Litex Industries CONNEXXTION TLEII44BNK5L, CONNEXXTION TLEII44OSB5L, CONNEXXTION TLEII52OSB5L, CONNEXXTION TLEII52BNK5L User Manual

ITEM #016887

016888

016889

016890

CONNEXXTION

MODEL #TLEII44BNK5L

TLEII44OSB5L

TLEII52BNK5L

TLEII52OSB5L

Español p. 20

®

Express Assembly

No Tools Required

ATTACH YOUR RECEIPT HERE

Purchase Date

Questions, problems, missing parts? Before returning to your retailer, call our customer

service department at 1-800-527-1292, 8:30 a.m. - 5 p.m., CST, Monday - Friday

4009654

1

TABLE OF CONTENTS

Safety Information ...............................................................................................................

Package Contents ..............................................................................................................

Hardware Contents

Preparation ........................................................................................................................... 5

Initial Installation ................................................................................................................... 5

Installing Safety Cable .......................................................................................................... 8

Wiring .................................................................................................................................. 9

Final Installation .................................................................................................................. 11

Installing Fan Without Light Kit ............................................................................................14

Operating Instructions ......................................................................................................... 15

Care and Maintenance ...................................................................................................

Troubleshooting ..................................................................................................................

...........................................................................................................................

.

. 2

.

. 4

.

.... 17

18

5

Limited Lifetime Warranty ...................................................................................................

SAFETY INFORMATION

READ AND SAVE THESE INSTRUCTIONS

• Do not discard fan carton or foam inserts. Should this fan need to be returned to the factory for

repairs, it must be shipped in its original packaging to ensure proper protection against damage that

might exceed the initial cause for return.

• Make sure all electrical connections comply with local codes, ordinances, the National Electrical

Code and ANSI/NFPA 70-1999. Hire a qualified electrician or consult a do-it-yourself wiring handbook

if you are unfamiliar with installing electrical wiring.

• Make sure the installation site you choose allows a minimum clearance of 7 ft. from the blades to the

floor and at least 30 in. from the end of the blades to any obstruction.

• After you install the fan, make sure all connections are secure to prevent the fan from falling.

• The net weight of TLEII44 is: 16.5 lbs.

• The net weight of TLEII52 is: 21 lbs.

19

DANGER

When using an existing outlet box, make sure the outlet box is securely attached to the building

structure and can support the full weight of the fan. Failure to do this can result in serious injury or

death. The stability of the outlet box is essential in minimizing wobble and noise in the fan after

installation is complete.

2

SAFETY INFORMATION

WARNING

To reduce the risk of fire, electrical shock or personal injury, mount fan to outlet box

marked "ACCEPTABLE FOR FAN SUPPORT OF 35 LBS. OR LESS" and use

mounting screws provided with the outlet box. Most outlet boxes commonly used for the

support of lighting fixtures are not acceptable for fan support and may need to be replaced.

Consult a qualified electrician if in doubt.

When mounting fan to a ceiling outlet box, use a METAL octagonal outlet box; do NOT use a

plastic outlet box. Secure the outlet box directly to the building structure. The outlet box and its

support must be able to support the moving weight of the fan (at least 35 lbs.).

To avoid personal injury, the use of gloves may be necessary while handling fan parts with

sharp edges.

To reduce the risk of fire, electrical shock or personal injury, wire connectors provided with this fan

are designed to accept only one 12-gauge house wire and two lead wires from the fan. If your

house wire is larger than 12-gauge or there is more than one house wire to connect to the

corresponding fan lead wires, consult an electrician for the proper size wire connectors to use.

To reduce the risk of fire or electrical shock, do not use the fan with any solid state speed control

device or control fan speed with a full range dimmer switch.

To reduce the risk of fire, electrical shock or personal injury, do not bend the blade arms when

installing them, balancing the blades or cleaning the fan. Do not insert objects between the

rotating fan blades.

To reduce the risk of personal injury, use only parts provided with this fan. The use of parts

OTHER than those provided with this fan will void the warranty.

Before proceeding, be sure to shut off electricity at main switch or circuit breaker in order to avoid

electrical shock.

CAUTION

Be sure outlet box is properly grounded and that a ground wire (green or bare) is present.

Before beginning installation, carefully check all screws, bolts and nuts on fan motor assembly to

ensure that they are secured.

NOTE: Dimmable to 10% with select dimmers.

