Op er a tor's Guide Warnings

W

arnings

WARNING! THE RADIO CONTROLLED MODEL HELICOPTER BUILT FROM THIS KIT IS

NOT A TOY, AND IS NOT MEANT FOR CHILDREN. IT IS A FLYING MACHINE

CAPABLE OF CAUSING PROPERTY DAMAGE AND SERIOUS BODILY HARM

TO THE OPERATOR AND SPECTATORS IF NOT BUILT AND OPERATED

CORRECTLY AND RESPONSIBLY. ROTATING COMPONENTS, ESPECIALLY

THE MAIN ROTOR BLADES, ARE AN EVER-PRESENT DANGER.

WARNING! Helicopters, by their nature, are not positively stable. Even if assembled and

adjusted properly, helicopters will not hold a particular flight position without constant

control inputs from the pilot, and will not automatically recover from an unwanted

flight attitude without pilot intervention.

WARNING! It is your exclusive responsibility to correctly and responsibly build, maintain and

operate this helicopter. Lite Machines has spent considerable time making this

product reliable and easy to build, but only the operator can ensure that it is safe.

Because the safe operation of this helicopter is beyond the control of the

manufacturer and distributor, the owner/operator assumes all risk of use.

WARNING! THIS PRODUCT CONTAINS CHEMICALS WHICH ARE KNOWN BY THE STATE

OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS AND/OR OTHER

REPRODUCTIVE HARM. Many common materials, such as metals, plastics, glues,

fuels, lubricants and coatings contain chemicals in varying amounts and

concentrations which will cause harm if introduced into the human body. Lite

Machines strives to produce safe and reliable products, and is interested in the

well-being of every user of its products. For more information on chemicals contained

in Lite Machines’ products, please contact Lite Machines Corporation. For further

information on toxic or dangerous chemicals, please refer to California’s health and

safety codes sections 25249.5-13.

LITE MA CHINES

Op er a tor's Guide Acknowledgments

A

cknowledgments

We thank all of those people who helped make Lite Machines Corporation possible.

We especially thank Mom and Dad. Without their help and constant encouragement

we could not have done this.

David and Paul Arlton

Lite Machines Corporation

Purdue Research Park

1291 Cumberland Avenue

West Lafayette, IN 47906

USA

PATENT

NOTICE

Tel: (765) 463-0959

Fax: (765) 463-7004

www.litemachines.com

Most aspects of Lite Machines helicopters including, but not limited to, the main

rotor, main rotor blades, tail rotor, tail rotor blades, Arlton Subrotor™ stabilizer,

Arlton Gyro™ stabilizer, swashplate, fuselage structure and configuration, radio

installation configuration, landing gear and drive train are either patented (U.S.

5305968, 5597138, 5609312, 5628620, 5749540, 5879131, 5836545, 5906476,

6053146, 6142419; Australia 681287, 686883; Europe 0605656, 95918276.7-2312,

95932305.6-2312, 96928019.7; France 0605656; Germany 69221307.4; U.K.

0605656), patent pending or patent applied-for in the United States and in other

countries. For information concerning patents and licensing, please contact Lite

Machines Corporation.

© Copyright Lite Machines Corporation, 2001. All rights reserved.

