Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 1/12

Installation Guide

Controller Series E100/E200/E400

Products

E100-AT / -MT /-DN /-CO

E200-AT / -MT /-DN/-CO

E400-AT / -MT /-DN/-CO

Content

IMPORTANT NOTES FOR E100/E200/E400 SERIES CONTROLLERS.....................2

SYSTEM OVERVIEW ............................................................................................................. 3

E100 SERIES FUNCTION AND WIRING...........................................................................4

POWER SUPPLY AND GROUNDING................................................................................5

DESCRIPTION OF THE CONNECTORS / INTERFACES ..............................................6

POWER SUPPLY REQUIREMENT...................................................................................10

ORDERING INFORMATION...............................................................................................10

DECLARATION OF CONFORMITY CE-MARKING.......................................................11

ERROR CODES.................................................................................................................... 12

CONTACT ADDRESSES ....................................................................................................12

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 2/12

Important notes for E100/E200/E400 series controllers

CAUTION !!

In order to assure a safe and error free operation, and to avoid

severe damage to system components, all system components

must be directly attached to a single ground bus that is earth or

utility grounded.

Each system component should be tied directly to the ground bus

(star pattern), rather than daisy chaining from component to

component. (LinMot motors are properly grounded through their

power cables when connected to LinMot controllers.)

All connectors must not be connected or disconnected while DC

voltage is present. Do not disconnect system components until all

LinMot controller LED’s have turned off. (Capacitors in the power

supply may not fully discharge for several minutes after input

voltage been disconnected). Failure to observe these precautions

may result in severe damage to electronic components in LinMot

motors and/or controllers.

Do not switch Power Supply DC Voltage.

All power supply switching

and E-Stop breaks should be done to the AC supply voltage of the

power supply.

Do not connect or disconnect the motors from controllers with

voltage present. Wait to connect or disconnect motors until all

LinMot controller LED’s have turned off. (Capacitors may not fully

discharge for several minutes after power has been turned off).

Failure to observe these precautions may result in severe damage

to electronic components in LinMot motors and/or controllers.

© 2010 NTI Ltd

This work is protected by copyright.

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including

photocopying, recording, microfilm, storing in an information retrieval system, not even for didactical use, or translating, in whole

or in part, without the prior written consent of NTI AG.

LinMot® is a registered trademark of NTI AG.

Note

The information in this documentation reflects the stage of development at the time of press and is therefore without obligation.

NTI AG. reserves itself the right to make changes at any time and without notice to reflect further tec hnical advance or product

improvement.

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 3/12

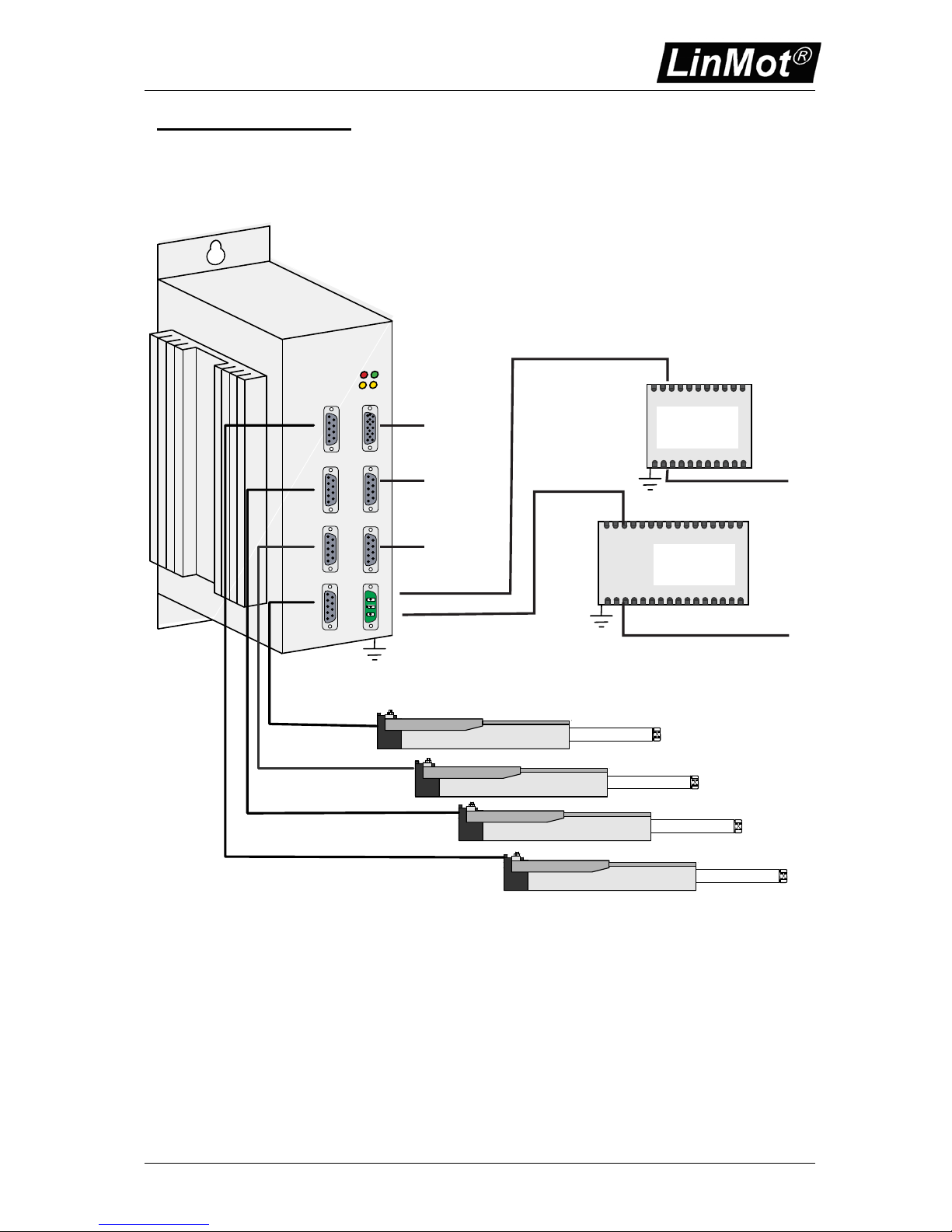

System Overview

Power Supply

Motor

24 ... 48 V

From AC Mains

1x115V AC

1x230V AC

RS232

Interface

to PC for

Configuration

Linear Motor with internal Position Feedback

Fault Ready

Stat A Stat B

Mot A

-->

Sys 1

-->-->

Mot B

-->

Sys 2

-->-->

Mot C

-->

Com

-->-->

Mot D

-->

PWR

-->-->

1

2

3

5

4

3

2

1

9

8

7

6

5

4

3

2

1

9

8

7

6

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

15

Power Supply

Signal

24 ... 48 V

Interfaces

to PLC or

PC

Interfaces

to PLC or

PC

From AC Mains

1x115V AC

1x230V AC

Power Supply Signal

Power Supply Motor

Complete E400 Controller based system (E100 and E200 controllers will only drive one respectively

two motors). Power Supply for Signal and Motor may be the same device (see later).

