Page 1

ELM2L

EMERGENCY LIGHTING UNIT

Installation and wiring …………………..…………......…………………………………… P. 2-3

Testing and maintenance ………...…………………………………………………………P. 4-5

NOTE: Product versions that comply with CA Title 20 are marked BC on the product label.

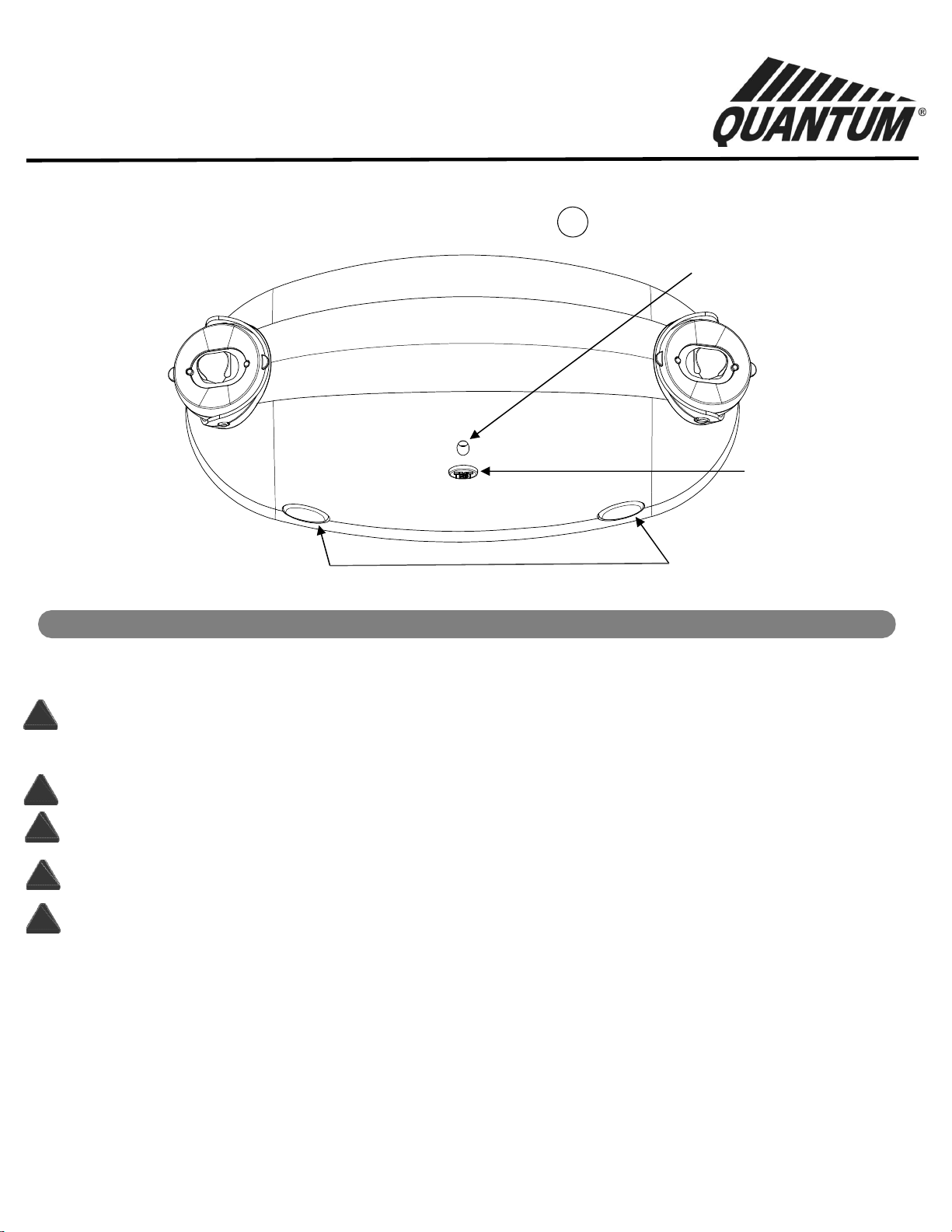

Remote test option

“TEST” button /

Status Indicator

Press latches to disengage

housing from mounting plate

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions

should always be followed, including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING:

!

SIGNIFICANT PROPERTY DAMAGE

maintaining this equipment. These instructions do not attempt to cover all installation and maintenance situations. If you do not understand

these instructions or additional information is required, contact Lithonia Lighting or your local Lithonia Lighting distributor.

WARNING:

!

ENERGIZED

WARNING:

!

WHICH MAY RESULT IN PERSONAL INJURY.

WARNING

!

from carton, handling, installing and maintaining this product.

WARNING:

(158° F), or incinerate. Replace battery only as directed on the battery label and page 5 of these instructions. Use of unauthorized battery voids

!

warranty and UL listing of this product, and may present a risk of fire or explosion.

•Disconnect A.C. power before servicing.

•All servicing should be performed by qualified personnel.

•Consult your local building code for approved wiring and installation.

•Do not use outdoors unless used with Acuity Brands accessories appropriate to the application.

•Do not mount near gas or electric heater.

•Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel.

•The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

•Do not use this equipment for other than intended use.

FAILURE TO FOLLOW THESE INSTRUCTIONS AND WARNINGS MAY RESULT IN DEATH, SERIOUS INJURY OR

- For your protection, read and follow these warnings and instructions carefully before installing or

RISK OF ELECTRIC SHOCK – NEVER CONNECT TO, DISCONNECT FROM OR SERVICE WHILE EQUIPMENT IS

.

DO NOT USE ABRASIVE MATERIALS OR SOLVENTS. USE OF THESE SUBSTANCES MAY DAMAGE FIXTURE,

: RISK OF PERSONAL INJURY – This product may have sharp edges. Wear gloves to prevent cuts or abrasions when removing

The battery used in this device may present a risk of fire or chemical burn if mistreated. Do not disassemble, heat above 70° C

SAVE THESE INSTRUCTIONS

AND DELIVER TO OWNER AFTER INSTALLATION

Page 2

page 2

IMPORTANT: Provide each unit with a single-phase AC un-switched power supply from a circuit used for normal lighting.

