Page 1

456 Series Fuse

Surface Mount Fuses

NANO2® > 456 Series

Description

The High Current NANO

mount fuse that is designed to support higher current

requirements of various applications.

2®

Fuse is a small square surface

PS

E

40A

20A, 25A, 30A

Agency Approvals

AGENCY AGENCY FILE NUMBER AMPERE RATING

E10480 20A, 25A, 30A, 40A

PS

E

NBK030308-JP1021 20A, 25A, 30A

Electrical Characteristics

% of

Ampere Rating

100% 4 hours, Minimum

200% 60 seconds, Maximum

Opening Time

Features

• Surfacemounthigh

current fuse

• Fullycompatiblewith

lead-free solder alloys

and higher temperature

profiles associated with

lead-free assembly

Applications

• Voltageregulatormodule

for PC server

• Coolingfansystemfor

PC server

• Storagesystempower

Additional Information

Datasheet

Resources

• RoHScompliantand

Halogen Free

• Availableinratingsof20

to 40 Amperes

• Basestationpower

supply

Samples

Electrical Specifications

Ampere

Rating

(A)

20 020. 125

25 025. 125

30 030. 125

40 040. 72

Notes:

1. Cold resistance measured at less than 10% of rated current at 23°C.

2. Agency Approval Table Key: X=Approved or Certified, P=Pending.

3. I2t values stated for 10 msec opening time.

Amp Code

Max

Voltage

Rating

(V)

Interrupting Rating

100A @125VAC

300A @ 65VAC

300A @ 100VDC

1000A @ 32VDC

500A @ 72VDC

100A @ 125VAC

300A @ 65VAC

500A @ 72VDC

1000A @ 32VDC

100A @ 125VAC

300A @ 65VAC

1000A @ 32VDC

500A @ 72VDC

180A @ 72VDC

600A @ 60VDC

Nominal

Cold Resistance

(Ohms)

0.00230 18 64.7 x x

0.00192 45 68.38 x x

0.00132 81 69.9 x x

0.00105 454 55 x

Nominal

Melting

2

t (A2 Sec.)

I

Nom Voltage

Drop

(mV)

Specifications are subject to change without notice.

