Operator’s Manual

VIKING PAPR 3350 WELDING HELMET

POWERED AIR-PURIFYING RESPIRATOR (PAPR)

WITH VIKING 3350 AUTO-DARKENING HELMET

PRODUCT NUMBER:

K3930-1

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

K#: (ex: K3930-1)

Serial: (ex: U1060512345)

WARNING: Users must read and understand the

user instructions prior to use. Use of this respirator

by untrained or unqualified people, or use that is not

in accordance with these user instructions, may

adversely affect respirator performance and may

be dangerous to your health. Keep this operator’s

manual for future reference.

IM10151 | Issue D ate May-17

© Lincoln Global, Inc. All Rights Reserved.

SAFETY WARNINGS – READ BEFORE USING

Refer to http: //www.lincolnelectric.com/safety for additional safety information.

SAFETY

FUMES AND GASES can be dangerous to your health

• Fumes from the normal use of welding

products contain significant quantities of

potentially hazardous compounds. See

consumable product label/insert.

• Keep your head out of fumes.

• Use enough ventilation or local exhaust to keep fumes and

gases from your breathing zone and general area.

• An approved respirator should be used unless exposure

assessments are below applicable exposure limits.

• When welding with electrodes which may require additional

ventilation such as stainless or hard facing (see instructions on

container or Safety Data Sheet (SDS) or on lead or cadmium

plated steel and other metals or coatings which produce highly

toxic fumes, keep exposure as low as possible and within

applicable OSHA PEL and ACGIH TLV limits using local exhaust

or mechanical ventilation. In confined spaces or in some

circumstances, outdoors, a respirator may be required.

Additional precautions are also required when welding on

galvanized steel.

.

NIOSH approval

IMPORTANT: THIS RESPIRATOR IS INTENDED TO BE USED BY

TRAINED INDIVIDUALS IN ACCORDANCE WITH

ALL THE PROVISIONS OF AN ORGANIZED

RESPIRATORY PROTECTION PROGRAM WHICH

COMPLIES WITH THE REQUIREMENTS OF THE

OSHA STANDARD 29 CFR 1910.134 AVAILABLE

FROM THE US DEPARTMENT OF LABOR,

OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION OR IN CANADA CONFORMANCE WITH

CSA Z94.4.

The Viking PAPR 3350 is approved in the USA by NIOSH for use

in environments where:

he Viking PAPR 3350 respirator components and filtration

T

media must be used only in configurations listed on the NIOSH

approval label. Refer to NIOSH approval label for list of approved

components.

This respirator is not capable of or approved for use in an area

which includes hazardous levels of gases . It is only effective to

filter out particulate contaminants.

ARC Rays can injure eyes and burn skin

• Before welding, always inspect helmet and

filter lens to be sure they are fitted

properly, in good condition and not

damaged.

• Check to see that the clear lens is clean and securely attached

to the helmet.

• Always wear safety glasses with side shields or goggles under

the welding helmet and protective clothing to protect your

skin from radiation, burns and spatter.

• Ensure that optical radiation from other welder’s arcs in the

immediate area does not enter in from behind the helmet

and auto-darkening filter.

• Stop welding immediately if the auto-darkening lens does not

darken when arc is struck. See instruction manual

for troubleshooting information.

• Do not weld in the overhead position while using this

helmet.

Note: Auto-darkening filters in Lincoln helmets are designed to

protect the user against harmful ultra-violet and infrared

rays both in the dark and light states. No matter what

shade the filter is set to, the UV/IR protection is always

present.

• Particulate concentrations are known and characterized.

• Particulate concentrations are not I mmediately Dangerous to

Life or Health (IDLH).

• Atmospheres are NOT oxygen deficient.

• Contaminant concentrations do not exceed the Maximum Use

Concentration (MUC) determined using the Assigned Protection

Factor (APF) for specific respirator system or the APF

mandated by specific government standards, whichever is

lower.

2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser

upon receipt by the carrier. Consequently, claims for material

damaged in shipment must be made by the purchaser against the

transportation company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built

with safety in mind. However, your overall safety can be increased

by proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED THROUGHOUT. And, most importantly,

think before you act and be careful.

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

This statement appears where the information must be followed

to avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc.

Use corrective lenses if necessary

to stay a reasonable distance

away from the arc.

READ and obey the Safety Data

Sheet (SDS) and the warning label

that appears on all containers of

welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to

keep the fumes and gases from

your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away

from your face.

If you de velop unusual symptoms, see your supervisor.

Perhaps the welding atmosphere and ventilation system

should be checked.

WEAR CORRECT EYE, EAR &

BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare

with protective screens or barriers.

