Page 1

Axial Lead & Cartridge Fuses

PICO® ll > Very Fast-Acting > 263 Series

263 Series, PICO® II 250 Volt, Very Fast-Acting Fuse

Description

The PICO

axial leaded fuse that achieves a 250V rating in a small

package.

Features

®

II 263 Series Fuse is a specially designed

PS

E

Agency Approvals

Agency Agency File Number Ampere Range

E10480 62mA - 5A

PS

E

JET 1896-31007-1001 1A - 5A

LR 29862 125mA - 5A

Additional Information

Datasheet

Resources

Samples

Electrical Characteristics

• 250Vrating

• Veryfast–acting

• Smallsize

• Widerangeofcurrent

rating available (62mA to

5A)

• RoHScompliant&

Halogen-free

• Wideoperating

temperature range

• Lowtemperature

de-rating

Applications

• Lightingsystem

• Ofceautomation

• Powersupply

• LCD/PDPTV

• LCDmonitor

• Audio/Videosystem

• Medicalequipment

Electrical Characteristics

% of Ampere

Rating

100% 4 Hours, Min.

200% 1 Second, Max.

300% 0.1 Second, Max.

Opening Time

machines

Ampere

Rating

(A)

0.062 .062 250

0.125 .125 250 1.75 0.00251 0.3 x x

0.250 .250 250 0.715 0.0165 0.235 x x

0.375 .375 250 0.391 0.0444 0.195 x x

0.500 .500 250 0.332 0.084 0.302 x x

0.750 .750 250 0.150 0.0411 0.176 x x

1. 0 0 0 01. 250 0.105 0.087 0.165 x x x

1.50 01. 5 250 0.0635 0.398 0.148 x x x

2.00 002. 250 0.0444 0.74 0.137 x x x

2.50 02.5 250 0.0340 1.197 0.128 x x x

3.00 003. 250 0.0274 1.77 0.1225 x x x

3.50 03.5 250 0.0224 2.33 0.1175 x x x

4.00 004. 250 0.0193 3.08 0.1125 x x x

5.00 005. 250 0.0145 5.55 0.1065 x x x

Amp Code

Max

Voltage

Rating

(V)

Interrupting

Rating

50 amperes

at 250 VAC

PSE: 100

amperes

at 125 VAC.

Nominal Cold

Resistance

(Ohms)

5.50 0.000192 0.74 x

Nominal

Melting

2

t (A2 sec)

I

Nom

Voltage Drop

(mV)

