognised File: E10480 315mA - 1A

315mA - 1A

Electrical Characteristics

% of Ampere

Rating

100%

135% 1 Hour, Maximum

200% 120 Seconds, Maximum

Ampere Rating Opening Time

4 Hours, Minimum

315mA - 1A

Electrical Characteristic

Amp Code Amp Rating

Voltage

Rating

Interrupting

Rating

• Inaccordance

with Underwriter’s

Laboratories Standard UL

248-14

• SuperiorInterrupting

rating of 10,000 Amperes

• Compactformfactorof

6.3×32mm

• Availableincartridgeand

axial lead

• RoHScompliantand

Lead-free

Applications

Used as supplementary protection in appliance or

utilization equipment to provide individual protection for

components or internal circuits.

Additional Information

Datasheet

Nominal Cold

Resistance

(mohms)

Resources

Nominal

Melting

2

t (A2 sec.)

I

Agency Approvals

Samples

.315 0.315 1000

.500 0.5 1000 3572 0.259 x x

001 1 1000 1580 0.449 x x

* 10KA@600Vac/dc also cURus approved. Add suffix “6”. Example: 0508.315MX6P.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

10kA @ 1000Vac

10kA @ 1000Vdc

9200 0.071 x x

Page 2

Axial Lead & Cartridge Fuses

300

240

Temperature (°C) - Measured on bottom side of board

3AB 1000Vac/DC High Voltage Fuse

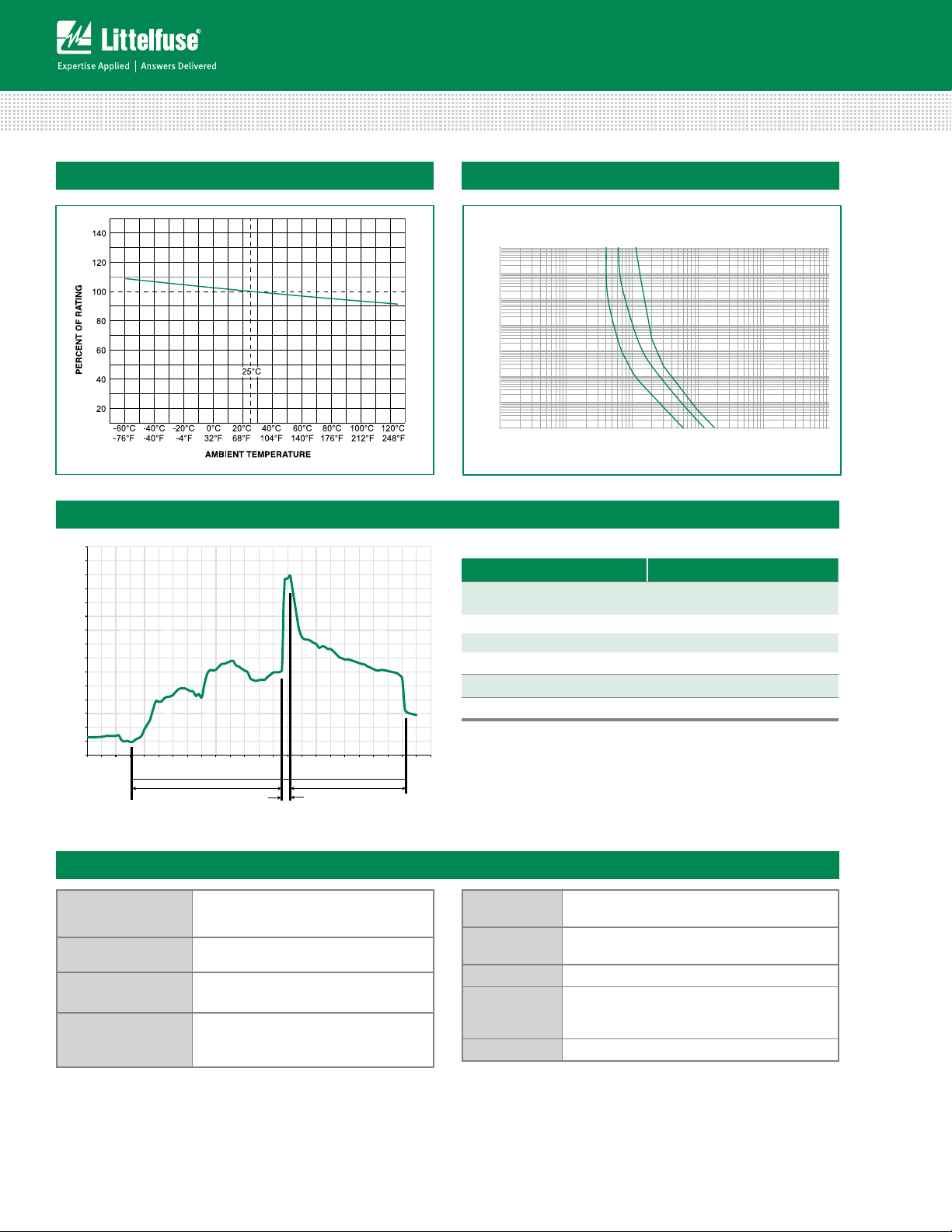

Average Time Current CurvesTemperature Rerating Curve

10000

1000

100

10

1

Time (seconds)

0.1

0.01

0.001

0.01 0.1 110 100

508.315

508.500

508001

Amps

Soldering Parameters - Wave Soldering

Recommended Process Parameters:

280

260

240

220

200

180

160

140

120

100

80

60

40

20

0

0

102030405060708090

Time (Seconds)

Preheat Time

100

110

120

130

140

150

160

170

180

190

200

210

220

230

Dwell Time

Cooling Time

Wave Parameter Lead-Free Recommendation

Preheat:

(Depends on Flux Activation Temperature)

Temperature Minimum:

Temperature Maximum:

(Typical Industry Recommendation)