“UVOLT” product versions operate from 120 volts through 347 volts. All other versions operate from 120 volts through 277 volts.

PRODUCT DAMAGE WILL OCCUR IF THE RATED INPUT VOLTAGE IS EXCEEDED.

NOTE: The battery must be connected to the charger board prior to applying AC power to the unit. Battery damage may occur if

the battery is connected longer than 24 hours without continuous AC power provided. See also “Important Battery Information”,

page 4.

NOTE: The maximum mounting height of ELM2L from ground is 11.7 feet, to meet the minimum illumination requirements of NFPA

101 (current Life Safety Code).

NOTE: Do not connect battery or power unit until remote units (if applicable) are fully connected and wires are isolated from other

potentials (i.e. remote wires shall be isolated from earth ground).

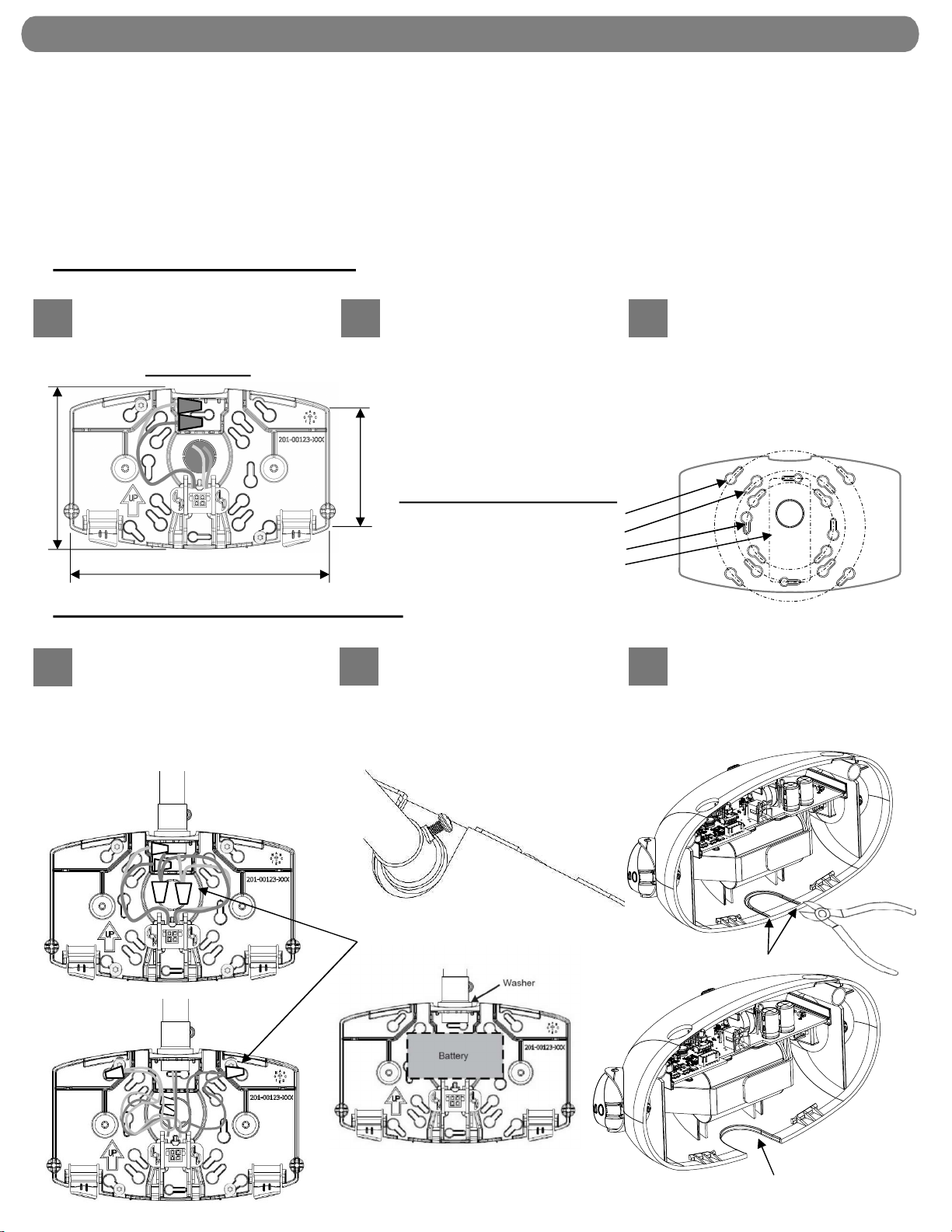

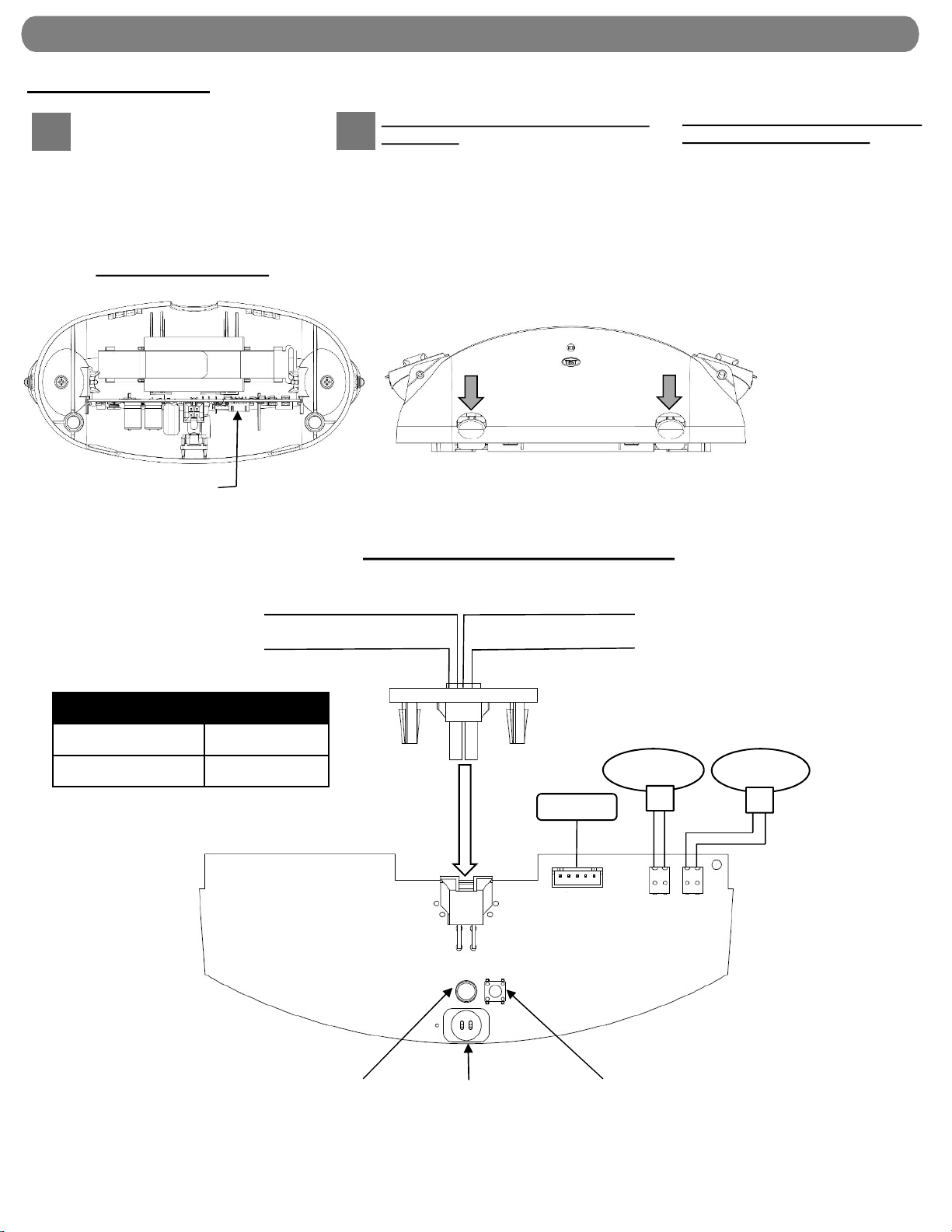

INSTALLATION and WIRING

JUNCTION BOX MOUNTING

-Some details shown below may vary-

On the mounting plate, remove the

1

round center knockout and the desired

pair of keyhole junction box knockouts.

Mounting Plate:

4-3/8”

7”

Route leads through the center

2 3

opening and use code-approved

connectors to make the connections.

(See Wiring Diagram, page 3). Dress

wires and connectors inside junction

box. Units with Remote Lamp Wires:

If no remote lamps are connected,

remote lamp leads (+ and - low voltage

DC) should be left capped and dressed

in mounting plate as shown.

