查询SG1825供应商

LIN DOC #: 1825

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

T HE I NFINITE P OWER OF I NNOVATION

DESCRIPTION

The SG1825C is a high-performance

pulse width modulator optimized for

high frequency current-mode power

supplies. Included in the controller

are a precision voltage reference,

micropower start-up circuitry, softstart, high-frequency oscillator,

wideband error amplifier, fast currentlimit comparator, full double-pulse

suppression logic, and dual totempole output drivers. Innovative

circuit design and an advanced linear

Schottky process result in very short

propagation delays through the

current limit comparator, logic, and

output drivers. This device can be

used to implement either currentmode or voltage-mode switching

power supplies. It also is useful as

a series-resonant controller to

frequencies beyond 1MHz. The

SG1825C is specified for operation

over the full military ambient temperature range of -55°C to 125°C.

The SG2825C is characterized for the

industrial range of -25°C to 85°C,

and the SG3825C is selected for the

commercial range of 0°C to 70°C.

PRODUCT HIGHLIGHT

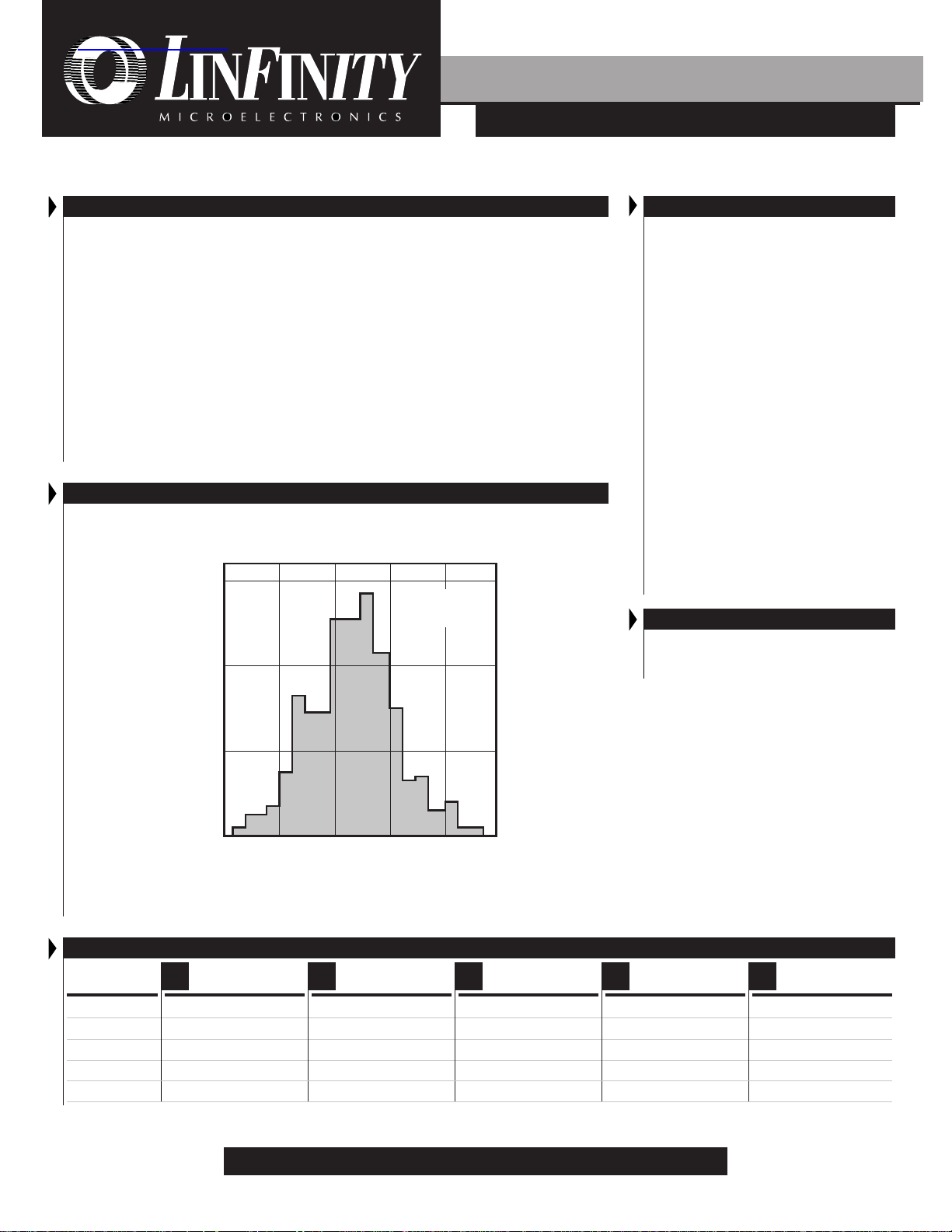

I NITIAL OSCILLATOR ACCURACY

15

10

Sample Size = 45

Sample Size = 279

Mean 411.887

Mean 401.661

Std. Dev. = 4.3

Std. Dev. = 3.8

N OT RECOMMENDED FOR NEW DESIGNS

KEY FEATURES

■■

■ IMPROVED REFERENCE INITIAL

■■

TOLERANCE (±1% max.)

