查询LX1681供应商

LX1681/1682

VOLTAGE-MODE PWM CONTROLLERS

T HE I NFINITE P OWER OF I NNOVATION

DESCRIPTION KEY FEATURES

The LX1681/1682 are monolithic, pulsewidth modulator controller ICs. They are

designed to implement a flexible, low cost

buck (step-down) regulator supply with minimal external components.

The LX1681 is a non-synchronous con-

troller; the LX1682 has a synchronous driver

for higher efficiency.

The output voltage is adjustable by

means of a resistor divider to set the voltage

between 1.25V and 4.5V.

Short-circuit current limiting can be

implemented without expensive current

sense resistors. Current is sensed using the

voltage drop across the R

— sensing is delayed for 1µs to eliminate

of the MOSFET

DS(ON)

MOSFET ringing errors.

NOTE: For current data & package dimensions, visit our web site: http://www.linfinity.com.

Hiccup-mode fault protection reduces

average power to the power elements during

short-circuit conditions.

Switching frequency is fixed at 200kHz

for optimal cost and space.

Under-voltage lockout and soft-start

for optimal start-up performance. The

LX1681/82 can be disabled by pulling the softstart pin to ground.

Small 8-pin SOIC packaging reduces

board space.

Optimized for 5V-to-3.3V or 5V-to-2.5V

conversion, the LX1681/82 can also be used

for converting 12V to 5V, 3.3V or other

voltages with high efficiency, eliminating the

need for bulky heat sinks.

P RODUCTION DATA SHEET

■ Fixed 200kHz Switching Frequency

■ Constant Frequency Voltage-Mode Control

Requires NO External Compensation

■ Hiccup-Mode Over-Current Protection

■ High Efficiency

■ Output Voltage Set By Resistor Divider

■ Under-Voltage Lockout

■ Soft-Start And Enable

■ Synchronous Rectification (LX1682)

■ Non-Synchronous Rectification (LX1681)

■ Small, 8-pin Surface Mount Package

APPLICATIONS

■ 5V to 3.3V Or Less Buck Regulators

■ FPGA Supplies

■ Microprocessor Chipset Supplies

(e.g. Camino, Whitney, etc.)