3-1/4”

Junction boxes accommodated:

4” Square

4” Octagon

3-1/2” Round or Octagon

Single Gang Box

Taking care not to pinch wires or

connectors dressed inside junction

box, secure mounting plate to

junction box screws.

NOTE: To ensure proper

engagement of the mounting plate

latches to the housing, DO NOT

OVER-TIGHTEN THE SCREWS.

CONDUIT SURFACE MOUNTING

NOTE: to avoid interference with components in the housing, use the most compact wire connectors appropriate to the wire gauge.

At upper center of the mounting plate,

1

remove the conduit connection

knockout. Also remove at least three

keyhole knockouts. Attach conduit and

secure mounting plate to wall surface

using fasteners with a minimum pullout

rating of 30 lbs. each.

Figure-2

Figure-3

See Wiring Diagram, page 3. Make

2 3

code-approved wire connections to

the AC power supply, and remote

lamps (if applicable). Dress wires

into slots so that the connectors are

secured as shown in Figure 2 or

Figure 3.

Orient conduit fitting so that

all portions of it clear the

edge of the knockout

Secure wire connectors near the

center or near the upper latches

Remove U-shaped knockout from

top center of housing. Hint: Use a

pair of wire cutters first to start a cut

in the thick portion at each side of

the knockout, then finish breaking it

out with pliers.

Cut

Use washer (Grainger

conduit fitting and rear housing if

conduit fitting interferes with battery.

#4DAX6)