IN SOME AREAS, protection from noise may be appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

AT ALL TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously

had been in contact with hazardous substances unless they are

properly cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release

highly toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat,

mechanical shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an

electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

WARNING

CAUTION

Safety 01 of 04 - 5/16/2018

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

WARNING: Breathing diesel engine exhaust

exposes you to chemicals known to the State

of California to cause cancer and birth defects,

or other reproductive harm.

• Always start and operate the engine in a

well-ventilated area.

• If in an exposed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information go to

www.P65 warnings.ca.gov/diesel

WARNING: This product, when used for welding or

cutting, produces fumes or gases which contain

chemicals known to the State of California to cause

birth defects and, in some cases, cancer. (California

Health & Safety Code § 25249.5 et seq.)

WARNING: Cancer and Reproductive Harm

www.P65warnings.ca.gov

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For

additional safety information, it is strongly recommended

that you purchase a copy of “Safety in Welding & Cutting ANSI Standard Z49.1” from the American Welding Society,

P.O. Box 351040, Miami, Florida 33135 or CSA Standard

W117.2-1974. A Free copy of “Arc Welding Safety” booklet

E205 is available from the Lincoln Electric Company,

22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated areas or vent the engine

exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame welding

arc or when the engine is running. Stop the

engine and allow it to cool before refueling to

prevent spilled fuel from vaporizing on contact

with hot engine parts and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

1.d. Keep all equipment safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF).

Welding current creates EMF fields around welding cables

and welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

SAFETY

Safety 02 of 04 - 5/16/2018

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

between the

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see It ems 6.c. and 8.

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

hardfacing (see instructions on container or SDS)

or on lead or cadmium plated steel and other

metals or coatings which produce highly toxic

fumes, keep exposure as low as possible and

within applicable OSHA PEL and ACGIH TLV limits

using local exhaust or mechanical ventilation

unless exposure assessments indicate otherwise.

In confined spaces or in some circumstances,

outdoors, a respirator may also be required.

Additional precautions are also required when

welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

Safety Data Sheet (SDS) and follow your employer’s safety

practices. SDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

SAFETY

Safety 03 of 04 - 5/16/2018

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and hot

materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

6.I. Read and follow NFPA 51B “Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, MA 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in Cylinders,” available from

the Compressed Gas Association, 14501 George Carter Way

Chantilly, VA 20151.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

SAFETY

Safety 04 of 04 - 5/16/2018

SA

T

ab

Po

Au

W

Par

F

l

we

to-

ar

ts

E

T

Y

A

r

c

N

I

O

S

S

tan

e

of

N

i

os

r

e

d

Res

p

Batter

I

n

s

tal

Fi

l

ter

Br

eath

S

h

ou

Res

p

A

i

r

Fl

A

i

r

Fl

P

r

ep

Don

Res

p

T

rou

Dar

H

elm

A

u

to-Darken

W

eld

Cartrid

S

h

ad

Cartrid

T

roub

H

elm

H

elm

Op

tion

r

an

ty

Pag

W

A

R

W

el

d

H

ap

d

ar

d

Con

ten

h

Cau

A

i

r

i

r

ator

y

O

l

i

n

g

I

n

s

i

n

l

d

er

i

r

ator

ow

ow

ar

i

n

n

in

g

irator

b

le

S

k

e

n

et/

Len

in

g

g

e

e

G

g

e

le

S

et

W

et

Replacem

al

In

for

e

s.

N

IN

i

n

g

p

r

ov

S

afety

ts

ti

on

-

Pu

r

S

p

p

er

Batter

tal

l

ati

g

T

u

S

tr

ap

Con

A

l

ar

Con

g

For

Proced

Main

h

ootin

i

n

g

s

H

elm

Op

u

id

e

an

d

hooting

arranty

A

cces

m

.

.

.

.

.

.

.

G

S

–

S

afety

al

.

.

.

W

.

.

.

.

.

.

.

.

s

an

i

f

yi

n

eci

fi

ati

on

y

on

.

.

b

e

I

n

I

n

s

tr

ol

m

O

p

tr

ol

.

.

.

Us

e

u

re

ten

g

He

l

m

In

form

in

g

Len

et

Op

eration

S

ettin

Len

In

s

ories

ati

on

.

.

.

.

.

.

.

R

.

.

.

.

ar

.

.

.

d

g

cati

s

.

.

P

ack

.

.

.

s

tal

tal

s

.

er

.

.

.

.

.

.

an

G

u

e

eratin

/

g

s

G

u

form

en

.

.

.

.

.

.

E

A

.

.

.

.

.

.

.

.

.

.

n

i

.

