Lionel GG1 Owner's Manual

Lionel

GG1 Electric Locomotive

Owner’s Manual

Lionel

GG1 Electric Locomotive

Owner’s Manual

71-8354-250

3/05

SYSTEM

featuring

and

Do not attempt to raise or lower the pantographs by hand.

Be sure that the pantographs have enough clearance on your layout.

Caution!

Congratulations!

C

ongratulations on your purchase of the Lionel GG1 Electric Locomotive! On the outside, this

locomotive features numerous prototypical details and expert decoration in your favorite

livery. Inside the body, this locomotive is equipped with some of the most advanced sounds and

controls in model railroading. The Lionel GG1 locomotive is ready for duty on your layout.

Do not attempt to raise or lower the pantographs by hand.

Features of this locomotive

• TrainMaster Command Control equipped—able to run in Command

Control Mode or in Conventional Transformer Control Mode

• Odyssey System for speed control with ON/OFF switch

• Refined Conventional Transformer Control Mode with lower starting

speeds and improved Odyssey System controls

• Operating pantographs deploy and retract according to direction, a TMCC

CAB-1 command, or with roof-mounted switches

• Pantograph lock-down prevents accidental operation on layouts with low

clearances

• RailSounds 5.0 sound system with new intelligible CrewTalk dialog and

more TowerCom announcements, each with different scenarios depending

on whether the locomotive is in motion or stopped

• RailSounds 5.0 effects simulate the raising and lowering of the

pantographs, perfectly synchronized with each operation

• Independently adjustable volume control—lower the level of background

effects such as the blower with the CAB-1 Remote Controller while keeping

operator-controlled effects such as the horn at full volume

• Dual FatBoy speakers for the ultimate in sound reproduction

• Realistic steam generator blow-off—a plume of smoke erupts from the stack

• Dual powerful maintenance-free motors with momentum flywheels

• Directional LED headlights

• Directional marker lights illuminate on the end opposite of the active

headlight

• Illuminated number boards

• Front and rear ElectroCouplers

• Traction tires

• Illuminated front cab interior

• Minimum Curve: O-72

Caution!

The following Lionel marks may be used throughout this instruction manual and are protected under law.

All rights reserved.

Lionel

®

, TrainMaster®, Odyssey®, RailSounds®, CrewTalk™, TowerCom™, DynaChuff™,

StationSounds™, Pullmor®, ElectroCoupler™, Magne-Traction®, CAB-1®Remote Controller,

PowerMaster

®

, Lionel ZW®, ZW®, PowerHouse®, TMCC®, Lionelville™, Lockon®, Wireless Tether™,

LionMaster

®

, FatBoy

™

The name FasTrack®is used with permission from Pitsco, Inc.

Table of contents

Quick Start

Conventional transformer operations 4

TrainMaster Command Control operations 4

Conventional transformer operations

Conventional operations 5

Operating your locomotive in the conventional environment 6

Locking your locomotive into a single direction 7

Operating your pantographs in the conventional environment 8-9

Operating your smoke unit in the conventional environment 9

Uncoupling your locomotive in the conventional environment 10

RailSounds 5.0 sound system operations

RailSounds 5.0 sound system operations 11

Installing the battery 12

Using the RailSounds 5.0 sound system in the conventional environment 13

Activating the CrewTalk dialog and TowerCom announcements

in the conventional environment 14

Installing a Lionel Sound Activation Button for conventional operation 15

Using the RailSounds 5.0 sound system in the TrainMaster Command Control environment 16