between

After knockout

removal

Page 3

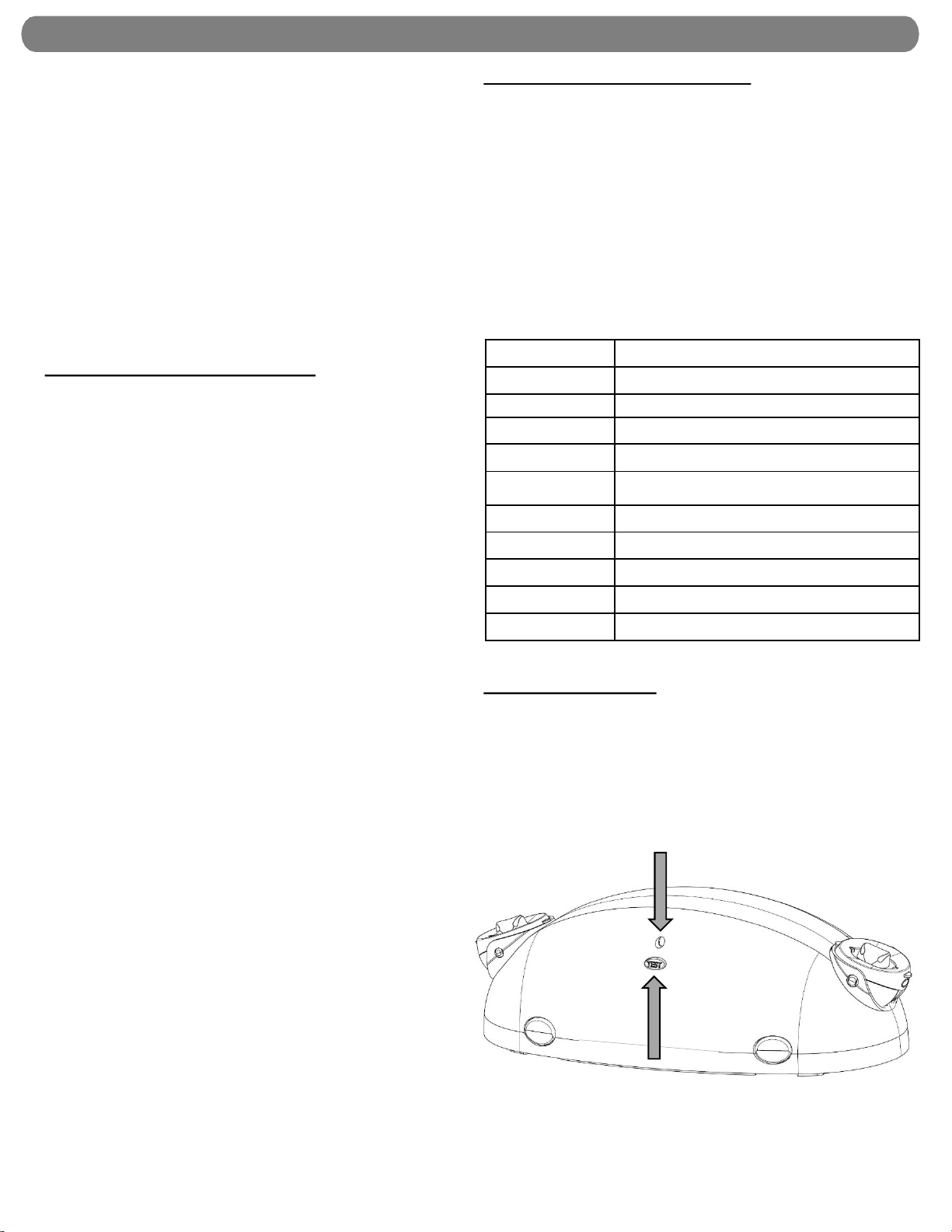

FINAL ASSEMBLY

INSTALLATION and WIRING (CONTINUED)

page 3

Connect the polarized battery plug to

4

the charger board. Make certain that

the battery cable is routed to avoid

interference with the AC input

connector or other components.

Battery Connection

Note: some details may vary

battery connector

Housing attachment to mounting plate:

5

Make certain all wires and connectors are

routed to avoid interference with other

components. Align latch openings on

underside of housing with latch buttons

on mounting plate. Firmly push housing

straight onto mounting plate, making

certain all four latches are fully engaged,

and the housing is closely aligned to the

mounting surface.

WIRING DIAGRAM

Federal Communications

Commission (FCC) Requirements:

This device complies with Part 15 of

the FCC Rules. This device may not

cause harmful interference.

Input from branch circuit. See label on

wire pair for voltage requirement.

Battery Type Total Load

NiCd 2.4W

LiFePO4 (LTP) 4.8W

DC output to the remote units. See label on wire

pair for positive and negative polarity colors

Battery

Lamp

Lamp

Status Indicator LED

Remote test Option

(standard with SDRT)