3

PACKAGE CONTENTS

C

Y

A

R

Z

B

E

G

H

D

J

V

S

U

W

P

N

F

M

Q

T

X

K

L

I

O

A

B

C

DESCRIPTIONPART

Downrod (preassembled) 1

Canopy (preassembled)

Mounting Bracket

QUANTITY

1

1

D Motor Housing 1

E

Yoke Cover (preassembled) 1

F Light Kit Fitter 1

(preassembled)

G

H

Blade

Bulb

I Finial Plate 1

5

3

(preassembled)

J Blade Screw Post 15

(preassembled)

K Hex Nut 2

(preassembled)

L Lock Washer 1

(preassembled)

M Switch Housing Cap 1

(preassembled)

IMPORTANT: You must use the parts

provided with this fan for proper installation and

safety.

DESCRIPTIONPART

QUANTITY

N Switch Housing Cap Screw 3

(preassembled)

O Finial (preassembled) 1

P Glass Shade 1

Q Rubber Washer 1

(preassembled)

R Balancing Kit 1

S Blade Arm 5

T Blade Arm Screw 10

(preassembled)

U Washer 10

(preassembled)

V Safety Screw 5

(preassembled)

W Metal Tab 5

(preassembled)

X Remote Pack 1

Y Remote Control Receiver 1

Z Safety Cable (preassembled) 1

4

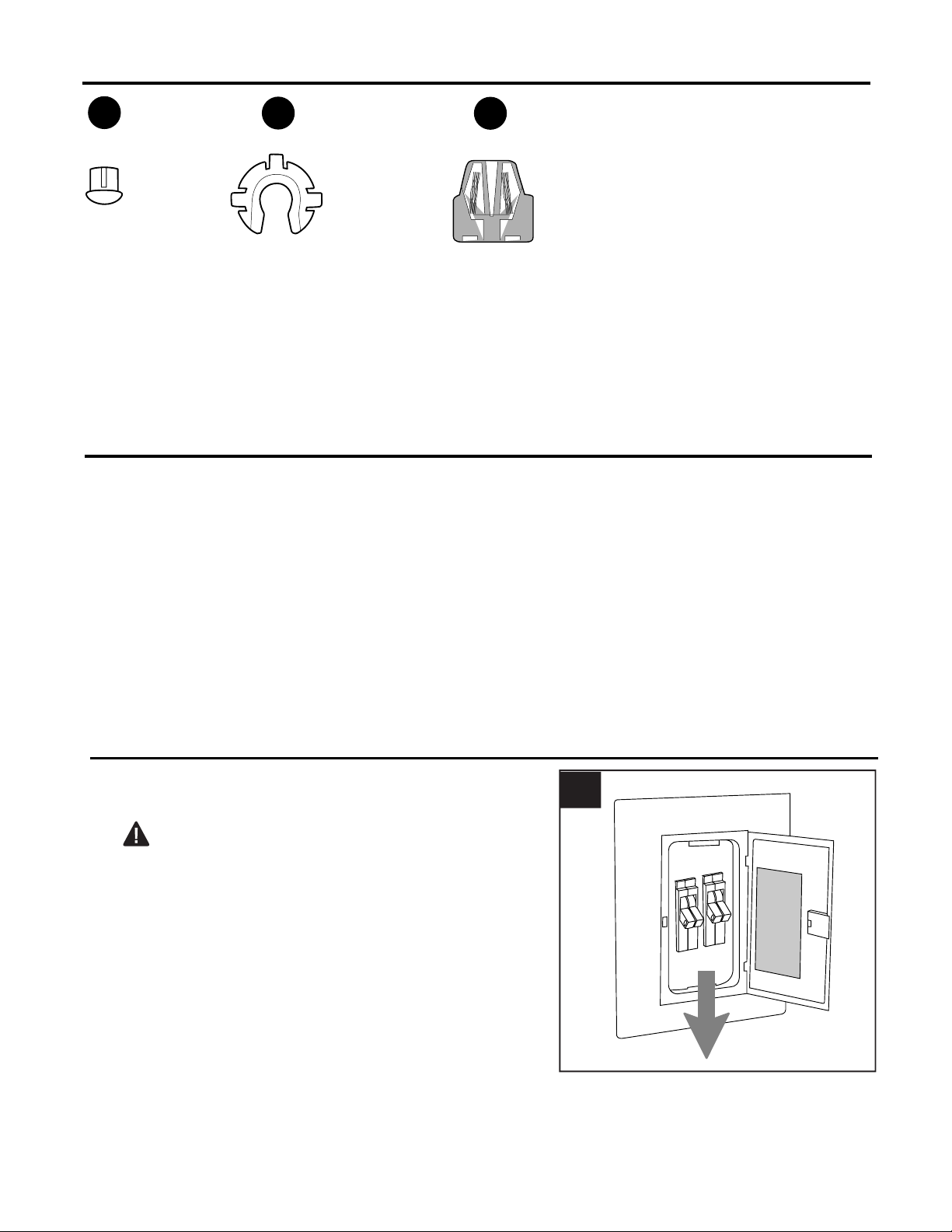

HARDWARE CONTENTS (shown actual size)