Activating the CrewTalk dialog and TowerCom announcements

in the Command Control environment 17

RailSounds 5.0 sound system dialog on a round trip 18

Odyssey System operations

Odyssey System operations 19

Odyssey System conventional (transformer) operation 19

Odyssey System Command Control operation 20

TrainMaster Command Control operations

TrainMaster Command Control operations 21

Operating your locomotive in the Command Control environment 21

CAB-1 Remote Controller commands 22

CAB-1 Remote Controller numeric keypad commands 23

CAB-1 numeric keypad table 24

Operating the pantographs in the Command Control environment 25-26

Operating the smoke unit in the Command Control environment 26

Tuning your locomotive’s performance 27-28

Assigning your locomotive a new ID# 29

Building a lash-up 30

Reprogramming your locomotive to restore features 31

Maintaining and servicing your locomotive

Adding fluid to your locomotive’s smoke generator 32

Lubricating your locomotive 33-34

Servicing your locomotive’s LEDs and lamps 35

Servicing the traction tires 35

Servicing the pantographs 35

Limited Warranty/Lionel Service 36

3

Quick Start

Conventional transformer operations

Do not attempt to raise or lower the pantographs by hand.

Be sure to remove the paper bands from around the pantographs before you operate

the locomotive.

1. Place your locomotive on Lionel or Lionel-compatible O-72 or larger

track.

2. Power your locomotive at 8-19 volts with your alternating current (AC)

transformer.

Do not power your locomotive with a direct-current (DC) transformer. Damage to

sensitive electronic components may occur.

3. Wait three to eight seconds as your locomotive determines whether it is in

a conventional environment or a TrainMaster Command Control

environment. The pantographs will operate automatically.

4. Move ‘em out! Press the DIRECTION button on your controller, then

throttle up.

TrainMaster Command Control operations

Do not attempt to raise or lower the pantographs by hand.

Be sure to remove the paper bands from around the pantographs before you operate

the locomotive.

T

o operate your locomotive in the Command Control environment, you need a Command

Base (available separately, 6-12911) and a CAB-1 Remote Controller (available separately,

6-12868). These products are available together in the TrainMaster Command Set (6-12969).

1. Turn off track power and plug in the Command Base.

2. Place your locomotive on Lionel or Lionel-compatible O-72 or larger

track.

3. Increase track voltage to full power or 19 volts AC.

Do not power your locomotive with a direct-current (DC) transformer. Damage to

sensitive electronic components may occur.

4. Press ENG and 1 to address your locomotive with your CAB-1 Remote

Controller. The pantographs will operate automatically.

5. Throttle up and move ‘em out.

4

Note!

Note!

Note!

Note!

Caution!

Caution!

Conventional transformer operations

Conventional operations

Y

our locomotive is capable of operating in the conventional environment with nothing more

than a standard Lionel alternating-current (AC) transformer.

In the conventional environment, your locomotive cycles through a repeating pattern of

operations: forward, neutral, reverse, neutral, and so on. To advance to the next operation, press

the DIRECTION button on your transformer. Alternately, you could use the throttle to briefly

turn off track power so that the locomotive advances to the next operation when power is

restored.

Once you cycle the locomotive into forward or reverse, you control your locomotive’s speed

by varying track voltage with the transformer’s throttle. To increase the speed of the locomotive,

you increase track voltage. To decrease the speed, you decrease track voltage. To stop the

locomotive and to change directions (or to enter neutral), track voltage is turned off or

interrupted.

Use the HORN and BELL buttons on your transformer (or separate buttons if your

transformer is not equipped with these controls, see page 15) to activate these features.

To experience all of your locomotive’s features, we recommend operating in the TrainMaster

Command Control environment. With a simple one-wire connection, you can use the CAB-1

Remote Controller to access all of the functions of your locomotive. Refer to pages 21-31 to see

how to operate your locomotive in the TrainMaster Command Control environment.

5

Conventional transformer operations

Operating your locomotive in the conventional environment

Do not attempt to raise or lower the pantographs by hand.

Be sure to remove the paper bands from around the pantographs before you operate

the locomotive.

1. Place your locomotive on Lionel or Lionel-compatible O-72 or larger

track.

2. Power your locomotive at 8-19 volts with your alternating current (AC)

transformer.

Power your locomotive with an alternating-current (AC) transformer only.