■ Rambus® RIMMTM Supplies

■ Hard Disk Drives

■ Computer Add-on Cards

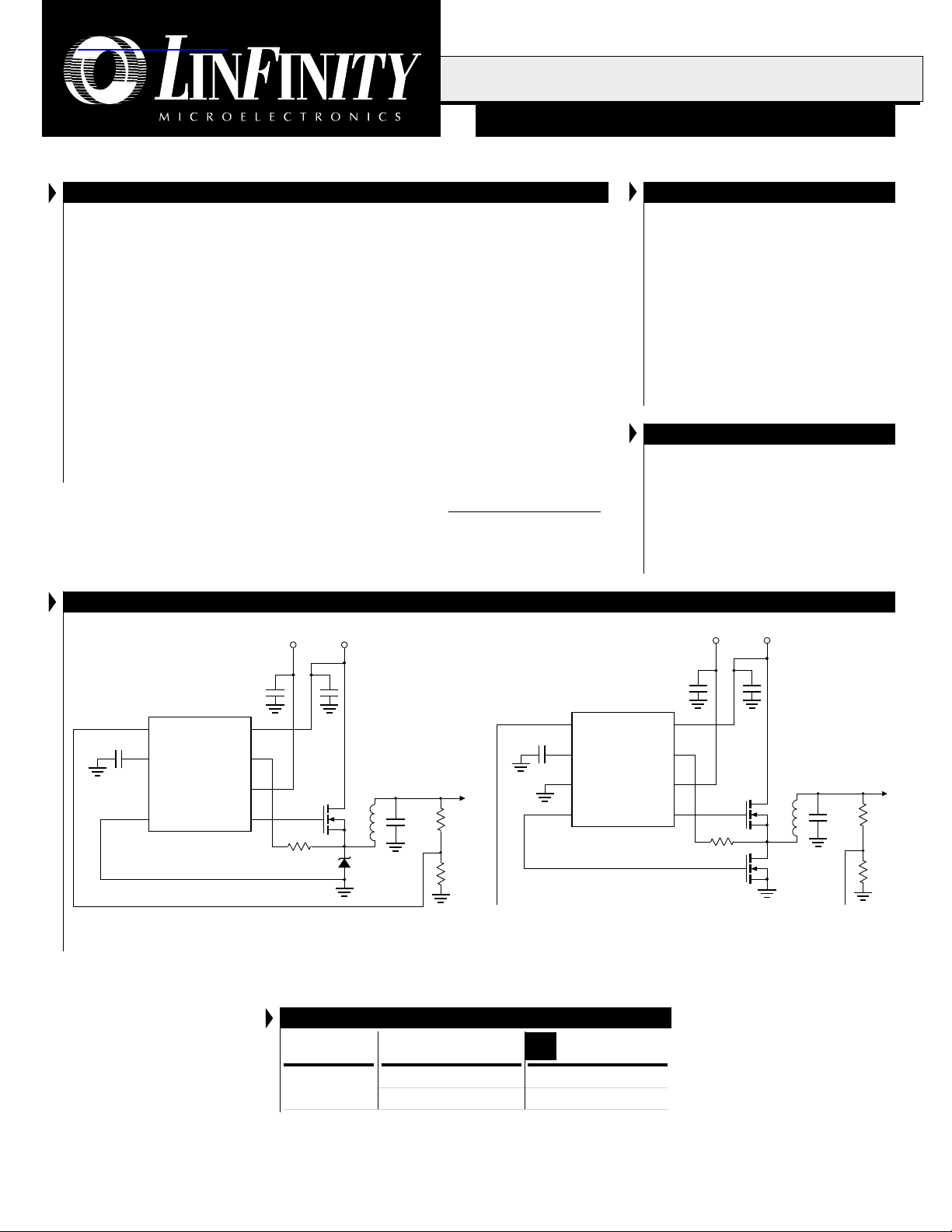

PRODUCT HIGHLIGHT

V

V

CS

V

TDRV

BOOST

12V

C

3

1µF

8

CC

7

6

C1

54

C

SS

0.1µF

V

BOOST

12V

C

3

1µF

1

V

FB

2

SS

LX1681

3

N.C.

GND

V

CS

V

TDRV

8

CC

7

6

C1

IRL3103S

54

R

SET

Q

1

V

IN

5V

C

1

1500µFx3

L

1

5µH

D

2

MBR2545

C

2

1500µF

x3

1

V

C

0.1µF

V

OUT

R

1

R

2

FB

SS

2

SS

LX1682

3

GND

BDRV

LX1681 NON-SYNCHRONOUS CONTROLLER LX1682 SYNCHRONOUS CONTROLLER

PACKAGE ORDER INFORMATION

T

(°C)

A

0 to 70

Output

Non-Synchronous LX1681CDM

Synchronous LX1682CDM

Note: All surface-mount packages are available in Tape & Reel,

append the letter "T" to part number. (i.e. LX1681CDMT)

Plastic SOIC

DM

8-pin

IRL3103S

R

SET

Q

1

V

IN

5V

C

1

1500µFx2

L

1

5µH

Q

2

IRL3103S

C

2

1500µF

x3

V

OUT

R

1

R

2

Copyright © 1999

Rev. 1.0 5/99

L INF INITY MICROELECTRONICS INC.

11861 WESTERN AVENUE, GARDEN GROVE, CA. 92841, 714-898-8121, FAX: 714-893-2570

1

LX1681/1682

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

ABSOLUTE MAXIMUM RATINGS (Note 1)