AA

BB

CC

Cap

Three-C Clip

Qty. 1

Qty. 15

+ 1 extra

Clip

(preassembled)

Qty. 6

PREPARATION

Before beginning assembly of product, make sure all parts are present. Place motor on carpet or on

foam to avoid damage to finish. Compare parts with package contents list and hardware contents list.

If any part is missing or damaged, do not attempt to install, operate or assemble the product.

Estimated Assembly Time: 60 minutes

Tools Required for Assembly (not included): Electrical Tape, Phillips Screwdriver, Pliers, Safety

Glasses, Stepladder and Wire Strippers

Helpful Tools (not included): AC Tester Light, Tape Measure, Do-It-Yourself Wiring Handbook and

Wire Cutters

INITIAL INSTALLATION

Turn off circuit breakers or fuse and wall switch to

1.

the fan supply line leads.

1

DANGER: Failure to disconnect power supply

prior to installation may result in serious injury or

death.

ON

OFF

ON

OFF

5

INITIAL INSTALLATION

Determine mounting method to use.

2.

A. Standard mount

B. Angle mount

Note: Flushmount and closemount options are not

available for this fan.

IMPORTANT: If using the angle mount, ensure the

ceiling angle is not steeper than 19°.

Check to make sure blades (G) will be at least

3.

30 inches from any obstruction. Check downrod

(A) length to ensure blades (G) will be at least 7 ft.

above the floor.

2

A

19° max.

B

3

30 in.

min.

4.

Secure mounting bracket (C) to outlet box (not

included) using screws, spring washers and flat

washers provided with the outlet box.

*NOTE: It is very important you use the proper

hardware when installing the mounting bracket

(C) as this will support the fan.

IMPORTANT: If using the angle mount, make

sure open end of mounting bracket (C) is installed

facing the higher point of the ceiling.

4

G

7 ft.

min.

ANGLE MOUNTSTANDARD MOUNT

C

C

Open End

6

INITIAL INSTALLATION

You may need to cut the lead wires back to simplify

5.

the wiring. If you decide to cut back the lead wires, it

is suggested you do so in the following manner:

5

Take the lead wires and make sure you have pulled

them all the way through the top of the downrod.

Start at the TOP of the hanging ball on the downrod

and measure 8 in. of lead wire, and then cut the

excess wire off with wire cutters (not included).

NOTE: If you do not cut back the lead wires, Steps

5 and 6 are not necessary and you may proceed

to Step 7 instead.

6.

If you cut back the lead wires in Step 5, strip 1/2 in.

of insulation from end of white wire. Twist stripped

ends of each strand of wire within the insulation

with pliers. Repeat Step 6 for black, blue (if

applicable) and green wires.

8 in.

Hanging

Ball

A

6

7.

Install hanging ball of downrod (A) into opening of

mounting bracket (C). Align one of the slots in

hanging ball with the tab in mounting bracket (C).

DANGER: Failure to align one of the slots in

hanging ball with the tab in mounting bracket (C)

may result in serious injury or death.