■■

■ IMPROVED OSCILLATOR INITIAL

■■

ACCURACY (±3% typ.)

■■

■ IMPROVED STARTUP CURRENT

■■

(500µA typ.)

■■

■ PROP DELAY TO OUTPUTS (50ns typ.)

■■

p 10V TO 30V OPERATION

p 5.1V REFERENCE TRIMMED TO ±1%

p 2MHZ OSCILLATOR CAPABILITY

p 1.5A PEAK TOTEM-POLE DRIVERS

p U.V. LOCKOUT WITH HYSTERESIS

p NO OUTPUT DRIVER "FLOAT"

p PROGRAMMABLE SOFTSTART

p DOUBLE-PULSE SUPPRESSION LOGIC

p WIDEBAND LOW-IMPEDANCE ERROR

AMPLIFIER

p CURRENT-MODE OR VOLTAGE-MODE

CONTROL

p WIDE CHOICE OF HIGH-FREQUENCY

PACKAGES

HIGH RELIABILITY FEATURES

■■

■ AVAILABLE TO MIL-STD-883B

■■

■■

■ LINFINITY LEVEL "S" PROCESSING AVAIL.

■■

5

Percentage of Units - %

0

390 395 400 405 410

415

Initial Oscillator Accuracy - KHz

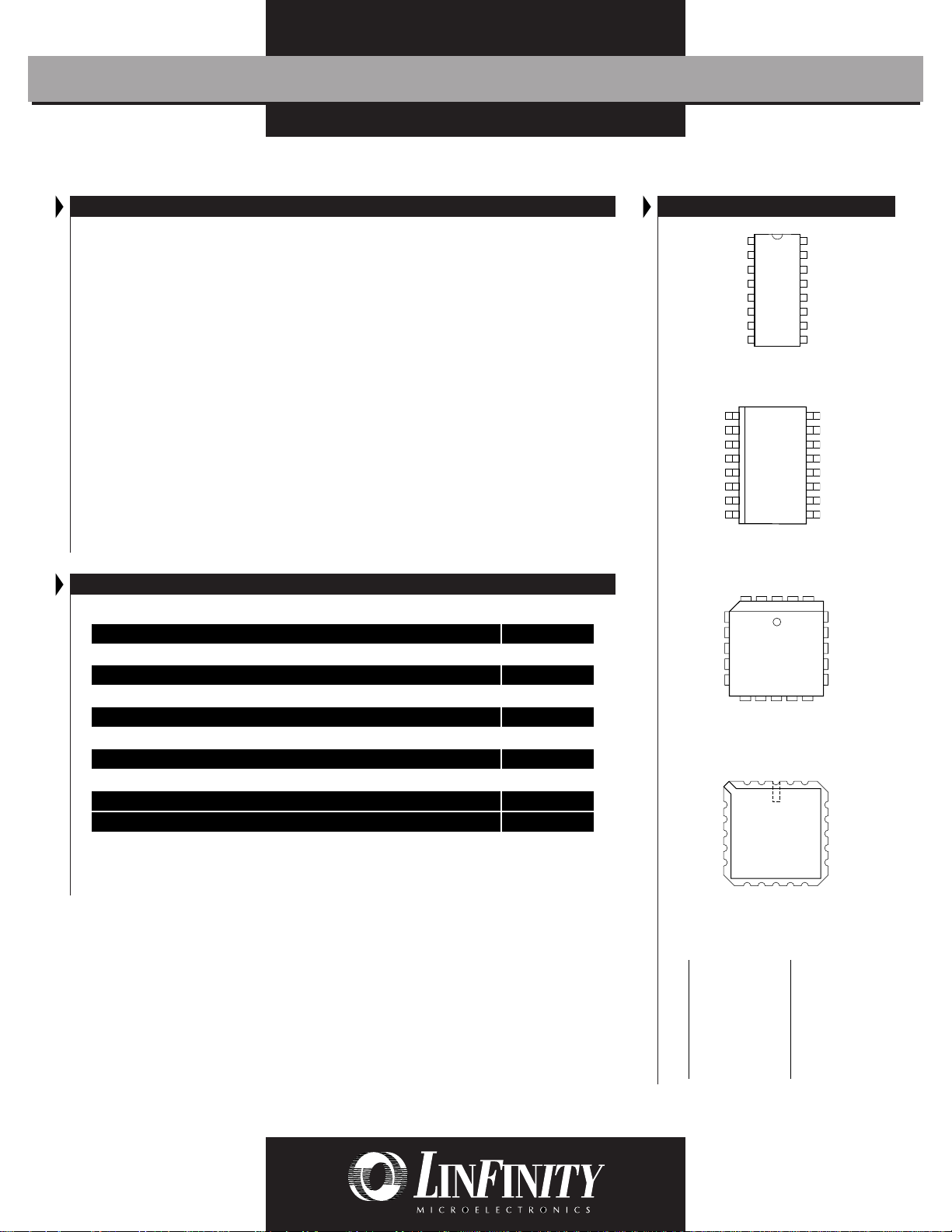

PACKAGE ORDER INFORMATION

T

(°C)