Agency Approvals

PS

E

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Page 2

Surface Mount Fuses

NANO2® > 456 Series

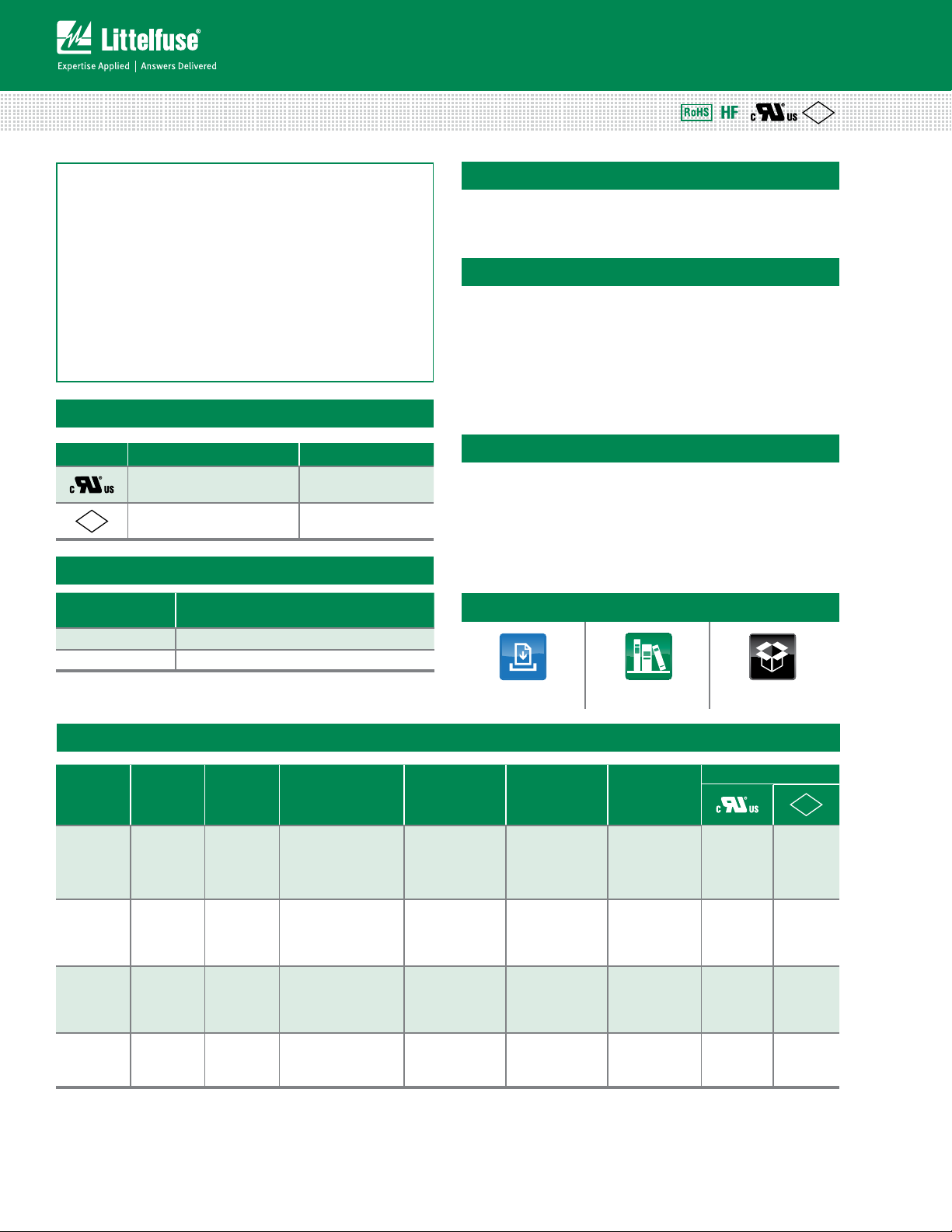

60

40

20

0 0

PERCENT OF UPRATING

Average Time Current CurvesTemperature Rerating Curve

40A

30A

20A

25A

100

20

40

60

120°C

140°C100°C80°C60°C40°C20°C0°C-20°C-40°C-60°C

248°F212°F176°F140°F104°F68°F32°F-4°F-40°F-76°F

AMBIENT TEMPERATURE

264°F

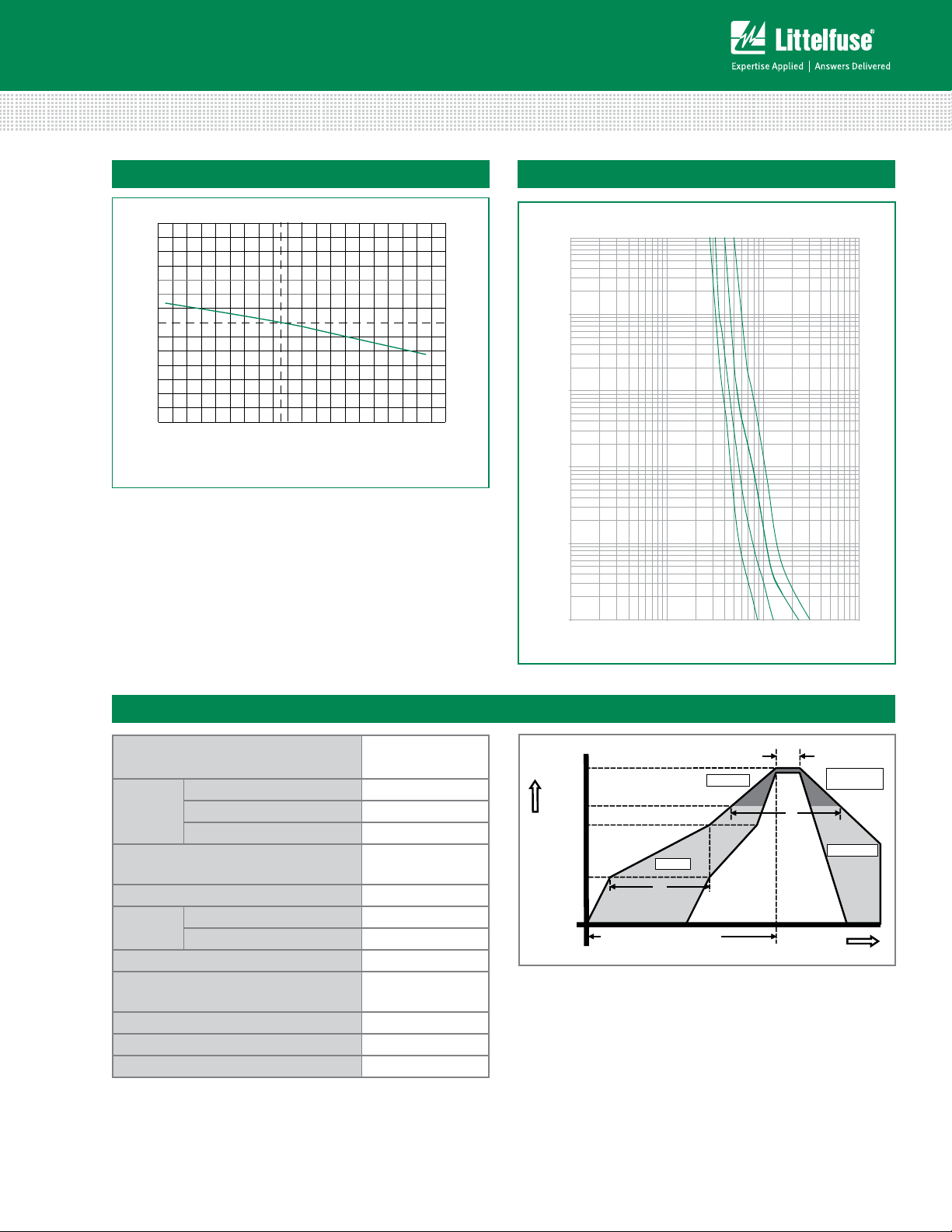

Soldering Parameters – Reflow Soldering

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (Min to Max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus Temp

(TL) to peak

T

to TL - Ramp-up Rate 5°C/second max.

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (tp)

Ramp-down Rate 5°C/second max.

Time 25°C to peak Temperature (TP) 8 minutes max.

Do not exceed 260°C

) 150°C

s(min)

) 200°C

s(max)

5°C/second max.

+0/–5

°C

20 – 40 seconds

PERCENT OF DOWNUPRATING

10

TIME IN SECONDS

1

0.1

0.01

1 10 100 1000

CURRENT IN AMPS

t

P

t

L

T

Temperature

S(max)

T

S(min)

T

P

T

L

25

time to peak temperature

Preheat

t

S

(t 25ºC to peak)

Ramp-up

Critical Zone

Ramp-down

Time

T

to T

L

P

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Page 3

Product Characteristics

20A, 25A, 30A:

Surface Mount Fuses

NANO2® > 456 Series

Materials

Body: Ceramic

Cap: Silver Plated Brass

Product Marking Body: Brand Logo, Current Rating

Insulation Resistance

MIL-STD-202, method 302, Test

Condition A (10,000 ohms, Minimum)

Solderability MIL-STD-202, Method 208

Resistance to

Soldering Heat

MIL-STD-202, Method 210,

Test Condition B (10 sec at 260