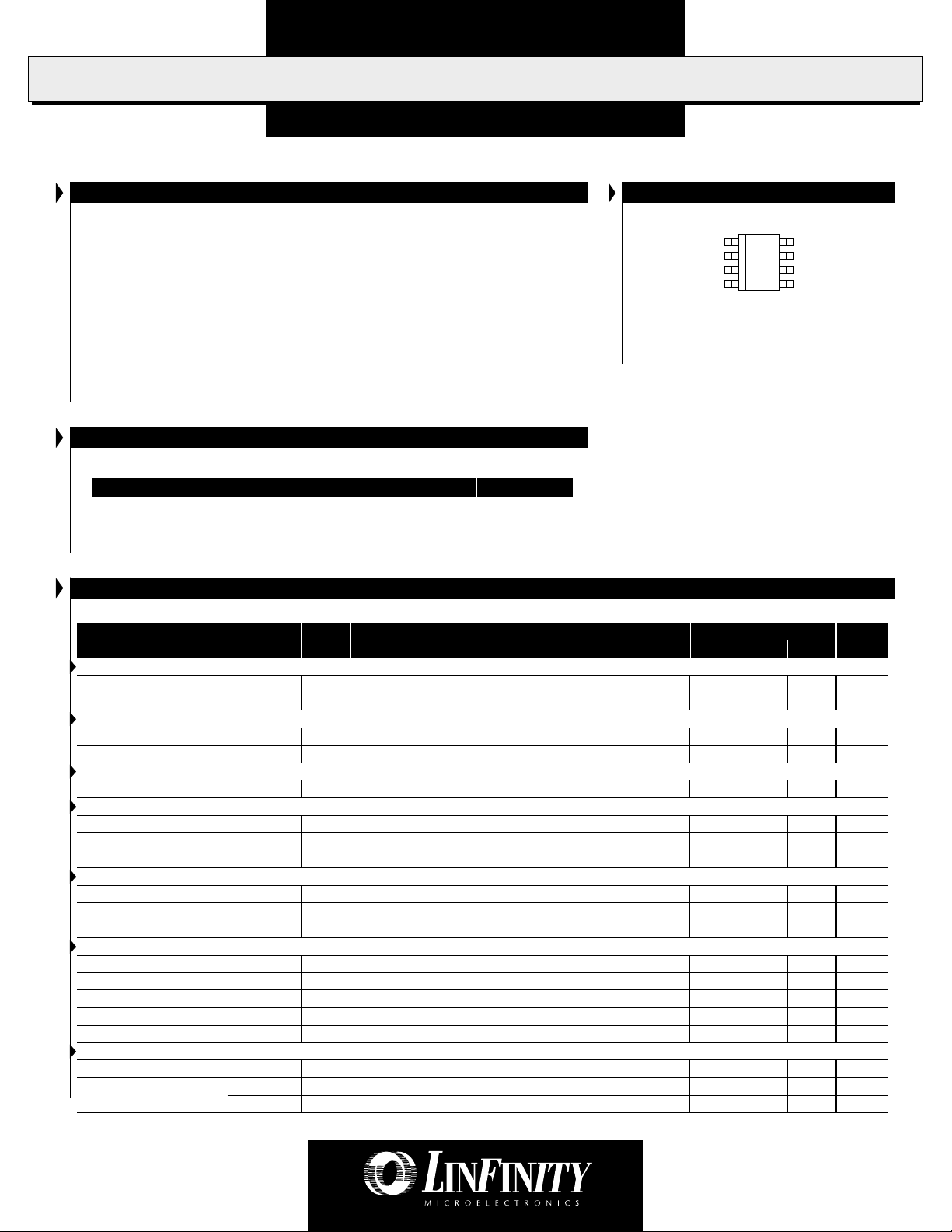

PACKAGE PIN OUTS

Supply Voltage (VC1) ............................................................................................18V

Supply Voltage (VCC) .............................................................................................. 7V

Output Drive Peak Current Source (500ns)....................................................... 1.0A

Output Drive Peak Current Sink (500ns)........................................................... 1.0A

Input Voltage (SS/ENABLE Pin) ............................................................. -0.3V to 6V

Operating Junction Temperature .................................................................... 150°C

Storage Temperature Range ........................................................... -65°C to +150°C

Lead Temperature (Soldering, 10 Seconds).................................................... 300°C

Note 1. Exceeding these ratings could cause damage to the device. All voltages are with

respect to Ground. Currents are positive into, negative out of the specified

terminal.

N.C. / GND*

GND / BDRV*

* Pin 3 = N.C. for LX1681, GND for LX1682

Pin 4 = GND for LX1681, BDRV for LX1682

1 8

V

FB

27

SS

36

45

DM PACKAGE

(Top View)

V

CC

CS

V

C1

TDRV

THERMAL DATA

DM PACKAGE:

THERMAL RESISTANCE-JUNCTION TO AMBIENT,

θθ

θ

θθ

JA

165°C/W

Junction Temperature Calculation: TJ = TA + (PD x θJA).

The θJA numbers are guidelines for the thermal performance of the device/pc-board

system. All of the above assume no ambient airflow.

ELECTRICAL CHARACTERISTICS

(

Unless otherwise specified, 4.75V < VCC < 5.25V and 10.8V < VC1 < 13.2V, 0°C ≤ TA ≤ 70°C. Test conditions: VCC = 5V, VC1 = 12V, T = 25°C.

Parameter

Symbol

Test Conditions

LX1681/1682

Min. Typ. Max.

Reference

Reference Voltage V

V

FB

= VFB , TA = 25°C

OUT

V

= VFB , 0°C ≤ TA ≤ 70°C

OUT

1.237 1.25 1.262 V

1.231 1.269 V

Oscillator

Frequency F

Ramp Amplitude V

OSC

RAMP

170 190 230 kHz

1.25 V

Error Amplifier

Input Resistance R

V

OUT

= V

FB

IN

20 kΩ

Current Sense

Current Set I

V

TRIP

Current Sense Delayed T

SETVCS

CSD

= VCC - 0.4V

Reference to V

40 45 µA

CC

-460 -400 -340 mV

1.1 µsec

Output Drivers

Drive Rise Time, Fall Time T

Drive High V

Drive Low V

CL = 3000pF

RF

DHISOURCE

DLISINK

= 20mA, VC1 = 12V

= 20mA, VC1 = 12V

50 ns

10 11 V

0.1 0.2 V

UVLO and Soft-Start (SS)