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 4/12

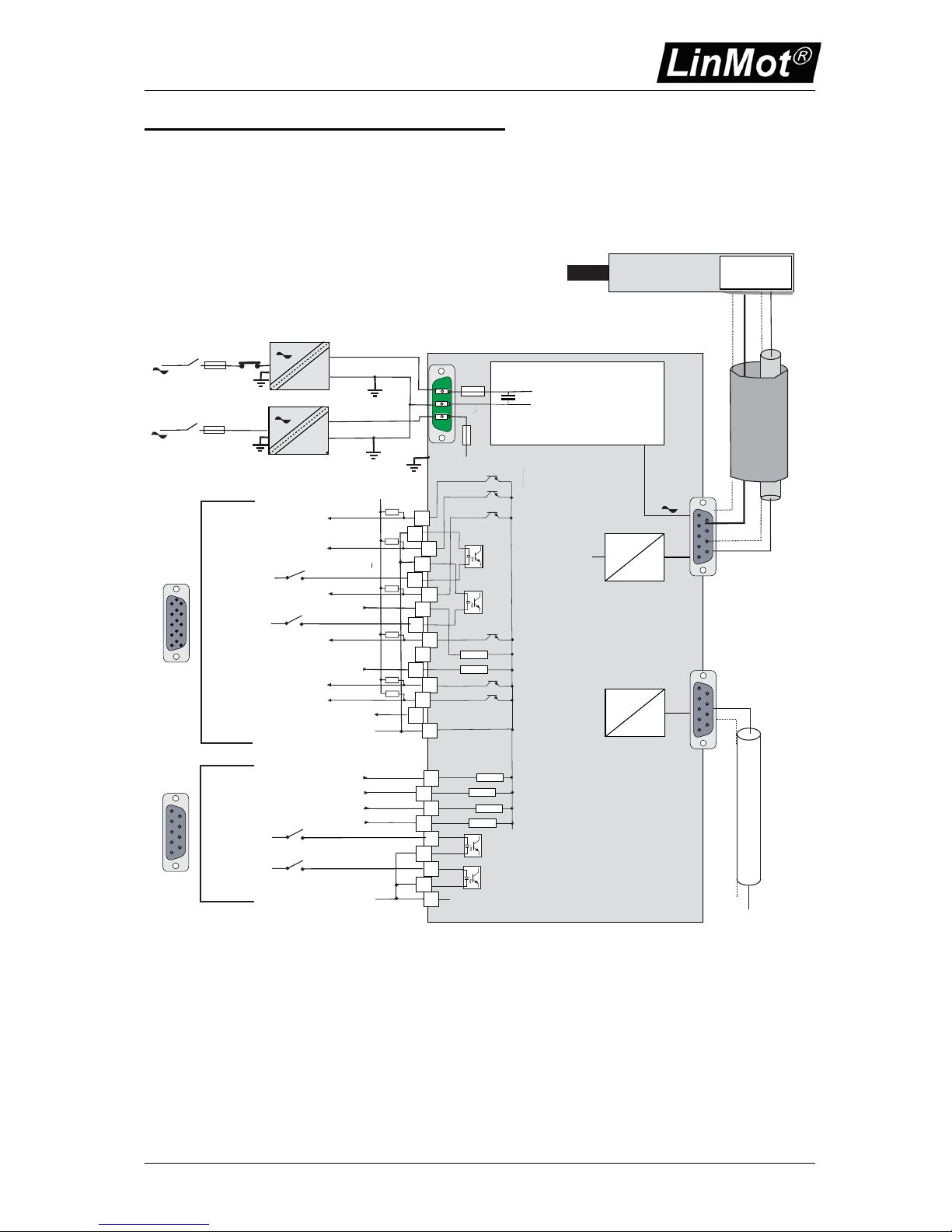

E100 series Function and Wiring

2-Phase Powerstage

24...48V DC

3A Phase Current

1

2

3

4

5

6

7

8

9

RS232

TTL

1

2

3

4

5

6

7

8

9

0-5V

A/D

Mot A ( addtional Motors B,C,D)

Com. RS232

Linear Motor

Motor Internal

Hall Sensors

Motor Phases*

Hall Sensors* /Temp Sensor

*use special double shielded Linear

Motor cable (see catalogue)

for RS232 PC connection use 1:1cable

Pin 2 - Pin 2, Pin 3 - Pin 3, Pin 5 - Pin 5

min. 0.5mm2 / AGW20 for 3A

AC-Mains

- Circuit Breaker

- Fuse

=

+

24...48VDC

Power Supply signal

PWR signal

GND

AC-Mains

- Circuit Breaker

- Fuse

Emergency

Stop Breaker

=

+

24...48VDC

Power Supply motor

PWR motor

GND

10 AT

0.5 AT

signal components

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

5

4

3

2

1

9

8

7

6

1

11

Emergency Stop -

6

1

7

2

12

8

3

13 14

15

9

10

4

5

GND

Output + 5 V (max 50mA)

Emergency Stop+

Freeze -

Freeze +

GND

100k

100k

Dig Out 6

Dig Out 5

Warn Out

Error Out

MSG / Dig Out 4

Pos Error / Dig Out 3

Dig In 6

Dig In 5

R

R

R

R

R

R

Trig/Analog IN 1

GND

GND

6

1

2

7

4

8

3

9

5

Trig/Analog IN 4

Trig/Analog IN 2

Trig/Analog IN 3

100k

100k

100k

100k

RUN +

RUN -

INIT +

INIT -

Sys 2

Sys 1

E100

Controller

+5 ..+ 24 V

use only

shielded cables

use only

shielded cables

use only

shielded cables

5 ... 24 V

5 ... 24 V

5 ... 24 V

5 ... 24 V

Ground Bus

Ground Bus

Ground Bus

Typical wiring of a single axes controller. Multiple axes controller have additional motor connectors.