J

Plastic DIP

N

16-pin

0 to 70 SG3825CN SG3825CDW SG3825CQ SG3825CJ

-25 to 85 SG2825CN SG2825CDW SG2825CQ SG2825CJ

-55 to 125 SG1825CJ SG1825CL

MIL-STD-883 SG1825CJ/883B SG1825CL/883B

DESC SG1825CJ/DESC SG1825CL/DESC

Note: All surface-mount packages are available in Tape & Reel. Append the letter "T" to part number. (i.e. SG3825CDWT)

FOR FURTHER INFORMATION CALL (714) 898-8121

Copyright © 1994

Rev. 1.3 6/96

Plastic Wide SOIC

DW

16-pin

Plastic LCC

Q

20-pin

Ceramic DIP

J L

16-pin

11861 WESTERN AVENUE, GARDEN GROVE, CA. 92841

Ceramic LCC

20-pin

1

PRODUCT DATABOOK 1996/1997

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

OT RECOMMENDED FOR NEW DESIGNS

N

ABSOLUTE MAXIMUM RATINGS (Note 1)

Input Voltage (VIN and VC) .......................................................................................... 30V

Analog Inputs:

Error Amplifier and Ramp ........................................................................-0.3V to 7.0V

Softstart and I

Digital Input (Clock) .................................................................................... 1.5V to 6.0V

Driver Outputs ........................................................................................ -0.3V to V

Source / Sink Output Current (each output):

/S.D. ................................................................................ -0.3V to 6.0V

LIM

C

+1.5V

Continuous .............................................................................................................. 0.5A

Pulse, 500ns ............................................................................................................ 2.0A

Softstart Sink Current................................................................................................ 20mA

Clock Output Current ................................................................................................. 5mA

Error Amplifier Output Current ................................................................................. 5mA

Oscillator Charging Current ....................................................................................... 5mA

Operating Junction Temperature:

Hermetic (J, L Package) ....................................................................................... 150°C

Plastic (DW, N, Q Packages) ............................................................................... 150°C

Storage Temperature Range...................................................................... -65°C to 150°C

Lead Temperature (soldering, 10 seconds) ............................................................ 300°C

Note 1. Exceeding these ratings could cause damage to the device.

THERMAL DATA

N PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

DW PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

Q PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

J PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

L PACKAGE:

THERMAL RESISTANCE-JUNCTION TO CASE,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

Junction Temperature Calculation: TJ = TA + (P

The θ

numbers are guidelines for the thermal performance of the device/pc-board

JA

system. All of the above assume no ambient airflow.

θθ

θ

θθ

JA

θθ

θ

θθ

JA

θθ

θ

θθ

JA

θθ

θ

θθ

JA

θθ

θ

θθ

JC

θθ

θ

θθ

JA

x θ

).

D

JA

65°C/W

95°C/W

80°C/W

80°C/W

35°C/W

120°C/W

PACKAGE PIN OUTS

INV. INPUT

N.I. INPUT

E/A OUTPUT

CLOCK

SOFTSTART

INV. INPUT

N.I. INPUT

E/A OUTPUT

CLOCK

R

C

RAMP

SOFTSTART

418

616

814

1 16

215

314

413

512

R

T

611

C

T

710

RAMP

89

J & N PACKAGE

(Top View)

1 16

215

314

413

512

T

611

T

710

89

DW PACKAGE

(Top View)

321

4

5

6

7

8

911121310

Q PACKAGE

(Top View)

3212019

9 11121310

20 19

V

REF

+V

IN

OUTPUT B

V

C

PWR GND

OUTPUT A

GROUND

I

/ S.D.

LIM

+V

REF

+V

IN

OUTPUT B

V

C

PWR GND

OUTPUT A

GROUND

I

/ S.D.

LIM

18

17

16

15

14

175

157

L PACKAGE

(Top View)

1. N.C.

2. INV. INPUT

3. N.I. INPUT

4. E/A OUTPUT

5. CLOCK

6. N.C.

7. R

T

8. C

T

9. RAMP

10. SOFTSTART

2

11. N.C.

12. I

/ S.D.