Powering your locomotive with a direct-current (DC) transformer may result in

damage to sensitive electronic components.

3. Wait three to eight seconds as your locomotive determines whether it is in

a conventional environment or a TrainMaster Command Control

environment. The pantographs will operate automatically.

When the locomotive has determined that a TrainMaster Command Base is not connected to

the track, the locomotive’s headlight will illuminate and the RailSounds sound system will

start. You are ready for operation in the conventional environment.

4. Move ‘em out!

Press the DIRECTION button on your transformer to sequence your locomotive through

the repeating pattern of operations: forward, neutral, reverse, neutral, and so on. You may

also briefly turn off track power to advance the locomotive to the next operating state. Adjust

the throttle until your locomotive moves at your desired speed.

When placing your locomotive on your layout for the first time, it will start out in

neutral. The RailSounds sound system will be silent, except for the pantograph

sounds. Thereafter, it will start in forward after every power interruption lasting five

seconds or longer.

Use the HORN and BELL buttons on your transformer to activate those features. Refer to

page 15 if your transformer is not equipped with those buttons. Adjust the volume using the

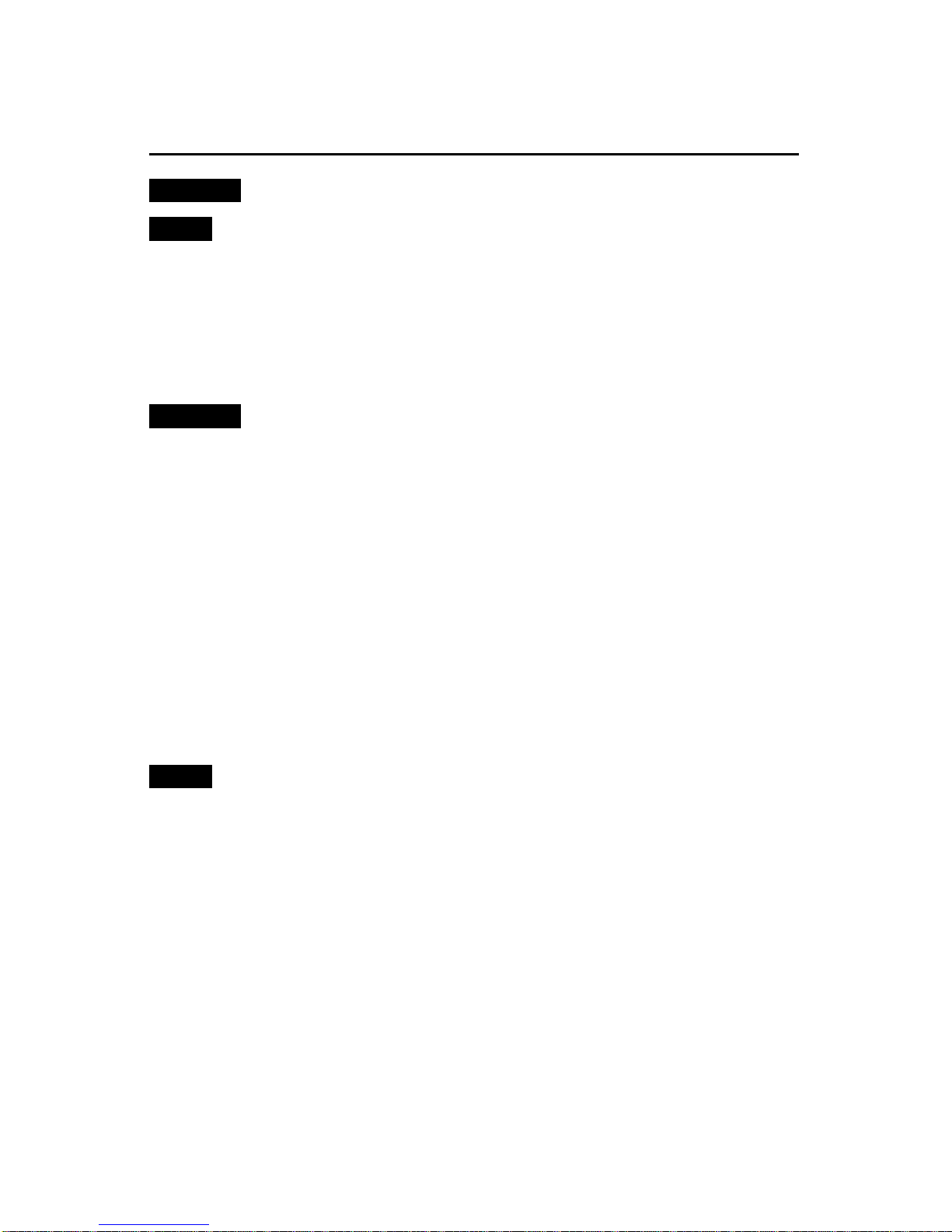

volume control knob located under the removable roof-top hatch. Refer to Figure 1 on page 7.

6

Note!

Caution!

Caution!

Note!

Conventional transformer operations

Locking your locomotive into a single direction

W

hen the Command reverse unit switch is in the RUN position, your locomotive sequences