Agency Approvals

PS

E

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Page 2

Axial Lead & Cartridge Fuses

PICO® ll > Very Fast-Acting > 263 Series

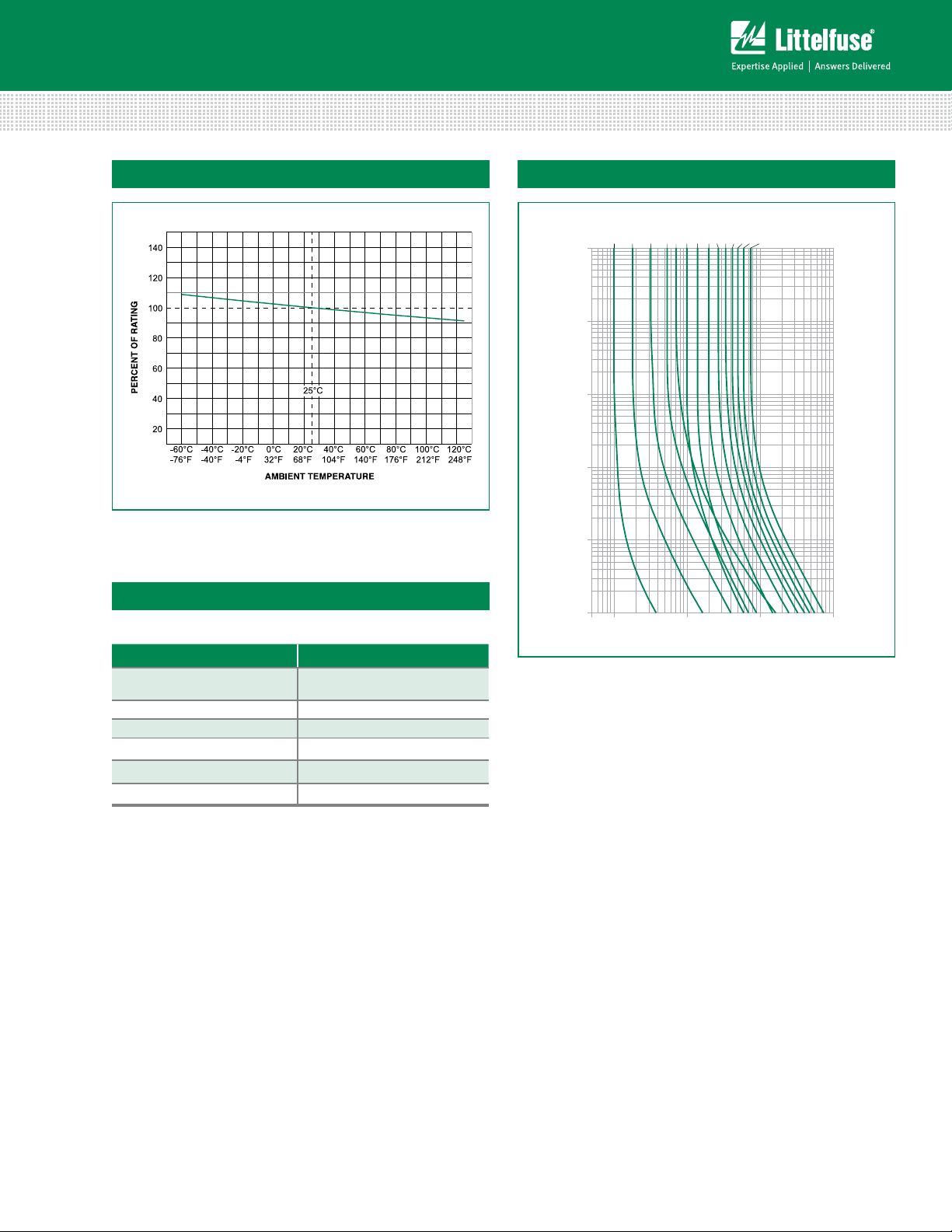

Temperature Rerating Curve

Note:

1. Derating depicted in this curve is in addition to the standard derating of 25% for

continuous operation.

Soldering Parameters

Recommended Process Parameters:

Wave Parameter Lead-Free Recommendation

Preheat:

(Depends on Flux Activation Temperature)

Temperature Minimum:

Temperature Maximum:

Preheat Time: 60-180 seconds

Solder Pot Temperature:

Solder Dwell Time: 2-5 seconds

(Typical Industry Recommendation)

100

° C

150

° C

260

° C Maximum

Average Time Current Curves

1/16A

1/8A

1/4A

3/8A

1/2A

100

10

1

TIME IN SECONDS

0.1

0.01

0.001

0.05 0.1 110 100

3/4A1A1 1/2A2A2 1/2A3A3 1/2A4A5A

CURRENT IN AMPERES

Recommended Hand-Solder Parameters:

Solder Iron Temperature: 350° C +/- 5°C

Heating Time: 5 seconds max.

Note: These devices are not recommended for IR or

Convection Reflow process.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/19/13

Page 3

Product Characteristics

F

L

3 1/2 A

250 V

F

L

3 1/2 A

250 V

27.78

(1.094")

27.78

(1.094")

7.11 (.280")

62.7 (2.468")

52.4 (2.062")*

0.64 (.025")

3.94 (.16")

MAX

6.35 (.25")

tape

5.0 (.197")

6.35 (.25")

tape

0263 xxxx W R T1 L

Axial Lead & Cartridge Fuses

PICO® ll > Very Fast-Acting > 263 Series

Encapsulated, Epoxy-Coated

Body: Solder Coated Copper Leads.

Materials

RoHS compliant

Product: Pure Tin–coated Copper wire

leads

Solderability MIL-STD-202. Method 208.

Product Marking Body marking, current rating and logo

Operating

Temperature

Shock

–55ºC to +125ºC

MIL-STD-202, Method 213, Test Condition

I (100 G’s peak for 6 milliseconds)

Dimensions

MIL-STD-202, Method 201 (10–55

Vibration

Hz); MIL-STD-202, Method 204, Test

Condition C (55–2000 Hz at 10 G’s

Peak)

Salt Spray

Insulation Resistance

(After Opening):

Resistance to Soldering

Heat

Thermal Shock

MIL-STD-202, Method 101,

Test Condition B (48 hrs.)

MIL-STD-202, Method 302,

Test Condition A (10,000 ohms

minimum at 100 volts)

MIL-STD-202, Method 210,

Test Condition C (10 sec. at 260ºC)

MIL-STD-202, Method 107, Test

Condition B (–55ºC to 125ºC)

Moisture Resistance MIL-STD-202, Method 106

MIL-STD-202, Method 211,

Lead Pull Force

Test Condition A (will withstand 7 lb.

axial pull test)

Part Numbering System

Series

Current Rating

Refer to Amp Code column of

Electrical Characteristics Table

Quantity

W = 3000

M = 1000

H = 100

Type of Packaging

R = Reel

A = Ammo Pack

X = Loose Pack

Lead Length

T1: 52.4mm (2.062”)*

RoHS + HF

Packaging

Packaging Option Packaging Specification Quantity

T1: 52.4mm (2.062”)

Tape and Reel

Notes: * T1 dimension is defined as the length of the component between the two tapes. The full component length is 62.7mm (2.468").

EIA 296

Please refer to available quantities

above in “Part Numbering System”

Quantity &

Packaging Code

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/19/13

Loading...

Loading...