LIM

13. GROUND

14. OUTPUT A

15. PWR GND

16. N.C.

17. V

C

18. OUTPUT B

19. +V

IN

20. V

REF

Copyright © 1994

Rev. 1.3 6/96

PRODUCT DATABOOK 1996/1997

H IGH-SPEED CURRENT-MODE PWM

N OT RECOMMENDED FOR NEW DESIGNS

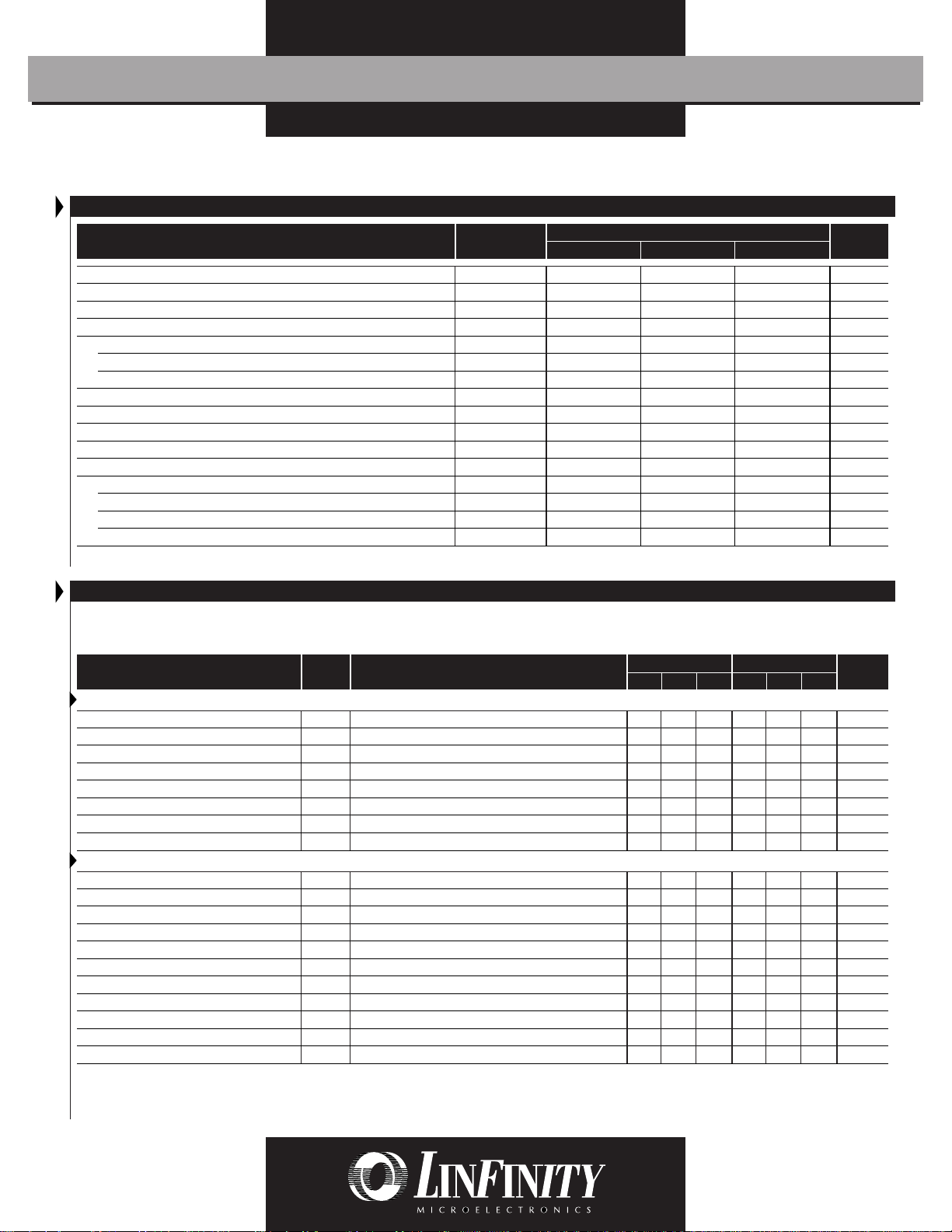

RECOMMENDED OPERATING CONDITIONS (Note 2)

Parameter Symbol Units

Supply Voltage Range

Voltage Amp Common Mode Range

Ramp Input Voltage Range

Current Limit / Shutdown Voltage Range

Source / Sink Output Current

Continuous

Pulse, 500ns

Voltage Reference Output Current

Oscillator Frequency Range

Oscillator Charging Current

Oscillator Timing Resistor R

Oscillator Timing Capacitor C

Operating Ambient Temperature Range:

SG1825C T

SG2825C T

SG3825C T

Note 2. Range over which the device is functional.

SG1825C/SG2825C/SG3825C

Recommended Operating Conditions

Min. Typ. Max.

10 30 V

1.5 5.5 V

0 5.0 V

0 4.0 V

200 mA

1.0 A

110mA

4 1500 kHz

0.030 3 mA

T

T

A

A

A

1 100 kΩ

0.470 10 nF

070°C

-25 85 °C

-55 125 °C

ELECTRICAL CHARACTERISTICS (Note 3)

(Unless otherwise specified, these specifications apply over the operating ambient temperatures for SG3825C with 0°C ≤ TA ≤ 70°C, SG2825C with

-25°C ≤ TA ≤ 85°C, SG1825C with -55°C ≤ TA ≤ 125°C, and V

and case temperatures equal to the ambient temperature.)