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 5/12

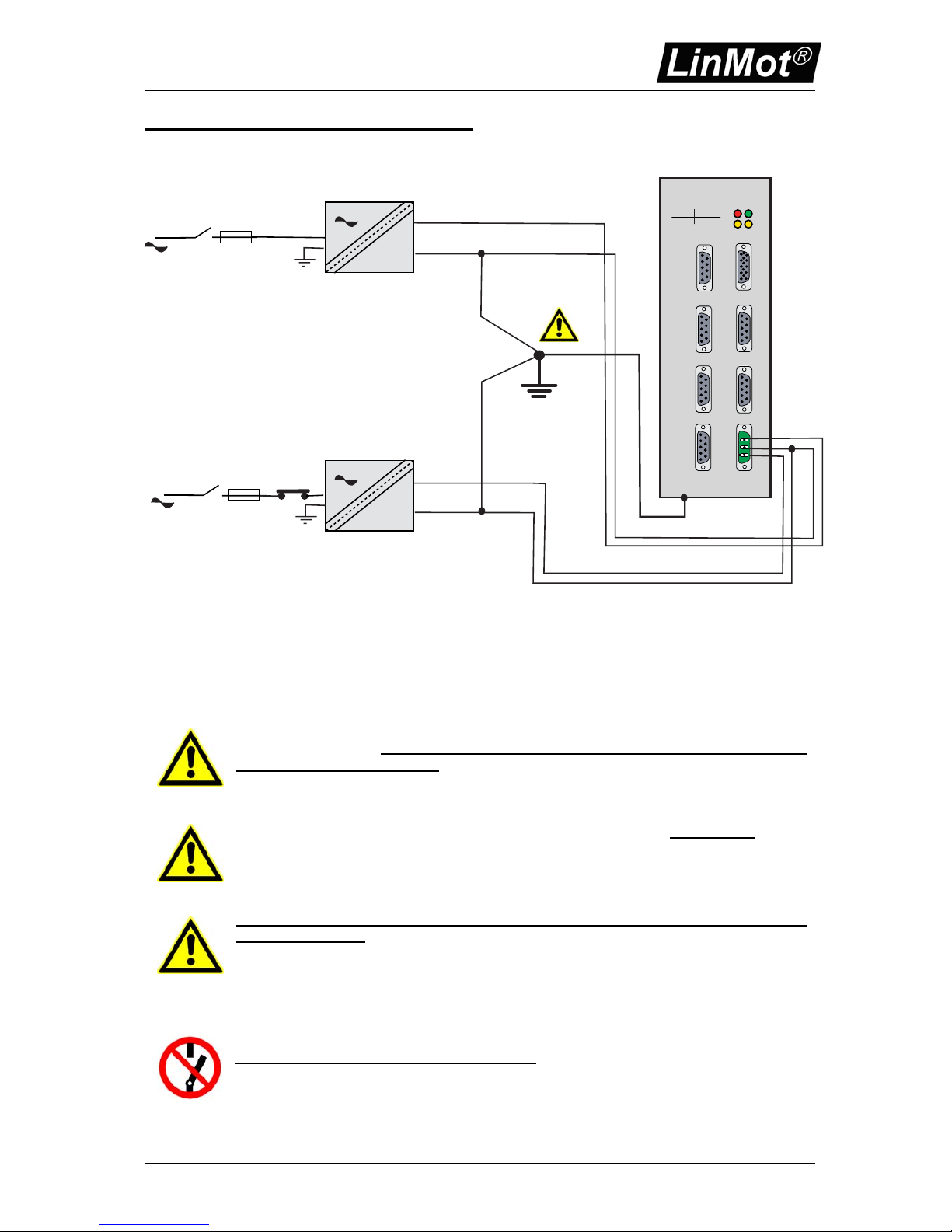

Power Supply and Grounding

Fault Ready

Stat A Stat B

Mot A

-->

Sys 1

-->-->

Mot B

-->

Sys 2

-->-->

Mot C

-->

Com

-->-->

Mot D

-->

PWR

-->-->

1

2

3

5

4

3

2

1

9

8

7

6

5

4

3

2

1

9

8

7

6

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

15

=

Galvanically Isolated Power Supply:

- Switch Mode Power Supply

- Transformer with Rectifier Bridge

+

24...48VDC

AC-Mains

- Circuit Breaker

- Fuse

All wires 1.5mm2 (AWG16)

AC-Mains

- Circuit Breaker

- Fuse

Emergency

Stop Breaker

-

=

Galvanically Isolated Power Supply:

- Switch Mode Power Supply

- Transformer with Rectifier Bridge

+

24...48VDC

-

PE

PWR signal

Power Supply signal

Power Supply motor

PWR motor

GND

GND

Ground Bus

Instead of two separated power supplies it may be possible to use only one power supply if there is no

need to control the signal power supply (logical devices of the controller) and the power supply of the

powerstage for the motors independently (see safety rules of the application).

In order to assure a safe and error free operation, and to avoid severe damage to

system components, all system components must be well grounded to either a

single earth or utility ground. This includes both LinMot and all other control system

components to the same ground bus.

Each system component should be tied directly to the ground bus (star pattern

), rather

than daisy chaining from component to component. (LinMot motors are properly

grounded through their power cables when connected to LinMot controllers.)

Power supply connectors must not be connected or disconnected while DC

voltage is present. Do not disconnect system components until all LinMot controller

LED’s have turned off. (Capacitors in the power supply may not fully discharge for

several minutes after input voltage been disconnected).Failure to observe these

precautions may result in severe damage to electronic components in LinMot motors

and/or controllers.

Do not switch Power Supply DC Voltage. All power supply switching and E-Stop

breaks should be done to the AC supply voltage of the power supply. Failure to observe

these precautions may result in severe damage to controller.