Revision VP8.3 1001

LITE MA CHINES

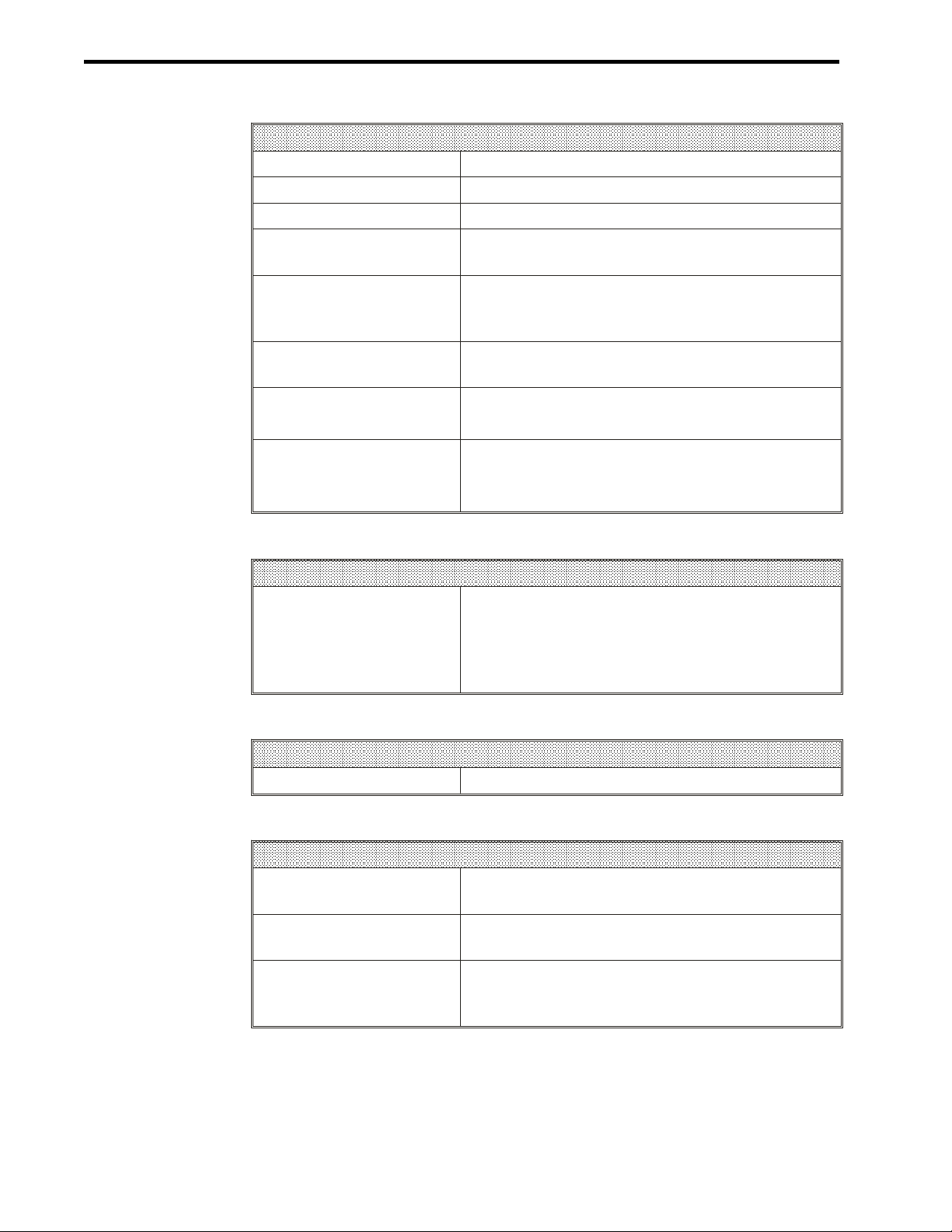

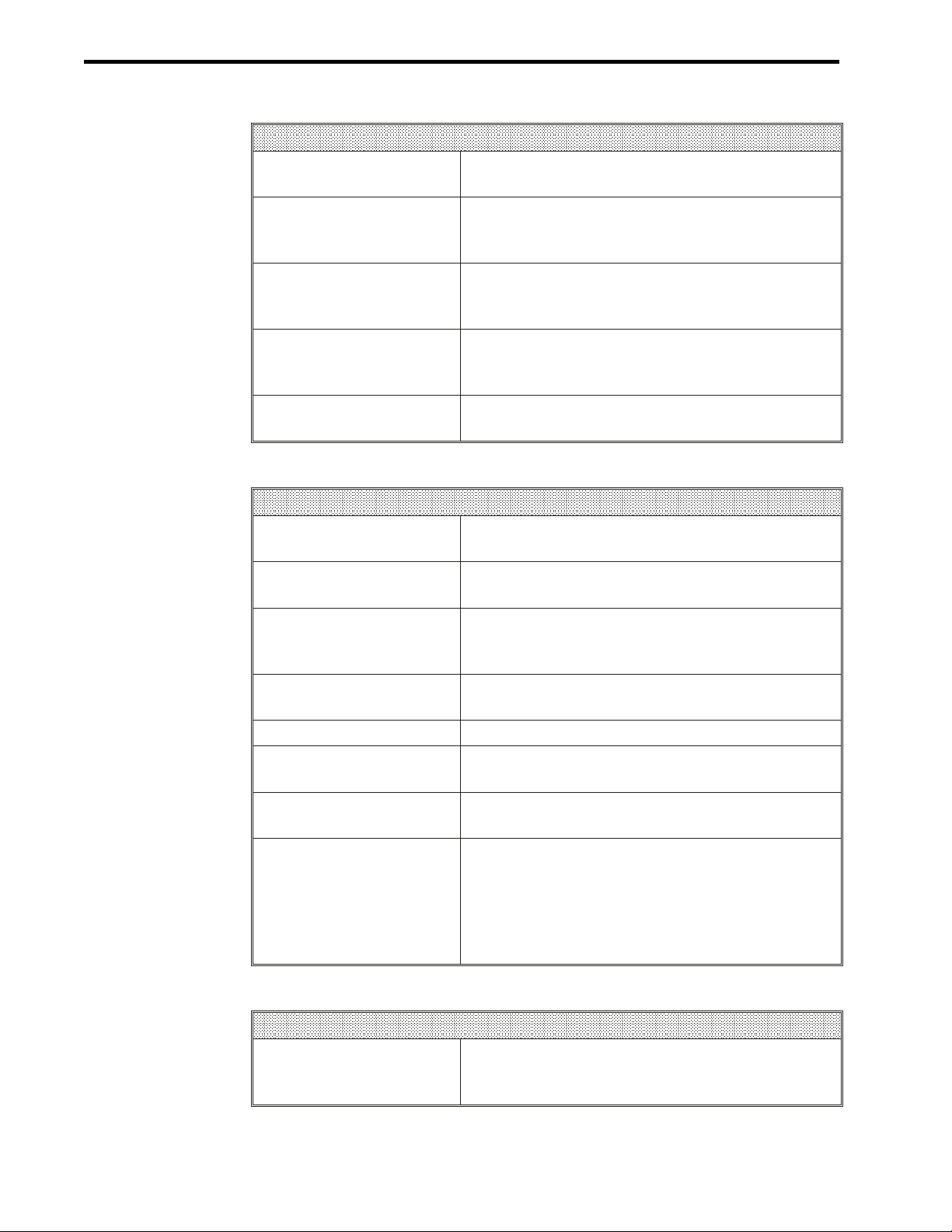

Op er a tor's Guide Table of Contents

T

able of Contents

Model Helicopter

Safety 1-1

Fuel Safety ...................1-1

Flight Safety...................1-2

Electric Power Safety ..............1-3

General Safety .................1-3

Terminology

and Controls 2-1

Helicopter Controls ...............2-2

Holding the Transmitter .............2-4

Electric Motors 3-1

The Corona Electric Helicopter .........3-1

Basic Theory of Electric Power .........3-1

Batteries.....................3-2

Electro-Magnetism and Electric Motors .....3-2

Brushed motors .................3-3

Adjustable Timing .............3-4

Brushless Motors ................3-5

Problems with Brushed Motors .........3-6

Three-Minute Motor Overhaul..........3-6

The Fusion 35 Speed Controller ........3-9

Arming the Fusion 35 ..............3-10

Optional RF Filter ................3-11

Cable Connections ...............3-11

Battery Elimination Circuitry (BEC) .......3-12

Charging Batteries ...............3-12

Battery Chargers ................3-13

Flying Weight ..................3-14

LITE MA CHINES

Op er a tor's Guide Table of Contents

Glow-Fuel Engines 4-1

General Operating Considerations .....4-1

Fuel Mixture and Compression .......4-1

The Importance of Clean Fuel .......4-3

Synthetic Oils ................4-3

Breaking-In a New Engine .........4-4

Engine Starting Summary..........4-4

Preferred Engine Starting Procedure ....4-5

Alternate Starting Method..........4-9

Adjusting Fuel Mixture and Compression..4-10

Inspecting SpiraLite Speed Glow Plugs...4-11

Electric Starter Effect on Glow Plug.....4-12

Main Rotor

Stability and Control 5-1

Rotor Blade Designations..........5-1

Blade Tracking ...............5-1

Dynamic Balancing .............5-3

Helicopter Stability .............5-3

Adjusting Main Rotor Blade Pitch......5-4

Stability and Climb Performance ......5-4

Learning to Fly 6-1

Training Gear ................6-2

Step 1: Learn the Left Stick .........6-3

Step 2: Practice Small Hops ........6-3

Step 3: Learn the Right Stick ........6-4

Main Rotor Controls.............6-5

Forward Flight and Translational Lift ....6-7

Circles....................6-8

Figure 8’s and Nose-In Hovering ......6-10

LITE MA CHINES

Descending from Altitude ..........6-11

Landing ...................6-11

Piezo Gyro Stabilizers ...........6-12

Adjusting the Arlton Gyro Stabilizer.....6-13

Tail Swing and Revo Mix ..........6-13

Op er a tor's Guide Table of Contents

Zen and the Art of

Helicopter Maintenance 7-1

General Maintenance ..............7-1

Engine Maintenance ..............7-1

Brushed Motor Maintenance ..........7-2

Radio Maintenance ...............7-2

Tail Rotor and Arlton Gyro Maintenance ....7-2

Main Rotor Maintenance ............7-3

Power Train Maintenance............7-3

Field Equipment Maintenance..........7-3

Making Repairs with CA and Glass Fiber ....7-4

Making Repairs with CA and Baking Soda ...7-5

Fixing a Bent Tail Boom.............7-5

Straightening a Bent Main Shaft ........7-5

How Helicopters Work 8-1

Introduction ...................8-1

Background and History .............8-2

Standard Helicopter Configuration .......8-2

Main Rotor Control ...............8-3

Main Rotor Stability ...............8-6

Retreating-Blade Stall ..............8-7

Anti-Torque Systems ..............8-8

Gyro Stabilizers .................8-9

Trouble-Shooting

Glow Engines 9-1

Trouble-Shooting

Brushed Motors

10-1

LITE MA CHINES

Op er a tor's Guide Model Helicopter Safety

M

odel Helicopter Safety

This section contains important safety information regarding proper handling and

operation of Lite Machines helicopters and accessories.

Fuel Safety

1. Use ONLY commercial fuel developed for model engine use. NEVER USE

GASOLINE, DIESEL, OR ANY OTHER FUEL! These fuels will ruin model

engines, and can explode and burn causing injury to YOU and OTHERS.

2. DO NOT OPERATE MODEL ENGINES INDOORS! Hot engine parts and

exhaust could ignite carpeting, drapery or furniture. Engine exhaust also

contains large amounts of unburned oil that will soil interior furnishings.

3. Never fuel or prime with the glow-plug battery connected to the engine. Sparks

from the electric connection could start a fuel fire.

4. Never fuel, prime, or operate your model while smoking.

5. Store fuel in a cool dry place protected from sunlight and from potential ignition

sources (anything burning, or anything that could start a fire if exposed to fuel

such as shorting or sparking battery terminals or the furnace in your home).

6. Remove excess fuel from your model with a cloth after refueling or priming. Raw

fuel can damage paint and is a potential fire source.

7. Do not store fuel in your model.

8. Fuel is poisonous and can cause death or blindness if swallowed. If swallowed,

induce vomiting and call for medical assistance immediately.

9. Fuel is an eye irritant. In case of contact with eyes, flush thoroughly with water.

10. Raw fuel will damage certain types of plastic. Prescription plastic lenses and the

clear plastic commonly used on radio transmitter meters will be damaged if

exposed to raw fuel (such as droplets sprayed from the engine during starting).

Wipe off immediately using spray window cleaner.

IF FIRE SHOULD OCCUR:

1. MODEL FUEL BURNS WITH A NEARLY INVISIBLE FLAME, BE VERY

CAREFUL!

2. Use a fire extinguisher, or smother fire with a CLEAN, heavy cloth. If fire persists,

GET AWAY! Better to lose the model than risk severe burns.

LITE MA CHINES 1-1

Op er a tor's Guide Model Helicopter Safety

Flight Safety

1. ALWAYS WEAR APPROPRIATE EYE PROTECTION WHEN OPERATING

YOUR MODEL. Fuel droplets, loose parts, and airborne debris ejected from your

model could cause serious injury or blindness. Select comfortable, well-fitting

eyewear with high-impact resistance such as shop glasses. Prescription glasses

made of glass are dangerous because they could shatter if struck sharply.

2. ALWAYS WEAR APPROPRIATE HEARING PROTECTION WHEN STARTING

AND ADJUSTING YOUR ENGINE. Many car, airplane and helicopter modelers

ignore the sound produced by the engines on their models. High volumes and

high frequencies produced by model engines can damage hearing. This damage

can be cumulative. Ear-phone and ear-plug style hearing protectors (sold in

sporting goods stores in the gun section) are inexpensive and effective at

reducing the most damaging and annoying qualities of engine sound. Once your

model is started and flying, hearing protection is usually not necessary.

3. NEVER STAND OR PLACE YOUR EYES OR FACE IN-LINE WITH ROTATING

MAIN ROTOR OR TAIL ROTOR BLADES. Loose parts or debris thrown outward

from rotating rotors could cause injury or blindness.

4. NEVER, EVER FLY NEAR OR OVER PEOPLE. Always keep your model at a

safe distance from yourself and spectators.

5. Use only those model engines designed specifically for your Lite Machines

helicopter. Use of more powerful engines (such as racing engines) is potentially

dangerous and voids all warranties.

6. Do not use fuel containing more than 35% nitromethane. The added power and

heat of high nitro fuels can damage both the engine and your model.

7. Never allow main rotor speed to exceed 2000 RPM (as by operating with blade

pitch set too low, or using a high powered engine with high nitro fuel). Rotor parts

could separate from the rotor head and cause serious injury or property damage.

Very high speeds can also damage the engine.

8. Fly only at approved flying fields or in open areas away from people and property.

Do not fly in residential areas.

9. Before turning on your radio, ensure that your radio frequency is not already in

use. Flying clubs have organized frequency sharing procedures.

10. Range check your radio prior to the first flight of each day. If your range check is

lower than normal, do not fly.

11. Prior to the first flight of each day, check all mechanics for smooth, unobstructed

operation. Before the main rotors reach flying speed, gently move all flight

controls and confirm proper function. Do not fly if anything is out of the ordinary.

12. Check for hidden damage after crashing, and replace any damaged

components.

13. Beginners should have the main rotors tracked, and model adjusted for flight by

an experienced modeler.

1-2 LITE MA CHINES

Op er a tor's Guide Model Helicopter Safety

Electric Power Safety

1. Electric power systems can be very dangerous. High electric currents can heat

wires, cause sparks and lead to fires and personal injury. DO NOT TO TOUCH

EXPOSED ELECTRIC COMPONENTS, AND NEVER FLY AT A SITE

LOCATED NEAR FLAMMABLE MATERIALS.

2. Electric motors are almost silent, and the main rotor and tail rotor blades of an

electric helicopter can start tuning unexpectedly causing serious injury. MAKE

SURE THE TRANSMITTER IS SWITCHED ON BEFORE CONNECTING THE

SPEED CONTROLLER AND BATTERY ON AN ELECTRIC HELICOPTER.

ALWAYS DISCONNECT THE BATTERY FROM THE SPEED CONTROLLER

WHEN CARRYING AN ELECTRIC HELICOPTER.

3. ALWAYS DISCONNECT THE MOTOR POWER CABLES WHEN ADJUSTING

THE RADIO SYSTEM ON A HELICOPTER SO THE MAIN ROTOR BLADES

CANNOT START TURNING. TO AVOID A SHORT CIRCUIT, BE CAREFUL

NOT TO TOUCH THE ENDS OF THE POWER CABLES TOGETHER.

4. Electric power systems, electronic components and batteries contain chemicals

such as lead and antimony which are known by the state of California to cause

cancer and birth defects.

General Safety

1. Periodically check tightness off all bolts, nuts, set screws and pins. Loose parts

could be ejected from your model causing injury or causing the model to crash.

2. Replace broken or worn components with original parts only. To prevent

recurring problems it is important to locate and understand the cause of failure

(including pilot error).

3. Never modify any part of the main rotor, tail rotor system or drive train.

Modifications could lead to part failure.

4. Always replace the main and tail rotor blades in sets if damaged.

5. Do not store your model in direct sunlight. Prolonged exposure to ultraviolet light

can weaken some types of plastics.

6. When flying in very cold conditions be aware that metals and plastics (even

flexible ones) can become brittle and break or shatter.

7. Keep your model, radio and field equipment clean and in good repair. While

cleaning and maintaining your model you can often find and fix potential

problems (such as loose or damaged parts) before they occur.

8. Do not use solvents to clean or degrease rotor blades. Solvents can attack the

plastic and cause the blades to fail unexpectedly resulting in serious injury.

LITE MA CHINES 1-3

Op er a tor's Guide Terminology and Controls

T

erminology and Controls

This section contains information on helicopter terminology and flight control

functions. Review the figures and become familiar with the names and functions of

the major components and controls. For more information on helicopter controls see

the How Helicopters Work section of this Operator’s Guide.