V

Start-Up Threshold V

CC5

Hysteresis

SS Resistor R

SS Output Enable V

Hiccup Duty Cycle DC

ST

SS

EN

HICCSS

VC1 > 4.0V

= 0.1µF, F

= 100Hz

REQ

4.0 4.25 4.5 V

0.10 V

20 kΩ

0.25 0.3 0.35 V

10 %

Supply Current

V

Dynamic Supply Current I

CC12

Static Supply Current 12V I

5V I

Out Freq = 200kHz, CL = 3000pF, Synch., VSS > 0.3V

CD

VC1VSS

VCCVSS

< 0.3V

< 0.3V

24 28 mA

57mA

10 12 mA

)

Units

PP

2

Copyright © 1999

Rev. 1.0 5/99

PRODUCT DATABOOK 1996/1997

LX1681/1682

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

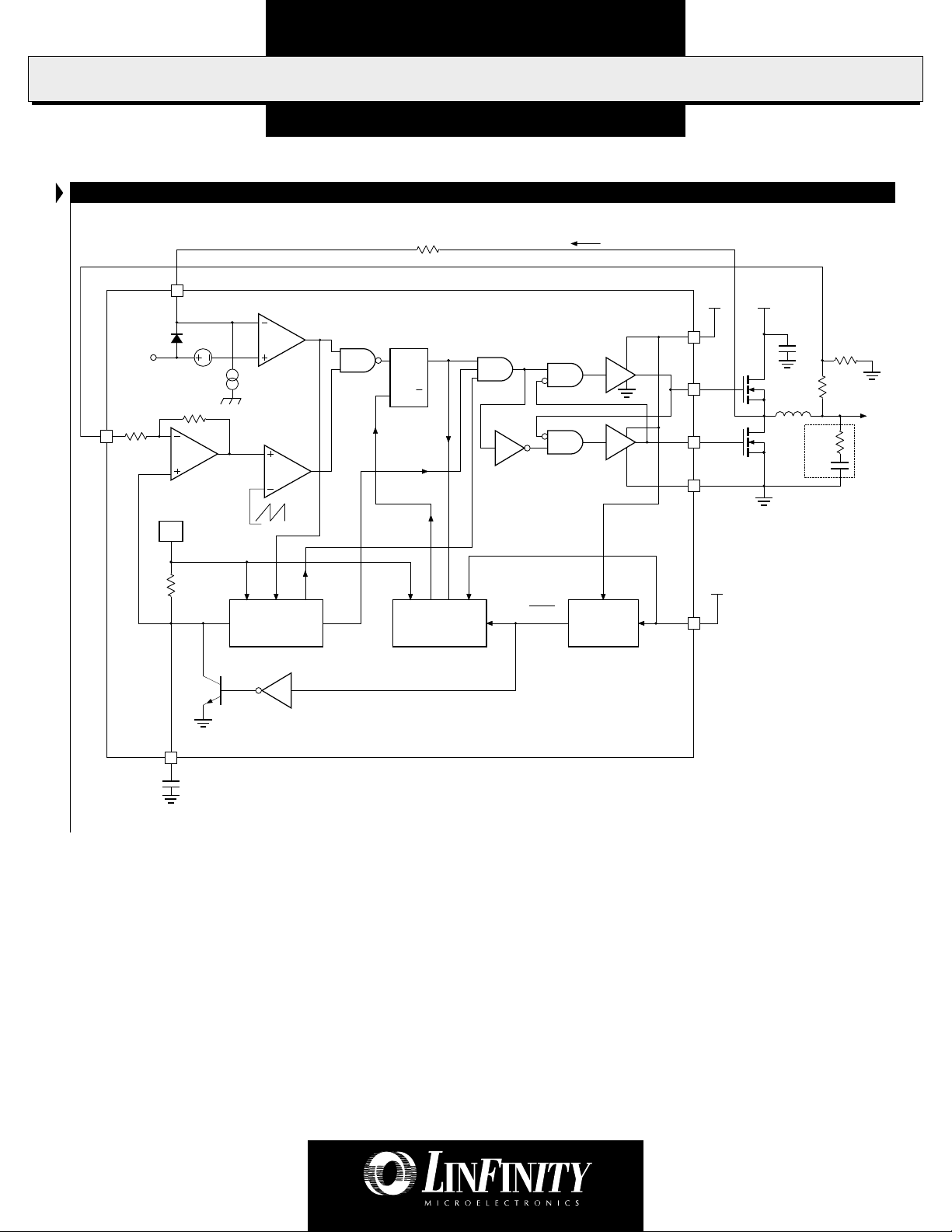

BLOCK DIAGRAM

I

SET

R

SET

CS

7

CS Comp

I

Error

Comp

RESET

PWM

R

Q

SQ

Set

V

RESET

V

TRIP

V

CC

I

SET

320k

20k

1

V

FB

Amplifier/

Compensation

6

5

4

3

+12V

V

C1

TDRV

BDRV

GND

VIN (5V)

