Lister Petter ALPHA LPW2, ALPHA LPWT4, ALPHA LPW4, ALPHA LPW3, NEW ALPHA LPWST4 Operator's Handbook Manual

...

1

ALPHA Series

NEW ALPHA Series

LPW/LPWS Engine

Operators' Handbook

P027-08270

2

Disclaimer

The information, specications, illustrations, instructions and statements contained within this publication

are given with Lister Petter's best intentions and are believed to be correct at the time of going to press.

Our policy is one of continued development and we reserve the right to amend any technical information

with or without prior notice. Whilst every effort is made to ensure the accuracy of the particulars contained

within this publication neither the Manufacturer, the Distributor nor the Dealer shall in any circumstances

be held liable for any inaccuracy or the consequences thereof.

The information given is subject to the Company’s current Conditions of Tender and Sale, is for the

assistance of users and is based upon results obtained from tests carried out at the place of manufacture. The

Company does not guarantee that the same results will be obtained elsewhere under different conditions.

© Copyright Lister Petter Limited, Dursley

GL11 4HS, England.

All rights reserved.

Associated Publications

Master Parts Manual ............P027-08041

Workshop Manual .................P027-08240

Technical Handbook ............ P027-08247

3

Introduction ..................................... 5

Engine Identication .............................5

Using this Handbook .............................5

Running-in ..............................................5

1. Safety Information ...................... 6

1.1 General Safety Information

Emergency Precautions

General Precautions

1.2 Personal Safety ...............................6

1.3 Precautions with Chemicals .........7

Fuel and High-Pressure Fluids ............ 7

1.4 Fuel System Precautions ...............8

1.5 Precautions with Filters

and Elements .....................................8

1.6 Precautions with Oil Seals ............9

1.7 Precautions with Batteries ............9

1.8 Precautions with Electrical

Systems ...............................................9

Wiring Cables ............................................9

Alternator ..................................................9

1.9 Waste Disposal Precautions ...... 10

1.10 Precautions before Starting ... 10

1.11 Lifting Precautions .................... 10

1.12 Precautions before Maintenance

10

2. Technical Data .......................... 11

2.1 Combustion Air

2.2 The Cooling System

3. Starting and Stopping .............. 12

3.1 General Information .................... 12

Start/Stop Control ..................................12

Oil Pressure Switch ................................12

Heater and Glow Plugs ..........................12

3.2 Key Start ....................................... 12

Starting LPW2, LPW3 and LPW4..... 12

Starting LPWS2, LPWS3, LPWS4 .... 13

Starting LPWT4 ......................................13

3.3 Failure to Start ............................. 13

3.4 Stopping (All Engines) ................. 13

4. Engine Fluids ............................14

Contents

5. Routine Maintenance ............... 16

5.1 Before Starting ............................. 16

5.2 Important Instructions ................ 16

5.3 Maintenance Schedule ............... 16

How to Service your Engine ...................16

After Servicing ........................................16

5.4 Drive Belt ...................................... 18

5.5 Cooling System ............................ 18

Draining the Cooling System .................18

Flushing the Cooling System ..........18

Filling the Cooling System .....................18

Coolant Capacity: Engine Block.............19

Coolant Capacity: Radiator ....................19

5.6 Lubricating Oil .............................. 19

Draining the Oil Sump ............................19

Relling the Oil Sump .............................19

Changing the Oil Filter............................20

5.7 Fuel System .................................. 20

Priming the Fuel System ........................20

Changing the Agglomerator ...................20

Changing the Fuel Filter ........................21

5.8 Air Cleaner .................................21

Light-Duty Air Cleaner ............................21

Cyclonic Air Cleaner ...............................21

5.9 Battery ........................................... 22

5.10 Long-Term Engine Storage ....... 22

Returning the Engine to Service............22

6. Troubleshooting ........................ 23

6.1 Method of Fault Diagnosis ......... 23

7. Maintenance Record ................25

Routine Maintenance......................... 25

Non Routine Maintenance ............... 33

8. Warranty .................................... 37

8.1 Standard Warranty Cover ........... 37

8.2 Extended Warranty Cover ........... 37

8.3 Conditions of Warranty ............... 37

8.4 Limitations of Warranty .............. 38

8.5 Purchase and Registration Details

of your Engine .................................. 38

8.6 Repairs under Warranty ............. 38

8.7 Contacting Lister Petter .............. 38

Index ..............................................39

4

2.1 Features of the LPW series diesel engines.

Oil Filter

Oil Filter

Adaptor

Fuel

Filter

Turbocharger

Lifting Eye

Radiator

Fan

LPW(S)T4

Radiator Fan

(may have 6 blades)

Alternator

Flywheel

Inlet Manifold

Starter Motor

Exhaust

Manifold

LPW3

Exhaust Manifold

Flywheel Housing

Sump

Drain Plug

Inlet Manifold

Oil Filter

Fuel Filter

LPWS2

Glow plugs

5

Introduction

This handbook explains the operation and

routine maintenance of Lister Petter watercooled diesel engines in the ALPHA (LPW)

and NEW ALPHA (LPWS) series.

Please note that If your engine is part of

a generating set, there is a separate operators' handbook for the genset, to explain

such features as the control module.

Engine Identication

To identify which model of Lister Petter

LPW(S) diesel engine you are using refer to

the engine serial number, which is stamped

on a plate attached to the engine. It identi-

es the type and build of the engine (see

table below) to enable the correct maintenance procedures to be carried out. Here

is a sample serial number:

06 001234 LPWS3 A 402

06 .........................Year code (06 = 2006)

001234 ...............Unique engine number

LPWS3 ................................ Engine model

A ............................Anti-clockwise rotation

402 ......................................Build number

The illustrations on page 4 show features

of the different engine models. When following the instructions in this handbook

you will need to be familiar with the parts

labelled.

Using this Handbook

Operating or servicing a diesel engine is

potentially dangerous. You must not attempt it unless you have the necessary

knowledge and experience.

Read each section thoroughly and carefully, taking note of all the information and

instructions given. This is for your safety and

to ensure the correct maintenance of your

engine. For specic aspects of operation

and maintenance, use the table of contents

(page 1) or the index (page 39) to nd the

section you need. Where instructions are

numbered in sequence, they must be followed in that order. This applies in particular to maintenance and repair procedures

(sections 5 and 6).

In cases of difculty, or to obtain spare

parts, please consult your local Lister Petter

distributor or dealer.

Running-in

To assist running-in all engines are des-

patched with an initial ll lubricating oil

which must be changed after 100 hours.

Your engine does not require gradual lightload running-in. Extended light-load running

should be avoided, as this could damage

the cylinder bore and allow lubricating oil

to enter the exhaust system.

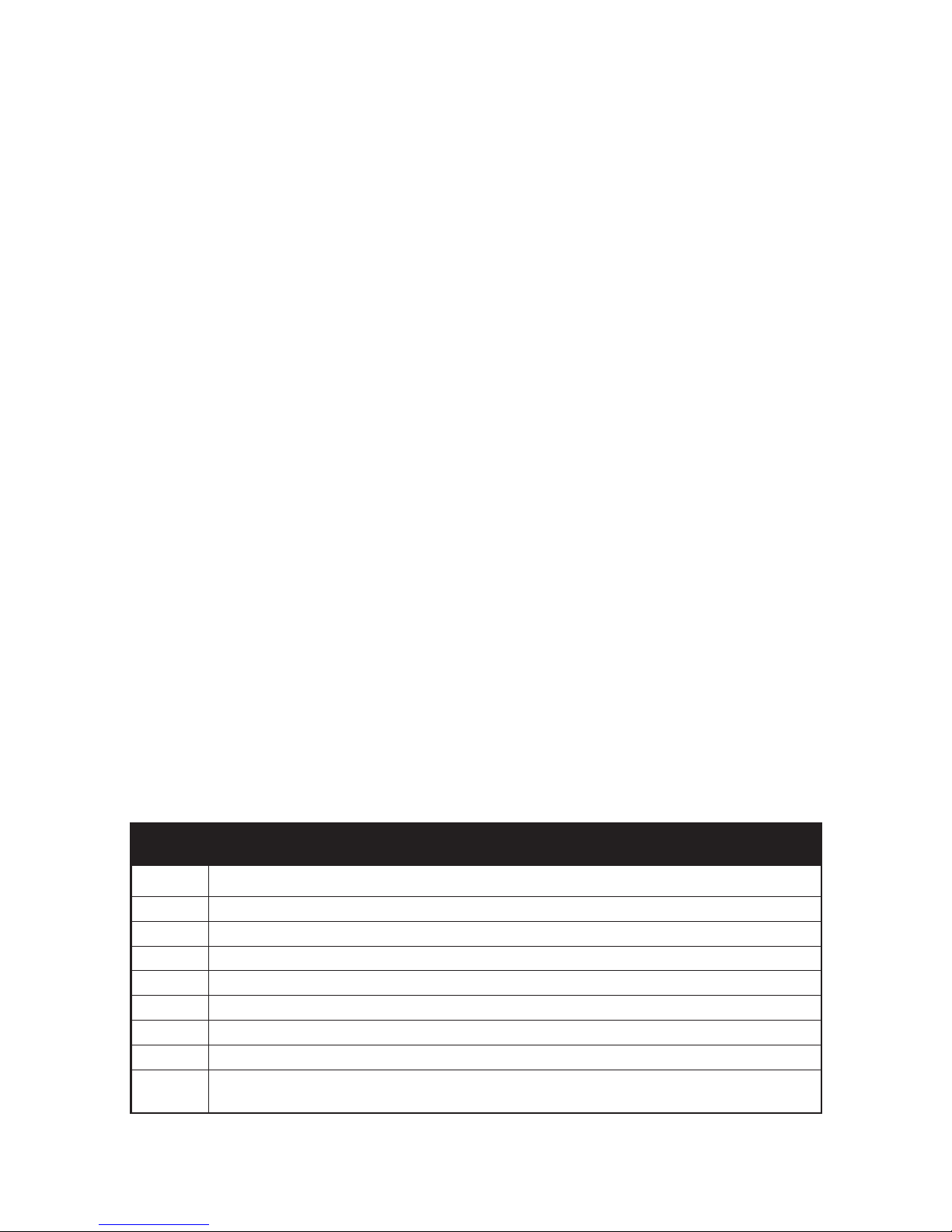

LPW Diesel Engine Models

Model Characteristic features

LPW2 Two cylinders, water-cooled, naturally aspirated, direct injection

LPW3 Three cylinders, water-cooled, naturally aspirated, direct injection

LPW4 Four cylinders, water-cooled, naturally aspirated, direct injection

LPWT4 Four cylinders, water-cooled, direct injection, turbocharged

LPWS2 Two cylinders, water-cooled, naturally aspirated, indirect injection, emission-compliant

LPWS3 Three cylinders, water-cooled, naturally aspirated, indirect injection, emission-compliant

LPWS4 Four cylinders, water-cooled, naturally aspirated, indirect injection, emission-compliant

LPWST4

Four cylinders, water-cooled, naturally aspirated, indirect injection, turbocharged,

emission-compliant

6

Read the information in this section carefully and follow all the advice given. Pay

especial attention to the cautions and

warnings demonstrated below, which are

used throughout this handbook.