Hint: If you want lasting respect from helicopter flyers, don’t call the main rotor and tail rotor

blades “propellers”, and don’t call the right-left cyclic (pronounced sigh’-click) and

fore-aft cyclic controls “aileron and elevator”. This reveals your true identity as an

airplane person and diminishes your credibility among helicopter pilots. Also, don’t

call the swashplate, “that thing with bearings in it connected to the main rotor.”

O-Heli part names

Figure 2-1.

LITE MA CHINES 2-1

Op er a tor's Guide Terminology and Controls

Helicopter Controls

To fly a model helicopter you must first understand the function of each flight control.

Fig. 2-2 through Fig. 2-5 illustrate the flight motions produced with the right cyclic

(pronounced “sigh-click”) stick on the transmitter. The right stick tips the rotating

main rotor in the direction of the stick motion and controls the direction of horizontal

O-Stick Roll

flight.

O-Stick pitch

Figure 2-2.

As shown in Fig. 2-2, moving the stick left and right tips the main rotor left and right

(like aileron control on an airplane).

Figure 2-3.

As shown in Fig. 2-3, moving the stick forward and backward (up and down) tips the

main rotor forward and backward (like the elevator control on an airplane). When

learning to use the right stick, it is helpful to think of it linked to an imaginary control

stick mounted vertically on top of the main rotor. As you push the transmitter stick

forward, you also push the imaginary control stick forward and tip the main rotor

forward. Imagine the same for backward, left and right.

2-2 LITE MA CHINES

Op er a tor's Guide Terminology and Controls

O-Stick yaw

Figure 2-4.

O-Stick throt tle

Fig. 2-4 and Fig. 2-5 show the ef fect of mov ing the left stick on the trans mit ter. The left

stick con trols the tail ro tor and throt tle.

As shown in Fig. 2-4, moving the left stick to the left and right changes the pitch of the

tail ro tor blades caus ing the he li cop ter to ro tate to the left or right (like steer ing a car).

Note that the left stick ro tates the NOSE to the left and right. Al ways con cen trate on

the NOSE when us ing the left stick to turn. You will be come con fused if you watch the

tail.

Figure 2-5.

Mov ing the left stick up and down in creases or de creases en gine speed caus ing the

he li cop ter to climb or de scend as shown in Fig. 2-5. On collective-pitch helicopters,

the left stick also controls the pitch angle of the main rotor blades.

LITE MA CHINES 2-3

Op er a tor's Guide Terminology and Controls

Holding the Transmitter

Model airplane fliers commonly hold their transmitter so only their thumbs touch the

transmitter sticks. When flying with thumbs, it is easy to unintentionally mix controls

O-Hands on trans mit ter

by moving the right stick up and to the right, and the left stick up and to the left.

Figure 2-6.

To control your helicopter more accurately, hold the control sticks with both your

thumbs and index fingers as shown in Fig. 2-6. It also helps to wear a transmitter neck

strap to support the transmitter and take the weight off your hands.

Note: Even though he drawings show the transmitter antenna retracted, always extend

your transmitter antenna before flying for the best possible radio range.

2-4 LITE MA CHINES

Op er a tor's Guide Electric Motors

E

lectric Motors

This section describes basic principles of electric powered flight and the operation of

Electro-Fusion brushed motors. If you have a gas-powered helicopter you can skip

this section.

The Corona Electric Helicopter

Before it made its first flight, the Corona electric helicopter was optimized by a

computer program to fly at maximum efficiency with Electro-Fusion brushed motors.

The rotor systems and motors were matched to achieve the best lift-to-drag ratio of

the rotor blades for a particular weight, speed and motor efficiency.

After computing the best design parameters, prototype parts were developed and

tested on an instrumented whirl stand to generate test data (such as lift, drag and air

velocity measurements) at dozens of points around the main rotor and tail rotor. The

measurements were fed back into the computer program to further optimize the

design.

There are many interrelated design variables in the Corona helicopter, so it is

practically impossible to optimize the design by trial and error. A basic understanding

of electric powered flight, however, will greatly aid you in successfully operating your

Corona helicopter.

Basic Theory of Electric Power

Electricity is commonly measured in units of volts (abbreviated “V”), amperes (“A”),

ohms (“Ω”) and watts (“W”). By analogy, electric current flowing through a wire is like

water flowing through a pipe.

Electric potential is measured in volts (positive and negative) and can be thought of

as pressure in a water pipe. If the pressure at one end of the pipe is higher than at the

other end, the pressure difference will push water through the pipe. If there is no

pressure difference, then no water will flow.

In a similar way, voltage difference in a wire pushes electrons through the wire from

the negative end of the wire to the positive end. If there is no voltage difference, no

electrons will flow. A seven-cell NiCad battery pack produces about 8.4 volts of

electric potential.

Electric current is measured in amperes (“amps” for short), and is related to the

amount of electrons (actually electron waves) flowing through a wire. A large

diameter wire can conduct more electrons than a small wire in the same way a large

LITE MA CHINES 3-1

Op er a tor's Guide Electric Motors

diameter pipe can carry more water than a small pipe. The Corona electric helicopter

normally flies on about 11 to 19 amps of electric current.

Electric resistance is measured in ohms and represented by the Greek letter omega

(Ω). Resistance slows down or inhibits the flow of electrons in a wire like a plug slows

down the flow of water in a pipe. When electric resistance inhibits the flow of

electrons, the energy of the electrons is converted to heat (this is how an electric

stove works). The Fusion 35 motor speed controller has an internal resistance of only

about 0.005 ohms (this is really low), and, as a result, stays cool in operation.

Power is measured in watts which is simply amps multiplied by volts. A Corona

electric helicopter drawing 12 amps from an 8.4 volt battery consumes 100.8 watts of

power (12A x 8.4V = 100.8 W).

Batteries

Batteries store electric energy in various ways, but each type of battery has a

characteristic voltage and a maximum current storage capacity. The

Nickel-Cadmium (NiCad) battery cells used in your Corona helicopter each produce

a maximum of about 1.2 volts.

Batteries can be connected end-to-end in “series” to increase voltage or side-to-side

in “parallel” to increase current capacity. Six-cells connected in series to form a

standard six-cell pack produce about 7.2 volts (1.2V x 6 cells = 7.2 volts). Seven-cells

connected in series produce about 8.4 volts (1.2V x 7 cells = 8.4 volts).

Battery capacity is measured in milliampere hours which is abbreviated “milliamphours” or “mAh”. A milliamp represents 1/1000th of an amp of current (0.001 A), and a

milliamp-hour represents 1/1000th of an amp of current flowing for one hour. A 2400

mAh battery can produce 2400 milliamps of current for one hour. This is the same as

2.4 amps for one hour, 1.2 amps for two hours or 0.6 amps for four hours.

All batteries and motors have internal resistance that causes them to heat up in

operation. The more current flowing through a battery or motor, the more heat

produced. Since the idea behind electric power is to convert the electric energy

stored in a battery to mechanical energy, any heat generated is a measure of

inefficiency and waste. Generally, expensive batteries have lower internal

resistance than cheap batteries, and provide longer flight times with more available

power.

Electro-Magnetism and Electric Motors

When electric current flows through a coil of copper wire, the current generates a

magnetic field (also called an “electro-magnetic” field). The strength of the magnetic

field depends on the voltage, current and number of winds in the coil. The strength of

the field can be greatly increased by winding the coils around a chunk of iron metal.

3-2 LITE MA CHINES

Op er a tor's Guide Electric Motors

Like all magnets, electro-magnets have a north pole and south pole. North and south

poles attract each other. When two magnets are placed next to each other, the

magnets tend to rotate so the north pole of one magnet aligns with the south pole of

the other.

Electric energy stored in a battery can be converted to mechanical energy by an

electric motor which uses electro-magnetic fields to rotate an output shaft. Model

motors come in two basic varieties, “brushed” and “brushless”, which differ in terms

of how electric current gets to the copper coils or “windings” inside the motor.

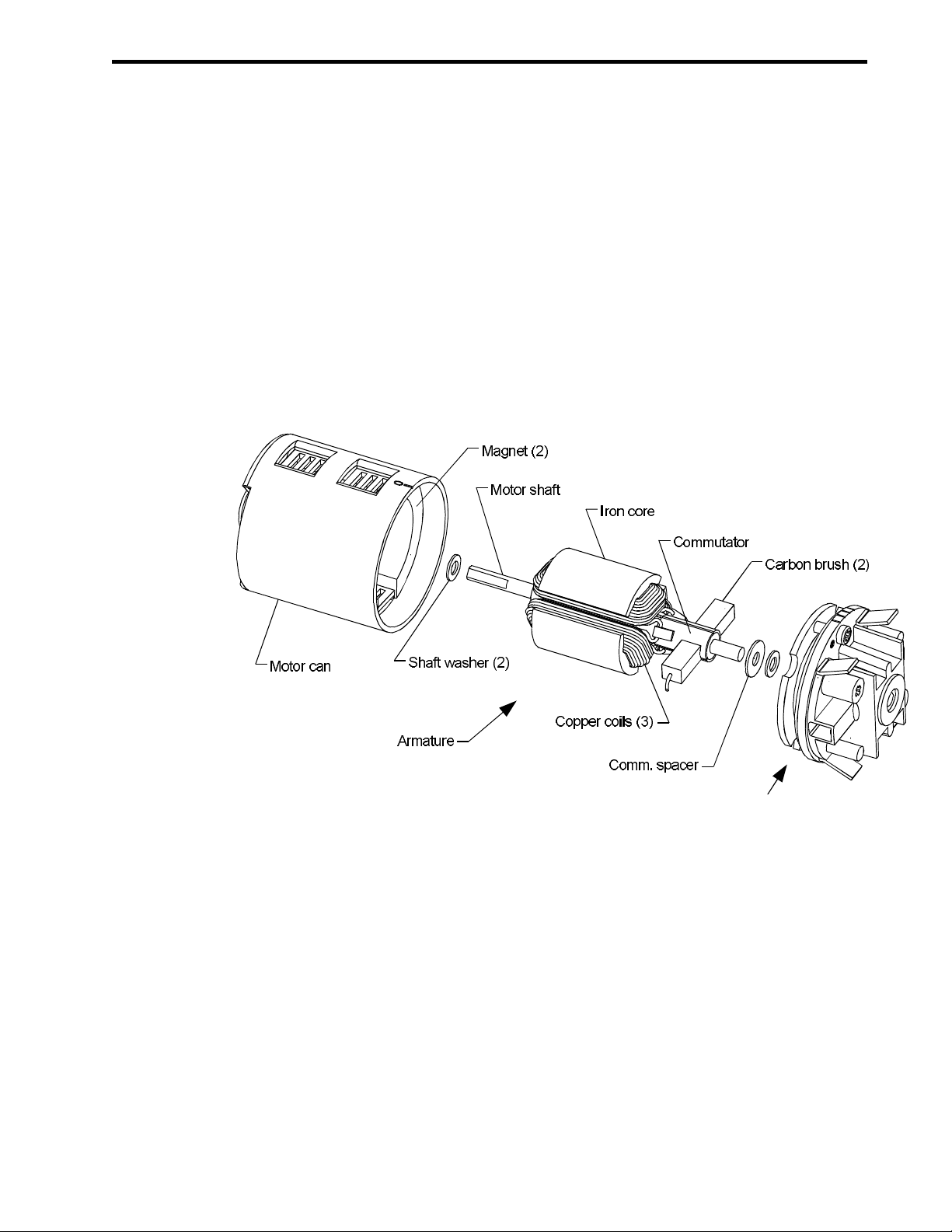

Brushed motors

O-Brushed mo tor op er a tion

Figure 3-1.