Min. copper layer thickness = 100µm

Min. copper trace width =20A, 30

10mm (20A, 30A) / 15mm (40A)

PCB

Recommendation for

Thermal Management

Alternate methods of thermal management may be used. In such cases,

under normal operations, the maximum temperature of the fuse body

should not exceed 80

environment.

Dimensions

3.120

[.123”]

1.70 typ

(0.067”)

Recommended Pad Layout

2.173

(.086”)

2.79

(.110”)

40A:

3.120

(.123”)

10.10

(.397”)

F

20 A

F

12.50

(.492)

40 A

6.10

(.240”)

12.60

(.496”)

4.445

(.175”)

O

O

C)

C in a 25OC

3.25

(.128”)

3.43

(.135”)

4.445

(.175”)

Operating Temperature -55OC to 125OC with proper derating

MIL-STD-202F, Method 107G,

Thermal Shock

Vibration

Moisture Sensitivity

Level

Test Condition B

(5 cycles -65

O

C to 125OC)

MIL-STD-202F, Method 201A

(10-55 Hz)

Level 1 J-STD-020C

MIL-STD-202F Method 106,

Moisture Resistance

Salt Spray

High Humidity (90-98%RH),

Heat (65

O

C)

MIL-STD-202F, Method 101D,

Test Condition B

MIL-STD-202, Method 213,

Mechanical Shock

Test Condition I (100 G’s peak for 6

milliseconds)

Part Numbering System

0456 020. E R

SERIES

AMP Code

Refer to Electrical

characteristics table

qUANTITY Code

E = 2500 pcs

D = 1500 pcs

PACKAGING Code

R = Tape and Reel

0.30

(.012”)

(.225”)

(.524”)

5.72

13.3

3.79

(.149”)

5.65

Recommended Pad Layout

(.222”)

Packaging

Rating Packaging Option Packaging Specification Quantity Quantity & Packaging Code

20A, 25A, 30A 24 mm Tape and Reel EIA RS-481-2 2500 ER

40A 24 mm Tape and Reel EIA RS-481-2 (IEC 286, part 3) 1500 DR

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Loading...

Loading...