V

T

查询LX8580供应商

LX8580

7A V

ERY LOW DROPOUT POSITIVE ADJUSTABLE REGULATOR

T HE I NFINITE P OWER OF I NNOVATION

DESCRIPTION KEY FEATURES

The LX8580 is a high-performance, very

low dropout voltage regulator, designed for

use with advanced microprocessors. This

product can be used with separate voltage

supplies for the control and power sections,

allowing a power section dropout voltage

as low as 100mV. The LX8580 can also be

used in a single voltage supply configuration,

with a dropout performance similar to that

of the LX8584 (1.3V at 7A).

The LX8580 is supplied in a five-

terminal TO-220 package, which allows the

NOTE: For current data & package dimensions, visit our web site: http://www.linfinity.com.

implementation of remote (Kelvin) voltage

sensing. This sensing compensates for

output voltage variations due to load

changes and resistive voltage drops in

connectors and board traces. Typical load

regulation measured at the sense pin is less

than 1mV for a load current step of 7mA

to 7A.

The LX8580 is ideal for generating a

secondary 2 - 2.5V low voltage supply on a

motherboard where a 3.3V supply is already

available.

PRODUCT HIGHLIGHT

SPECIAL CAPABILITIES OF THE LX8580 TO ALLOW 44%

SMALLER LDO THERMAL DISSIPATION

P RODUCTION DATA SHEET

■■

■ Low Dropout, 800mV Max. at 7A

■■

Output Current in Dual Supply Mode

■■

■ Fast Transient Response

■■

■■

■ Remote Sensing

■■

! 1mV Load Regulation

! Adjustable Output

! No Supply Sequencing Problems in Dual

Supply Mode

APPLICATIONS

■ Microprocessor Supplies

■ 3.3V to 2.5V Processor Power Supplies

■ High-Current Regulators

■ Post Regulators for Switching Supplies

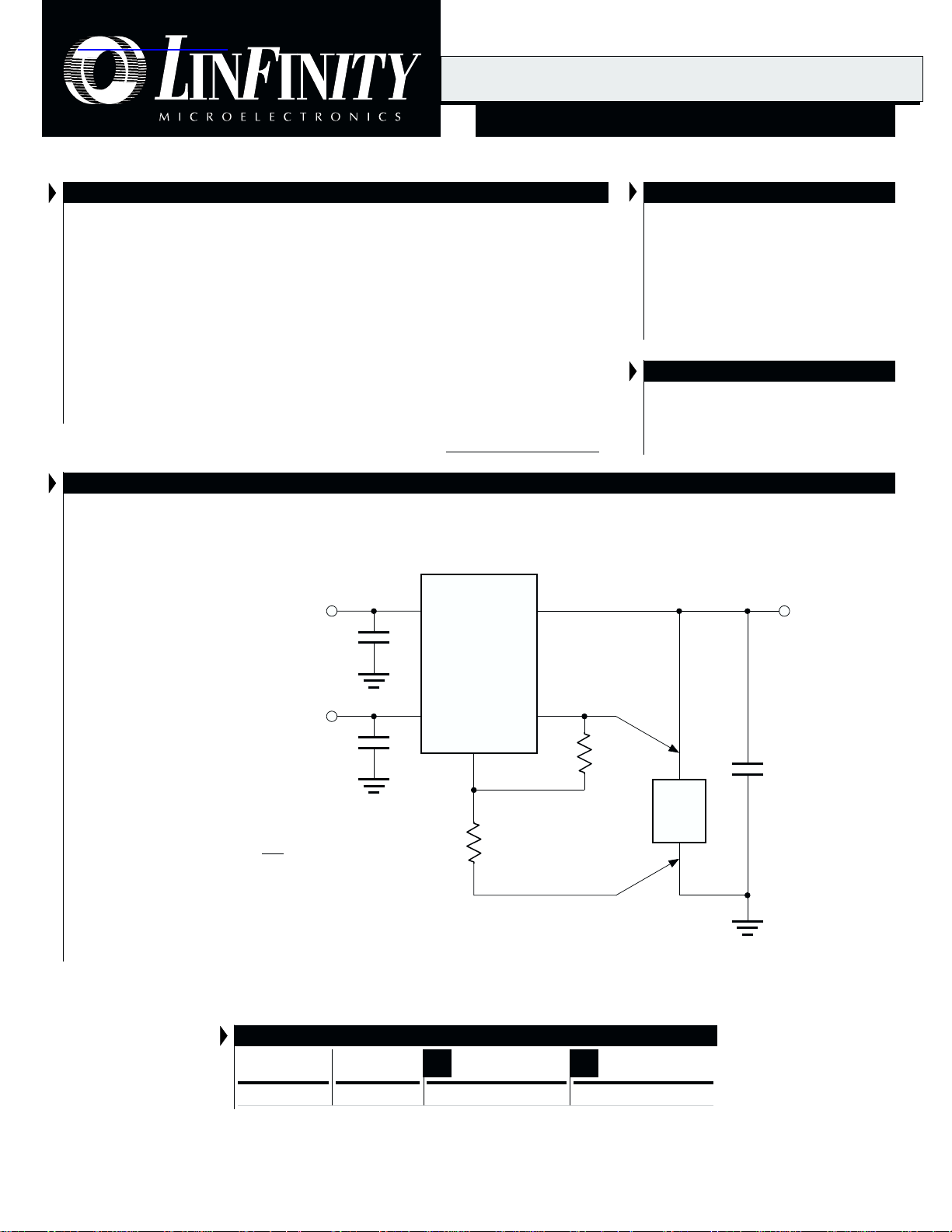

CTRL

³ V

+ 1.3V Max

OUT

4

V

CTRL

OUTPUT

3

V

OU

LX8580

5

V

V

PWR

³ V

OUT

+ V

DROPOUT

PWR

SENSE

ADJUST

2

R

V

= V

OUT

REF

B