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 6/12

Description of the connectors / Interfaces

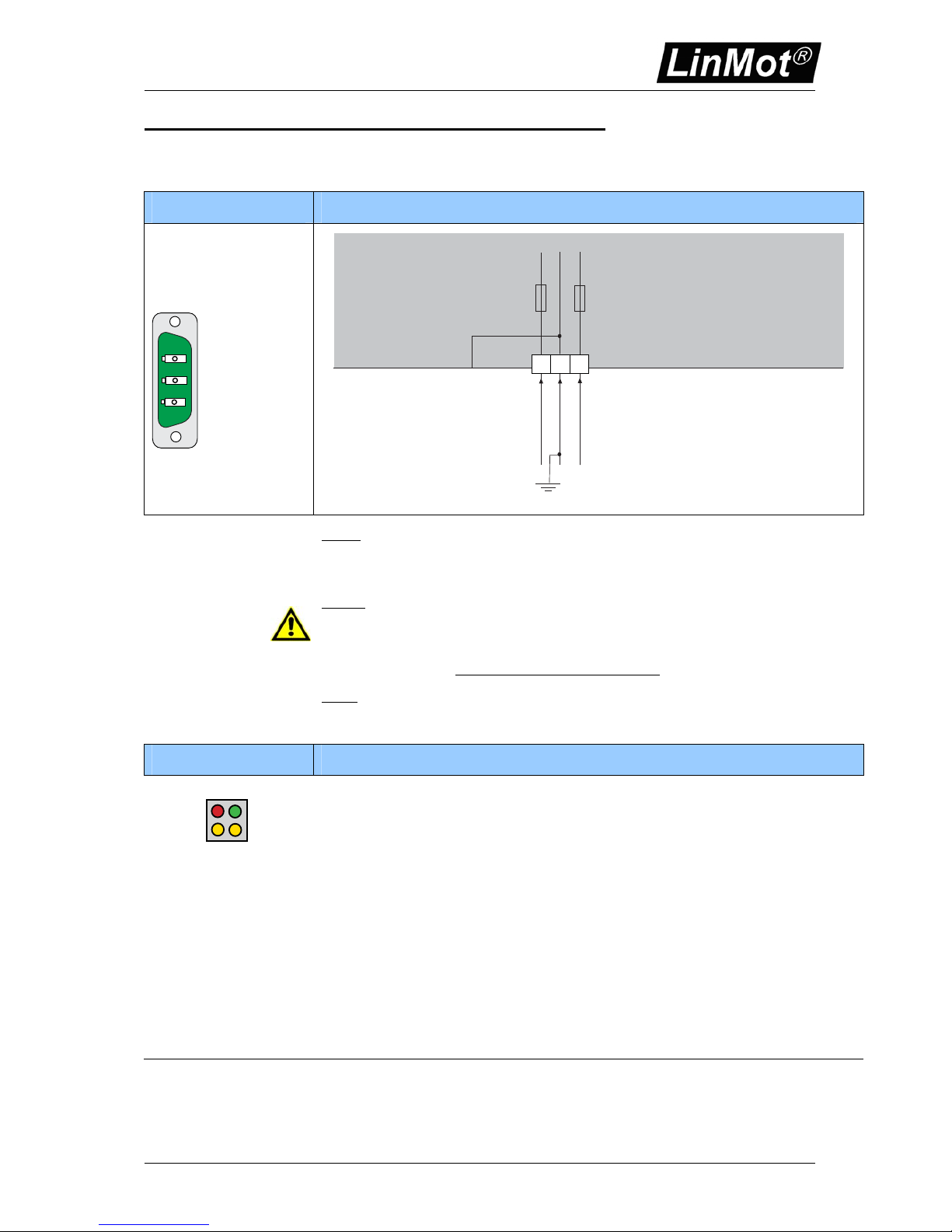

Power Supply

1 PWR Signal+

2 GND

3 PWR Motor+

Power Connector

GND

24...48VDC

24...48VDC

GND internally

connected to

controller housing

Internal

Fuse 10AT

Supply GND

must be externally connected

to earth (Ground Bus)

1

PWR Signal +

GND

2

3

PWR Motor +

24...48VDC

24...48VDC

Internal

Fuse 500mAT

Supply:

Supply Voltage 24...48VDC. Absolute max. Rating 48VDC + 10%

Supply voltage for PWR Signal and PWR Motor may be different

Motor Supply GND must be externally connected to earth

Caution:

By exceeding 53VDC supply voltage, the controller will go into error state. Voltage higher than 55 VDC

will damage the controller!

Do not switch Power Supply DC Voltage. All power supply switching and E-Stop breaks should be

done to the AC supply voltage of the power supplies

Power supply connectors must not be connected or disconnected

while DC voltage is present.

Wiring:

1.5 mm² (AWG16), max length 5 m

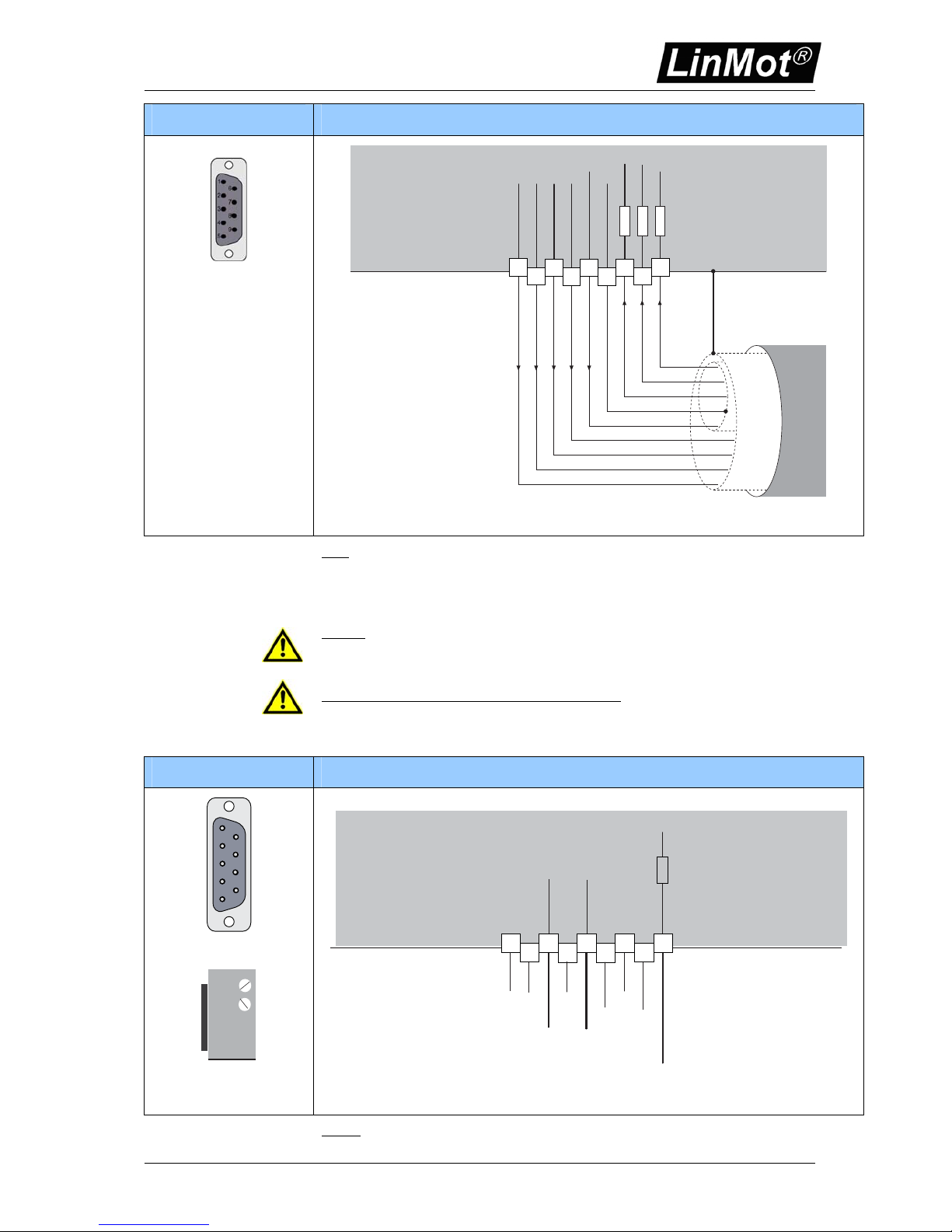

LED State Display

Fault Ready

Stat A Stat B

Ready Green

Stat A Yellow

Stat B Yelllow

Fault red

READY The system has started correctly

STAT A Coding for the actual operating state

STAT B Coding for the actual operating state

The display of the various operating states is shown on the last page of this manual..

FAULT An error has occurred

(In the state ERROR a blink code of the STAT LEDs A and B tells what the actual

error is. The blink codes are explained in chapter ‘Service’of the user Manual.)

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 7/12

Mot A (B,C,D) Motor Connector

DSUB-9 (female)

Cosine

Sine

AGND

+5VDC

Phase 2-

Phase 2+

Phase 1-

Phase 1+

2k2

2k2

10k

Temp.

+5VDC

6

1

2

748

3

9

5

black

green

yellow

inner shield

grey

blue

pink

white

red

Outer shield connected

to connector housing

GND GND

+5VDC

Mot A (B,C,D)

GND

Extension Cable

Note:

- Use only special double-shielded Linear Motor Cable (see datasheet ‘extension cables’)

- Use +5V (Pin 3) and AGND (Pin 8) only for motor internal Hall Sensor supply (max. 100mA).

- Do NOT connect AGND (Pin 8) to ground or earth!

- Inner shield (AGND) and outer shield (earth) must be isolated to each other.

Caution:

- Wrong Motor wiring may damage Linear Motors and/or Servo Controller.

- If you are assembling motor cables by your own, double check motor wiring carefully before power

up.

Do not connect or disconnect the motors from controllers

with voltage present. Wait to connect or disconnect motors until all LinMot controller LED’s have turned off. (Capacitors may not fully discharge for

several minutes after power has been turned off).Failure to observe these precautions may result in severe damage to electronic components in LinMot motors and/or controllers.

Com COM (RS-232, RS-485, CAN)

5

4

3

2

1

9

8

7

6

DSUB-9 (male)

ID high

ID low

ID for RS485 and CAN

(Controller from the bottom)

GND

GND

6

1

2

748

3

9

5

RS-232 TX

1k0

RS-232 RX

CAN L

CAN H

RS-485 Y (TX+)

RS-485 A (RX+)

RS-485 B (RX-)

RS-485 Z (Tx-)

RS232: 9.6kBaud, use 1:1 connection cable to PC

RS485 and CAN needs external termination (see manual)