CAUTION

This caution draws attention to special

information or procedures which must

be correctly observed, to avoid damage

to, or destruction of, equipment.

WARNING

This warning draws attention to special

information or procedures which must

be strictly observed. Failure to do so may

result in personal injury.

WARNING

THIS WARNING DRAWS ATTENTION TO

SPECIAL INFORMATION OR PROCEDURES WHICH MUST BE STRICTLY OBSERVED. FAILURE TO DO SO MAY RESULT

IN SERIOUS INJURY OR DEATH.

1.1 General Safety Information

Starting and operating any diesel engine is

potentially dangerous. Do not attempt to do

so unless you have the necessary knowledge and experience. Ensure that anyone

attempting to start and operate your diesel

engine has been propertly trained and instructed in the correct procedures.

CAUTION

Follow all safety instructions accurately.

Carefully read and follow all safety information and instructions in this manual.

Observe the safety and informative sym-

bols on your engine and equipment.

Emergency Precautions

• Be prepared with suitable equipment

and knowledge in case a re starts.

• Identify a location from which calls to

the emergency services can be made if

necessary.

• Ensure a third party knows where you are

working and when you leave the working

area.

General Precautions

• Ensure the engine is securely mounted.

• Ensure that there is a generous supply of

cooling and combustion air available.

• Keep the engine and surrounding area

clean.

• Some accessories may require guards

which must be supplied and tted by

the purchaser. Keep all safety guards in

position.

• Do not make any unauthorised modications as these may affect the safe operation of the engine and put the operator

at risk.

1.2 Personal Safety

• Wear personal protective clothing and

safety equipment appropriate to the

work being done.

• Keep clear of moving parts at all times.

WARNING

KEEP THE BODY AND CLOTHING CLEAR

OF MOVING OR HOT PARTS AT ALL TIMES.

CONTACT OF MOVING PARTS WITH UNPROTECTED SKIN CAN CAUSE SEVERE

BURNS. ENTANGLEMENT WITH ROTATING

EQUIPMENT CAN CAUSE SERIOUS INJURY

OR DEATH.

• Tie long hair back securely.

• Wear close-tting clothing.

• Do not wear a necktie, scarf, loose cloth-

ing or necklace when working close to a

running engine.

1. Safety Information

7

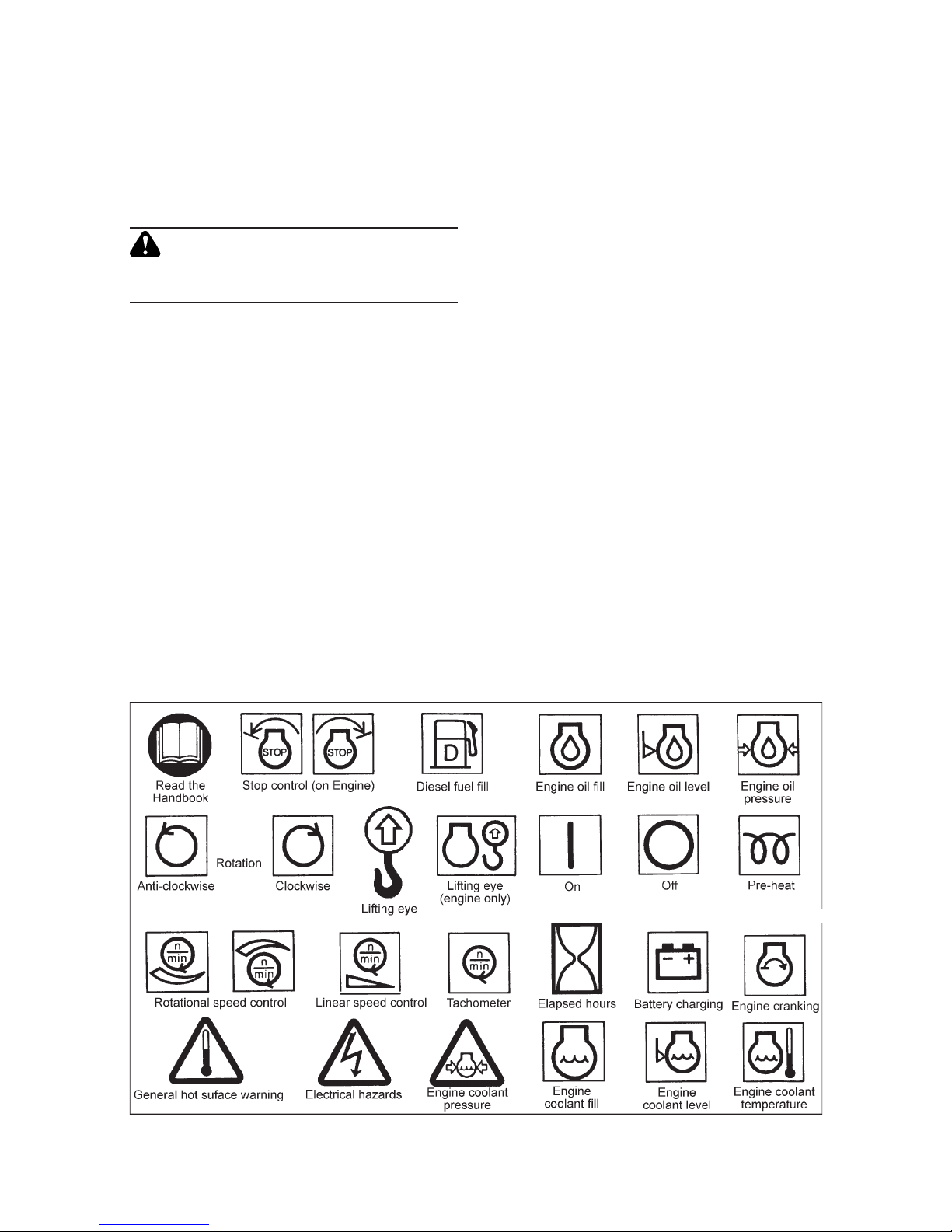

1. Safety Symbols This gure identies the ISO 8999 symbols currently used by Lister Petter.

• Where possible, remove rings and other

jewellery to prevent entanglement in

moving parts. These items could also

cause a short circuit if any part of the

electrical system is being worked on.

WARNING

Prolonged exposure to loud noise can

cause impairment, or loss, of hearing.

• Wear suitable ear protection against

objectionable or uncomfortable loud

noise.

• To avoid loss of concentration, do not

use music or radio headphones while

operating an engine.

• When undertaking maintenance, do not

work under any plant that is only held by

overhead lifting equipment.

• Where appropriate, make sure that

guards are properly tted.

1.3 Precautions with Chemicals

Protect yourself from exposure to hazardous chemicals at all times, as this can

cause serious injury. Potentially hazardous

chemicals include lubricants, fuel, coolant concentrate, battery acid, paint and

adhesives.

Manufacturers' safety data sheets will

provide specic details of the physical and

health hazards, safety and emergency

procedures and any necessary personal

protection equipment required while working with hazardous materials.

• Handle uids with care at all times.

• Rectify any fuel, coolant or oil leak as

soon as is practicable and clean up any

spillages when they occur.

• Remove any build-up of grease, oil or

debris.

• If any fluid other than lubricating oil

comes into contact with the skin, clean

off immediately. In the case of lubricating

oil, clean off as soon as is practicable.

Fuel and High-Pressure Fluids

• Store fuel and other ammable liquids

away from re hazards.

• Always stop the engine before refuel-

ling.

1. Safety Information

8

• Do not overll the fuel tank.

• When working with fuel do not smoke or

work near to heaters or other re haz-

ards.

• High-pressure uids are extremely hazardous. Never allow any part of the body

to come into contact with high-pressure

fuel oil, compressed air or hydraulic oil,

for example when testing fuel injection

equipment.

WARNING

Do not expose pressurised containers to

heat, and do not incinerate or puncture

them.

WARNING

NEVER TOUCH OR INGEST HIGH-PRESSURE FLUIDS SUCH AS HYDRAULIC OIL,

COMPRESSED AIR OR FUEL OIL. THIS

COULD LEAD TO SERIOUS INJURY, OR

DEATH.

1.4 Fuel System Precautions

WARNING

NEVER ALLOW ANY UNPROTECTED SKIN

TO COME INTO CONTACT WITH THE INJECTOR SPRAY AS FUEL MAY ENTER THE

BLOODSTREAM WITH FATAL RESULTS.

WARNING

Never make unauthorised adjustments

to the emission-compliant fuel injection

pumps. This could be dangerous and

invalidates warranty claims. In the USA

unauthorised adjustment of emission

critical components is prohibited by Federal Law, incurring civil penalty.

• When priming or checking the fuel injection pump timing, care must be taken to

wipe any spilled fuel from the outside of

the engine.

• Always t a new joint when a union has

been disturbed.

• Special care must be taken to see that

there is no leakage from the joints of the

fuel pipe connection to the pump.

• When tightening or loosening fuel injection pump delivery connections use two

spanners to prevent un-sealing of fuel

pump delivery valve holders.

• When refitting the fuel pipe from the

pump to the injector, the connection to

the injector must be tightened before

the connection to the fuel pump. This

procedure will ensure that there is no

leakage from these joints.

• It is most important that all fuel joints are

tight and leak proof.

• Always ll the fuel tank through a ne

strainer. It is best to do this at the end of

the engine work period so that any sediment stirred up has time to settle before

the engine is used again, and the risk of

condensation contaminating the fuel is

minimised. If using a can, avoid tipping

out the last few drops.