1 + + I

R

A

x R

ADJ

B

R

B

PACKAGE ORDER INFORMATION

T

(°C)

A

0 to 125 0.1V - 0.8V LX8580-00CP LX8580-00CDD

Dropout

Voltage

Plastic TO-220

P

5-pin

1

R

A

LOAD

Plastic TO-263

DD

5-pin

Copyright © 1999

Rev. 1.0 11/99

L INF INITY MICROELECTRONICS INC.

11861 WESTERN A VENUE, GARDEN G ROVE, CA. 92841, 714-898-8121, FAX: 714-893-2570

1

LX8580

V

PRODUCT DATABOOK 1996/1997

7A V

ERY LOW DROPOUT POSITIVE ADJUSTABLE REGULATOR

P RODUCTION DATA SHEET

ABSOLUTE MAXIMUM RATINGS (Note 1)

Power Dissipation ......................................................................................Internally Limited

V

Input Voltage ........................................................................................................... 7V

PWR

Input Voltage ......................................................................................................... 13V

V

CTRL

Operating Junction Temperature

Plastic (P Package) ................................................................................................ 150°C

Storage Temperature Range ...................................................................... -65°C to 150°C

Lead Temperature (Soldering, 10 seconds) ............................................................. 300°C

Note 1. Exceeding these ratings could cause damage to the device. All voltages are with respect

to Ground. Currents are positive into, negative out of the specified terminal.

THERMAL DATA

P PACKAGE:

THERMAL RESISTANCE-JUNCTION TO TAB,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

DD PACKAGE:

THERMAL RESISTANCE-JUNCTION TO TAB,

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

Junction Temperature Calculation: TJ = TA + (PD x θJA).

The θJA numbers are guidelines for the thermal performance of the device/pc-board system.

All of the above assume no ambient airflow.

