Page 1

RoHS

0201 MLA Varistor Series

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > 0201 MLA Series

Description

New 0201-size MLA Multi-Layer Varistor (MLV) series can

protect small electronic products from electrostatic discharge

(ESD) and electrically fast transients (EFT).

It's ultra-compact 0201 size, the smallest form factor available

for MLV devices, is ideal for compact handheld products.

The ML Series is manufactured from semiconducting ceramics,

and is supplied in a leadless, surface mount package.

Plating consists of Silver base material (which is fired on to the

Zno dialectric), Nickel barrier plated under-layer and Matte-Tin

outer surface plate.

Features

Absolute Maximum Ratings

Steady State Applied Voltage:

Maximum DC Voltage (V

Maximum AC Voltage (V

Transient:

Non-Repetitive Surge Current, 8/20μs

Waveform, (I

)

TM

) 5.5 V

M(DC)

) 4.0 V

M(AC)RMS

Unit

4.0 A

• Ultra-small 0201 size for

minimal board space

• Low capacitance (33pF)

for high data rates to

minimize signal distortion

• Meets IEC 610004-2 for ESD

• Low leakage (<25μa)

• Multilayer ceramic

construction technology

• Inherently Bi-directional

• Stable performance

over wide operating and

storage temperature

range -40°C to +85°C

• Operating voltage

V

M(DC)

• Rated for surge

current (8 x 20μs)

Temperature:

Operating Ambient Temperature Range (T

Storage Temperature Range (T

) -40 to +85 ºC

STG

) -40 to +85 ºC

A

Applications

• Portable / handheld

electronic devices

• Mobile communications

/ cellular phones

• USB, video and audio ports

• Data, diagnostic I/O ports

• Computer / DSP products

• Industrial instruments

including non-life sustaing

medical equipment

• Analog signal / sensor lines

Device Ratings and Specifications

Maximum Ratings @ +85ºC

Part Number

Maximum Continuous

Working Voltage

V

M(DC)

(V) (V) (A) (V) (V) (V) (pF)

V

M(AC)

Maximum Nonrepetitive Surge

Current (8/20μs)

I

TM

Maximum

Clamping Voltage

at 1A (8/20μs)

V

C

V5.5MLA020133NR 5.5 4.0 1 28.0* 8.0 14.0 33.0

V5.5MLA020147NR 5.5 4.0 1 26.0* 8.0 14.0 47.0

V5.5MLA020164NR 5.5 4.0 1 26.0* 8.0 14.0 64.0

Notes:

- Typical leakage at 25ºC at V

- End surface finish of Matte-Tin with Nickel under-layer on Silver base material

- Standard packing quantity 15,000 per reel, 7" reel

: 0201 size <10μA typical, <25μA maximum

M(DC)

Specifications @ +25ºC

Nominal Voltage at 1mA

DC Test Current

V

N(DC)

Min V

Max C

N(DC)

Typical

Capacitance at

f = 1MHz

0201 MLA Series

= 5.5V

©2010 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/0201MLA.html for current information.

Revision: June 28, 2010

0201 MLA Varistor Series

Page 2

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > 0201 MLA Series

Reliability and Environmental Specifications

Judge Criteria Test Condition

Solderability > 95% solder coverage 245 +/- ºC, 3 +/- 1 sec.

Leaching Resistance > 95% solder coverage 245 +/- ºC, 3 +/- 1 sec.