7

C

Tab

Slot

A

7

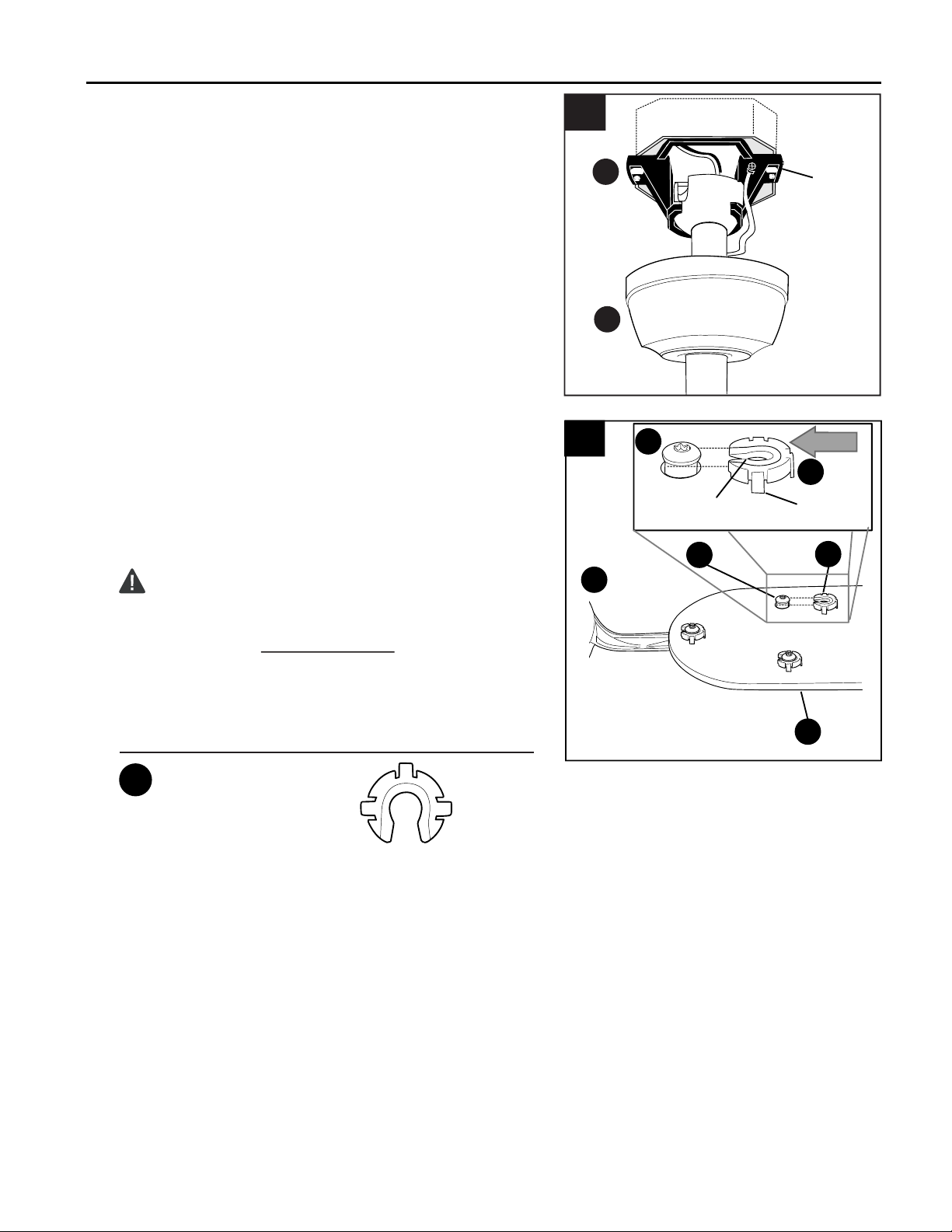

INSTALLING SAFETY CABLE

Adjust safety cable (Z) length by loosening screw

1.

and nut on the safety cable vice and pulling on the

cable. Adjust slack in cable to a hands length and

secure vice by re-tightening screw and nut

securely. The loop at the end of the safety cable (Z)

should just fit over the threads on the wood screw.

1

Loop

Wood

Screw

Test safety cable (Z) by pulling on loose end of

cable with pliers. If the safety cable (Z) slips, the

screw and nut on the vice must be set tighter.

2.

Find a secure attachment point (wood ceiling joist

recommended) and secure safety cable (Z). Use a

heavy-duty wood screw, washer and lock washer

(all not included) to secure safety cable (Z) loop.

NOTE: Extra cable slack can be left in ceiling area.

Vice

Z

2

Wood Joist

Nut

Screw

Wood Screw,

and Washer

Loop

Z

8

WIRING

WARNING: To reduce the risk of fire, electrical shock or personal injury, each quick connect

clip provided with this fan is designed to accept only one 12-gauge house wire and one lead wire

from the fan. If your house wire is larger than 12-gauge or there is more than one house wire to

connect to the corresponding fixture lead wires, consult an electrician.

CAUTION: Be sure outlet box is properly grounded and that a ground (green or bare) wire is present.

WARNING: The wires from the outlet box must be connected to a corresponding color of the

fan's wires. Be sure wire colors match before making connections. If house wires are different

colors than referred to in the following steps, stop immediately. A professional electrician is

recommended to determine wiring.

WARNING: Using a full range dimmer switch (not included) to control fan speed will cause

a loud humming noise from fan. To reduce the risk of fire or electrical shock, do NOT use a full

range dimmer switch to control fan speed.

1.