C

IN

R

2

R

1

L

V

CORE

ESR

C

OUT

C

SS

V

REF

SS

2

SS/ENABLE

Hiccup

Hiccup

Ramp

UVLO

Oscillator

FIGURE 1 — Block Diagram

UVLO

+5VR

8

V

CC

Copyright © 1999

Rev. 1.0 5/99

3

LX1681/1682

Pin Pin Number

Name Description LX1681 LX1682

V

FB

SS Soft-start and hiccup capacitor pin. During start up the voltage of this pin controls the 2 2

GND Ground for IC 43

TDRV Gate drive for upper MOSFET 5 4

BDRV Gate drive for lower MOSFET 5

V

C1

CS Over-current set. Connect resistor between CS pin and the source of the upper MOSFET to 7 7

V

CC

Voltage feedback — 1.25V reference is connected to a resistor divider to set desired 1 1

output voltage.

output voltage. An internal 20kΩ resistor and the external capacitor set the time constant

for soft-startup. Soft-start does not begin until the supply voltage exceeds the UVLO

threshold. When over-current occurs, this capacitor is used for timing hiccup.

The PWM can be disabled by pulling the SS pin below 0.3V.

Separate supply for MOSFET gate drive. Connect to 12V 6 6

set current-limit point.

IC supply voltage (nominal 5V) and high side drain sense voltage. 8 8

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

FUNCTIONAL PIN DESCRIPTION

4

Copyright © 1999

Rev. 1.0 5/99

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

THEORY OF OPERATION

LX1681/1682

GENERAL DESCRIPTION

The LX1681/82 are voltage-mode pulse-width modulation controller integrated circuits. The internal oscillator and ramp

generator frequency is fixed at 200kHz. The devices have

internal compensation, so that no external compensation is

required.

POWER UP and INITIALIZATION

At power up, the LX1681/82 monitors the supply voltage to both

the +5V and the +12V pins (there is no special requirement for

the sequence of the two supplies). Before both supplies reach

their under-voltage lock-out (UVLO) thresholds, the soft-start

(SS) pin is held low to prevent soft-start from beginning; the

oscillator control is disabled and the top MOSFET is kept OFF.

SOFT-START

Once the supplies are above the UVLO threshold, the soft-start

capacitor begins to be charged up by the reference through a

20kΩ internal resistor. The capacitor voltage at the SS pin rises

as a simple RC circuit. The SS pin is connected to the amplifier's

non-inverting input that controls the output voltage. The output

voltage will follow the SS pin voltage if sufficient charging

current is provided to the output capacitor.

The simple RC soft-start allows the output to rise faster at the

beginning and slower at the end of the soft-start interval. Thus,

the required charging current into the output capacitor is less at

the end of the soft-start interval so decreasing the possibility of

an over-current. A comparator monitors the SS pin voltage and

indicates the end of soft-start when SS pin voltage reaches 95%

of V

.

REF

OVER-CURRENT PROTECTION (OCP) and HICCUP

The LX1681/1682 family uses the R

together with a resistor (R

The comparator senses the current 1µs after the top MOSFET is

) to set the actual current limit point.

SET

of the upper MOSFET,

DS(ON)

switched on. Experiments have shown that the MOSFET drain

voltage will ring for 200-500ns after the gate is turned on. In

order to reduce inaccuracies due to ringing, a 1µs delay after gate

turn-on is built into the current sense comparator. The comparator draws a current (I

resistor is selected to set the current limit for the application.

When the sensed voltage across the R

resistor exceeds the 400mV V

outputs a signal to reset the PWM latch and to start hiccup mode.

), whose magnitude is 45µA. The set

SET

plus the set

threshold, the OCP comparator

TRIP

DS(ON)

The soft-start capacitor (CSS) is discharged slowly (10 times

slower than when being charged up by RSS). When the voltage

on the SS/ENABLE pin reaches a 0.3V threshold, hiccup finishes

and the circuit soft-starts again. During hiccup, the top MOSFET

is OFF and the bottom MOSFET remains ON.

Hiccup is disabled during the soft-start interval, allowing the

circuit to start up with the maximum current. If the rise speed

of the output voltage is too fast, the required charging current to

the output capacitor may be higher than the limit-current. In this

case, the peak MOSFET current is regulated to the limit-current

by the current-sense comparator. If the MOSFET current still

reaches its limit after the soft-start finishes, the hiccup is triggered

again. The hiccup ensures the average heat generation on both

MOSFET’s and the average current to be much less than that in

normal operation, if the output has a short circuit.