100

° C

150

° C

Preheat Time: 60-180 seconds

Solder Pot Temperature:

260

° C Maximum

Solder Dwell Time: 2-5 seconds

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

Product Characteristics

Materials

Terminal Strength

Solderability

Cap : Nickel–plated brass

Leads : Tin-plated Copper

MIL-STD-202G, Method 211A,

Test Condition A

Reference IEC 60127 Second Edition

2003-01 Annex A

Cap1 : Brand logo, current and voltage

Body : Ceramic

Product Marking

ratings

Cap2 : Series and agency approval marks

Operating

–55ºC to 125ºC.

Temperature:

Thermal

Shock:

MIL-STD-202G, Method 107G, Test Condition B

(5 Cycles -65ºC to +125ºC).

Vibration MIL-STD-202G, Method 201A

Humidity MIL-STD-202G, Method 103B, Test Condition

A: High relative humidity (95%) and elevated

temp (40ºC) for 240 hours

Salt Spray MIL-STD-202G, Method 101E, Test Condition B

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Page 3

Axial Lead & Cartridge Fuses

0508 MX Exxxx

P

3AB 1000VAC / DC High Voltage Fuse

Dimensions

Measurements displayed in millimeters (inches)

508 000P Series

(cartridge)

6.35±0.3

(.25")

31.75±1.12

(1.25")

Axial Lead Diameter:

0.81±0.05 (.032")

Axial Lead Material:

Tin-coated copper

508 000EP Series

(axial leaded)

6.985±0.3

32.72±1.12

(1.288")

Axial Lead Length:

Standard Length:

39.68 (1.56") TYP.

Short Lead Option:

12.70 (0.50”) TYP

(.275")

Packaging

Packaging Option Packaging Specification Quantity

508 Series

Bulk N/A 1000 MX N/A

Bulk N/A 1000 MXE N/A

Part Numbering System

Series

Amp Code

Refer to Amp Code column of

Electrical Characteristics Table

Quantity Code

M = 1000

Packaging Code

X = Filler

Option Codes

Blank : Cartidage Type Fuse

E : Axial Lead Fuse

Lead-free

Quantity & Packaging

Code

Reel Size

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Loading...

Loading...