High Temperature Exposure

Thermal Shock

Operating Life

Bias Humidity

Δ Vv / Vv < 10% 1000 hours 85ºC, un-powered

Δ Vv / Vv < 10% -45 to +85 ºC, 30 min. cycle, 5 cycles

Δ Vv / Vv < 10% 85 ºC, DC working voltage 1000 hours

Δ Vv / Vv < 10% 40 ºC / 85% RH, DC working voltage 1000 hours

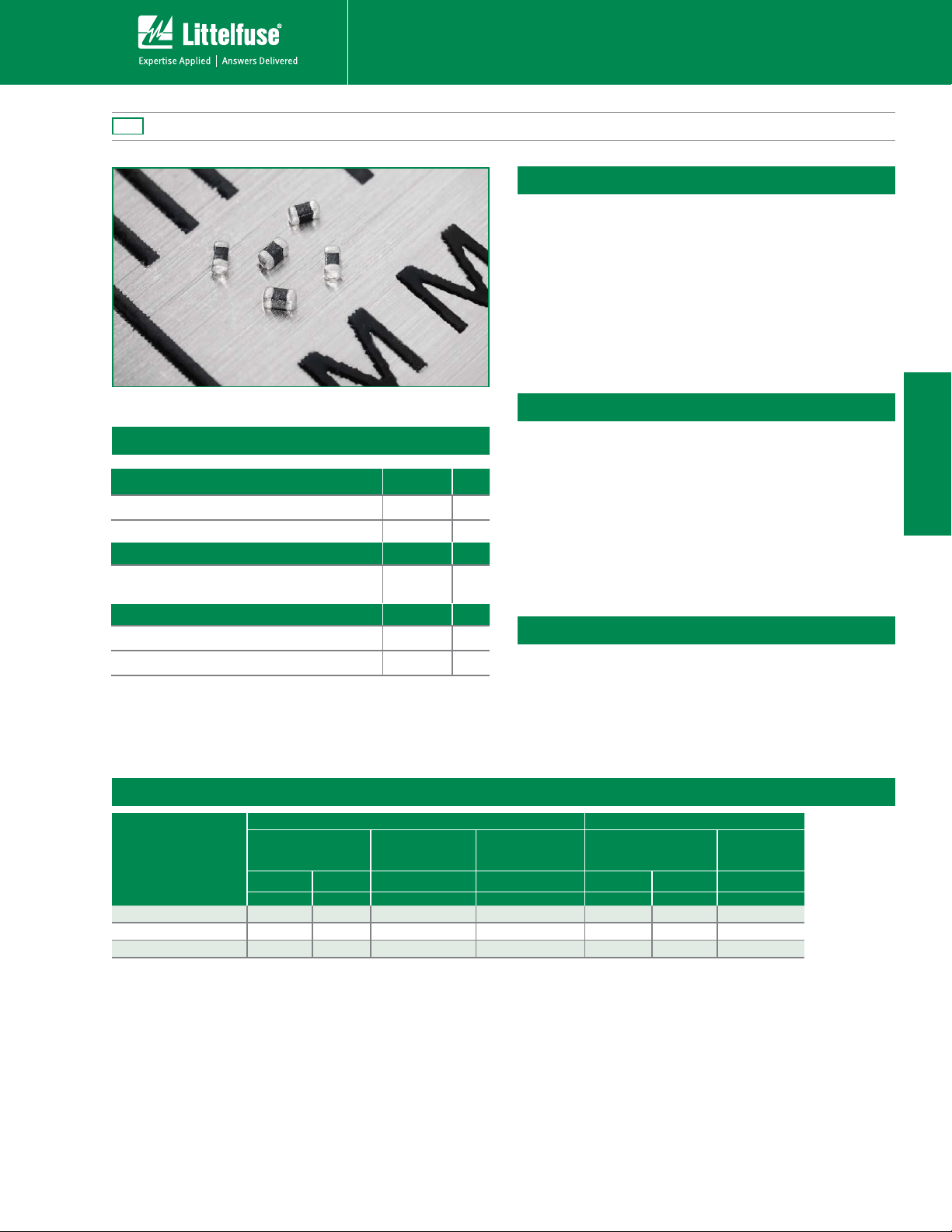

Peak Pulse Current Test Waveform for Clamping Voltage

100

50

0

PERCENT OF PEAK VALUE

O

1

T

T

1

T

2

01 = Virtual Origin of Wave

T = Time from 10% to 90% of Peak

T1 = Rise Time = 1.25 x T

T2 = Decay Time

Example - For an 8/20 μs Current Waveform:

8μs = T1 = Rise Time

20μs = T2 = Decay Time

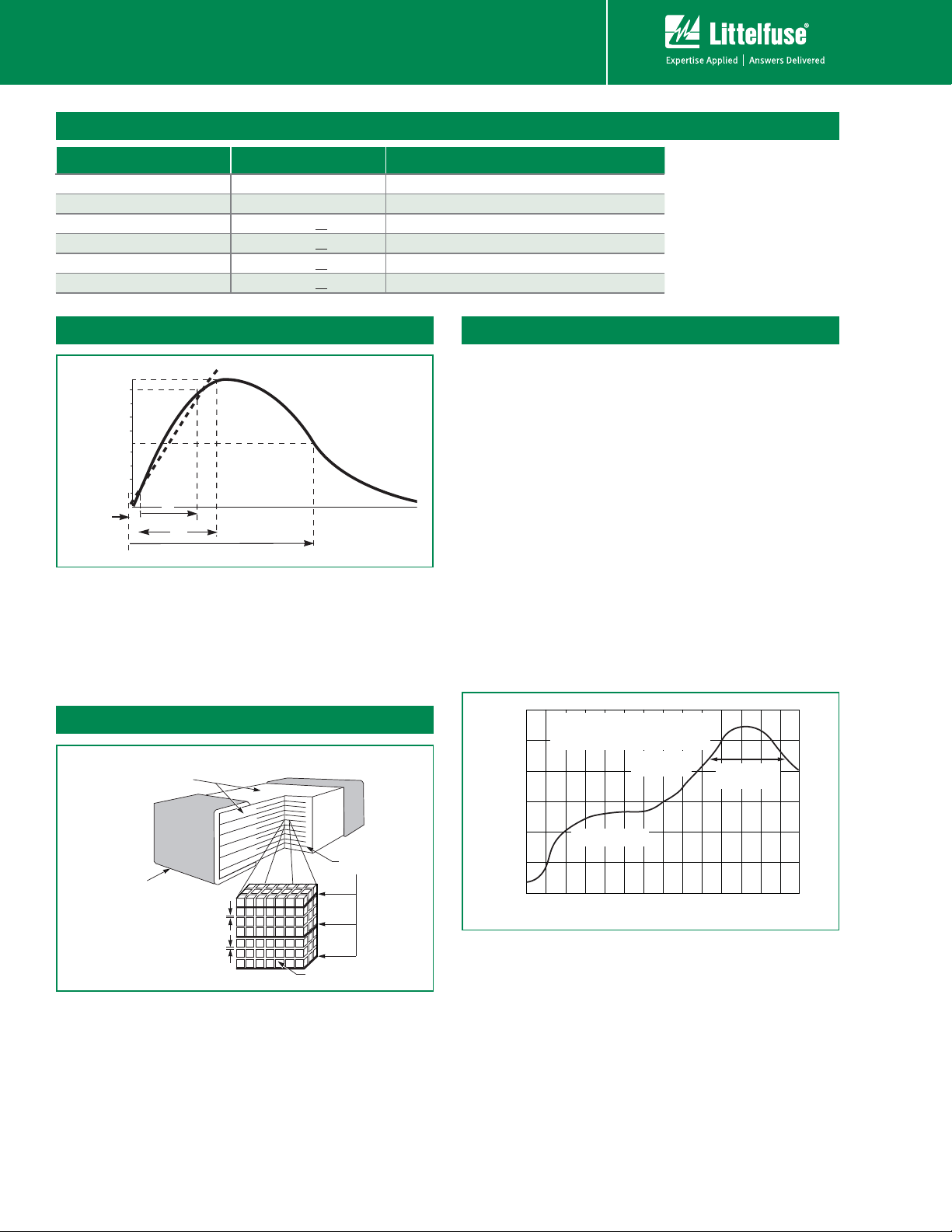

Multilayer Internal Construction

FIRED CERAMIC

DIELECTRIC

TIME

Lead–free (Pb-free) Soldering Recommendations

To avoid the possibility of generating stresses due to

thermal shock, a preheat stage in the soldering process

is recommended, and the peak temperature of the solder

process should be rigidly controlled.

When using a reflow process, care should be taken to

ensure that the ML chip is not subjected to a thermal

gradient steeper than 4 degrees per second; the ideal

gradient being 2 degrees per second. During the soldering

process, preheating to within 100 degrees of the solder's

peak temperature is essential to minimize thermal shock.