Test Switch

Page 4

page 4

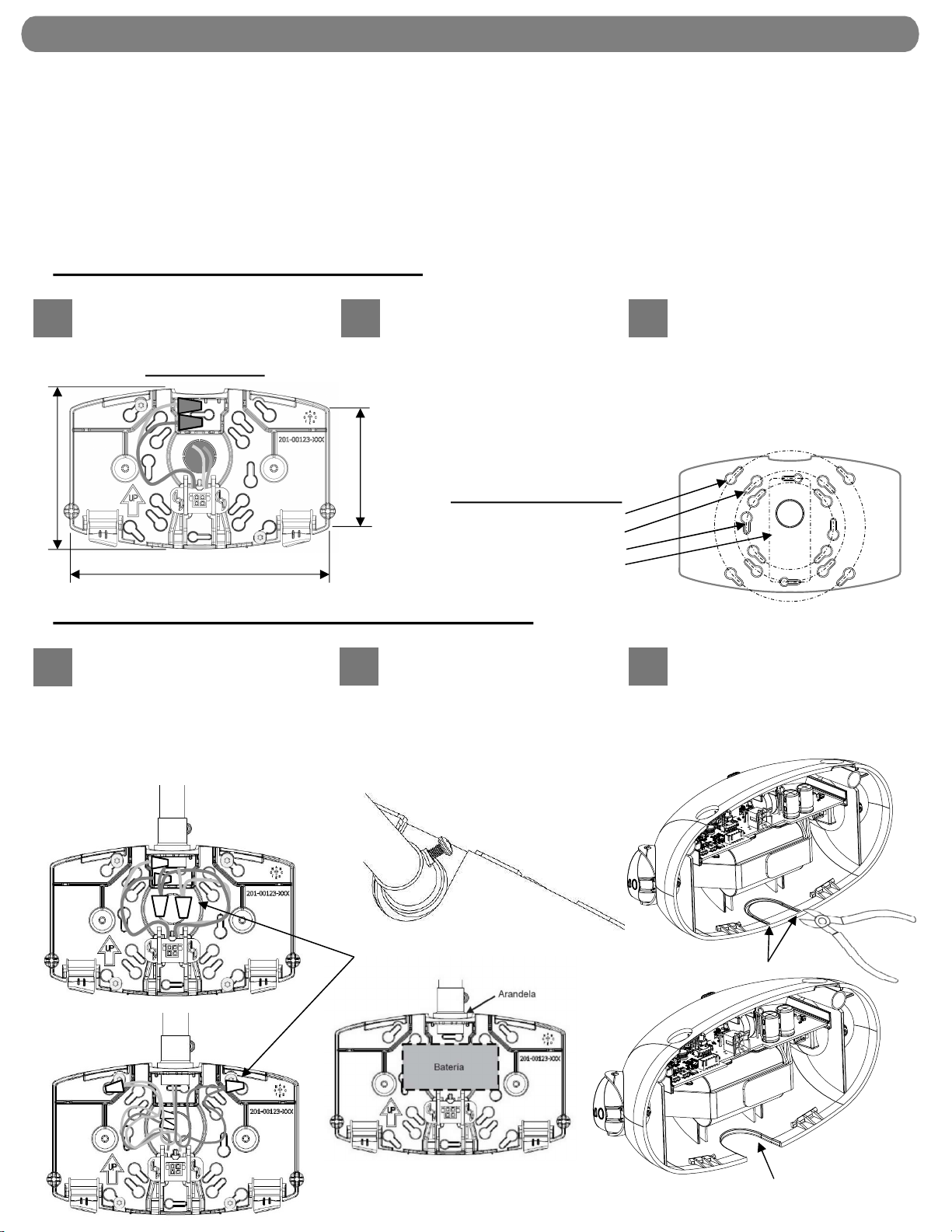

TESTING and MAINTENANCE

NOTE: Emergency lighting systems should be tested in

accordance with NFPA 101 or as often as local codes

require, to ascertain that all components are operational.

NOTE: Allow batteries to charge for 24 hours before initial

testing.

Manual testing:

If the batteries are sufficiently charged, either press and release

the “TEST” button or use the ELA LRT (remote tester accessory

for SDRT units only) on the bottom of the unit to activate a 30second test, during which the lamps will turn on. After a unit’s

first 30-second test is complete, a test in progress may be

cancelled at any time by pressing and releasing the “TEST”

button again.

Self-Diagnostics (SDRT feature)

Units with this option automatically perform a 5-minute selfdiagnostic test of the charging electronics, battery, and lamps

every 30 days, and a 90-minute test every year, indicating

system status as shown in the table at right. First self test

occurs after 15 days of continuous AC Power.

Postponing a self-test:

If an automatic self-test occurs at a time when it is not desirable

for the unit lamps to be on, it can be postponed for 8 hours

either by pressing and releasing the “TEST” button or by using

ELA LRT (remote tester accessory).

IMPORTANT BATTERY INFORMATION:

Batteries are perishable items. For best results, it is

recommended that the batteries receive an initial charge within

the first six months of the manufacture date of the fixture. The

manufacture date can be found on the outside of the unit

packaging and on the product label as part of the Date Code /

Series. The first two digits in the date code represent the year

and the second two digits represent the month. In many cases,

batteries beyond the initial charge recommendation time frame

will recover if fully charged soon after installation. If such a

battery does not recover after a full initial charge, it should be

replaced.

Unit Status Indications

The “TEST” button illuminates to indicate the following conditions:

Indication: Status:

Off Unit is off

Flashing green

Solid amber Battery is charging

Solid green

Flashing R / G

1x red flashing Battery failure (SDRT only)

2x red flashing Lamp failure (SDRT only)

3x red flashing Charger / electronics failure (SDRT only)

Unit is in Emergency operation or Test

Battery is fully charged

Manual test, battery not fully charged (SDRT

only)

Cancelling emergency operation:

Press and hold the “TEST” button for several seconds or

activate using the ELA LRT (remote tester accessory), during

which the status indicator will flash until the lamps turn off. This

restores the AC Reset state in which the unit is shipped.

Load-Learning feature:

Self-Diagnostic units automatically ‘learn’ their total connected

lamp load during the first scheduled self-test (~15 days). The

load-learning function can also be initiated manually by

pressing and holding the “TEST” button for 7 seconds (count

flashes), during this period the lamps will turn on. After 7

seconds, release the button, the lamps will turn off within 2

seconds indicating load learn complete. If lamps stay on longer,

load learn was not successful. This manual load-learning

feature should be initiated whenever the total connected lamp

load of the unit is changed, or a lamp is replaced.

NOTE: Manual load-learning functions cannot be initiated if

there is inadequate charge in the batteries. If this is so, wait

until the unit indicates full battery charge (solid green status

indication) before initiating the manual load-learning function.

Clearing a failure indication:

After a failure condition has been corrected and power is

restored to the unit, clear the failure indication either by

pressing the “TEST” button once or by activating remote Test

option once.

Flashing R/Amber Unable to charge

Solid Red Battery is disconnected

Remote Test (SDRT):

Units with the self-diagnostics/remote test feature allows

manual test activation using a laser pointer. Aim the laser

beam straight onto the circular area labeled near the “TEST”

button for a few moments to activate a 30-second test. (See

also “Manual testing”) A test in progress may be cancelled by

aiming the beam at the test area again. NOTE: The remote

tester should not be used to initiate the Load Learning feature.

SDRT: aim laser pointer here

TEST” button

“

(ELA LRT sold separately)

Page 5

TESTING and MAINTENANCE

BATTERY REPLACEMENT

Unit features and battery details shown may vary. See also “Battery Connection”, page 3.

page 5

Disconnect battery from charger board.

1

Release battery strap.

BATTERY HANDLING WARNINGS:

• Dispose of used batteries promptly.

• Keep away from children.

• Do not disassemble.

• Do not dispose of in fire.

LAMP REPLACEMENT

Remove lamp bezel as shown

1

below.

collar button

Replace battery, secure the strap

2 3

snugly, and reconnect to the charger

board.

LiFePO4 Battery

Battery Strap

For Velcro strap: Release and reuse

Gently bend the snap at each side of

the collar outward to release the lamp

2

assembly.

and strip back 1/4in. Connect stripped

wires to the replacement lamp,

following the yellow/blue polarity as

marked.

Cut wires near lamp board

Release snaps

gently

Re-assemble the unit (see also

step 5, page 3).

NiCd Battery

Replace the lamp assembly firmly

3

under the snaps on the collar, making

sure the lamp wires are not pinched.

Replace the bezel.

Battery support

Bezel

Collar

Carefully flex this edge free from collar button

CHARGER BOARD REPLACEMENT

With the unit oriented as in the below

1

view, flex the channel at the left end

of the charger board outward to

release and remove it. Unplug the

battery and other connections. See

“Lamp Replacement” above, to

disconnect the lamp wires from the

charger board.

Connect the lamp wires to the new

2

charger board, following the

yellow/blue polarity as marked.