through a repeating pattern of operations: forward, neutral, reverse, neutral, and so on.

To “lock” your locomotive into a single direction (for example, to operate in forward only),

you can deactivate the Command reverse unit’s sequencing function. Refer to Figure 1 for the

location of the Command reverse unit switch.

1. Use your transformer’s DIRECTION button or interruptions in track power to get your

locomotive moving in the desired direction or into neutral.

2. Slow the locomotive down without stopping (reduce the throttle without turning off track

power).

3. Slide the Command reverse unit switch to the PROG position. At this point, the locomotive is

“locked” into your chosen direction.

To restore the forward-neutral-reverse sequence, turn off track power and slide the

Command reverse unit switch back to the RUN position.

7

Figure 1. Switch locations

P

E

N

T

A

R

U

N

↔

D

O

W

N

S

I

G

N

A

L

S

O

U

N

D

↔

R

A

I

L

S

O

U

N

D

C

O

M

M

A

N

D

R

E

V

E

R

S

E

P

R

O

G

↔

R

U

N

P

A

N

T

A

R

U

N

↔

L

O

C

K

S

M

O

K

E

O

F

F

↔

O

N

O

D

Y

S

S

E

Y

O

F

F

↔

O

N

F

R

O

N

T

PANTA

RUN ↔ DOWN

SIGNALSOUND ↔ RAILSOUND

COMMAND REVERSE

PROG ↔ RUN

PANTA

RUN ↔ LOCK

SMOKE

OFF ↔ ON

ODYSSEY

OFF ↔ ON

Volume

control

knob

Conventional transformer operations

Operating your pantographs in the conventional environment

To prevent damage to your locomotive, do not raise or lower the pantographs by

hand. Be sure that the pantographs have enough clearance on your layout.

Be sure to remove the paper bands from around the pantographs before you operate

the locomotive.