In a “brushed” motor, electric current flows through carbon brushes that slide on a

copper commutator ring attached to the motor output shaft as shown in Fig. 3-1. The

commutator ring generally has three segments attached to three coils of copper wire

each wrapped around an iron core. The motor shaft, commutator, coils and iron core

are collectively referred to as the motor “armature”.

As the armature rotates, the brushes conduct current to each segment on the

commutator and through one coil after another. The energized coils produce

magnetic fields that pull the coils toward permanent magnets mounted on the inside

of the motor body (also called the motor “can”). As each coil passes a permanent

magnet, the brush associated with that coil slides onto the next commutator

segment. This de-energizes the coil and energizes the next one in sequence.

LITE MA CHINES 3-3

Op er a tor's Guide Electric Motors

The speed of rotation of a brushed motor is determined by the load on the motor, the

amount of current passing through the coils, the number of turns or winds in the coils

and the operating voltage. Motors running at high voltage are generally more efficient

because less current is needed to generate power, so less energy is lost as heat.

Also, motors with fewer turns have more power and run faster, but are generally less

efficient than motors with more turns.

Brushed motors are easy to manufacture, but are inefficient to operate. Only about

75% of the electric enery entering the motor is converted to mechanical energy. The

rest is converted to heat by the electric resistance of the brushes and by conflicting

O-Brushed eff graph

magnetic fields inside the motor.

As shown in Fig. 3-2, which is a graph of motor efficiency at various motor speeds,

brushed motors are most efficient within a very small speed range. Outside of this

range efficiency drops quickly, and most of the electric energy entering the motor is

converted to heat. When a motor operates outside its efficient speed range the motor

body becomes very hot (sometimes too hot to touch), and the motor coils can burn

out.

Adjustable Timing

Motor coils cannot energize instantly when current is applied. This poses a problem

for brushed motors running at high speed because the coils energize at the wrong

time and generate conflicting magnetic fields that push on the permanent magnets

when they should be pulling (and vice versa). Some brushed motors, such as the

Electro-Fusion motor on your Corona helicopter, have adjustable timing to address

3-4 LITE MA CHINES

Figure 3-2.

Op er a tor's Guide Electric Motors

this problem. To adjust the point at which the brushes touch the commutator

segments, the motor end-bell can be rotated relative to the motor body.

“Advanced” timing gives the coils more time to develop a strong magnetic field so

they can pull on the permanent magnets longer and with less magnetic conflict.

Timing of the Electro-Fusion motor on the Corona helicopter is usually set between

15 and 20 degrees for best results.

Brushless Motors

Brushless motors require no brushes. The copper coils are usually located on the

outer surface of the motor case (instead of on the spinning armature) where they can

be connected directly to a power supply. The permanent magnets are mounted on

and rotate with the output shaft. A small, computerized speed controller turns the

coils on and off at the appropriate time to operate the motor at a particular speed.

Brushless motors are more difficult and expensive to manufacture than brushed

motors, but are more efficient and powerful. With no brushes to burn out, the coils can

carry very high currents. Since the computer operated speed-controller can be

programmed to turn the coils on and off at just the right time, the power loss

O-Brushless eff graph

associated with conflicting magnetic fields is very low.

Figure 3-3.

Efficiencies of good brushless motors approach 90% (that is, 90% of the battery

power going into a brushless motor ends up rotating the output shaft). As shown in

Fig. 3-3, brushless motors also can operate efficiently over a wide speed range. At

such high efficiencies, brushless motors tend to run cooler than brushed motors

because less electric power is wasted as heat.

LITE MA CHINES 3-5

Op er a tor's Guide Electric Motors

Problems with Brushed Motors

Electro-Fusion motors are modified versions of standard 540-size brushed motors.

The original 540-size motors made in the 1980’s produced about 50 watts of power,

but Electro-Fusion motors can produce as much as 150 watts with the same size

brushes. Since the brushes and commutator on modern motors handle more power,

they wear down more quickly. Brush and commutator wear is the primary source of

power loss in brushed motors.

Motor brushes are typically made of carbon, copper and silver, and vary in hardness.

When a brushed motor turns at high speed, the ends of the brushes and commutator

slide against each other and wear down. If the brushes have hard spots, or wear

unevenly, the commutator can also wear unevenly. As the gap between the

commutator and brushes becomes more uneven, small sparks jump between the

brushes and commutator and accelerate the wear of both. This uneven gap also

increases electric resistance.

As resistance goes up, so does the heat generated by the current flowing through the

brushes and commutator. This heat eventually burns the brushes and turns them a

deep blue color. When this happens, brush manufacturers say, certain lubricating

components are burned out further accelerating brush wear.

Once a brush has worn down to the point where it no longer touches the commutator

it must be replaced. If the commutator wears unevenly, it must be resurfaced on a

commutator lathe or the entire armature must be replaced.

Commutator surface finish is possibly the most overlooked problem with brushed

motors because relatively few modelers take apart and inspect their motors. As high

electric currents pass between the motor brushes and commutator, the surface of the

commutator heats up and oxidizes turning a deep black color. This black finish

increases the electric resistance of the commutator/brush connection and consumes

battery power. Removing the black surface finish can restore electric conductivity

and proper commutator function.

Three-Minute Motor Overhaul

For the best long-term performance of your Electro-Fusion motor, service your motor

every six to ten flights using this simple three-minute procedure.

1. Disconnect the flight battery from the speed controller, and the power cables

from the motor, but leave the motor in your Corona helicopter.

2. Remove the motor pinion gear.

3. Pull the brushes out past the end of the brush springs so the brushes do not catch

on the commutator washer.

3-6 LITE MA CHINES

Op er a tor's Guide Electric Motors

O-Re move end-bell

Figure 3-5.

O-Worn brush and comm

4.

Loosen (but do not remove) the end-bell screws. Rotate the end-bell assembly,

and pull it off the motor as shown in Fig. 3-5.

5. Remove the armature from the motor can.

Figure 3-4.

6.

Inspect the brushes. If the brushes are less than 3/16” (5 mm) long, or if the

brushes are burnt and discolored, replace with new ones.

Warning! DO NOT USE REPLACEMENT BRUSHES WITH A SERRATED OR WAVY

RUNNING SURFACE. The serrated surface will cut into the commutator and

damage it.

LITE MA CHINES 3-7

Op er a tor's Guide Electric Motors

7. If the commutator is worn unevenly as shown in Fig. 3-4, replace the entire

O-Comm clean #1

armature with a new one. This will significantly increase motor power.

O-Comm clean #2

Figure 3-6.

8.

If the commutator surface is smooth but dark and discolored, clean it with a

LiteBrite commutator cleaning pad until it is a shiny copper color (six to ten twists

by hand) as shown in Fig. 3-6.

9.

Run a hobby knife in the slots between the commutator segments to remove

loose particles as shown in Fig. 3-7.

3-8 LITE MA CHINES

Figure 3-7.

Op er a tor's Guide Electric Motors

10. If the commutator was clean when you opened the motor, wait a few more flights

before cleaning it the next time. If it was dark and discolored, clean it more

frequently.

11. Clean the inside of the motor can and motor end-bell with a paper towel.

12. Lightly lubricate the motor shaft with Lite Lube heavy oil, and install the armature

in the motor can. Do not oil the commutator segments because the oil will quickly

O-Mo tor tim ing

wear off and stick dirt to the inside of the motor.

Figure 3-8.

13.

Make sure the plastic shaft washers are properly installed, and reassemble the

end-bell to the motor case. Set the end-bell timing mark between 15 and 20

degrees as shown in Fig. 3-8, and tighten the end-bell screws. Do not

over-tighten the end-bell screws or you will bend the internal locking ring.

The Fusion 35 Speed Controller

The Fusion 35 brushed motor speed controller by Castle Creations is a specially

designed microprocessor-based switching controller capable of delivering up to 35

amps of current to your Electro-Fusion brushed motor. The Fusion 35 controller

switches battery current on and off at up to 2800 times per second to control motor

speed.

Battery elimination circuitry (BEC) in the Fusion 35 controller supplies power to the

receiver and servos on your Corona helicopter, and eliminates the need for a

separate receiver battery. Built in filtering capacitors reduce electrical noise and

possible radio interference generated by the motor brushes. A special arming feature

reduces the possibility of accidental motor starting, and a soft-start function smoothly

accelerates the rotor blades to reduce the possibility of gear train damage. If the radio

LITE MA CHINES 3-9

Op er a tor's Guide Electric Motors

receiver loses transmitter signal for more than two seconds, an additional safety

feature turns off power to the motor.

Warning! Electric power systems can be very dangerous. High electric currents can heat wires,

cause sparks and lead to fires and personal injury. DO NOT TO TOUCH EXPOSED

ELECTRIC COMPONENTS, AND NEVER FLY AT A SITE LOCATED NEAR

FLAMMABLE MATERIALS.

Warning! Electric motors are silent, and the main rotor and tail rotor blades of an electric model

helicopter can start tuning unexpectedly or uncontrollably causing serious injury.

ALWAYS USE CAUTION AND MAKE SURE THE TRANSMITTER IS SWITCHED

ON BEFORE CONNECTING THE SPEED CONTROLLER AND BATTERY ON A

HELICOPTER.

Warning! ALWAYS DISCONNECT THE MOTOR POWER CABLES WHEN ADJUSTING THE

RADIO SYSTEM ON A HELICOPTER SO THE MAIN ROTOR BLADES CANNOT

START TURNING UNEXPECTEDLY, AND BE CAREFUL NOT TO TOUCH THE

ENDS OF THE POWER CABLES TOGETHER TO AVOID A SHORT CIRCUIT.

Arming the Fusion 35

To reduce the possibility of accidental starting of the main rotor blades, the Fusion 35

controller will not deliver motor power until it is armed. To arm the Fusion 35, perform

the following steps.

1. Insure that all controller and motor connections are correct, and that the Fusion

35 controller is plugged into the throttle channel on your radio receiver.