Reconnect the battery and other

components (if included). For

insertion of PCB, insert right side of

PCB first, followed by left side

(click should be heard).

Connector under

the PCB

Make sure all wires are routed as

3

before, so as not to interfere with

proper assembly of the housing

onto the mounting plate. Reassemble the unit (see also step 5,

page 3).

2

1

Page 6

Part # 912-00026-002

Rev. C, 1/15/2018

LIFE SAFETY SOLUTIONS

TEL: 800-334-8694 www.lithonia.com

© Acuity Brands Lighting, Inc. 2018

All Rights Reserved.

Page 7

ELM2L

UNIDAD DE ILUMINACIÓN DE EMERGENCIA

Instalación y cableado …………………..…………......…………………………………..Pág. 2-3

Prueba y mantenimiento ………...…………………………………………………………Pág. 4-5

NOTA: Las versiones de producto que cumplen con el Título 20 de California están marcadas con “BC” en la etiqueta del producto.

Opción de prueba remota

Botón “TEST”

(PRUEBA)/

indicador de estado

Presione los pestillos para

desenganchar la carcasa de la

placa de montaje.

MEDIDAS DE SEGURIDAD

Cuando se utilizan aparatos eléctricos, deben tomarse

precauciones básicas de seguridad, incluidas las siguientes:

LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD.

ADVERTENCIA: EL INCUMPLIMIENTO DE ESTAS INSTRUCCIONES Y ADVERTENCIAS PUEDE PROVOCAR LA MUERTE,

LESIONES GRAVES O DAÑOS IMPORTANTES A LA PROPIEDAD.

!

instrucciones antes de instalar o realizar el mantenimiento de este equipo. Estas instrucciones no pretenden abarcar todas las situaciones de

instalación y mantenimiento

distribuidor local de Lithonia Lighting.

ADVERTENCIA:

!

ENCUENTRE EN FUNCIONAMIENTO

ADVERTENCIA: NO UTILICE MATERIALES NI SOLVENTES ABRASIVOS. EL USO DE ESTAS SUSTANCIAS PUEDE DAÑAR LOS

!

APARATOS, LO QUE PUEDE OCASIONAR LESIONES PERSONALES.

ADVERTENCIA

!

abrasiones al extraer el producto de la caja, manipularlo, instalarlo o repararlo.

ADVERTENCIA:

!

correctamente. No desmontar, calentar a más de 70 °C (158 °F) o incinerar. Cambie la batería solo como se indica en la etiqueta de la batería y en

la página 5 de estas instrucciones. El uso de una batería no autorizada anula la garantía y la certificación UL de este producto, y puede presentar

un riesgo de incendio o explosión.

•Desconecte la fuente de CA antes de realizar el mantenimiento.

•Todo el mantenimiento debe ser realizado por personal calificado.

•Consulte su código local de edificación para conocer los tipos de cableado y instalación aprobados.

•No utilice el aparato al aire libre, a menos que se utilice con los accesorios Acuity Brands apropiados para la aplicación.

•No haga instalaciones cerca de calefactores eléctricos o a gas.

•El equipo debe ser montado en lugares y a alturas en las que no podrá ser fácilmente manipulado por personal no autorizado.

•El uso de equipos auxiliares no recomendados por el fabricante puede ocasionar una condición insegura.

•No utilice este equipo para otros usos distintos al indicado.

: RIESGO DE LESIONES PERSONALES: este producto puede tener bordes afilados. Use guantes para evitar cortes o

. Si no comprende estas instrucciones o necesita información adicional, comuníquese con Lithonia Lighting o su

RIESGO DE DESCARGA ELÉCTRICA. NO CONECTE, DESCONECE NI REPARE EL EQUIPO MIENTRAS ESTE SE

La batería utilizada en este dispositivo puede presentar un riesgo de incendio o quemadura química si no se utiliza

IMPORTANTES

Para su protección, lea y siga cuidadosamente estas advertencias e

.

CONSERVE ESTAS INSTRUCCIONES Y ENTRÉGUELAS

AL PROPIETARIO DESPUÉS DE LA INSTALACIÓN

Page 8

página 2

IMPORTANTE: Proporcione a cada unidad una fuente de CA no conmutada monofásica de un circuito utilizado para la iluminación

normal.

Las versiones del producto “UVOLT” funcionan con 120 voltios hasta 347 voltios. Todas las demás versiones funcionan con 120 voltios

hasta 277 voltios. EL PRODUCTO PUEDE DAÑARSE SI SE EXCEDE EL VOLTAJE DE ENTRADA.

NOTA: La batería debe estar conectada a la placa del cargador antes de aplicar la alimentación de CA a la unidad. La batería puede

dañarse si permanece conectada durante más de 24 horas sin alimentación de CA continua. Vea también “Información importante de

la batería”, página 4.

NOTA: Para cumplir con los requisitos mínimos de iluminación de la NFPA 101 (Código actual de Seguridad Humana), la máxima altura

de montaje de ELM2L desde el suelo es de 11.7 pies.

NOTA: No conecte la batería o la unidad de alimentación hasta que las unidades remotas (si corresponde) estén totalmente conectadas

y los cables estén aislados de otros potenciales (es decir, los cables remotos deben aislarse de la toma de tierra).

INSTALACIÓN Y CABLEADO

MONTAJE DE LA CAJA DE UNIÓN

Algunos detalles que se muestran a continuación pueden variar.

En la placa de montaje, retire el orificio

1

troquelado central redondo y el par de orificios

troquelados de la caja de conexiones.

Placa de montaje:

4 3/8 in

7 in

La ruta conduce a través de la abertura

central y utiliza los conectores con código

2 3

aprobado para realizar las conexiones.

(Vea el diagrama de cableado en la página

3). Organización de los cables y los

conectores dentro de la caja de conexiones.

Unidades con cables de lámparas

remotas: Si no se conectan las lámparas

remotas, los cables de estas lámparas (DC

de bajo voltaje + y -) deben quedar tapados

y colocados dentro de la placa de montaje

como se muestra.