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 8/12

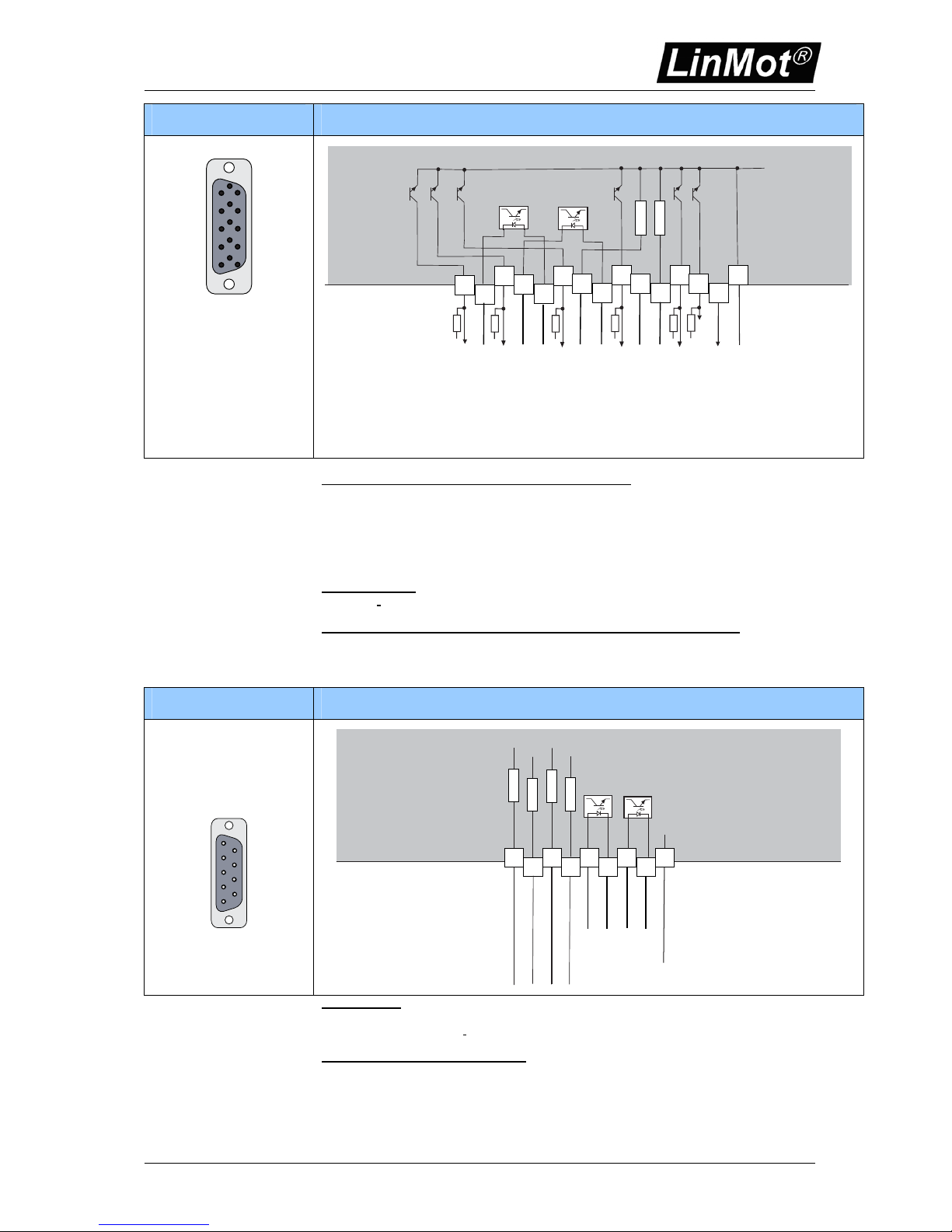

Sys 1 System Connector 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

DSUB-15 (female)

Sys 1

1

11

Emergency Stop -

6

1

7

2

12

8

3

13 14

15

9

10

4

5

GND

Output + 5 V (max 50mA)

Emergency Stop +

Freeze -

Freeze +

GND

100k

100k

do not connect !!

Dig Out 6

Dig Out 5

Warn Out

Error Out

MSG / Dig Out 4

Pos Error / Dig Out 3

Dig In 6

Dig In 5

R

V+

R

V+

R

V+

R

V+

R

V+

R

V+

Emergency Stop (active low) / Freeze input (active high)

Optical isolated inputs

Input voltage: 0 …. 24V

for logical zero < 2V

for logical one > 3.5V

Input current: < 20 mA (internally limited to 20 mA)

Update rate: 1.6 ms

Dig In 5 / Dig In 6

max. 24V,

input resistance 100kOhm for logical zero < 2V for logical one > 3.5V

Dig Outputs: Dig Out 6, Pos Error Out, MSG, Error Out, Warn Out, Dig Out 5

Open Collector max 24V / 50 mA)

