Page 1

468 Series Fuse

Surface Mount Fuses

Thin Film > 1206 Size > Slo-Blo® > 468 Series

Description

The 468 Series Time-Lag (Slo-Blo®) SMF is a small (1206

size) thin-film device designed for secondary protection

of circuits used in space constrained applications such as

hand-held portable electronic devices.

This series is 100% lead-free and meets the requirements

of the RoHS directive. New Halogen-Free 468 Series

fuses are available–to order use the “HF” suffix. See Part

Numbering section for additional information.

Agency Approvals

AGENCY AGENCY FILE NUMBER AMPERE RANGE

E10480 500MA - 3A

LR29862 500MA - 3A

Electrical Characteristics for Series

% of Ampere

Rating

100% 4 hours, Minimum

200% 1 sec., Min.; 120 sec., Max.

300% 0.05 sec., Min.; 1.5 sec., Max

800% 0.0015 sec., Min.; .05 sec., Max.

Opening Time at 25

O

C

Additional Information

Datasheet

Resources

Samples

Features

• Complieswith

electronic industry

environmental standards

for lead reduction.

• Productiscompatible

with lead-free solders

and higher temperature

• Packageisvisually

distinct from fastacting version for easy

identification.

• Topsidemarkingallows

visual verification of

amperage rating.

profiles.

• Timedelayfeature

withstands high inrush

currents and prevents

nuisance openings.

Applications

Secondary protection for space constrained applications:

• Cellphones

• Batterypacks

• DVDplayers

• Harddiskdrives.

• Digitalcameras

Electrical Specifications by Item

Ampere

Rating

(A)

0.50 .500 63

1. 0 0 00 1. 63 0.08250 0.1270 94.70 0.0947 x x

1.50 01. 5 63 0.04750 0.2880 82.32 0.1235 x x

2.00 002. 63 35 amperes @63 VAC

2.50 02.5 63 0.02240 1.0110 73.92 0.1848 x x

3.00 003. 32 50 amperes @32

1. Measured at 10% of rated current, 25˚C.

2. Measured at rated voltage.

Amp

Code

Max

Voltage

Rating

(V)

Interrupting

Rating

50 amperes @63

VAC/VDC

50 amperes @63

VDC

VAC/VDC

Nominal Cold

Resistance

(Ohms)

0.27000 0.0310 156.77 0.0784 x x

0.03240 0.5060 77.27 0.1545 x x

0.01950 1.2700 72.95 0.2189 x x

Nominal

Melting

2

t (A2sec)

I

Nom

Voltage

Drop

(mV)

Nom

Power

Dissipation

(W)

Specifications are subject to change without notice.

Approvals

© 2013 Littelfuse, Inc.