Parameter

Symbol

=15V. Low duty cycle pulse testing techniques are used which maintains junction

IN=VC

Test Conditions

SG1825C/2825C

Min. Typ. Max. Min. Typ. Max.

SG3825C

Units

Reference Section

Output Voltage TJ = 25°C, IL = 1mA

Line Regulation VIN = 10 to 30V

Load Regulation IL = 1 to 10mA

Temperature Stability (Note 3) Over Operating Temperature

Total Output Range (Note 3) Over Line, Load, and Temperature

Output Noise Voltage (Note 3) f = 10Hz to 10kHz, IL = 0mA

Long Term Stability (Notes 3 &4) TJ = 125°C, t = 1000hrs

Short Circuit Current V

REF

= 0V

5.05 5.10 5.15 5.05 5.10 5.15 V

215 215 mV

515 515 mV

0.2 0.4 0.2 0.4 mV/°C

5.00 5.20 5.00 5.20 V

50 200 50 µV

525 525 mV

-15 -50 -100 -15 -50 -100 mA

RMS

Oscillator Section (Note 5)

Initial Accuracy TJ = 25°C, C

≤ 10pF

CLK

Voltage Stability VIN = 10 to 30V

Temperature Stability (Note 3) Over Rated Operating Temperature

Total Frequency Limits (Note 3) Over Line and Temperature

Minimum Frequency R

Maximum Frequency R

Clock High Level I

Clock Low Level I

= 100KΩ, C

T

= 1KΩ, C

T

= -1mA

CLK

= -1mA

CLK

= 0.01µF

T

= 470pF

T

Ramp Peak Voltage

Ramp Valley Voltage

Valley-to-Peak Amplitude

Note 3. This parameter is guaranteed by design and process control, but is not 100% tested in production.

Note 4. This parameter is non-accumulative, and represents the random fluctuation of the reference voltage within some error band when observed

over any 1000 hour period of time.