3 1/4 in

Cajas de unión alojadas:

Cuadrada de 4 in

Octagonal de 4 in

Redonda u octagonal de 3 1/2 in

Caja de salida individual

Teniendo cuidado de no presionar los

cables o conductores organizados dentro

de la caja de unión, fije la placa de

montaje a los tornillos de la caja de unión.

NOTA: Para asegurar que los pestillos de

la placa de montaje estén correctamente

enganchados a la carcasa, NO AJUSTE

DEMASIADO LOS TORNILLOS.

MONTAJE EN SUPERFICIE DEL CONDUCTO

NOTA: Para evitar interferencia con los componentes de la carcasa, use los conectores más compactos apropiados para el calibre de los cables.

En la parte superior del centro de la placa

de montaje, retire el orificio troquelado para

1

la conexión del conducto. También retire al

menos tres orificios troquelados. Conecte

el conducto y fije la placa de montaje a la

superficie de la pared con tornillos con una

calificación mínima de retiro de 30 libras

cada uno.

Figura-2

Figura-3

Vea el diagrama de cableado en la

página 3. Conecte las conexiones de

2 3

cable con código aprobado en la

fuente de alimentación de CA y en las

lámparas a distancia (si corresponde).

Organice los cables en las ranuras de

manera que los conectores estén

asegurados, como se muestra en las

figuras 2 o 3.

Dirija el conducto adecuado

para que todas las partes de

este lleguen al borde del

agujero troquelado

Fije los conectores de cable cerca

del centro o cerca de los pestillos

superiores

Retire el agujero troquelado en forma

de U de la parte superior central de la

carcasa. Sugerencia: Utilice primero

un par de cortacables para iniciar un

corte en la parte gruesa en cada lado

del troquelado y, a continuación,

termine de retirarlo con las pinzas.

Cortar

Use la arandela (Grainger # 4DAX6)

entre el accesorio del conducto y la

carcasa trasera si la conexión del

conducto interfiere con la batería.

Luego de retirar el

troquelado

Page 9

MONTAJE FINAL

INSTALACIÓN Y CABLEADO (CONTINUACIÓN)

página 3

Conecte el enchufe de la batería

4

polarizado a la placa del cargador.

Asegúrese de verificar el recorrido del

cable para evitar interferencias con el

conector de entrada de CA o con otros

componentes.

Conexión de la batería

Nota: Algunos detalles pueden variar.

conector de la

batería

Accesorios de la carcasa para la placa

5

de montaje:

Asegúrese de que todos los cables y los

conectores sigan una ruta para evitar la

interferencia con otros componentes. Alinee

las aberturas de los pestillos en el lado inferior

de la carcasa con los botones de los pestillos

en la placa de montaje. Presione firmemente

la carcasa directamente sobre la placa de

montaje, asegurándose de que los cuatro

pestillos estén completamente enganchados

y la carcasa esté estrechamente alineada con

la superficie de montaje.

DIAGRAMA DEL CABLEADO

Requisitos de la Comisión Federal

de Comunicaciones (FCC):

Este dispositivo cumple con la Parte

15 de las reglas de la FCC. Este

dispositivo puede no ocasionar

interferencias perjudiciales.

Cables de entrada de CA. Consulte la etiqueta en el par

de alambres para conocer los requisitos de voltaje.

Tipo de batería Carga total

NiCd 2,4 W

LiFePO4 (LTP) 4,8 W

Lámpara remota cables de salida de CC. Consulte la etiqueta en el

par de alambres para los colores de polaridad positiva y negativa.

Lámpara

Batería

Lámpara

Led indicador de estado

Opción de prueba remota

(estándar con SDRT)

Interruptor de prueba

Page 10

página 4

2 intermitencias de

3 intermitencias de

PRUEBA Y MANTENIMIENTO

NOTA: Los sistemas de iluminación de emergencia deben ser

probados de acuerdo con la norma NFPA 101 o con la

regularidad que exijan los códigos locales, para verificar que

todos los componentes sean operativos.

NOTA: Deje que las baterías se carguen por 24 horas antes

de la prueba inicial.

Prueba manual:

Si las baterías tienen carga suficiente, presione y suelte el botón

“TEST”, o use el ELA LRT (accesorio del comprobador remoto

solo para unidades SDRT) en la parte inferior de la unidad para

activar una prueba de 30 segundos durante la cual las lámparas

se encenderán. Después terminar la primera prueba de 30

segundos, se puede cancelar una prueba en curso en cualquier

momento al pulsar y soltar el botón "TEST" de nuevo.

Autodiagnóstico (característica SDRT)

Las unidades con esta opción realizan automáticamente una

prueba de autodiagnóstico de 5 minutos en los dispositivos

electrónicos de carga, la batería y las lámparas cada 30 días, y

una prueba de 90 minutos al año, la cual indica el estado del

sistema como se muestra en la tabla de la derecha. La primera

autoevaluación se produce después de 15 días de alimentación de

CA continua.

Postergación de una autoevaluación:

Si una autoevaluación automática se produce en un momento en que

no es conveniente que las lámparas de la unidad estén encendidas,

se puede postergar la operación durante 8 horas al presionar o soltar

el botón “TEST”, o al usar la ELA LRT (accesorio probador remoto).

Operación de cancelación de emergencia:

Mantenga presionado el botón “TEST” por varios segundos o

active utilizando ELA LRT (accesorio de prueba remoto), durante

los cuales el indicador de estado será intermitente hasta que las

luces se apaguen. Esto restaura el estado de restablecimiento CA

en el que se envía la unidad.

Función de aprendizaje de carga:

Las unidades de autodiagnóstico “aprenden” automáticamente su

carga total de la lámpara conectada durante la primera

autoevaluación programada (aproximadamente 15 días). La función

de aprendizaje de carga también puede iniciarse manualmente al

mantener presionado el botón “TEST” por 7 segundos (contar las

intermitencias), durante los cuales las lámparas se encenderán.

