Page 1

0402L Series

POLY-FUSE® Resettable PTCs

Surface Mount > 0402L Series

Description

The 0402L Series PTC provides surface mount

overcurrent protection for applications where space is at

a premium and resettable protection is desired.

Features

Agency Approvals

AGENCY AGENCY FILE NUMBER

E183209

R50119118

• RoHS compliant, lead-free

and halogen free

• Fast response to fault

currents

• Compact design saves

board space

• Low resistance

Applications

• USB peripherals

• Disk drives

• CD-ROMs

• Plug and play protection

for motherboards and

• Low-prole

• Compatible with high

temperature solders

• 0402 size- the smallest

PPTC in the market

compatible with high

temperature solders

• PDAs / digital cameras

• Game console port

protection

• Tablet and Notebook PCs

• E-readers

peripherals

Electrical Characteristics

Part Number

I

hold

(A)

Maximum Time

Current

(A)

To Trip

Time

(Sec.)

I

V

I

(A)

trip

max

(Vdc)

(A)

max

P d typ.

(W)

Resistance

R

min

(Ω)

R

1max

(Ω)

0402L010SL 0.10 0.30 6 40 0.5 0.50 1. 0 0 0.150 2.000 X X

0402L020SL 0.20 0.50 6 40 0.5 1. 00 1. 0 0 0.100 1.250 X X

0402L035SL 0.35 0.70 6 50 0.5 8.00 0.10 0.050 0.700 X X

0402L050SL 0.50 1. 00 6 50 0.5 8.00 0.10 0.040 0.400 X X

Agency

Approvals

I

= Hold current: maximum current device will pass without tripping in 20°C still air.

hold

I

= Trip current: minimum current at which the device will trip in 20°C still air.

trip

V

= Maximum voltage device can withstand without damage at rated current (I max)

max

I

= Maximum fault current device can withstand without damage at rated voltage (V

max

P d = Power dissipated from device when in the tripped state at 20°C still air.

R

= Minimum resistance of device in initial (un-soldered) state.

min

R

= Maximum resistance of device at 20°C measured one hour after tripping or reow soldering of 260°C for 20 sec.

1max

Caution: Operation beyond the specied rating may result in damage and possible arcing and ame.

)