370 400 430 370 400 430 kHz

0.2 2 0.2 2 %

58 58 %

350 450 350 450 kHz

4 4 kHz

1.5 1.5 MHz

3.9 4.5 3.9 4.5 V

2.3 2.9 2.3 2.9 V

2.6 2.8 3.0 2.6 2.8 3.0 V

0.7 1.0 1.25 0.7 1.0 1.25 V

1.6 1.8 2.0 1.6 1.8 2.0 V

Copyright © 1994

Rev. 1.3 6/96

3

PRODUCT DATABOOK 1996/1997

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

OT RECOMMENDED FOR NEW DESIGNS

N

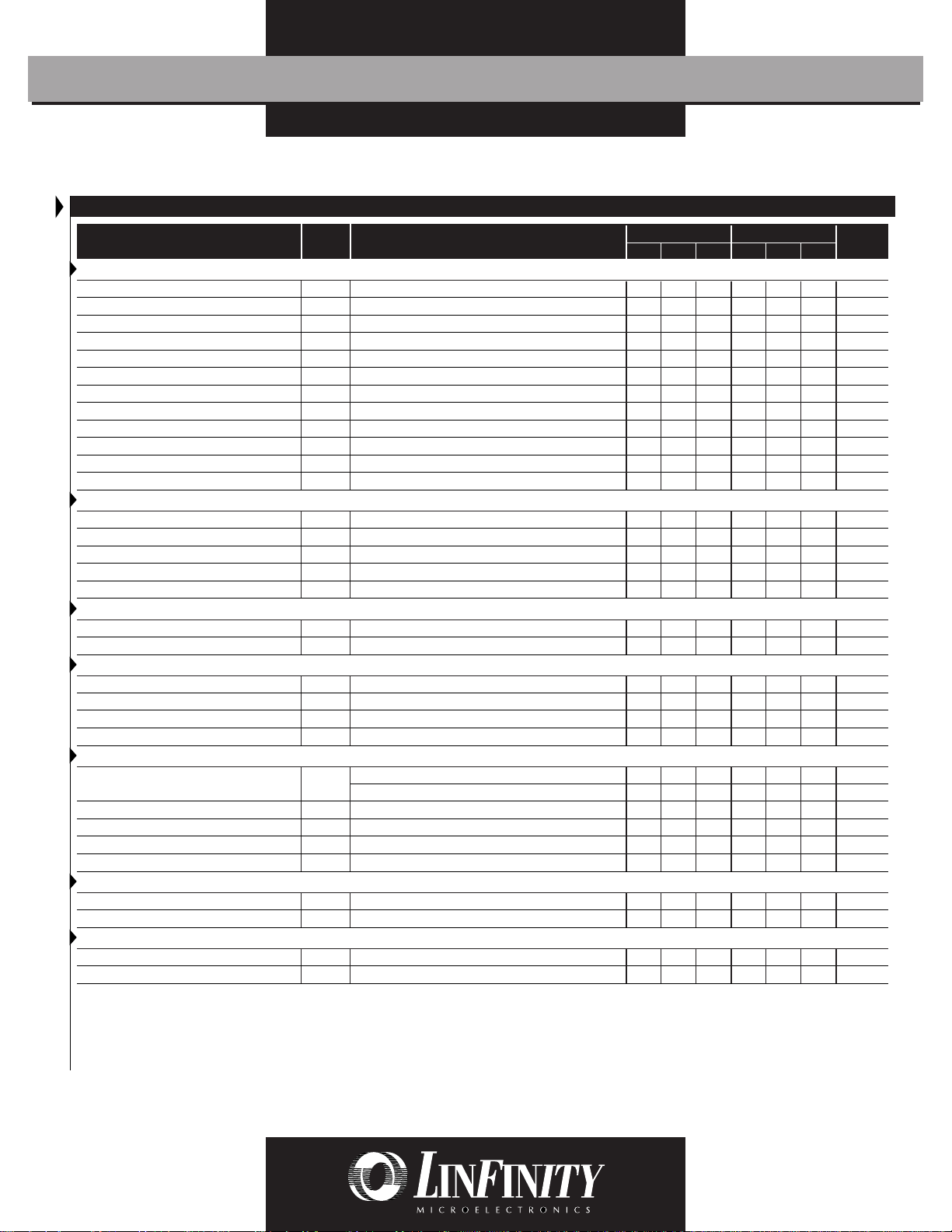

ELECTRICAL CHARACTERISTICS (Cont'd.)

Parameter

Symbol

Test Conditions

Error Amplifier Section (Note 6)

Input Offset Voltage R

Input Bias Current V

Input Offset Current V

DC Open Loop Gain A

Common Mode Rejection Over Rated Voltage Range, V

Power Supply Rejection VIN = 10V to 30V, V

Output Sink Current V

Output Source Current V

Output High Voltage I

Output Low Voltage I

Unity Gain Bandwidth (Note 3) A

Slew Rate (Note 3)

≤ 2KΩ, V

S

ERROR

ERROR

VOLVERROR

ERROR

ERROR

ERROR

ERROR

VOL

= 2.5V

= 2.5V

= 1 to 4V

= 1V

= 4V

= -0.5mA

= 1mA

= 0dB

ERROR

= 2.5V

ERROR

ERROR

= 2.5V

PWM Comparator Section (Note 5 & 7)

Ramp Input Bias Current

Minimum Duty Cycle V

Maximum Duty Cycle (Note 8) V

ERROR

ERROR

= 1V

= 4V

Zero Duty Cycle Threshold

Delay to Driver Output (Note 3) V

= 0V to 2V, V

RAMP

ERROR

= 2V

Softstart Section

CSS Charge Current V

CSS Discharge Current V

SOFTSTART

SOFTSTART

= 0.5V

= 1.0V

Current Limit / Shutdown Section (Note 9)

I

Input Bias Current

LIM

Current Limit Threshold

Shutdown Threshold

Delay to Driver Output (Note 3) V

SHUTDOWN

= 0V to 1.2V

Output Drivers Section (each output)

Output Low Level I

Output High Level I

VC Standby Current VC = 30V

Output Rise / Fall Time (Note 3) CL = 1000pF

= 20mA

SINK

I

= 200mA

SINK

SOURCE

I

SOURCE

= 20mA

= 200mA

Undervoltage Lockout Section

Start Threshold Voltage

UV Lockout Hysteresis

Supply Current Section (Note 5)

Start Up Current VIN = 8V

Operating Current V

Note 5. F

Note 6. VCM = 1.5V to 5.5V.

Note 7. V

Note 8. 100% duty cycle is defined as a pulsewidth equal to one oscillator period.

Note 9. V(I

= 400kHz (R

OSC

= 0V, unless otherwise specified.

RAMP

/S.D.) = 0V to 4.0V, unless otherwise specified.

LIM

= 3.65kΩ, C

T

= 1.0nF).

T

, V

, V(I

INV

RAMP

/S.D.) = 0V, V

LIM

N.I.

= 2.5V

= 1V

SG1825C/2825C

Min. Typ. Max. Min. Typ. Max.