Over-current protection can also be implemented using a

sense resistor, instead of using the R

for greater set-point accuracy. See Application Information

of the upper MOSFET,

DS(ON)

section.

Copyright © 1999

Rev. 1.0 5/99

OSCILLATOR FREQUENCY

An internal oscillator sets the switching frequency at 200 kHz.

5

LX1681/1682

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

APPLICATION INFORMATION

OUTPUT INDUCTOR

The output inductor should be selected to meet the requirements

of the output voltage ripple in steady-state operation and the

inductor current slew-rate during transient.

The peak-to-peak output voltage ripple is:

V

= ESR * I

RIPPLE

RIPPLE

where

(V

- V

IN

I

= *

RIPPLE

is the inductor ripple current, L is the output inductor

I

RIPPLE

value and ESR is the Effective Series Resistance of the output

OUT

f

* L

SW

V

)

OUT

V

IN

capacitor.

I

should typically be in the range of 20% to 40% of the

RIPPLE

maximum output current. Higher inductance results in lower

output voltage ripple, allowing slightly higher ESR to satisfy the

transient specification. Higher inductance also slows the inductor current slew rate in response to the load-current step change,

∆I, resulting in more output-capacitor voltage droop. The

inductor-current rise and fall times are:

T

= L * ∆I/(VIN – V

RISE

OUT

)

and

T

= L * ∆I/V

FALL

OUT

When using electrolytic capacitors, the capacitor voltage

droop is usually negligible, due to the large capacitance.

OUTPUT CAPACITOR

The output capacitor is sized to meet ripple and transient

performance specifications. Effective Series Resistance (ESR) is

a critical parameter. When a step load current occurs, the output

voltage will have a step that equals the product of the ESR and

the current step, ∆I. In an advanced microprocessor power

supply, the output capacitor is usually selected for ESR instead

of capacitance or RMS current capability. A capacitor that

satisfies the ESR requirement usually has a larger capacitance and

current capability than strictly needed. The allowed ESR can be

found by:

ESR * (I

where I

load current step change, and VEX is the allowed output voltage

RIPPLE

+ ∆I ) < V

RIPPLE

EX

is the inductor ripple current, ∆I is the maximum

excursion in the transient.

OUTPUT CAPACITOR (continued)

Electrolytic capacitors can be used for the output capacitor,

but are less stable with age than tantalum capacitors. As they age,

their ESR degrades, reducing the system performance and

increasing the risk of failure. It is recommended that multiple

parallel capacitors be used, so that, as ESR increases with age,

overall performance will still meet the processor’s requirements.

There is frequently strong pressure to use the least expensive

components possible, however, this could lead to degraded

long-term reliability, especially in the case of filter capacitors.

Linfinity’s demonstration boards use Sanyo MV-GX filter capacitors, which are aluminum electrolytic, and have demonstrated

reliability. The Oscon series from Sanyo generally provides the

very best performance in terms of long term ESR stability and

general reliability, but at a substantial cost penalty. The MV-GX

series provides excellent ESR performance at a reasonable cost.

Beware of off-brand, very low-cost filter capacitors, which have

been shown to degrade in both ESR and general electrolytic

characteristics over time.

INPUT CAPACITOR

The input capacitor and the input inductor are to filter the

pulsating current generated by the buck converter to reduce

interference to other circuits connected to the same 5V rail. In

addition, the input capacitor provides local de-coupling the buck

converter. The capacitor should be rated to handle the RMS

current requirement. The RMS current is:

I

= IL √ d(1-d)

RMS

where IL is the inductor current and the d is the duty cycle. The

maximum value, when d = 50%, I

output in the range of 2 to 3V, the required RMS current is very

= 0.5IL. For 5V input and

RMS

close to 0.5IL.

SOFT-START CAPACITOR

The value of the soft-start capacitor determines how fast the

output voltage rises and how large the inductor current is

required to charge the output capacitor. The output voltage will

follow the voltage at SS pin if the required inductor current does

not exceed the maximum current in the inductor.

The SS pin voltage can be expressed as:

-t/RssC

VSS = V

where V

resistor and capacitor. The required inductor current for the

(1-e

SET

is the reference voltage. RSS and CSS are soft start

SET

ss

)

output capacitor to follow the SS-pin voltage equals the required

6

Copyright © 1999

Rev. 1.0 5/99

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

APPLICATION INFORMATION

LX1681/1682

SOFT-START CAPACITOR (continued)

capacitor current plus the load current. The soft-start capacitor

should be selected so that the overall inductor current does not

exceed it maximum.