.

.

.

Li

m

R

e

sp

on

.

.

.

.

.

.

.

.

.

l

ati

l

ati

.

.

.

.

.

ati

.

.

.

.

.

.

.

.

.

for

ce

ide

t

Se

ation

s

S

Featu

s

.

.

Rep

id

e

t

Parts

.

.

.

.

.

.

.

.

.

.

.

.

D

.

.

n

.

.

.

.

on

.

.

.

.

.

B

E

F

O

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

g

s

for

.

.

.

.

.

.

.

.

.

.

.

i

tati

on

i

r

a

t

o

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

on

.

.

.

.

.

on

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Res

p

irator

an

d

S

For

Res

c

ti

on

.

.

.

.

.

.

.

.

.

.

.

p

ecification

g

In

s

tru

res

.

.

.

.

.

.

.

.

.

.

.

.

.

lacem

en

for

H

elm

ation

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

R

E

.

.

.

.

.

.

.

.

.

.

P

ow

.

.

.

.

.

s

.

.

.

r

Se

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

torag

p

irator

.

.

.

.

.

.

.

.

ction

.

.

.

.

.

.

.

.

.

t.

et

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

U

SE

.

.

.

.

.

.

.

.

er

.

.

.

.

.

.

.

.

c

t

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

e.

.

.

.

.

.

.

.

s

.

.

.

.

.

.

.

.

.

.

.

.

Cartrid

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

TABLE OF CONTENTS

P

a

g

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

S

ou

r

ces

an

d

W

i

r

e

Feed

er

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3

th

r

u

6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.7

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 8

i

o

n

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 8

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

9

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

0

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

1

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

3

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

4

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

5

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

7

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.18

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

18

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

19

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.20

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

20

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 21

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

22

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

23

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 24

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.25

ge

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

26

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 27

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 27

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 27

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 28

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 28,

29

7

IKING PAPR 3350 WELDING HELMET

V

NIOSH CAUTIONS AND LIMITATIONS

A – Not for use in atmospheres containing less than 19.5%

oxygen.

B – Not for use in atmospheres immediately dangerous to life or

ealth.

h

– Do not exceed maximum use concentrations established by

C

regulatory standards.

F – Do not use powered air-purifying respirators if airflow is less

than four cfm (115 lpm) for tight fitting

facepieces or six cfm (170 lpm) for hoods and/or helmets.

I – Contains electrical parts that may cause an ignition in

flammable or explosive atmospheres.

J - Failure to properly use and maintain this product could result

in injury or death.

L – Follow the manufacturer’s User’s Instructions for changing

cartridges, canister and/or filters.

M – All approved respirators shall be selected, fitted, used, and

maintained in accordance with MSHA, OSHA, and other

applicable regulations.

N – Never substitute, modify, add, or omit parts. Use only exact

eplacement parts in the configuration as specified by the

r

manufacturer.

O - Refer to User’s Instructions, and/or maintenance manuals for

information on use and maintenance of these respirators.

P - NIOSH does not evaluate respirators for use as surgical

masks.