SG3825C

Units

15 15 mV

0.6 3 0.6 3 µA

0.1 1 0.1 1 µA

60 95 60 95 dB

75 95 75 95 dB

85 110 85 110 dB

1 2.5 1 2.5 mA

-0.5 -1.3 -0.5 -1.3 mA

4.0 4.7 5.0 4.0 4.7 5.0 V

0 0.5 1.0 0 0.5 1.0 V

3 5.5 3 5.5 MHz

6 6 V/µsec

-1 -5 -1 -5 µA

00%

85 85 %

1.1 1.25 1.1 1.25 V

50 80 50 80 ns

39203920 µA

11 mA

±15 ±10 µA

0.9 1.0 1.1 0.9 1.0 1.1 V

1.25 1.40 1.55 1.20 1.40 1.55 V

50 80 50 80 ns

0.25 0.40 0.25 0.40 V

1.2 2.0 1.2 2.0 V

13.0 13.5 13.0 13.5 V

12.0 13.0 12.0 13.0 V

150 500 150 500 µA

30 60 30 60 ns

8.8 9.2 9.7 8.8 9.2 9.7 V

0.4 0.8 1.2 0.4 0.8 1.2 V

0.5 1.2 0.5 1.2 mA

22 33 22 33 mA

4

Copyright © 1994

Rev. 1.3 6/96

+V

D

GND

CLOCK

RAMP

PRODUCT DATABOOK 1996/1997

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

N OT RECOMMENDED FOR NEW DESIGNS

BLOCK DIAGRAM

V

REF

+9V

15

IN

10

4

R

5

T

C

6

T

1.25V

7

REFERENCE

REGULATOR

OSCILLATOR

16

+ 4.0V

Q

T

Q

S

RQ

V

13

11

OUTPUT A

OUTPUT B

14

POWER GN

12

C

E/A OUTPUT

N.I. INPUT

INV. INPUT

SOFTSTART

3

2

ERROR

1

8

FIGURE INDEX

Application Circuits

FIGURE #

1. HIGH-SPEED LAYOUT AND BYPASSING

2. MICROPOWER STARTUP

3. SOFTSTART FAST RESET

4. OSCILLATOR SYCHRONIZATION

5. OSCILLATOR FUNCTIONAL DIAGRAM

6. VOLTAGE AMPLIFIER CONNECTIONS

7. DRIVING SHIELDED CABLE

9µA

+ 1.0V

+ 1.4V

9

I

/S.D.

LIM

Copyright © 1994

Rev. 1.3 6/96

5

PRODUCT DATABOOK 1996/1997

C

T

R

T

10

12

6

PWR GND

GND

+V

IN

15

0.1µF

+ V

IN

5

SG1825C

CLK

4

C

T

R

T

10

12

6

PWR GND

GND

+V

IN

15

0.1µF

5

SG1825C

V

REF

16

CLK

4

C

T

R

T

MASTER SLAVE

+

V

C

C

SS

10

12

13

PWR GND

GND

+V

IN

15

0.1µF

+ V

IN

1µF

8

SG1825C

R

1

100W

C

SOFTSTART

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

OT RECOMMENDED FOR NEW DESIGNS

N

APPLICATION INFORMATION

HIGH-SPEED LAYOUT AND BYPASSING

The SG1825C, like all high-speed circuits, requires extra attention to external

conductor and component layout to minimize undesired inductive and

capacitive effects. All lead lengths must be as short as possible. The best

printed circuit board choice would be a four-layer design, with the two

internal planes supplying power and ground. Signal interconnects should

be placed on the outside, giving a conductor-over-ground-plane

(microstrip) configuration. A two-sided printed circuit board with one side

dedicated as a ground plane is next best, and requires careful component

placement by a skilled pc designer.

Two supply bypass capacitors should be employed: a low-inductance

0.1µF ceramic within 0.25 inches of the +VIN pin for high frequencies, and

a 1 to 5µF solid tantalum within 0.5 inches of the V

reservoir for the high-peak output currents. A low-inductance .01µF bypass

pin to provide an energy

C

for the reference output is also recommended.

MICROPOWER STARTUP

Since the SG1825C typically draws 700µA of supply current before turning

on, a low power bleeder resistor from the rectified AC line supply is all that

is required for startup. A start capacitor, C

current from the bleeder resistor. When the turn-on threshold voltage is

, is charged with the excess

S

reached, the PWM circuit becomes active, energizing the power transistors.

The additional operating current required by the PWM is then provided by

a bootstrap winding on the main high-frequency power transformer.

APPLICATION FIGURES

FIGURE 1. HIGH-SPEED LAYOUT and BYPASSING

16

V

REF

L1

GND

L2

SG1825C

15

+V

0.1µF

V

IN

FIGURE 2. MICROPOWER STARTUP

240

120

R

PWR GND

GND

IN

B

C

S

+ V

13

V

C

12

10

1µF

15

0.1µF

IN

V

REF

0.01µF

TO POWER TRANSFORMER

SG1825C

13

V

C

POWER

12

GND

10

GND

+V

IN

1µF

SOFTSTART CIRCUIT / OUTPUT DUTY CYCLE LIMIT

The softstart pin of the SG1825C is held low when either the chip is in the

FIGURE 3. SOFTSTART FAST RESET

micropower mode, or when a voltage greater than +1.4 volts is present at

the I

is clamped to the Softstart pin voltage, providing a ramp-up of peak charging

pin. The maximum positive swing of the voltage error amplifier

LIM/S.D.

currents in the power semiconductors at turn-on.

In some cases, the duration of the Shutdown signal can be too short to

fully discharge the softstart capacitor. The illustrated resistor/discrete PNP

transistor configuration can be used to shorten the discharge time by a factor

of 50 or more. When the internal discharge transistor in the SG1825C turns

on, current will flow through surge limit resistor R1. As the resistor drop

approaches 0.6 volts, the external PNP turns on, providing a low resistance

discharge path for the energy in the softstart capacitor. The capacitor will

be rapidly discharged to +0.7 volts, which corresponds to zero duty cycle

in the pulse width modulator.