Typical pull-up Resistor R: for V+ = 5V supply: R= 150 Ohm / 0.25 W

For V+ = 24V supply: R=820 Ohm / 1W

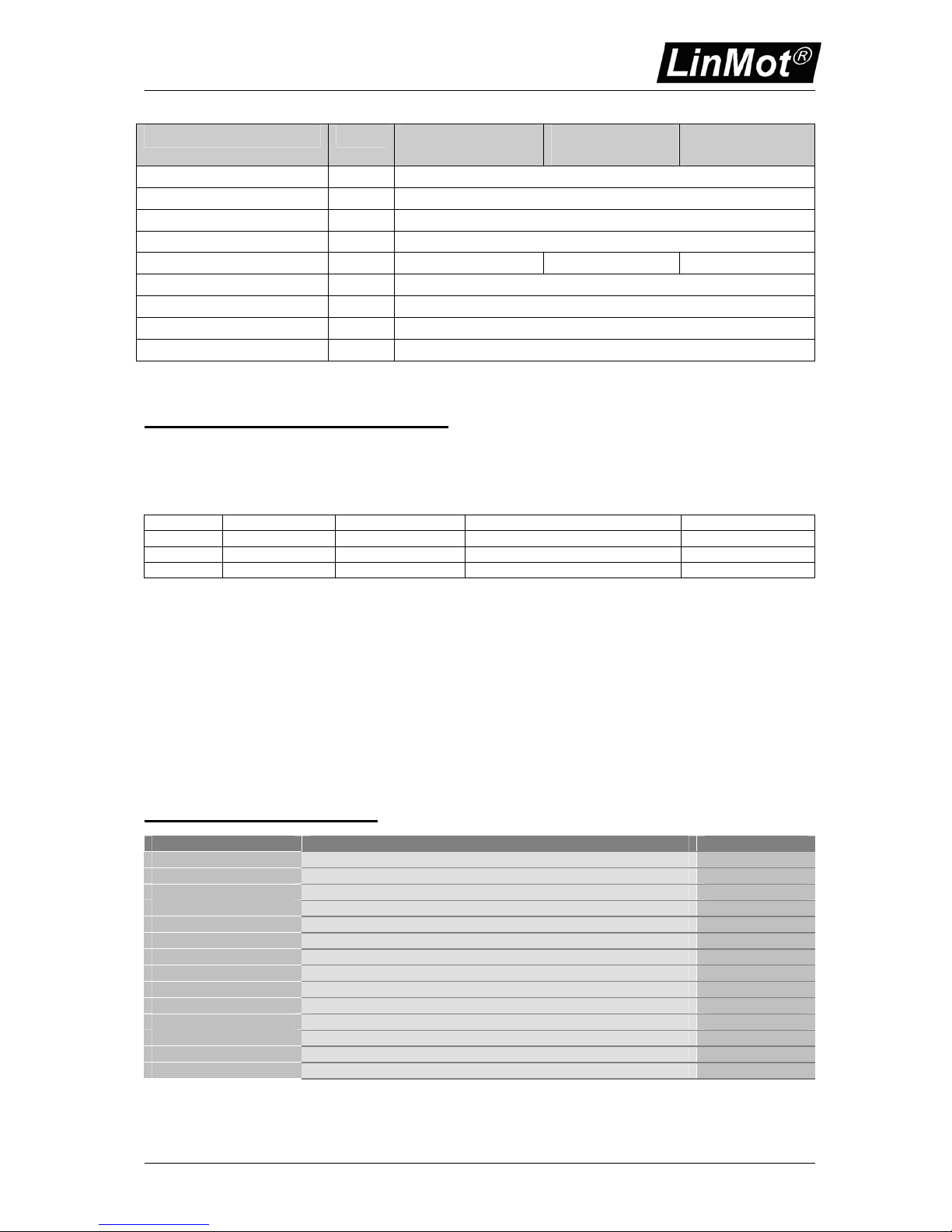

Sys 2 System Connector Sys2

5

4

3

2

1

9

8

7

6

DSUB-9 (male)

Trig/Analog IN 1

Sys 2

GND

GND

6

1

2

748

3

9

5

Trig/Analog IN 4

Trig/Analog IN 2

Trig/Analog IN 3

GND

100k

GND

100k

GND

100k

GND

100k

RUN +

RUN -

INIT +

INIT -

Trig/Analog IN

Input can be used as analog inputs between 0 … 10V (10 bit resolution) input resistance 100kOhm

or digital inputs (max. 24V,

input resistance 100kOhm) for logical zero < 2V for logical one > 3.5V

RUN (active high) / INIT (active high)

Optical isolated inputs

Input voltage: 0 …. 24V

for logical zero < 2V

for logical one > 3.5V

Input current: < 20 mA (internally limited to 20 mA)

Update rate: 1.6 ms

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 9/12

Mechanical Dimension

Dimensions

LinMot

®

-E400

176

55

70

210

119

Centers

194

Fixings for

2 x M5 screws

Dimensions in mm

Recommended mounting for multiple controller installation

Fixings for

2 x M5 screws

Dimensions in mm

LinMot

®

-E400

LinMot

®

-E400

LinMot

®

-E400

50

50

50

50

100

100

100

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 10/12

E100

Single axes controller

E200

2 axes controller

E400

4 axes controller

Width mm (in) 70 (2.8)

Height mm (in) 210 (8.3)

Height without fixings mm (in) 176 (6.9)

Depth mm (in) 119 (4.7)

Weight Kg (lb) 1.1 (2.4) 1.2 (2.7) 1.3 (2.9)

Case IP 40

Storage Temperature °C -25…70

Operating Temperature °C 0…50

Max. Case Temperature °C 65

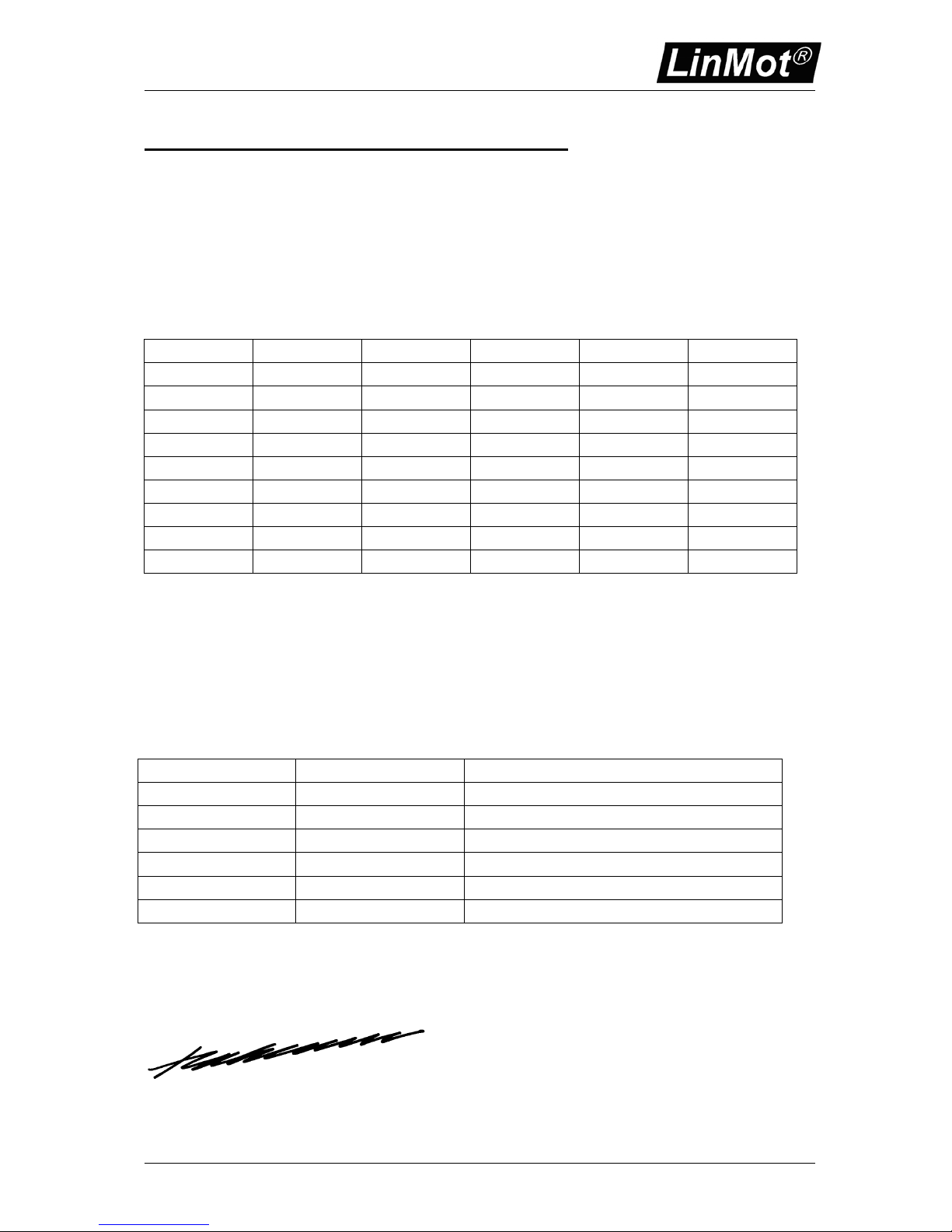

Power Supply Requirement

Power Supply motor

The calculation of the needed power for the Motor supply is depending on the application and the used motor(s).