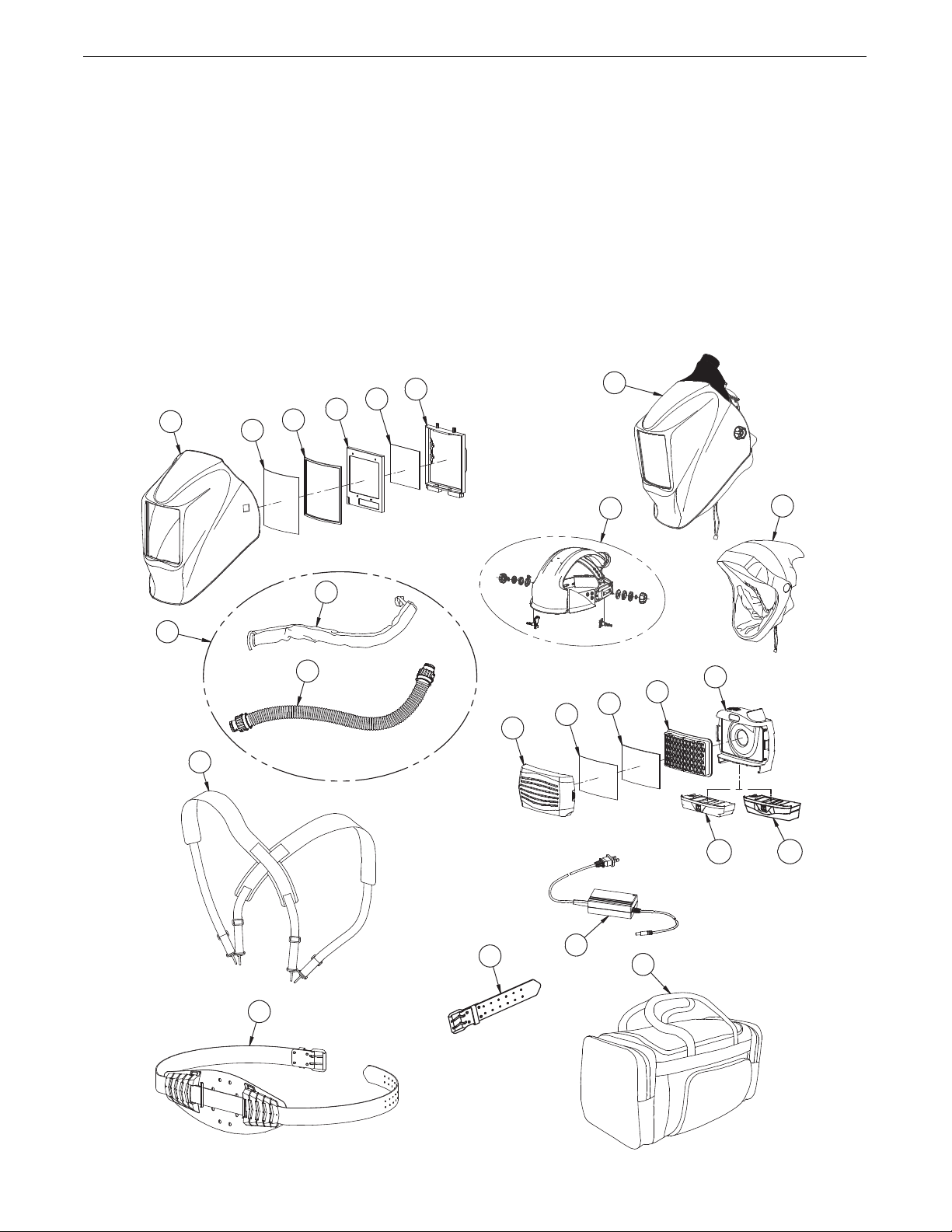

POWERED AIR-PURIFYING RESPIRATOR SECTION

RESPIRATOR SPECIFICATIONS

Size of Blower Assembly 8” W x 7.5” T x 3” D (203 x 191 x 76 mm)

Weight of Blower (including battery, belt, and filters) 47 oz. (1338 g)

Weight of Helmet Assembly 32 oz. (899 g)

Air Flow Low Speed: 170+ lpm (6+ cfm)

High Speed: 210+ lpm (7.4+ cfm)

Operating Temperature 23°F to 131°F (-5°C to 55°C)

Storage Temperature 23°F to 131°F (-5°C to 55°C)

Battery Type Lithium Ion (Rechargeable)

Battery Charge Time About three hours

Battery Life Approximately 500 charges

Belt Size

Helmet Compliance ANSI Z87.1-2010, CSA Z94.3, CE EN 379

Respirator Approval

Assigned Protection Factor

(3)

(1)

(2)

29 to 52 in. (736 to 1321 mm)

NIOSH 42 cfr 84 Approved Powered Air-Purifying Respirator (PAPR)

25

(1) Refer to NIOSH respirator approval label for system configuration.

(2) APF=25 for loose fitting Powered Air-Purifying Respirator according to OSHA 3352-02 2009, when the employer implements a con-

tinuing, effective respirator program in compliance with the Respiratory Protection Standard (29 CFR 1910.134).

(3) Belt size maximum of 60 in.(1524 m) with belt extension accessory (see Parts Page in this manual)

8

VIKING PAPR 3350 WELDING HELMET

Battery

Pack

Battery

Terminal

Battery

Charger

Indicator

Light

BATTERY OPERATION

WARNING

Battery Safety

Keep battery away from fire or heat as this may cause

•

the battery to explode and may result in serious injury

or death.

• Battery should be charged with supplied Li-ion charger

only. Charge in an open, well-ventilated location.

• The charger is designed only for use indoors.

• Do not allow the battery to get wet.

• Do not attempt to disassemble or repair the battery.

There is no maintenance on Li-ion batteries.

• Battery disposal – battery must be disposed of properly

or recycled.

Charging of battery pack

• Charge battery before first use or if battery has not

been used for one week. Always recharge the battery

before it becomes fully discharged.

• Batteries not in use should be charged at least once a

year.

Remove battery pack from blower assembly. Connect charger cord

to battery terminal. Plug charger into 120/240 VAC receptacle. The

battery pack does not need to be discharged before it is charged.