FREQUENCY SYNCHRONIZATION

FIGURE 4. OSCILLATOR SYCHRONIZATION

Two or three SG1825C oscillators may be locked together with the

interconnection scheme shown, if the devices are within an inch or so of

each other. A master unit is programmed for desired frequency with R

as usual. The oscillators in the slave units are disabled by grounding C

C

T

and by connecting RT to V

clock of the master with the wire-OR connection shown.

. The logic in the slave units is locked to the

REF

and

T

T

Many SG1825Cs can be locked to a master system clock by wiring the

oscillators as slave units, and distributing the master clock to each using a

tree-fanout geometry.

6

Copyright © 1994

Rev. 1.3 6/96

PRODUCT DATABOOK 1996/1997

V

V

V

REF

2

1

3

R

3

RZC

P

R

4

POSITIVE

OUTPUT

VOLTAGE

V

REF

2

1

3

R

3

RZC

P

V

REF

2

V

ERROR

V

ERROR

FIGURE B

FIGURE A

R

1

R

2

R

1

R

2

NEGATIVE

OUTPUT

VOLTAGE

R

4

SG1825C/SG2825C/SG3825C

H IGH-SPEED CURRENT-MODE PWM

N OT RECOMMENDED FOR NEW DESIGNS

APPLICATION INFORMATION

OSCILLATOR

The oscillator frequency is programmed by external timing components R

T

and CT. A nominal +3.0 volts appears at the RT pin. The current flowing

through R

current to flow out the C

a linear ramp. When the upper threshold of +2.8 volts is reached, a

is mirrored internally with a 1:1 ratio. This causes an identical

T

pin, charging the timing capacitor and generating

T

discharge network reduces the ramp voltage to +1.0, where a new charge

cycle begins.

The Clock output pin is LOW (+2.3 volts) during the charge cycle, and

HIGH (+4.5 volts) during the discharge cycle. The Clock pin is driven by

an NPN emitter follower, and so can be wire-ORed. Each Clock pin can drive

a 1mA load. Since the internal current-source pulldown is approximately

400µA, the DC fan-out to other SG1825C Clock pins is at least two.

The type of capacitor selected for C

frequencies, non-ideal characteristics such as effective series resistance

is very important. At high

T

(ESR), effective series inductance (ESL), dielectric loss and dielectric

absorption all affect frequency accuracy and stability. RF capacitors such as

silver mica, glass, polystrene, or COG ceramics are recommended. Avoid

high-K ceramics, which work best in DC bypass applications.

ERROR AMPLIFIER

The voltage error amplifier is a true operational amplifier with lowimpedance output, and can be gain-stabilized using conventional feedback

techniques. The typical DC open-loop gain is 95dB, with a single lowfrequency pole at 100Hz.

The input connections to the error amplifier are determined by the

polarity of the power supply output voltage. For positive supplies, the

common-mode voltage is +5.1 volts and the feedback connections in Figure

A are used. With negative outputs, the common-mode voltage is half the

reference, and the feedback divider is connected between the negative

output and the +5.1 volt reference as shown in Figure B.

APPLICATION FIGURES

FIGURE 5. OSCILLATOR FUNCTIONAL DIAGRAM

3V

I

R

R

T

5

IC = I

C

T

6

R

2.8V 1.0V

FIGURE 6. VOLTAGE AMPLIFIER CONNECTIONS

SG1825C

+ 5.1V

4

400µA

CLOCK

+ 4.5

+ 2.3

OUTPUT DRIVER

The output drivers are designed to provide up to 1.5 Amps peak output

current. To minimize ringing on the output waveform, which can be

destructive to both the power MOSFET and the PWM chip, the series

FIGURE 7. DRIVING SHIELDED CABLE

inductance seen by the drivers should be as low as possible.

One solution is to keep the distance between the PWM and MOSFET gate

as short as possible, and to use carbon composition series damping resistors.

SG1825C

13

V

C

FARADAY SHIELD

A Faraday shield to intercept radiated EMI from the power transistors is

usually required with its choice.

A second approach is to place the MOSFETs some distance from the PWM

chip, and use a series-terminated transmission line to preserve drive pulse

W

11

24

*

50W

50W

fidelity. This will minimize noise radiated back to the sensitive analog

circuitry of the SG1825C. A Faraday shield may also be required.

If the drivers are connected to an isolation transformer, or if kickback

through C

peak Schottky diodes will limit undershoot to less than -0.3 volts.

Copyright © 1994

Rev. 1.3 6/96

of the MOSFET is severe, clamp diodes may be required. 1 Amp

GD

PWR GND

12

GND

10

* SCHOTTKY CLAMP MAY BE REQUIRED

7

Loading...

Loading...