The following table shows a recommendation for general applications.

Controller Voltage/ Power LinMot Switched- Power Supply Part-Nr.

E100 1 motor 48 V / 150 W S01-48/150 0150-1940

E200 Up to 2 motors 48 V / 300 W S01-48/300 0150-1941

E400 Up to 4 motors 48 V / 300 W S01-48/300 0150-1941

Power Supply signal

24 … 48 V / 5 W

Regeneration of Power

The Ex00 controller don’t use a regeneration resistor. In most application the recuper ated energy will not become

an issue. In cases where the motor power supply voltage will exceeds the voltage limits because of recuper ation

an additional capacitor between ‘PWR motor’ and ‘GND’ should be used. Typical: 22’000 uF.

Ordering Information

Servo Controller Description Art. No.

E100-AT Analog Trigger Controller 1 Axis (48V/3A) 0150-1601

E100-MT Multi Trigger Controller 1 Axis (48V/3A) 0150-1611

E100-DN DeviceNet Controller 1 Axis (48V/3A) 0150-1641

E100-CO CanOpen Controller 1 Axis (48V/3A) 0150-1669

E200-AT Analog Trigger Controller 2 Axis (48V/3A) 0150-1602

E200-MT Multi Trigger Controller 2 Axis (48V/3A) 0150-1612

E200-DN DeviceNet Controller 2 Axis (48V/3A) 0150-1642

E200-CO CanOpen Controller 2 Axis (48V/3A) 0150-1670

E400-AT Analog Trigger Controller 4 Axis (48V/3A) 0150-1604

E400-MT Multi Trigger Controller 4 Axis (48V/3A) 0150-1614

E400-DN DeviceNet Controller 4 Axis (48V/3A) 0150-1644

E400-CO CanOpen Controller 4 Axis (48V/3A) 0150-1672

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 11/12

Declaration of Conformity CE-Marking

Manufacturer: NTI AG

LinMot

®

Technoparkstrasse 1

8005 Zurich

Switzerland

Tel.: +41 (0) 1 445 22 82

Fax: +41 (0) 1 445 22 81

Products: LinMot

®

Controllers

Type Art.-No. Type Art-No. Type Art.-No.

E100-AT 0150-1601 E100-MT 0150-1611

E200-AT 0150-1602 E200-MT 0150-1612

E400-AT 0150-1604 E400-MT 0150-1614

E100-DN 0150-1641 E100-CO 0150-1669

E200-DN 0150-1642 E200-CO 0150-1670

E400-DN 0150-1644 E400-CO 0150-1672

The product must be mounted and used in strict accordance with the installation instruction contained

within the User’s Manual, a copy of which may be obtained from NTI Ltd.

I declare that as the authorized representative, the above information in relation to the

supply/manufacture of this product is in conformity with the stated standards and other related

documents in compliance with the protection requirements of the Electromagnetic Compatibility (EMC)

Directive 2004/108/EC.

Standards Complied with:

EMI EN 55011 Class A

EN 61000-6-4

Electromagnetic EN 61000-4-2 4 kV / 8kV

Suspectibility EMC EN 61000-4-4 1 kV / 2kV

EN 61000-6-2 EN 61000-4-3 10 V/m

EN 61000-4-6 10 V

ENV 50204 10 V/m

Company

NTI Ltd.

Spreitenbach, July 28, 2010

----------------------------------------------------------R. Rohner / CEO NTI AG

Controller Series E100/200/400

NTI AG Installation: E100/E200/E400 series / 28.07.2010 Page 12/12

Error codes

Error display When an error occurs it is displayed by means of the blinking of at least one of the four

LEDs on the front of the servo controller.

Ready LED The Ready LED is ON as soon as the supply voltage for the processor is guaranteed and

the system has started up correctly. Communication with the PC over the serial interface is only

possible when this LED is ON.

The following table summarizes the blink codes and their meaning:

F

LED Description

Fault Stat A Stat B

z ~ 3Hz

HW system error: Hardware error in the servo controller.

2x z ~ 1Hz SW1 System error: Software error in the servo controller. The system

software wasn’t loaded successfully.

z ~ 1Hz

off

off

SW2 System error: Software error in the servo controller. The system

software wasn’t loaded successfully.

On z ~ 2Hz z ~ 2Hz

Generic fault: The exact error message may be displayed

with the error inspector.

2x z

The supply voltage for the Power circuitry is too low.

3x z

The supply voltage for the Power circuitry is too high.

4x z

The supply voltage for the Signal circuitry is too low.

5x z

The supply voltage for the Signal circuitry is too high.

6x z

The servo controller is too hot.

8x z

Application Software Error (see manual)

1x z

The motor is overloaded.

2x z

The motor is too hot.

3x z

Following error.

4x z

The slider is missing from the motor.

6x z

The initialization was not completed successfully.

7x z

Incorrect motor type configured or damaged motor.

On

1x z: Mot A

2x z: Mot B

3x z: Mot C

4x z: Mot D

8x z A referenced motion profile for a motor is missing. Selected motion

profile not valid for actual drive type.

on LED is ON z LED blinks shortly (ca. ¼s)

off LED is OFF LED blinks longer (ca. 1½s)

Contact Addresses

NTI AG

LinMot Tel.: +41 (0)56-419 91 91

Haerdlistrasse 15 Fax: +41 (0)56-419 91 92

CH-8957 Spreitenbach E-Mail: office@linmot.com

Schweiz Web: www.linmot.com

LinMot Inc. Sales: 877-546-3270

5750 Townline Road 262-743-2555

Elkhorn Tech. Service: 877-804-0718

WI 53121 262-743-1284

USA Fax: 800-463-8708

262-723-6688

E-Mail: sales@linmot-usa.com

Web: www.linnmot-usa.com

Loading...

Loading...