The charger indicator light will turn red in color when battery pack is

being charged. When battery pack is finished charging, the indicator

light will turn green letting the user know that the battery is fully

charged (normal charge time approximately 3 hours). Although it is

okay to leave the battery pack connected to the charger, it is

recommended that once the battery pack is fully charged to

disconnect battery pack from charger.

FIGURE 1

9

INSTALLING BATTERY PACK

Blower

Unit

Battery

Pack

Latch

O

p

e

n

VIKING PAPR 3350 WELDING HELMET

FIGURE 2

Slide battery pack into blower unit just below filter cover until battery

pack latch snaps into position. It is very important that the battery

pack snaps into position. This makes sure the battery pack is locked

in place and will not slide out causing possible nuisance shutoffs

while in use.

To remove battery pack, simply push down on latch to release and

slide battery pack out from blower unit.

10

VIKING PAPR 3350 WELDING HELMET

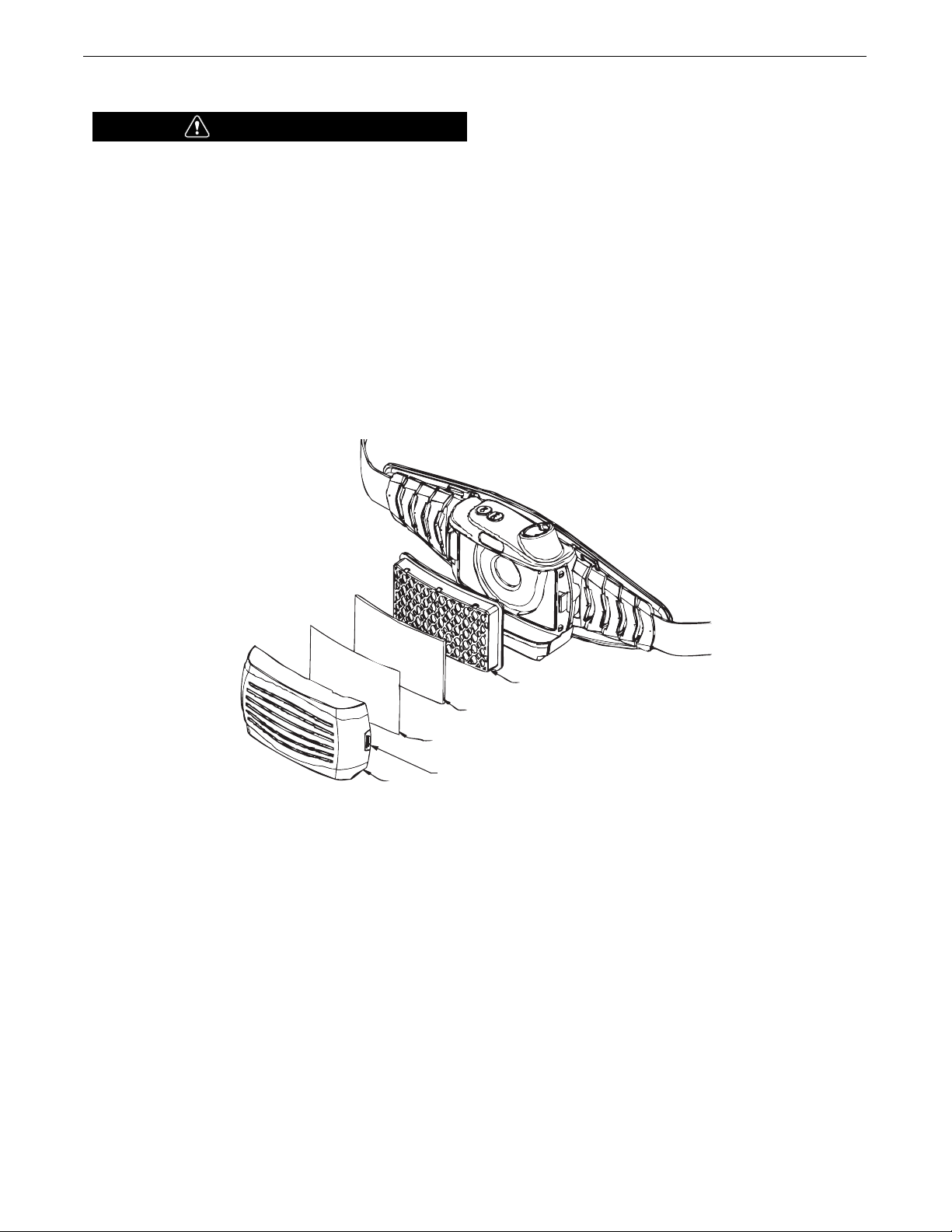

Particulate

Filter

Pre-Filter

Spark

Screen

Latch

Filter

Cover

FILTER INSTALLATION

WARNING

Filter Safety

• Do not use the respirator without the spark screen, prefilter, and the HE particulate filter (HEPA) installed. The

NIOSH approval of this PAPR is with the spark screen,

pre-filter and HE particulate filter installed using

respirator without any of these items is not in accordance

with NIOSH approval and may be dangerous to your

ealth.

h

• Replace air filters when damaged or clogged. DO NOT

wash, clean with compressed air or reuse dirty air filters.