θθ

θ

θθ

JT

θθ

θ

θθ

JA

θθ

θ

θθ

JT

θθ

θ

θθ

JA

3.0°C/W

60°C/W

3.0°C/W

60°C/W

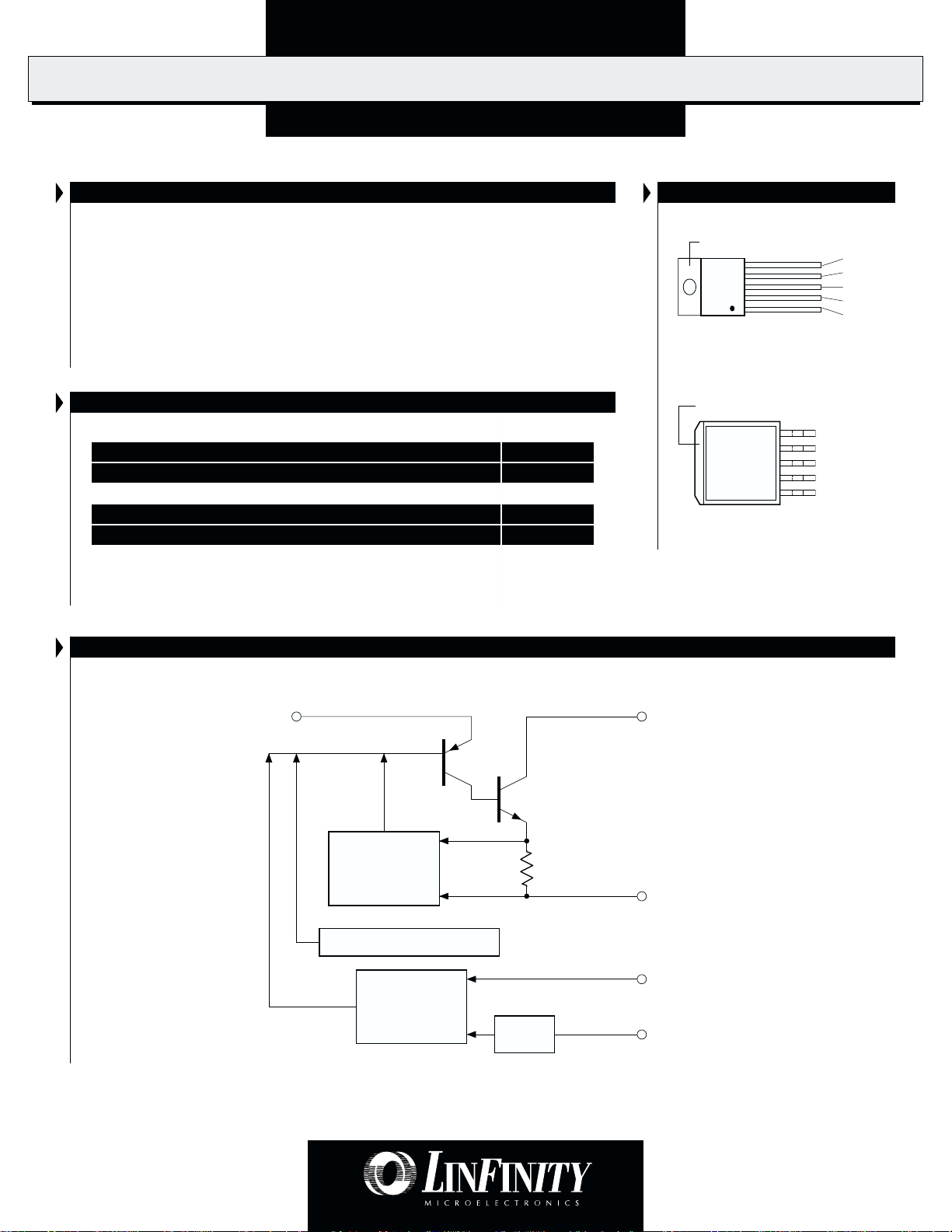

PACKAGE PIN OUTS

TAB IS OUTPUT

5

1

P PACKAGE

(Top View)