Make the necessary wiring connections for

remote control operation as detailed below and in

the figure. For each wire connection, use one of

WHITE SUPPLY WIRE

1

BLACK SUPPLY WIRE

GROUND (GREEN OR BARE)

GROUND

(GREEN OR BARE)

the clips (CC).

CAUTION: Assistance from another person is

recommended for this step.

Connect all GROUND (GREEN) wires from fan

(on downrod (A), if applicable, and mounting

bracket (C)) to BARE/GREEN supply wire from

ceiling.

Connect BLACK wire (labeled AC IN L) from

remote control receiver (Y) to BLACK supply wire

from ceiling.

BLUE

FROM

FAN

FROM

RECEIVER

WHITE

BLACK

BLACK

WHITE

BLUE

WHITE

AC IN N

WHITE

BLACK

FROM

CEILING

FROM

RECEIVER

BLACK

AC IN L

Connect WHITE wire (labeled AC IN N) from

remote control receiver (Y) to WHITE supply wire

from ceiling.

Connect WHITE wire (labeled TO MOTOR N)

from remote control receiver (Y) to WHITE wire

from motor housing (D).

NOTE: To release a wire from clip (CC), twist

and pull the wire at the same time. This may

require some force.

Y

Connect BLACK wire (labeled TO MOTOR L)

from remote control receiver (Y) to BLACK wire

from motor housing (D).

NOTE: Pull on each wire to make sure wires

are secure in the clip (CC).

Connect BLUE wire (labeled FOR LIGHT) from

remote control receiver (Y) to BLUE wire from

motor housing (D).

WARNING: Never connect ground wire to

white or black power supply wires.

Hardware Used

CC

Clip x 6

9

WIRING

Wrap electrical tape (not included) around each

2.

individual clip (CC) down to the wire.

WARNING: Make sure no bare wire or wire

strands are visible after making connections. Place

green and white connections on opposite side of box

from the black and blue connections.

Gently push wires and clips (CC) into outlet box.

Gently slide remote control receiver (Y) flat-side up

3.

into mounting bracket (C). Turn spliced/taped wires

upward and gently push wires into outlet box. Let

antenna from remote control receiver (Y) hang to the

side.

NOTE: The remote control included with this fan

meets the following requirements:

a. Not for use with solid state fans.

b. Electrical rating: 120V / 60 Hz;

motor amps:1.25 MAX.;

light watts: 190

(Incandescent only)

Should you choose to use a different remote control

with this fan, it must also meet these same

requirements.

2

3

CC

Antenna

Y

CC

CC

C

A

10

FINAL INSTALLATION

1.

Raise canopy (B) toward ceiling and allow it to

attach to mounting bracket (C) using the magnets

mounted on each side of the mounting bracket (C).

Align the preassembled blade screw posts (J) on

2.

blade arms (S) with the holes on a blade (G).

Press up on the blade arm firmly so the blade screw

posts (J) come through the holes in the blade (G),

then slide a three-C clip (BB) onto each blade screw

post (J).

Repeat for each blade arm (S) and blade (G).

WARNING: To reduce the risk of personal injury,

make sure the friction detents on three-C clip (BB)

face down and recessed groove faces up. Slide

three-C clips (BB) completely under blade screw

posts (J) so edges of blade screw posts (J) are

captured by the recessed groove on the three-C clips

(BB).