2. Turn on your transmitter and make sure the transmitter batteries are charged.

3. Connect your Fusion 35 controller to your battery (you should hear a single beep

from the motor).

4. If this is the first time you are running this controller or receiver, disconnect the

motor power cables and perform a radio range check. If the range check is good,

then reconnect the motor cables.

Warning! DO NOT RANGE CHECK YOUR RADIO WITH THE MOTOR POWER CABLES

CONNECTED. IF THE RECEIVER LOSES TRANSMITTER RADIO SIGNAL

THE MOTOR COULD START UNEXPECTEDLY.

5. Move the transmitter throttle stick to full-low for two seconds. You should hear the

motor beep once.

3-10 LITE MA CHINES

Op er a tor's Guide Electric Motors

6. Move the throttle stick to middle-stick position for two seconds. You should hear

the motor beep again.

7. Move the throttle stick back to full-low for two seconds. You should hear the

motor beep twice and your Fusion 35 is now armed.

Note: If electrical noise becomes excessive, or if radio signal is lost for more than two

seconds, the Fusion 35 will disarm and stop the motor. To rearm, hold the throttle

stick in full-low for four seconds.

Optional RF Filter

The Fusion 35 controller includes built-in filter capacitors to reduce the radio

interference generated by electric motors commonly referred to as “radio-frequency

interference,” “RF noise” or “electrical noise”. DO NOT install additional filter

capacitors between the motor power cables and motor case because this will

interfere with the proper operation of the Fusion 35 controller.

If radio interference becomes a problem, you may install a single 0.1 µF ceramic disk

capacitor between the unused motor solder tabs. This will reduce electrical noise.

After modifying or adding filter capacitors, always test your motor, controller and

radio before flying.

Warning! DO NOT USE TANTALUM OR ELECTROLYTIC CAPACITORS AS ELECTRICAL

NOISE FILTERS BECAUSE THEY CAN EXPLODE AND/OR CAUSE FIRES AND

BURNS.

Cable Connections

The Fusion 35 controller includes a factory-installed Lite Machines connector on the

battery power cable. You must install a corresponding Lite Machines connector to the

wire leads on your battery pack and check the connections to your controller to insure

proper polarity.

Generally, the red (positive) wire of your speed controller should be connected to the

red (positive) wire on your battery pack. Similarly, the black (negative) wires should

be connected to each other. For more information on battery connections, see the

Battery section of the Corona Construction Manual.

The push-on, spade-style connecters on the motor side of your Fusion 35 controller

should fit firmly onto the solder tabs of your Electro-Fusion motor. If the tabs are too

loose or too tight, adjust them carefully with a pliers or small screw driver.

LITE MA CHINES 3-11

Op er a tor's Guide Electric Motors

Warning! IF THE POSITIVE AND NEGATIVE BATTERY CONNECTIONS TO YOUR SPEED

CONTROLLER ARE REVERSED, YOU WILL PERMANENTLY DAMAGE YOUR

SPEED CONTROLLER. THIS DAMAGE IS NOT COVERED UNDER WARRANTY.

Warning! Do not install a fuse between your speed controller and battery. If the fuse blows the

controller and radio receiver will have no power.

Warning! Always perform a radio range check after installing a new speed controller. IF YOUR

RADIO DOES NOT PASS A RANGE CHECK, DO NOT FLY.

Battery Elimination Circuitry (BEC)

The battery elimination circuitry (BEC) in the Fusion 35 controller powers the

airborne radio control system in your Corona helicopter, so you do not need a

separate receiver battery. The BEC will operate with battery packs having up to ten

NiCad cells, but works best with packs of six to eight cells. Packs with over eight cells

develop higher voltages that the BEC must reduce in order to power the radio

receiver and servos. The voltage reduction process generates heat that wastes

battery power.

If you wish to use more than ten cells in your battery packs you must use a separate

battery to power your radio control system. To do so you must first cut the red power

wire from your Fusion 35 controller to the receiver (contact Castle Creations before

doing this). Insulate the exposed end of the cut wire so it does not short circuit the

controller or battery. Be sure to test your radio system before flying your Corona

helicopter after this or any other modification.

Charging Batteries

The Corona helicopter is designed to operate with Electro-Fusion brushed motors

and either six or seven-cell sub-C NiCad battery packs. Electro-Fusion 7 motors work

best with seven-cell packs. Electro-Fusion 6 motors work best with six-cell packs.

The Corona helicopter generally performs best with seven-cell packs because the

added weight increases main rotor speed in hover (which increases stability).

Seven-cell packs also produce higher voltages (8.4 vs. 7.2 volts) which increase

maximum motor power. If you decide to use six-cell battery packs, purchase a

specially configured Electro-Fusion 6 motor to improve flight times.

While NiCad batteries can be fast-charged hundreds of times, it is best to “condition”

new battery packs before use on a Corona helicopter. To condition a new battery

pack, charge it slowly over night at a current of 1/10 of the rated battery capacity. For

3-12 LITE MA CHINES

Op er a tor's Guide Electric Motors

instance, charge a new 2400 mAh battery pack at about 240 mA for ten hours before

flying it on your helicopter or fast-charging it at a high current (3-5 amp) setting.

Since flight times generally run in the range of five to seven minutes, but charging

times run thirty to sixty minutes, it is best to charge several battery packs for each

flying session. For best performance, recharge or peak-charge batteries

immediately before flying, and do not let charged batteries sit overnight. Batteries

that have been left in a fully-charged condition overnight sometimes exhibit an

“overnight effect” which limits the amount of power they can deliver in the morning.

Discharging and recharging these batteries usually reverses this effect.

NiCad batteries that are repeatedly discharged to the same level can develop a

discharge “memory”. Subsequent discharges will tend to stop at this level effectively

limiting battery output. To prevent discharge memory from developing, always

completely discharge your battery packs (by flying your Corona helicopter) before

recharging them or storing them for extended periods of time.

Since NiCad batteries loose power rather quickly at the end of a flight, it is a good idea

to time your flights with a watch. This will insure you are close to the ground when the

batteries get low.

Warning! NEVER STORE BATTERIES IN A CHARGED STATE, OR CARRY CHARGED

BATTERIES TOGETHER OR WITH ANYTHING THAT CONDUCTS

ELECTRICITY. The batteries can short circuit and cause serious fires, personal

injury and property damage.

Battery Chargers

Battery chargers and proper charging technique are very important to the successful

long-term operation of your Corona electric helicopter. A poorly designed or

malfunctioning charger can permanently damage your battery packs in one or two

charges, and reduce the maximum power they produce. Considering that you may

eventually invest hundreds of dollars in batteries to power your radio-controlled

models, it is best to purchase a high quality charger from the start, rather than

purchasing an inexpensive charger first and ruining several expensive battery packs.

Some computer controlled fast-chargers can be connected to a wall outlet or a

standard 12-volt automobile battery, and some display the battery charging

parameters on a computer screen. The computer screen provides important

information about the charging status and capacity of your batteries, and can give

you clues to problems in your electric system such as when a cell in your battery pack

is going bad.

LITE MA CHINES 3-13

Op er a tor's Guide Electric Motors

Flying Weight

Proper flying weight is an important factor in electric helicopter flight. Without enough

weight, the main rotor blades turn too slowly, and stability and control power are

reduced. This is especially noticeable in high winds. For this reason, a heavier

seven-cell battery is preferred over a lighter six-cell battery in the Corona helicopter.

The Corona helicopter is designed to operate efficiently with an Electro-Fusion 7

motor and a seven-cell NiCad battery at a flying weight of about 44 ounces (1250 g).

The Corona flies best with an Electro-Fusion 6 motor and six-cell battery at a weight

of about 42 ounces (1190 g). While the Corona will lift more weight than this, too

much weight can overload a brushed motor and reduce flight times. If you want to lift a

heavy scale fuselage then consider using a brushless motor.

Flight times generally increase by about one second for each gram of weight

removed. Removing a 40 gram (1.5 ounce) canopy will increase flight times by about

40 seconds. Many people practice hovering without a canopy, but it is best to install

the canopy for forward flight so you can tell which way your helicopter is going when it

is far away from you.

3-14 LITE MA CHINES

Op er a tor's Guide Glow-Fuel Engines

G

low-Fuel Engines

Lite Machines gas helicopters are powered by Norvel Vmax-6 and Vmax-7 helicopter

engines. In both engines, the crankshaft is supported by one or more durable bronze

bushings to withstand the side-loads generated by gear driven rotor systems. Each

engine has five directional transfer ports for easier starting and extra lugging power.

The unique throttle/muffler design provides precise throttle control, and traps

exhaust gases inside the cylinder to keep the glow plug hot for a lower, more reliable

idle. The Vmax-7 engine further includes a thermal insulator between the muffler and

crankcase to reduce the flow of heat from the muffler to the engine, and six mounting

lugs to support the increased power.

General Operating Considerations

If you are a beginner, you can cut your learning time in half by locating someone who

knows about Norvel engines and Lite Machines helicopters. Local hobby shops

usually have a list of model airplane/helicopter clubs in your area. Whether you fly a

helicopter or an airplane, you should not fly alone.

Warning! MAKE SURE SOMEONE IS ALWAYS NEARBY TO HELP YOU IF YOU NEED

ASSISTANCE OR HURT YOURSELF WHILE OPERATING YOUR HELICOPTER.

ADULT SUPERVISION IS STRONGLY RECOMMENDED FOR MINORS.

Operating conditions can affect engine life. Helicopters operate close to the ground,

and kick up dust and sand that can scratch the inside of the piston cylinder, or clog the

carburetor making the engine impossible to start or adjust. Avoid flying over loose

dirt, and use a fuel filter to remove dirt from the fuel.

Over time, you will learn to gauge the condition of your engine by the sound it

produces. A high-pitched, even tone usually means the engine is running well. A

slightly lower tone, with an uneven warble may indicate that the engine is too hot or

overloaded. If you have engine problems, refer to the Engine Trouble-Shooting

section of this Operator’s Guide.

Fuel Mixture and Compression

The two most important factors affecting the performance of your Norvel engine are

fuel/air mixture and compression. In operation, air and fuel enter a piston engine

through the carburetor and flow into the cylinder above the piston. As the piston

moves up within the cylinder, it compresses the fuel/air mixture against the hot glow

plug at the top of the cylinder. At a certain point the fuel/air mixture ignites, pushing

the piston down and producing useful power.

LITE MA CHINES 4-1

Op er a tor's Guide Glow-Fuel Engines

The needle valve on the carburetor meters the amount of fuel mixed with the air. Too

much fuel (too “rich”) causes the engine to slow down and lose power. Too little fuel

(too “lean”) causes the engine to over-heat, slow down and lose power. Vmax

engines operate best within a needle valve range of about +1/4 to -1/4 turn.

Proper compression is needed for a reliable idle as well as maximum power.