• Funnels are very difcult to keep clean

in dusty conditions. Wash them before

and after use and wrap them up when

not required, or ll the tank direct from

a small-mouthed screw-capped can.

• The fuel injection equipment is manufactured to very accurate limits and the

smallest particle of dirt will destroy its

efciency.

CAUTION

Keep the fuel free from water and contaminants.

1.5 Precautions with Filters

and Elements

• Used lters and elements contain some

of the ltered liquid and should be han-

dled and disposed of with care.

• After handling new or used elements,

wash your hands thoroughly.

WARNING

Do not allow fuel or new or used lubricating oil to come into contact with unprotected skin. It is dangerous and could

cause skin irritation.

1. Safety Information

9

1. Safety Information

WARNING

Take careful precautions with lters and

elements. The materials used in the manufacture and treatment of some types may

cause irritation or discomfort if they come

into contact with the eyes or mouth, and

they may give off toxic gases if burnt.

1.6 Precautions with Oil Seals

Some engines may be tted with seals or

'O' rings manufactured from Viton or a similar material. When these substances are

exposed to abnormally high temperatures,

in excess of 400°C (752°F), an extremely

corrosive acid is produced.

WARNING

IF AN OIL SEAL CONTAINING VITON (OR

SIMILAR MATERIAL) DEGENERATES, IT

PRODUCES AN EXTREMELY CORROSIVE

ACID THAT CANNOT BE REMOVED FROM

THE SKIN. IF YOU SEE SIGNS OF DECOMPOSITION, OR ARE IN DOUBT, WEAR

DISPOSABLE HEAVY-DUTY GLOVES.

• If in any doubt about an oil seal, always

wear disposable heavy-duty gloves.

1.7 Precautions with Batteries

Batteries contain hazardous sulphuric acid.

Great care therefore needs to be taken

when using them.

• Do not smoke near batteries and keep

sparks and ames away from them. Do

not work near to heaters or other re

hazards.

• Switch off the battery charger before

connecting or disconnecting the charger

leads. Disconnect the battery negative

(earth) lead rst and reconnect last.

• Keep the top of the battery well venti-

lated during charging.

• Never 'ash' connections.

• Never use a damaged battery.

• Do not attempt to charge a frozen bat-

tery; it may explode. Instead, warm the

battery to 16°C (60°F).

WARNING

Take especial care with batteries, which

contain highly corrosive sulphuric acid

which is poisonous, will burn skin and

clothing, and will cause permanent damage including blindness if splashed into

the eyes. If acid accidentally comes into

contact with skin, eyes or clothes, ush it

away with copious amounts of fresh water

and seek medical aid.

1.8 Precautions with Electrical

Systems

• Ensure that the battery is of sufcient

capacity to start the engine down to its

minimum operating temperature, taking into account any drag that may be

imposed on the engine by the type of

trans mission that is attached to it.

• Ensure that the battery and all engine

wiring cables are of sufcient size to

carry the currents required.

• Check that the engine-mounted alternator is of sufcient output to cope with

the total electrical load required by the

machine to which it is tted.

Wiring Cables

Ensure that the engine wiring cables are:

• Bound together in a loom and adequately

supported.

• Routed to avoid any hot surfaces, particularly the exhaust system.

• Not in contact with any rough surfaces

or sharp corners so as to avoid any pos-

sibility of chang taking place.

Alternator

The following points must be strictly observed when an alternator is tted, otherwise serious damage can be done.

• Never connect a battery into the system

without checking that the voltage and

polarity are correct.

• Never remove any electrical cable while

the battery is connected in the circuit.

• Never disconnect the battery unless the

10

engine has stopped and all switches are

in the off position.

• Always ensure that cables are tted to

their correct terminals.

CAUTION

A short circuit or reversal of polarity will

ruin diodes and transistors.

• Never 'ash' any connection to check the

current ow.

• Never experiment with any adjustments

or repairs to the system.

• Always disconnect the battery and alternator before commencing any electric

welding when a pole strap is directly or

indirectly connected to engine.

1.9 Waste Disposal Precautions

• Extreme care must be taken to ensure

that waste oil, fuel, lter elements, cool-

ant concentrate, battery electrolyte, solvents or other toxic wastes are disposed

of in accordance with local regulations to

prevent contamination.

WARNING

To avoid contamination and personal

injury, never dispose of toxic or other

waste except in accordance with ofcial

regulations.

1.10 Precautions before Starting

WARNING

Starting any diesel engine can be dangerous in the hands of inexperienced people.

Engine operators must be instructed in

the correct procedures before attempting

to start any engine.

• Ensure that the engine is free to turn

without obstruction.

• Check that the lubricating oil level is

correct. The oil sump must be lled to

the ‘full’ mark on the dipstick; do not

overll.

• Check that the radiator is lled to within

13-25 mm (0.5-1.0 in) below the neck of

the radiator ller.

• Check that the fuel supply is adequate

and the system is primed.

• Ensure that the battery is connected,

fully charged and serviceable.

• Where possible, disengage the driven

equipment while starting.

1.11 Lifting Precautions

Engine lifting eyes are tted to ALPHA and

NEW ALPHA engines. The following points

must be considered before attempting to

lift the engine.

• Ensure any lifting equipment to be used

has the correct capacity to lift the engine.

• Ensure that the lifting equipment is designed to give a vertical lift from directly

above the engine lifting eye.

• Check that the engine lifting eyes are not

damaged and that they are secure.

• The engine lifting eyes are suitable for

lifting the engine and accessory assem-

blies originally tted by Lister Petter.

WARNING

Engine lifting eyes must not be used to lift

the complete plant.

WARNING

DO NOT WORK UNDER ANY PLANT THAT

IS ONLY HELD BY OVERHEAD LIFTING

EQUIPMENT.

1.12 Precautions before

Maintenance

• Understand the service procedures before commencing any work.

• Ensure all starting devices are removed

or isolated before beginning any work on

engine or plant.

• Ensure the work area is clean, dry, well

ventilated and has adequate lighting.

• Ensure that all persons using equipment

or processes in connection with the

maintenance of plant and mach inery

have received adequate and suitable

training.

1. Safety Information

11

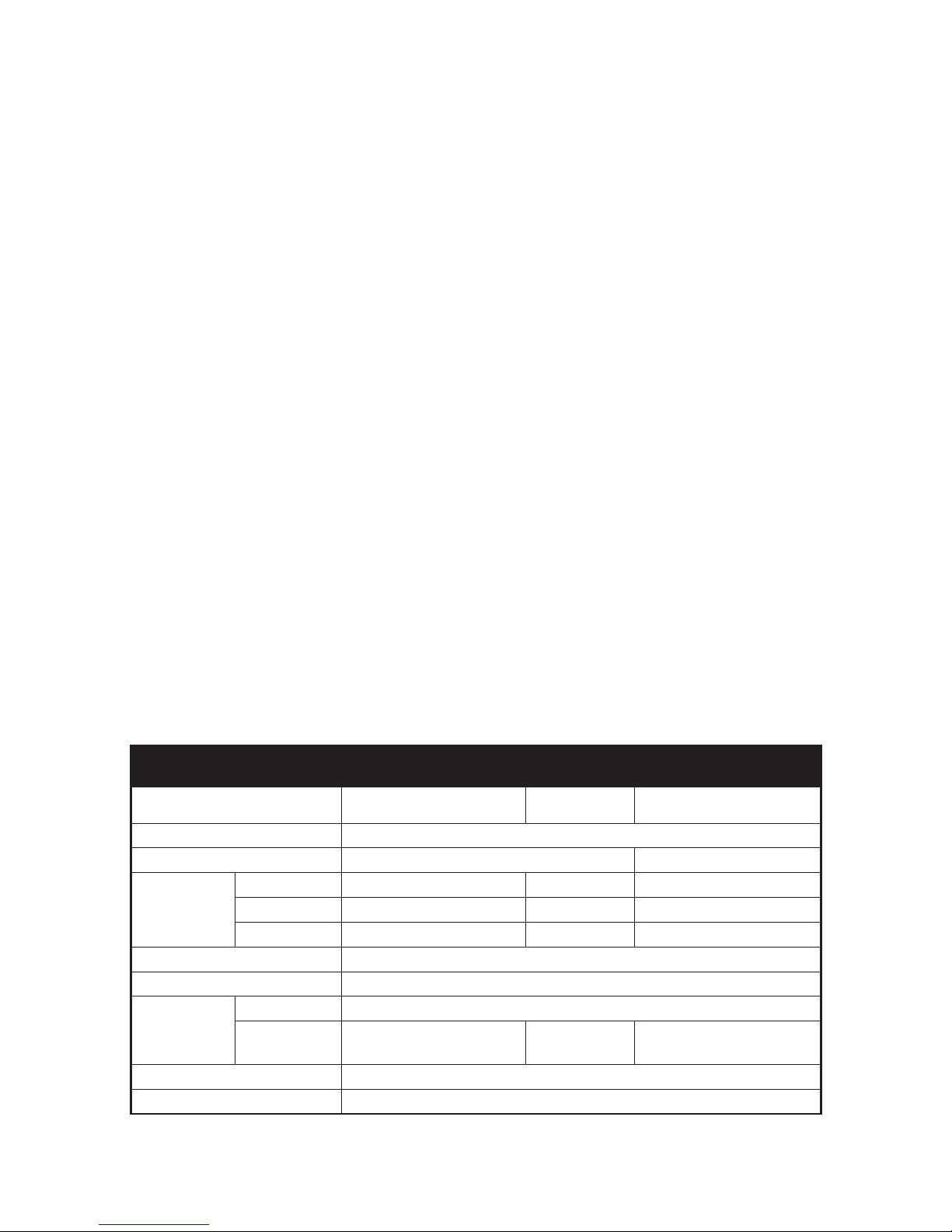

2. Technical data for Lister Petter LPW and LPWS engines.

Table 2 gives technical data for all the engines in the Lister Petter ALPHA (LPW) and

NEW ALPHA (LPWS) range.

2.1 Combustion Air

Engine performance is affected by ambient temperature, which is taken to mean

the temperature of the air entering the

engine.

The temperature of the combustion air is

measured at the air inlet manifold, or the air

cleaner, and the temperature of the cooling

air is measured at the radiator fan inlet. The

higher of these two temperatures is taken

as being ambient temperature as far as

engine ratings are concerned.