Y

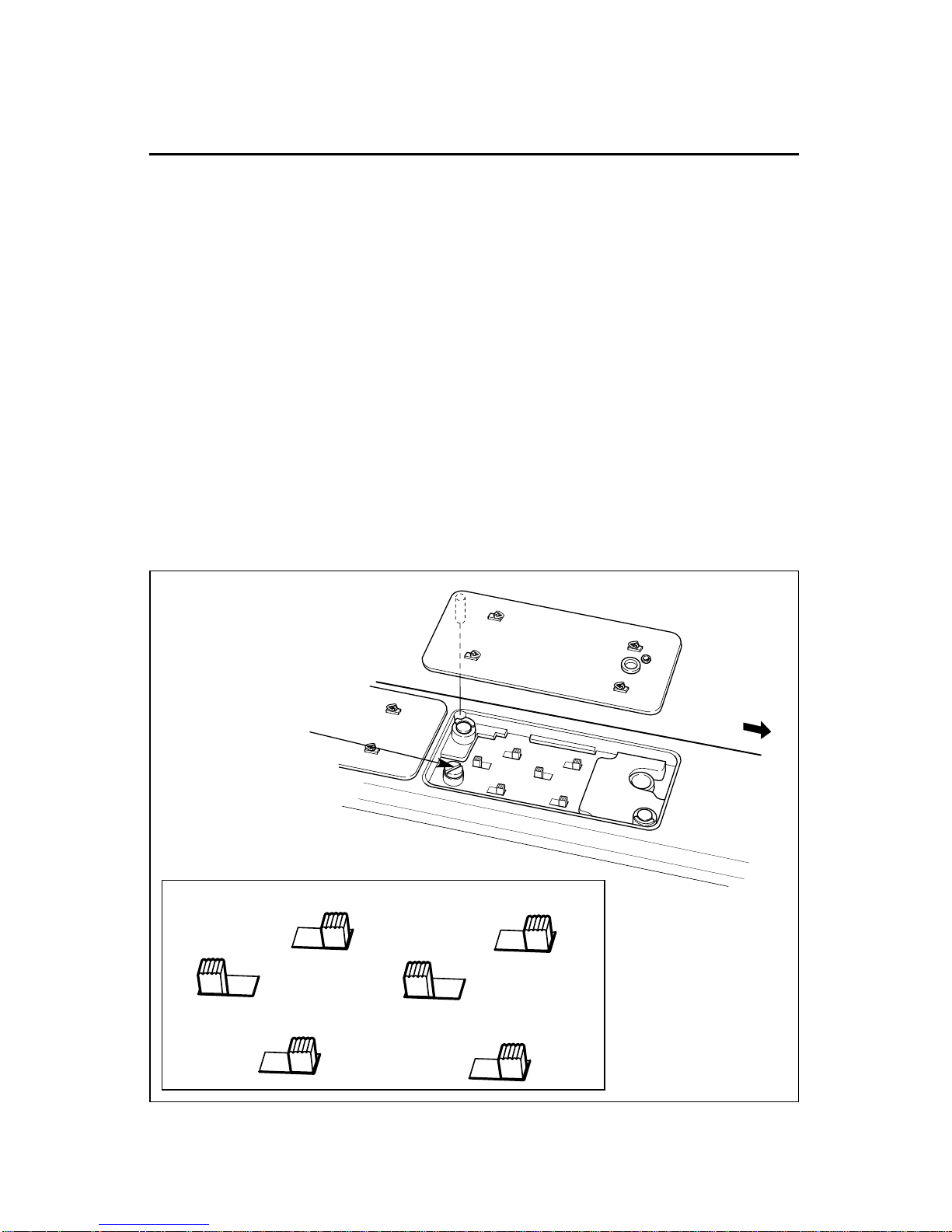

our GG1 locomotive is equipped with two operating pantographs. Do not raise or lower the

pantographs by hand, or you will damage the locomotive. Be sure that the pantographs

clear all bridges, signals, and other objects on your layout. Refer to Figure 2 to determine the

proper clearance.

The operation of the pantographs corresponds with the direction of travel. When the

locomotive is in neutral, both pantographs are raised. If the locomotive travels forward, only the

rear pantograph is raised. If the locomotive travels backward, only the front pantograph is

raised. After a direction change, the lowered pantograph raises, and then there

is a ten-second delay before the pantographs change positions.

Caution!

8

6.25"

3"

Figure 2. Locomotive clearance

Note!

Conventional transformer operations

Operating your pantographs in the conventional environment

(continued)

Locking down the pantographs in the conventional environment

If you have bridges, signals, or other trackside structures with low clearance, you will need

to lock down the pantographs. Follow these steps to lock both pantographs in the lowered

position.

1. Turn off track power.

You must turn off track power before sliding the RUN/DOWN switch to the DOWN

position.