Compression is adjusted on Vmax engines by inserting or removing thin copper

washers under the glow plug. If compression is set too high, the fuel/air mixture

ignites too soon. This does not affect top-end power appreciably, but the engine may

stop abruptly while idling. If compression is too low, the engine may not produce

enough power for normal flying.

Compression is affected by air density. Anything that increases or decreases air

density increases or decreases compression. The elevation of your flying site and

the local temperature both affect air density and have a major influence on

compression.

As elevation and air temperature increase, air density decreases. To maintain the

same compression at high elevations and air temperatures, the volume in the

cylinder above the piston must be reduced slightly by removing washers from under

the glow plug.

For instance, if you fly at a high elevation (5000 ft or 1524m at Denver, Colorado,

USA), you will use fewer washers under the glow plug than at a lower elevation (700 ft

or 213m at Lafayette, Indiana, USA). Also, if you fly when the outside air temperature

is 75°F (24°C), and the temperature drops to 40°F (4°C) you may need to add

additional glow plug washers before flying again. The large temperature drop will

otherwise affect engine idle because the cold, dense air increases compression.

When air density decreases, less fuel and air enter the engine on each piston stroke.

This means that the engine will not produce as much power at high elevations or high

temperatures where the air is thin. Lift produced by the main rotors depends upon air

density in a similar way. The performance of all aircraft (including full size

helicopters) degrades considerably at high elevations and on hot days.

Hint: The compression rules for Vmax-6 engines are to start with 15% nitro fuel and two

washers under the glow plug. Add an additional washer for each 5% of nitro above

15%, and add an additional washer if the outside air temperature drops below 50°F

(10°C). Remove one washer for every 2000’ (600m) above sea level. For example,

with 25% nitro fuel start with four washers. If the air temperature is 40°F (4.4°C) add

one washer. If flying at 3000’ (900m) remove one washer.

Hint: Vmax-7 engines generally prefer high nitro (25%) and high compression, so use two

to three fewer washers on the Vmax-7 than on the Vmax-6.

4-2 LITE MA CHINES

Op er a tor's Guide Glow-Fuel Engines

The Importance of Clean Fuel

All model glow-fuel engines use a glow plug containing a platinum metal coil. The

platinum metal in the coil acts as a catalyst and ignites the air/fuel mixture in the

engine. To operate properly, the air/fuel mixture must actually touch the surface of

the platinum coil.

If the surface of the coil is coated with anything, even if only a few atoms thick, and

invisible to the eye, the catalytic reaction cannot occur and the engine will run poorly

or not at all. Around ninety percent of all reported engine problems can be traced to

contaminated fuel that coats the glow plug coil and prevents the plug from operating

properly.

Many varieties of rubber will dissolve in glow fuel and quickly foul a glow plug coil.

Use only silicone fuel tubing and plastic (polyethylene, polypropylene or nylon)

containers to store or transfer fuel.

Note: DO NOT USE RUBBER FUEL BULBS, SYRINGES WITH RUBBER PLUNGERS

OR NEOPRENE FUEL LINES TO TRANSFER FUEL INTO YOUR HELICOPTER.

RUBBER WILL CONTAMINATE YOUR FUEL AND FOUL YOUR GLOW PLUG.

Certain brands of model engine fuel contain chemical additives (such as anti-rust

compounds) that can foul glow plugs. Some engines will run on these fuels for a flight

or two, but then loose power. Some engines will not start at all. Do not use fuels that

contain chemical additives such as anti-rust compounds with your Norvel engine.

There is no practical way of cleaning a contaminated glow plug coil. Discard

contaminated glow plugs when changing to a new fuel or after using rubber in the fuel

system.

Hint: Use the Lite Machines Lil’ Squeezer fuel system to quickly fuel and de-fuel your

helicopter. The Lil’ Squeezer fuel system consists of a fuel storage bottle that

protects your fuel from sunlight during storage, and a filtered transfer tube that will

not contaminate your fuel with rubber byproducts.

Synthetic Oils

Some brands of fuel contain synthetic oils that break down at relatively low

temperatures. During a hot, lean run, synthetic oil may not provide sufficient

lubrication to the engine piston and cylinder, and the piston may seize inside the

cylinder or otherwise damage the engine.

Do not use fuels containing only synthetic oil with your Norvel engines. Use fuels

containing castor oil or castor/synthetic oil blends. For instance, if you like Morgan’s

brand fuels, do not use Morgan’s Cool Power fuel with synthetic oil (the green stuff).

Instead, use Morgan’s Omega fuel with castor/synthetic oil blend (the pink stuff).

LITE MA CHINES 4-3

Op er a tor's Guide Glow-Fuel Engines

Breaking-In a New Engine

All piston engines have a break-in period (from ten minutes to over an hour) in which

they do not produce peak power. The piston and cylinder of Norvel engines are

selectively matched at the factory to fit tightly at top-dead-center (where the piston is

at the top of the cylinder). During break-in, the piston and cylinder wear together to

form a perfect fit that will last the life of the engine.

To break-in your new Norvel engine, run it rich (where it runs slowly and unevenly) for

two to three minutes before leaning it out. Then alternately run lean (where it just

starts to speed up and run steadily) for two minutes and then rich for two minutes for a

total of about 20 minutes or two tanks of fuel. This lean-rich break-in procedure not

only wears the surfaces of the piston and cylinder, but also heats and cools the

engine and relieves built-in stresses in the metal of the piston and cylinder.

You may break-in your new engine on a test stand or in your helicopter. Always use a

Lite Machines heat sink on the engine in your helicopter. If you use an airplane style

glow head without the heat sink, your engine will overheat and seize. NEVER run

your engine a test stand without an airplane propeller. The propeller not only cools

the engine, but produces drag which keeps the engine from over-speeding.

Warning! NEVER RUN A HELICOPTER ENGINE ON AN ENGINE STAND WITH ONLY THE

CLUTCH FROM YOUR HELICOPTER OR WITHOUT A PROPELLER. THE

CLUTCH SHOES CAN BE THROWN OFF AT HIGH SPEED AND CAUSE

SERIOUS INJURIES AND PROPERTY DAMAGE.

Engine Starting Summary

This section provides a short summary of proper engine starting procedures for your

Lite Machines helicopter. For more detailed information, refer to the Preferred

Engine Starting Procedure section of this Operator’s Guide.

1. Fill the fuel tank with fuel.

2. Turn on your transmitter and receiver.

3. Open the engine needle valve 2-1/2 turns.

4. Connect your glow plug battery to the glow plug.

5. Start turning the engine with a Lite Machines high-speed electric starter.

6. While still turning the engine with the starter, hold your finger over the carburetor

intake for one second to prime the engine (keep turning the engine with the

electric starter).

7. Remove the electric starter from the engine every two seconds to see if it is

running.

8. Repeat step 6 and 7 as required.

4-4 LITE MA CHINES

Op er a tor's Guide Glow-Fuel Engines

Preferred Engine Starting Procedure

This section contains a detailed, step-by-step procedure for starting the Norvel

engine in your Lite Machines helicopter. Since you will probably want to try flying your

helicopter once the engine is running, you should first read the Main Rotor Stability

and Control and Learning to Fly sections of this Operator’s Guide. Starting the engine

with a helper is strongly recommended. Priming and adjusting the engine are much

easier with the aid of a friend.

1. Bring all necessary equipment with you to the flying field including hand tools like

pliers and wrenches, Lite Machines electric starter and battery, and a supply of

paper towels and spray cleaner.

2. Wear eye and hearing protection.

Warning! ALWAYS WEAR EYE AND HEARING PROTECTION, SUCH AS

HIGH-IMPACT SAFETY GLASSES AND EAR-PLUGS, WHEN OPERATING

YOUR ENGINE. ANYONE HELPING YOU SHOULD WEAR EYE AND

HEARING PROTECTION AS WELL. PROPER EYEWEAR NOT ONLY HELPS

PROTECT YOUR EYES FROM THE SPINNING ROTORS, BUT ALSO FROM

OIL DROPLETS AND DEBRIS THROWN OUTWARD BY THE SPINNING

ENGINE AND CLUTCH.

3. Fill the fuel tank to within 1/4" of the top with model engine fuel containing 15% to

25% nitromethane and castor oil or a castor/synthetic oil blend.

Warning! NEVER FUEL YOUR HELICOPTER WHILE THE GLOW-PLUG BATTERY IS

CONNECTED TO THE ENGINE. SPARKS FROM THE ELECTRIC

CONNECTION COULD START AN INVISIBLE FUEL FIRE.

4. Make sure your radio frequency is clear.

Warning! Two radios cannot operate on the same frequency (channel) at the same time. If

you turn on your transmitter, and it is on the same frequency (channel) as the

transmitter of someone who is already flying, the flying aircraft will lose control

and crash.

5. After you are sure that your frequency is clear, turn on the radio (transmitter first)

and check the operation of all controls. If this is the first flight of the day, perform a

radio range check. With the transmitter antenna fully collapsed, slowly walk away

LITE MA CHINES 4-5

Op er a tor's Guide Glow-Fuel Engines

from the model while moving one of the controls. You should get at least 50 feet

away before losing signal (this distance varies with different radio equipment).

Do not start your engine or fly if the radio fails the range check.

Warning! NEVER RANGE CHECK WITH THE ENGINE RUNNING! THE ENGINE MAY

GO TO FULL POWER AS YOU EXCEED THE OPERATING RANGE OF THE

RADIO.

6. Fully extend the transmitter antenna before starting the engine.

7. If starting the engine for the first time, carefully turn the needle valve clockwise

with a small screwdriver until fully closed, then open it counter-clockwise 2 to

2-1/2 turns.