Hardware Used

1

2

C

B

J

Recessed

Groove

X

J

S

Magnet

BB

Friction

Detents

BB

G

BB

Three-C clip x 15

11

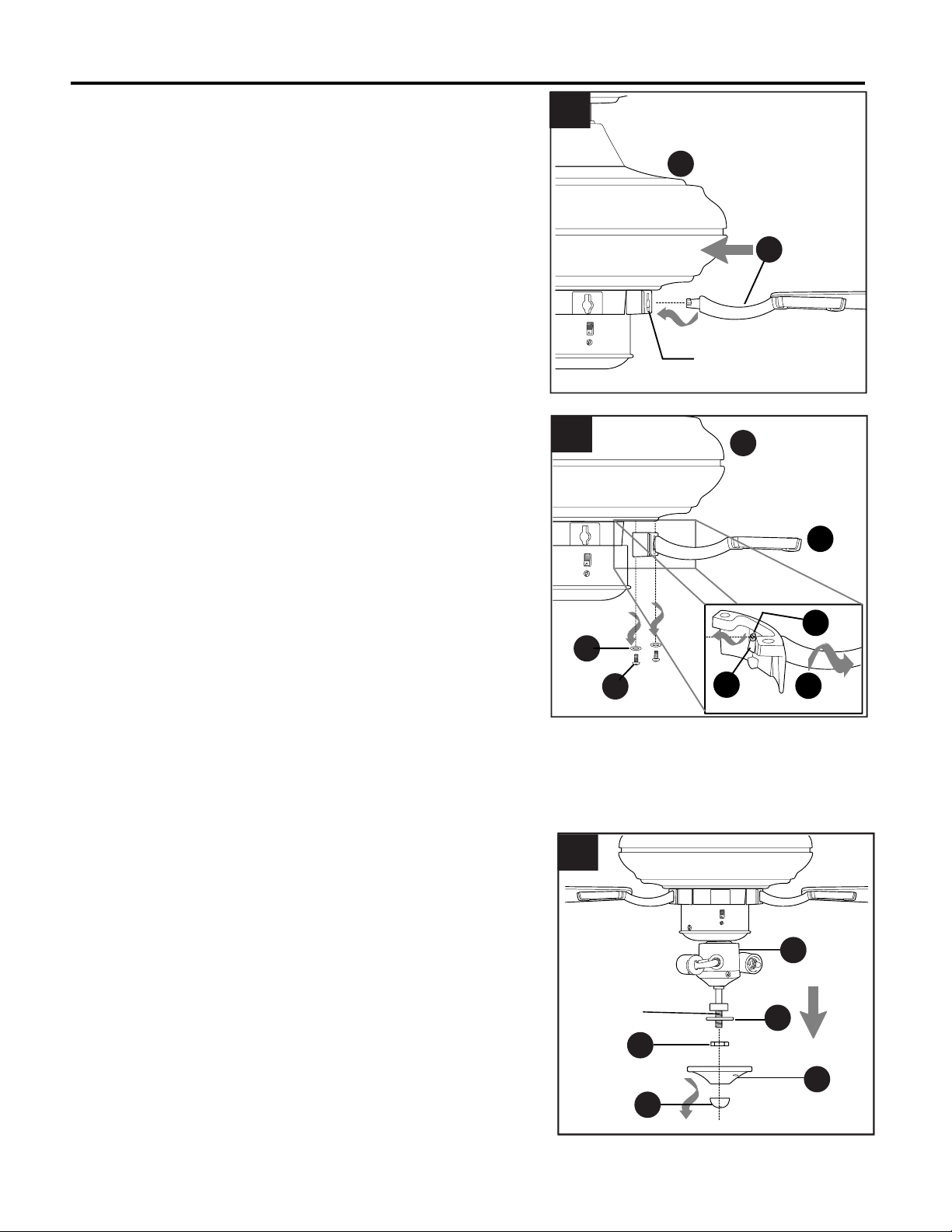

FINAL INSTALLATION

3.

Insert the end of one blade arm (S) into the

keyhole slot on the motor housing (D). Twist blade

arm (S) clockwise to lock in place.

Repeat with remaining blade arms (S).

4.

Should it become necessary to remove blade arm (S)

from motor housing (D), follow these steps:

Remove blade arm screws (T) and washers (U) from

underside of motor housing (D) and remove blade arm

assembly. Remove safety screw (V) and metal tab (W)

from blade arm wall. Twist blade arm (S)

counterclockwise to remove from blade arm wall.

3

4

D

Keyhole

Slot

J

S

D

S

To reinstall blade arm (S), reattach metal tab (W) to

blade arm wall with safety screw (V). Reattach blade

arm wall to motor housing (D) with blade arm screws

(T) and washers (U). Refer to step 3 to reinsert blade

arm (S).

U

T

W

V

S

NOTE: To install the fan without the light kit, proceed to INSTALLING FAN WITHOUT LIGHT KIT on

page 14.

If you wish to use the fan WITH the light kit,

5.

5

remove finial (O), finial plate (I), rubber washer (Q)

and hex nut (K) from the threaded rod at the bottom

of the light kit fitter (F). Save hardware for later use.

F

Threaded

Rod

K

Q

12

I

O

FINAL INSTALLATION

6.

Install bulbs (H).

CAUTION: When replacing bulb(s), allow

bulb(s) and glass shade to cool down before

touching.

6

Place rubber washer (Q) inside glass shade (P)

7.

over center hole. Align hole in center of glass

shade (P) with threaded rod on light kit fitter (F).

Push up gently on glass shade (P) until threaded

rod comes through hole. Secure glass shade (P)

with hex nut (K).

CAUTION: Do NOT overtighten hex nut (K)

as glass may crack or break.

Then, align hole in center of finial plate (I) with

threaded rod and push up. Secure glass shade

with finial (O).

CAUTION: Do NOT overtighten finial (O) as

glass may crack or break.