Once the soldering process has been completed, it is

still necessary to ensure that any further thermal shocks

are avoided. One possible cause of thermal shock is hot

printed circuit boards being removed from the solder

process and subjected to cleaning solvents at room

temperature. The boards must be allowed to cool gradually

to less than 50º C before cleaning.

300

250

200

150

MAXIMUM TEMPERATURE 260˚C,

TIME WITHIN 5˚C OF PEAK

20 SECONDS MAXIMUM

RAMP RATE

<3˚C/s

60 - 150 SEC

> 217˚C

METAL END

TERMINATION

0201 MLA Varistor Series

DEPLETION

REGION

DEPLETION

REGION

GRAINS

METAL

ELECTRODES

Revision: June 28, 2010

100

TEMPERATURE °C

50

0

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0

PREHEAT ZONE

TIME (MINUTES)

Please refer to www.littelfuse.com/series/0201MLA.html for current information.

Specifications are subject to change without notice.

©2010 Littelfuse, Inc.

Page 3

Product Dimensions (mm)

Varistor Products

Surface Mount Multilayer Varistors (MLVs) > 0201 MLA Series

PAD LAYOUT DIMENSIONS

C

B

NOTE : Avoid metal runs in this area, parts not

recommended for use in applications using

Silver (Ag) epoxy paste.

NOTE

A

Part Numbering System

V 5.5 0201

MLA xx N

DEVICE FAMILY

Littelfuse TVSS Device

MAXIMUM DC

WORKING VOLTAGE

MULTILAYER SERIES

DESIGNATOR

DEVICE SIZE:

0201 = .024 inch x .012 inch

(0.6 mm x 0.3 mm)

CHIP LAYOUT DIMENSIONS

E

D

W

L

R

PACKING OPTIONS

R = 7in (178mm) Diameter Reel, Paper Carrier Tape

15,000 items per reel

END TERMINATION OPTION

N = Nickel Barrier Option

(Matte Tin outer surface, plated on Nickel underlayer

plated on silver base metal)

CAPACITANCE OPTION

33 = 33pF

47 = 47pF

64 = 64pF

Dimension

0201 Size

IN MM

A 0.055 1.40

B 0.020 0.50

C 0.020 0.50

D (max.) 0.014 0.35

E 0.008 -/+0.004 0.20 -/+0.10

L 0.024 -/+0.002 0.60 -/+0.05

W 0.012 -/+0.002 0.30 -/+0.05

0201 MLA Series

Tape and Reel Specifications

D

0

K

0

t

D

1

1

Symbol Description

A

Width of Cavity 0.36 -/+0.02

0

Length of Cavity 0.70 -/+0.02

B

0

W Width of Tape 8.0 -/+0.1

F Distance Between Drive Hole Centers and Cavity Centers 3.5 -/+0.05

E Distance Between Drive Hole Centers and Tape Edge 1.75 -/+0.05

Distance Between Cavity Centers 2.0 -/+0.05

P

1

Axial Drive Distance Between Drive Hole Centers & Cavity Centers 2.0 -/+0.05

P

2

Axial Drive Distance Between Drive Hole Centers 4.0 -/+0.1

P

0

Drive Hole Diameter 1.55 -/+0.05

D

0

Top Tape Thickness 0.42 -/+0.02

T

1

NOTE: It is recommended that parts be kept in the sealed bag provided and that parts be used as soon as possible when removed from bags.

P

0

P

2

E

F

B

0

P

1

A

0

For T and H Pack Options: PLASTIC CARRIER TAPE

For R Pack Options: EMBOSSED PAPER CARRIER TAPE

W

EMBOSSMENT

TOP TAPE

Dimensions in

Millimeters

0201

8mm

NOMINAL

PRODUCT

IDENTIFYING

LABEL

178mm

OR 330mm

DIA. REEL

©2010 Littelfuse, Inc.

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/0201MLA.html for current information.

Revision: June 28, 2010

0201 MLA Varistor Series

Loading...

Loading...