8. Connect your Lite Machines high-speed electric starter to a 12-volt starter

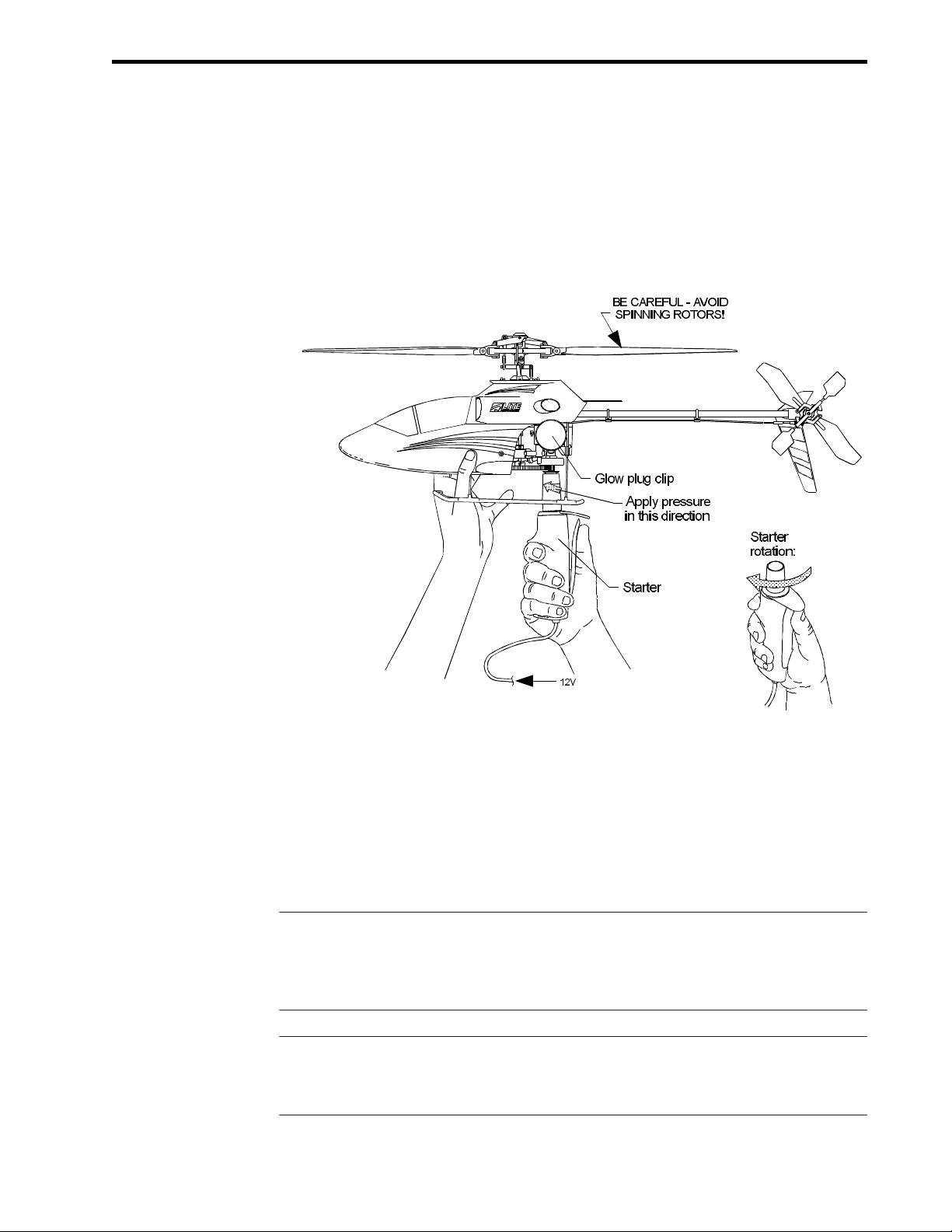

battery. The starter should spin in the direction shown in Fig. 4-1. If not, reverse

the starter wires on the battery.

(OSIDSTRT)

4-6 LITE MA CHINES

Figure 4-1.

Op er a tor's Guide Glow-Fuel Engines

9. Connect the glow plug to a 1.2 volt battery or a hobby power panel.

Note: Lite Machines SpiraLite Speed and Norvel Freedom XL glow plugs require 1.2

volts. The best way to power a Lite Machines or Norvel glow plug is with a DuBro

Kwik-Start clip. Never wire the glow plug directly to 12 volts (like your car battery)

or the plug will burn out.

10. Connect the glow plug clip to the glow plug on the engine as shown in Fig. 4-1 and

Fig. 4-2.

(OISOSTRT Place ment)

Figure 4-2.

LITE MA CHINES 4-7

Op er a tor's Guide Glow-Fuel Engines

Warning! ALWAYS WEAR EYE AND HEARING PROTECTION. Model engines throw out

oil droplets when running. It is nearly impossible to avoid getting oil on you while

starting the engine.

12. Move the transmitter throttle stick (left stick) to about ½ throttle, and the throttle

trim lever to full. Hold the rotor head with one hand, and tilt your helicopter on its

side with the right skid on the ground as shown in Fig. 4-1 and Fig. 4-2.

13. Spin the engine with the electric starter. Push firmly, but not excessively on the

starter cone as shown in Fig. 4-1.

14. The fuel line from the tank must be full of fuel before the engine will start. While

you spin the engine with the starter, ask your helper to hold a finger over the

carburetor inlet for one second. This will draw fuel from the tank into the engine.

You may need to repeat this procedure several times before the engine will fire.

Hint: If your engine is new it may not turn easily against compression. It will turn more

easily after running for about 30 minutes.

15. If the starter slips on the starter cone, the piston may be hydraulically locked. Do

not force it to turn or you could damage the engine. Remove the heat sink and

glow plug and spin the engine with the electric starter for one second to clear the

excess fuel from the cylinder and crankcase. Replace the glow plug and heat

sink, and clean the oil off the starter cone and the rubber insert on the starter with

a paper towel.

16. If the engine refuses to pop, remove the heat sink and glow plug, and connect the

glow plug to the glow plug clip (be careful, it gets very hot). The entire coil should

glow bright orange (not visible in direct sunlight). If it does not, the glow plug or

glow plug clip may be bad, or the glow plug battery may need charging.

Hint: All glow plugs have a limited useful life. When you suspect that a glow plug is

going bad, replace it with a new one. If engine performance improves, the old

glow plug was bad.

17. When the engine starts, immediately lower the throttle so that the clutch shoes do

not wear against the clutch bell. Be careful, if the throttle is set too high the clutch

will engage and rotate the whole fuselage (and tail rotor) toward you.

18. Remove the glow plug clip, and place your helicopter on its skids on the ground

so that the main rotor can rotate freely.

4-8 LITE MA CHINES

Op er a tor's Guide Glow-Fuel Engines

Alternate Starting Method

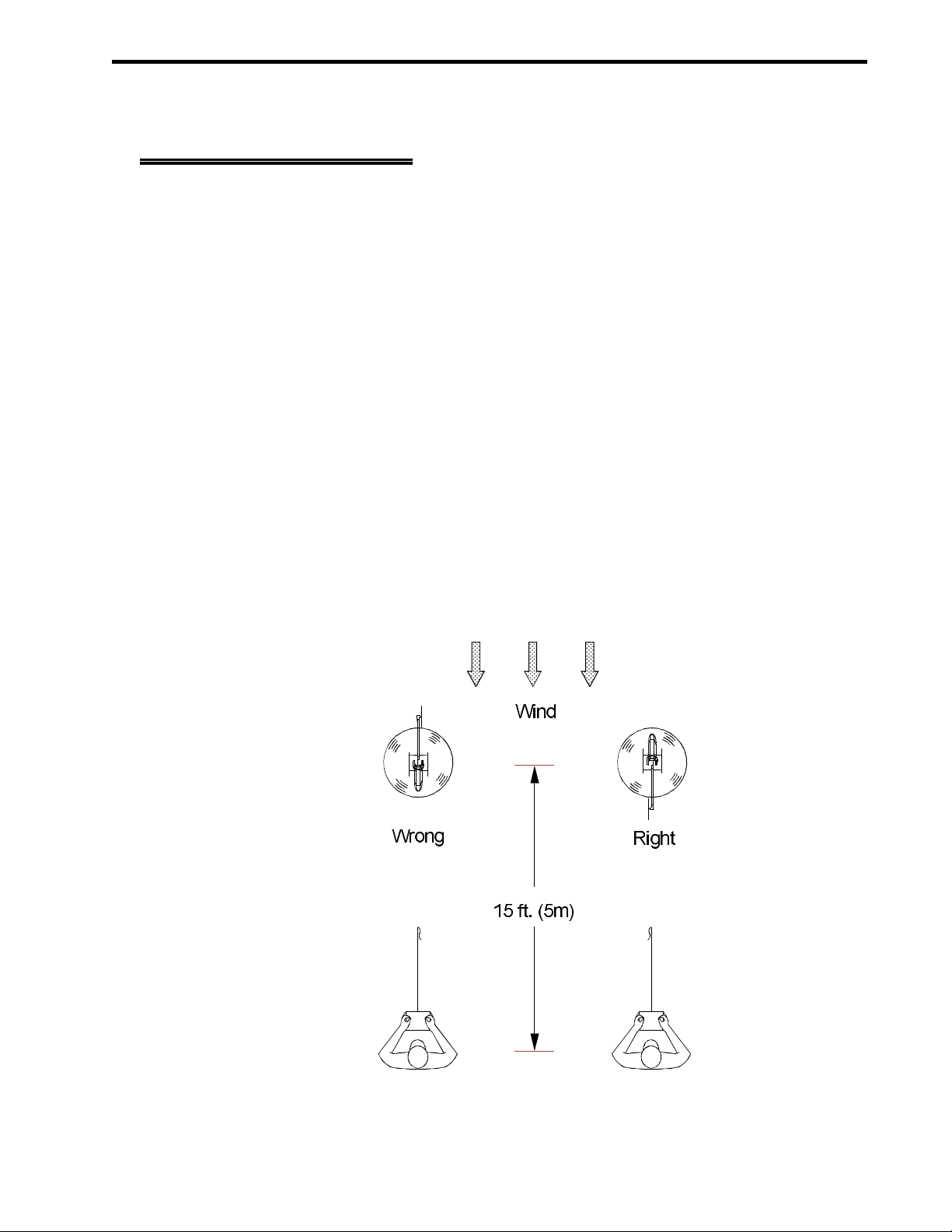

Fig. 4-3 illustrates an alternate starting method requiring two people − one to hold

and start the helicopter and another to hold and operate the transmitter. This starting

method is illustrated for completeness and because the engine sometimes starts

more easily when held vertically. This method is not preferred because of the

proximity of the rotating rotor blades to the person holding the helicopter.

(OALTSTRT)

Figure 4-3.

Before starting the engine, make sure your helper knows how to operate the controls

on the transmitter, and knows to never move the cyclic controls (right stick) while the

rotors are turning. Hold your helicopter by the canopy and front landing gear struts as

shown in Fig. 4-3 with the main rotor above and tilted away from you. Once the engine

is running, lower the throttle and place the helicopter on the ground.

Warning! THE CYCLIC CONTROLS ARE VERY POWERFUL. KEEP IN MIND THAT THE

HELICOPTER COULD ROTATE OUT OF YOUR GRASP AND STRIKE YOUR

HANDS, ARMS OR FACE. RAPIDLY ROTATING ROTOR BLADES CAN CAUSE

SERIOUS INJURY.

Warning! NEVER, EVER ATTEMPT THE ALTERNATE STARTING METHOD WITH A

LARGER HELICOPTER! THE ROTATING ROTOR BLADES ON A LARGE

HELICOPTER CAN BE LETHAL!

LITE MA CHINES 4-9

Op er a tor's Guide Glow-Fuel Engines

Adjusting Fuel Mixture and Compression

This section describes a step-by-step procedure for adjusting fuel mixture and

compression on Norvel engines.