Every effort should be taken to ensure

that the air cleaner draws in combustion

air at a consistent ambient temperature.

2. Technical Data

Lister Petter LPW, LPWT, LPWS and LPWST

engines are able to run satisfactorily at

ambient temperatures up to the standard

engine reference condition of 25°C (77°F)

without derating. If the combustion air temperature rises above this temperature, the

rated power must be reduced in accordance

with the relevant standard:

LPW/LPWT ........................... ISO 3046

LPWS ................................... ISO 14396

Generating Sets ................... ISO 8528

The maximum permitted ambient temperature is 52°C (125°F).

2.2 The Cooling System

Cooling is by a radiator with water circulation being assisted by an engine mounted,

centrifugal, belt driven water pump using

a single belt.

Technical Data

LPW series model LPW2, LPW3, LPW4 LPW(S)T4 LPWS2, LPWS3, LPWS4

Rotation Anticlockwise (when looking on the ywheel)

Type of injection Direct Indirect

Firing order:

2 cylinders 1 - 2 n/a 1 - 2

3 cylinders 1 - 2 - 3 n/a 1 - 2 - 3

4 cylinders 1 - 3 - 4 - 2 1 - 3 - 4 - 2 1 - 3 - 4 - 2

Electrical system 12v negative earth

Starter battery charging 12v engine-mounted alternator

Oil pressure

at idle 1.0 bar (14.5 lbf in2)

3000

r/min

1

2.0 bar

(29.0 lbf in2)

2.5 bar

(36.3 lbf in2)

2.0 bar

(29.0 lbf in2)

Oil sump capacity Refer to table 5.6.3a: Sump Capacity (page 19).

Coolant capacity Refer to table 5.5: Engine Block Coolant Capacity (page 18).

Note: 1. Oil Pressure at 3000 r/min is with the oil at 110 oC (230 oF).

12

The following information is of a general

nature and should be read in conjunction

with the manufacturers' instructions for any

other equipment you are using.

WARNING

Do not attempt to start or operate a diesel engine unless you have been properly

trained. Read the safety information in

section 1 and the information below on

controls and the starting procedures.

CAUTION

DO NOT USE ETHER-BASED COLD-START

AIDS UNDER ANY CIRCUMSTANCES.

WARNING

DO NOT BREATHE EXHAUST GASES. THEY

CONTAIN CARBON MONOXIDE, A COLOURLESS, ODOURLESS GAS THAT CAN CAUSE

UNCONSCIOUSNESS AND DEATH.

CAUTION

On LPWT4 engines, ensure that the turbocharger housing is full of oil. Failure to

do so can result in serious damage to the

bearing. Run on 'no load' after starting

for 30 seconds, to ensure an adequate

oil supply to the turbocharger, and for 30

seconds before stopping to allow the heat

from the bearing to dissipate.

3.1 General Information

Start/Stop Control

The basic engine has a plastic knob tted

to the control. Other variants for automatic

or remote operation are available.

Engines not tted with a fuel control sole-

noid have a spring clip to hold the engine

control in the stop position.

WARNING

Use suitable hand protection when stopping the engine, as the stop control may

be hot after prolonged running.

3. Starting and Stopping

Oil Pressure Switch

If an oil-pressure switch bypass button is

tted it must be depressed during engine

cranking, and until the engine attains full

speed.

Heater and Glow Plugs

LPW: a 345 W heater plug (A) may be tted

to the inlet manifold.

LPWT4: a 696 W heater plug (A) is tted in

the inlet manifold.

LPWS: a 12v glow plug (B) is tted in each

cylinder and a 696 W heater plug (A) is also

tted in the inlet manifold as standard.

3.1 Heater and glow plugs. A: Manifold heater plug.

B: Cylinder glow plug.

3.2 Key Start

Before starting your engine read the cautions, warnings and the general information

above.

Starting LPW2, LPW3 and LPW4

1. With reference to gure 3.2.1, move the

engine control lever (A) clockwise until it

is against the stop screw (B).

2. On variable speed engines move the

speed control to the fast position.

3. Turn the key clockwise to the start position. Immediately the engine starts the

key must be turned anticlockwise to the

run position.

3.2.1 Start control.

13

3. Starting and Stopping

4. On variable speed engines reduce the

engine speed as necessary.

Starting LPWS2, LPWS3, LPWS4

1. With reference to gure 3.2.1, move the

engine control lever (A) clockwise until it

is against the stop screw (B).

2. On variable speed engines move the

speed control to the fast position.

3. For ambient starting temperatures above

-10°C (14°F) turn the key clockwise and

hold it in the preheat position for 5 to

10 seconds before turning it to the start

position.

For ambient starting temperatures below

-10°C (14°F) turn the key clockwise to

the preheat position for 15 to 20 seconds before turning the key to the start

position.

Immediately the engine starts the key

must be turned anticlockwise to the run

position.

4. On variable speed engines reduce the

engine speed as necessary.

Starting LPWT4

1. With reference to gure 3.2.1, move the

engine control lever (A) clockwise until it

is against the stop screw (B).

2. On variable speed engines move the

speed control to the fast position.

3. For ambient starting temperatures above

-10°C (14°F) turn the key clockwise and

hold it in the preheat position for 10 to

15 seconds before turning it to the start

position.

For ambient starting temperatures below

-10°C (14°F) turn the key clockwise to

the preheat position for 15 to 20 sec-

3.2.2 Key start.

onds before turning the key to the start

position.

Immediately the engine starts the key

must be turned anticlockwise and held

in the preheat position until the engine

has attained full speed.

4. When the engine has attained full speed

turn the key anticlockwise to the run

position.

5. On variable speed engines reduce the

engine speed as necessary.

3.3 Failure to Start

Should the engine fail to start within 30

seconds, release the key and, after allowing

sufcient time for all moving parts to stop,

attempt to restart.

3.4 Stopping (All Engines)

CAUTION

It is recommended that LPWT4 engines

run on 'no load' for 30 seconds before

stopping to allow the heat from the turbocharger bearing to dissipate.

1. If possible, remove the load from the

engine.

2. If a variable speed control is tted reduce

the engine speed.

3. On engines tted with a fuel control solenoid turn the key to the off position.

On engines not tted with a fuel control

solenoid move the engine control lever

anticlockwise into the stop position

(gure 3.4) and turn the key to the off

position.

CAUTION

Turning the key to the off position alone

will not stop the engine unless a fuel

control solenoid is tted.

3.4 Stop control.

14

4.1 Fuel Specication

The engine must be used only with diesel

fuel oil that conforms to one of the following:

• BS 2869:1988 Class A2;

• BS EN590:1995 Class A1;

• USA Specifi cation ASTM D-975-77

Grades 1-D and 2-D;

• BSMA 100 Class M1 for marine use.

The fuel must be a distillate and not a

residual oil or blend.

Vaporising oils are not suitable as fuels

for Lister Petter engines.

4.1.1 LPWS Bio

LPWS Bio is a specially developed engine

range that will run on B100 (100% biofuel)

as well as on those fuels specied above.

CAUTION

Although the engines may operate on

fuels outside the above specications,

such operation may result in excessive

wear and damage.

CAUTION

It is of the utmost importance to keep fuel

free from water and other contaminants.

The fuel injection equipment is manufactured to very accurate limits, and the

smallest particle of dirt will destroy its

efciency.

4.2 Oil Specication

To assist running-in, all engines are des-

patched with an initial ll lubricating oil

which must be changed, with the lter, after

the rst 100 hours.

All subsequent oil changes must be as

specied in 5. Routine Maintenance.

• The temperatures cited in gure 4.3 are

the ambient temperatures at the time

when the engine is started (see 2.2

Combustion Air). If monograde oils are

used and running ambient temperatures

are signicantly higher than starting temperatures, a higher viscosity oil should

be selected, subject to satisfactory starting performance. Multi grade oils may be

used to overcome the problem.

• Where ambient temperatures are variable and it is not practical to continually

change oils accordingly, a suitable multigrade oil is recommended to ensure

adequate starting performance at the

lowest temperature likely to be encountered.

• The engines must be run on heavy-duty

lubricating oils. Straight mineral oils

are not suitable, neither are oils of less

detergency than specied.

• API CF-4, API CG-4, API CH or API CI oils

must be used in all engines.

• For engines in long-running installations

Lister Petter should be consulted.

Oil Viscosity

Figure 4.3 shows the recommended oil

viscosity ranges for various °C ambient

temperatures from cold start to maximum

running.

Non-synthetic oils at very low tempera-

tures will suffer from wax crystallisation, so

synthetic oils are recommended for these

conditions.

SAE 5W-20 oils are recommended on

the basis that they are fully synthetic and

are technically suitable for use up to 25°C

(77°F). (Monograde SAE 5W is not normally available as a synthetic oil therefore

does not appear in the chart.)

SAE 30 and 10W-30 oils may be used at

up to 52°C (126°F), but oil consumption

may be affected. 10W-40, 15W-40 and

20W-40 multi grades are recommended

for continuous full-load operation at this

temperature. (Monograde SAE 40 oils are

not recommended.)

4. Engine Fluids

15

4. Engine Fluids

4.2 Recommended oil viscosity grades for different temperature ranges.

Note A: intermittent running; note B; synthetic oils only. NB. The formula for conversion from degrees

Fahrenheit to degrees Centigrade is°F = (1.8 x °C) + 32.

In order to maintain the cold-starting

characteristics of any recommended grade

it is essential that oil changes are made

within the Lister Petter recommendations

(see 5. Routine Maintenance).

An oil change is recommended immediately if the engine fails to reach its normal

cold-start cranking speed owing to excessive oil viscosity.

CAUTION

Dilution of the lubricating oil with fuel

will adversely affect cold starting and will

increase oil consumption.

4.3 Coolant* Mixture Concentration

To determine the amount of coolant con-

centrate to be added, rst calculate the

total coolant capacity by adding together

the engine and radiator volumes (see 5.5.4

Coolant Capacity).

A 50% concentration of coolant additives

by volume must be maintained under all

operating conditions. If a component fails

due to an incorrect coolant concentration

being used it will not be covered by the LP

warranty.

When topping up coolant please ensure

that the “top up” is of the correct concentrate mix and not just water.