TAB IS OUTPUT

5

4

3

2

1

DD PACKAGE

(Top View)

V

PWR

V

CTRL

OUTPUT

ADJUST

SENSE

V

PWR

V

CTRL

OUTPUT

ADJUST

SENSE

BLOCK DIAGRAM

Control

CTRL

Power

V

PWR

Current

Limiting

Amplifier

OUTPUT

Thermal Overload

Voltage

SENSE

Regulation

Amplifier

V

REF

ADJUST

2

Copyright © 1999

Rev. 1.0 11/99

PRODUCT DATABOOK 1996/1997

LX8580

7A V

ERY LOW DROPOUT POSITIVE ADJUSTABLE REGULATOR

P RODUCTION DATA SHEET

ELECTRICAL CHARACTERISTICS

(Unless otherwise specified, these specifications apply over the operating ambient temperatures 0°C ≤ TA ≤ 125°C. Low duty cycle pulse testing

techniques are used which maintains junction and case temperatures equal to the ambient temperature.)

Parameter

Reference Voltage V

Line Regulation ∆V

Load Regulation

Thermal Regulation

Thermal Resistance R

Ripple Rejection V

Control Pin Current (Note 3) I

Adjust Pin Current I

Current Limit I

Dropout Voltage (Control Section) V

Minimum V

(V

- V

PWR

Dropout Voltage (Power Section) V

Minimum V

(V

- V

PWR

(V

= 0) V

ADJ

Minimum Load Current V

Note 2. Dropout is caused by either minimum control voltage (V

the output voltage. The specifications represent the minimum input/output voltage required to maintain 1% regulation.

(Note 2) V

CTRL

)V

OUT

(Note 2) V

PWR

)V

OUT

Symbol

REF

(VIN)

REF

∆V

(I

)

REF

OUT

∆V

(Pwr) 30ms Pulse

OUT

θJT

CTRL

ADJ

θ(MAX)VCTRL

- V

CTRL

OUTVPWR

- V

PWR

OUTVCTRL

Test Conditions

V

= 2.75V, V

CTRL

V

= 2.7V to 6V,

CTRL

V

= 2.7V to 6V,

CTRL

V

= 2.5V to 12V, V

CTRL

= 2.5V to 12V, V

V

CTRL

V

= 2.75V, V

CTRL

Control Circuitry/Power Transistor

= V

CTRL

PWR

V

= 2.75V, V

CTRL

V

= 2.75V, V

CTRL

V

= 2.75V, V

CTRL

V

= 2.75V, V

CTRL

V

= 2.75V, V

CTRL

= 2.75V, V

= 2.05V, I

= 2.05V, I

PWR

= 2.05V, I

PWR

V

= 2.05V, I

PWR

V

= 2.05V, I

PWR

= 2.75V, I

= 2.75V, I

CTRL

= 2.75V, I

CTRL

= 2.75V, I

CTRL

V

= 2.75V, I

CTRL

V

= 2.75V, I

CTRL

V

= 2.75V, I

CTRL

= 5V, V

CTRL

= 2V, I

PWR

V

PWR

V

PWR

PWR

PWR

= 2.1V, I

PWR

= 3.75V Avg, V

= 2.05V, I

PWR

= 2.05V, I

PWR

= 1.75V, I

PWR

= 2.05V, I

PWR

= 2.05V, I

PWR

= 2.05V, ∆V

PWR

= 100mA

LOAD

= 1A

LOAD

= 2.75A

LOAD

= 4A

LOAD

= 7A

LOAD

= 100mA

LOAD

= 1A

LOAD

= 2.75A

LOAD

= 4A, TJ = 25°C

LOAD

= 4A

LOAD

= 7A, TJ = 25°C

LOAD

= 7A

LOAD

= 3.3V, V

PWR

) or minimum power voltage (V

CTRL

= 10mA, TJ = 25°C

LOAD

= 1.75V to 5.5V, I

= 2.05V to 5.5V, I

= 1.75V to 5.5V, I

= 1.75V to 5.5V, I

= 10mA to 7A (V

LOAD

= 1V

RIPPLE

= 100mA

LOAD

= 4A

LOAD

= 4A

LOAD

= 7A

LOAD

= 0mA (V

LOAD

OUT

= 0V

ADJ

= 10mA to 4A

OUT

= 10mA to 7A

OUT

= 10mA, TJ = 25°C

LOAD

= 10mA

LOAD

, V

= 0V, I

P-P

ADJ

ADJ

= 100mV (V

= 0)