1. Set your helicopter on the ground with the engine idling. Slide a heavy pole or

wood plank from side to side over the landing gear skids and between the wire

struts in order to weigh your helicopter to the ground. With the helicopter safely

grounded, you can adjust the needle valve at full power. Slowly open the throttle.

If the helicopter lifts into the air, place a heavier weight across the skids.

2. Move the throttle stick and throttle trim lever on the transmitter to full throttle.

3. Carefully reach under the rotor blades and slowly open (screw out) the needle

valve until the engine runs roughly (four-strokes). This fuel/air mixture is too rich.

Warning! MOVE SLOWLY AND CAREFULLY ANY TIME YOU WORK NEAR THE

ROTATING ROTOR BLADES! DO NOT TOUCH THE ROTATING ROTOR

BLADES WITH YOUR HAND OR ARM! ALSO WATCH OUT FOR THE

ROTATING TAIL ROTOR BLADES!

4. Slowly close (screw in) the needle valve. The engine will run faster and

smoother, and the engine sound will increase in pitch. At some point you will hear

it slow down again. This mixture setting is too lean. The optimum needle valve

setting lies about half way between the rich and lean settings. It is best to operate

with a slightly rich mixture since the engine will run cooler.

5. Open (screw out) the needle valve to the optimum point half way between the rich

and lean settings.

6. Close the throttle (throttle trim is still high). The engine should idle smoothly, and

slowly enough that you can hold the main rotor without feeling much clutch drag.

If the engine runs too fast, try reducing throttle trim slightly. If it stops suddenly,

the compression may be too high - add another copper washer under the glow

plug and adjust the needle valve. BE CAREFUL, THE HEAT SINK IS HOT!

Hint: Never hold the rotor head while tightening or loosening the heat sink, because

you could bend the main shaft. Instead, hold the crutch near the tail boom

7. Open the throttle to full, and listen closely to the engine sound. The engine should

smoothly and rapidly increase speed to a maximum. If it sputters and increases

speed slowly or four-strokes (runs rough) it may be slightly rich, so screw IN the

needle valve slightly. If it reaches top speed and then sags or “warbles” it may be

lean, so screw OUT the needle valve slightly.

4-10 LITE MA CHINES

Op er a tor's Guide Glow-Fuel Engines

8. If the needle valve seems to be adjusted correctly but the engine does not

produce much power, it may not yet be broken-in or the compression may be set

too low. Try removing a washer from under the glow plug and readjusting the

needle valve. Handle glow plug washers carefully; they bend easily. Discard

damaged washers.

9. After the needle valve and compression are set, they need not be adjusted for the

rest of the day unless the temperature (air density) changes. If it gets cooler,

adjust the needle valve out (rich) slightly.

Inspecting SpiraLite Speed Glow Plugs

This section refers to the operation of SpiraLite Speed glow plugs, and not to Norvel

Freedom XL glow plugs.

To start your Norvel engine, the coil in your SpiraLite Speed glow plug must glow

bright orange. To test a glow plug, connect it to a glow plug battery with a glow plug

clip, and cup your hands around the plug to keep it out of direct sunlight. BE

CAREFUL, THE PLUG WILL GET HOT QUICKLY. The entire coil should glow bright

orange. If no part of the coil glows bright orange, disconnect the glow plug clip and

check your battery and wire connections.

(OGLOWPLG)

If only a portion of the coil glows orange, then the coil may be touching itself and

creating an electrical short circuit, or touching the glass insulation sealing the top of

the plug and losing heat. In either case, disconnect the glow plug clip and

CAREFULLY separate the loops of the coil from each other, and lift the coil slightly

away from the glass insulation with the tip of a hobby knife as shown in Fig. 4-4. Test

the glow plug again before installing it in your engine.

Figure 4-4.

LITE MA CHINES 4-11

Op er a tor's Guide Glow-Fuel Engines

Electric Starter Effect on Glow Plug

Norvel engines usually start easily. On-going difficulty with engine starting is

sometimes a sign of a field-equipment problem.

Many fliers have a field box with a small 5 Ah motorcycle battery connected to a

power panel which powers the glow plug and electric starter motor. Common

high-torque electric starters designed to start .40 and .60 sized engines are too slow

to start small engines and sometimes draw too much current from the field box

battery.

Even though a glow plug may appear to glow orange (hot) when connected to the

field box battery by itself, it may cool substantially when an electric starter is

operated. This means that the glow plug will stop working just as the starter motor

begins to spin the engine, so the engine may not start. The plug will heat up again

when the starter motor is turned off, making it appear as though the plug is working

properly.

To check for this problem, plug a glow plug clip and a standard electric starter into a

power panel. Connect the glow plug clip to a glow plug, and cup your hands around

the plug to keep it out of direct sunlight. The coil should glow bright orange. Be

careful, the plug will get hot quickly.

Turn on the electric starter. If the field box battery is small, old, or low on charge, the

plug coil will cool and stop glowing. Turn off the starter and the plug will again glow

orange. Also, try operating the starter in one second pulses. Notice that the glow plug

remains hot longer if the starter is pulsed.

4-12 LITE MA CHINES

Op er a tor's Guide Main Rotor Stability and Control

M

ain Rotor Stability and Control

To fly properly and produce maximum lift, the rotor blades of your helicopter must be

adjusted correctly. This section contains information on setting up and tracking the

main rotor blades, and understanding helicopter stability and flight performance.

Refer to the How Helicopters Work section of this Operator’s Guide for more

information on main rotor systems.

Rotor Blade Designations

Lite Machines rotor blades each have a blade number that describes the blade

design and size. Series 1 blades, which are standard on Model 110 and earlier

helicopters, are not marked. Blades having different numbers are incompatible with

each other, so do not use two blades with different numbers on the same rotor head.

Blade designations have thee parts: the series number, length and tip pitch. For

example, the blade designation S2 13 x 0 is read “series 2, 13 inch length, zero

degrees tip pitch”. Blade length is measured from the center of the flapping bolt hole

to the tip of the main rotor blade or from the center of the rotor shaft to the tip of the tail

rotor blade. Blade pitch is relative to the blade grip.

Warning! Series 2 main rotor blades are susceptible to damage by solvents and other

chemicals. DO NOT USE SOLVENTS, SUCH AS ACETONE, TO CLEAN THE MAIN

ROTOR BLADES! BLADES CLEANED WITH SOLVENTS CAN FAIL WITHOUT

WARNING WHEN ROTATING AT HIGH SPEED CAUSING SERIOUS INJURIES.

Use only soap or glass cleaners that are safe for plastic eye glass lenses.

Warning! DO NOT ATTEMPT TO REPAIR DAMAGED ROTOR BLADES. REPAIRED

BLADES CAN FAIL WITHOUT WARNING WHEN ROTATING AT HIGH SPEED

AND CAUSE SERIOUS INJURIES.

Blade Tracking

The main rotor blades on your helicopter must operate at the same pitch angle. If

they do not, one blade will fly higher than the other causing an imbalance and

vibration. This vibration absorbs engine power and can damage the helicopter.

Before adjusting blade pitch, your first need to know which blade is pitched high and

which is pitched low. To do this, stick a 1/4" (6mm) wide piece of highly visible tape

(tracking tape) near the tip of one blade and another about an inch (25mm) from the

tip of the other blade. Don’t worry about causing an imbalance; you will remove the

tape when the blades are tracked.

LITE MA CHINES 5-1

Op er a tor's Guide Main Rotor Stability and Control

O-Tracking out

Figure 5-1.

Start the engine as outlined in the Preferred Engine Starting Procedure section of this

Operator’s Guide. Once the engine is running properly, open the throttle until your

helicopter is just about to lift off (about half throttle). Look at the tips of the rotating

rotor blades (but never place your eyes or face in-line with the blades). If you see two

blade images as shown in Fig. 5-1, then the blades are out of track (one blade is flying

higher than the other).

Note: Before starting the engine, make sure that all radio and starting equipment batteries

are completely charged as per the manufacturer’s instructions. If the radio batteries

die while you are flying, you will lose control and crash.

O-Tracking in

Figure 5-2.

As the main rotor spins, look at the tracking tape and note which blade is flying higher.

Stop the rotor and adjust the length of the two mixing-arm/swashplate pushrods to

increase the pitch of the low blade and decrease the pitch of the high blade.

Remember that if you decrease the length of one of the pushrods, you must increase

the length of the opposite one by the same amount to keep the linkages from binding.

When the blades track properly as shown in Fig. 5-2, remove the tracking tape.

5-2 LITE MA CHINES

Op er a tor's Guide Main Rotor Stability and Control

Dynamic Balancing

If the main rotor blades are tracking properly, but the helicopter still vibrates

noticeably, the main rotor may not be properly balanced. To dynamically balance the

main rotor without removing it from the helicopter, stick a small piece of blade

balancing tape to one of the main rotor blades and run the main rotor at flight speed. If

the vibration level decreases, the extra weight of the trim tape is improving the

balance. If the vibration increases then remove the tape, stick it to the opposite blade

and spin the main rotor again. Try different sizes of trim tape until you find one that

minimizes the vibration. Repeat this procedure for the Arlton Subrotor stabilizer.

Helicopter Stability

Helicopters by their nature are not positively stable. At best, they are neutrally stable.

The concepts of positive stability and neutral stability can be illustrated by placing

He li cop ter sta bil ity

marbles in a bowl and on a table top as shown in Fig. 5-3.

Figure 5-3.

If you nudge the marble in the bowl with your finger, it will roll back and forth and

finally come to rest where it started in the center of the bowl. This is positive stability;

the marble always ends up where it started. If, on the other hand, you push the marble

on the table, it will continue to roll until you stop it, and will sit still until you push it

again. This is neutral stability; the marble stays put until pushed, and keeps moving

until stopped.

Helicopters act like the marble on the table. When correctly trimmed they tend to

remain in one spot until moved, and tend to keep moving until stopped. Unlike the

marble, however, helicopters vibrate and fly in air that is always swirling and rolling.

As a result they do not stay in one place for very long, and require constant small

control inputs to hover over a spot on the ground. The marble on the table would act

more like a helicopter if you shook the table and tilted it back and forth. You would

have to constantly push the marble from different directions to keep it in one spot.

LITE MA CHINES 5-3

Op er a tor's Guide Main Rotor Stability and Control

Adjusting Main Rotor Blade Pitch

Main rotor blade pitch on Lite Machines helicopters is adjusted by interchanging the

blade grips that hold the blades to the rotor head. Blade grips are available in even

numbered two-degree increments from two degrees to six degrees and are called

two-grips, four-grips and six-grips. Odd-numbered grips are not available.

Six-grips increase natural blade pitch by six degrees, and are identified by six raised

dots on the top of the grips. To change blade pitch from six degrees to five degrees,