The specication of the coolant concentrate should comply with one of the

following:

BS6580 : 1985;

MIL-A-11755D;

MIL-A-46153/B.

* Coolant dened as the combination of water,

corrosion inhibitor and antifreeze.

16

5.2 Important Instructions

• Remove the battery before carrying out

any maintenance work on an engine.

• Disconnect the battery and alternator

before commencing any electric welding

when a pole strap is directly or indirectly

connected to the engine.

• Fuel pumps and injectors can only be

checked and set off the engine using

suitable specialist test equipment.

5.3 Maintenance Schedule

The table on page 17 sets out the frequency

with which maintenance and servicing

tasks should be performed. This is the

minimum frequency required to keep your

engine running at peak performance with

trouble-free operation.

The instructions are based on average

operating conditions. Air cleaners, lubri-

cating oil and fuel lters will require more

frequent attention if conditions are very

dusty. Decarbonising may be required more

often if the engine has been running on light

loads for long periods.

How to Service your Engine

Instructions are given in the remaining sections of this chapter.

After Servicing

• It is essential to ensure that nuts and

bolts are tightened to the torques speci-

ed in the Workshop Manual.

• When re-assembling an engine lubricate

all moving parts with engine oil.

• Renew nuts and bolts that have been

taken from high-stress locations. In

particular nuts and/or bolts from the

connecting rods should be renewed.

CAUTION

Long periods of light or ‘no load’ running

early in the engine’s life may lead to

cylinder bore glazing and high oil con-

sumption.

5. Routine Maintenance

This section is designed primarily for use

by trained technicians but it does contain

sufcient information, illustrations and detail to allow the operator to perform basic

maintenance work.

WARNING

Routine maintenance must be performed

by qualied personnel who are conversant

with the hazards of oil, fuel, electricity

and machinery.

This work can be carried out only if the

necessary hand and service tools are avail-

able. When the user has insufcient tools,

experience or ability to carry out adjustments, maintenance and repairs this work

should not be attempted.

Where accurate measurements or torque

values are required they can only be made

using calibrated instruments.

CAUTION

Under no circumstances should makeshift

tools or equipment be used, as their use

may adversely affect safe working procedures and engine operation.

These recommendations and instructions cover several engine models, therefore they are of a general nature.

The engine may include optional equip-

ment not specically covered in this book.

5.1 Before Starting

Before starting any dismantling procedure

read 1. Safety Information and Pre cau tions.

Consider the following:

• Do you know and understand the engine

and all the related systems?

• Do you have sufficient electrical and

mechanical knowledge and skills to

understand the symptoms?

• Do you have suitable electrical diagnos-

tic equipment available?

• Do you have, or have access to, the nec-

essary Lister Petter spare parts?

17

1. See also Table 1 above. 2. Inspect more frequently if fuel is contaminated. Inspect regularly on engines

in low-duty cycle applications, for example, stand-by generating sets.

5. Routine Maintenance

Maintenance Schedule

At all times

Continuously monitor engine performance.

Observe the correct oil and lter change periods

as specied below.

1. Oil and Filter Change Periods (hrs=hours)

Ambient

temperature

LPWS(T) LPWT LPW

Every: Every: Every:

Above 35°C

(95°F)

125 hrs 125 hrs 250 hrs

Up to 35°C

(95°F)

250 hrs 250 hrs 500 hrs

Every Day

Check the level and condition of lubricating oil.

Check the coolant level.

Check the level and supply of fuel.

Examine the cooling fan for damage.

Clean the air cleaner if the engine is operating

under very dusty conditions.

After the rst 100 hours

Marine propulsion engines: check idling speed

and reset if necessary.

Change the initial ll lubricating oil1.

Renew the oil lter.

Every 125 hours

1

Do all the above, and the following:

Clean the air cleaner if the engine is operating

under moderately dusty conditions.

Check for fuel, coolant and oil leaks.

Check the serviceability of the battery.

Every 250 hours

1

Do all the above, and the following:

Check the condition and tension of the radiator

drive belt.

Check the radiator ns for contamination or

blockage.

Clean the fuel injector nozzles if exhaust is dirty.

Renew the fuel lter element if the fuel is not

perfectly clean.

Every 500 hours

Do all the above, and the following:

Renew the fuel lter element.

Renew the air cleaner element.

Check the air induction systems for leaks,

damage and restrictions.

Change the lubricating oil1.

Renew the oil lter1.

LPWT4: Clean the crankcase breather canister

and hoses.

Every 1000 hours

Do all the above, and the following:

Check all external nuts, bolts and unions for

tightness.

Ensure that all guards are rmly attached and

are not damaged.

Replace the fuel-lift pump diaphragm.

2

Every 2000 hours

Do all the above, and the following:

Drain and clean the engine-mounted fuel tank,

if tted.

Check the engine and speed controls for free

movement.

Clean and check, and if necessary replace, the

fuel injector nozzles.

Check the radiator ns and radiator fan blades

for damage.

Replace the radiator fan drive belt, irrespective

of its condition.

Check the lubricating oil pressure.

Renew the air cleaner element.

Every year

Drain, ush and rell the cooling system,

adding new coolant concentrate to a 40%

concentration.

Drain and replace the lubricating oil and lter,

irrespective of their condition, if the engine

has run for less than 250 hours in the

preceding twelve months.

On marine engines, change the air cleaner

element.if it was not changed at the

prescribed intervals.

Every two years

Replace the coolant hoses, irrespective of their

condition.

When necessary

Undertake a decake/major overhaul.

18

5. Routine Maintenance

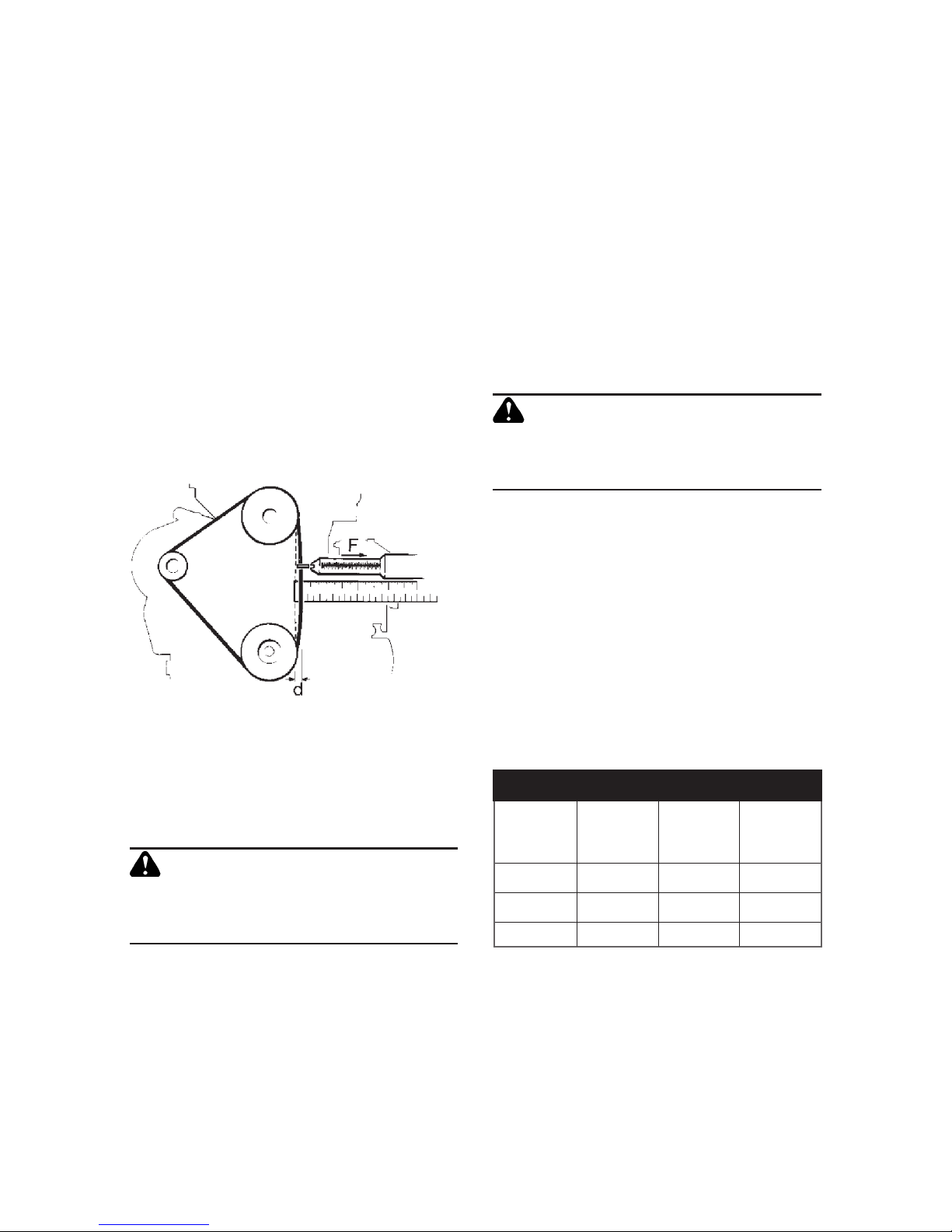

5.4 Checking drive-belt tension. F denotes force

and d dentoes distance.

5.4 Drive Belt

The tension of the drive belt (see gure 5.4)

must be checked:

1. After the rst 50 hours;

2. Every 250 hours;

3. After an overhaul when the belt is retted

or replaced.

4. The drive belt must be replaced every

2000 hours, irrespective of its condition.

When a new belt is correctly tted and tensioned, a force (F) of 31.0 —33.5 N (7.0—7.5

lbf) is required to deect it a distance (d) of

3.5mm (0.14in).

On subsequent checking and adjustment

a force (F) of 22.0-24.0N (5.0-5.4lbf) is

required to deect it a distance (d) of 3.5

mm (0.14 in).

Flushing the Cooling System

1. With the bottom hose removed, ush

the radiator through the ller with clean

fresh water, preferably using a hose pipe,

until clean water emerges.

2. With the top and bottom hoses re-

moved from the engine, ush the engine

through the top hose with clean fresh

water, preferably using a hose pipe, until

clean water emerges.

3. Replace the hoses.

Filling the Cooling System

CAUTION

Under some circumstances an air lock can

occur when lling the system, causing a

false level indication.