ADJ

= 4A

OUT

= 0)

= 0)

ADJ

). Both parameters are specified with respect to

PWR

Note 3. The control pin current is the drive current required for the output transistor. This current will track output current with roughly a 1:100 ratio.

The minimum value is equal to the quiescent current of the device.

LX8580

Min. Typ. Max.

Units

1.243 1.250 1.257 V

1.237 1.250 1.263 V

1.237 1.250 1.263 V

13mV

26mV

27mV

0.002 0.020 %/W

0.65 2.70 °C/W

60 80 dB

310mA

30 60 mA

33 70 mA

60 120 mA

60 120 µA

7.1 9 A

0.90 1.15 V

1.00 1.15 V

1.05 1.18 V

1.06 1.20 V

1.10 1.30 V

0.05 0.17 V

0.10 0.22 V

0.20 0.38 V

0.30 0.40 V

0.30 0.50 V

0.52 0.62 V

0.56 0.80 V

510mA

Copyright © 1999

Rev. 1.0 11/99

3

LX8580

K

Pin # Description

PRODUCT DATABOOK 1996/1997

7A V

ERY LOW DROPOUT POSITIVE ADJUSTABLE REGULATOR

P RODUCTION DATA SHEET

FUNCTIONAL PIN DESCRIPTION

SENSE 1

ADJUST 2

OUTPUT 3

V

CTRL

V

PWR

5.0V

"Electronic Heatsink"

This pin is the positive side of the reference voltage for the device. With this pin it is possible to Kelvin-sense the output voltage

at load.

This pin is the negative side of the reference voltage for the device. Ripple rejection can be improved by adding a small bypass capacitor

from the Adjust pin to ground. The capacitor value should be selected so that C

and RA is the value of the resistor between the output and sense leads of the LX8580.

This is the power output of the device.

4

This pin is the voltage supply pin for the control circuitry of the device. The current flow into this pin will be about 1% of the output

current. For the device to regulate, the voltage at this pin must be between 1.0V and 1.3V greater than the output voltage.

5

This is the collector of the power section of the LX8580. The output load current is supplied through this pin. For the device to

regulate, the voltage at this pin must be between 0.1V and 0.8V greater than the output voltage (higher output currents require higher

voltages between V

and OUTPUT).

PWR

BASIC APPLICATION CIRCUIT

≤ 1 / 2πFRRA , where FR is the ripple frequency

R

Tantalum

4 x 19 2W 5%

(Parallel Connected)

33µF 10V

V

OUT

= 2.775

2.89 (MAX)

2.67 (MIN)

OUTPUT

V

CTRL

LX8580

SENSE

V

0.259

Resistor reduces

thermal load

on LDO heatsink

to 6.9W

PWR

Tantalum

100µF

10V

ADJUST

*Note

1219

1%

1479

1%

LOAD

6000µF

(4X Sanyo 6mV 1500G

6.3V 1500µF)

5A

*Note: For improved transient response, add capacitor as shown (typical 15µF).

PRODUCTION DATA - Information contained in this document is proprietary to LinFinity, and is current as of publication date. This document

may not be modified in any way without the express written consent of LinFinity. Product processing does not necessarily include testing of all

parameters. Linfinity reserves the right to change the configuration and performance of the product and to discontinue product at any time.

4

SYSTEM GROUND

Copyright © 1999

Rev. 1.0 11/99

Loading...

Loading...