The capacitor current to follow the SS-pin voltage is:

I

= C

Cout

where C

should be in the range of 0.1 to 0.2µF.

OUT

dV

OUT

dt

is the output capacitance. The typical value of C

C

OUT

=

-(t/RssCss)

e

*

C

SS

During the soft-start interval the load current from a microprocessor is negligible; therefore, the capacitor current is approximately the required inductor current.

OVER-CURRENT PROTECTION

Current limiting occurs at current level ICL, when the voltage

detected by the current sense comparator is greater than the

current sense comparator threshold, V

I

So,

* R

CL

R

SET

+ I

* R

DS(ON)

V

- ICL * R

TRIP

= =

I

SET

SET

SET

DS(ON)

= V

(400mV).

TRIP

TRIP

400mV - ICL * R

45µA

DS(ON)

Example:

For 10A current limit, using IRL3303 MOSFET (26mΩ R

0.4 - 10 * 0.026

R

= = 3.1k

SET

45 * 10

-6

Ω

DS(ON)

):

Current Sensing Using Sense Resistor

The method of current sensing using the R

MOSFET is economical, but can have a large tolerance, since the

R

can vary with temperature, etc. A more accurate alterna-

DS(ON)

tive is to use an external sense resistor (R

to the current sense comparator is the supply voltage to the IC

SENSE

of the upper

DS(ON)

). Since one input

(VCC - pin 8), the sense resistor could be a PCB trace (for

construction details, see Application Note AN-10 or LX1668 data

sheet).

The over-current trip point is calculated as in the equations

above, replacing R

DS(ON)

with R

SENSE

.

Example:

For 10A current limit, using a 5mΩ sense resistor:

V

- (ICL * R

R

TRIP

= = = 7.8k

SET

I

SET

SENSE

)

0.4 - 10 * 0.005

45 x 10

-6

Ω

OUTPUT ENABLE

The LX1681/82 FET driver outputs are driven to ground by

pulling the soft-start pin below 0.3V.

PROGRAMMING THE OUTPUT VOLTAGE

The output voltage is sensed by the feedback pin (V

a 1.25V reference. The output voltage can be set to any voltage

above 1.25V (and lower than the input voltage) by means of a

SS

resistor divider (see Product Highlight).

V

= V

OUT

Note: Keep R

(1 + R1 /R2 )

REF

and R2 close to 100Ω (order of magnitude).

1

FET SELECTION

To insure reliable operation, the operating junction temperature

of the FET switches must be kept below certain limits. The Intel

specification states that 115°C maximum junction temperature

should be maintained with an ambient of 50°C. This is achieved

by properly derating the part, and by adequate heat sinking. One

of the most critical parameters for FET selection is the R

resistance. This parameter directly contributes to the power

dissipation of the FET devices, and thus impacts heat sink design,

mechanical layout, and reliability. In general, the larger the

current handling capability of the FET, the lower the R

be, since more die area is available.

TABLE 1 - FET Selection Guide

This table gives selection of suitable FETs from International Rectifier.

Device R

@I

DS(ON)

ΩΩ

10V (m

Ω)T

ΩΩ

@ Max. Break-

D

= 100°C down Voltage

C

IRL3803 6 83 30

IRL22203N 7 71 30

IRL3103 14 40 30

IRL3102 13 56 20

IRL3303 26 24 30

IRL2703 40 17 30

All devices in TO-220 package. For surface mount devices (TO-263 /

D2-Pak), add 'S' to part number, e.g. IRL3103S.

Heat Dissipated In Upper MOSFET

The heat dissipated in the top MOSFET will be:

P

= (I2 * R

D

Where t

and fS is the switching frequency.

is switching transition line for body diode (~100ns)

SW

For the IRL3102 (13mΩ R

will result in typical heat dissipation of 1.92W.

* Duty Cycle) + (0.5 * I * VIN * tSW * fS )

DS(ON)

), converting 5V to 2.0V at 15A

DS(ON)

) which has

FB

DS(ON)

DS(ON)

will

Copyright © 1999

Rev. 1.0 5/99

7

PRODUCT DATABOOK 1996/1997

t

LX1681/1682

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

APPLICATION INFORMATION

FET SELECTION (continued)

Synchronous Rectification – Lower MOSFET

The lower pass element can be either a MOSFET or a Schottky

diode. The use of a MOSFET (synchronous rectification) will result

in higher efficiency, but at higher cost than using a Schottky diode

(non-synchronous).

Power dissipated in the bottom MOSFET will be:

5V Input

P

= I2 * R

D

[IRL3303 or 1.76W for the IRL3102]

* [1 - Duty Cycle] = 3.51W

DS(ON)

Non-Synchronous Operation - Schottky Diode

A typical Schottky diode, with a forward drop of 0.6V will dissipate

0.6 * 15 * [1 – 2/5] = 5.4W (compared to the 1.8 to 3.5W dissipated

by a MOSFET under the same conditions).