7

H

P

F

K

O

H

Q

I

If you wish to use the remote control bracket from

8.

remote pack (X), install screws from remote pack (X)

through bracket and into the desired installation site.

The remote control transmitter from remote pack (X)

rests inside the bracket.

8

Wall

Bracket

Screws

Remote Control

Bracket

13

INSTALLING FAN WITHOUT LIGHT KIT

If you do NOT wish to use the light kit, remove 3

1.

switch housing cap screws (N) from switch housing

cap (M) located on switch housing preassembled to

motor housing (D). Pull down gently on switch

housing cap (M).

Locate wires in switch housing labeled FOR LIGHT

and gently pull molex connections apart in order to

disconnect switch housing cap (M) from switch

housing.

2.

Remove the hex nut (K) and lock washer (L)

from the threaded rod at the top of the light kit

fitter (F). Unscrew the switch housing cap (M) to

remove it from the light kit fitter (F), and then

gently feed the BLACK and WHITE wires from

the light kit fitter (F) through the hole in the

middle of the switch housing cap (M).

1

N

2

Molex

Connections

WHITE

K

L

D

Switch Housing

M

BLACK

M

3.

Place cap (AA) firmly in hole in middle of switch

housing cap (M). Align holes in switch housing cap

(M) with holes in switch housing, then re-tighten

switch housing cap screws (N) previously removed.

Hardware Used

AA

Cap

x 1

3

F

Switch

Housing

N

N

AA

M

14

OPERATING INSTRUCTIONS

CAUTION: The remote control transmitter can be programmed to multiple receivers or fans. If this

is not desired, turn wall switch off to any other programmable receiver or fan.

FCC Compliance Notice for Remote Control

Modifications not approved by the party responsible for compliance could void the user's authority

to operate the equipment.

*NOTE: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

* Reorient or relocate the receiving antenna.

* Increase the separation between the equipment and receiver.

* Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

1.

Remove battery cover from back of remote

control transmitter in remote pack (X). Install

battery from remote pack (X) with positive (+)

end toward top of remote control transmitter.

Replace battery cover on remote control

transmitter.

WARNING: Choking Hazard - Small parts.

Keep battery away from children.

CAUTION: “DO NOT DISPOSE OF BATTERIES IN FIRE, BATTERIES MAY EXPLODE OR

LEAK.” - When disposing of household alkaline batteries, it is best to check with your local and

state recycling or household hazardous waste coordinators concerning the specifics of the program

in your area. You may also locate a recycling center by calling 1-800-8-BATTERY or

1-877-2-RECYCLE or visit www.epa.gov/epawaste/index.htm or www.earth911.org for more

information.

1

Battery

Cover

Remote

Control

Transmitter

(back

side)

Battery

X

15

OPERATING INSTRUCTIONS

Restore electrical power. Within 30 seconds of

2.

restoring electrical power, press and hold the “0”

button on the remote control transmitter for 5 seconds

or until light on the fan blinks twice. Use the remote

control transmitter to test the light and fan functions to

confirm the learning process is complete.

NOTE: Remove protective covering from front of

remote control transmitter and discard.

IMPORTANT: To prevent damage to remote control

transmitter, remove the battery if not used for long

periods. Store the remote control transmitter away

from excess heat or humidity.

Operation buttons on the panel of the remote control

3.

transmitter:

3 button for fan HIGH speed

2 button for fan MEDIUM speed

1 button for fan LOW speed

0 button to turn fan OFF

button to turn light ON or OFF

2

Remote Control Transmitter

3

Tap button quickly to turn lights off or on. Hold

button down to increase or decrease lights. If you

press button in excess of 0.7 seconds, it

becomes a dimmer. The lights vary cyclically in

8 seconds. The light button has an auto resume

function, which keeps the light at the same

brightness as the last time it was turned off.

4.

Use the fan reverse switch on the switch housing to

optimize your fan for seasonal performance. A

ceiling fan will allow you to raise your thermostat

setting in summer and lower your thermostat

setting in winter without feeling a difference in your

comfort.

NOTE: Wait for fan to stop before moving the

reverse switch.

Remote Control Transmitter

4

Reverse

Switch

Switch

Housing

16

OPERATING INSTRUCTIONS

4a. In warmer weather, setting the reverse switch

in the DOWN position will result in downward

airflow creating a wind chill effect.

4b. In cooler weather, setting the reverse switch in

the UP position will result in upward airflow that

can help move stagnant, hot air off the ceiling

area.