1. Ensure the hoses have been replaced.

2. Rell the system with clean fresh water

and coolant concentrate to a 40% concentration while bleeding air from the

system at a suitable point. The radiator

should be lled to within 13.0 —25.0

mm (0.5—1.0 in) below the neck of the

radiator ller.

3. Run the engine for a short time and

check the coolant level.

Coolant Capacity: Engine Block

Table 5.5.

Engine Block Coolant Capacity

LPW2

LPWS2

LPW3

LPWS3

LPW4

LPWT4

LPWS(T)4

litres 2.1 2.5 3.0

pints 3.7 4.4 5.3

US gallons 0.55 0.66 0.79

Coolant Capacity: Radiator

There are a number of radiator options

available for LPW, LPWT and LPWS engines,

including some which may not have been

originally tted by Lister Petter.

For these reasons it is advisable to

ascertain the radiator capacity which must

5.5 Cooling System

Draining the Cooling System

WARNING

The cooling system is pressurised and extreme care must be taken when removing

the radiator cap if the engine is hot.

1. Place a suitable container under the

radiator bottom hose if the coolant is to

be retained.

2. Slacken the clips of the hose and slide

the hose off.

3. Remove the radiator ller cap.

4. Allow sufcient time for the system to

drain.

19

Draining the Oil Sump

Before draining the oil read 1.5 Precautions

with Filters and Elements and 1.6 Precautions with Oil Seals.

The oil sump drain plugs are located on

the oil lter side and the gear end of the

crankcase. It is better if the engine has

been run immediately before draining, as

the warm oil will drain more quickly.

1. Remove the oil ller cap.

2. Remove the drain plug and allow the oil

to run into a suitable retainer.

3. Clean the drain plug threads and coat

them with Hylomar PL32/M, Loctite 572

or Hylogrip 760.

4. Replace the plug and tighten it.

Relling the Oil Sump

Table 5.6.3a gives the sump capacity

(excluding the lter) of all engines in the

LPW range.

Sump Capacity

(Figures exclude the lter)

LPW2

LPWS2

LPW3

LPWS3

LPW4

LPWT4

LPWS(T)4

All builds except 28, 51, 52, 57, 58, 59

litres 3.00 3.75 5.50

pints 5.28 6.60 9.68

US gallons 0.79 0.99 1.45

Builds 28, 51, 52, 57, 58, 59

litres 5.85 8.25 11.5

pints 10.29 14.52 20.23

US gallons 1.55 2.18 3.03

Table 5.6.3.

5. Routine Maintenance

then be added to that given in the table

above under Engine Block before determin-

ing the amount of coolant concentrate to be

added to maintain a 40% concentration.

The capacity of hoses on remote radiator applications must also be taken into

consideration.

5.6 Lubricating Oil

Check the lubricating oil daily using the

dipstick, and top up when necessary with

oil of the correct type and specication (see

section 4.2 Oil Specication). Table 5.6.3b

gives the capacity between the dipstick

marks of all engines in the LPW range.

Capacity Between Dipstick Marks

LPW2

LPWS2

LPW3

LPWS3

LPW4

LPWT4

LPWS(T)4

All builds except 28, 51, 52, 57, 58, 59

litres 0.90 0.95 1.20

pints 1.58 1.67 2.11

US gallons 0.24 0.25 0.32

Builds 28, 51, 52, 57, 58, 59

litres 1.50 1.75 2.20

pints 2.64 3.08 3,87

US gallons 0.39 0.46 0.58

Table 5.6.1.

Change the lubricating oil and filter for

the rst time at 100 hours and then as

specied in 5.3. Maintenance Schedule

(table 1).

CAUTION

Continuous operation under heavy loads

in ambient temperatures above 35°C

(95°F) causes the oil to deteriorate more

quickly.

20

5. Routine Maintenance

3. Screw the new lter onto the crankcase

lter adaptor, or lter mounting bracket

facing, until the rubber joint just makes

contact with the crankcase facing of

mounting bracket.

4. Screw the lter on a further quarter to

half a turn.

5. Start the engine and run it for a few

minutes to circulate the oil.

6. Stop the engine and allow time for the oil

to drain down and check the level on the

dipstick.

7. Add more oil if necessary.

5.7 Fuel System

Priming the Fuel System

1. Ensure there is sufcient fuel.

2. Figure 5.7.1 shows the two types of lter.

Release the bleed screws (A) on the lter

and re-tighten when no further air bubbles are expelled.

3. On variable speed engines move the

speed control to the fast position.

4. Move the engine stop/run control from

the stop to the run position (gure 3.3.2,

page 13).

5. Operate the fuel-lift pump by hand.

1. Ensure the new oil meets the correct

specication and viscosity, as given in

4.2 Oil Specication.

2. Fill the sump through the oil ller (A) to

the upper mark on the dipstick.

3. Start the engine and run it for a few

minutes to circulate the oil.

4. Stop the engine and allow time for the

oil to drain down. Check the level on the

dipstick.

5. Add more oil if necessary.

CAUTION

Do not overll with oil. If a cylinder-head

oil filler is fitted the oil must only be

poured into the ller at a rate which enables it to drain into the crankcase. If the

oil is poured in too quickly it can ood the

crankcase breather holes and escape into

the inlet manifold and cylinders.

Changing the Oil Filter

The full-ow lter is a spin-on cartridge type

located on the crankcase door.

Only approved lters should be used,

as these have high-temperature-resistant

joints, adequate lter paper characteristics

and a rigid case. Other lters may have the

same external dimensions and thread as

the genuine one but may fail in service.

Before changing the lter read 1.5 Pre-

cautions with Filters and Elements.

1. Use a band-type gripping tool to remove

the lter from the engine.

2. Lightly grease or oil the face of the rub-

ber joint on the new lter.

5.6.1 The oil ller (A) and dipstick handle.

Changing the Agglomerator

Before starting, read 1.5 Precautions with

Filters and Elements and study figure

5.7.2.

1. Before removing the agglomerator cartridge (A) from the agglomerator head

(B) you should rst drain the water from

the agglomer ator by unscrewing the

drain tap (C).

2. Using a suitable strap wrench, unscrew

the cartridge (A) from the head (B).

5.7.1 Priming the fuel lter: the bleed screws are

denoted by A.

21

3. Screw a new cartridge onto the head and

hand-tighten it.

Changing the Fuel Filter

The element should be renewed every 500

hours, or more frequently if for any reason

the fuel is known to be dirty.

Before changing the lter read 1.5 Pre-

cautions with Filters and Elements.

1. Isolate the fuel supply or drain the

tank.

2. Unscrew the centre bolt (A) of the lter

assembly.

3. Discard the old element (B) and t a

replacement.

4. Fill the fuel tank and prime the system

(see 5.7.1 Priming the Fuel System).

5. Run the engine and check to see that no

fuel is leaking from the lter.

ture above the standard engine reference

condition of 25°C (77°F) will incur an

engine derate factor.

Light-Duty Air Cleaner

The snout is normally tted lying horizontally and pointing towards the gear end,

although the cleaner itself can be rotated

through 360°.

1. Release the three cover clips (A).

2. Lift off the cover (B).

3. Lift out the element (C).

4. Fit a new element.

5. Replace the cover and clips.

5. Routine Maintenance

5.7.2. The agglomerator:

cartridge (A); head (B);

drain tap (C).

5.7.3 Changing the fuel lter. The centre bolt is

denoted by A and the old element by B.

5.8.1 The light-duty air cleaner.

5.8.2 The cyclonic

air cleaner.

5.8 Air Cleaner

Every effort should be taken to ensure that

the air cleaner draws in combustion air at

the prevailing ambient temperature.

Any increase in combustion air tempera-

Cyclonic Air Cleaner

A cyclonic air cleaner can be remote or

engine-mounted over the ywheel housing. In either case it is connected to the

engine by a moulded rubber hose secured

by jubilee clips.

1. Regularly remove the dust cap (A) and

empty out all the dust.

2. Gain access to the paper element by

undoing the two over-centre clips (B).

3. Remove the element.

22

5. Routine Maintenance

4. Clean the element by directing a lowpressure compressed-air nozzle up and

down the pleats from inside the element.

5. Inspect the element for damage by placing a suitable light source inside it. If

the element is found to have any holes

it must be replaced.

5.9 Battery

Check the battery as follows.

1. Wear protective gloves and goggles.

2. Clean the top of the ller-plug area.

3. Remove the ller plugs and check that

the electrolyte level is 6.0—9.0 mm

(0.25—0.37 in) above the tops of the

separators.

4. If necessary, top up with distilled water.

In cold weather distilled water should

only be added immediately before running the engine.

5. Replace and tighten the ller plugs.

6. Check that the terminal connections are

tight; petroleum jelly will help to protect

them from corrosion.

CAUTION

BATTERIES CONTAIN SULPHURIC ACID

WHICH CAN CAUSE SEVERE BURNS AND

PRODUCE EXPLOSIVE GASES. IF ACID

IS S PLA SHED ON T HE SK IN, EYE S

OR CLOTHES FLUSH WITH COPIOUS

AMOUNTS OF FRESH WATER AND SEEK

IMMEDIATE MEDICAL AID.

5.10 Long-Term Engine Storage

If the engine is not required for a period of

a few weeks it should be run on full load for

approximately 45 minutes once a month

If the engine will not be required for some

months, prepare it for storage as follows.

CAUTION

As a direct result of combustion the lubricating oil may contain harmful acids and

therefore it should not be left in the sump

if it is known that the engine will not be

used for extended periods.

1. Replace the fuel in the tank with a small

supply of suitable inhibition uid.

2. Drain the lubricating oil from the sump

and rell with new oil.

3. Run the engine for a period to circulate

the oil through the system and to ensure

the inhibition uid is passed through the

fuel pumps and injectors.

4. Stop the engine, drain the cooling system

and drain the lubricating oil from the

sump.

The crankshaft should not be turned

until the engine is again required for

service.

The inhibition uid should be left in the

fuel system.

5. Seal all openings on the engine with

tape.

6. Remove the batteries and store them

fully charged after coating the terminals

with petroleum jelly.

7. Grease all external bright metal parts

and the speed control linkage.

8. Tie labels on to the engine, clearly stating

what steps have been taken to inhibit the

engine during storage.

Returning the Engine to Service

Refer to the appropriate sections for the

relevant detailed instructions necessary to

complete this work.