2. With track power off, slide the RUN/DOWN switch to the DOWN position.

3. Be sure that the RUN/LOCKOUT switch is in the RUN position.

4. Power up the track. Both pantographs will lower.

Cycle the locomotive into neutral, then slide the RUN/DOWN switch to the RUN position to

resume automatic operation of the pantographs.

Locking the pantographs in your desired position

To lock the pantographs in any position (both up, both down, one up, one down, etc.),

simply operate the locomotive until the pantographs are in your desired position and slide the

RUN/LOCKOUT switch to the LOCKOUT position. Your locomotive will now operate with the

pantographs in your desired position. When you are ready to resume normal operations, cycle

the locomotive into neutral, then slide the switch back to the RUN position.

Operating the smoke unit in the conventional environment

Y

our locomotive is equipped with a smoke unit to simulate the operation of the steam

generator. When the smoke unit switch is in the ON position, always be sure that there is a

small amount of smoke fluid in the smoke generator. To turn off the smoke unit, slide the

smoke unit switch to the OFF position. See Figure 1 on page 7 for the switch locations.

When you first power up your locomotive, the smoke unit requires approximately 30 seconds

to warm up. The smoke unit will automatically turn on for five seconds. The smoke unit will

also turn on for five seconds after every five minutes of continuous operation in a single

operational state (in forward, reverse, or neutral and after changes in direction) and after

changes in direction. Be sure to install a nine-volt battery for the smoke unit to

operate while the locomotive is in neutral. See page 12.

Always be sure that there is smoke fluid in the smoke unit when the smoke unit

switch is in the ON position. When smoke production decreases, add more smoke

fluid as discussed on page 32.

9

Caution!

Note!

Conventional transformer operations

Uncoupling your locomotive in the conventional environment

Y

our locomotive features two ElectroCouplers that are released by remote control at any

point around your layout in the TrainMaster Command Control environment.

In the conventional environment, the ElectroCouplers will not open manually or by using a

Remote-Control Track section. To couple your locomotive in the conventional environment, you

must rely on a piece of rolling stock equipped with a magnetic coupler. Simply release the

magnetic coupler and couple the rolling stock to the locomotive, even if the ElectroCoupler is

closed.