Agency

Revised: 12/19/13

Page 2

Surface Mount Fuses

0

Current in Amperes

Time in Seconds

5A

Thin Film > 1206 Size > Slo-Blo® > 468 Series

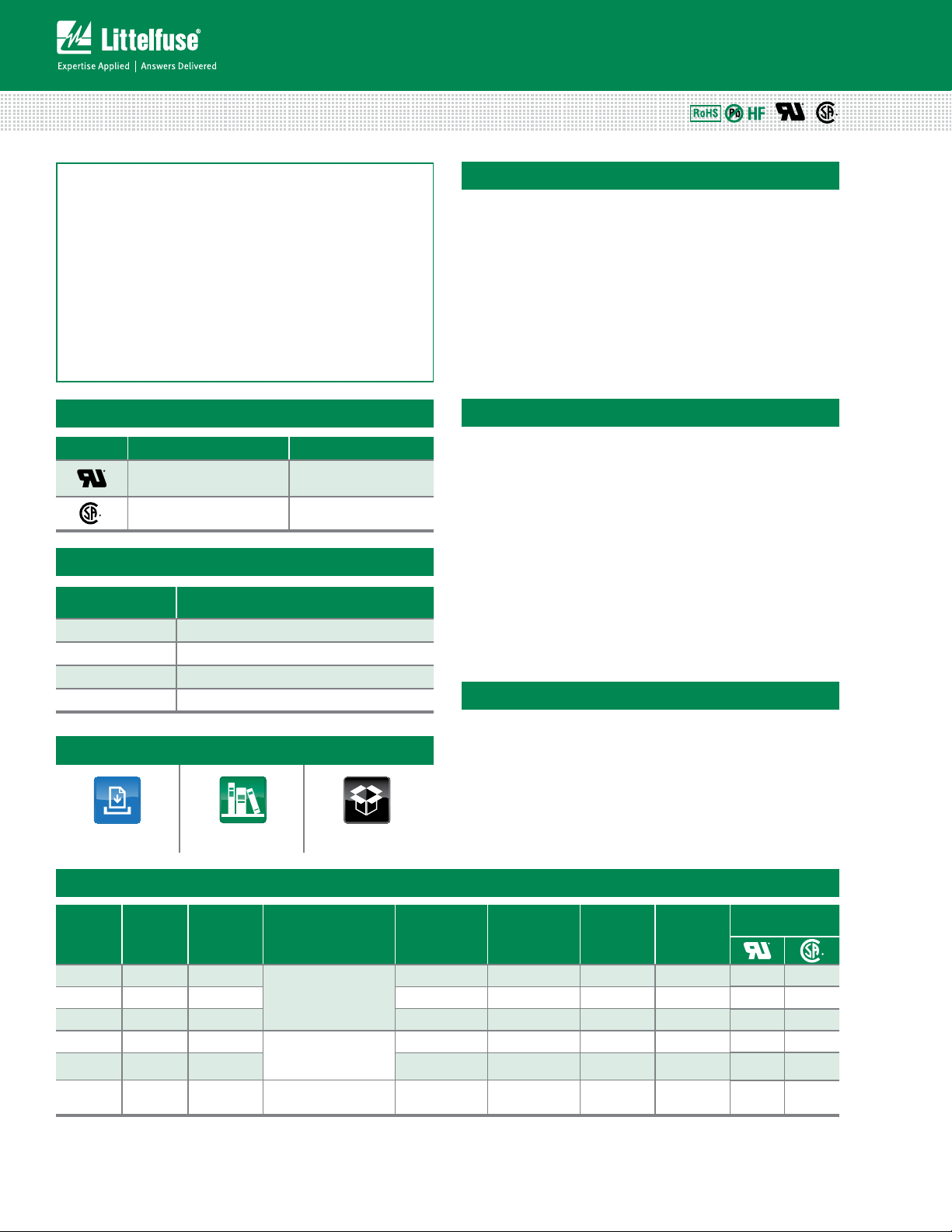

Average Time Current CurvesTemperature Rerating Curve

Note:

1. Derating depicted in this curve is in addition to the standard derating of 25% for

continuous operation.

Example:

For continuous operation at 70 degrees celsius, the fuse should be deratedas follows:

I = (0.75)(0.80)I

2. The temperature derating curve represents the nominal conditions. For questions

about temperature derating curve, please consult Littelfuse technical support

for assistance.

= (0.60)I

RAT

RAT

0.01

0.001

1A

100

10

1

0.1

.5A

3A

2.