max

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 01/17/14

Page 2

POLY-FUSE® Resettable PTCs

Surface Mount > 0402L Series

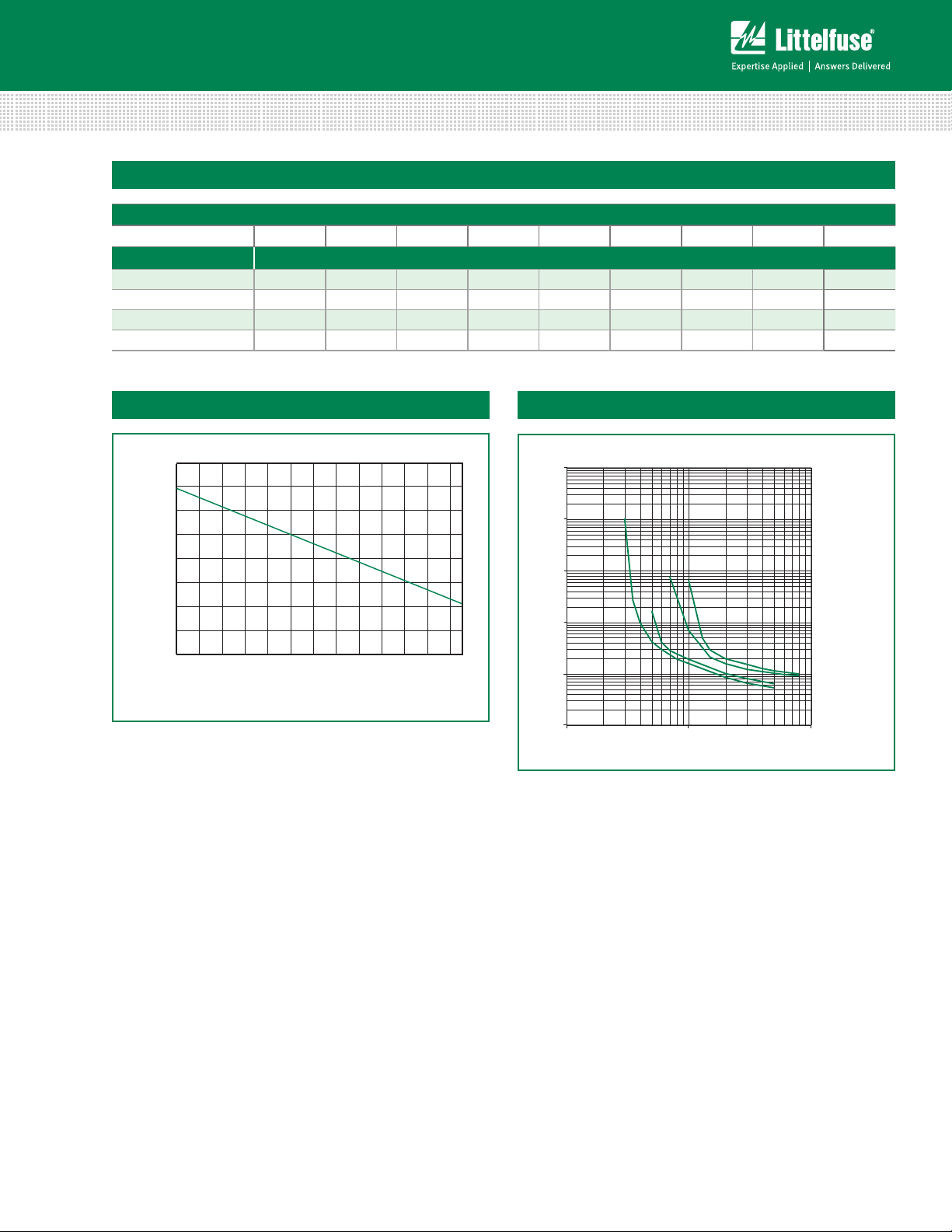

Temperature Rerating

Ambient Operation Temperature

-40°C -20°C 0°C 20°C 40°C 50°C 60°C 70°C 85°C

Part Number

0402L010SL 0.15 0.13 0.12 0.10 0.09 0.07 0.06 0.05

0402L020SL 0.29 0.27 0.24 0.20 0.17 0.14 0.11 0.10

0402L035SL 0.51 0.47 0.41 0.35 0.30 0.25 0.20 0.18

0402L050SL 0.74 0.67 0.59 0.50 0.43 0.36 0.29 0.26

Hold Current (A)

0.01

0.03

0.07

0.10

Temperature Rerating Curve

170%

150%

130%

110%

90%

70%

50%

Percentage of Rated Current

30%

10%

-40 -30 -20 -10010 20 30 40 50 60 70 80

Temperature (°C)

Average Time Current Curves

100.00

10.00

1.00

0.10

Time in Seconds

0.01

0.00

0.10 1.00 10.00

The average time current curves and Temperature Rerating curve performance is affected

by a number or variables, and these curves provided as guidance only. Customer must

verify the performance in their application.

Time-to-Trip Curve

A

C

D

B

Current in Amperes

A-0402L010SL

B-0402L020SL

C-0402L035SL

D-0402L050SL

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 01/17/14

Page 3

Soldering Parameters

R

R

o

POLY-FUSE® Resettable PTCs

Surface Mount > 0402L Series

Prole Feature Pb-Free Assembly

Average Ramp-Up Rate (T

Temperature Min (T

Pre Heat:

Time Maintained

Above:

Temperature Max (T

Time (Min to Max) (ts)

Temperature (TL)

Temperature (tL)

Peak / Classication Temperature (TP) 260

Time within 5°C of actual peak

Temperature (tp)

to TP) 3°C/second max

S(max)

)

150°C

s(min)

)

200°C

s(max)

60 – 180 secs

217°C

60 – 150 seconds

+0/-5

20 – 40 seconds

°C

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (TP) 8 minutes Max.

Physical Specifications

Terminal Material

Solder-Plated Copper

(Solder Material: Matte Tin (Sn))

t

T

P

amp-up

Ramp-up

T

L

T

S(max)

T

S(min)

Temperature

25

time to peak temperature

-- All temperature refer to topside of the package, measured on the package body surface

-- If reow temperature exceeds the recommended prole, devices may not meet the

performance requirements

-- Recommended reow methods: IR, vapor phase oven, hot air oven, N2 environment for

lead

-- Recommended maximum paste thickness is 0.25mm (0.010 inch)

-- Devices can be cleaned using standard industr y methods and solvents

-- Devices can be reworked using the standard industry practices

PreheatPreheat

t

S

P

t

L

Ramp-down

amp-d

Time

Critical Zone

tL to t

P

Environmental Specifications

Operating/Storage

Temperature

-40°C to +85°C

Lead Solderability

Meets EIA Specication RS186-9E,

ANSI/J-STD-002, Category 3.