Después de 7 segundos, suelte el botón; las lámparas se apagarán

en 2 segundos, lo que indica que se completó el aprendizaje de

carga. Si las lámparas permanecen encendidas durante más tiempo,

significa que el aprendizaje de carga no pudo completarse. Esta

característica de aprendizaje de carga manual debe iniciarse siempre

que la unidad de la lámpara conectada esté totalmente cargada o que

una lámpara sea reemplazada.

INFORMACIÓN IMPORTANTE SOBRE LAS BATERÍAS:

Las baterías son productos perecederos. Para obtener mejores

resultados, se recomienda que las baterías reciban una carga inicial

dentro de los primeros seis meses posteriores a la fecha de

fabricación del aparato. La fecha de fabricación se encuentra en el

exterior del empaque de la unidad y en la etiqueta del producto,

como lo establece el código de fecha/número de serie. Los dos

primeros dígitos del código de fecha representan el año y los

segundos dos dígitos representan el mes. En muchos casos, las

baterías, más allá del marco de tiempo recomendado para la carga

inicial, se recuperarán completamente si son cargadas después de

la instalación. Si este tipo de baterías no se recupera después de

una carga inicial completa, estas deben ser reemplazadas.

Indicaciones sobre el estado de la unidad

El botón "TEST” se ilumina para indicar las siguientes condiciones:

Indicación: Estado:

Apagado La unidad está apagada.

Luz verde

intermitente

Luz ámbar fija La batería se está cargando.

Luz verde fija La batería está totalmente cargada.

Rojo/verde

intermitente

1 intermitencia de

luz roja

luz roja

luz roja

Luz roja/ámbar

intermitente

Luz roja fija La batería está desconectada.

Prueba remota (SDRT):

Las unidades con autodiagnóstico / función de prueba remota

permiten la activación manual de la prueba usando un puntero láser.

Dirija el puntero láser directamente sobre el área circular etiquetada

cerca del botón “TEST” durante unos instantes para activar una

prueba de 30 segundos. (Vea también “Prueba manual”). Si desea

cancelar una prueba en curso, dirija nuevamente el puntero láser

sobre el área de prueba.

NOTA: probador remoto no debe usarse para iniciar la función de

aprendizaje de carga.

SDRT: apunte aquí con el puntero láser

La unidad está en modo de Emergencia o

Prueba.

Prueba manual, la batería no está

completamente cargada (solo SDRT).

Falla en la batería (solo SDRT).

Falla en la lámpara (solo SDRT).

Falla en el cargador o los dispositivos

electrónicos (solo SDRT).

No se puede cargar.

(ELA LRT se vende por separado)

NOTA: Las funciones de aprendizaje de carga manuales no

pueden iniciarse si las baterías no tienen carga suficiente. Si esto

es así, espere hasta que la unidad indique que la batería ha sido

totalmente cargada (indicador de estado verde fijo) antes de iniciar

la función de aprendizaje de carga manual.

Aclaración de indicaciones de falla:

Después de corregir un error y luego de que se restablezca la

alimentación de la unidad, desactive la indicación de error al

presionar el botón “TEST” una vez o al activar la opción de prueba

remota una vez.

Botón “TEST”

Page 11

PRUEBA Y MANTENIMIENTO

página 5

REEMPLAZO DE LA BATERÍA:

Las características de la unidad y los detalles de la batería que se muestran pueden variar. Vea también “Conexiones de batería” en la página 3.

Desconecte la batería del cargador

incorporado. Suelte la cinta de la batería.

1

2 3

ADVERTENCIAS PARA EL

MANEJO DE LA BATERÍA:

• Desechar las baterías usadas

inmediatamente.

• Mantener fuera del alcance de los niños.

• No desmontar.

• No arrojar al fuego.

REEMPLAZO DE LA LÁMPARA:

Retire el bisel de la lámpara como

1

se muestra a continuación.

botón del cuello

2

Reemplace la batería, asegure bien la

cinta y vuelva a conectarla a la placa

del cargador.

Batería LiFePO4

Cinta de la

batería

Para la correa de velcro: liberación y reutilización

Doble con cuidado el encaje en cada lado

del cuello hacia afuera para liberar el

ensamblaje de la lámpara. Corta los

cables cerca de la placa de la lámpara

y tira hacia atrás 1 / 4in. Conecte los

cables pelados a la lámpara de

reemplazo, siguiendo la polaridad

amarilla / azul marcada.

Vuelva a ensamblar la unidad (consulte

también el paso 5 en la página 3).

Batería NiCd

Reemplace el ensamblaje de la lámpara

firmemente bajo el encaje en el cuello,

3

asegurándose de que los cables de la

lámpara presenten pellizcos. Reemplace

el bisel.

Soporte de la

batería

Bisel

Cuello

Flexione cuidadosamente este borde y apártelo

del botón del cuello

Conector debajo

del PCB

REEMPLAZO DEL CARGADOR INCORPORADO:

Con la unidad orientada como se

muestra a continuación, flexione el

1

canal en el extremo izquierdo de la

placa del cargador hacia afuera para

soltar y retirarlo. Desconecte la batería

y otras conexiones. Vea “Reemplazo de

lámpara” más arriba para desconectar

los cables de la lámpara de la placa del

cargador.

Conecte los cables de la lámpara a la

nueva placa del cargador, siguiendo la

2

polaridad amarillo/azul como se indica.

Vuelva a conectar la batería y los otros

componentes (si están incluidos). Para

insertar el PCB, inserte el lado derecho

del PCB en primer lugar, seguido del

lado izquierdo (debe escuchar un “clic”).

Suelte los

encajes con

cuidado

Asegúrese de direccionar todos los

cables como antes, de manera que

3

no interfieran con el correcto

ensamblaje de la carcasa sobre la

placa de montaje. Vuelva a

ensamblar la unidad (consulte

también el paso 5 en la página 3).

2

1

Page 12

N.º de pieza: 912-00026-002

Rev. C, 1/15/2018

SOLUCIONES DE SEGURIDAD PERSONAL

TELÉFONO: 800-334-8694 www.lithonia.com

© Acuity Brands Lighting, Inc. 2018

Todos los derechos reservados.

Loading...

Loading...