Littelfuse 501 User Manual

Surface Mount Fuses

Ceramic Fuse > 501 Series

501 Series – High Current 1206 Fast-Acting Fuse

Description

The 501 Series is a 100% Lead-free, RoHS compliant and

Halogen-free fuse series designed specifically to provide

over- current protection to circuits that operate under high

working ambient temperature up to 150°C.

The general design ensures excellent temperature stability

and performance reliability.

2

The high I

t values which is typical in the Littelfuse

Ceramic Fuse family, ensure high inrush current withstand

capability.

Features

• 100%Lead-free,RoHS

compliant and Halogenfree

• Suitableforbothleaded

and lead-free reflow /

wave soldering

• NotebookPC

• DC-DCConverter

Agency Approvals

AGENCY AGENCY FILE NUMBER AMPERE RANGE

E10480 10A - 20A

LR29862 10A - 20A

• OperatingTemperature

from -55ºC to +150ºC

• Designedtoprovide

over-current protection

in high current voltage

regulator module (VRM)

applications

Applications

• VoltageRegulator

Module (VRM)

Equipment

Electrical Characteristics for Series

% of Ampere

Rating

100% 10A – 20A 4 Hours, Minimum

350% 10A – 20A 5 Seconds, Maximum

Ampere Rating Opening Time at 25ºC

Additional Information

Datasheet

Resources

Samples

Electrical Specifications by Item

Ampere

Rating

(A)

10 010. 32

12 012. 32 0.00321 20.341 0.04891 0.5870 x x

15 015. 32 0.00250 36.100 0.04605 0.6908 x x

20 020. 32 0.00200 54.760 0.05936 1.1871 x x

Notes:

1. DC Interrupting Rating tested at rated voltage with time constant < 0.5 msec.

2. Nominal Resistance measured with < 10% rated current.

3. Nominal Melting I

4. Nominal Voltage Drop measured at rated current after temperature has stabilized and

with fuse mounted on board with 3-oz Cu trace.

Max. Voltage

Amp

Code

Rating

(V)

2

t measured at 1 msec. opening time. For other I2t data refer to chart.

Interrupting

Rating

1

(DC)

150 A @ 32 VDC

Nominal

Resistance

(Ohms)

0.00427 10.385 0.05679 0.5679 x x

Nominal

Melting I2T

2

(A2Sec.)

Nominal Voltage

Drop At Rated

3

Current (V)

Devices designed to carry rated current for 4 hours minimum. It is recommended that

devices be operated continuously at no more than 80% rated current. See “Temperature

Rerating Curve”for additional rerating information.

Devices designed to be mounted with marking code facing up.

Nominal Power

Dissipation At

4

Rated Current (W)