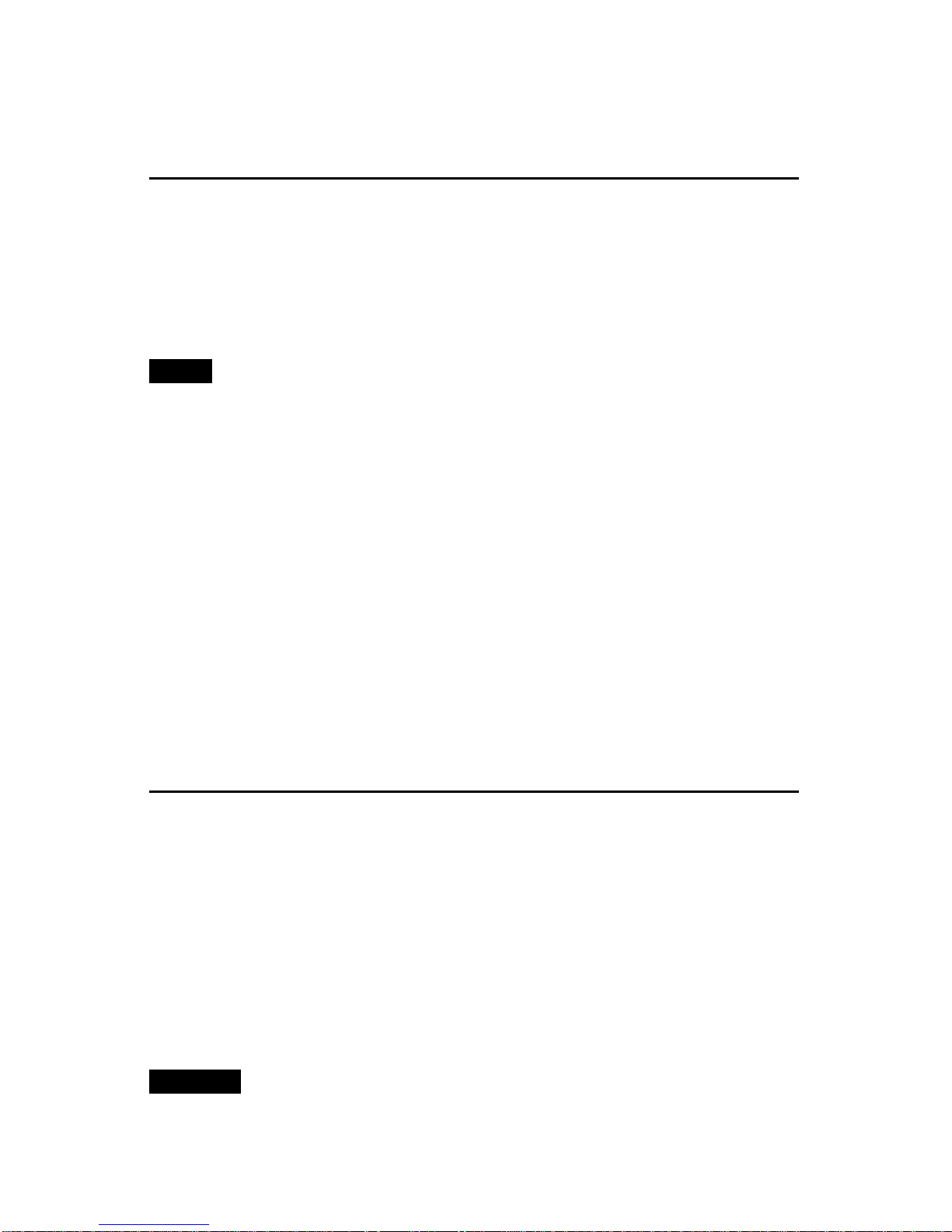

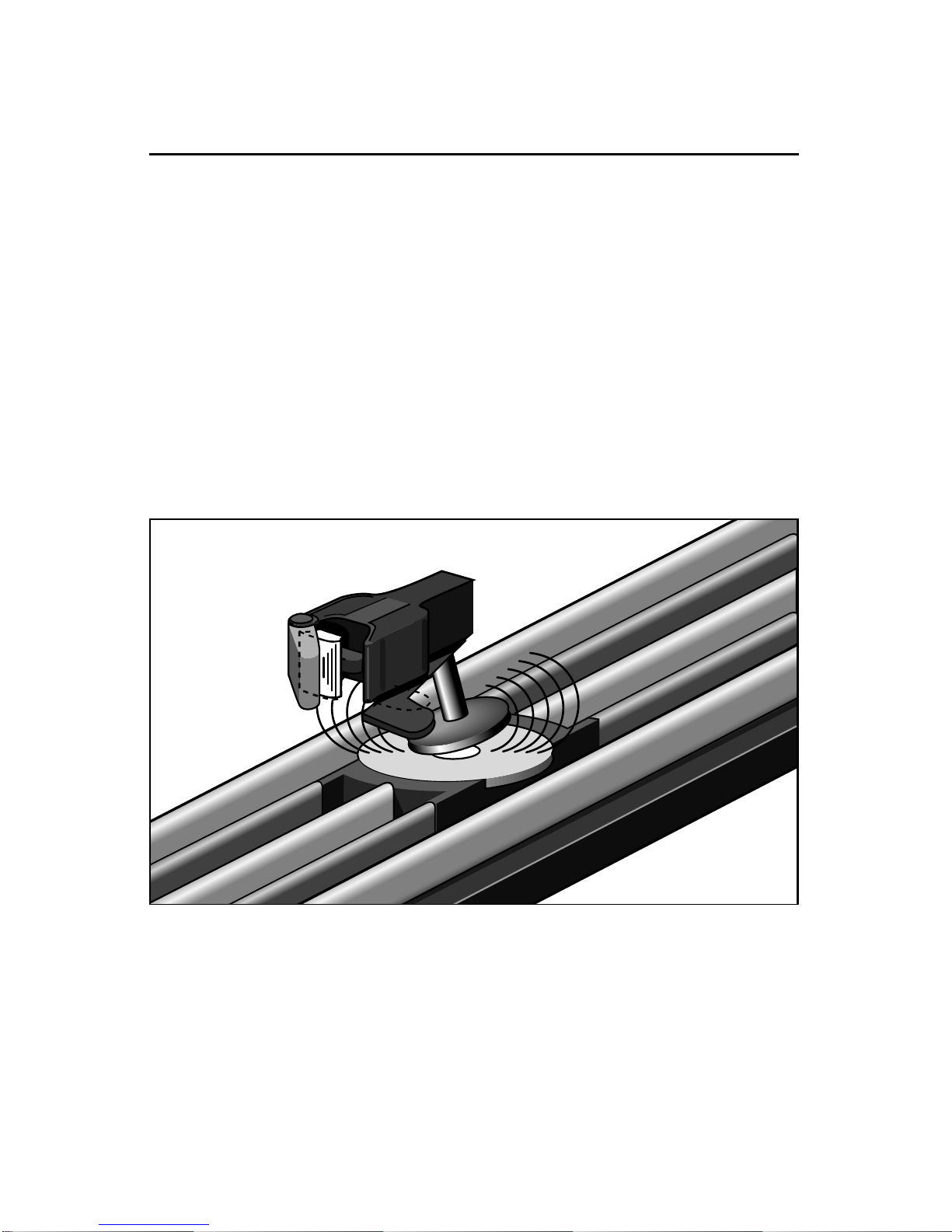

Keep in mind that you may still make use of Lionel Remote-Control Track sections (6-65530

for O gauge; 6-12746 and 6-65149 for O-27 gauge; and 6-12020 for FasTrack layouts) with the

magnetic couplers on the rolling stock. Place the trigger disc on the magnetic coupler over the

central coil on the Remote-Control Track section, then press UNCOUPLE on the track section’s

controller. As illustrated in Figure 3, the magnetic field pulls the disc downward, releasing the

coupler.

10

Figure 3. Magnetic coupler operation

Remote-Control

Track Section

11

RailSounds 5.0 sound system operations

RailSounds sound system operations

Y

our locomotive is equipped with the Lionel RailSounds 5.0 sound system, the most realistic

model railroad sound system in the world. The RailSounds sound system brings the sounds

of the railroad to your layout through high quality sound recordings of real locomotives.

When you operate your locomotive in the conventional environment, you get the realistic

sounds of the electric motor, which automatically rev up as the speed of the locomotive

increases. You can sound the locomotive’s horn or activate the ringing of the mechanical bell.

CrewTalk dialog and TowerCom announcements are triggered with the horn button on your

controller. When you are through with operations and power down the track, your locomotive’s

RailSounds sound system starts a realistic shutdown sequence (a nine-volt alkaline battery is

required, see page 12).

When you operate your locomotive in the TrainMaster Command Control environment, you

get full control of the RailSounds 5.0 sound system. In addition to the horn and bell sounds, the

locomotive’s RPM sounds automatically rev up, and you can also set a particular RPM level

using your CAB-1 Remote Controller. In the Command Control environment, the release of the

ElectroCouplers is accompanied by a coupler release sound. Use the BRAKE button, and listen

for the sound of squealing metal. You can also trigger CrewTalk dialog and TowerCom

announcements, which simulate the interaction between the locomotive crew and the

dispatcher. Whenever you choose to shutdown your locomotive, the realistic shutdown sequence

commences (a nine-volt alkaline battery is required if track power is turned off, see page 12).

Loading...

Loading...