Maximum Device Surface

Temperature in Tripped State

Passive Aging

Humidity Aging

125°C

+85°C, 1000 hours

-/+10% typical resistance change

+85°C, 85% R.H.,100 hours

-/+15% typical resistance change

MIL–STD–202, Method 107G

Thermal Shock

+85°C/-40°C 20 times

-30% typical resistance change

Solvent Resistance

MIL–STD–202, Method 215

No change

MIL–STD–883C, Method 2007.1,

Vibration

Condition A

No change

Moisture Sensitivity Level Level 1, J–STD–020C

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 01/17/14

Page 4

POLY-FUSE® Resettable PTCs

C

Device Top and Bottom Marking and Dimensions are Similar

Side

View

D

Marking code

varies by device

-- See Electrical

Characteristics table

E

A

B

FF

Solder Pad Layout

Device Dimensions

H

G

Surface Mount > 0402L Series

Dimensions

Device Dimension Solder Pad

Part Number

0402L010SL 0.03 0.05 0.85 1.15 0.01 0.03 0.35 0.65 0.01 0.02 0.20 0.60 0.004 0.02 0.10 0.45 - 0.02 - 0.40 0.02 0.60 0.02 0.40 0.03 0.70

0402L020SL 0.03 0.05 0.85 1.15 0.01 0.03 0.35 0.65 0.01 0.02 0.20 0.60 0.004 0.02 0.10 0.45 - 0.02 - 0.40 0.02 0.60 0.02 0.40 0.03 0.70

0402L035SL 0.03 0.05 0.85 1.15 0.01 0.03 0.35 0.65 0.01 0.02 0.20 0.60 0.004 0.02 0.10 0.45 - 0.02 - 0.40 0.02 0.60 0.02 0.40 0.03 0.70

0402L050SL 0.03 0.05 0.85 1.15 0.01 0.03 0.35 0.65 0.01 0.02 0.20 0.60 0.004 0.02 0.10 0.45 - 0.02 - 0.40 0.02 0.60 0.02 0.40 0.03 0.70

A B C D E F G H

inch mm inch mm inch mm inch mm inch mm

Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max Min Max

inch mm inch mm inch mm

Part Ordering Number System

0402 L xxx K R

SERIES

Packaging

Part Number Ordering Number I

0402L010SL 0402L010SLKR 0.10 010

0402L020SL 0402L020SLKR 0.20 020 10,000 KR

0402L035SL 0402L035SLKR 0.35 035 10,000 KR

0402L050SL 0402L050SLKR 0.50 050 10,000 KR

PACKAGING STYLE

R: Tape & Reel

QUANTITY CODE

K: 10000

I

HOLD CURRENT CODE

HOLD

(Refer to Electrical Characteristics Table)

L: LITTELFUSE SURFACE MOUNT PPTC

DEVICE SIZE CODE

hold

(A) I

Code Packaging Option Quantity

hold

Quantity & Packaging

10,000 KR

Tape & Reel

Codes

© 2014 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 01/17/14

Page 5

Tape and Reel Specifications

W

C

D

H

Reel Specifications

W

1

F

W

4

W

3

W

2

Tape Specifications

T

t

P

d

C

t

P

s

P

w

P

h

D

d

D

s

T

w

TAPE SPECIFICATIONS: EIA-

481-1 (mm)

0402L010SL

0402L020SL

0402L035SL

0402L050SL

POLY-FUSE® Resettable PTCs

Surface Mount > 0402L Series

REEL DIMENSIONS:

EIA-481-1 (mm)

C

t

D

d

D

s

P

d

P

h

P

s

P

w

T

t

T

w

Leader

min.

Trailer min.

0.05 ± 0.01

1.5 ± 0.1 W 9.0 ± 0.5

4.0± 0.1 D Ø60 ± 0.5

0.41± 0.1 F Ø13.0 ± 0.2

1.12± 0.1 C Ø178 ± 1

2.0 ± 0.1 W

0.62 ± 0.1 W

0.61 ± 0.1

8.0 ± 0.1 W

390 W

160

Tape and Reel Diagram

H 12.0± 0.5

2.2 ± 0.5

1

3.0± 0.5

2

4.0 ± 0.5

W

3

5.5 ± 0.5

4

5.5+0.5

4

Specifications are subject to change without notice.

© 2014 Littelfuse, Inc.

Revised: 01/17/14

Loading...

Loading...