1. Remove the tie-on labels and all the

protective coverings from openings and

apertures.

2. Check the drive belt for deterioration and

correct tension.

Check to ensure that the drive-belt pulley

grooves are free from corrosion.

3. Fill the fuel tank.

4. Rell the cooling system, adding new

coolant to a 40% concentration.

5. Rell the oil sump with new oil of the

correct specication and viscosity.

6. Remove the batteries from store and

recharge them if necessary. Reconnect

them to the engine.

Coat the terminals with petroleum jelly.

7. Start the engine and check for coolant,

fuel and oil leaks before applying load.

23

6. Troubleshooting

When an engine does not operate as ex-

pected it can be difcult to diagnose the

cause. The table in this chapter suggests

a number of possible causes of various

problems, together with recommended

solutions. The operator should check carefully which of these applies in a particular

case. Many of the suggested solutions can

be carried out by the operator, guided by

section 5. Routine Maintenance. Where

indicated1 you should seek assistance

from an experienced engineer (who must

refer to the Workshop Manual). The list is

of a general nature as it covers the basic

engine; your particular application may be

different.

Before starting any maintenance proce-

dure please read 1. Safety Information and

Precautions, taking especial note of 1.8.

6.1 Method of Fault Diagnosis

1. Diagnose the problem by checking and

eliminating the easiest causes rst. In the

case of electrical problems always check

the battery rst.

2. Double-check your observations.

3. Carry out the recommended solution, or

request an engineer to do this.

A comprehensive list of problems and

the methods of correction is given in the

Workshop Manual. If you are in any doubt,

contact your Lister Petter distributor.

Troubleshooting

Problem Cause Solution

Difculty

starting or

failure to

start

Incorrect starting procedure. Refer to section 3.

Unsuitable lubricating oil or fuel. Refer to section 4.

No fuel in the tank or the lter is

choked.

Rell the tank and prime the fuel system or

replace the lter.

Air in the fuel system. Prime the fuel system.

Water or dirt in the fuel system. Drain, ush, rell and prime the fuel system.

Faulty injector or pump.

Replace the injector or pump or have it

serviced.

Discharged battery or poor

battery connections.

Recharge or replace the battery. Check the

terminals are tight.

Fuel control solenoid not

energised.

Check the shutdown devices of the electrical

system.

1

Starter motor

does not

operate

Loose or corroded connections. Clean and tighten the connections.

Worn out battery. Replace the battery.

Faulty starter panel or

connections.

Adjust the connections and/or replace the

panel.

Battery will

not charge

Loose or corroded connections. Clean and tighten the connections.

Worn-out battery. Replace the battery.

Loose alternator drive belt. Replace or re-tension the drive belt.

Engine speed

unstable

Poor quality fuel. Drain, ush, rell and prime the fuel system.

Fuel system restriction. Replace fuel lter.

Restriction in induction system. Replace air cleaner element.

Fault in fuel lift pump. Replace diaphragm and/or pump.

1

1. Requires an experienced engineer.

24

Troubleshooting

Problem Cause Solution

Overheating

Radiator fan belt too slack. Adjust belt tension.

Overload. Reduce the load.

Lubricating oil level too low. Rell the sump.

Recirculation of exhaust gases or

cooling air.

Redesign exhaust and ventilation system.

1

Radiator cooling ns blocked. Clean the ns of all obstruction.

Low level of coolant. Check for leaks and rell.

Cooling system obstructed. Drain, ush and rell the system.

Engine stops

Lack of fuel. Check the system.1 Rell the tank.

Air in the fuel system. Prime the fuel lter.

Water in the fuel system. Drain, ush, rell and prime the fuel system.

Choked fuel lter. Replace the lter.

Choked air lter. Dismantle and clean the cap and element.

Overload. Reduce the load.

Overheating. See Overheating section.

Loss of compression. Check the piston rings and the valves.

1

Loss of electrical supply to the fuel

pump solenoid.

Check the electrical feed.

1

Automatic shutdown, if protective

devices are tted.

Investigate the cause and rectify.

1

Lack, or loss,

of power

Loss of compression. Check the piston rings and the valves.

1

Choked air lter. Dismantle and clean the cap and element.

Poor quality fuel. Drain, ush, rell and prime the fuel system.

Choked exhaust system. Dismantle and clean.

1

Overload. Reduce the load.

Choked fuel lter. Replace the lter.

Worn engine. Give the engine a major overhaul.

1

Undercharging

Excessive electrical load from

added accessories.

Remove accessories or t higher output

alternator.

1

Poor electrical connections to

alternator or battery.

Inspect, clean and rectify the cause.

Faulty battery. Test and recharge or replace.

Faulty alternator. Test and if necessary replace.

Overcharging Faulty alternator. Test and if necessary replace.

Battery

requires

excessive

amounts of

water

Battery case leaking.

Clean surrounding area and replace the

battery.

Defective battery. Test or replace the battery.

Battery charging rate is too high.

Check the alternator output and battery

charging system.

1

6. Troubleshooting

1. Requires an experienced engineer.

25

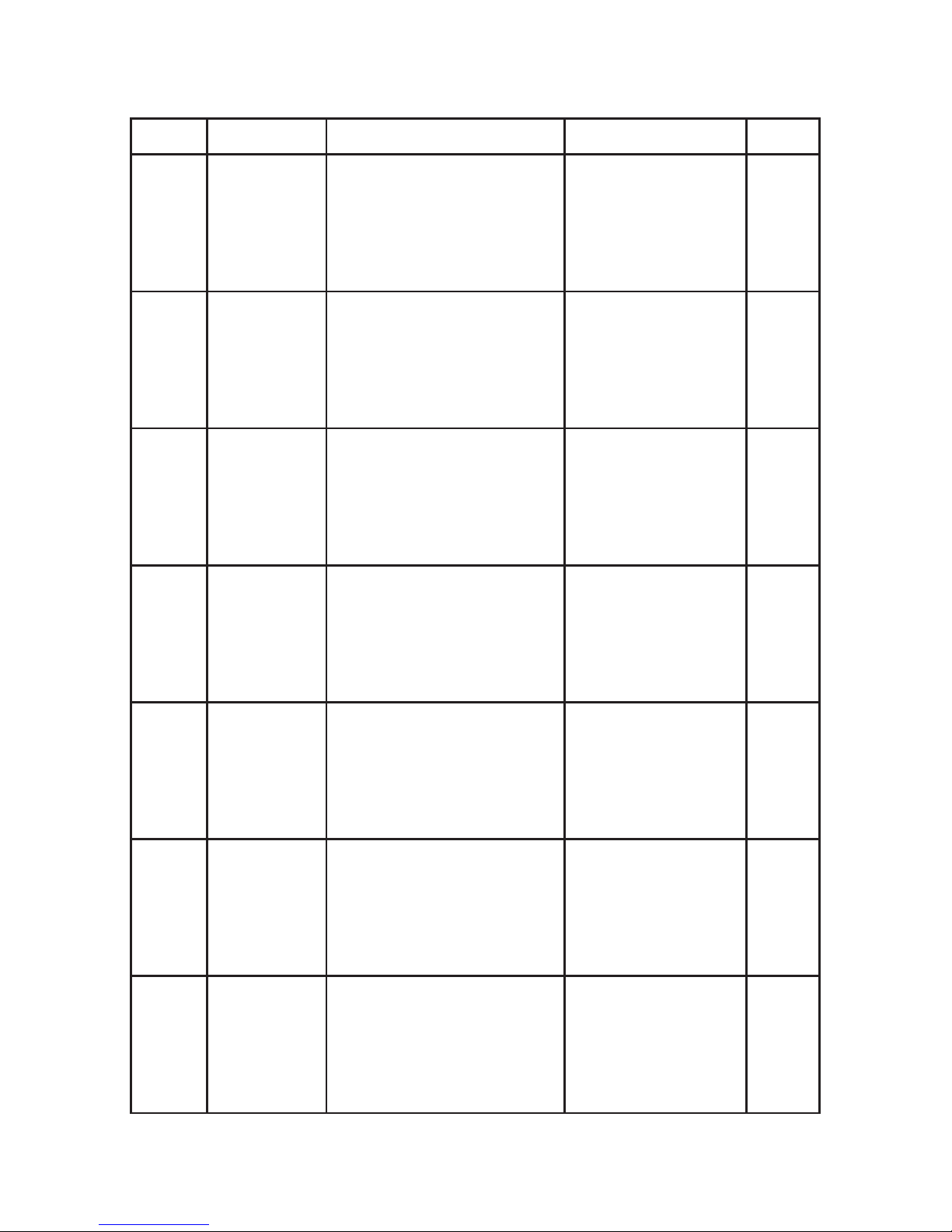

7. Maintenance Record

Hours run Work done by Details of service Distributor/Dealer Stamp Date

Your Lister Petter engine must be properly maintained using the timings and procedures described in this manual. You must be familiar with the routine tasks set

out in 5. Engine Servicing, and their correct frequency as described in 5.3 Maintenance

Schedule. Details of the maintenance work carried out on the engine during the rst

5000 hours, except the daily checks, must be recorded in the spaces allocated in this

section: pages 21-5 for routine maintenance and pages 26-8 for records of non-routine

maintenance.