4c. IMPORTANT: Reverse switch must be set

either completely UP or completely DOWN for

fan to function. If the reverse switch is set in the

middle position, fan will not operate.

4a

4c

4b

CARE AND MAINTENANCE

At least twice each year, lower canopy (B) to check downrod (A) assembly, and then tighten all screws

on fan. Clean motor housing (D) with only a soft brush or lint-free cloth to avoid scratching the finish.

Clean blades (G) with a lint-free cloth. You may occasionally apply a light coat of furniture polish to

wood blades for added protection.

IMPORTANT: Shut off main power supply before beginning any maintenance. Do not use water or a

damp cloth to clean the ceiling fan.

Bulb Replacement: Use medium-base 9-watt LED bulbs or incandescent/CFL equivalents.

Battery Replacement: Use 9-volt alkaline battery.

17

TROUBLESHOOTING

WARNING: Before beginning work, shut off the power supply to avoid electrical shock.

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Fan does not move. 1. Reverse switch not engaged.

1. Push switch firmly either up or

down.

2. Power is off or fuse is blown.

3. Faulty wire connection.

2. Turn power on or check fuse.

3. Turn power off. Loosen canopy

and check all connections.

Noisy operation.

Excessive wobbling.

1. Blades are loose.

2. Cracked blade.

3. Full range dimmer switch.

4. Fan is new.

1. Blades are loose.

2. Blade arms incorrectly attached.

3. Unbalanced blades.

4. Fan not securely mounted.

5. Fan too close to vaulted ceiling.

6. Set screw(s) on motor housing yoke

is (are) not tightened properly.

7. Set screw on hanging ball is not

tightened properly.

1. Tighten all blade screws.

2. Replace blade.

3. Replace with an approved

speed control device.

4. Allow fan a “break in” period of a

few days, especially when

running the fan at Medium and

High speeds.

1. Tighten all blade screws.

2. Re-install blade arms.

3. Switch one blade with a blade

from the opposite side or use

blade balancing kit (R).

4. Turn power off. Carefully loosen

canopy and verify that mounting

bracket is secure.

5. Use a longer downrod or move

fan to another location.

6. Tighten yoke set screw(s)

securely.

7. Carefully loosen and lower

canopy and verify that set screw

on hanging ball is tightened

securely.

Fan operates but

light fails (if

applicable).

1. Bulb(s) not installed correctly.

2. Wires in outlet box not wired

properly.

3. Wall switch to fan is off.

4. Wires not connected properly.

1. Re-install bulb(s).

2. Check wires in outlet box and, if

necessary, re-wire according to

instructions on pages 8 and 9.

3. Make sure wall switch to fan

4. Check molex connections in light

kit fitter are connected properly.

NOTE: A small amount of "wobble" is normal and should not be considered a defect.

18

is

on.

LITEX LIFETIME LIMITED WARRANTY

LITEX INDUSTRIES, LTD. warrants this fan to the original household purchaser for indoor use under

the following provisions:

1-YEAR WARRANTY: LITEX INDUSTRIES, LTD. will replace or repair any fan which has faulty

performance due to a defect in material or workmanship. Contact Customer Service at

1-800-527-1292 to arrange for return of fan. Return fan, shipping prepaid, to Litex Industries, Ltd. We

will repair or ship you a replacement fan, and we will pay the return shipping cost.

5-YEAR WARRANTY: LITEX INDUSTRIES, LTD. will repair or replace, at no charge to the original

purchaser, any fan motor that fails to operate satisfactorily when failure results from normal use.

RETURN FAN MOTOR ONLY, shipping prepaid, to Litex Industries. We will repair or ship purchaser a

replacement motor and Litex will pay the return shipping cost.

6-YEAR to LIFETIME LIMITED WARRANTY: LITEX INDUSTRIES, LTD. will repair the fan, at no

charge to the original purchaser for labor only, if the fan motor fails to operate satisfactorily when

failure results from normal use. Parts used in the repair will be billed to the purchaser at prevailing

prices at time of repair.

The purchaser shall be responsible for all costs incurred in the removal, reinstallation and shipping of

the product for repairs.

This warranty does not apply when damage from mechanical, physical, electrical or water abuse

results in causing the malfunction. Deterioration of finishes or other parts due to time or exposure to

salt air is specifically exempted under this warranty.

Neither Litex Industries nor the manufacturer will assume any liability resulting from improper

installation or use of this product. In no case shall the company be liable for any consequential

damages for breach of this, or any other warranty expressed or implied whatsoever. This limitation as

to consequential damages shall not apply in states where prohibited.

JMLI1708

19

Loading...

Loading...