• Use specific replacement filters specified in this manual.

Use of other filters is in violation of the NIOSH approval

of the respirator system. Refer to NIOSH respirator

approval label for system configuration.

FIGURE 3

Install the spark screen, pre-filter, and particulate filter in filter cover

exactly as shown.

Install the filter cover assembly to the blower unit by engaging tabs

on filter cover into bracket on blower unit and rotate assembly to

close. Push filter cover assembly down until latch clicks into position

securing filter cover assembly. Make sure the filter cover assembly

is secure to the blower unit body. Inspect both latching side of cover

and opposite side to see that the filter cover is properly secured.

To replace filter, push latch into release filter cover and replace filter

as shown in figure 3. Refer to NIOSH respirator approval label and/or

parts page at the back of this operator’s manual for proper filters to

be used with this respirator.

11

VIKING PAPR 3350 WELDING HELMET

Breathing

Tube

Breathing

Tube Connector

Receptacle

O-Ring

BREATHING TUBE INSTALLATION

WARNING

Breathing tube safety

Be sure breathing tube is properly installed or non-

•

filtered air may enter the helmet.

• Be sure o-ring is properly installed on tube connector and

there are no visible signs of cuts or tears on o-ring.

Replace o-ring if damaged.

• Do not use respirator if o-ring is missing.

FIGURE 4

Connecting breathing tube to blower

Align pins of tube connector with channels in blower unit receptacle.

Insert connector as far as it will go into blower unit and the turn

connector 1/8 of a turn clockwise to secure this end of breathing

tube.

Connecting breathing tube to helmet

Align pins of tube connector with channels in helmet receptacle.

Insert connector as far as it will go into helmet receptacle and the

turn connector 1/8 of a turn clockwise to secure this end of breathing

tube. If tube is twisted, disconnect one end of breathing tube.

Untwist tube and re-attach.

To remove breathing tube turn connector 1/8 of a turn counter

clockwise and pull connector out to release from helmet or blower

unit.

12

VIKING PAPR 3350 WELDING HELMET

Shoulder Strap

Assembly

Hook

Belt Attachment

Location

SHOULDER STRAP INSTALLATION

Connect hooks (4 total) on shoulder strap assembly to belt attachment

points as shown.

FIGURE 5

13

RESPIRATOR CONTROLS

180

VIKING PAPR 3350 WELDING HELMET

FIGURE 6

WARNING

Respirator Use

If an alarm sounds or the blower vibrates, leave the work

area immediately. Do not remove the respirator until you

are in a safe area.

Starting the Respirator

Press ON button for 1 to 2 seconds until the blower is activated. An

audible sound will be heard and the user interface will light up. The

blower will always start at the low air flow setting (180 lpm).

Pressing the ON button again will switch to the high air flow setting

(210 lpm). The user interface will show the air flow setting chosen.

Stopping the Respirator

Press OFF button for 2 seconds until blower stops. When pressing

OFF button, an audible beeping sound indicates the OFF button has

been depressed. Beeping sound will stop and the user interface will

darken when blower unit is off.

Battery Level Indicator

This indicator gives the user an estimate of the battery life

remaining. When three full bars show up in the display, the battery

is fully charged.

Filter Life Indicator

This indicator gives the user an estimate of the filter life remaining.

When three full bars show up in the display, the filter is in need of

changing. When zero bars show up in the display, the particulate

filter is clean. As the bars appear, the filter is becoming clogged and

a reduction in battery life is expected. Operating respirator with

filter indicator showing a clogged filter will significantly reduce the

battery life/run time.

14

VIKING PAPR 3350 WELDING HELMET

BLOCK AIR FLOW

WITH HAND

AIR FLOW ALARM OPERATION

Air Flow Alarm

• The control system of the blower unit maintains the air flow rates

consistently throughout the operating time. If the air flow alarm is

activated, the filter may need to be replaced and/or breathing tube

as become blocked.

h

FIGURE 7

• Always test air flow alarm prior to using respirator.

• If an alarm sounds or the blower vibrates, leave work area

immediately. Do not remove the respirator until you are in a safe

area.