7.1 Routine Maintenance

26

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

27

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

28

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

29

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

30

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

31

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

32

7. Maintenance Record: Routine Maintenance

Hours run Work done by Details of service Distributor/Dealer Stamp Date

33

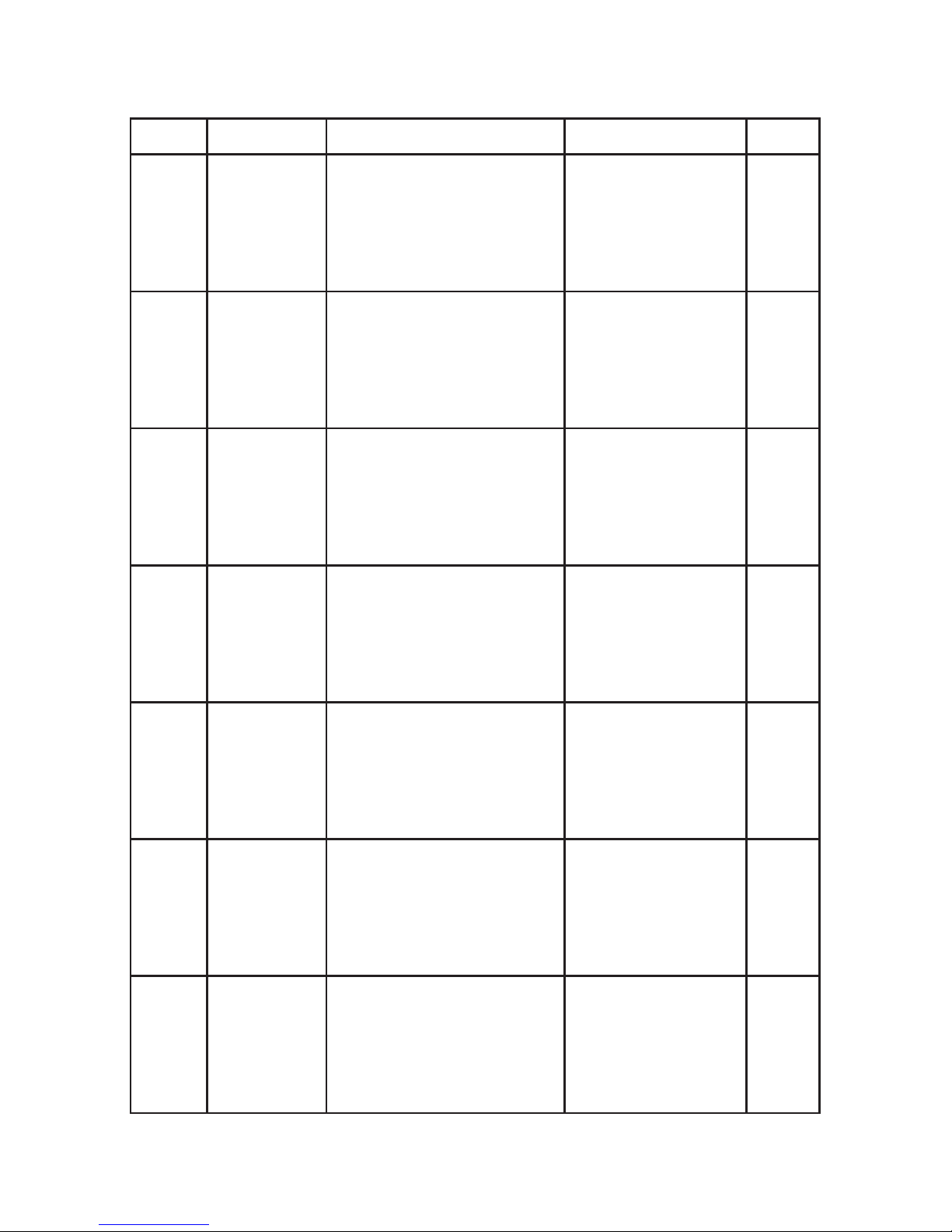

Hours run Work done by Details of non-routine service Distributor/Dealer Stamp Date

7.2 Non-Routine Maintenance

34

7. Maintenance Record: Non-Routine Maintenance

Hours run Work done by Details of non-routine service Distributor/Dealer Stamp Date

35

7. Maintenance Record: Non-Routine Maintenance

Hours run Work done by Details of non-routine service Distributor/Dealer Stamp Date

36

7. Maintenance Record: Non-Routine Maintenance

Hours run Work done by Details of non-routine service Distributor/Dealer Stamp Date

37

On receipt of your engine please ll in the

section on page 38. This information will

be required in the event of a claim under

your two-year warranty, according to the

conditions set out below.

8.1 Standard Warranty Cover

The standard warranty includes twoyear/5000-hour cover for all non-serviceable1 components, parts and labour,

beginning on the date of delivery to the

original retail purchaser, and is transferable. It is subject to the conditions set out

below in 8.3 Conditions of Warranty and

the limitations set out in 8.4 Limitations

of Warranty.

8.2 Extended Warranty Cover

In order to extend the warranty period beyond the initial two-year period you must

register the engine with a Lister Petter

dealer within 28 days of receipt. A list of

dealers is available at www.lister-petter.

co.uk.

The extended warranty gives fiveyear/5000-hour cover, beginning on the

date of delivery to the original retail purchaser, and is transferable. It includes the

following:

Years 1 and 2: all non-serviceable1 compo-

nents, parts and labour.

Year 3: core engine2, parts and labour.

Year 4: core engine, parts and labour.

Year 5: core engine, parts only.

8.3 Conditions of Warranty

For the warranty to be valid, servicing must

be carried out in accordance with 5. Routine

Maintenance and with the timings set out

in 5.3 Maintencance Schedule. Detailed

records of servicing must be kept; see 7.

Maintenance Record. Servicing must be by

approved dealers or competent engineers.

The conditions of warranty are:

• The maintenance record must be completed.

• Oils and other fluids must be to the

specications/grades given in 4. Engine

Fluids or as instructed in the Workshop

Manual.

• Only genuine Lister Petter service parts

must be used.

• When Lister Petter parts are purchased

from a dealer, this must be noted, with

the dealer 's stamp, in 7. Maintenance

Record, and receipts for the parts must

be retained. The dealer is authorised

to stamp the maintenance record only

following the sale of genuine parts, to a

competent engineer, intended to be used

on the warrantable Lister Petter engine.

• Evidence will be required of engine

hours run and should be entered in 7.

Maintenance Record. Evidence of equip-

ment used to record engine hours may

be requested in the event of a warranty

claim. If no hour recorder is tted, twelve

hours per calendar day will be used as a

basis for the hours-run calculation.

8. Warranty

Notes:

1. Serviceable items (unless defective) include, but are not limited to: air lters, fuel lters, oil lters, injector nozzles,

drive belts and lubricants and coolants (unless used on an authorised repair).

2. The term 'core engine' excludes the radiator/heat exchanger, starter motor and starting systems, alternator, water

pump, exhaust, fan belts, oil seals and fuel injection equipment.

3. This warranty gives the purchaser specic legal rights; the purchaser may also have other rights, which vary by

country or state.

Continued

38

• The installation should be in accordance

with data supplied by the Lister Petter

Applications Department.

• Long-term light-load and cold-engine

running will invalidate the warranty.

8.4 Limitations of Warranty

• The seller does not accept responsibility

for any business costs or other losses

which may result from the warrantable

failure.

• The seller is not responsible for failures

resulting from misapplication, abuse or

neglect, including: operating with inadequate cooling; the use of non-approved

or contaminated fuels or lubricants; lack

of, or incorrect, maintenance; incorrect

repair; improper storage; incorrect starting, stopping or operating procedures;

the use of non-approved parts; fair wear

Engine Serial Number: .............................................................................................................

Purchased from: ......................................................................................................................

............................................................................................................................................

............................................................................................................................................

Purchase Date: ..........................................................................................................................

Date Registered with Lister Petter: ..........................................................................................

Plant Type: .................................................................................................................................

Plant Number: ...........................................................................................................................

8. Warranty

and tear; and serviceable items (see

note 1).

8.5 Purchase and Registration

Details of your Engine

Please ll in the section below with your

purchase and registration details. This

information will be required in the case of

a claim under warranty.

8.6 Repairs under Warranty

• Lister Petter must be contacted and authorisation given before any warrantable

work is commenced.

8.7 Contacting Lister Petter

Lister Petter Limited, Dursley GL11

4HS, England; telephone +44 (0)1453

546732; website www.lister-petter.co.uk.

39

Index

agglomerator .................. 20-1

air cleaner

cyclonic ........................21-2

light-duty ......................... 21

ambient temperature .......... 13

battery ...............9, 22, 23, 24

belt tension ........................ 18

cold start ............................. 15

coolant capacity ....11, 18-19

cooling system ....... 11, 18-19

dipstick .........................19, 20

lling ................................... 18

ushing .............................. 18

drive-belt tension ............... 18

failure to start ..............13, 23

fuel specication ................ 14

fuel system .....................20-21

agglomerator ...............20-21

sump, draining/lling ..19-20

viscosity ........................... 15

problem-solving ................23-4

running-in ..............................2

safety precautions ..........6-10

safety symbols ......................7

serial number .......................5

servicing, routine ............16-22

starting

LPW ............................12-13

LPWS ..........................12-13

LPWT4 ........................12-13

stopping ............................. 13

storage ............................... 22

technical data .................... 11

temperature, ambient ....... 13

troubleshooting ..............23-4

warranty ........................... 37-8

lter element ..............8, 21

priming ............................ 20

glow plugs .......................... 12

heater plug ........................12

key parts ...............................3

lubricating oil ................ See oil

maintenance

routine servicing ........16-22

schedule ......................... 17

record ........................... 23-36

models ..........................2, 4, 5

oil

change periods ............... 19

lter .............................8, 19

lter change periods ......19

pressure switch .............. 12

specication ...............14-15

sump capacity ................. 19

40

CALIFORNIA

Proposition 65 Warning

Engine exhaust and some of its constituents are known to the State of California

to cause cancer, birth defects, and other reproductive harm.

UK

Lister Petter Limited, Dursley, Gloucestershire GL11 4HS England

Tel: +44 (0)1453 544141; Fax: +44 (0)1453 546732

E-mail: sales@lister-petter.co.uk http://www.lister-petter.co.uk

USA

Lister Petter Americas Inc. 815 E. 56 Highway, Olathe, Kansas 66061 USA

Tel: +1 913 764-3512; Fax: +1 913 764-5493

E-mail: info@lister-petter.com; http://www.lister-petter.com

FRANCE

Lister Petter France, 17 Avenue de l'Escouvrier, Zone d'Activites,

95842 Sarcelles Cedex, France

Tel: +33 (0)1 39330420; Fax: +33 (0)1 34195760

E-mail: commercial@lister-petter-france.fr

INDIA

Lister Petter Private Limited, 102 Beaver Gradeur, Baner, Pune 411045 India

Tel: +91 20 729 3284; Fax: +91 20 729 3287

CHINA

Lister Petter China, Jinan Fuqiang Power Co. Ltd,

Shandong Zhangqiu Industrial Area, Jinan 250220, P.R. China

Tel: +86 531 8558 4852; Fax: +86 531 8558 4820

ALPHA (LPW and LPWS including LPWS Bio)

Engine Operators' Handbook

P027-08270; copyright Lister Petter Ltd

February 2009, Issue 2

Loading...

Loading...