Agency Approvals

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Surface Mount Fuses

Ceramic Fuse > 501 Series

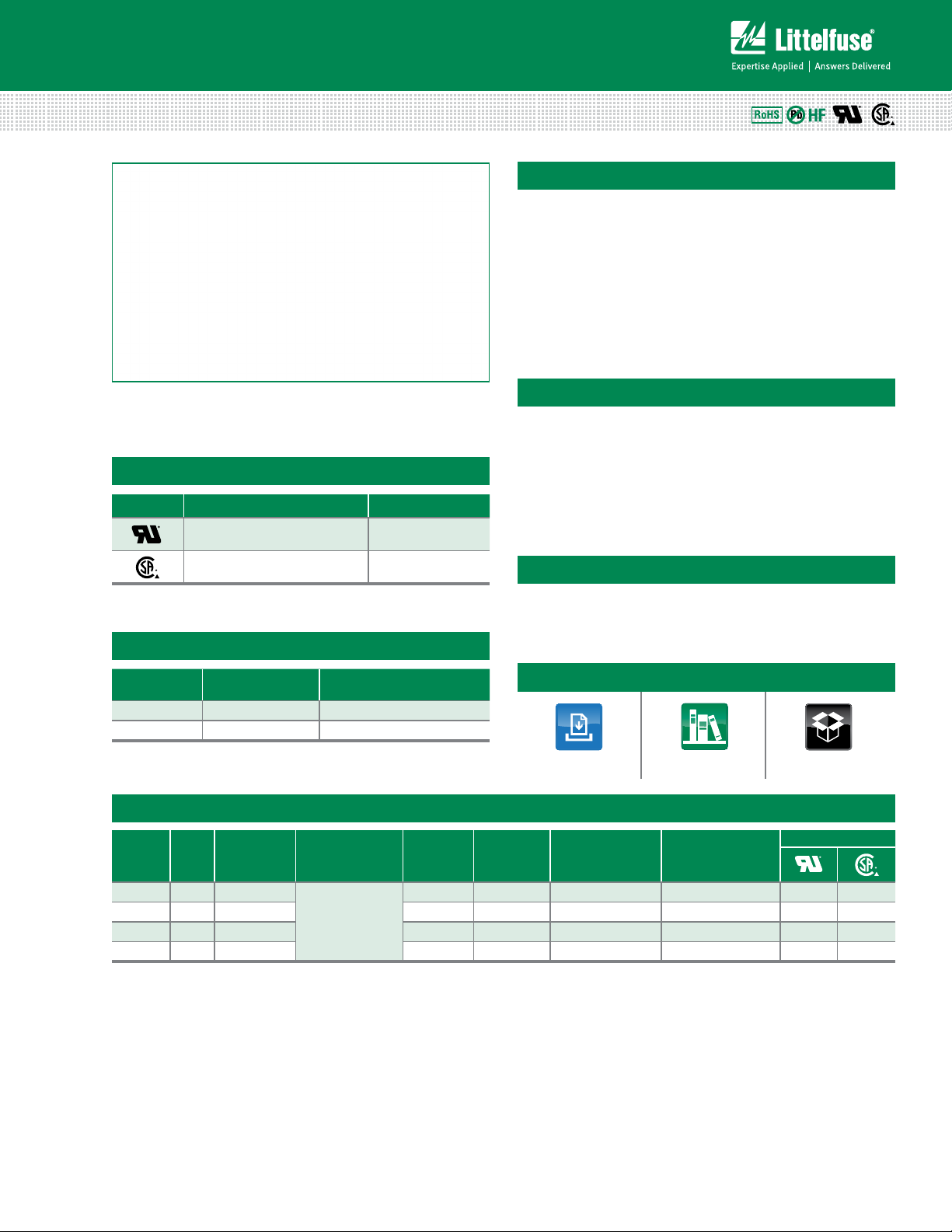

Temperature Rerating Curve

140

120

100

80

PERCENT OF RATING

60

40

-65 -45 -25 -5 15 35 55 75 95 115 135 155

TEMPERATURE (°C)

Note:

1. Rerating depicted in this curve is in addition to the standard rerating of 20% for

continuous operation.

Example:

For continuous operation at 75 degrees celsius, the fuse should be rerated as follows:

I = (0.80)(0.85)I

RAT

= (0.68)I

RAT

Average Time Current Curves

10

1

0.1

TIME IN SECONDS

0.01

0.001

1 10 100 1000

CURRENT IN AMPERES

15A

10A

12A

20A

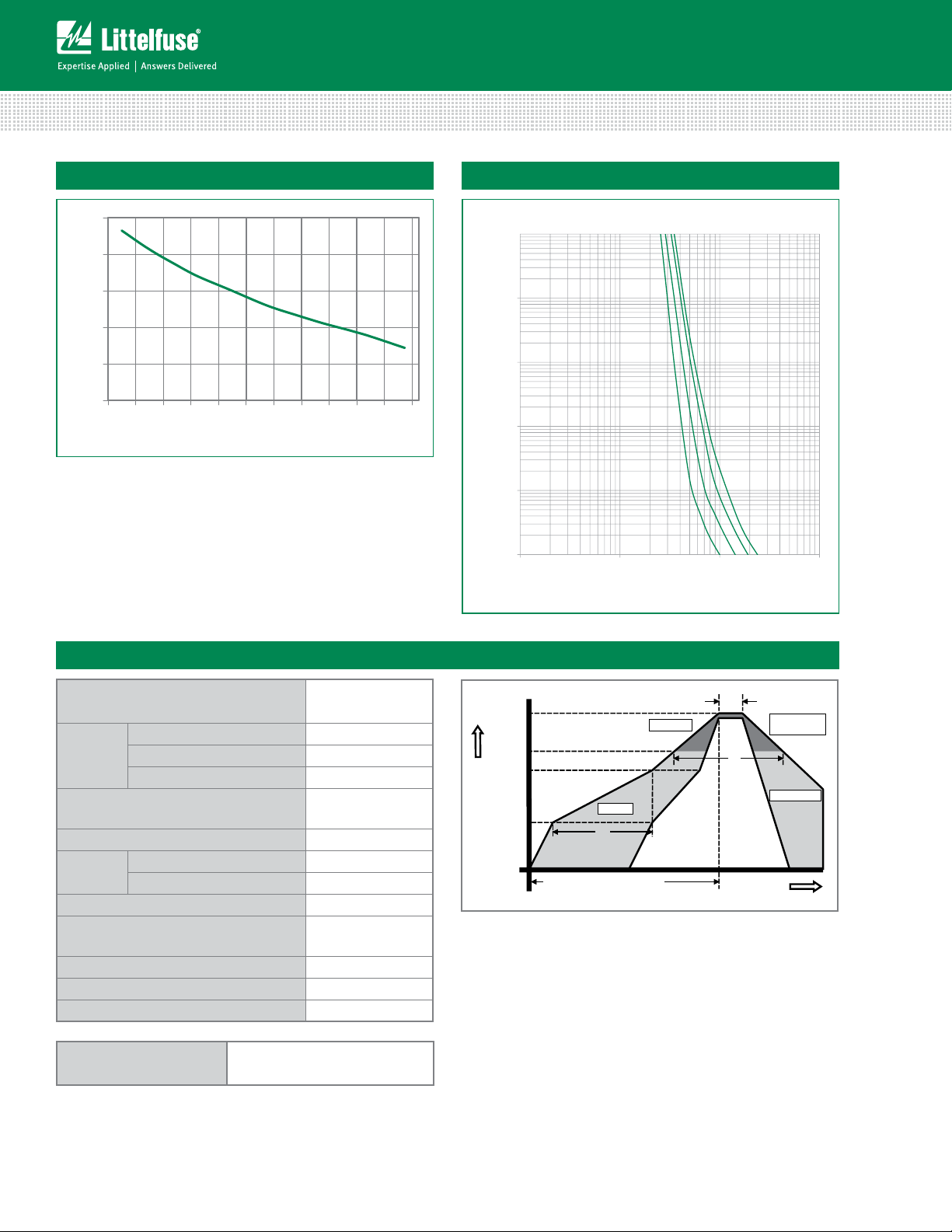

Soldering Parameters

Reflow Condition Pb – free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (Min to Max) (ts) 60 – 180 seconds

Average Ramp-up Rate (Liquidus Temp

(T

) to peak)

L

to TL - Ramp-up Rate 5°C/second max.

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 6°C/second max.

Time 25°C to peak Temperature (T

Do not exceed 260°C

Wave Soldering 260°C, 10 seconds max.

) 150°C

s(min)

) 200°C

s(max)

3°C/second max.

+0/-5

°C

10 – 30 seconds

) 8 minutes max.

P

Temperature

T

S(max)

T

T

T

S(min)

25

P

L

time to peak temperature

(t 25ºC to peak)

Preheat

t

S

Ramp-up

t

P

Critical Zone

T

to T

L

P

t

L

Ramp-down

Time

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Loading...

Loading...