Testing of Air Flow Alarm

Testing of air flow alarm must always be done in a safe enviroment.

Disconnect breathing tube from helmet. Start blower unit and block

air flow by placing your hand over the end of the breathing tube as

shown. Hold your hand over end of tube as shown until alarm sounds

and blower vibrates (approximately 15 to 30 seconds).

If the alarm does not activate return unit for repair and do not use.

15

AIR FLOW CONTROL

VIKING PAPR 3350 WELDING HELMET

FIGURE 8

Adjust Air Flow Baffle as shown. Air flow baffle allows for air to be

distributed to all three air outlets (open position) or to be shutoff

(closed position) to the forehead outlet pushing more air to the other

two side air outlets. Baffle can also be adjusted to reduce the amount

of air being delivered from the forehead air outlet. This allows the

user to adjust the amount of air delivered at multiple outlets to

provide maximum comfort. The default position for this baffle will be

open for air to be distributed to all three air outlets.

There is also a Front Air Director to change the direction of the air

exiting the front air outlet. The Front Air Director does not affect the

volume of air exiting the front air outlet but may be adjusted by the

user to enhance comfort.

NOTE: Varying the air flow baffle will not adversely affect respiratory

protection.

16

PREPARING FOR USE

VIKING PAPR 3350 WELDING HELMET

FIGURE 9

Before using Respirator – Check the Following Items

1. Blower Assembly

• Verify the air filter is proper for application and is NIOSH

approved for use with this respirator. Verify the spark screen,

pre-filter and particulate filter are properly installed and

securely latched.

2. Breathing Tube

• Make sure tube is not damaged and connected properly to the

blower unit and helmet.

3. Battery

• Verify connection to blower unit is secure and that battery is

fully charged.

4. Air Flow/Air Flow Alarms

• Start blower unit and verify air flow rate is being maintained by

checking for air flow alarm activation. Test to verify air flow

alarm is working (see page 15 for procedure).

5. Helmet/Hood

• Inspect helmet for damage and replace if necessary. If air from

blower is not being supplied to helmet, see troubleshooting

guide (page 15).

17

VIKING PAPR 3350 WELDING HELMET

DONNING PROCEDURE FOR RESPIRATOR

WARNING

Respirator Safety

Do not enter a hazardous area until you are sure the

•

respirator equipment is functioning correctly and

properly worn.

• Leave the contaminated area immediately if the alarm

sounds or the blower vibrates. Do not remove

equipment until you are in a safe area.

• It is recommended that the user practice the donning

and wearing of the respirator before attempting to use

the respirator for respiratory protection.

• Do not use the powered air-purifying respirator without

all filter components or with blower turned off or

hazardous levels of oxygen and carbon dioxide may

accumulate in the helmet.

Donning respirator

NOTE: Make sure all procedures within preparing for use have

been completed, prior to donning.

1. Put the blower assembly on against your lower back with hose

extending upwards. Extend arms through shoulder straps, allow

straps to go over shoulders and belt around waist. Adjust

shoulder straps and belt so blower unit rests against lower back

properly.

2. Start the blower unit by pressing the ON button. Adjust air flow

rate.

3. Connect the hose to the helmet assembly. Put on helmet and

adjust so helmet fits snug on head. Tighten drawing string of face

covering to establish a seal around head.

WARNING

Respirator Maintenance And Storage

Replace damaged or dirty air filters. Filters cannot be

•

washed or cleaned with compressed air. Never reuse a

dirty air filter.

• Never use solvents or abrasive cleaning solutions to

clean the respirator. Keep water and other fluids out of

blower assembly.

Maintain accurate records of filter replacement and respirator

maintenance.

The respirator components should be cleaned after each use. Use of

a soft cloth dampened with a mild soap and water solution to wipe all

external surfaces of blower unit clean. Allow to dry.

Factors including product usage and workplace contamination levels

affect the life of the filters. Replace filters if air flow is reduced

because of dirty filter and according to the filter change schedule

established by your Safety Director and an Industrial Hygienist.

Inspection of blower assembly and breathing tube after each use is

good practice. Replace breathing tube if damaged or if inside of tube

is dirty.

Storage of respirator should be in a clean, dry, cool place with the

filter and battery removed for blower assembly if respirator will not

be used for an extended period of time.

Respirator removal

NOTE: Leave contaminated area before removing the helmet

and blower unit.

1. Take off helmet and disconnect hose from helmet.

2. Turn off blower unit by pressing OFF button.

3. Release belt, remove straps from shoulders and remove blower

unit off of your lower back.

After use, the respirator components must be cleaned, inspected

and prepared for reuse (battery charged).