2A

1.5A

010110

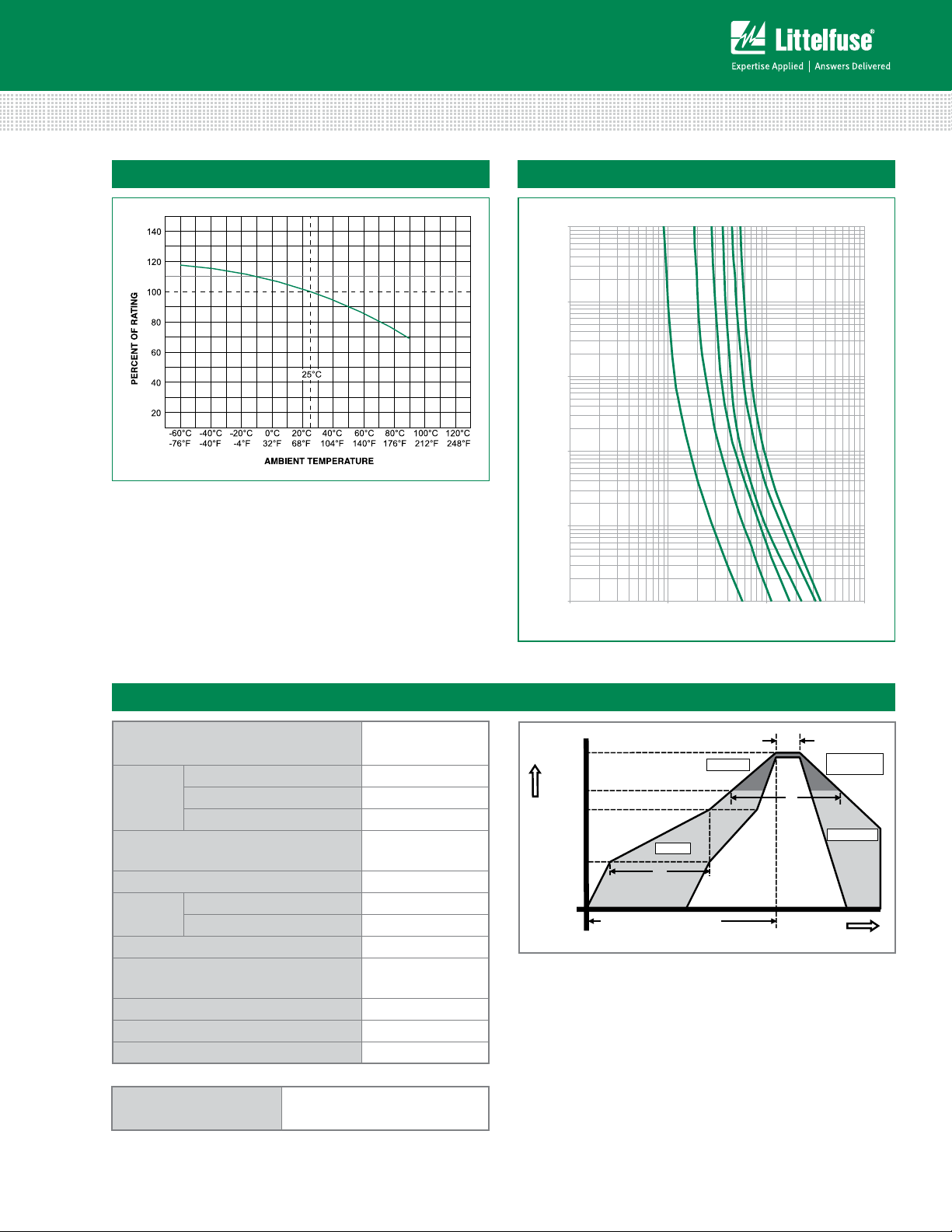

Soldering Parameters

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (Min to Max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus Temp

(T

) to peak

L

to TL - Ramp-up Rate 5°C/second max

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 5°C/second max

Time 25°C to peak Temperature (T

Do not exceed 260°C

Wave Soldering 260°C, 10 seconds max.

) 150°C

s(min)

) 200°C

s(max)

5°C/second max

+0/- 5

20 – 40 seconds

) 8 minutes Max.

P

°C

T

Temperature

S(max)

T

S(min)

T

P

T

L

25

time to peak temperature

Preheat

t

S

(t 25ºC to peak)

Ramp-up

t

P

Critical Zone

T

to T

L

P

t

L

Ramp-down

Time

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Page 3

Product Characteristics

Surface Mount Fuses

Thin Film > 1206 Size > Slo-Blo® > 468 Series

Body: Epoxy Substrate

Materials

Terminations: 100% Tin over Nickel over

Copper

Element Cover Coat: Conformal Coating

O

–55

Operating

Temperature

C to 90OC. Consult temperature

rerating curve chart. For operation above

90°C please contact Littelfuse

Thermal Shock Withstands 5 cycles of – 50

O

C to 125OC

Vibration

Insulation Resistance

(After Opening)

Resistance to

Soldering Heat

Humidity MIL-STD-202F, Method 103B, Condition D

Dimensions Part Marking System

MARKING CODE VARIES

WITH AMPERAGE RATING

(SEE CHART)

3.18

(.125")

1.65

(.065")

1.52

(.060")

WAVE SOLDER

2.03

(.080")

(.190")

4.83

1.27

(.050")

1.52

(.060")

.66

(.026")

Coating

2.03

(.080")

1.52

(.060")

1.14

(.045")

3.81

(.150")

INFARED SOLDER

.58

(.023")

Amp

Code

Marking

Code

.500 TF

0 01. TH

01.5 TK

002. TN

02.5 TO

003. TP

Part Numbering System

SERIES

AMP Code

The dot is poisitioned before the Packaging Suffix with whole ratings and

within the numbering sequence for

fractional ratings. Refer to Amp Code

column in the Electrical Specifications

table.

PACKAGING Code

NR = Tape and Reel, 5000 pcs

‘HF’ SUFFIX

HALOGEN FREE ITEM

Withstands 10-55 Hz per MIL-STD-202F,

Method 201A and

10-2000 Hz at 20 G’s per MIL-STD-202F,

Method 204D, Condition D

Greater than 10,000 ohms.

MIL-STD-202G, Method 210F,

Condition D

0468002.NRHF

Example:

1.5 amp product is

046801.5NRHF (2 amp

product shown above).

Packaging

Packaging Option Packaging Specification Quantity

Tape & Reel – 8mm tape EIA-481 Rev. D (IEC 60286, part 3) 5000 NR

Quantity &

Packaging Code

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Loading...

Loading...