This power loss becomes much more significant at lower duty

cycles. The use of a dual Schottky diode in a single TO-220

package (e.g. the MBR2535) helps improve thermal dissipation.

Operation From A Single Power Supply

The LX1681/1682 needs a secondary supply voltage (VC1) to

provide sufficient drive to the upper MOSFET. In many applications with a 5V (VCC) and a 12V (VC1) supply are present. In

situations where only 5V is present, VC1 can be generated using

a bootstrap (charge pump) circuit, as shown in Figure 4 (Typical

Applications section).

The capacitor (C4) is alternatively charged up from VCC via the

Schottky diode (D2), and then boosted up when the FET is turned

on. This scheme provedes a VC1 voltage equal to 2 * VCC - VDS(D2),

or approximately 9.5V with VCC = 5V. This voltage will provide

sufficient gate drive to the external MOSFET in order to get a low

R

. Note that using the bootstrap circuit in synchronous

DS(ON)

rectification mode is likely to result in faster turn-on than in nonsynchronous mode.

LAYOUT GUIDELINES - THERMAL DESIGN

A great deal of time and effort were spent optimizing the thermal

design of the demonstration boards. Any user who intends to

implement an embedded motherboard would be well advised to

carefully read and follow these guidelines. If the FET switches

have been carefully selected, external heatsinking is generally not

required. However, this means that copper trace on the PC board

must now be used. This is a potential trouble spot; as much

copper area as possible must be dedicated to heatsinking the FET

switches, and the diode as well if a non-synchronous solution is

used.

In our VRM module, heatsink area was taken from internal

ground and VCC planes which were actually split and connected

with VIAS to the power device tabs. The TO-220 and TO-263

cases are well suited for this application, and are the preferred

packages. Remember to remove any conformal coating from all

exposed PC traces which are involved in heatsinking.

LX168x

Outpu

GND

FIGURE 2 — Enabling Linear Regulator

General Notes

As always, be sure to provide local capacitive decoupling close to

the chip. Be sure use ground plane construction for all highfrequency work. Use low ESR capacitors where justified, but be

alert for damping and ringing problems. High-frequency designs

demand careful routing and layout, and may require several

iterations to achieve desired performance levels.

Power Traces

To reduce power losses due to ohmic resistance, careful consideration should be given to the layout of traces that carry high

currents. The main paths to consider are:

■ Input power from 5V supply to drain of top MOSFET.

■ Trace between top MOSFET and lower MOSFET or Schottky

diode.

■ Trace between lower MOSFET or Schottky diode and ground.

■ Trace between source of top MOSFET and inductor and load.

All of these traces should be made as wide and thick as possible,

in order to minimize resistance and hence power losses. It is also

recommended that, whenever possible, the ground, input and

output power signals should be on separate planes (PCB layers).

See Figure 2 – bold traces are power traces.

Layout Assistance

Please contact Linfinity’s Applications Engineers for assistance

with any layout or component selection issues. A Gerber file with

layout for the most popular devices is available upon request.

Evaluation boards are also available upon request. Please

check Linfinity's web site for further application notes.

8

Copyright © 1999

Rev. 1.0 5/99

PRODUCT DATABOOK 1996/1997

VOLTAGE-MODE PWM CONTROLLERS

P RODUCTION DATA SHEET

APPLICATION INFORMATION

LX1681/1682

C

SS

0.1µF

V

BOOST

12V

C

3

1

V

FB

2

SS

V

CS

8

CC

7

R

SET

LX1681

3

N.C.

GND

TDRV

FIGURE 3 — Current Sensing Using Sense Resistor

6

V

C1

54

Q

V

IN

5V

C

1

R

SENSE

V

1

L

1

D

2

V

IN

C

OUT

R

1

2

R

2

5V

Copyright © 1999

Rev. 1.0 5/99

C

1

V

V

CS

8

CC

7

6

C1

54

D

2

C

4

L

Q

1

R

SET

1

Q

2

C

SS

0.1µF

1

2

3

V

FB

SS

GND

BDRV

LX1682

TDRV

FIGURE 4 — Bootstrap Circuit For 5V Only Operation

PRODUCTION DATA - Information contained in this document is proprietary to LinFinity, and is current as of publication date. This document

may not be modified in any way without the express written consent of LinFinity. Product processing does not necessarily include testing of

all parameters. Linfinity reserves the right to change the configuration and performance of the product and to discontinue product at any time.

V

OUT

R

C

1

2

R

2

9

Loading...

Loading...