18

VIKING PAPR 3350 WELDING HELMET

TROUBLE SHOOTING GUIDE FOR RESPIRATOR

PROBLEMS

(SYMPTOMS)

o air flow to helmet from blower.

N

Blower supplies insufficient air to

helmet.

Low airflow alarm (audible & vibratory).

Battery alarm (audible & vibratory).

User detects odor or taste of contaminants or feels eye or throat irritation.

POSSIBLE

CAUSE

. Blower not ON.

1

2. Battery not charged.

. Battery connection not being

3

made.

4. Breathing tube blocked.

1. Breathing tube connections not

properly connected.

2. Clogged filter.

1. Breathing tube is blocked.

2. Filter inlet is covered.

3.Clogged filter.

1. Low battery.

1. Incorrect respirator for application.

2. Hose connections loose allowing

air to enter downstream of blower.

3. Filter

RECOMMENDED

COURSE OF ACTION

. Press ON button.

1

2. Charge battery.

. Verify battery pack is securely

3

latched into blower unit.

4. Clear obstruction from blower out-

let and/or hose.

1. Check breathing tube connections

to blower and helmet.

2. Replace filter.

1. Clear obstruction from blower out-

let and/or hose

2. Make sure inlet to filter not

restricted.

3. Replace filter.

1.Charge battery or replace battery

as required.

1. Consult onsite Industrial Hygienist

or safety director for proper equipment for work environment.

2. Check hose connections to blower

and helmet.

3. Leave area wearing respirator.

Check filter and replace if necessary.

Battery run time is too short.

The motor runs “faster than normal”

(increased sound level).

1. Inadequate charging.

2. Clogged filter.

3. Battery faulty.

1. Filter is getting clogged.

1. Fully charge battery.

2. Replace filter.

3. Replace battery with new one.

1. Replace filter and pre-filter as

required.

19

VIKING PAPR 3350 WELDING HELMET

AUTO-DARKENING HELMET SECTION

HELMET/LENS INFORMATION

The Auto-Darkening Lens in this welding helmet will automatically

change from light state (Shade 3.5) to dark state (5-13) when arc is

initiated.

The lens automatically returns to a light state when the arc stops.

Before welding, match your welding application to the shade

indicated on the shade guide setting chart. (See Page 20) Also adjust

the sensitivity setting to your welding application/environment.

This Auto-Darkening Welding Helmet is designed for use with

GMAW, GTAW, SMAW welding, or Plasma Arc and air carbon arc

cutting.

The Auto-Darkening Lens provides protection from harmful UV and

IR radiation, in both dark and light states. No matter what shade the

lens is set to, the UV/IR protection is always present.

The Auto-Darkening Lens contains four sensors to detect the light

from the welding arc, resulting in the lens darkening to a selected

welding shade.

• Do not use solvents or abrasive cleaning detergent.

• Keep the sensors and solar cell clean.

• If cover lens is spattered or covered with dirt, it should be replaced

immediately.

• Use only replacement parts specified in this manual.

• Do not use the helmet without inside and outside cover lenses

properly installed.

• Do not use the auto-darkening lens if damaged by shock, vibration

or pressure.

20

VIKING PAPR 3350 WELDING HELMET

AUTO-DARKENING LENS SPECIFICATIONS

Optical Class 1/1/1/1 (per EN 379)

LCD Viewing Area 95 x 85 mm (3.74 x 3.34 in.)

Cartridge Size 114 x 133 mm (4.50 x 5.25 in.)

UV/IR Protection Up to Shade DIN 16 at all times

Arc Sensors 4

Light State Shade DIN 3.5

Variable Welding Shades DIN 5 to 13

Shade Control Dial knob – full adjustment

Power Supply Solar cells – with Battery

Low Battery Warning Red Light

Battery CR2450 Lithium (1 Required)

Power On/Off Fully automatic

Light to Dark Switching Time 0.00004 sec. (1/25,000 sec.)

Dark to Light Switching Time 0.1 sec. (Short) to 1.0 sec. (Long)

Sensitivity Control Variable and Grind

TIG Rating DC ≥2 amps, AC ≥2 amps,

Operating Temperature (helmet) 14°F to 131°F (-10° to 55°C)

Storage Temperature (helmet) -4° to 158°F (-20°C to 70°C)

Compliance of Helmet ANSI Z87.1-2010/CSA Z94.3/CE EN 379

21

VIKING PAPR 3350 WELDING HELMET

Crown Adjustment

Tilt Adjust

Lever

Fore-Aft

Adjustment

Tilt

Adjustment

Push in & Rotate

to Adjust

Ratchet

Knob